Method for removing metal zinc from high-concentration gallium raw material

A metal zinc, high-concentration technology, applied in the field of metal zinc removal, can solve problems such as being unsuitable for large-scale industrial applications, and achieve the effects of low industrial operation cost, cost reduction, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

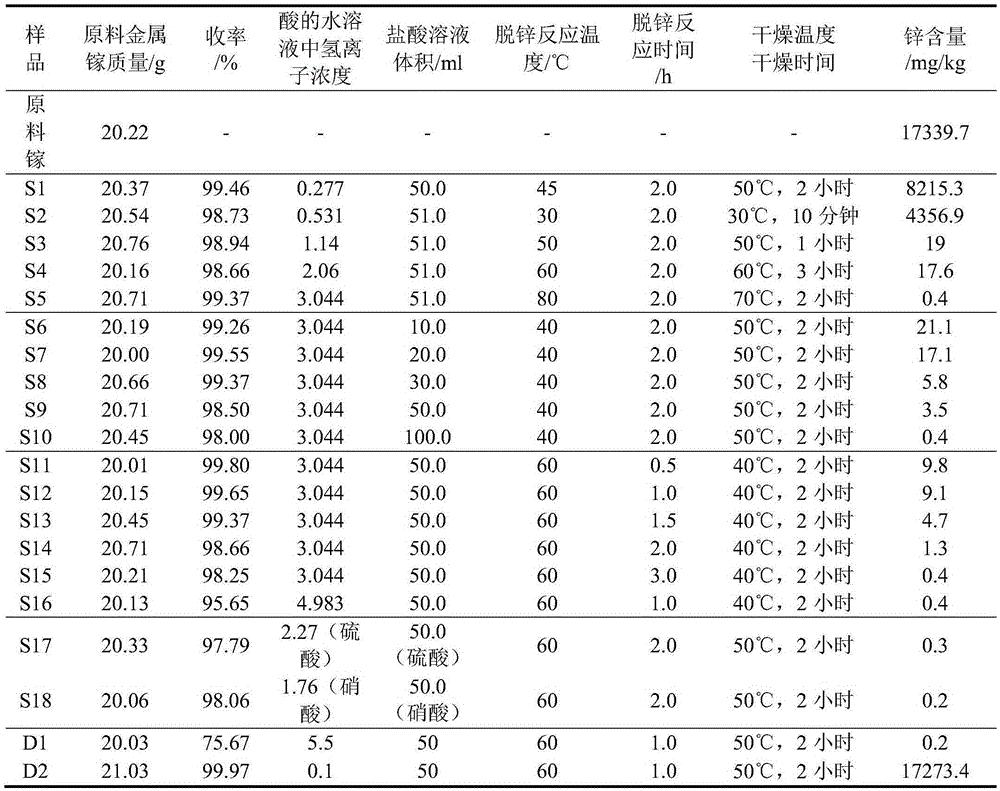

[0036] The operation process of this embodiment is carried out in a nitrogen atmosphere. 20.37 grams of gallium raw material (zinc content is 17339.7 mg / kg, gallium content is 98.266 mass %, Chalco Shandong Branch) and 50 milliliters of 0.277 mol / liter hydrochloric acid solution After mixing in an ultrasonic oscillator, shake at 45° C. for 2 hours to obtain a mixed phase containing metal fluid and water.

[0037] Let the mixed phase containing metal fluid and water stand, separate the metal fluid phase and the water phase, put the metal fluid phase into a vacuum oven at 50°C and dry for 2 hours to obtain the gallium raw material product S1, and the product yield is 99.46% by mass .

[0038] As shown in Table 1, the zinc content of the gallium raw material product S1 is 8215.3 mg / kg.

Embodiment 2-18

[0040] The operation steps of Examples 2-18 are the same as those of Example 1, and gallium raw material products S2-S18 are obtained. The specific data and results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com