Tungstenic functional mesoporous molecular sieve catalyst for preparation of glutaric acid based on glutaraldehyde oxidation and preparation method of catalyst

A technology for oxidative production of glutaric acid and catalyst, applied in molecular sieve catalyst, physical/chemical process catalyst, carboxylate preparation, etc., can solve the problems of low activity, high price, harsh synthesis conditions, etc. loss, the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

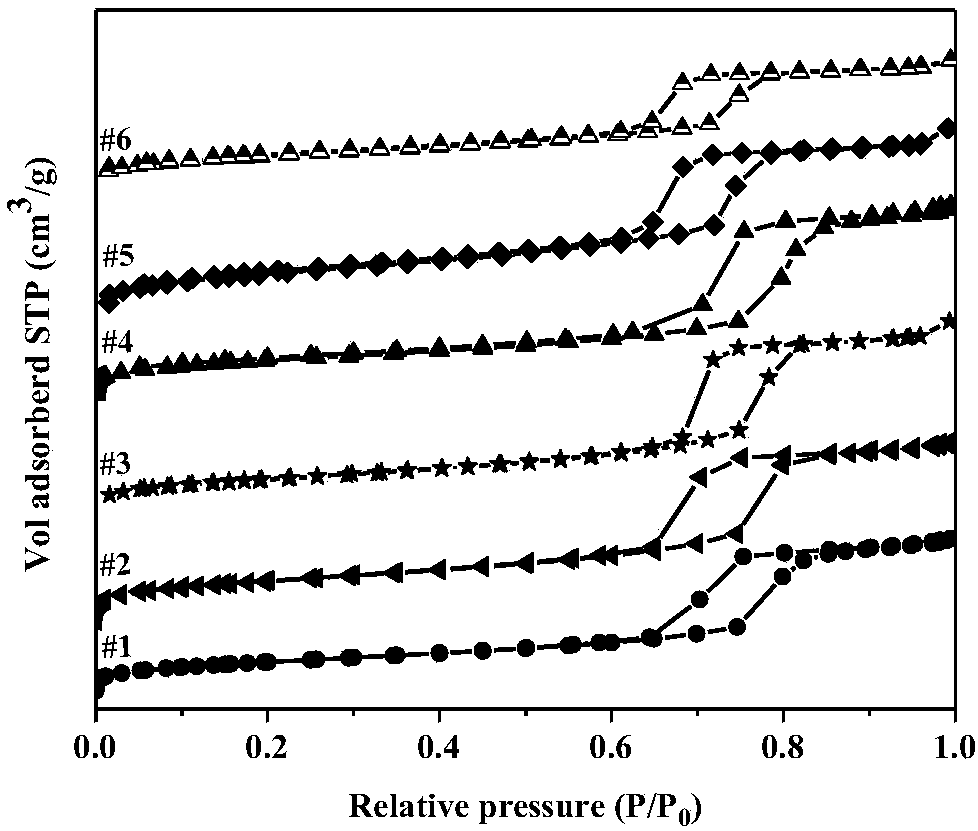

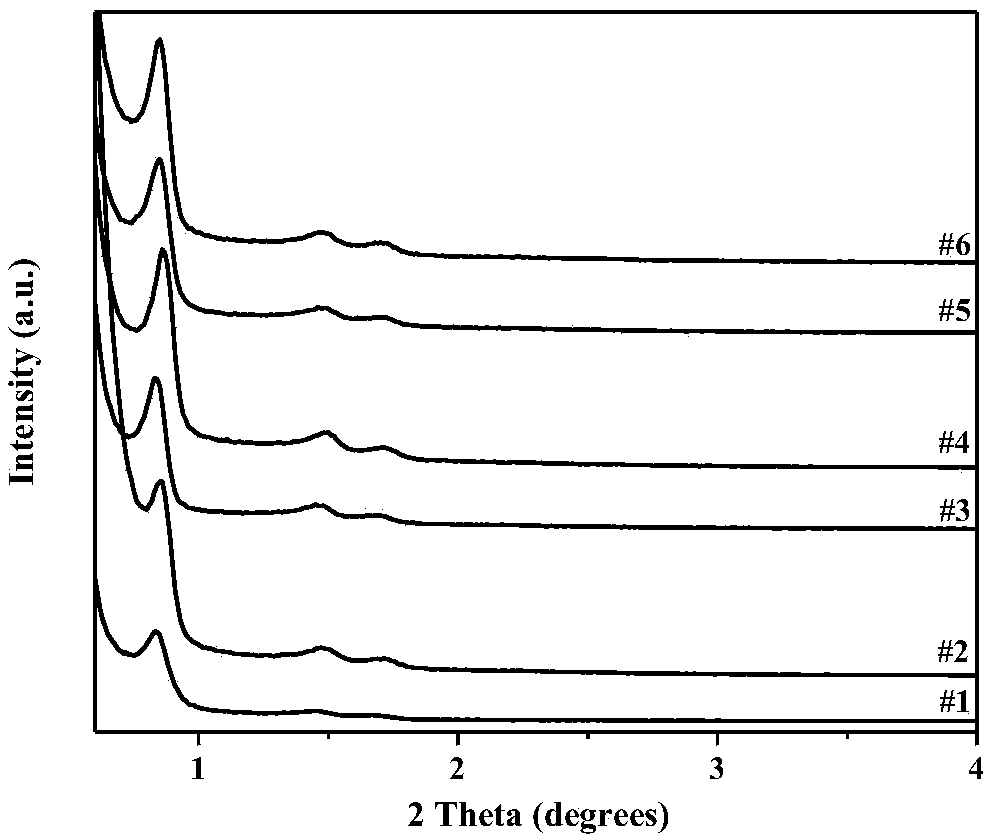

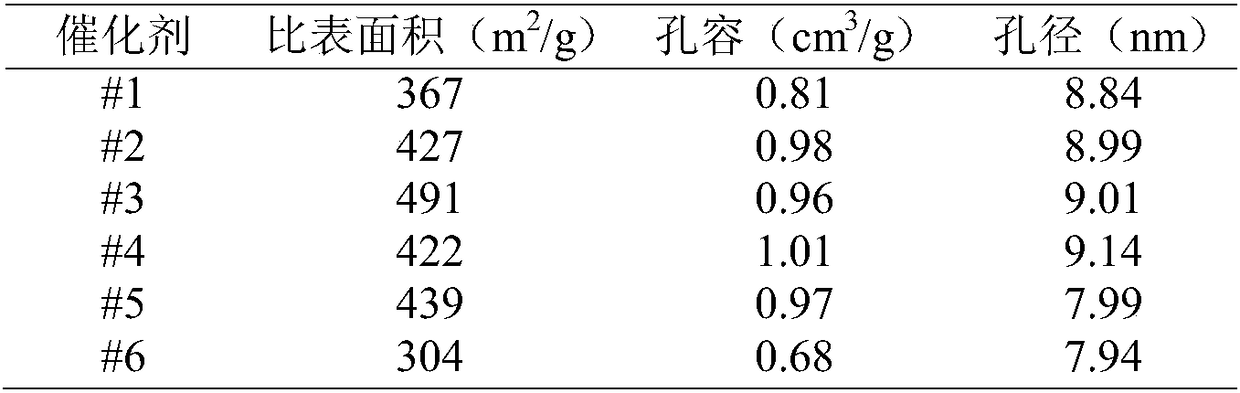

[0032] Disperse 1g of mesoporous molecular sieve SBA-15 in 10g of benzene, stir at 25°C for 2h, add 0.05g of 3-aminopropyltriethoxysilane, stir, reflux at 110°C for 8h, filter, and dry at 100°C to obtain solid powder a; The solid powder a was subjected to Soxhlet extraction in benzene, dried at 100°C to obtain solid powder b; 18 mL of dichloromethane was added to the solid powder b, stirred for 2 h, 0.1 g of trifluoromethanesulfonic acid was added, and stirred for 6 h , filtered, washed with ethanol, and dried at 100°C to obtain solid powder c; add 66 mL of an aqueous solution containing 0.2 g of sodium tungstate to the solid powder c, stir for 12 hours, filter, wash with water, and dry at 100°C to obtain solid powder d. The solid powder d is the catalyst, numbered #1.

Embodiment 2

[0034] Disperse 1g of mesoporous molecular sieve SBA-15 in 16g of toluene, stir at 29°C for 2.6h, add 0.07g of n-propyltrimethoxysilane, stir, reflux at 122°C for 9.6h, filter, and dry at 100°C to obtain solid powder a; The solid powder a was subjected to Soxhlet extraction in toluene, and dried at 100°C to obtain solid powder b; add 24 mL of dichloromethane to the solid powder b, stir for 2.4 h, add 0.28 g of trifluoromethanesulfonic acid, and stir 7.2h, filter, wash with ethanol, dry at 100°C to obtain solid powder c; add 37.5mL aqueous solution containing 0.15g of 12-phosphotungstic acid to the solid powder c, stir for 19.2h, filter, wash with water, and dry at 100°C to obtain solid Powder d, the solid powder d is the catalyst, numbered #2.

Embodiment 3

[0036]Disperse 1g of mesoporous molecular sieve SBA-15 in 22g of xylene, stir at 33°C for 3.2h, add 0.09g of diphenyldichlorosilane, stir, reflux at 134°C for 11.2h, filter, and dry at 100°C to obtain solid powder a; The solid powder a is subjected to Soxhlet extraction in xylene, dried at 100°C to obtain solid powder b; add 30 mL of dichloromethane to the solid powder b, stir for 3.8 hours, add 0.46 g of trifluoromethanesulfonic acid, and stir 8.4h, filter, wash with ethanol, dry at 100°C to obtain solid powder c; add 30mL aqueous solution containing 0.15g of 18-phosphoditungstic acid to the solid powder c, stir for 26.4h, filter, wash with water, and dry at 100°C to obtain solid Powder d, the solid powder d is the catalyst, numbered #3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com