Micro-nano structure copper-based catalyst and preparation method and application thereof

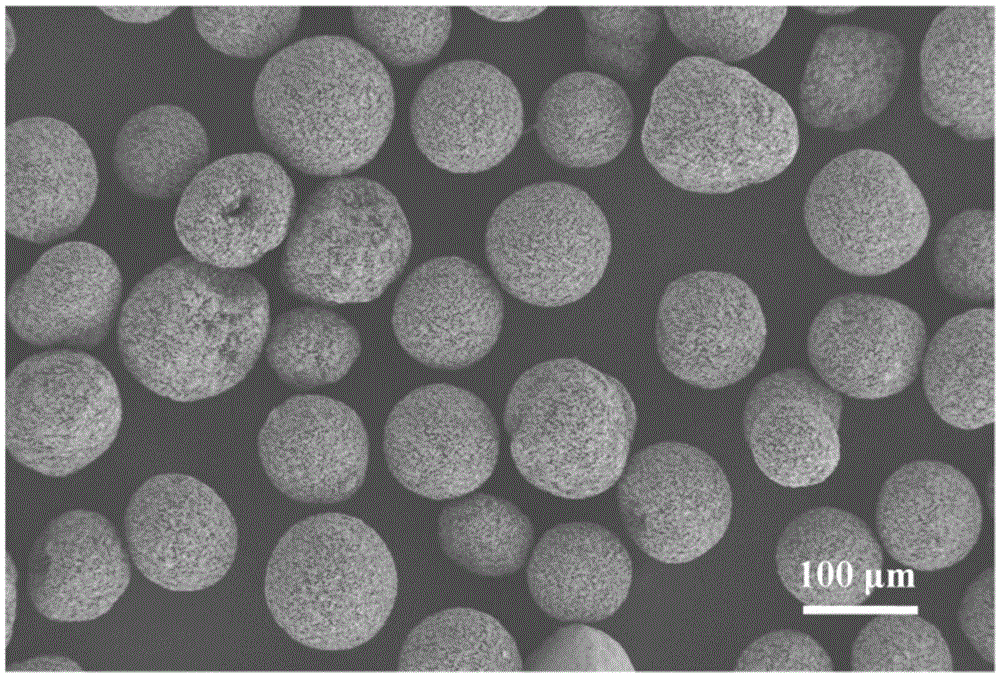

A copper-based catalyst, a technology of micro-nano structure, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high dispersion of active copper particles, affecting catalytic reaction activity, and sintering of copper nanoparticles. , to achieve the effect of improving the load and dispersibility, large interaction, and high dispersity of metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of catalyst: 9.112gCu(NO 3 ) 2 .3H 2 O, 5.483gZn(NO 3 ) 2 .6H 2 O, 53.946g (NH 4 ) 2 CO 3 Dissolve in 175mL of ammonia solution (25wt%), add deionized water to the total volume of the solution to 500mL, stir to make it completely dissolved, to obtain the precursor salt solution, the precursor salt solution is transferred to a four-necked flask, and placed In an oil bath, add 10g of Al to it while stirring 2 o 3 Carrier, continue to react for 1h. Heat the oil bath to 120°C and continue stirring for a certain period of time. After the stirring is stopped, the supernatant of the solution becomes colorless, which is the end point of the reaction. After the reaction, wash with deionized water for 3 times, and dry the obtained precipitate at 100°C overnight, and bake the dried sample at 400°C for 4 hours to prepare the copper-based micro-nano structure material CuO / ZnO / Al 2 o 3 .

[0029] Take 1.00 g of the above sample and put it in a fixed-bed r...

Embodiment 2

[0031] Preparation of catalyst: 1.519gCu(NO 3 ) 2 .3H 2 O, 0.914gZn(NO 3 ) 2 .6H 2 O, 4..496g (NH 4 ) 2 CO 3Dissolve in 29mL of ammonia solution (25wt%), add deionized water to it until the total volume of the solution is 500mL, stir to make it completely dissolved to obtain a precursor salt solution, transfer the precursor salt solution to a four-necked flask, and place In an oil bath, add 10g of Al to it while stirring 2 o 3 Carrier, continue to react for 1h. Heat the oil bath to 50°C and continue to stir for a certain period of time. After the stirring is stopped, the supernatant of the solution becomes colorless, which is the end of the reaction. After the reaction, wash with deionized water for 3 times, and dry the obtained precipitate at 60°C overnight, and bake the dried sample at 200°C for 8 hours to prepare copper-based micro-nano structure material CuO / ZnO / Al 2 o 3 .

[0032] Take 1.00 g of the above sample and put it in a fixed-bed reactor, and first re...

Embodiment 3

[0034] Preparation of catalyst: 2.283gCu(Ac) 2 , 1.127gZn(Ac) 2 , 8.991g (NH 4 ) 2 CO 3 Dissolve in 58mL of ammonia solution (25wt%), add deionized water to it until the total volume of the solution is 500mL, stir to make it dissolve completely, obtain the precursor salt solution, transfer the precursor salt solution into a four-necked flask, and place In an oil bath, add 10g of Al to it while stirring 2 o 3 Carrier, continue to react for 1h. Heat the oil bath to 90°C and continue to stir for a certain period of time. After the stirring is stopped, the supernatant of the solution becomes colorless, which is the end of the reaction. After the reaction, wash with deionized water for 3 times, and dry the obtained precipitate at 70°C overnight, and bake the dried sample at 350°C for 6 hours to prepare the copper-based micro-nano structure material CuO / ZnO / Al 2 o 3 .

[0035] Take 1.00g of the above sample and put it in a fixed-bed reactor, and first reduce it at 230°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com