Method for producing feed-grade bluestone by using cupreous etching waste liquor of circuit board

A copper etching and circuit board technology, applied in copper sulfate and other directions, can solve the problems of inapplicability, high cost, and inability to directly apply arsenic removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

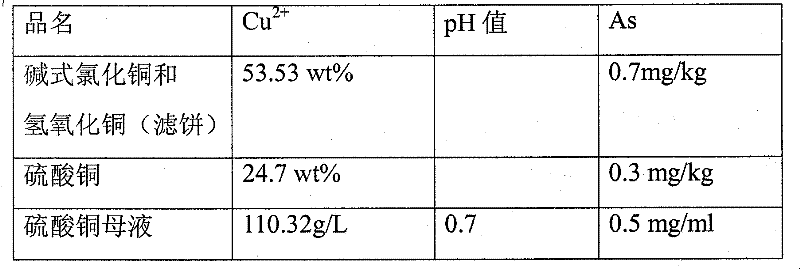

Examples

Embodiment 1

[0026] Example 1: Removal of arsenic from acid water and alkaline water to produce copper sulfate

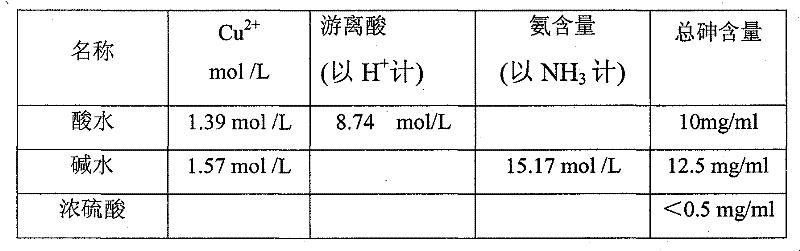

[0027] The following table 1 shows the test data of related materials:

[0028] Table I

[0029]

[0030] Towards 5m 3 Put 300L of acid water into the reaction kettle, and slowly add the hydrogen peroxide solution under stirring until the solution becomes transparent. Add 50kg of iron sulfate (containing Fe 3+ About 18wt%), stir to dissolve, add 3m under stirring 3 Alkaline water has a pH of 7.62. After adding 140L of concentrated ammonia water to pH 8.0, there is no basic copper chloride and copper hydroxide precipitation in the solution, then adding activated carbon, the input amount is 10kg activated carbon per cubic meter of solution. Continue to stir and react for 30 minutes, release the materials to be filtered under pressure, clean the reaction kettle with a small amount of water, and filter the washing liquid and materials together. The filter residue is placed uniformly and...

Embodiment 2

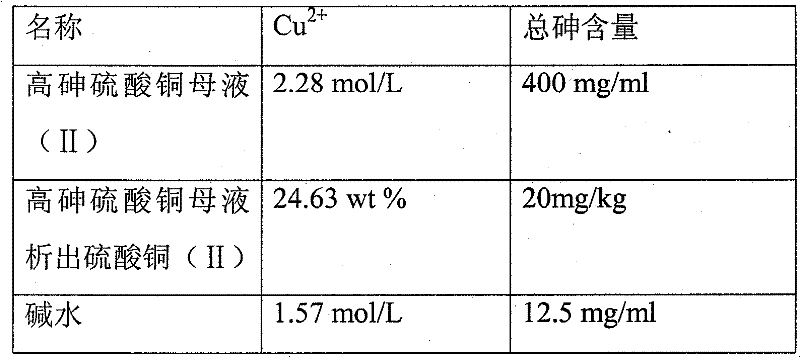

[0034] Example 2: Using high arsenic copper sulfate mother liquor, alkaline water, and ammonia water as raw materials, produce copper sulfate after removing arsenic from the high arsenic copper sulfate mother liquor and alkaline water

[0035] Arsenic in acid water and alkaline water exists in the form of arsenate and arsenite (mainly copper arsenate and copper arsenite). Copper arsenate and copper arsenite are insoluble in water but soluble in acid. The pH value of the mother liquor of copper sulfate crystallization is generally around 1, which can dissolve most of the arsenate and enrich the arsenic in the mother liquor of copper sulfate crystallization. :

[0036] Table Three

[0037] Name

[0038] Put 500L high arsenic copper sulfate mother liquor into 5m3 reactor, slowly add 1L hydrogen peroxide solution under stirring, add 50kg iron sulfate (containing Fe 3+ About 18wt%) to dissolve it. Add 2.5m under stirring 3 Alkaline water, add 200L of concentrated ammonia water, until...

Embodiment 3

[0042] Example 3: Using high-arsenic copper sulfate mother liquor and alkaline water as raw materials to produce copper sulfate after removing arsenic from the high-arsenic copper sulfate mother liquor and alkaline water

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com