Gas-liquid-solid three-phase counter-current reaction device and method for pyrolytic reaction of carbamic acid ester

A carbamate and pyrolysis reaction technology, which is applied in the field of gas-liquid-solid three-phase countercurrent reaction devices, can solve the problems of poor radial heat transfer effect of three-phase reactors, and achieves overcoming uneven radial temperature distribution and reducing Possibility, effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

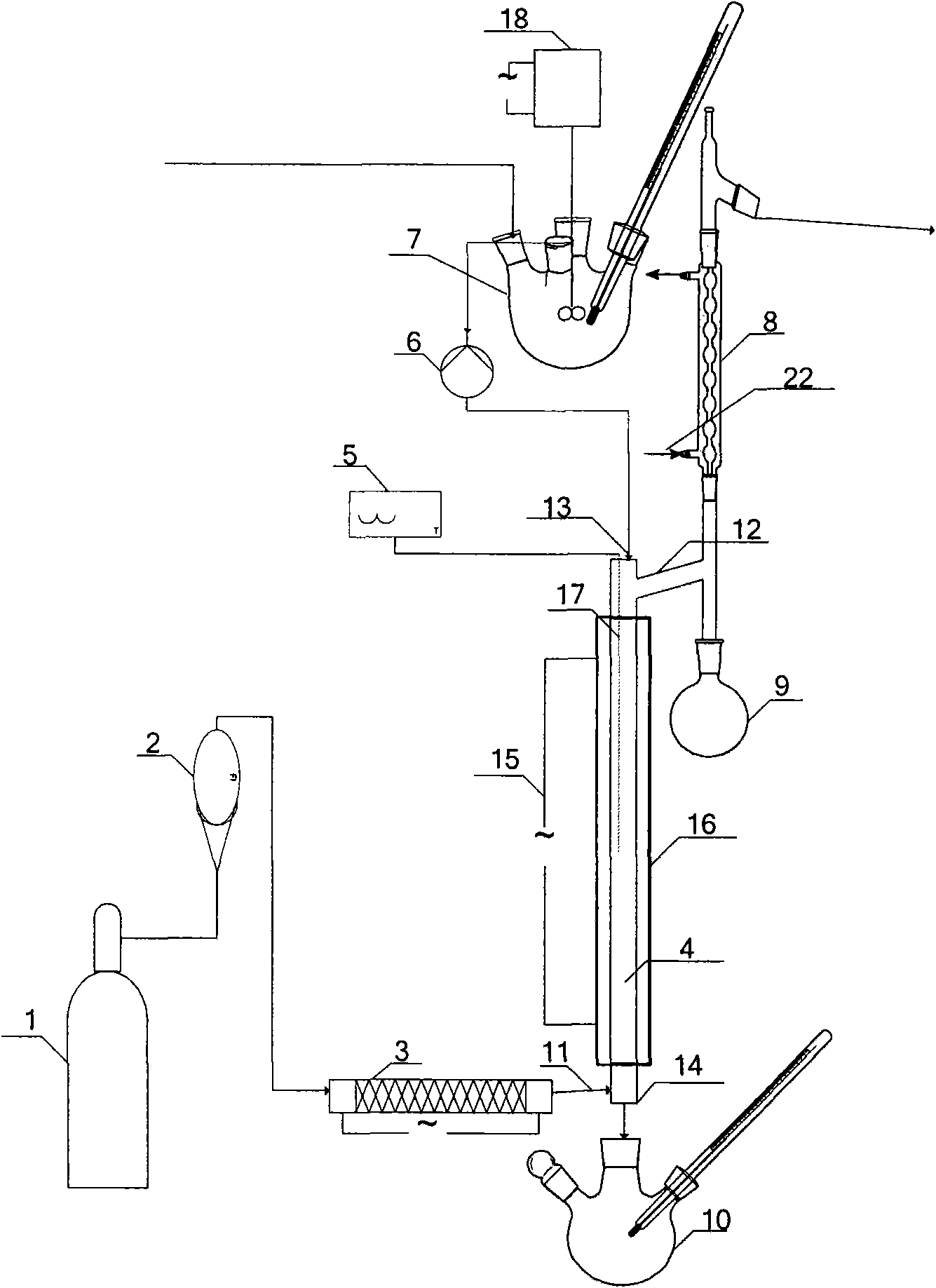

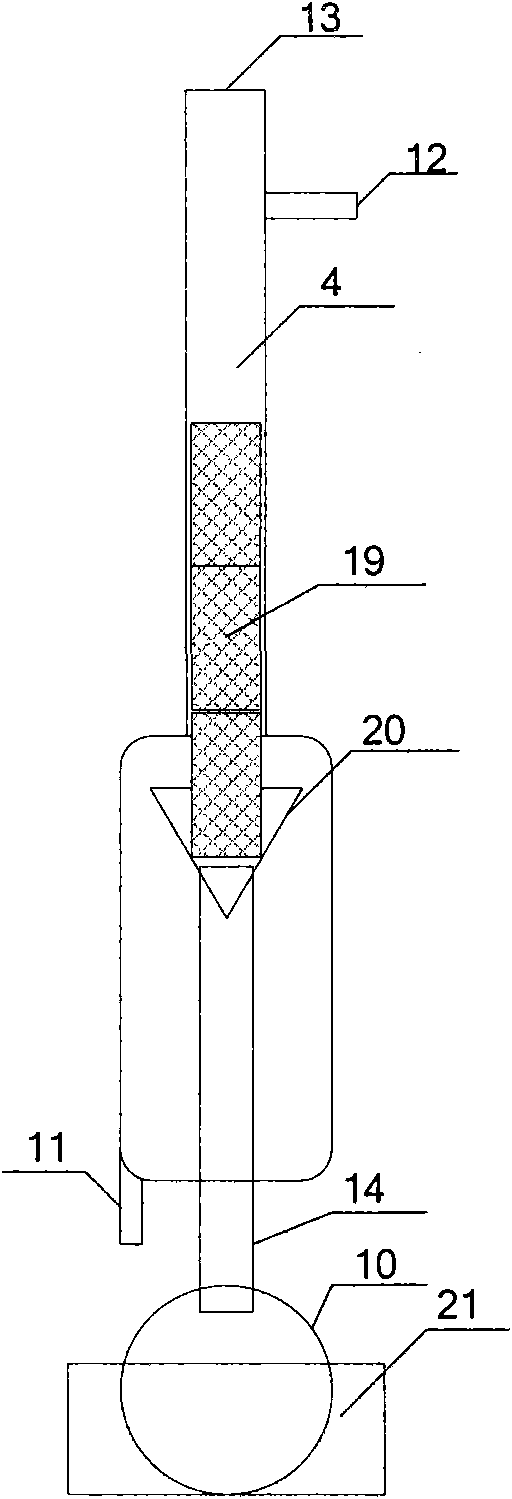

[0032] see figure 1 and figure 2 . The raw material liquid of wt (MDC)=3.0% is preheated to 180 ℃ in storage tank 7 (MDC: diphenylmethane dicarbamate methyl ester), v (N 2 )=150mL / min carrier gas (nitrogen) is preheated to 180°C in the carrier gas preheater 3, and the heat carrier 19 is preheated to 250°C. After the preheating is completed, feed materials, wherein the thermal decomposition reaction temperature is 270° C., and the reaction time is 12 minutes. The raw material liquid and the nitrogen gas are fully countercurrently contacted in the reactor, and the by-product methanol is brought out by the nitrogen gas, which is condensed and collected by the condenser 8, wherein the condensation temperature is -10°C, and the reacted feed liquid flows into the product collection bottle 10 through the feed liquid outlet 14, And condensed preservation, wherein, the condensation temperature is 5 ℃. The results show that the thermal decomposition reaction of MDC is a step-by-ste...

Embodiment 2

[0034] See Example 1. The raw material liquid is preheated to 220°C, the carrier gas (nitrogen) is preheated to 220°C, the heat carrier is preheated to 270°C, the methanol condensation temperature is -25°C, the product condensation temperature is 0°C, and the thermal decomposition reaction temperature is 270°C. The reaction time is 15 minutes. The results showed that under the above reaction conditions, the conversion rate of MDC was close to 100%, and the total molar yield of MMI and MDI reached 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com