A copper fluoride-based hydrotalcite-like catalyst and its preparation method and application

A hydrotalcite, copper fluoride technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of difficult control, cumbersome and time-consuming introduction of fluoride ions, and improve methanol selection. high CO2 conversion rate, and the effect of a large number of strong basic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

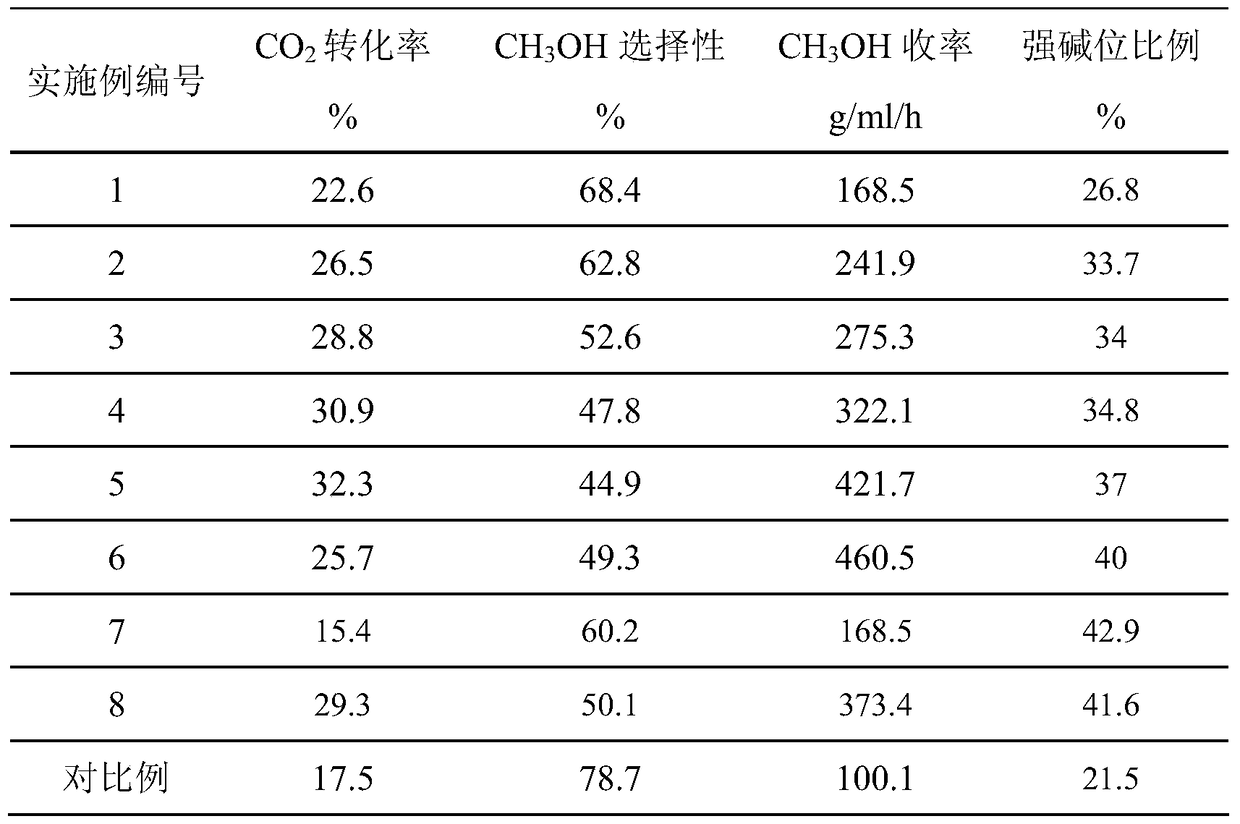

Examples

Embodiment 1

[0033] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.05 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to form a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 20°C, fully stir during the dropping process, and keep the final pH value at 8. After the precipitation reaction is completed, the obtained The product was aged at 70° C. for 24 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 70° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 270° C. for 12 h under a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. The carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=5.0MPa, T=230°...

Embodiment 2

[0035] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.15 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to form a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 20°C, fully stir during the dropping process, and keep the final pH value at 9. After the precipitation reaction is completed, the obtained The product was aged at 70° C. for 24 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 80° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 290° C. for 8 h under a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. The carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=5.0MPa, T=250°C...

Embodiment 3

[0037] According to Cu / Zn=2, (Cu+Zn) / Al=2, Na 3 AlF 6 / Al(NO 3 ) 3 =0.25 ratio (molar ratio), copper nitrate, zinc nitrate, aluminum nitrate and Na 3 AlF 6 Dissolve in deionized water to make a mixed aqueous solution, add dropwise to 1.0mol / L sodium hydroxide solution at 25°C, fully stir during the dropping process, and keep the final pH value at 9. After the precipitation reaction, the obtained The product was aged at 80° C. for 12 h under stirring, and then the obtained precipitate was washed several times with deionized water, and then vacuum-dried at 90° C. overnight to obtain a fluorinated hydrotalcite-like material. The obtained material was heat-treated at 300° C. for 8 h in a pure hydrogen atmosphere to obtain a copper fluoride-based hydrotalcite-like catalyst. Carbon dioxide hydrogenation to methanol reaction is carried out in a stainless steel reactor with an inner diameter of 6mm, and the reaction conditions are as follows: P=4.0MPa, T=270°C, GHSV=5000h -1 , n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com