TiO2 Polycrystalline foamed ceramic catalyst, preparation method thereof and method of using catalyst to catalyze waste plastics and biodiesel to produce hydrocarbons

A foamed ceramic, biodiesel technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as unfavorable large-scale production, complex reaction process, unfavorable cleaning Production and other problems, to achieve the effect of easy industrialized continuous production, simple preparation process, and improved low temperature flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

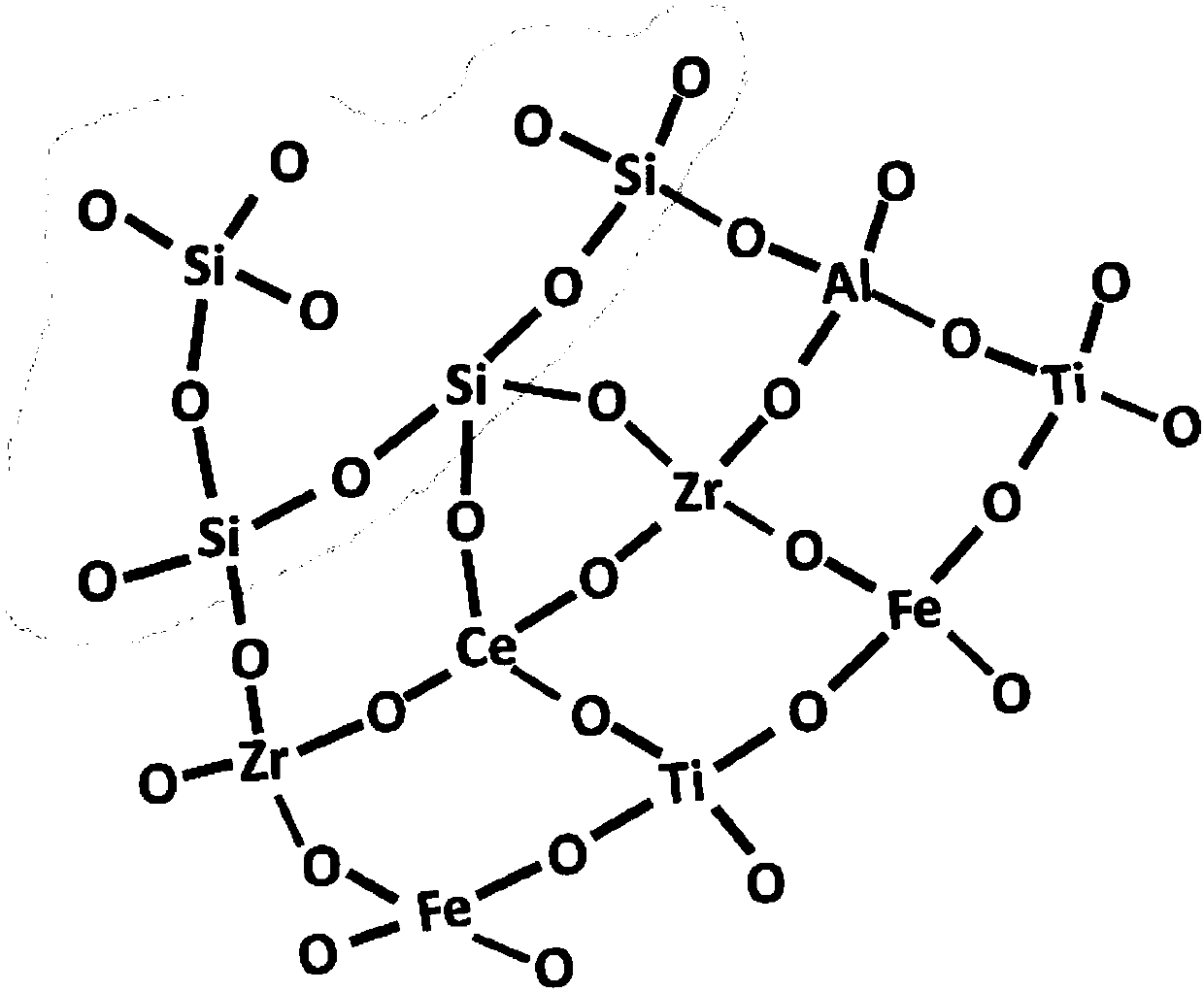

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of WC polycrystalline foam ceramic catalyst

[0040] Weigh 2Kg of ammonium paratungstate and carbon black respectively and add them into the ball mill, add zirconia balls and absolute ethanol according to the ratio of 1.5:2 to form a slurry, and then wet-mill for 10h. The obtained slurry was spray-dried at 100°C to obtain a precursor. Then the precursor was put into a vacuum muffle furnace and calcined at 1650°C and 10Pa for 4h to obtain a crude WC product with excess carbon black content. The WC crude product was put into an atmosphere furnace, calcined at 600 °C for 4 h under air conditions to remove excess carbon black to obtain WC powder.

[0041] Weigh 1.5Kg WC, 0.11Kg nickel nitrate, 0.21Kg pseudo-boehmite, 0.32Kg silica gel, 0.32Kg basic zinc carbonate, 0.37Kg ammonium bicarbonate, 0.49Kg starch by weight respectively, add them to the powder mixer and mix for 10h, Put the mixed material into a screw press to make a cylinder with a diameter of 2m...

Embodiment 2

[0046] The catalyst used in Example 2 was prepared according to the method disclosed in Example 1, and the preparation method is detailed in Example 1.

[0047] The pyrolysis gasification furnace filled with waste plastic PE was purged with nitrogen gas for 30 minutes, the pyrolysis temperature was set to 350°C, and the pyrolysis gasification rate of waste plastics was controlled to be 2 L / min by means of temperature programming. The cracked gas enters the gas filter filled with TiO 2 The fixed bed reactor of polycrystalline foam ceramic catalyst is catalytically reformed at 250 °C, the purpose is to catalyze waste plastics to produce a large amount of H 2 . Then the obtained oil-containing gas and waste oil biodiesel co-flow into a fixed-bed reactor filled with WC polycrystalline foam ceramic catalyst. -1 Condition, the reaction is 0.8h. The resulting product is separated and removed by a gas-liquid separator to remove CO and CO. 2 , H2 , CH 4 After mixing with low-carbo...

Embodiment 3

[0049] The catalyst used in Example 3 was prepared according to the method disclosed in Example 1, and the preparation method is detailed in Example 1.

[0050] The waste plastic PET was added to the pyrolysis gasification furnace, and the whole system was purged with nitrogen for 30 minutes. The cracked gas enters the gas filter filled with TiO 2 The fixed bed reactor of polycrystalline foam ceramic catalyst is catalytically modified at 350 °C, the purpose is to catalyze waste plastics to produce a large amount of H 2 . Then the obtained oil-containing gas and waste oil biodiesel co-flow into a fixed-bed reactor filled with WC polycrystalline foam ceramic catalyst. -1 Condition, the reaction is 0.8h. The resulting product is separated and removed by a gas-liquid separator to remove CO and CO. 2 , H 2 , CH 4 After mixing with low-carbon hydrocarbons, it enters the vacuum fractionation tower to divide the reaction products, and collects the distillate at the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com