Copper fluoride based hydrotalcite-like catalyst, method for preparing same and application of copper fluoride based hydrotalcite-like catalyst

A technology of hydrotalcite and copper fluoride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of hydroxyl compounds. It can solve the problems of difficult control of the amount of fluoride ion introduced, agglomeration, and time-consuming, etc., to improve methanol selection. The effect of high stability, stable performance, and a large number of strong alkaline sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

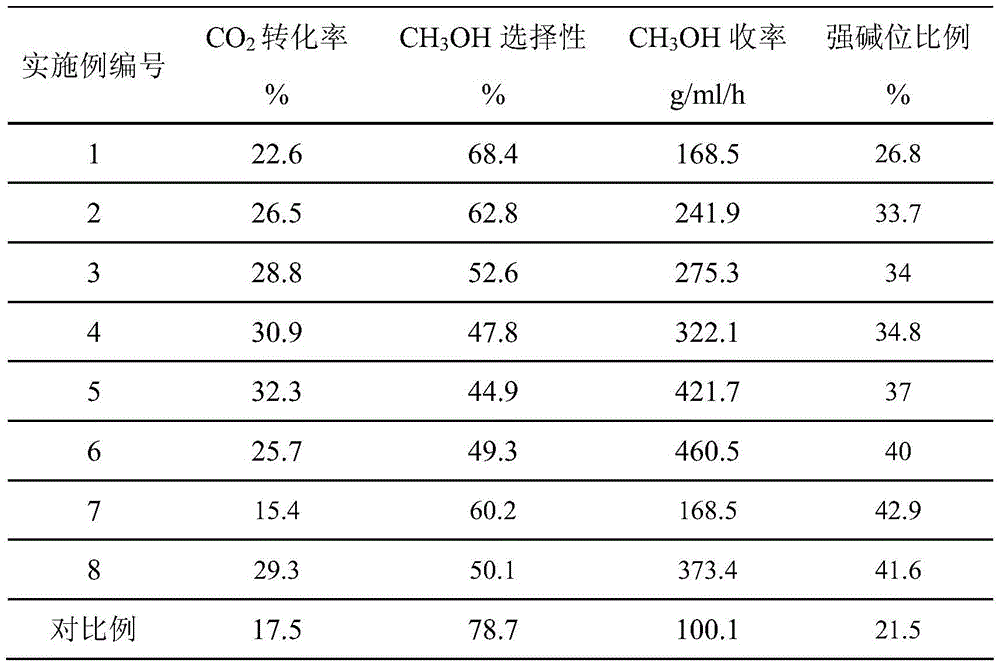

Examples

Embodiment 1

[0033] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.05 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to form a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 20°C, fully stir during the dropping process, and keep the final pH value at 8. After the precipitation reaction is completed, the obtained The product was aged at 70° C. for 24 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 70° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 270° C. for 12 h under a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. The carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=5.0MPa, T=230°...

Embodiment 2

[0035] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.15 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to form a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 20°C, fully stir during the dropping process, and keep the final pH value at 9. After the precipitation reaction is completed, the obtained The product was aged at 70° C. for 24 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 80° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 290° C. for 8 h under a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. The carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=5.0MPa, T=250°C...

Embodiment 3

[0037] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.25 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to make a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 25°C, fully stir during the dropping process, and keep the final pH value at 9. After the precipitation reaction, the obtained The product was aged at 80° C. for 12 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 90° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 300° C. for 8 h in a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. Carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=4.0MPa, T=270°C, GHSV=5000h -1 , n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com