Pervaporation blend membrane for separating methanol-tetrahydrofuran

A technology of pervaporation and tetrahydrofuran, applied in chemical instruments and methods, semi-permeable membrane separation, membrane and other directions, can solve the problems of few types of azeotropes, high price, complicated process, etc., and achieve good mechanical strength and anti-pollution ability, Good industrial application prospects, simple preparation process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

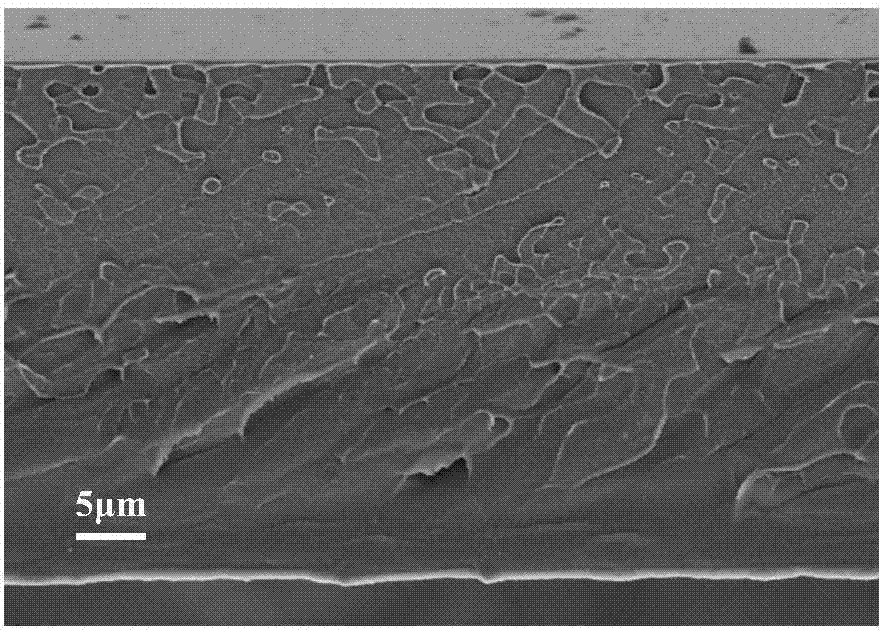

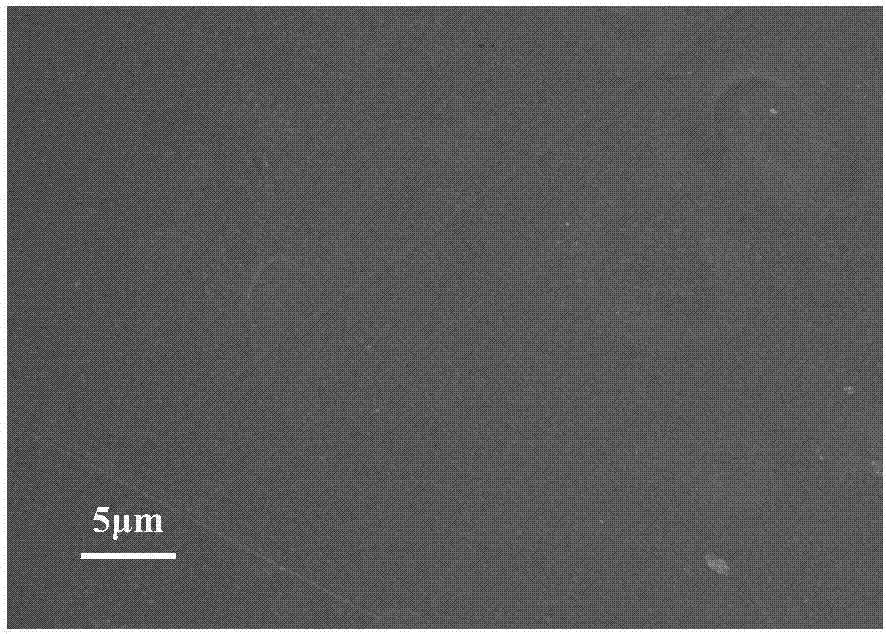

[0034] Weigh 8.5g of P84 polyimide and 1.5g of cellulose acetate into 30g of N-methylpyrrolidone, and stir rapidly at 25°C for 12h until the polymer is completely dissolved to obtain P84 polyimide / cellulose acetate cast film solution; put the casting solution on a glass plate after standing, pumping, and defoaming, put it in a vacuum oven at 60°C for at least 24h, and then anneal at 120°C for 3h to obtain P84 polyimide / cellulose acetate Blend film (85wt% / 15wt%).

Embodiment 2

[0036] Weigh 9.0g of P84 polyimide and 1.0g of cellulose acetate and add it to 30g of N,N-dimethylformamide, and stir rapidly at 25°C for 12h until the polymer is completely dissolved to obtain P84 polyimide / acetic acid Cellulose film casting solution; pour the casting film solution on a glass plate after standing, pumping, and defoaming, put it in a vacuum oven at 60°C for at least 24 hours, and then anneal at 120°C for 3 hours to obtain P84 polyimide / cellulose acetate blend film (90wt% / 10wt%).

Embodiment 3

[0038] Weigh 8.0g of P84 polyimide and 2.0g of cellulose acetate into 30g of dimethyl sulfoxide, and stir rapidly at 25°C for 12h until the polymer is completely dissolved to obtain a P84 polyimide / cellulose acetate cast film solution; put the casting solution on a glass plate after standing, pumping, and defoaming, put it in a vacuum oven at 60°C for at least 24h, and then anneal at 120°C for 3h to obtain P84 polyimide / cellulose acetate Blend film (80wt% / 20wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com