Patents

Literature

44results about How to "Easy to achieve industrial scale-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

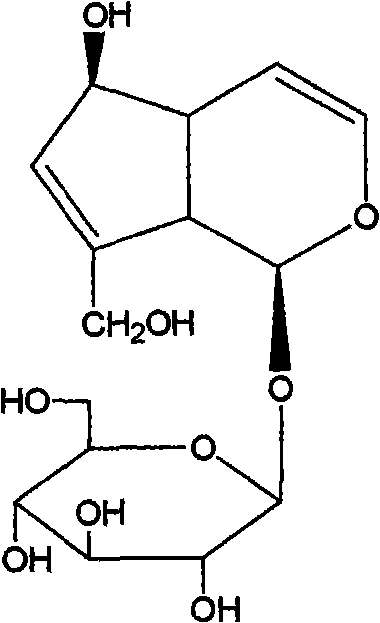

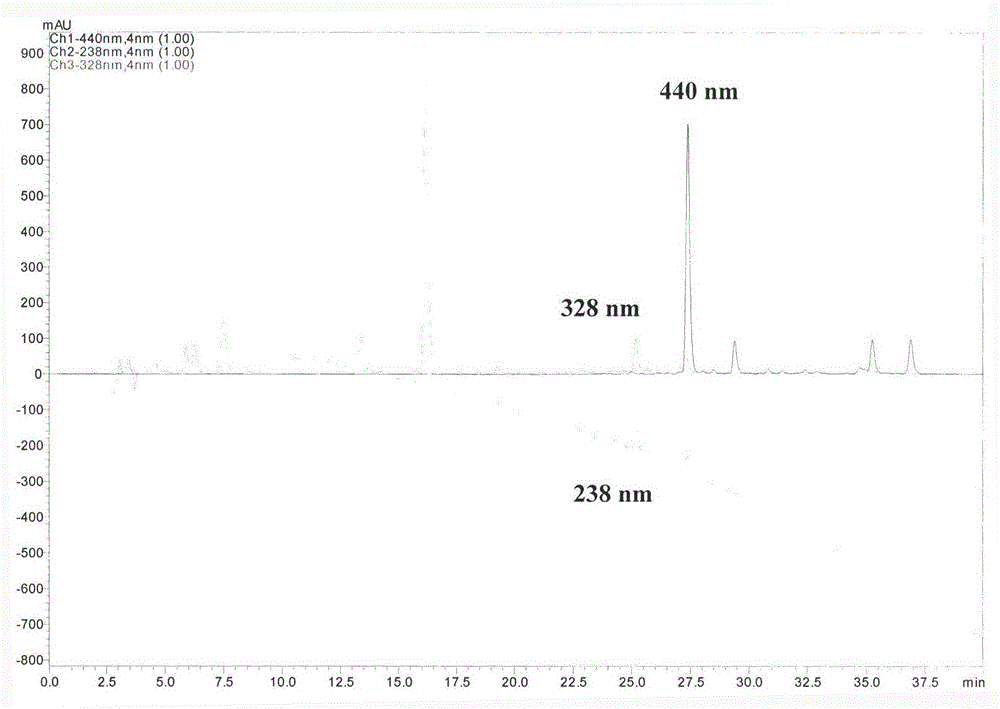

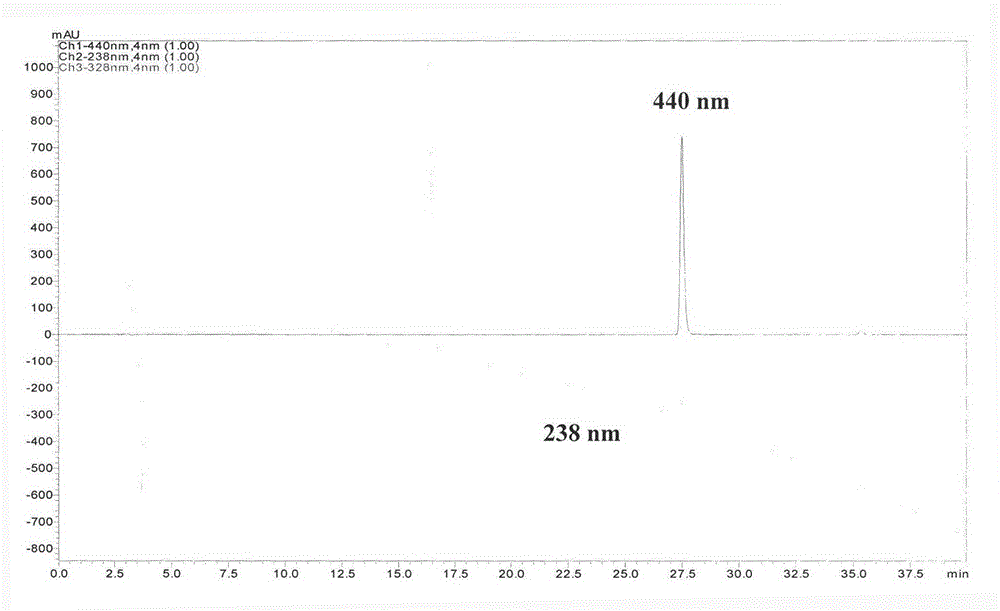

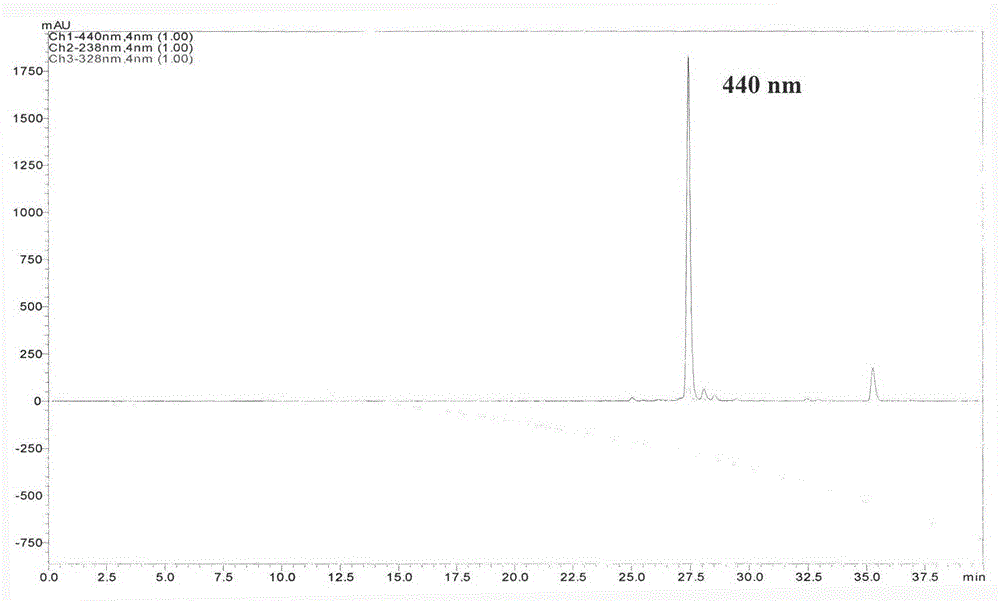

Preparation method of high pure crocin and geniposide

InactiveCN103387489ARealize comprehensive utilizationEfficient use ofSugar derivativesNatural dyesChlorogenic acidGradient elution

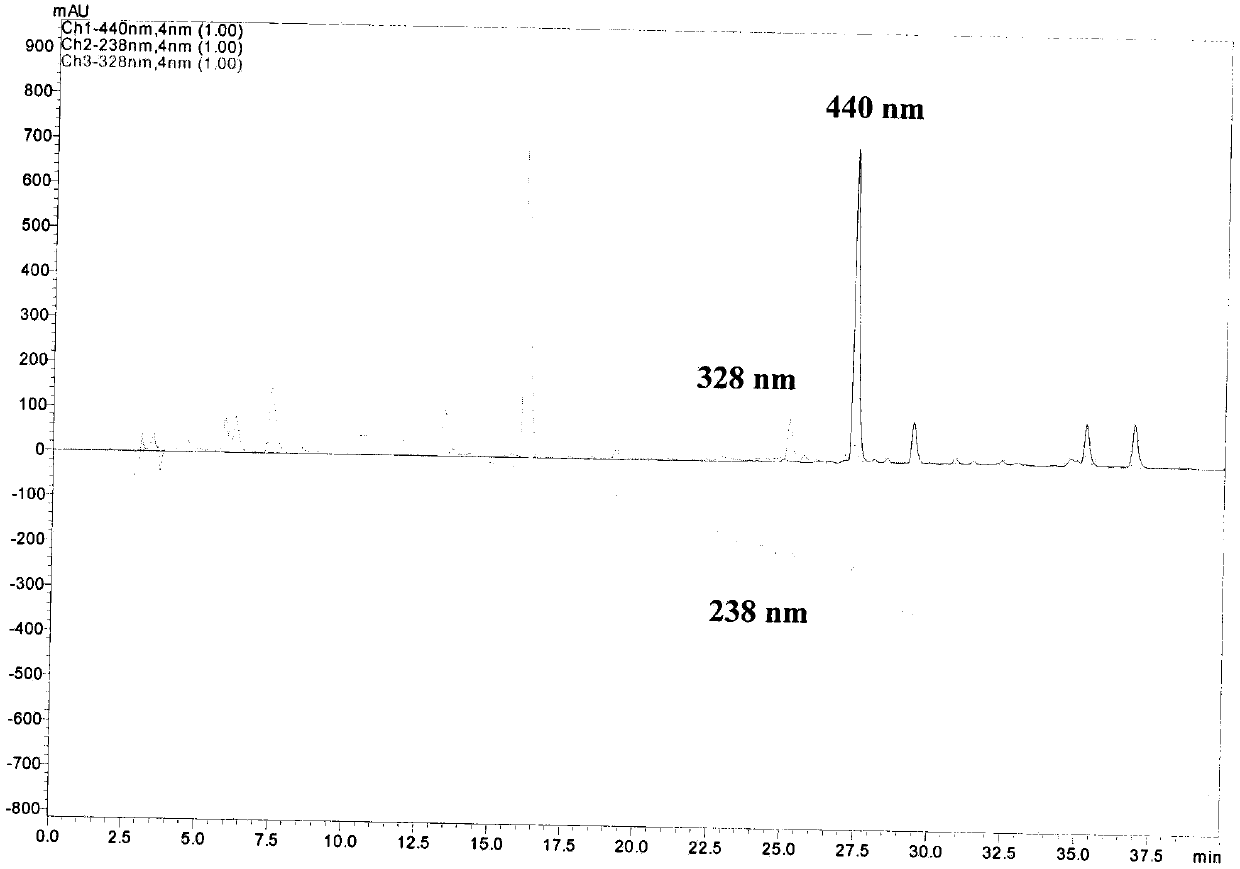

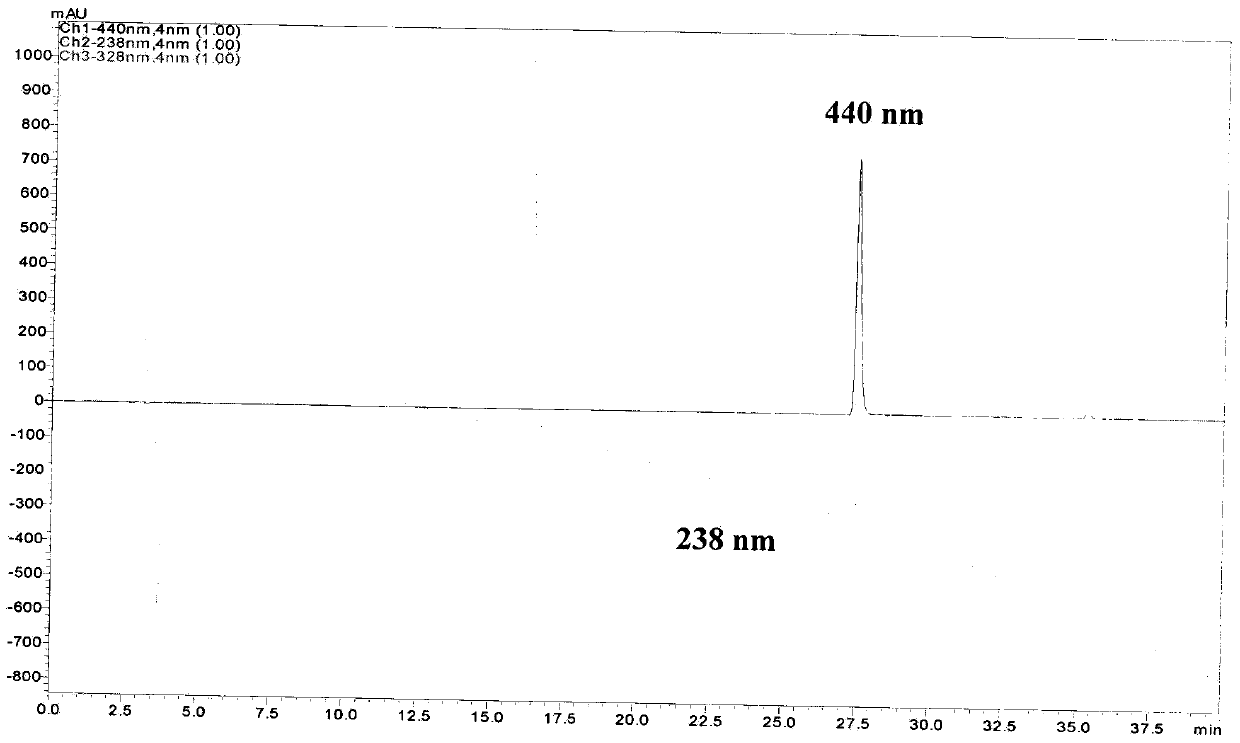

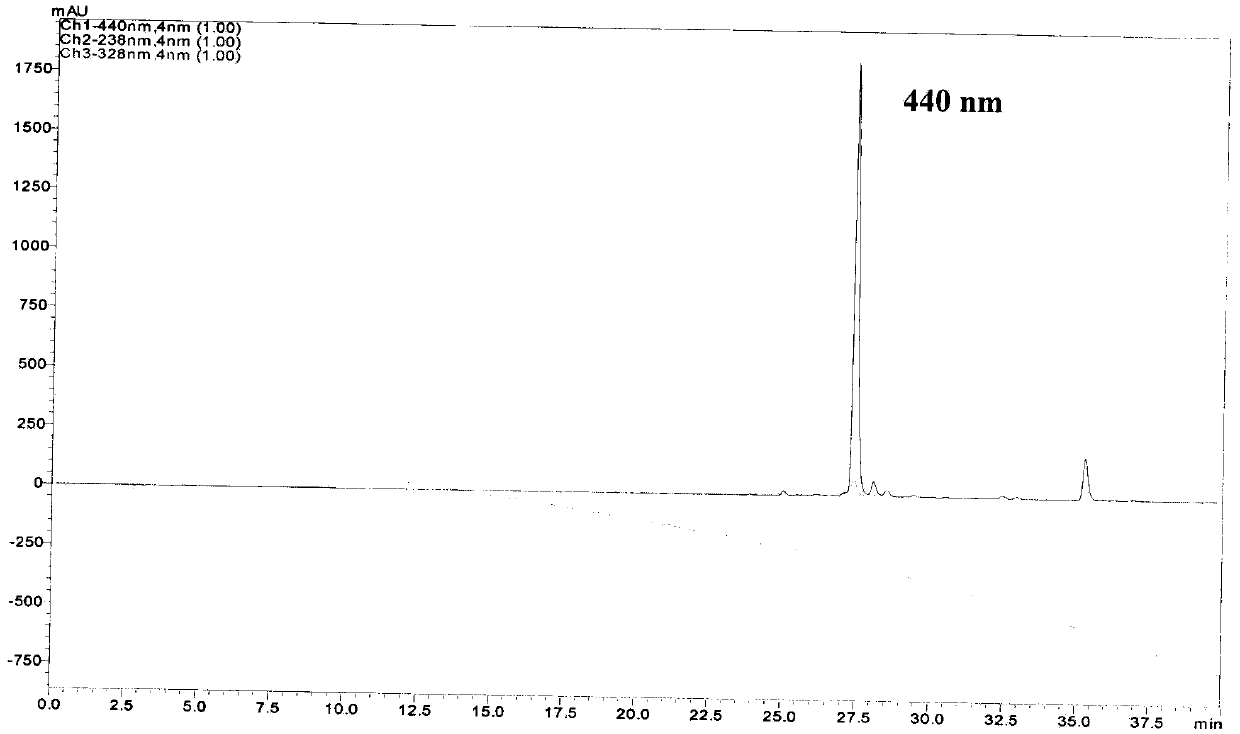

The invention discloses a preparation method of high pure crocin and geniposide. The preparation method comprises following main steps: selecting raw materials of gardenia ellis plants, extracting with water or an alcohol-water mixed solution, merging the extracting solutions, condensing, filtering, subjecting the obtained extracting solution to an adsorption treatment by macroporous resin, then performing gradient elution with a ethanol-water mixed solution, obtaining geniposide and gardenia yellow refined extracts; subjecting the geniposide refined extract to a recrystallization treatment with ethyl acetate so as to obtain the geniposide product; subjecting the gardenia yellow refined extract to go through column chromatography, which has been pressurized and stuffed with modified silica gel, to separate, and obtaining the high pure crocin product (color value larger than 600) and a chlorogenic acid component. The products have the advantages of high purity, simple technology, strong operability and convenience for automation, comprehensive utilization of the plant resources is achieved, the solvent is convenient to recycle and reuse, and the preparation method is easy to apply to the industrial amplification.

Owner:SUZHOU QIUSHI HERBAL HEALTH TECH CO LTD

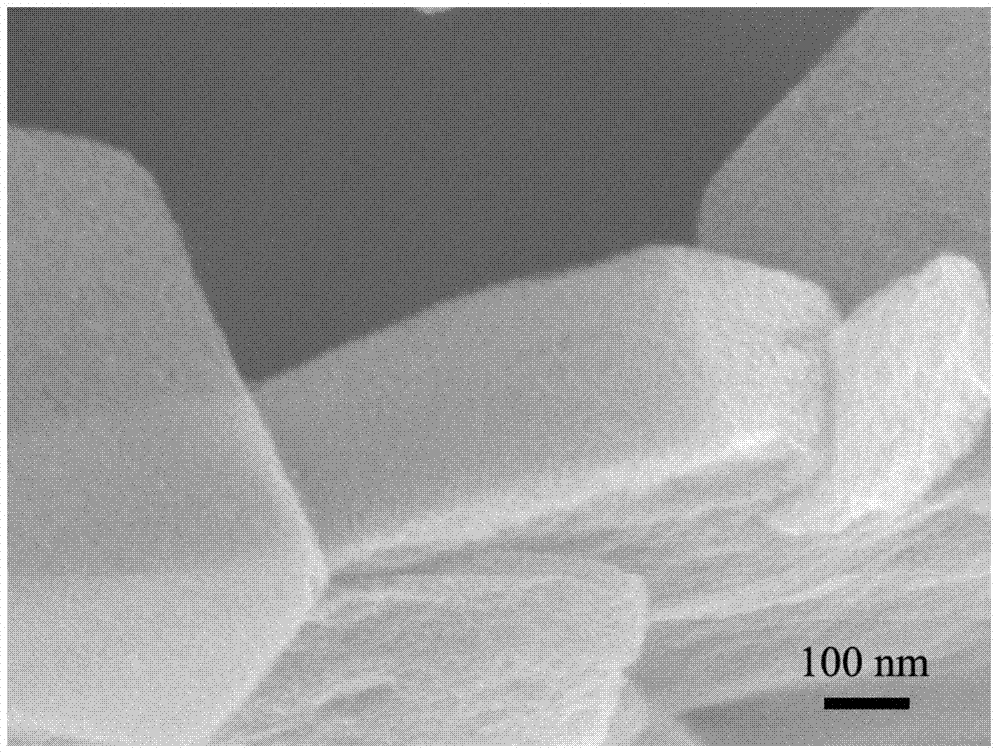

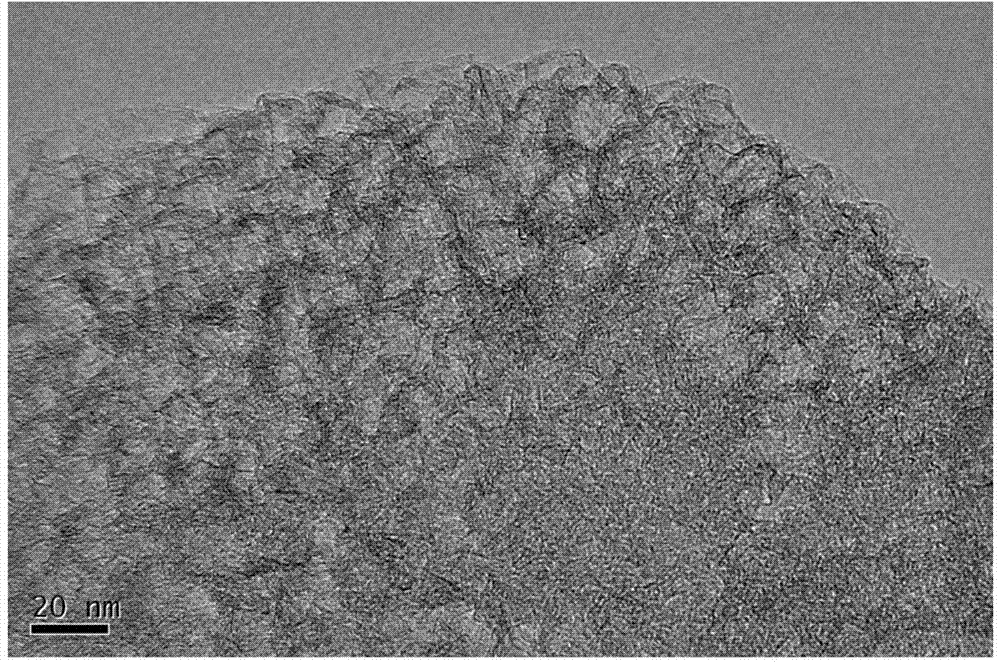

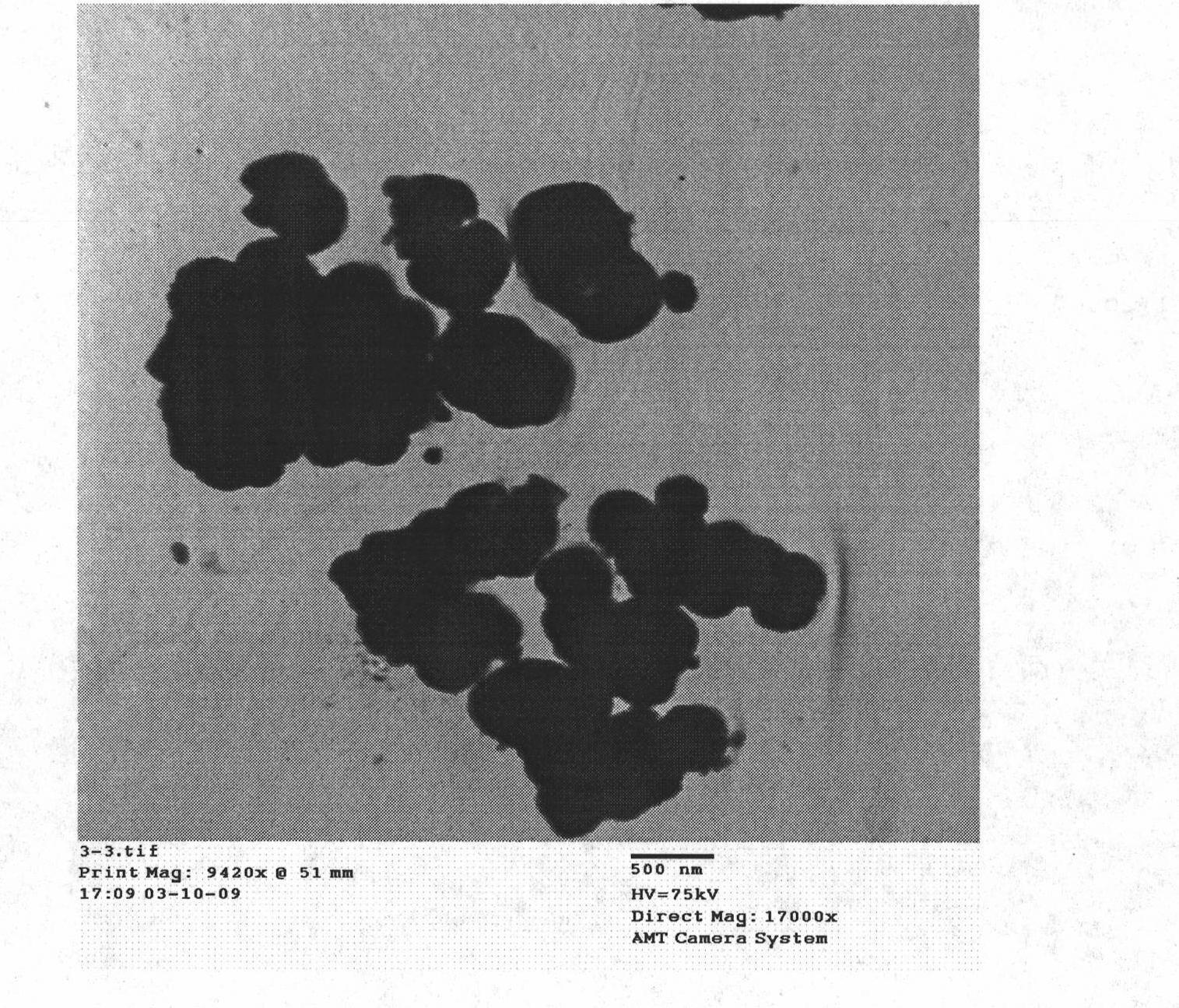

Mesoporous graphene foam as well as preparation method thereof

ActiveCN103482611AStable structureLarge specific surface areaGrapheneNanotechnologyDraw ratioElectric properties

The invention belongs to the technical fields of a novel material as well as preparation, and particularly relates to mesoporous graphene foam as well as a preparation method thereof. The invention realizes hydrothermal preparation of a magnesium oxide texture structure and preparation of the mesoporous graphene foam by using textured magnesium oxide as a template. The mesoporous graphene foam material has abundant mesoporous structures and excellent electric property and can be used as an electrode material of batteries and supercapacitors, so that the energy density and the power density of the batteries or the supercapacitors are expectedly improved to a great extent. The cycling stability of the mesoporous graphene foam material is increased, and the mesoporous graphene foam material combined with materials with high draw ratio or the mesoporous graphene foam material can soften energy storage apparatuses. The advantages have important meaning for realization of commercialization of a new generation of energy storage apparatuses for electromobiles and development of smaller, lighter and flexible portable mobile power supplies. The business prospect is wide. Meanwhile, preparation processes of the high temperature hydrothermal method and a fluidized bed can realize engineering enlargement, so that the method is expected to be industrialized.

Owner:TSINGHUA UNIV

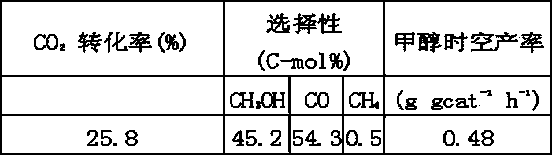

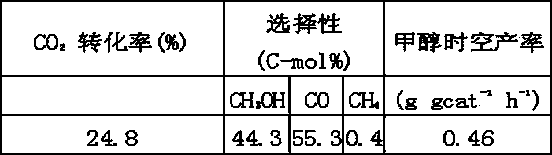

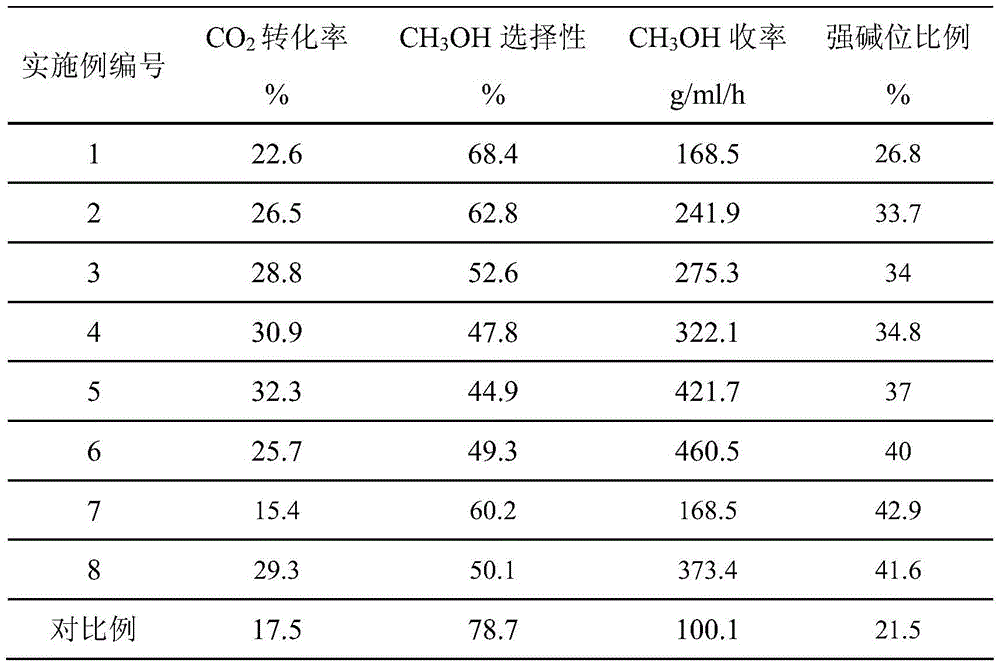

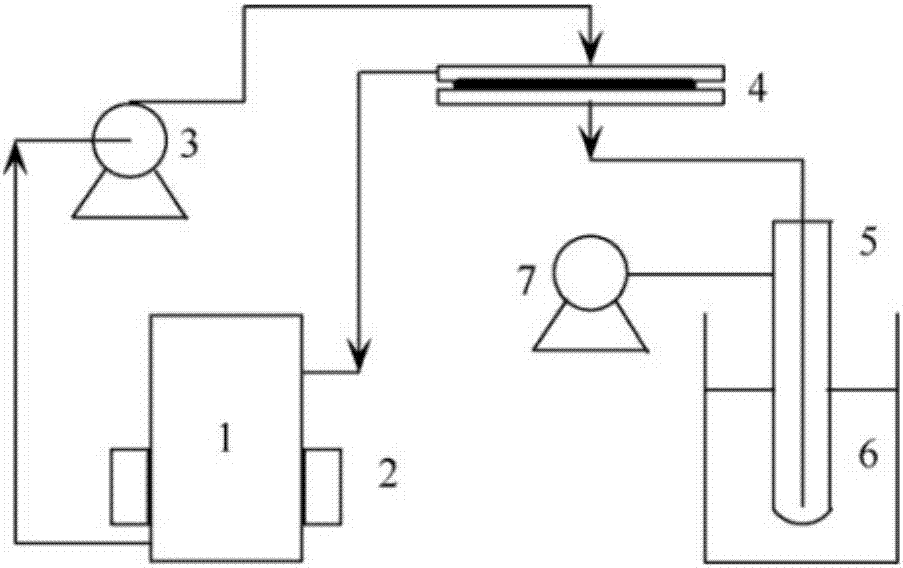

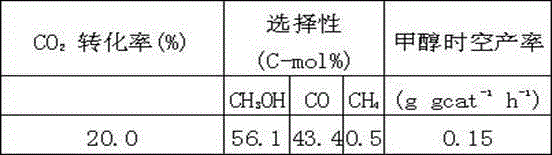

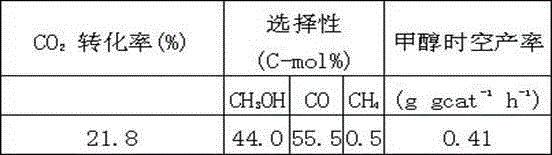

Catalyst for synthesizing methanol through CO2 hydrogenation as well as preparation method and application

ActiveCN103721719ALarge specific surface areaGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystHalogen

The invention discloses a catalyst for synthesizing methanol through CO2 hydrogenation, comprising Cu, Zn, Al, X, halogen and oxygen elements, oxides and halides, wherein the molar ratio of [Cu+Zn+MA] to [Al+Mb] is 2-18; the molar ratio of Cu to Zn is 0.5-5; the molar ratio of MA to [Cu+Zn] is 0-5; the molar ratio of MB to Al is 0-9; the molar ratio of halogen to Al is 0.05-5; MA and MB cannot be 0 at the same time; MA represents a mono-valent or divalent metal ion in X; MB represents a trivalent and / or tetravalent metal ion in X; X is one or a combination of more elements of Li, K, Mg, B, Ga, In, transition metal elements and rare-earth metal elements. The catalyst has the advantages of high carbon dioxide conversion rate, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

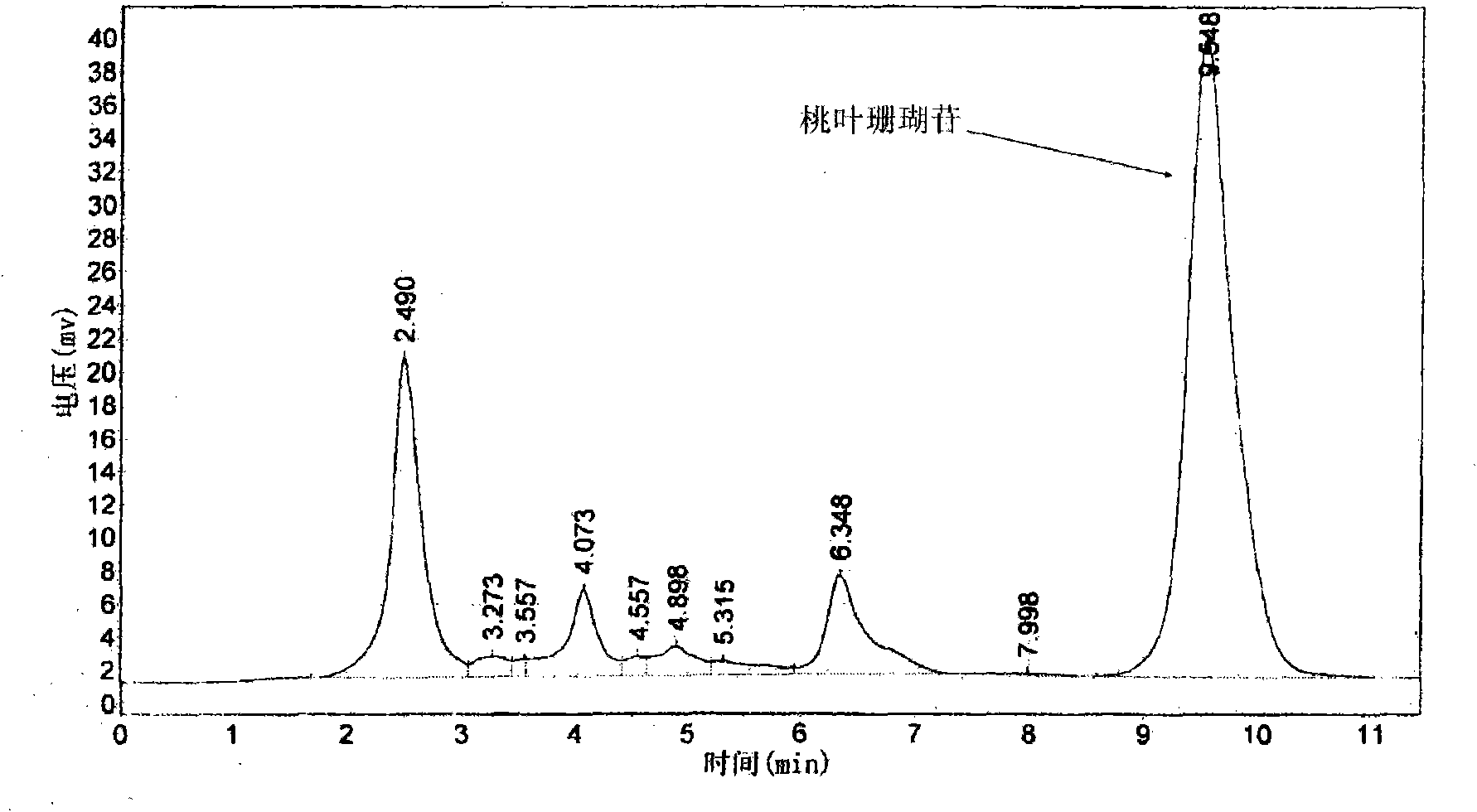

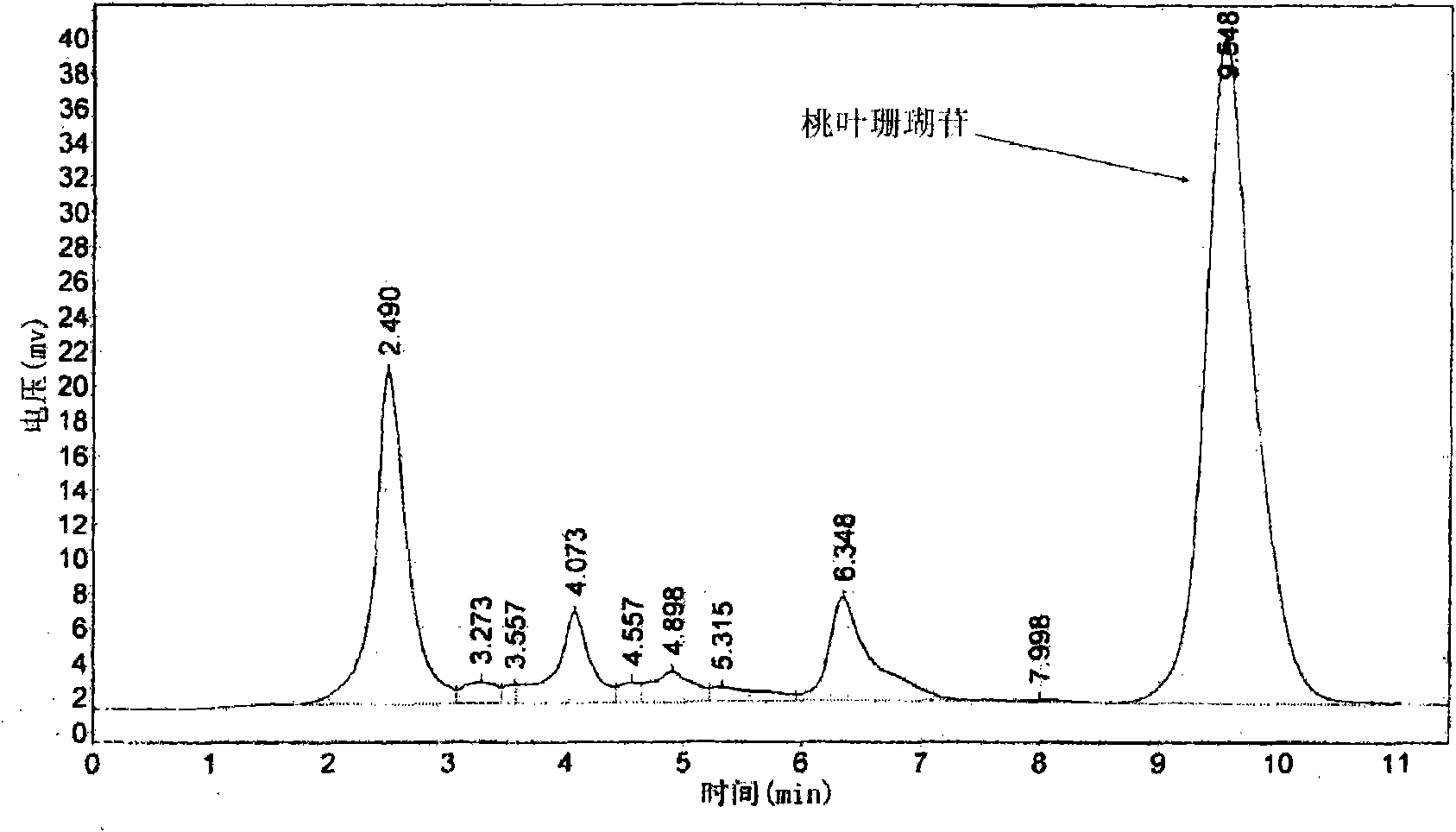

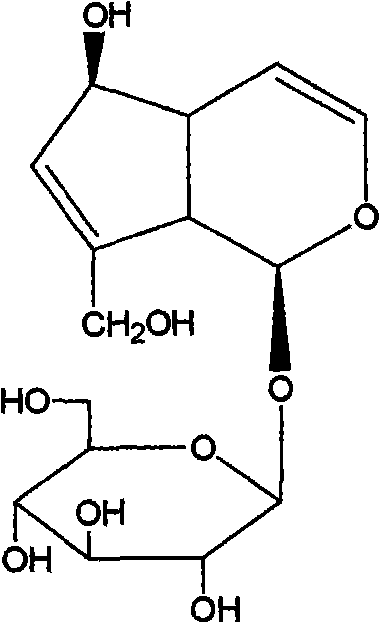

Technological process for extracting aucubin from fruits of eucommia ulmoides oliver

InactiveCN101982471ANo pollution in the processMeet the needs of developmentNervous disorderSugar derivativesAucubinSolvent

The invention relates to a technological process for extracting aucubin from fruits of eucommia ulmoides oliver, which comprises the following steps: cutting the fruits of the eucommia ulmoides oliver into pieces, extracting with water or ethanol solution as an extraction solvent, and purifying the obtained extracting solution with macroporous resin to obtain the aucubin the purity of which is more than 50%. The technological process has the advantages of low toxicity, safety, short process time, no environmental pollution, simple and convenient operation, easy industrialization enlargement, high yield and good purity of the product, thus meeting various needs for development of drugs taking the fruits of the eucommia ulmoides oliver as main raw materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

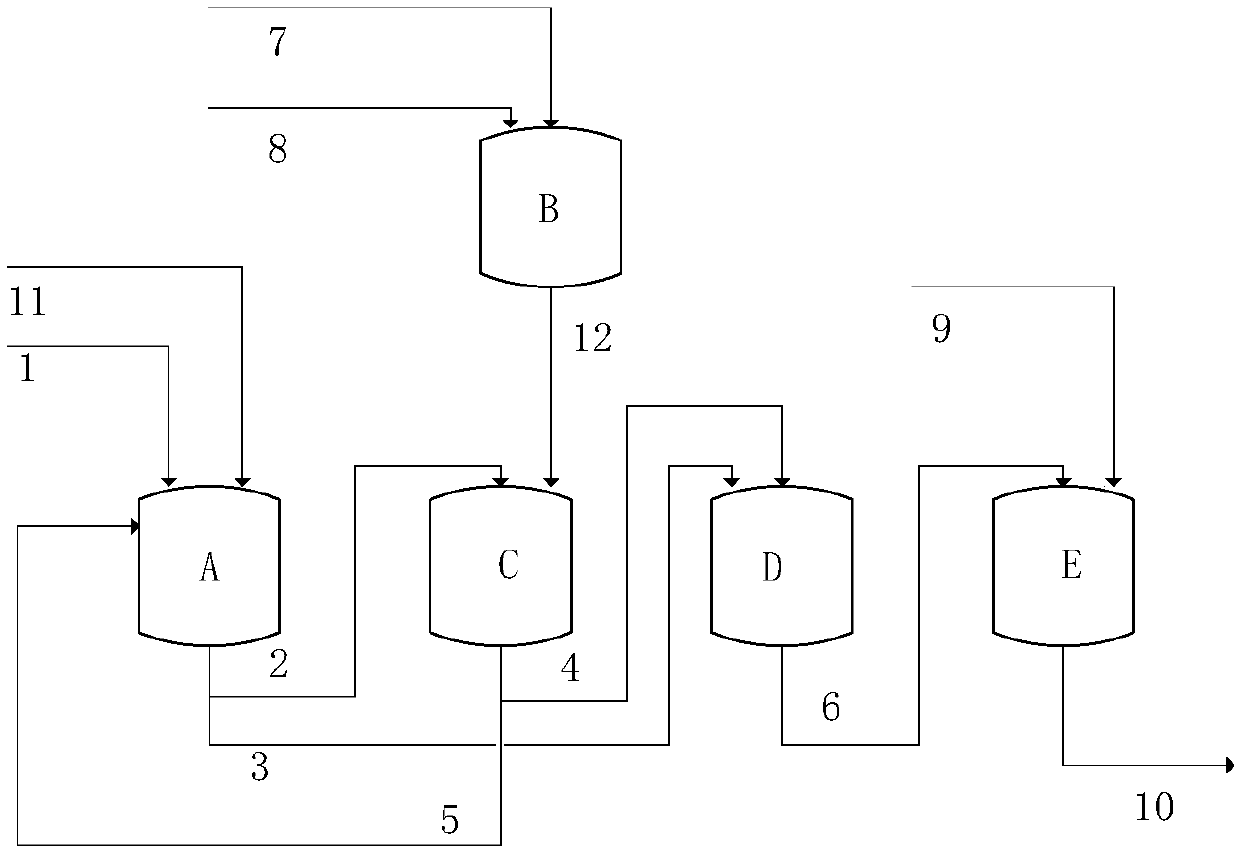

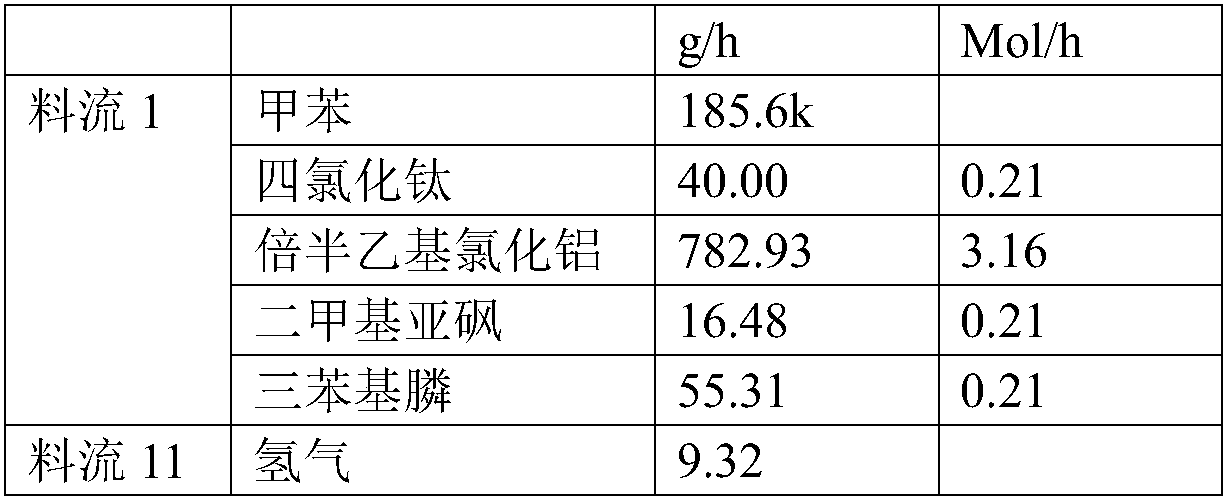

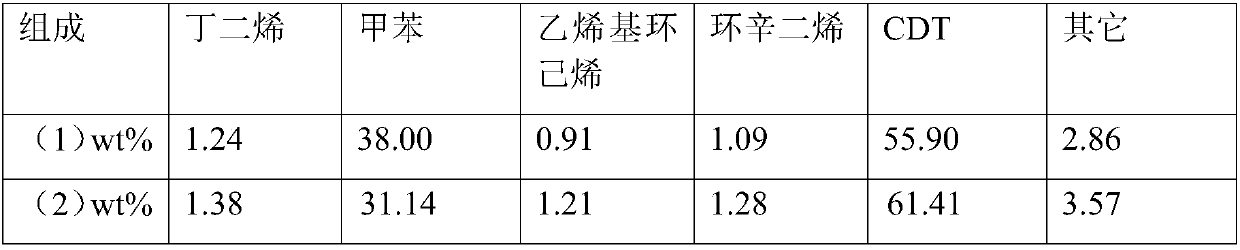

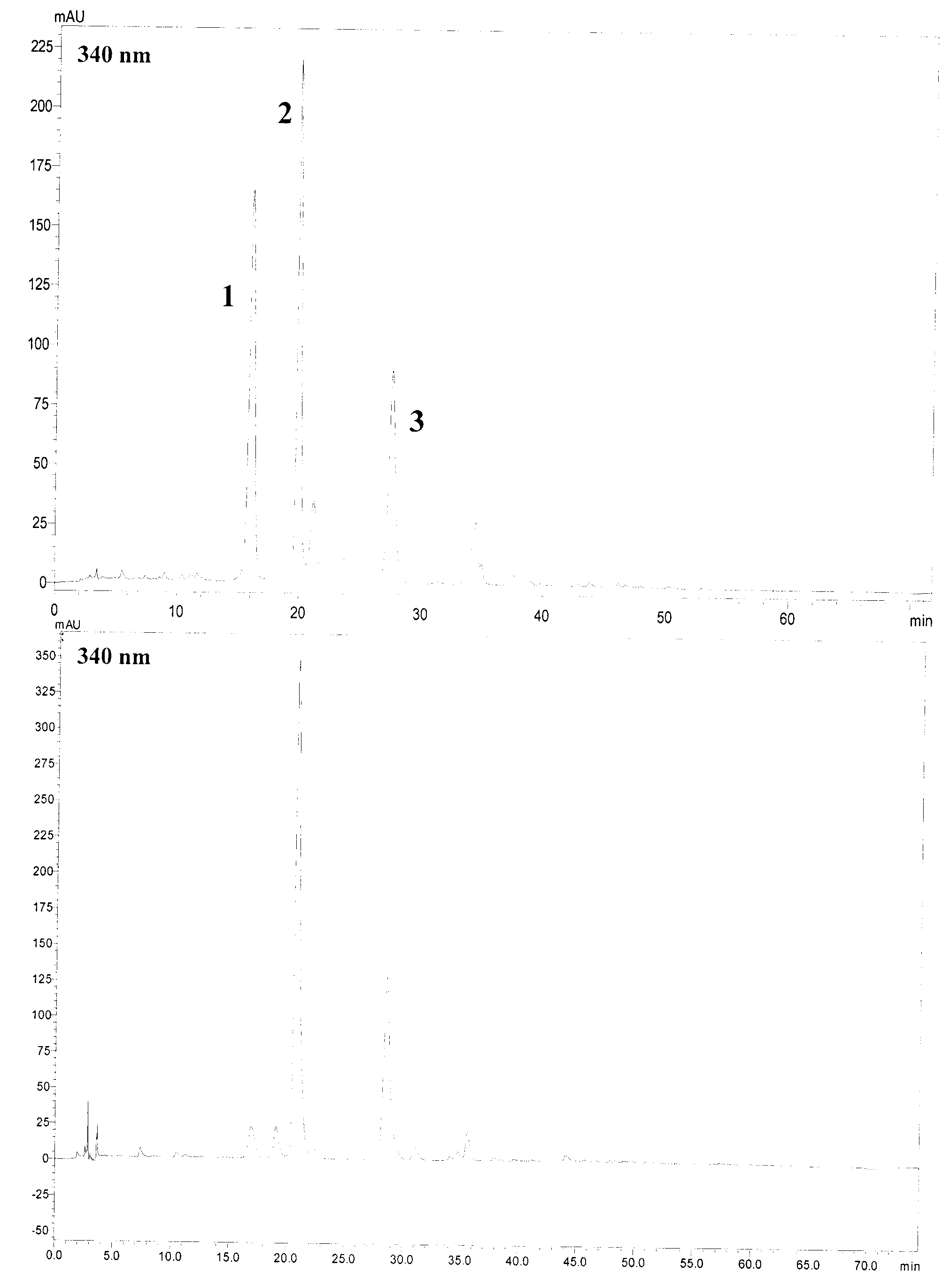

Method for continuously producing cyclododecatriene

ActiveCN109867578AActive influenceEffective quenchingDistillation purification/separationHydrocarbonsCyclododecatrienePre treatment

The invention relates to a method for continuously producing cyclododecatriene. The method comprises the following steps: (1) mixing butadiene with an organic metal compound to obtain a material flowcontaining butadiene, carrying out a butadiene cyclization tripolymerization reaction on the material flow containing butadiene in a polymerization reactor under the action of a catalyst solution to obtain a reaction liquid containing cyclododecatriene; (2) feeding the reaction liquid containing cyclododecatriene and the other part of the catalyst solution into an aging reactor for carrying out areaction; and (3) feeding the reaction liquid obtained by the aging reactor into a quenching reactor, and quenching the reaction by adopting a polyamine substance as a quenching agent to obtain a quenched reaction liquid containing cyclododecatriene. According to the method disclosed by the invention, the butadiene is pretreated first, so that the polymerization reaction process is not influencedby impurities which are carried in by raw materials, and efficiency of the catalyst is increased; and meanwhile, the reaction is quenched by adopting a catalyst quenching agent, so that a post-treatment process is simplified, and production efficiency is improved.

Owner:WANHUA CHEM GRP CO LTD

Flavone C-glycoside extract and preparation method thereof

The invention discloses a preparation method of a high-purity flavone C-glycoside extract. The preparation method mainly comprises the following steps of: selecting vegetable drugs rich in flavone C-glycoside, extracting by adopting water or an ethanol-water mixed solvent, and optionally further separating, purifying and concentrating as required to obtain a flavone C-glycoside extract concentrated solution, wherein the concentrated solution is dissolved and diluted into a defined amount of acid water or an alcohol-containing aqueous solution to carry out an acid hydrolysis reaction, the obtained extract hydrolysate is further separated and purified by adopting fillers such as macroporous resin and the like, and high-purity (more than 60%) flavone C-glycoside extract is obtained. The preparation method disclosed by the invention adopts an acid hydrolysis control technology, and other flavone C-glycoside derivatives in plants can be converted into corresponding flavone C-glycoside components, so that content and purity of a flavone C-glycoside component are obviously increased, a process is simple, operability is strong, and industrialization amplification is easy to achieve.

Owner:SUZHOU UNIV

Solid base catalyst for synthesizing dimethyl carbonate by transesterification method and its preparation method and application

ActiveCN105879892BLow temperature and high activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationTransesterificationSolid base

The invention provides a solid base catalyst for synthesizing dimethyl carbonate through a transesterification method. The components are Ca-Al-O-X, wherein the mole content of Ca ranges from 15% to 35%, the mole content of Al ranges from 5% to 30%, the mole content of X ranges from 0.1% to 10%, the balance is O, and X is CO3<2-> or NO3<-> or F<-> or Cl<-> or Br<->. The solid base catalyst has the advantages that the use temperature is low, the conversion rate of propylene carbonate under the low-temperature condition is high, and the yield of dimethyl carbonate is high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

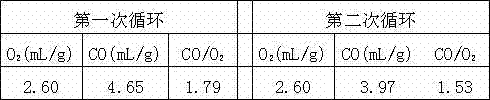

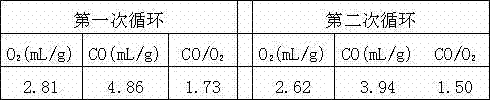

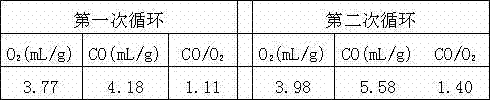

Catalyst for preparing carbon monoxide by decomposing carbon dioxide, as well as preparation method and application thereof

ActiveCN103464134AImprove thermal stabilityHigh surface areaCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsChemical compositionCerium

The invention relates to a catalyst for preparing carbon monoxide by decomposing carbon dioxide, which is a composite metal oxide obtained by doping Mg and Ca in a cerium-zirconium solid solution. The chemical composition of the catalyst is expressed by the following general formula: Ce0.8-xZr0.2MxO2-x, wherein x equals 0.02-0.1, M is doping metal Mg or Ca, and x is the molar fraction of the doping metal. The catalyst disclosed by the invention has the advantages of high activity, high thermal stability and long service life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

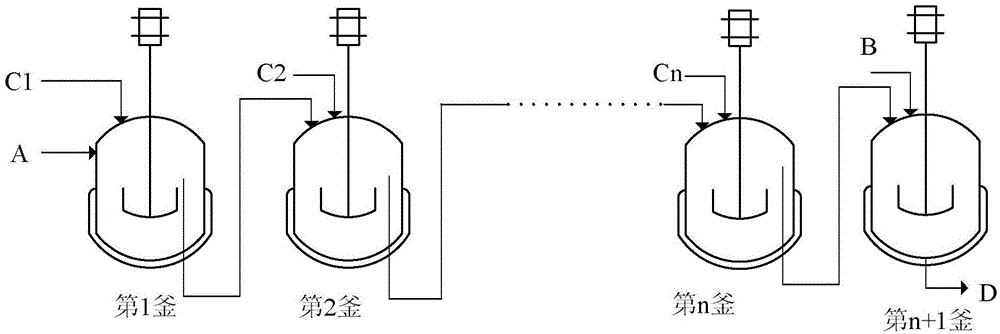

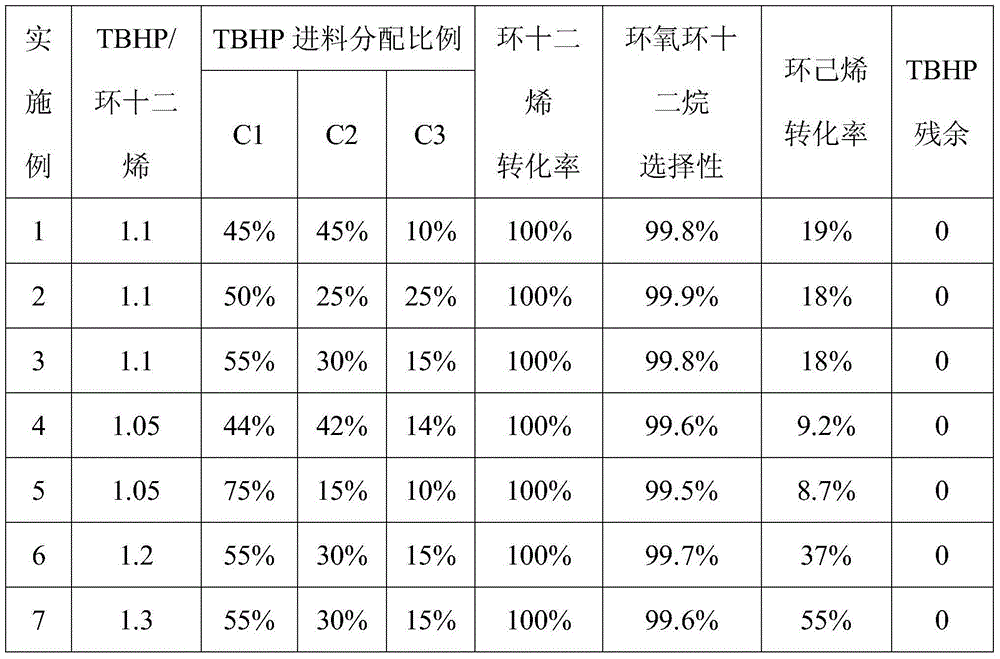

A method of continuously preparing 1,2-epoxycyclododecane

The invention relates to a method of preparing 1,2-epoxycyclododecane through epoxidation cyclododecene by utilization of tert-butyl hydroperoxide (TBHP). According to the method, addition of the TBHP is controlled under the existence of a catalyst, and the system concentration of an oxidant is controlled by adopting a batch addition manner to reduce generation of side reactions, thus ensuring complete conversion of the cyclododecene and achieving high selectivity of the main product 1,2-epoxycyclododecane. The excess TBHP is converted by adding another low-molecular-weight olefin to cogenerate a low-molecular-weight epoxy compound, thus ensuring safety of subsequent separation and facilitating process amplification.

Owner:WANHUA CHEM GRP CO LTD +1

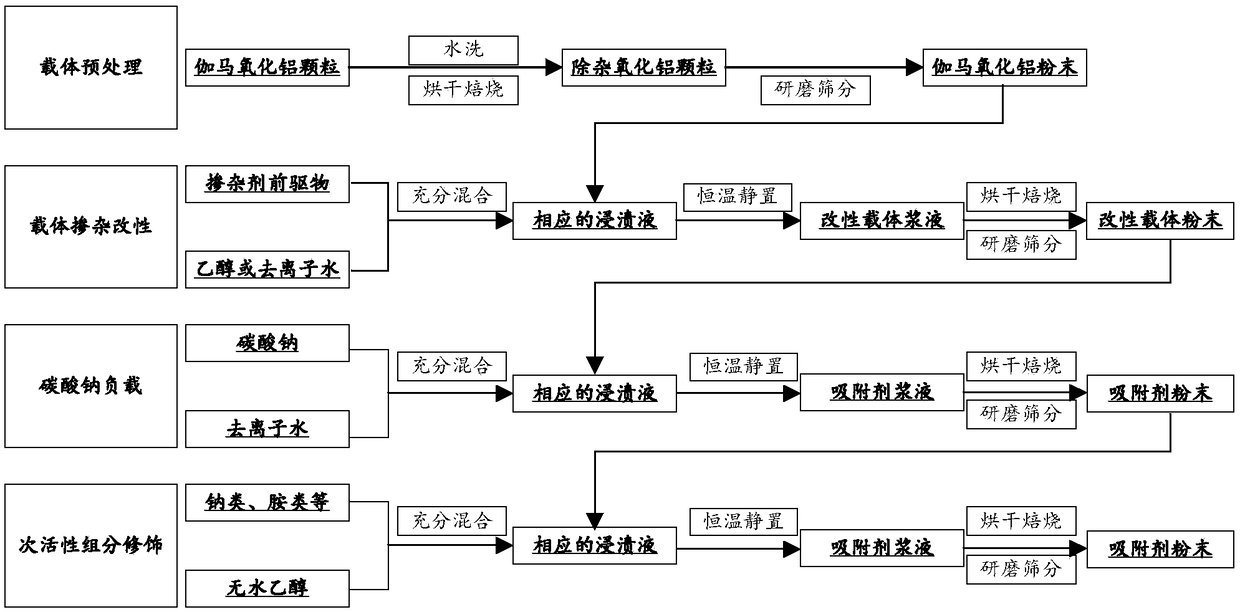

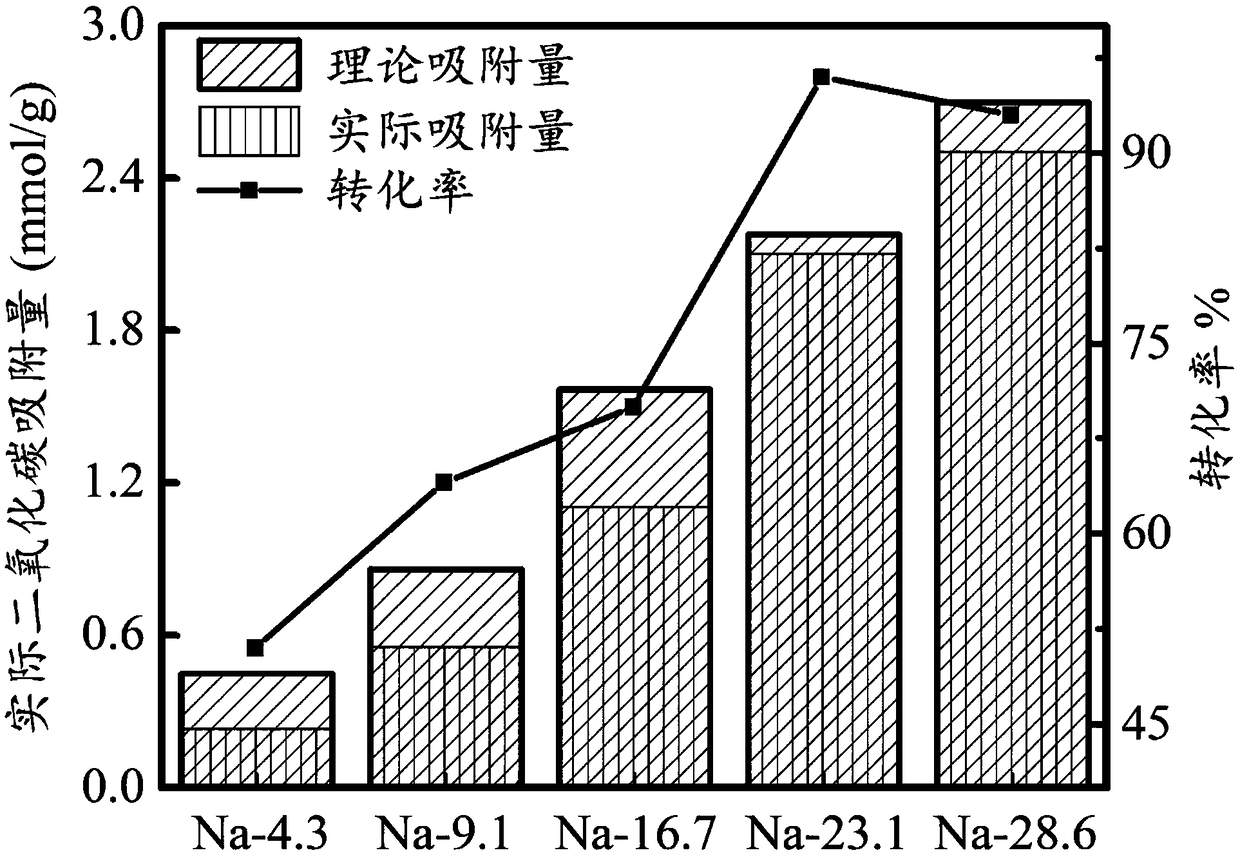

Preparation method of efficient sodium-based solid decarburization adsorbent

InactiveCN108514861AGuaranteed not to be brokenIncrease the number ofGas treatmentOther chemical processesSorbentDesorption

The invention discloses a preparation method of an efficient sodium-based solid decarburization adsorbent. Pre-treatment including washing, roasting and grinding is conducted on a gamma aluminium oxide carrier; an incipient-wetness impregnation method is adopted, wherein the carrier is impregnated in dopant impregnation liquid with the electrolyte cation concentration of 0.1-2.0 mol / L for 6-8 hours, and then the carrier is subjected to drying, roasting and grinding for standby use; a modified carrier obtained in the last step is impregnated in an isovolumetric sodium carbonate solution with the concentration of 0.8-3.8 mol / L for 6-8 hours and subjected to drying, roasting and grinding for standby use; furthermore, a modified adsorbent is impregnated in another sodium-based amino secondaryactive component solution for 6-8 hours and subjected to drying, roasting and grinding, and finally, the target adsorbent is obtained. The adsorbent is mainly applied to thermal power plant tail smokecarbon dioxide purification, and the adsorption / desorption conditions are mild; meanwhile,the adsorbent has the advantages that the preparation method is simple, raw materials are cheap and easy to obtain, large-scale production is feasible, the adsorbent is stable in structure, all components are evenly dispersed, and the decarburization performance is efficient and stable and the like.

Owner:SOUTHEAST UNIV

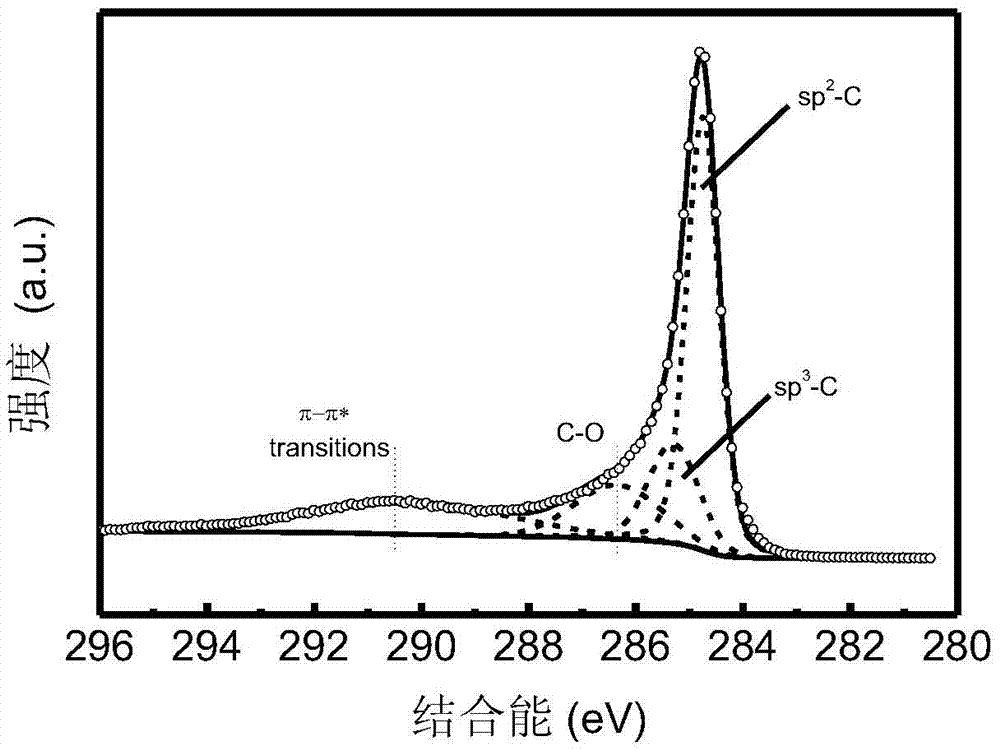

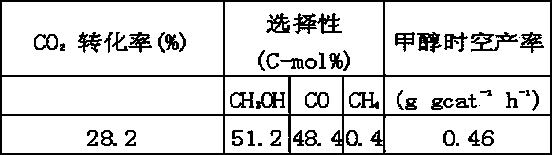

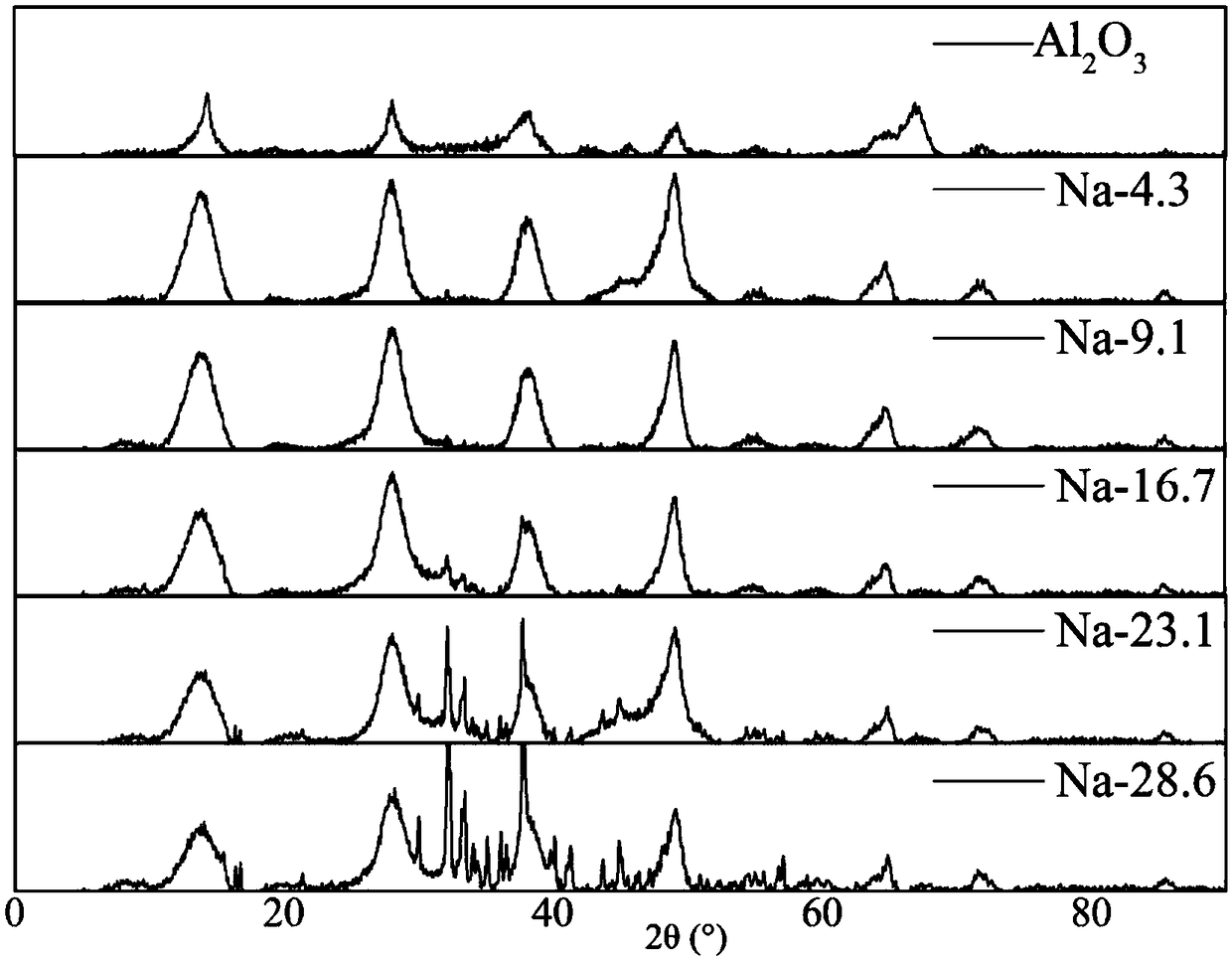

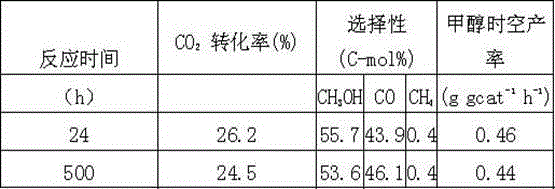

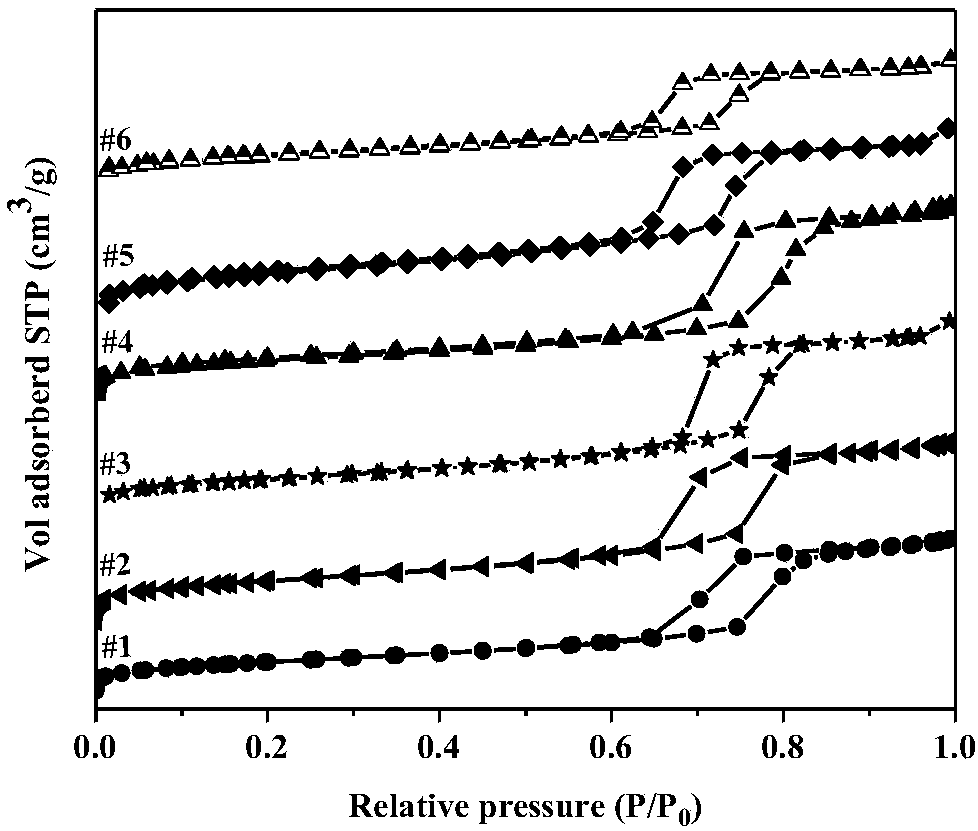

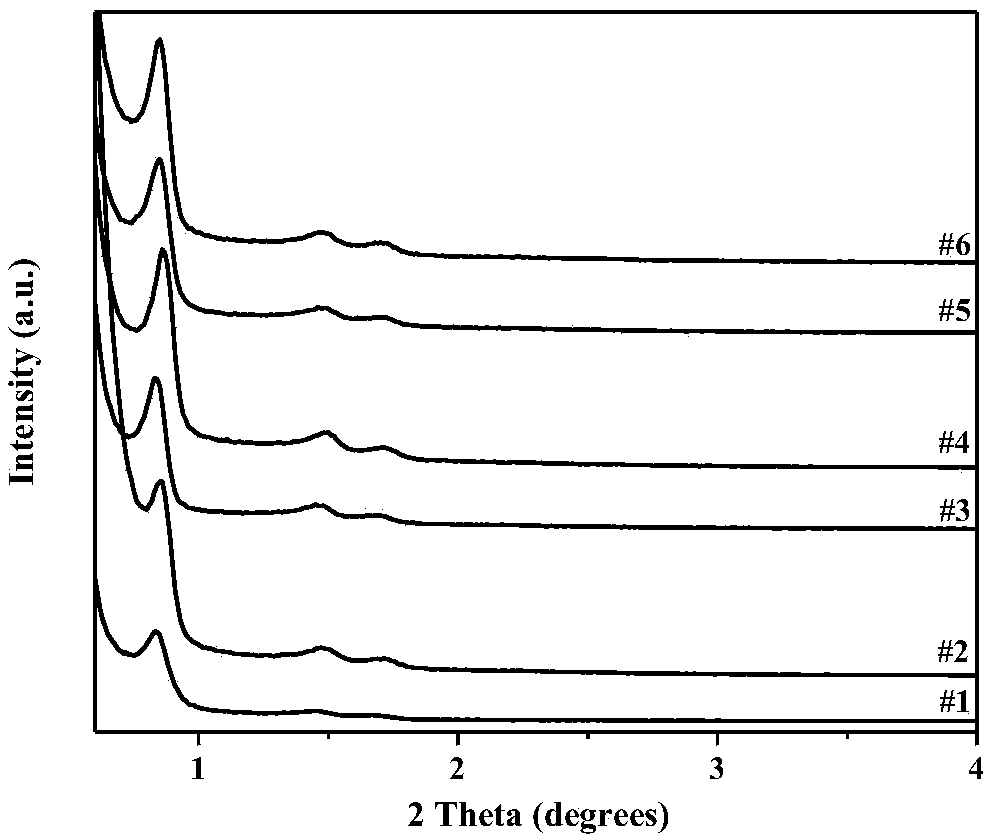

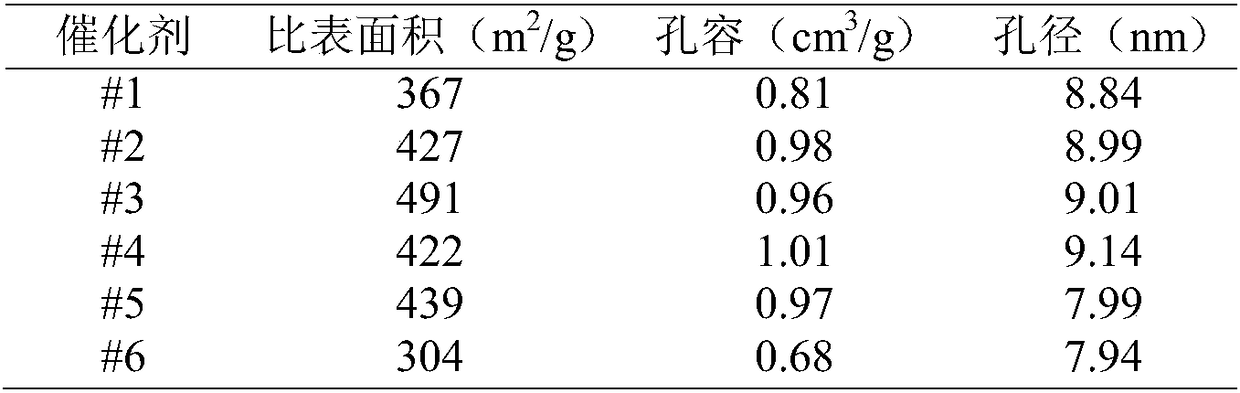

Copper fluoride based hydrotalcite-like catalyst, method for preparing same and application of copper fluoride based hydrotalcite-like catalyst

ActiveCN105618088AHigh dispersion of metal elementsGood dispersionPhysical/chemical process catalystsOrganic compound preparationCopper fluorideHydrogenation reaction

The invention discloses a copper fluoride based hydrotalcite-like catalyst, a method for preparing the same and application of the copper fluoride based hydrotalcite-like catalyst. The copper fluoride based hydrotalcite-like catalyst comprises Cu, ZnO, Al2O3 and fluoride. A molar ratio of Cu elements to Zn elements is 2, a ratio of a total molar number of the Cu elements and the Zn elements to a molar number of Al elements is 0.5-4, and a molar ratio of F elements to the Al elements is 0.29-2.57. The copper fluoride based hydrotalcite-like catalyst, the method and the application have the advantages that the copper fluoride based hydrotalcite-like catalyst is high in metal element dispersion degree and strongly alkaline site quantity and favorable for dissociating and adsorbing H2 and stably adsorbing CO2, and is stable in performance during CO2 hydrogenation reaction operation, and the methanol selectivity can be obviously enhanced while a high CO2 conversion rate is guaranteed; the method is simple and is easy to implement, and industrial up-scale can be facilitated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

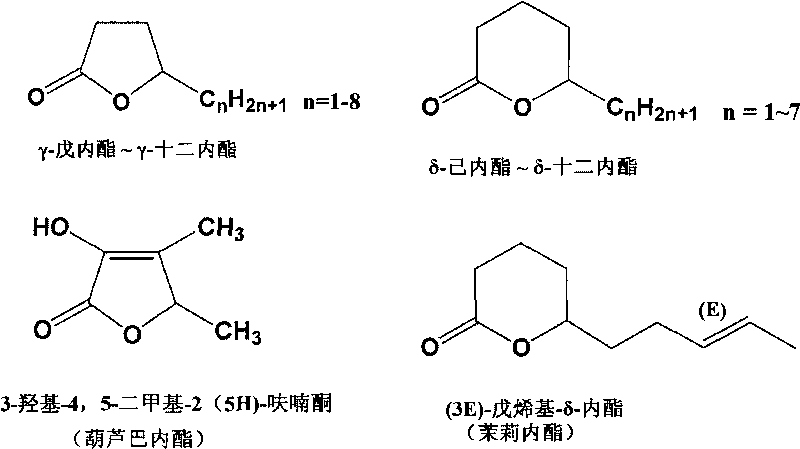

Preparation method of optical pure gamma/delta-lactone spice

InactiveCN101693857APure aromaLike authenticityOrganic chemistryEssential-oils/perfumesColumn temperatureChiral stationary phase

The invention discloses a preparation method of optical pure gamma / delta-lactone spice, comprising the following steps of utilizing the supercritical CO2 fluid chromatography, selecting a proper chiral stationary phase, and directly resolving racemic gamma / delta-lactone spice under the conditions that the column temperature is 30-40 DEG C, the column pressure is 7-20 MPa , and the modifier content in CO2 mobile phase is 0.5%-10% v / v to obtain the optical pure R and S configuration gamma / delta-lactone spice products. The preparation method has the advantages of green, environment protection, mild operation condition, high separating speed, high optical purity of products, easy realization of industrial enlargement and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

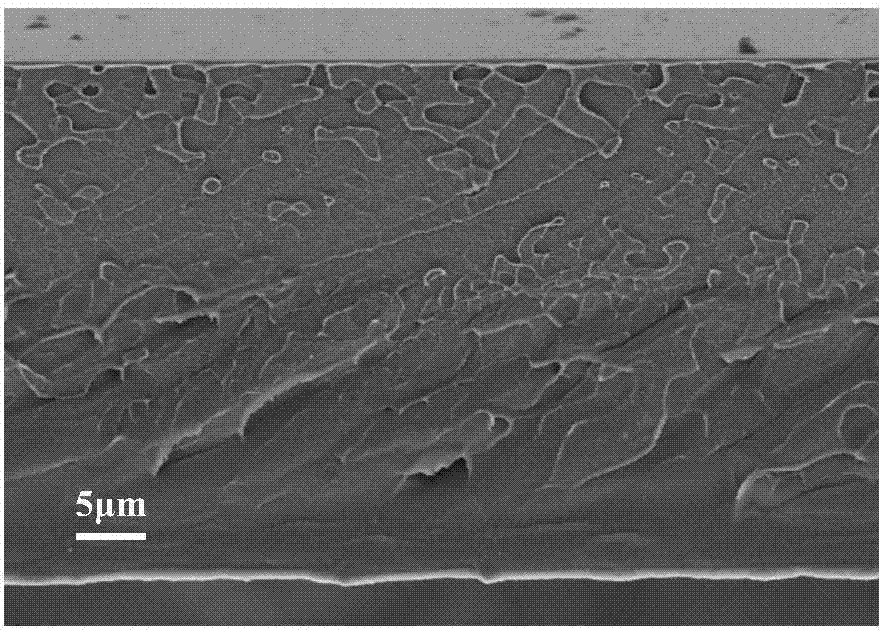

Pervaporation blend membrane for separating methanol-tetrahydrofuran

ActiveCN107281942AEasy to makeRaw materials are easy to getSemi-permeable membranesMembranesCellulose acetateVaporization

The invention relates to a pervaporation blend membrane for separating a mixture methanol and tetrahydrofuran and a preparation method of permeation vaporization blend membrane. The pervaporation membrane with a uniform and compact structure is prepared by virtue of a blending method by adopting P84 polyimide and cellulose acetate as basic raw materials. The pervaporation blend membrane has the beneficial effects that the blend membrane gives priority to the permeation of methanol and can separate the methanol and tetrahydrofuran mixture and purify the tetrahydrofuran; the pervaporation method adopted to separate the methanol-tetrahydrofuran mixture has the advantages of high separation efficiency, simple equipment, low energy consumption, no pollution and the like; and the blend membrane is excellent in separation performance and high in chemical stability, the materials for preparing the membrane is conventional, easy to get and low in price, and the industrialized production is facilitated.

Owner:CHANGZHOU UNIV

Catalyst for synthesizing fluorenone and preparation method and application thereof

ActiveCN109772326AImprove performanceEasy to separateOrganic compound preparationCatalyst activation/preparationCobalt(II,III) oxideCopper(II) oxide

The invention relates to a catalyst for synthesizing fluorenone and a preparation method and application thereof, and belongs to the technical field of catalysts. The catalyst is prepared from, by mass, 0-100% of tri-cobalt trioxide and 0-100% of copper oxide, and the sum of the mass percentages of the tri-cobalt trioxide and the copper oxide is 100%; the catalyst for synthesizing the fluorenone is prepared by a sol-gel method or a gel method. The catalyst has the advantages of low cost, high conversion rate, high selectivity, mild reaction condition, good stability and easy separation of reactants.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of carbon dioxide hydrogenation synthesis methanol catalyst and preparation method and application

ActiveCN103721719BLarge specific surface areaGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystHalogen

The invention discloses a catalyst for synthesizing methanol through CO2 hydrogenation, comprising Cu, Zn, Al, X, halogen and oxygen elements, oxides and halides, wherein the molar ratio of [Cu+Zn+MA] to [Al+Mb] is 2-18; the molar ratio of Cu to Zn is 0.5-5; the molar ratio of MA to [Cu+Zn] is 0-5; the molar ratio of MB to Al is 0-9; the molar ratio of halogen to Al is 0.05-5; MA and MB cannot be 0 at the same time; MA represents a mono-valent or divalent metal ion in X; MB represents a trivalent and / or tetravalent metal ion in X; X is one or a combination of more elements of Li, K, Mg, B, Ga, In, transition metal elements and rare-earth metal elements. The catalyst has the advantages of high carbon dioxide conversion rate, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

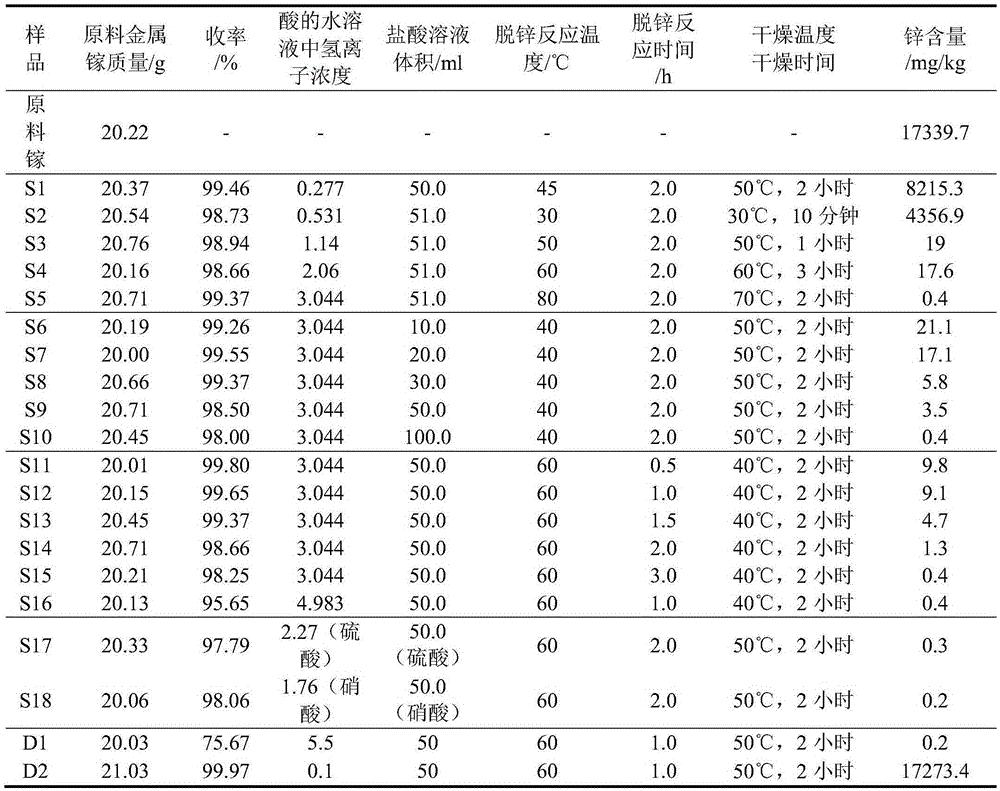

Method for removing metal zinc from high-concentration gallium raw material

The invention discloses a method for removing metal zinc from a high-concentration gallium raw material. The method comprises the steps that the gallium raw material and an acid water solution are mixed and subjected to dezincification reaction, and a mixed phase containing metal fluid and water is obtained; the mixed phase is separated to obtain a metal fluid phase and a water phase; and then the obtained metal fluid phase is dried, and a gallium product with the metal zinc removed is obtained, wherein the temperature of the dezincification reaction is 30-80 DEG C, the time of the dezincification reaction is 0.5-5 h, and the concentration of hydrogen ions in the acid water solution is 0.2-5 mol / l. The method can separate and remove metal zinc impurities from the high-concentration gallium raw material to obtain the high-concentration gallium product and is low in cost and easy to operate.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

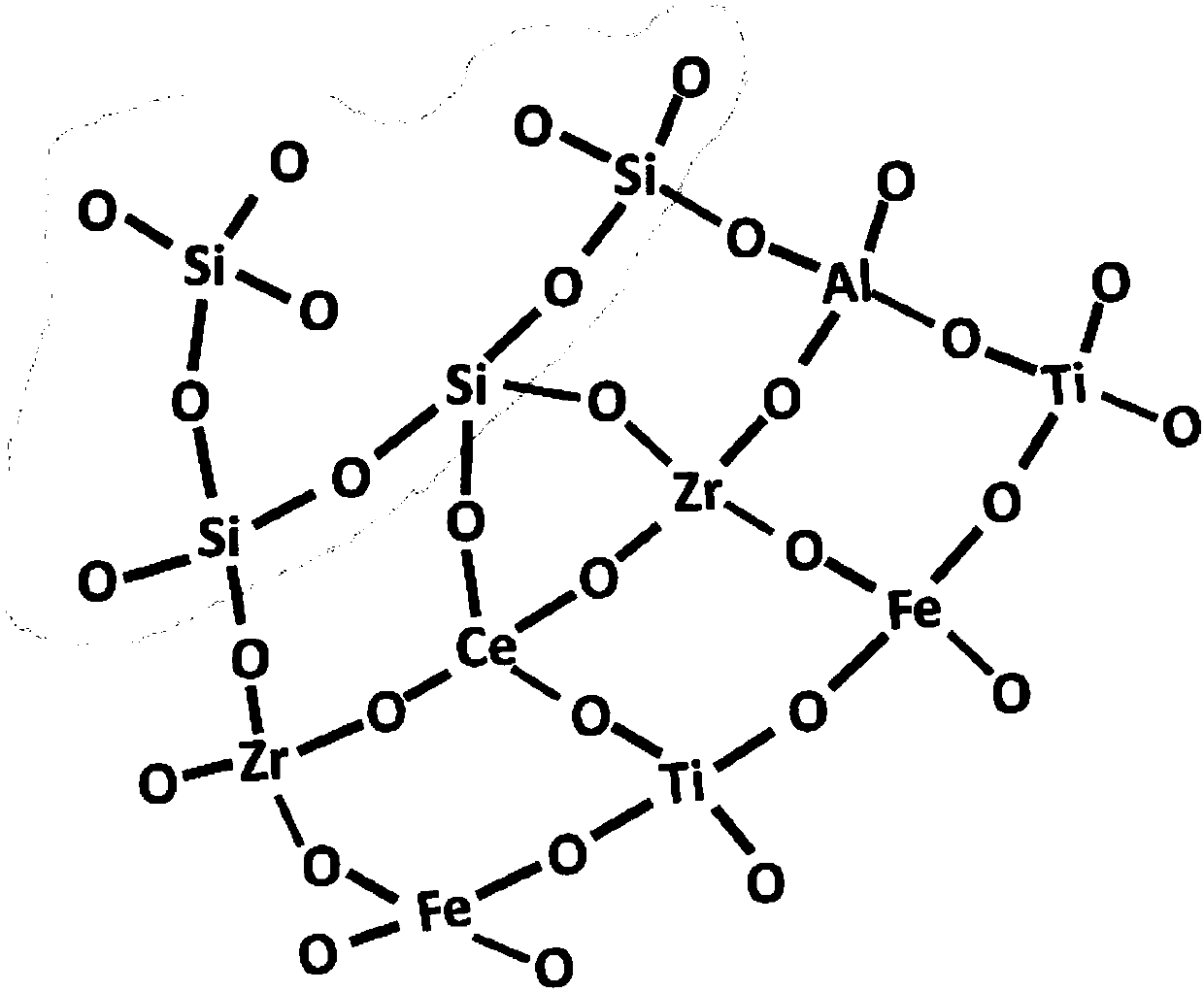

TiO2 Polycrystalline foamed ceramic catalyst, preparation method thereof and method of using catalyst to catalyze waste plastics and biodiesel to produce hydrocarbons

ActiveCN107617441AReduce generationImprove low temperature fluidityBiofuelsTreatment with plural serial refining stagesBiodieselIsomerization

The invention discloses a TiO2 polycrystalline foamed ceramic catalyst which is of double-layer porous structure, having an outermost layer of Ti-Fe-O solid solution, a middle layer of Zr-Al-Ce-O solid solution and a core of silica gel; the molar ratio of Ti, Fe, Zr, Al, Ce and O is (2.2-3.5):(1.0-1.5):(1.4-1.8):(2.6-3.0):(0.01-0.05):(15-18). The invention discloses a preparation method of the TiO2 polycrystalline foamed ceramic catalyst and also discloses a method of using the TiO2 polycrystalline foamed ceramic catalyst to catalyze waste plastics and biodiesel to produce hydrocarbons; wasteplastics are used as hydrogen donors, a WC polycrystalline foamed ceramic catalyst is used as a hydrodeoxygenation and isomerization catalyst, and the TiO2 polycrystalline foamed ceramic catalyst is used as a catalytic modifying catalyst, and biodiesel is catalyzed in a lab fixed-bed reactor to perform hydrodeoxygenation and isomerization to obtain liquid hydrocarbon fuels by conversion.

Owner:KUSN INNOVATION INST OF NANJING UNIV

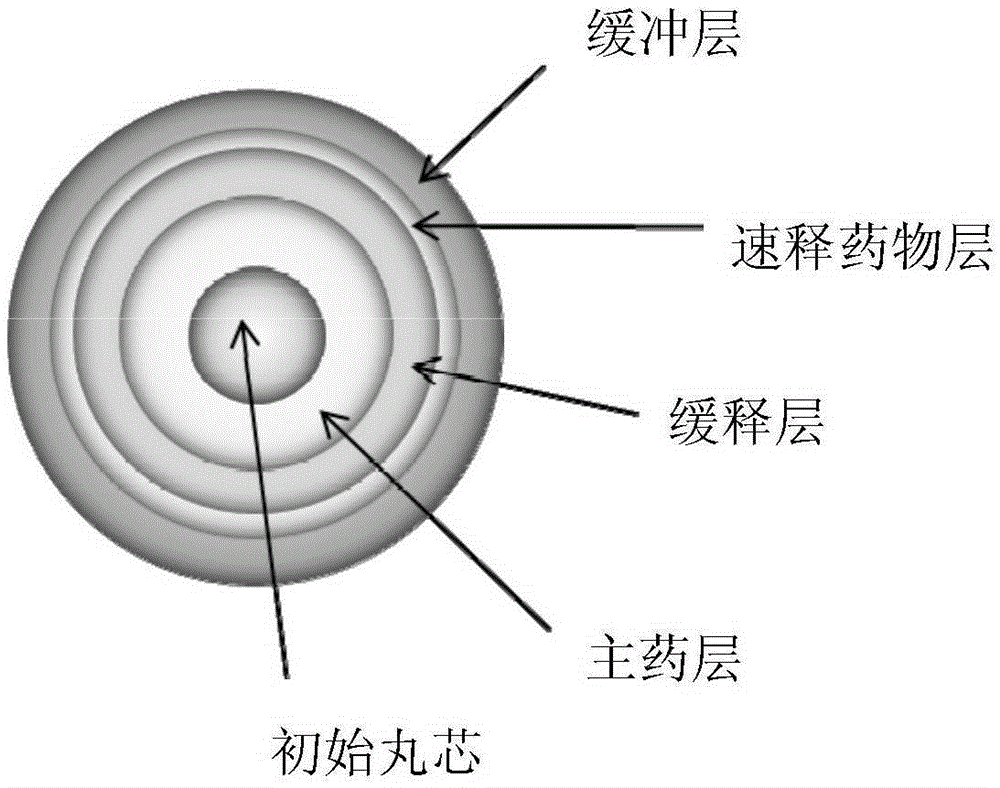

Metroprolol succinate sustained-release pellet and preparation method thereof

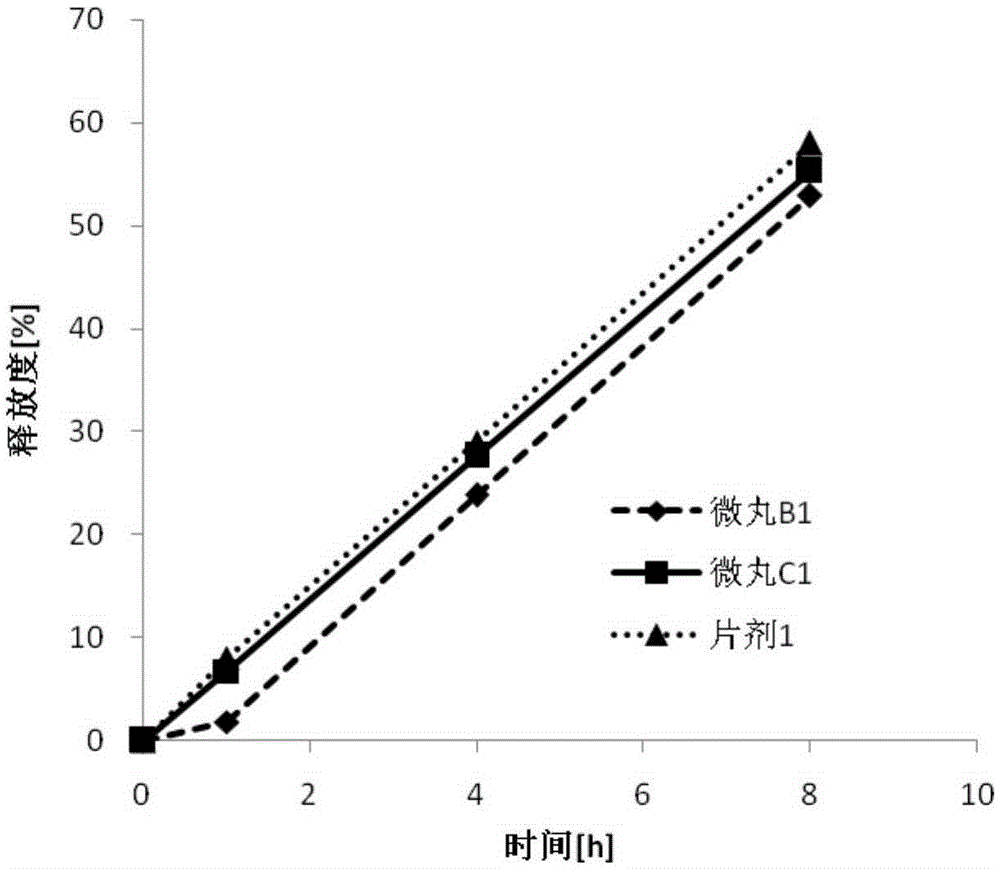

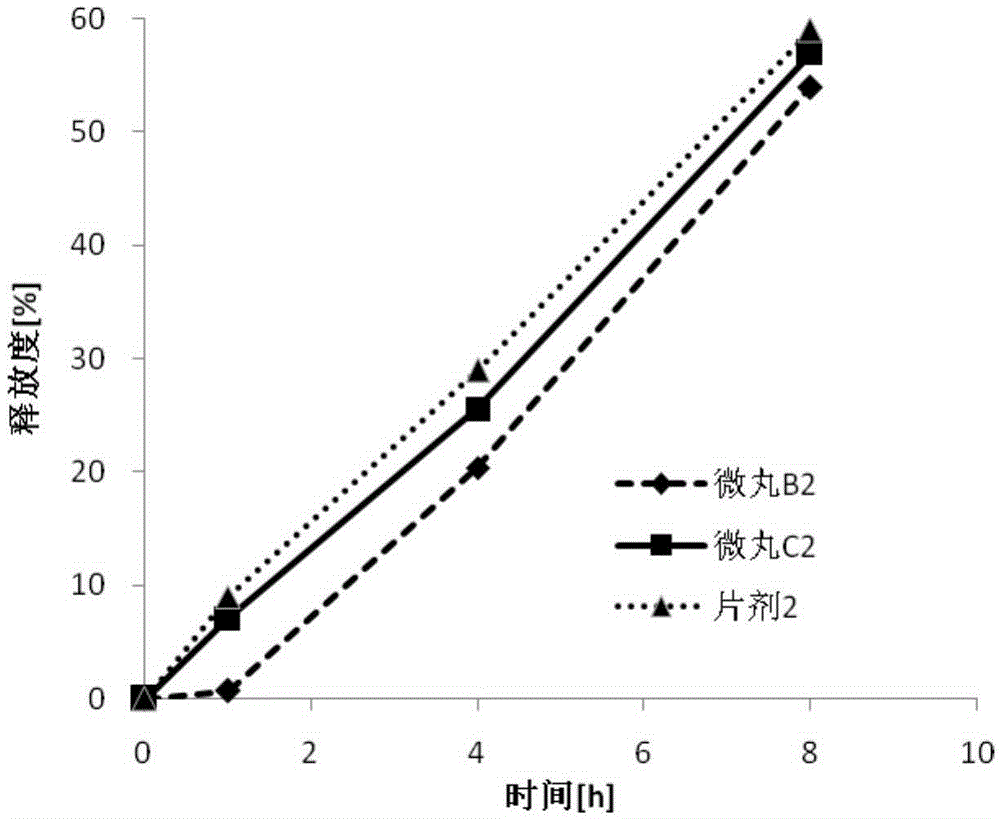

InactiveCN106420623AImprove quality controlWill not swellOrganic active ingredientsPill deliveryPhosphoric acidSustained release pellets

The invention discloses a metroprolol succinate sustained-release pellet. The metroprolol succinate sustained-release pellet sequentially comprises a hollow pellet core, a main medicine layer, a sustained-release layer, a quick-release medicine layer and a selectable buffer layer from inside to outside. According to a method in the United States Pharmacopeia, the release degree of the metroprolol succinate sustained-release pellet is determined in 50 ml of phosphoric acid buffer solution medium with the pH of 6.8 through a paddle method at the speed of 50 rpm, the sustained-release pellet can release 5% or above of metroprolol succinate within one hour and meets limit requirements specified in the United States Pharmacopeia, and a linear release curve is presented within the first eight hours.

Owner:YAOPHARMA CO LTD

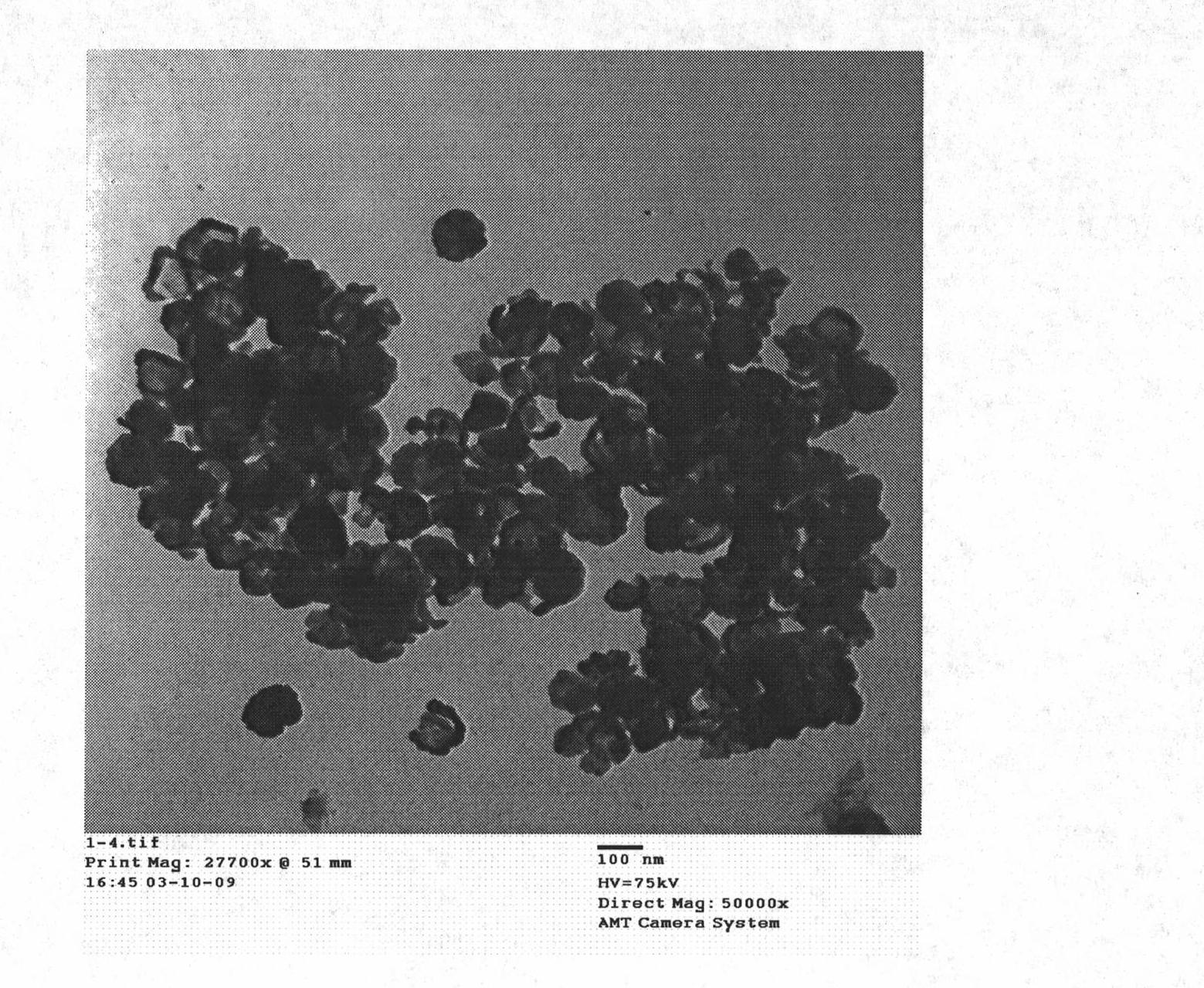

Method for preparing oxide nano-materials by melted hydrated salt

InactiveCN101519191BEasy to manufactureEasy to prepareOxide/hydroxide preparationSolventMetal halides

The invention relates to a method for preparing oxide nano-materials by hydrated salt. The method is as follows: melted hydrated salt or compound melted hydrated salt is taken as solvent and reacts wiThe invention relates to a method for preparing oxide nano-materials by hydrated salt. The method is as follows: melted hydrated salt or compound melted hydrated salt is taken as solvent and reacts with metal oxides, metal halides, metal hydroxides or metal oxyacid salts under the closed reaction condition; and the oxide nano-materials are obtained by washing, separation and drying. By adopting thth metal oxides, metal halides, metal hydroxides or metal oxyacid salts under the closed reaction condition; and the oxide nano-materials are obtained by washing, separation and drying. By adopting the melted hydrated salt, the method is suitable for preparing simple binary oxides, and is more suitable for preparing complex ternary, quaternary and multi-component oxides. The method has the advantae melted hydrated salt, the method is suitable for preparing simple binary oxides, and is more suitable for preparing complex ternary, quaternary and multi-component oxides. The method has the advantages of large-scale preparation, environment protection, synthesis at low temperature, and the like, and is particularly suitable for the industrially large-scale and environmental-friendly preparationges of large-scale preparation, environment protection, synthesis at low temperature, and the like, and is particularly suitable for the industrially large-scale and environmental-friendly preparationof the oxide nano-materials. of the oxide nano-materials.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

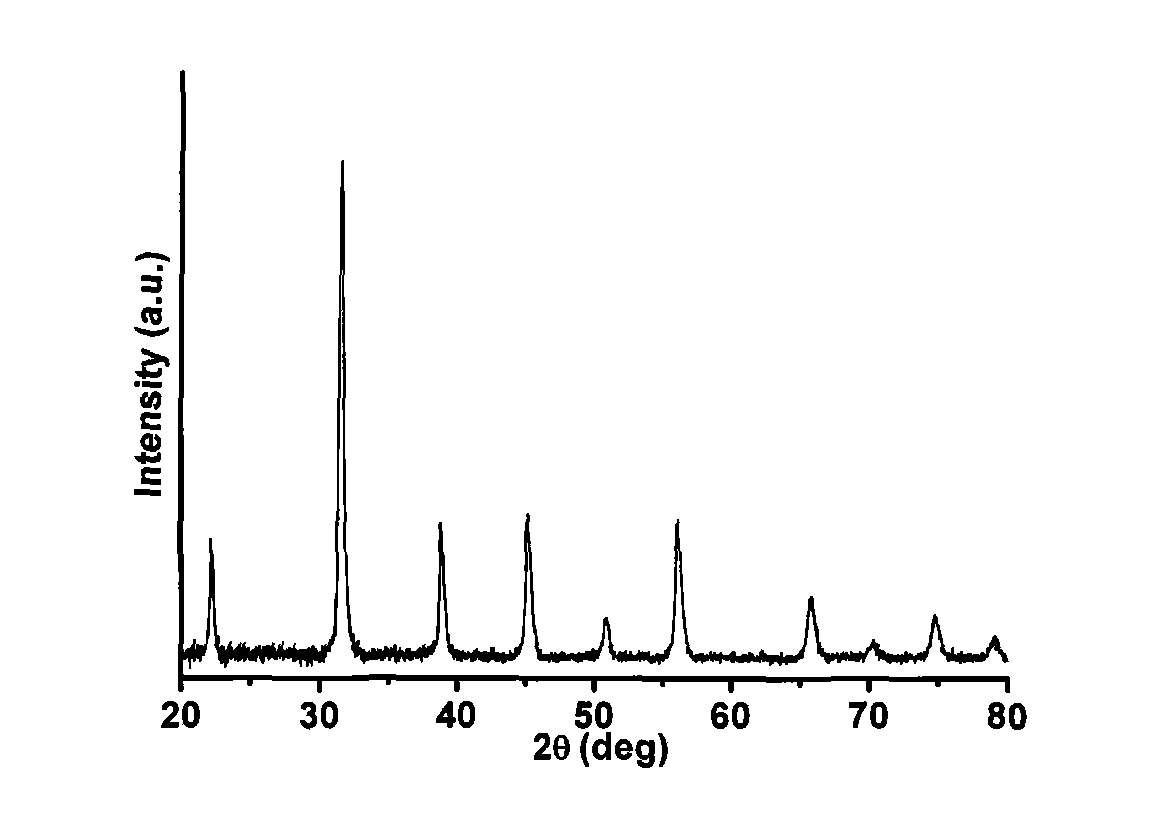

Process for preparing iron site doped LiFePO4/C through spray drying method

InactiveCN104701503AImprove performanceHigh specific capacityCell electrodesHigh rateNon noble metal

The present invention discloses a process for preparing iron site doped LiFePO4 / C through a spray drying method. The technical scheme comprises that a spray drying method is adopted to prepare a series of valence-variable transition metal Fe site doped LiFe1-xMxPO4 / C (M is Co, Mn, Ni, V, and Cu) composite materials, and the optimization process shows that the prepared sample has the best electrochemical performance when the doping amount of V or Ni is 3% so as to significantly improve the specific capacity of the material at the high rate and significantly improve the cycle stability of the material. The process of the present invention has the following characteristics that the bulk phase doping and the industrial scaling-up are easily achieved through the spray drying method, and the selected doped elements are the transition metals which are the non-noble metals, such that the high-performance doped LiFePO4 / C positive electrode material prepared by using the spray drying method has the great prospects.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

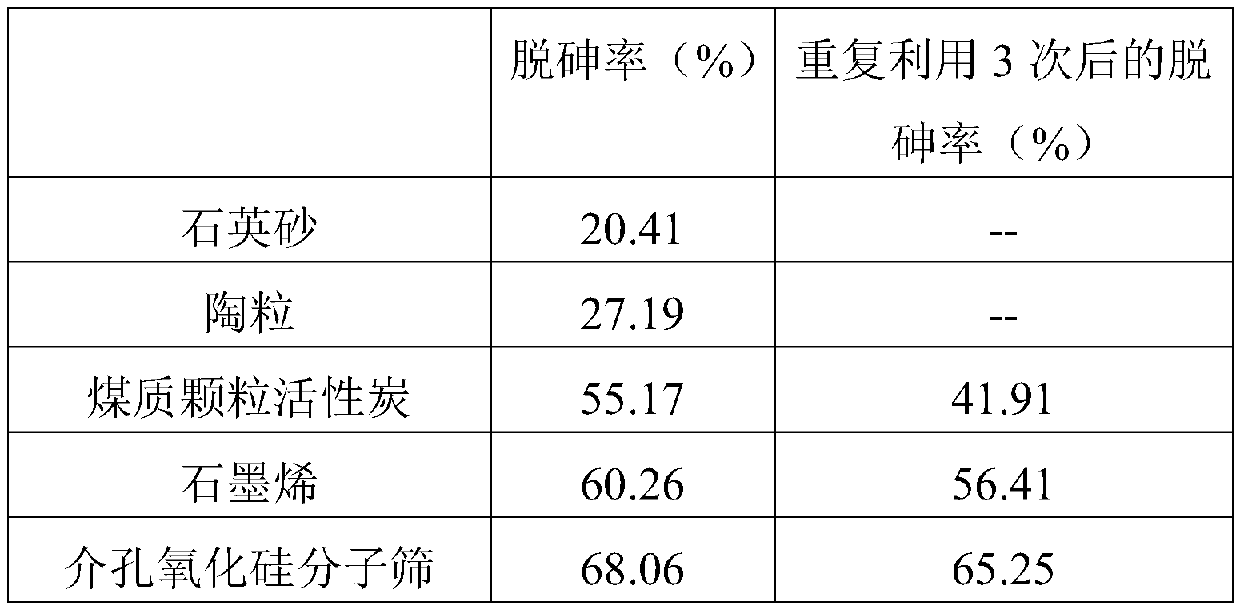

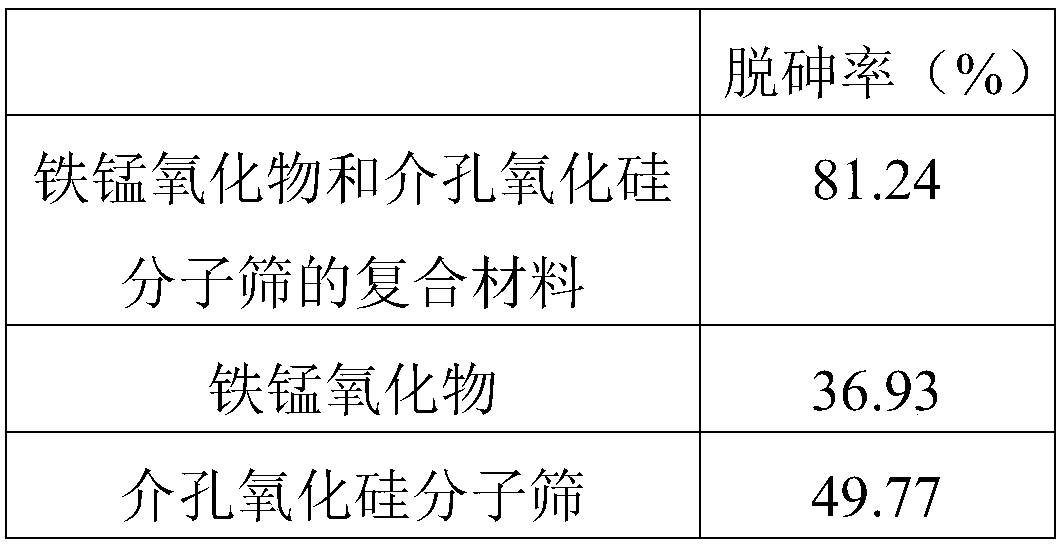

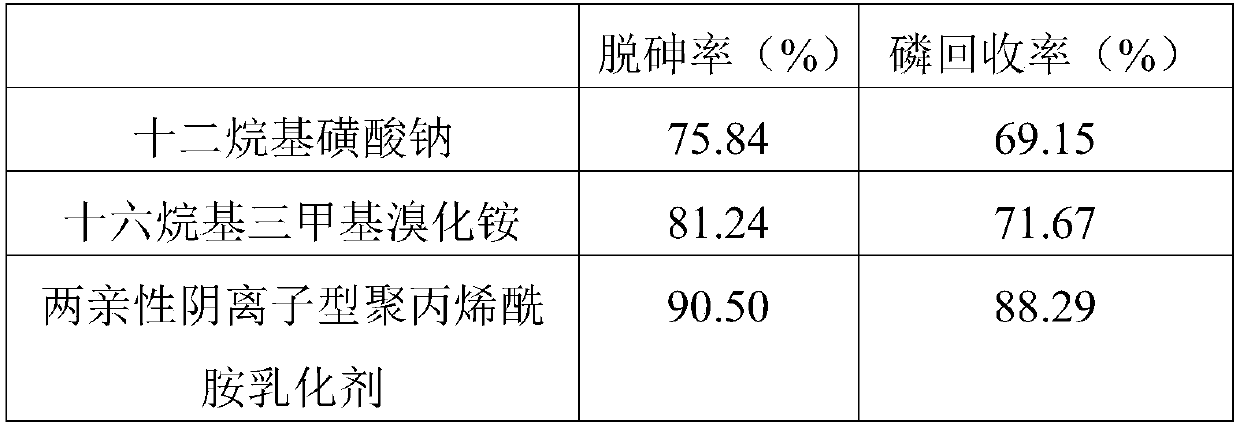

Yellow-phosphorus purification technology

ActiveCN109607501AHigh arsenic removal rateHigh recovery ratePhosphorus compoundsSorbentYellow phosphorus

The invention discloses a yellow-phosphorus purification technology. The yellow-phosphorus purification technology includes the following steps that I yellow phosphorus and hydrogen peroxide are heated and stirred, and the yellow phosphorus is separated and washed; II the yellow phosphorus after being washed in the step I and an arsenic-removing adsorbent are heated and stirred, and the yellow phosphorus is separated and washed; III the yellow phosphorus after being washed in the step II is added into an oxidation reinforcing agent and nitric acid, heating and stirring are carried out, and theyellow phosphorus is separated and washed; IV the yellow phosphorus after being washed in the step III and an iron-removing adsorbent are heated and stirred, and the yellow phosphorus is separated and washed. The yellow-phosphorus purification technology is simple in process, safe in operation, high in arsenic-removing rate and iron-removing rate and excellent in phosphorus recovery rate, and industrial amplification is easy to achieve.

Owner:中州新材料(杭州)有限公司

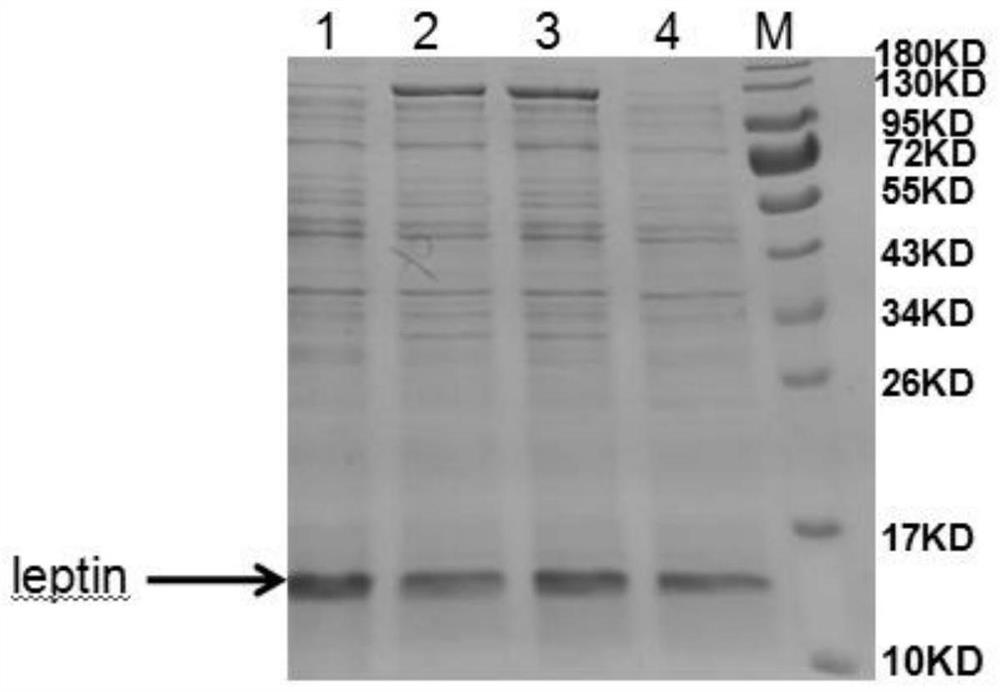

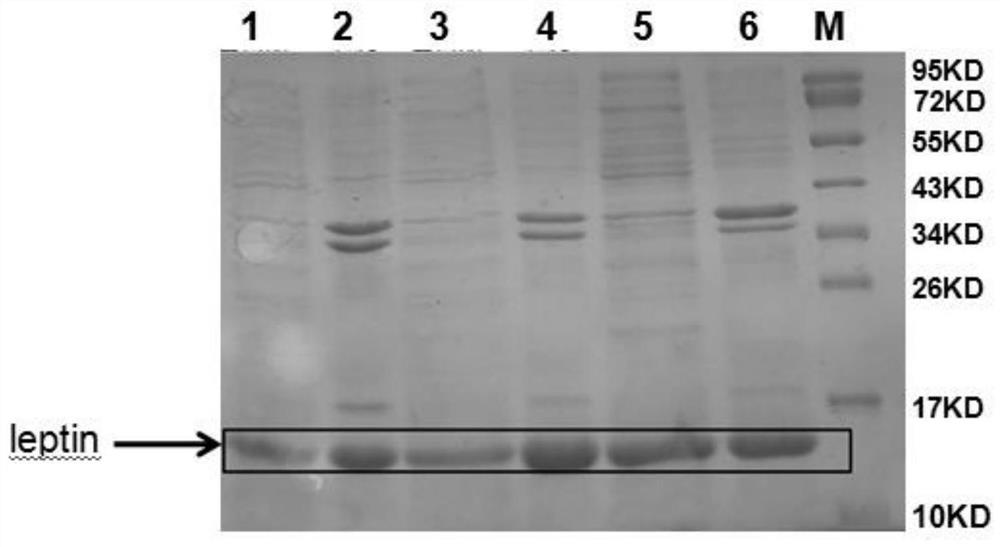

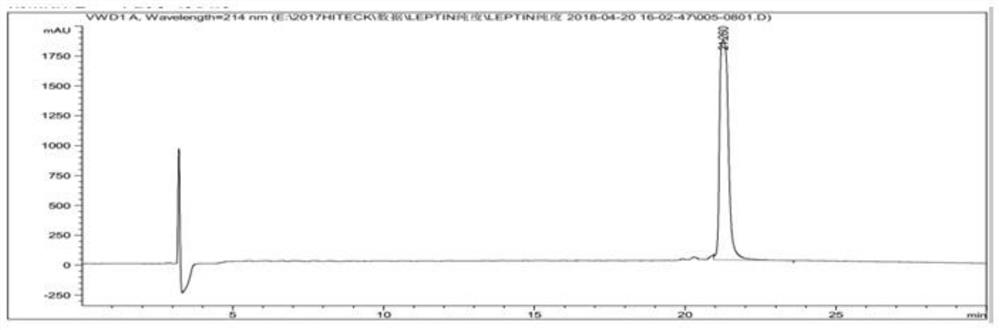

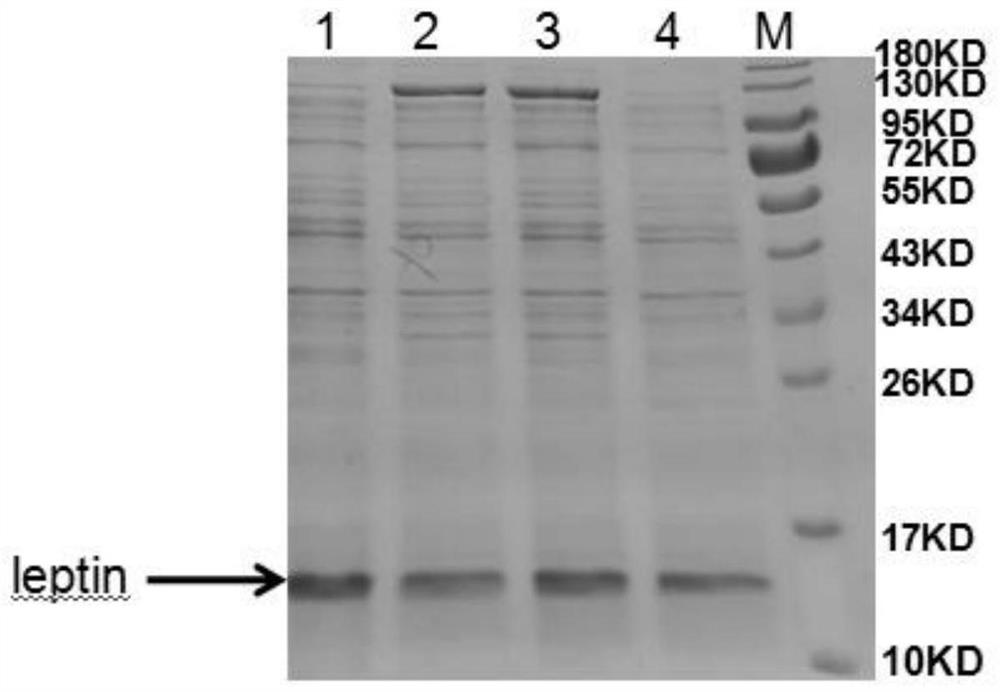

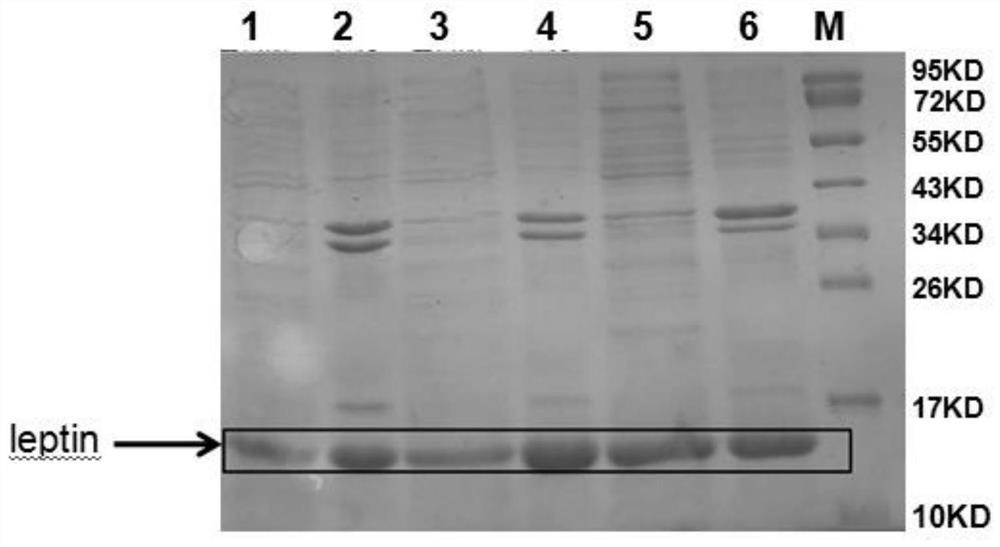

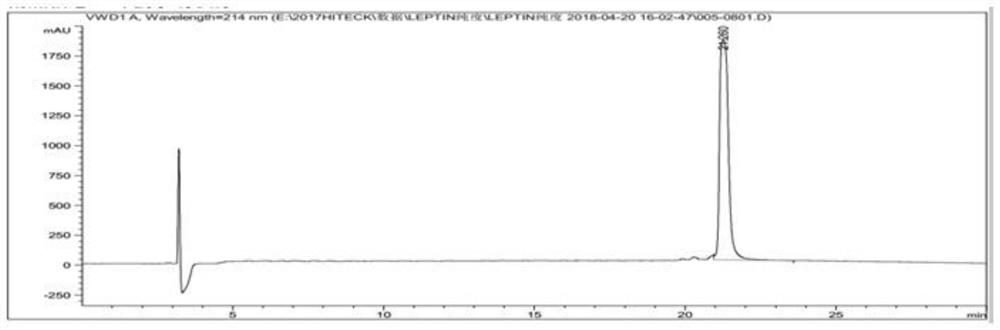

Preparation method of metreleptin

ActiveCN111848774APrevent oxidationAvoid degradationObesity gene productsPeptide preparation methodsInclusion bodiesProtein target

The invention discloses a preparation method of metreleptin, which specifically comprises the following steps: expressing metriptostine genes through a prokaryotic expression system to obtain an inclusion body, dissolving the inclusion body, and carrying out hydrophobic chromatography renaturation to obtain metriptostine protein. Inclusion body dissolution and hydrophobic chromatography renaturation are both carried out in a mild mode, and an antioxidant and / or a metal chelating agent can also be added in the process so as to inhibit oxidation and degradation of target protein. The metreleptinprepared by the method is easy to realize industrial amplification, high in renaturation efficiency, high in yield and good in biological activity.

Owner:WUHAN HITECK BIOLOGICAL PHARMA

A kind of preparation method of mettriptine

ActiveCN111848774BPrevent oxidationAvoid degradationObesity gene productsPeptide preparation methodsInclusion bodiesAntioxidant

The invention discloses a method for preparing mettriptin, specifically, the mettriptin gene is expressed through a prokaryotic expression system to obtain inclusion bodies, the inclusion bodies are dissolved, and hydrophobic chromatography renaturation is performed to obtain mettriptin protein. Both inclusion body solubilization and hydrophobic chromatographic renaturation are carried out in a gentle manner, and antioxidants and / or metal chelating agents can also be added during the process to inhibit the oxidation and degradation of the target protein. The method for preparing mettriptin is easy to realize industrial scale-up, high renaturation efficiency, high yield and good biological activity.

Owner:WUHAN HITECK BIOLOGICAL PHARMA

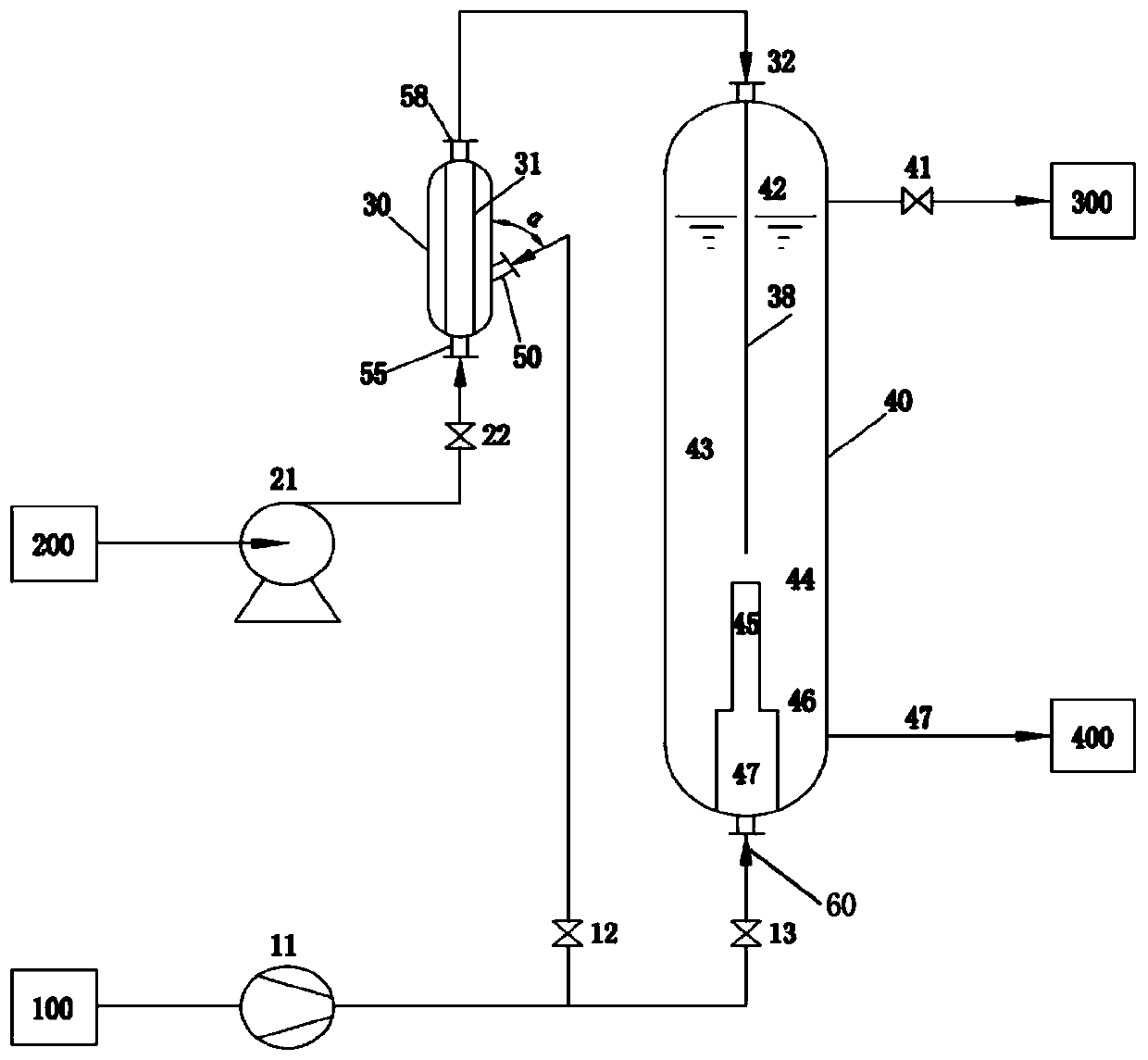

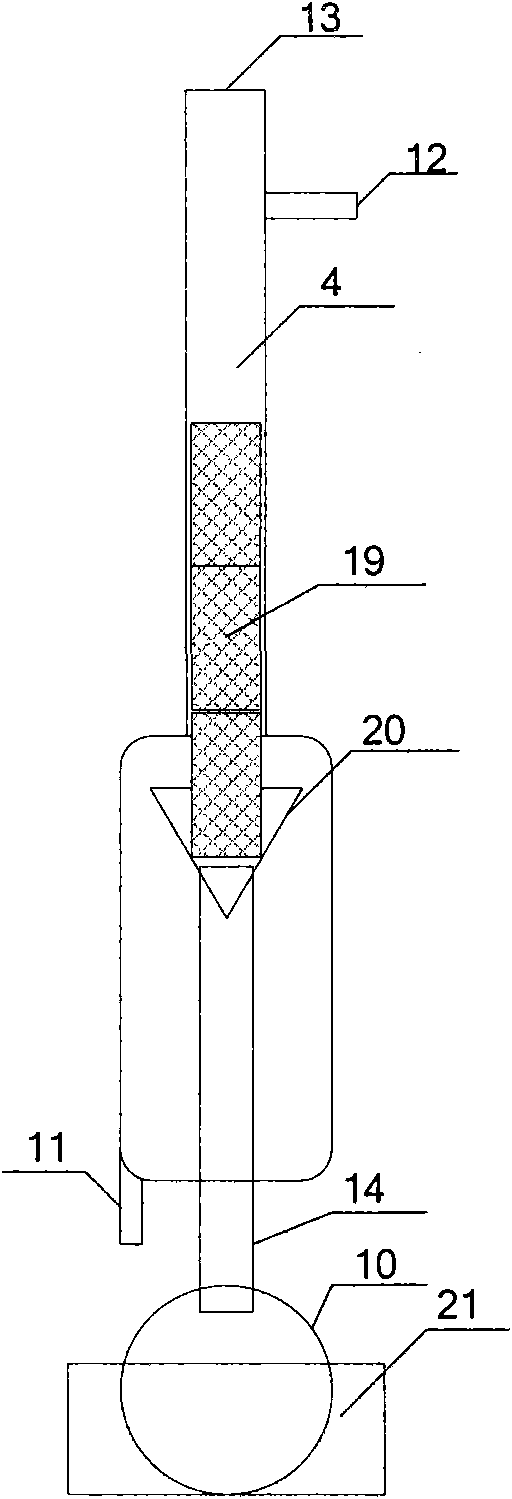

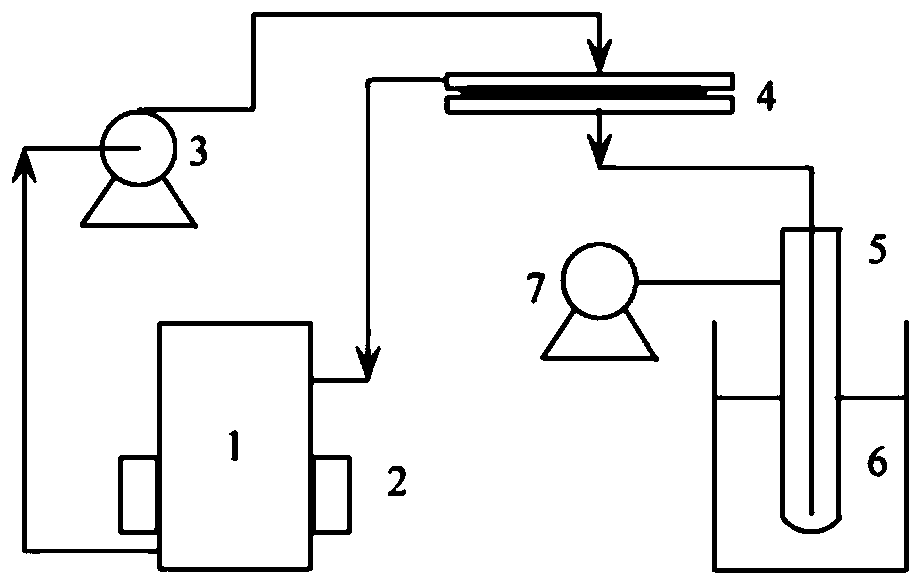

Micro-nano scale multiphase flow process enhanced reaction device

PendingCN110420609AWide range of industrial applicationsIncrease profitProcess control/regulationMicro nanoVolumetric Mass Density

A micro-nano scale multiphase flow process enhanced reaction device includes a compressor, a feed pump, a micro-nano multi-phase flow generation device, and a multi-phase flow process enhanced reactor. According to fluid flux or hydraulic loading in the micro-nano multi-phase flow generation device, the multi-phase flow process enhanced reactor can be composed of two or more micro-nano multi-phaseflow micro-element generators connected in parallel. A dispersion medium generator and a base are disposed inside the multi-phase flow process enhanced reactor. Compared with conventional bubbling towers, packed beds and stirred tank type gas-liquid reactors, multi-phase fluid produced by the device can make the gas-liquid two specific surface area increase by 1-2 orders of magnitude to 10<4>-10<5> m<2> / m<3>, a liquid side total volume mass transfer coefficient kL[alpha] value in a gas-liquid two-phase reaction controlled by a liquid film can be significantly increased to a range of 0.5-10 s<-1>, and the device has obvious competitive advantages in terms of phase microscopic transmission efficiency, molecular diffusion transfer rate, gas-liquid phase ratio interfacial area, specific energy input density, comprehensive energy efficiency, device operation stability, safety guarantee, and the like.

Owner:杭州烃能科技研究有限公司

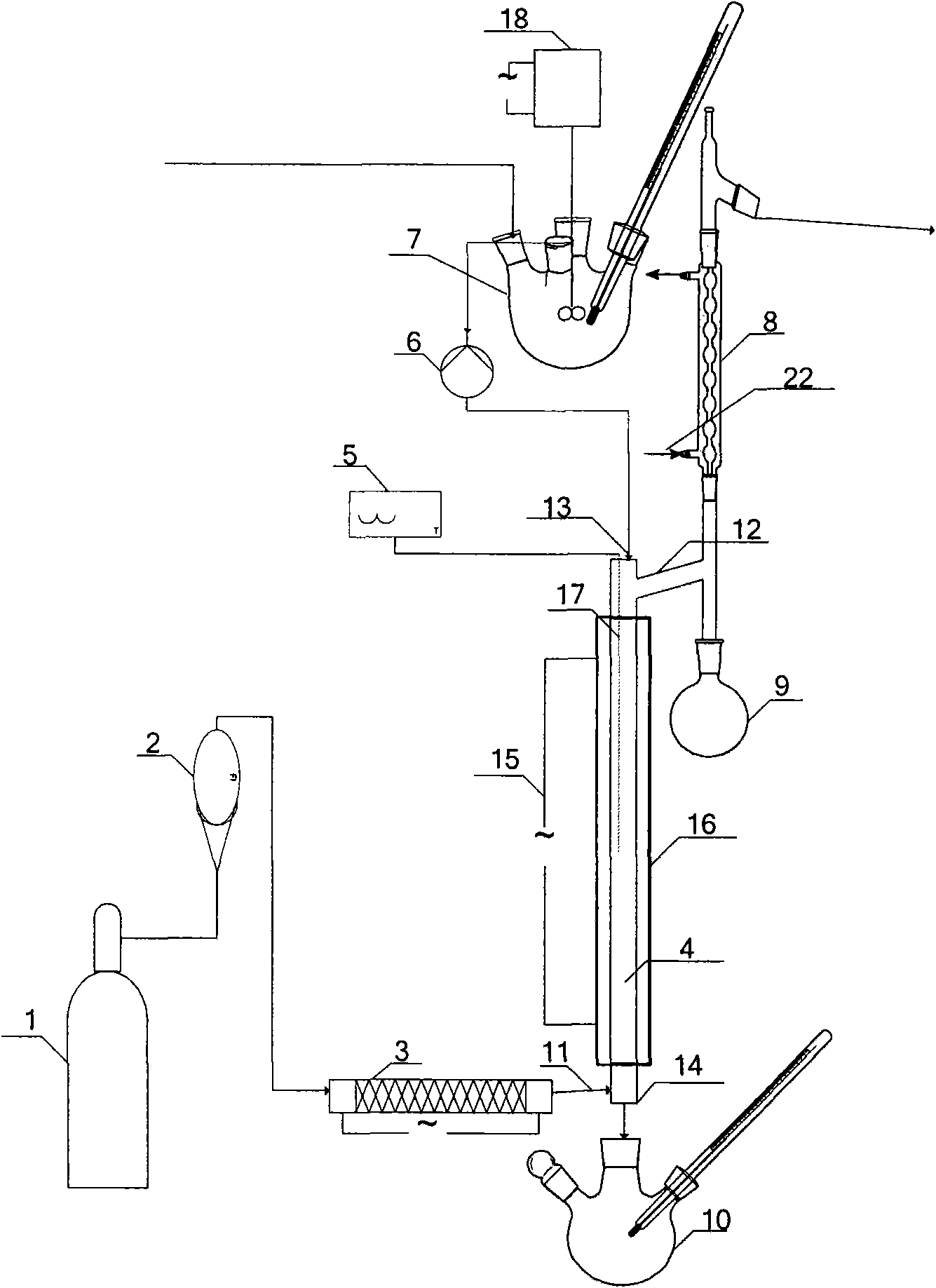

Gas-liquid-solid three-phase counter-current reaction device and method for pyrolytic reaction of carbamic acid ester

ActiveCN101870665BImprove heat transfer performanceUniform temperature distributionPreparation from carbamatesHeat carrierAlcohol

The invention discloses a gas-liquid-solid three-phase counter-current reaction device and a gas-liquid-solid three-phase counter-current reaction method for pyrolytic reaction of carbamic acid ester, and belongs to the technical field of pyrolytic reaction of carbamic acid ester. The reaction device comprises a reactor, a carrier gas preheating part, a feeding part, a product collecting part, a byproduct collecting and condensing part, a gas outlet and a feed liquid outlet. The upper part of the reactor is provided with a feed liquid inlet, the bottom of the reactor is provided with a gas inlet, and gas and liquid in the reactor are in counter-current contact so as to form a gas-liquid-solid three-phase counter-current reactor; carrier gas is preheated by the preheater, and enters the reactor through the gas inlet; the reaction feed liquid is preheated in the feeding part, and enters the reactor through the feed liquid inlet; in the reactor, the reaction feed li quid and the carrier gas are in counter-current contact fully, heat is transferred by a heat carrier, and the pyrolytic reaction is carried out; the carrier gas brings byproducts alcohols out from the gas outlet on the upper part of the reactor, and the reaction feed liquid is moved through the feed liquid outlet on the bottom of the reactor; and the byproduct collecting and condensing part collects, condenses and recovers the byproducts alcohols. The device and the method have the advantages of quick heat and mass transfer of gas, liquid and solid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

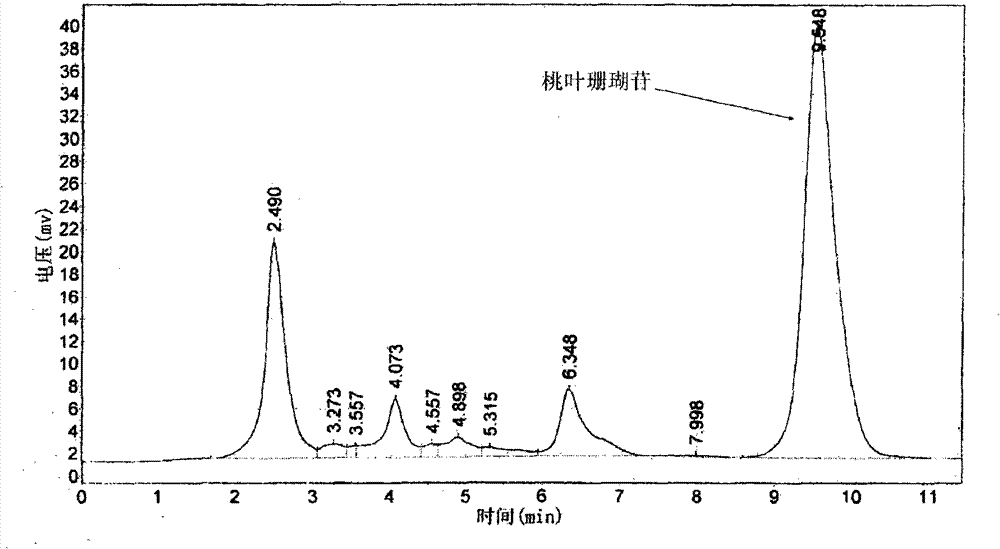

Preparation method of high pure crocin and geniposide

InactiveCN103387489BRealize comprehensive utilizationEfficient use ofSugar derivativesNatural dyesChlorogenic acidGenipin

The invention discloses a preparation method of high pure crocin and geniposide. The preparation method comprises following main steps: selecting raw materials of gardenia ellis plants, extracting with water or an alcohol-water mixed solution, merging the extracting solutions, condensing, filtering, subjecting the obtained extracting solution to an adsorption treatment by macroporous resin, then performing gradient elution with a ethanol-water mixed solution, obtaining geniposide and gardenia yellow refined extracts; subjecting the geniposide refined extract to a recrystallization treatment with ethyl acetate so as to obtain the geniposide product; subjecting the gardenia yellow refined extract to go through column chromatography, which has been pressurized and stuffed with modified silica gel, to separate, and obtaining the high pure crocin product (color value larger than 600) and a chlorogenic acid component. The products have the advantages of high purity, simple technology, strong operability and convenience for automation, comprehensive utilization of the plant resources is achieved, the solvent is convenient to recycle and reuse, and the preparation method is easy to apply to the industrial amplification.

Owner:SUZHOU QIUSHI HERBAL HEALTH TECH CO LTD

Catalyst, preparation method and application of carbon dioxide decomposition to prepare carbon monoxide

ActiveCN103464134BImprove thermal stabilityGood cycle reaction stabilityCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsChemical compositionDecomposition

The invention relates to a catalyst for preparing carbon monoxide by decomposing carbon dioxide, which is a composite metal oxide obtained by doping Mg and Ca in a cerium-zirconium solid solution. The chemical composition of the catalyst is expressed by the following general formula: Ce0.8-xZr0.2MxO2-x, wherein x equals 0.02-0.1, M is doping metal Mg or Ca, and x is the molar fraction of the doping metal. The catalyst disclosed by the invention has the advantages of high activity, high thermal stability and long service life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technological process for extracting aucubin from fruits of eucommia ulmoides oliver

InactiveCN101982471BNo pollution in the processMeet the needs of developmentNervous disorderSugar derivativesAucuba chinensisSolvent

The invention relates to a technological process for extracting aucubin from fruits of eucommia ulmoides oliver, which comprises the following steps: cutting the fruits of the eucommia ulmoides oliver into pieces, extracting with water or ethanol solution as an extraction solvent, and purifying the obtained extracting solution with macroporous resin to obtain the aucubin the purity of which is more than 50%. The technological process has the advantages of low toxicity, safety, short process time, no environmental pollution, simple and convenient operation, easy industrialization enlargement, high yield and good purity of the product, thus meeting various needs for development of drugs taking the fruits of the eucommia ulmoides oliver as main raw materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A pervaporation blend membrane for separating methanol-tetrahydrofuran and its preparation method

ActiveCN107281942BEasy to makeRaw materials are easy to getMembranesSemi-permeable membranesCellulose acetateChemical stability

The invention relates to a pervaporation blend membrane for separating a mixture methanol and tetrahydrofuran and a preparation method of permeation vaporization blend membrane. The pervaporation membrane with a uniform and compact structure is prepared by virtue of a blending method by adopting P84 polyimide and cellulose acetate as basic raw materials. The pervaporation blend membrane has the beneficial effects that the blend membrane gives priority to the permeation of methanol and can separate the methanol and tetrahydrofuran mixture and purify the tetrahydrofuran; the pervaporation method adopted to separate the methanol-tetrahydrofuran mixture has the advantages of high separation efficiency, simple equipment, low energy consumption, no pollution and the like; and the blend membrane is excellent in separation performance and high in chemical stability, the materials for preparing the membrane is conventional, easy to get and low in price, and the industrialized production is facilitated.

Owner:CHANGZHOU UNIV

Tungstenic functional mesoporous molecular sieve catalyst for preparation of glutaric acid based on glutaraldehyde oxidation and preparation method of catalyst

InactiveCN108355703ANot easy to loseMaintain a two-dimensional hexagonal structureMolecular sieve catalystsOrganic compound preparationMolecular sieveGlutaric acid

The invention belongs to the technical field of catalysts and relates to a tungstenic functional mesoporous molecular sieve catalyst for preparation of glutaric acid based on glutaraldehyde oxidationand a preparation method of the catalyst. The catalyst is a functional mesoporous molecular sieve SBA-15 supported tungstic catalyst (W-SBA-15), and tungsten is introduced into a framework of a functional mesoporous molecular sieve SBA-15 with a post-synthesis method. The method comprises steps as follows: the mesoporous molecular sieve SBA-15 is dispersed in a solvent and stirred, an organosilaneagent is added, a mixture is stirred, subjected to reflux, filtered, dried, subjected to Soxhlet extraction and dried, dichloromethane is added, stirring is performed, trifluoromethanesulfonic acid is added, stirring, filtering, ethanol rinsing and drying are performed, then a tungsten source is added, stirring, filtering, water washing and drying are performed, and the catalyst is obtained. Themethod is easy to operate. The prepared tungstenic functional mesoporous molecular sieve SBA-15 heterogeneous catalyst is highly ordered in porous structure, tungsten species is highly dispersed, andultrahigh stability is obtained. The prepared W-SBA-15 heterogeneous catalyst is applied to a reaction of preparation of glutaric acid based on glutaraldehyde oxidation, conversion rate of glutaraldehyde can reach 99% or higher, yield of glutaric acid can reach 98% or higher, and the catalyst can be repeatedly used 20 times or more with unchanged activity.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com