Patents

Literature

99results about How to "Adequate mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing mash gas from municipal sludge through dry method anaerobic fermentation

ActiveCN101935139ASmall volumeReduce heating energy consumptionWaste processingWaste based fuelBiomassChemistry

The invention relates to a method for producing mash gas from municipal sludge through dry method anaerobic fermentation, which belongs to the field of solid waste reclamation, and can overcome the difficulties difficult mass transfer, difficult gas overflow and the like caused by dewatered sludge which has high viscosity, no fluidity, no gaps and the like. The method comprises the following steps of: performing biological pre-drying on the dewatered sludge, and stacking the dewatered sludge in an aerobic environment for 2 to 3 days; adding the material after the biological pre-drying into anaerobic granular sludge or biogas residues to perform inoculation, and performing static starting for 6 to 8 days; performing acidogenic fermentation on the material under an aerobic or anaerobic condition, performing spiral band type or anchor type stirring, and adjusting the pH if necessary; performing methanogenesis fermentation on the material after acid production under an anaerobic condition, performing extruding type stirring, keeping the temperature of the material to be 35+ / -1 DEG C, and keeping the pH between 6.6 and 7.5; and performing refluxing inoculation on part of the biogas residues, and performing aerobic compost stabilization on the rest of the biogas residues. The method can be used for beneficial utilization of the municipal sludge and the recovery of biomass energy sources, and compared with wet fermentation, the method can save equipment investment and land occupation.

Owner:TONGJI UNIV

Method for enhancing dry-process fermentation stability of sludge by adding kitchen waste

ActiveCN102030456AReduce heating energy consumptionSmall volumeBio-organic fraction processingClimate change adaptationGeneration rateEnergy recovery

The invention relates to a method for enhancing dry-process fermentation stability of sludge by adding kitchen waste, belonging to the field of solid waste recycling. The invention can solves the problems of low acidifying degree of hydrolysis, insufficient substrates for producing methane, overhigh pH value, ammonium salt accumulation, inhibition of gas generation and the like caused by high viscosity of dewatered sludge, high TS concentration, low C / N value and the like. The method comprises the following steps: pulverizing kitchen waste, mixing the kitchen waste and dewatered sludge in the weight ratio of 1:10-15, putting the mixture in a fermentation tank to ferment, and sufficiently stirring, wherein in the fermentation process, the temperature of the materials is kept at 35+ / -1 DEG C, and the oxidation-reduction potential is smaller than or equal to -300mV; when the pH value rises to 7.5 and the methane content rises to higher than 35%, adding the kitchen waste into the fermentation tank again in batches, wherein the addition amount of the kitchen waste each time accounts for 5-10 wt% of the dewatered sludge, the pH value of the mixed materials is preferably greater than or equal to 6.6, and the preferable addition time is when the pH value of the materials rises to higher than 7.5; and when the methane content is lower than 35% and the gas generation rate obviously decreases, finishing the fermentation. The invention can be used for municipal sludge recycling and energy recovery. Compared with wet fermentation, the invention can save equipment investment and soil occupation.

Owner:TONGJI UNIV

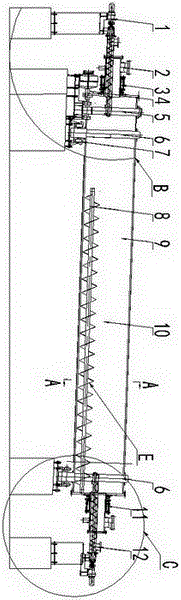

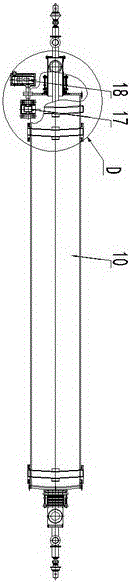

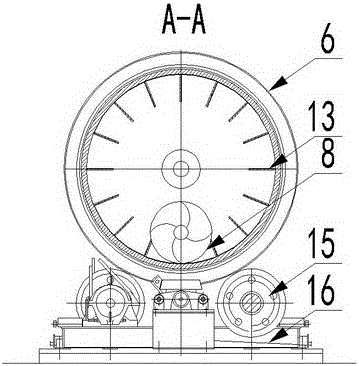

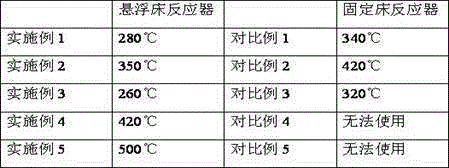

Using method of reactivation drying rotary furnace for preparing activated clay

ActiveCN106311193AImprove qualityPrevent dehydrationSilicaSulfur compoundsEnvironmental resistanceRotary furnace

The invention relates to the technical field of environment protection and cyclic economy, in particular to a using method of a reactivation drying rotary furnace for preparing activated clay. The method is characterized by including the using methods of the reactivation drying rotary furnace, a carrier roller assembly, a driving gear assembly, a screw feeder and a screw discharger. H+ electronegativity and crystal water of the activated clay are protected against destroy, and therefore quality of the activated clay is improved. A reactivation drying rotary furnace body is a closed production device, it is avoided that irritant gas is generated in a working space to become hazard factors of an occupational disease, and pollution to air environment is avoided.

Owner:来安县永阳知识产权运营有限公司

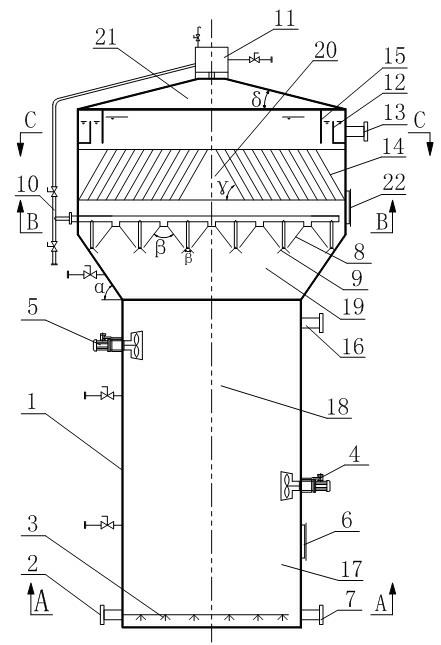

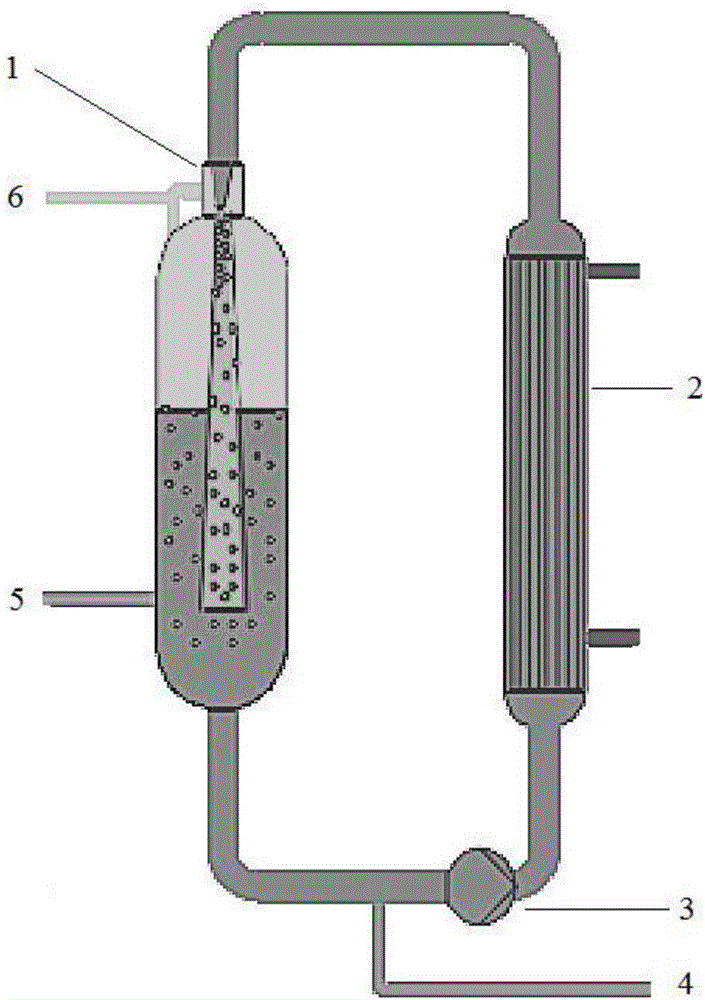

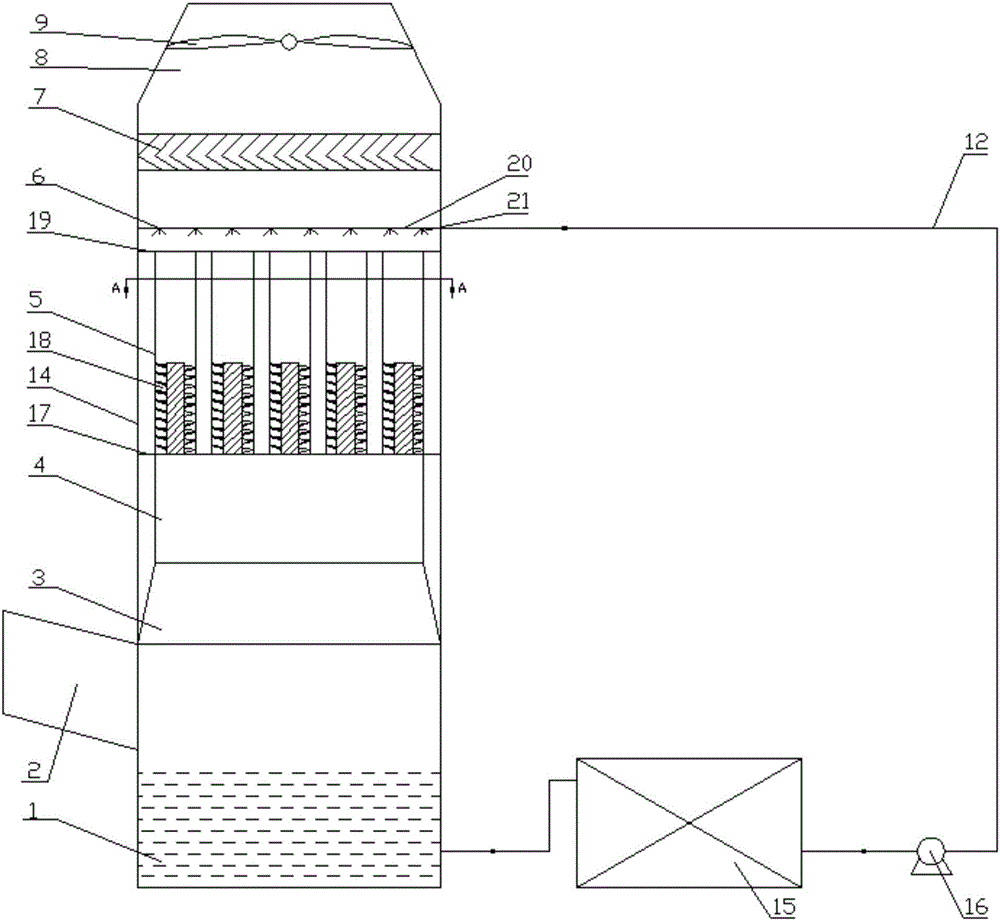

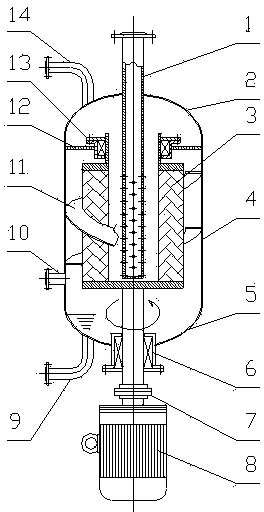

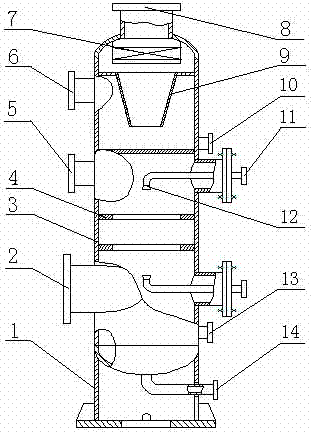

Efficient anaerobic bioreactor

ActiveCN102491511AEasy to operateCoherent work processTreatment with anaerobic digestion processesDecompositionWater pipe

The invention discloses an efficient anaerobic bioreactor, which comprises a reactor, a water sealing tank and an exhaust pipe, wherein a mud-water mixing region, a suspension region, a three-phase separation region, a precipitation region and an air chamber are formed inside the reactor body from bottom to top; the mud-water mixing region, the suspension region, the three-phase separation regionand the precipitation region are communicated in sequence; the outer side wall of the reactor body is connected with a water inlet pipe, a water outlet pipe and a mud discharge pipe; the water inlet pipe is communicated with the mud-water mixing region; the water outlet pipe is communicated with the precipitation region; the mud discharge pipe is communicated with the suspension region; the watersealing tank is arranged at the top end of the reactor body, and is communicated with the air chamber; a three-phase separator connected with the exhaust pipe is arranged in the three-phase separation region; and the three-phase separator is communicated with the water sealing tank through the exhaust pipe. Partitioned treatment is performed during decomposition of organic matters in waste water,so that the function of each functional region is enhanced, and the reactor has high treatment efficiency, is convenient to operate, and runs stably.

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

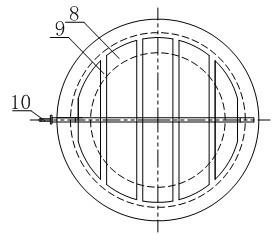

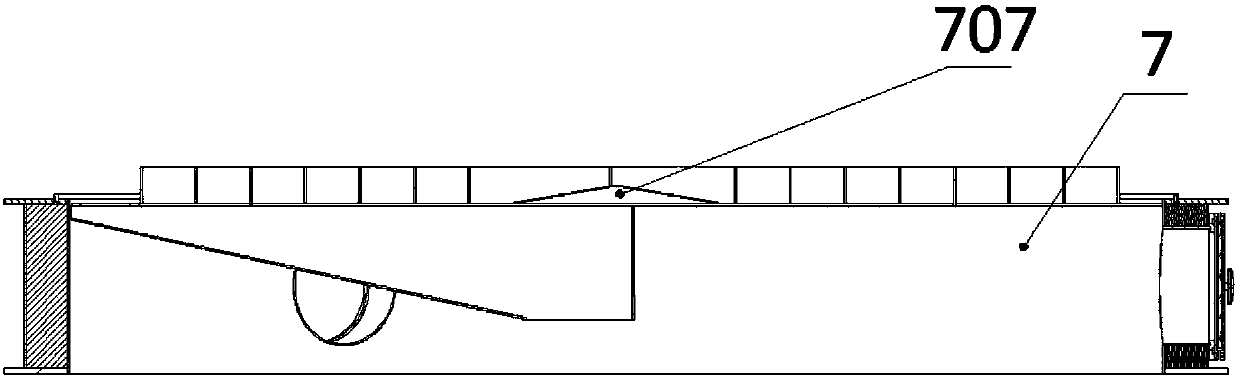

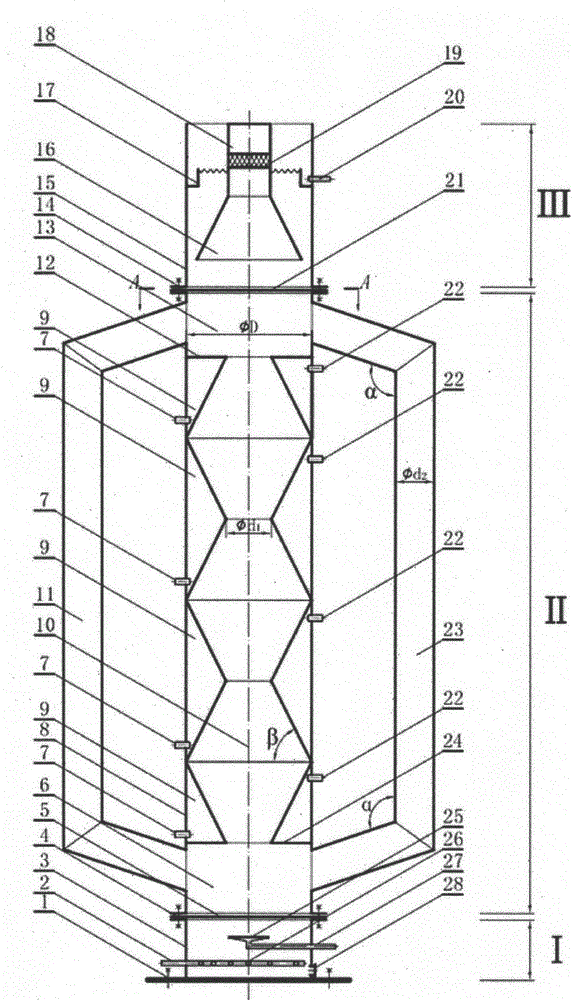

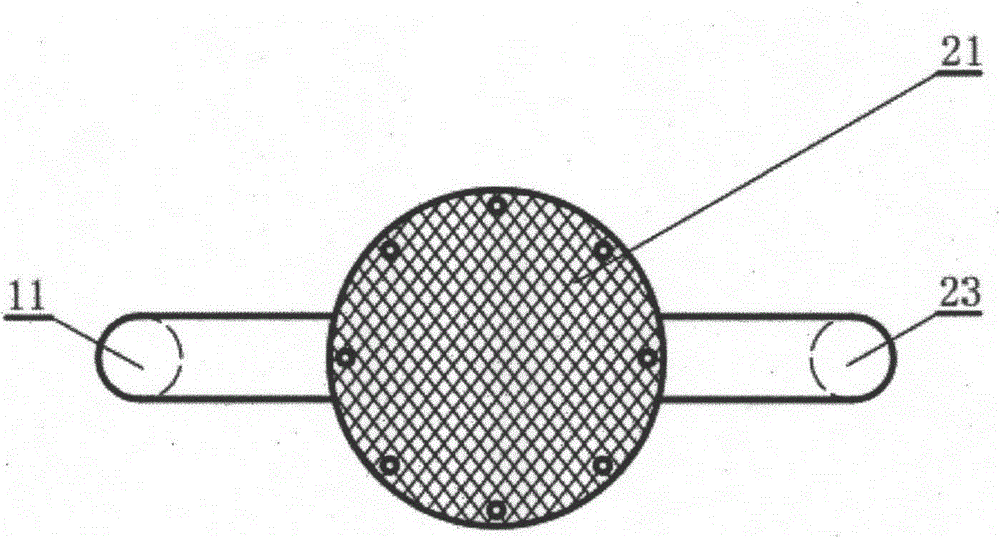

Composite type multilayer spiral vibrating countercurrent drying machine

PendingCN108036632AObserve the drying condition in timeSolve the problem of accumulation and blockageDrying gas arrangementsDrying chambers/containersAir filterPulp and paper industry

The invention relates to a composite type multilayer spiral vibrating countercurrent drying machine. The composite type multilayer spiral vibrating countercurrent drying machine comprises a pluralityof drying discs, and the multiple drying discs are arranged in a stacked mode to form a drying box body; the drying box body is mounted on a base, a vibrating motor is mounted in the base, and the drying discs comprise boxes, heat preservation layers, screening plates, spiral sheets, material falling openings and material falling grooves; the drying disc on the top layer is provided with a feedingcabin and an air outlet, the air outlet is provided with a temperature sensor, and an automatic feeding device is mounted on the feeding cabin; the drying disc on the bottom layer is provided with anair inlet, the air inlet is connected with an air inlet tube, and a temperature sensor is arranged in the air inlet tube; and the drying disc on the bottom layer is further provided with a discharging cabin, the air inlet tube is connected with air inlet equipment, and the air inlet equipment comprises a blower, a heater and an air filter, wherein the blower, the heater and the air filter are arranged sequentially in the flow direction of air. According to the composite type multilayer spiral vibrating countercurrent drying machine, materials and hot air flow in the reverse direction, the heat efficiency is extremely high, the drying efficiency is improved, and the problem that the materials are accumulated and thus difficult to clean is solved.

Owner:江西赫柏康华制药设备有限公司 +1

New preparing method of allyl alcohol random polyether glycidyl ether

InactiveCN106478937AIncrease mass transfer rateIncreased mass transfer rates over conventional stirred tank reactorsKinetic controlSide reaction

The invention discloses a new preparing method of allyl alcohol random polyether glycidyl ether. The preparing method comprises the steps of adding an allyl alcohol random polyether raw material in a jet loop reactor based on a venturi effect through a feed inlet of materials, conducting deoxygenization and pumping into inert gases to be subjected to replacement protection, and opening an external circulating pump to be subjected to high speed spraying mixture; controlling the temperature at 30-120 DEG C, slowly adding an epoxy chloropropane raw material and an alkali raw material into the jet loop reactor through the feed inlet of epoxy chloropropane and the feed inlet of the material respectively, and the like. Due to the fact that the system belongs to a system of kinetic control, and a side reaction is inhibited sufficiently, thus the selectivity of a reaction system is higher. The new preparing method is especially applicable to allyl alcohol random polyether of which molecular tail end is secondary hydroxyl, the color luster of the finally obtained product, namely, the allyl alcohol random polyether glycidyl ether product, is less than 40, and the stop end rate of the product is more than 96%.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

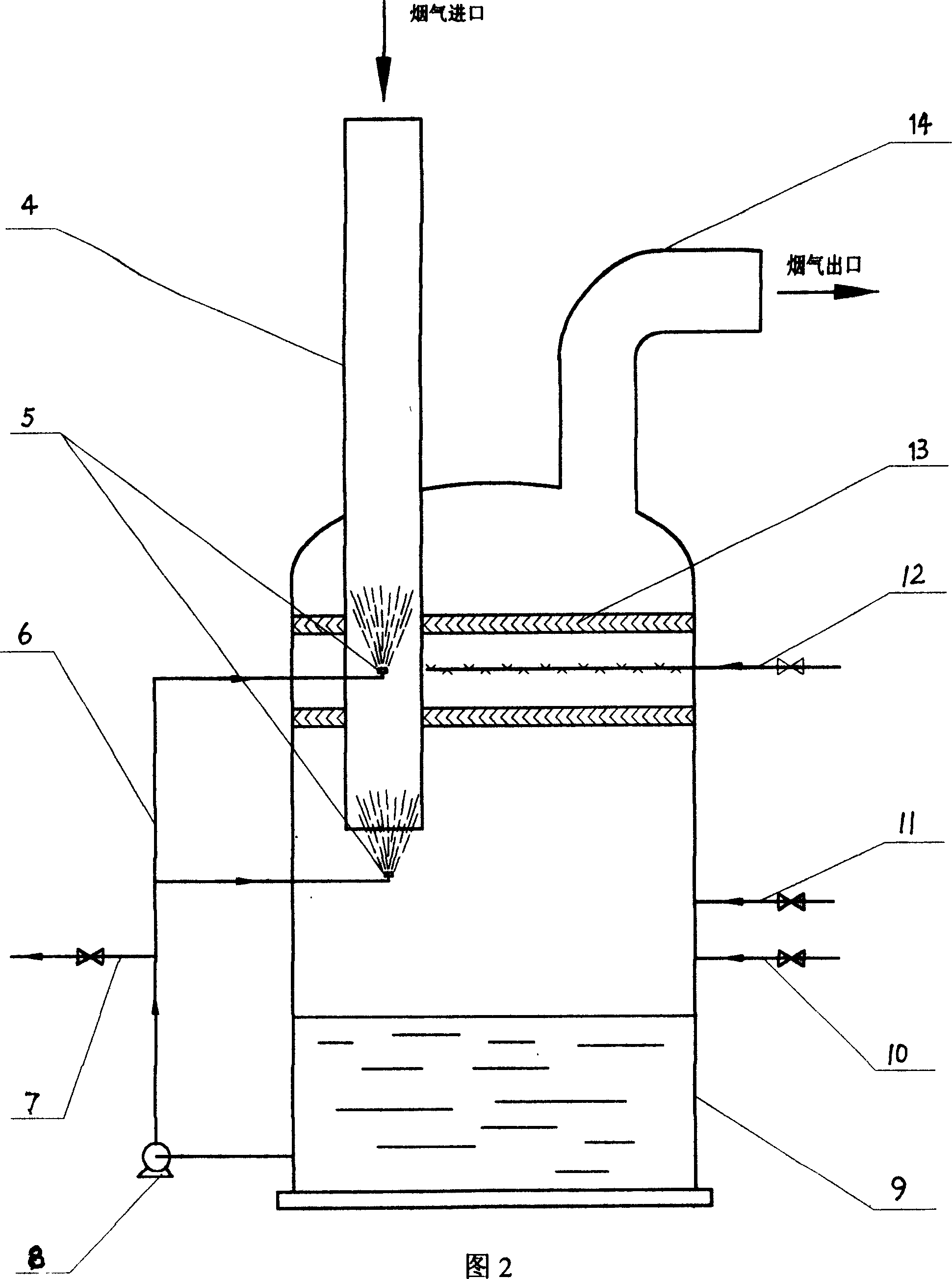

Ammonia-acid method SO2 tail gas adsorption process using dynamic wave washer

ActiveCN1559652AGuaranteed emission standardsSatisfied with the effectDispersed particle separationEngineeringProcess engineering

An application of power wave washer in absorbing CO2 from the tail gas generated by ammona-acid method is disclosed. In said power wave washer, the fume containing CO2 flows downward and the circulating liquid is prayed up ward. They are collided to generate a foam region, wheremore than 95% of CO2 in absorbed by said circulating liquid.

Owner:富民薪冶工贸有限公司

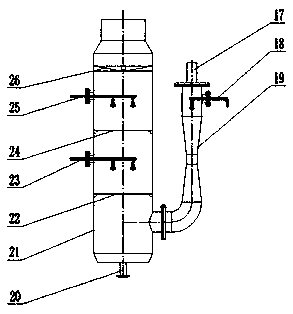

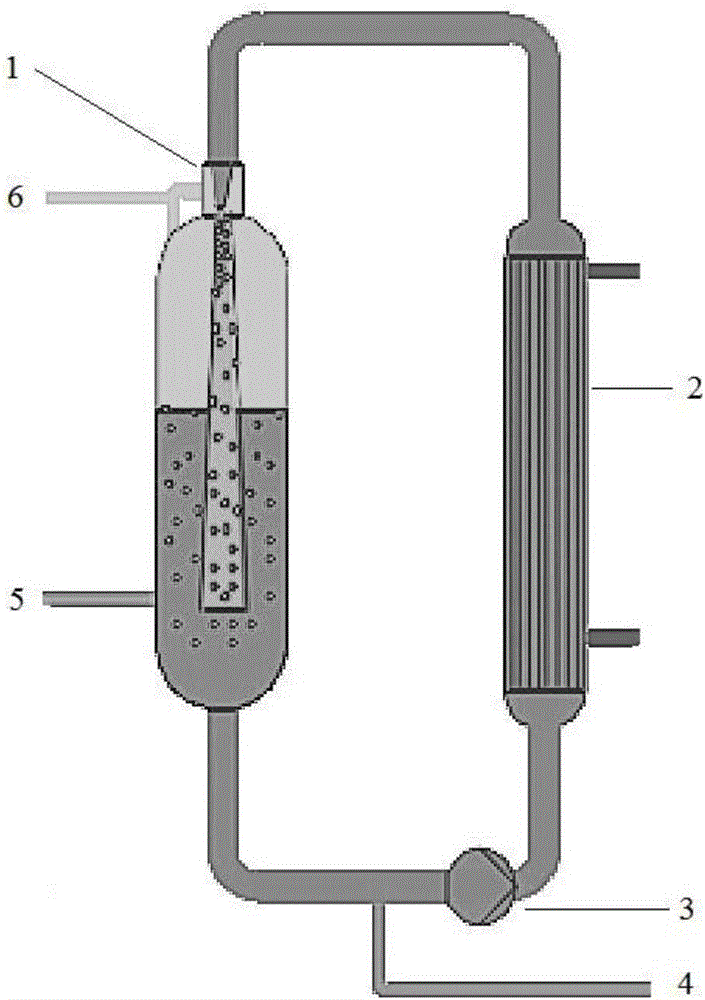

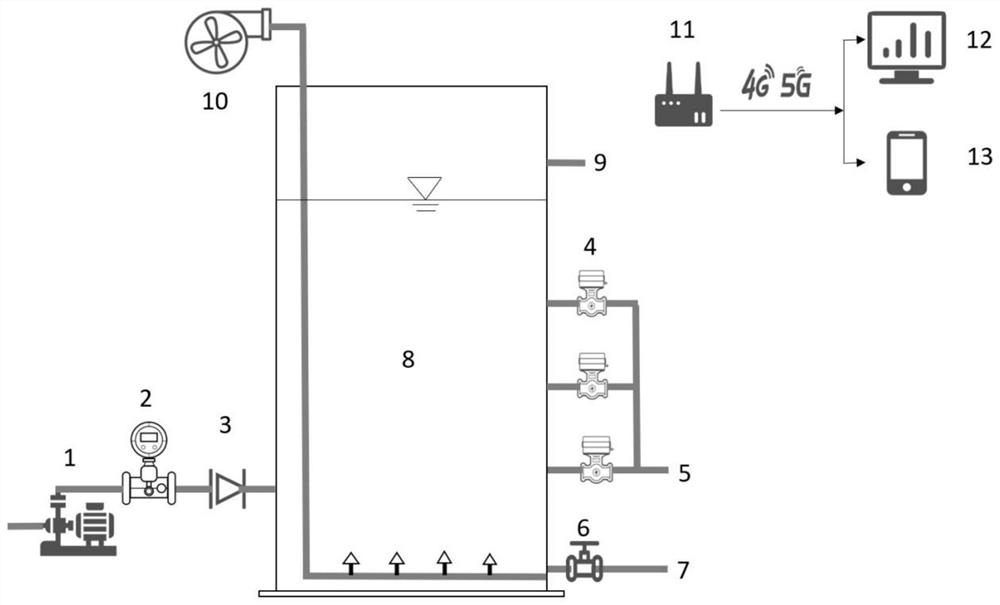

Air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor

InactiveCN104085986AImproved resistance to shock loadsSimple structureTreatment with aerobic and anaerobic processesNitrogen removalOxygen

The invention discloses an air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor. The air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor is characterized by comprising a water distributing section, a reaction section and a separating section, wherein the water distributing section comprises a lower short circular barrel; a water distributor and a microporous aeration plate are arranged in the barrel, and the water distributor is communicated with a water inlet tube; the microporous aeration plate is communicated with a gas inlet tube; the reaction section comprises a long circular barrel, and a multi-stage Venturi tube is arranged in the long circular barrel; a flow-splitting region and a mixing region are respectively formed between the two ends of the multi-stage Venturi tube and the port of the long circular barrel, and are communicated by left and right circulating tubes to form circulation; the separating section comprises an upper short circular barrel, and a water outlet and gas outlet system is arranged in the barrel. By virtue of arranging the microporous aeration plate, the mixing region and the multi-stage Venturi tube, vortex flow fields are formed in the multi-stage Venturi tube, so that the mass transfer efficiency among gas, liquid and solid phases is effectively enhanced. Besides, the structure is combined with the flow-splitting region, the left circulating tube and the right circulating tube to form external circulation, so that an aerobic-anoxic alternating environment is formed, and therefore, the reactor has a nitrification and denitrification biological nitrogen removal function.

Owner:DONGHUA UNIV +1

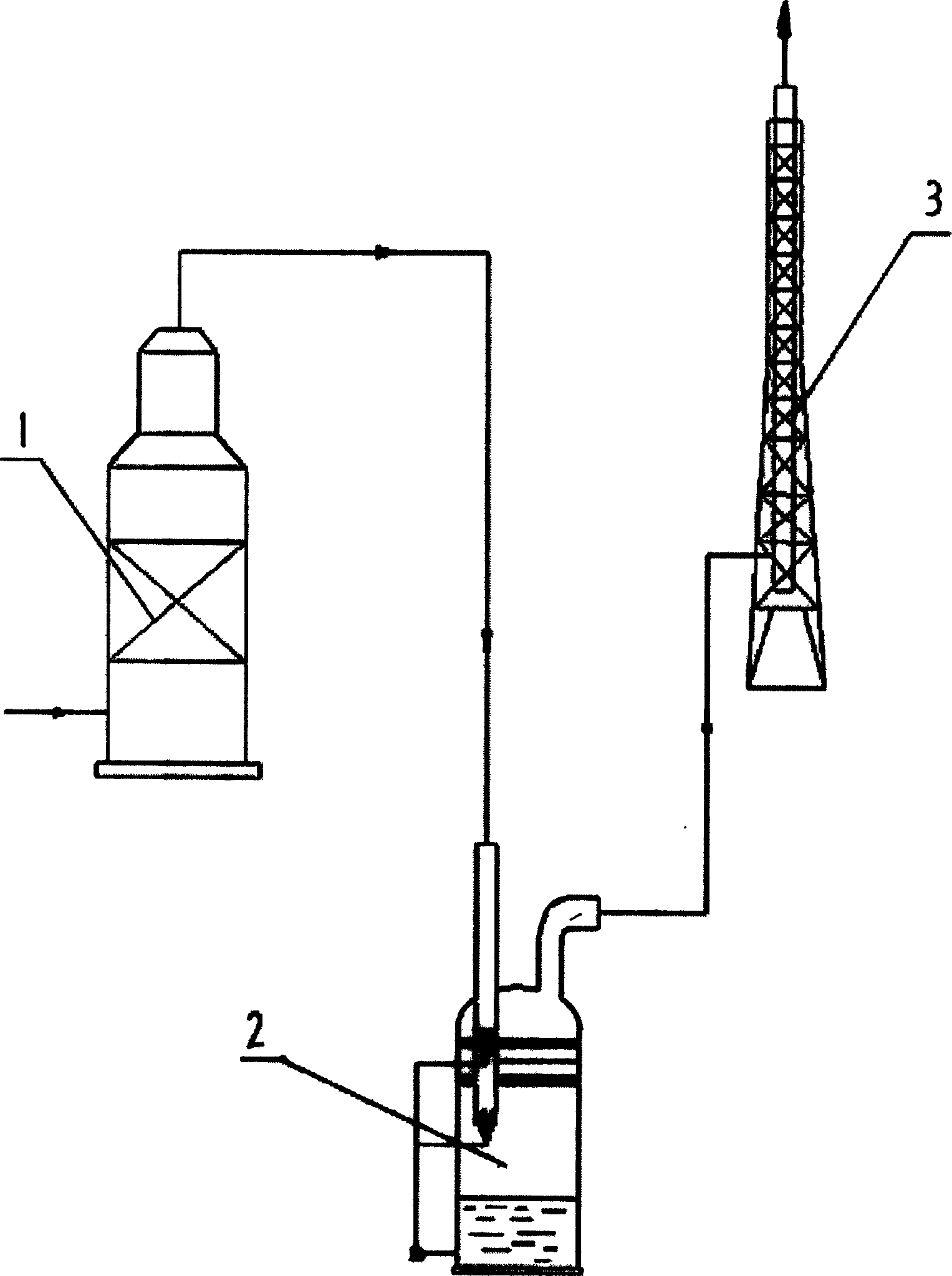

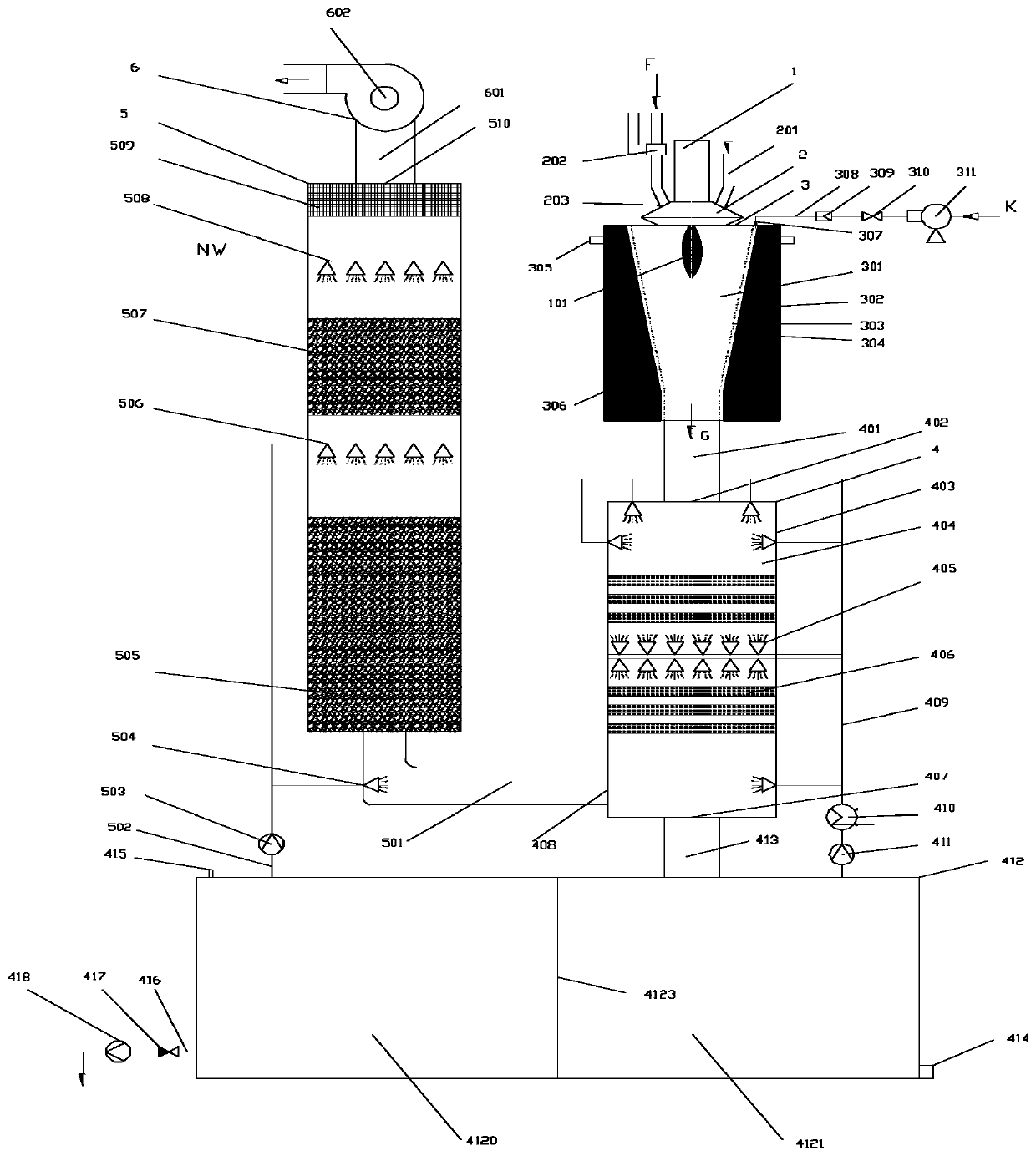

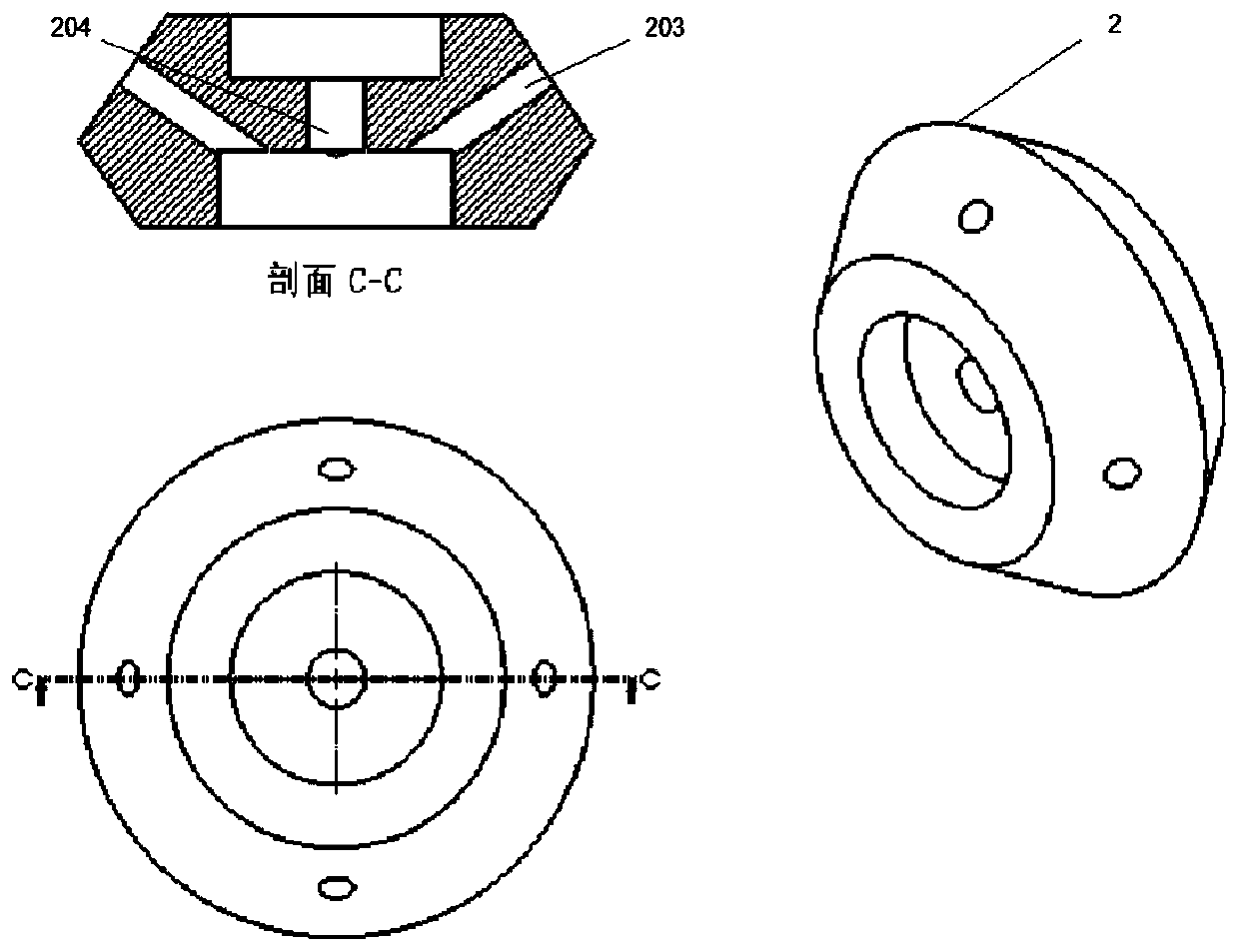

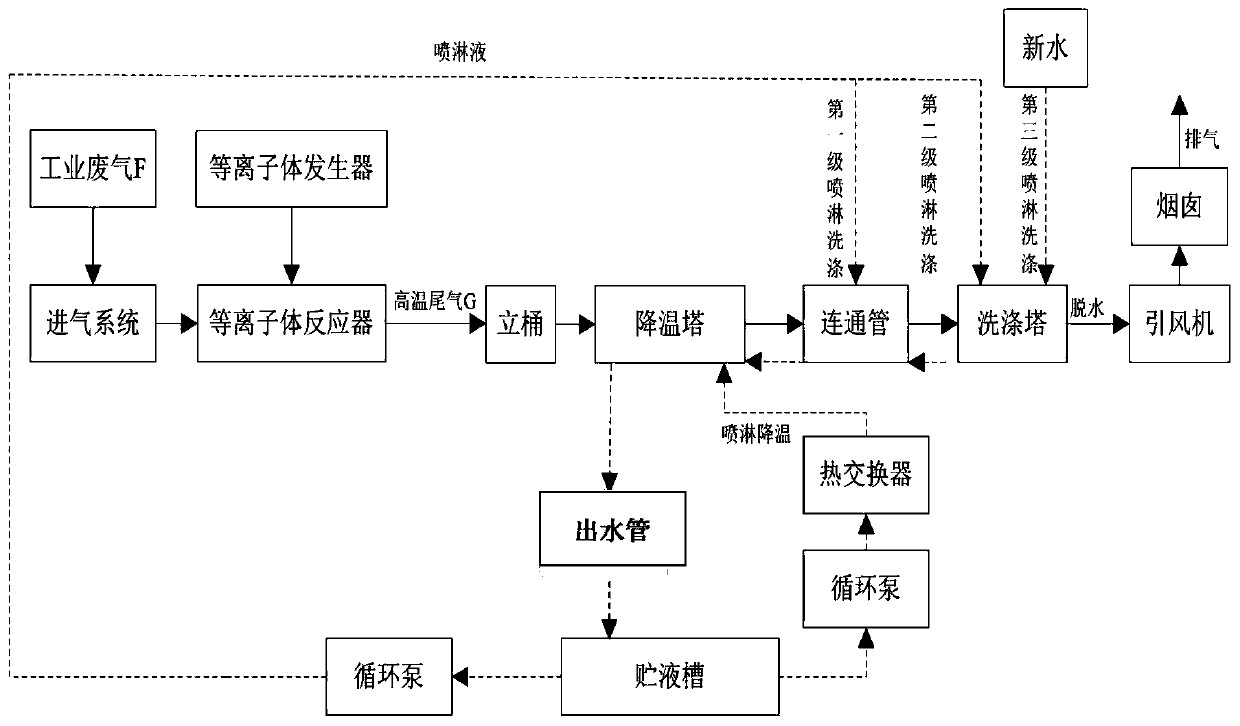

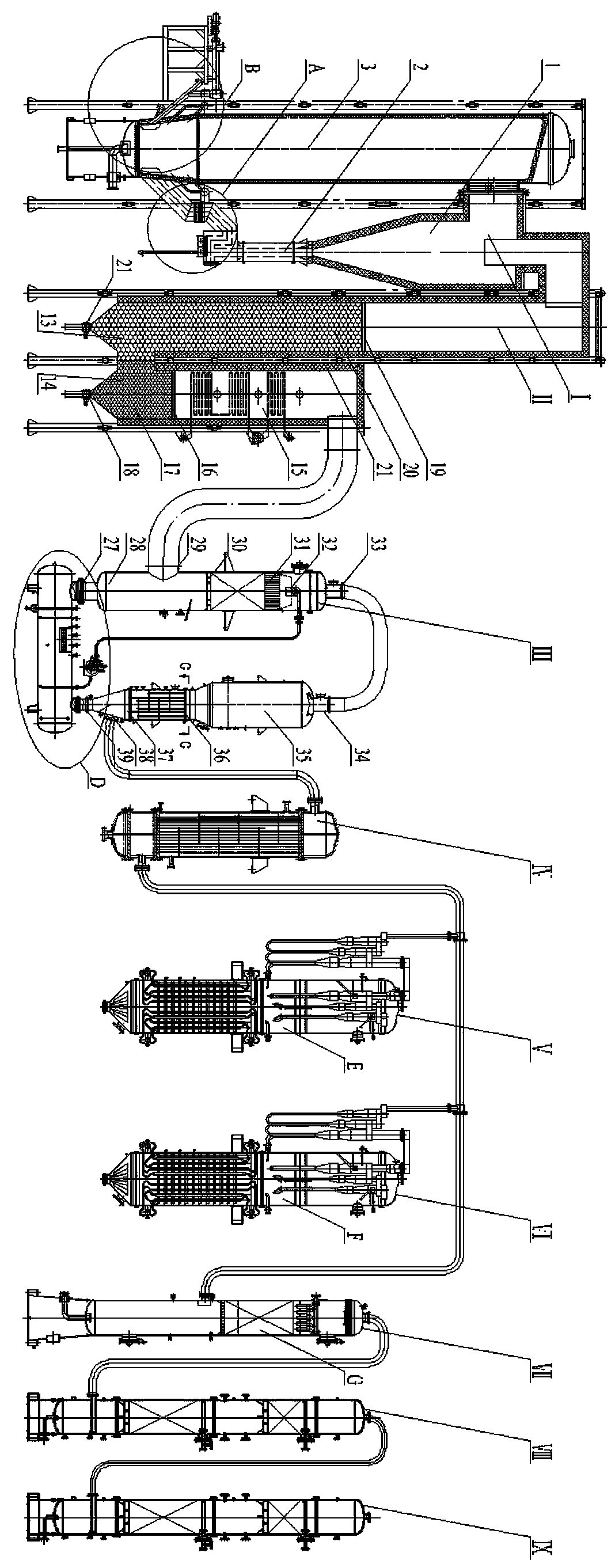

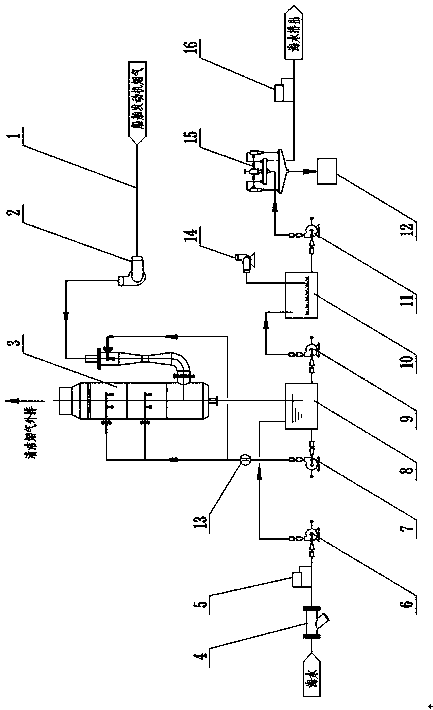

Plasma waste gas treatment device and method

ActiveCN109821373AFully contactedAdequate responseUsing liquid separation agentEnvironmental engineeringQuenching

The invention provides a plasma waste gas treatment device and method, and belongs to the technical field of waste gas treatment.The plasma waste gas treatment device comprises a thermal reaction system, an air inlet system, a cooling system, a multistage purification washing system, an exhaust system and a liquid circulating system, and the structureis compact, safe and reliable.The plasma wastegas treatment method comprises the following steps of: carrying out high-temperature cracking reaction after waste gas to be treated enters into the thermal reaction system through the air inlet system, and carrying out quenching and preliminary purification after entering the cooling system; carrying out washing and purification for a plurality of times after entering the multistage washing system; finally discharging the waste gas from a chimney through a dehydration layer under the action of an induced draft fan.The waste gas is subjected to high-temperature cracking, cooling, preliminary purification and multistage purification, so that the purification speed is obviously improved; and the waste gas which can be treated by the method comprises perfluorides, inflammable substances, corrosion, poisons and the like, the purification is thorough, the method is safe and reliable.

Owner:上海高笙集成电路设备有限公司

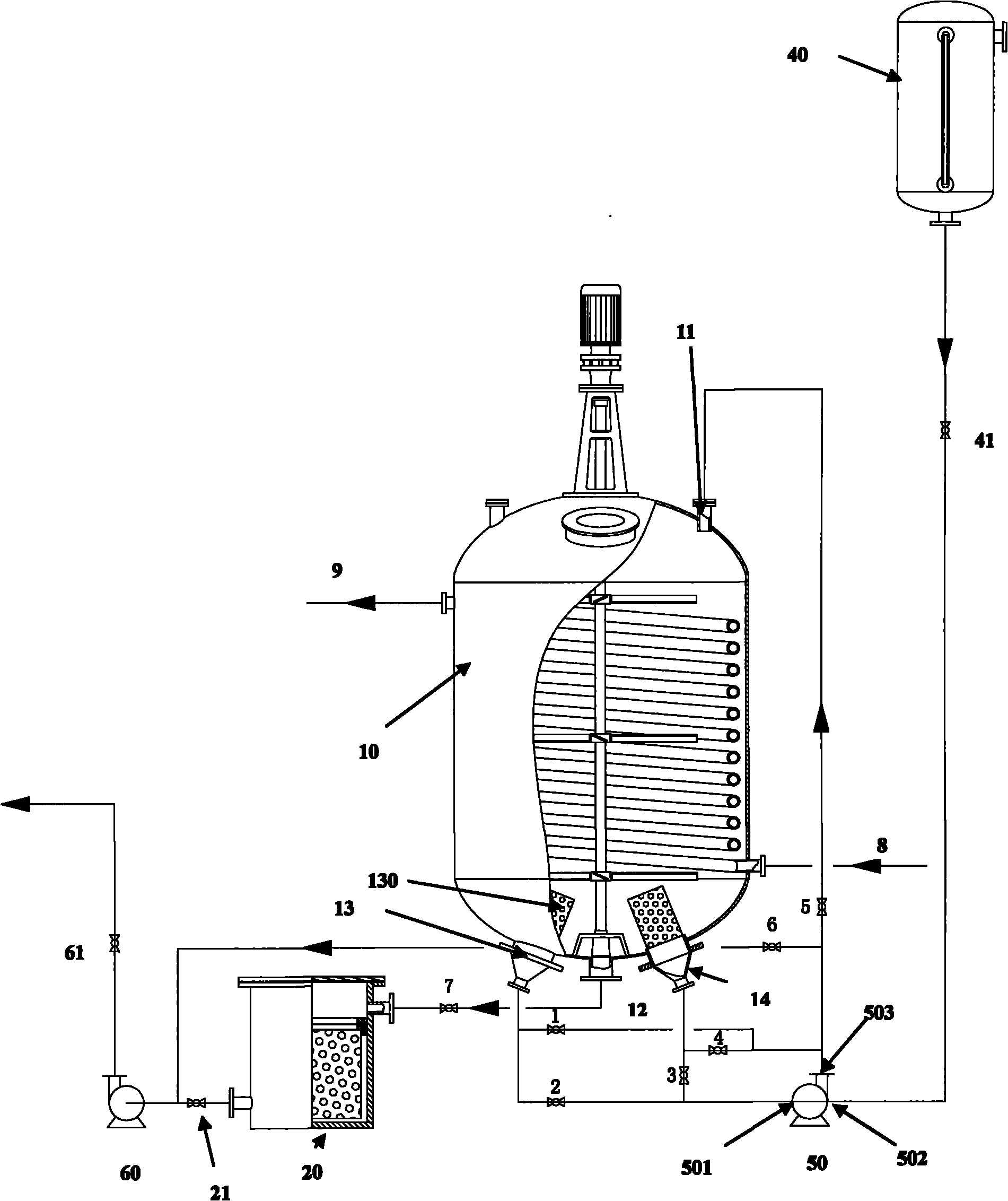

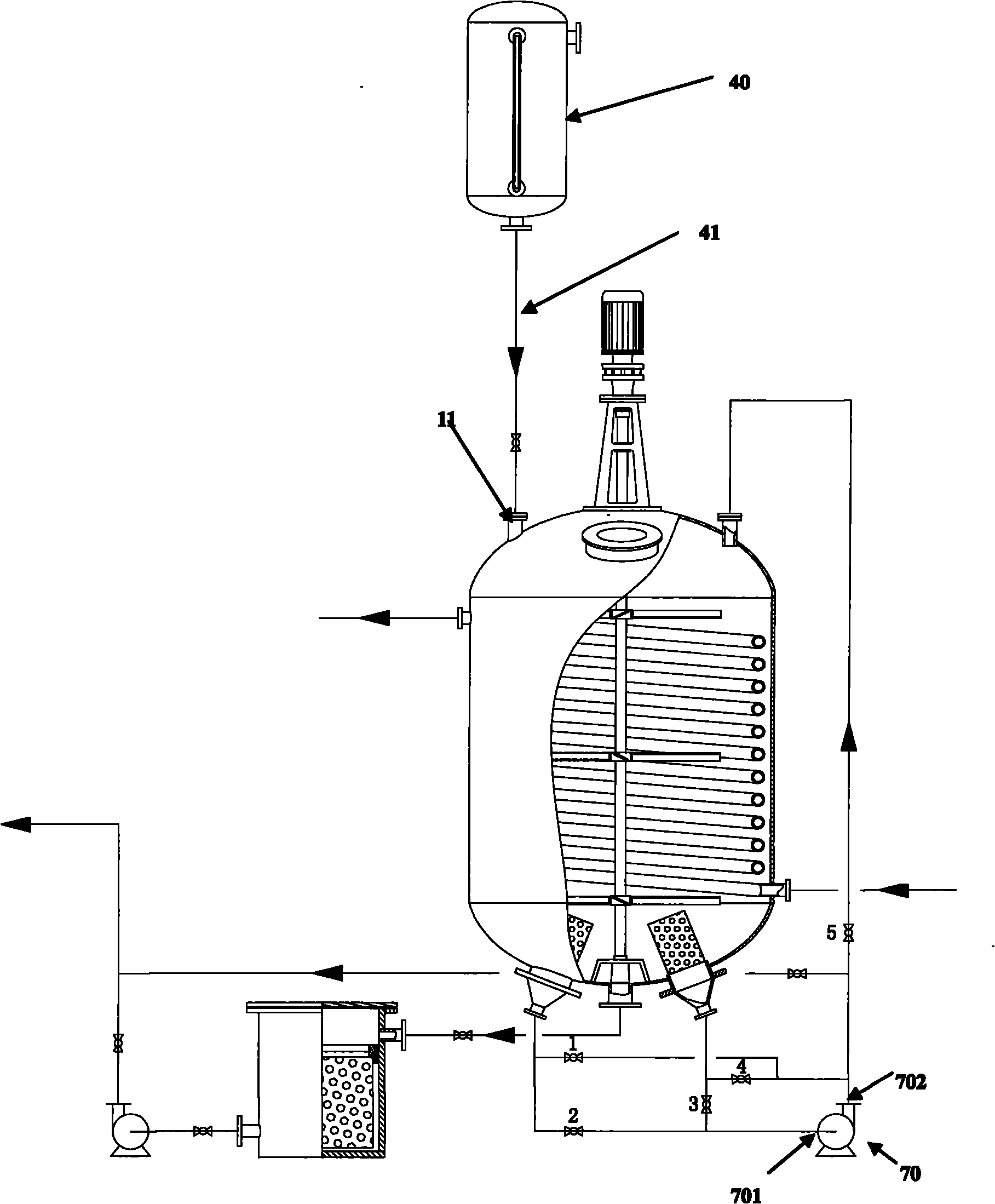

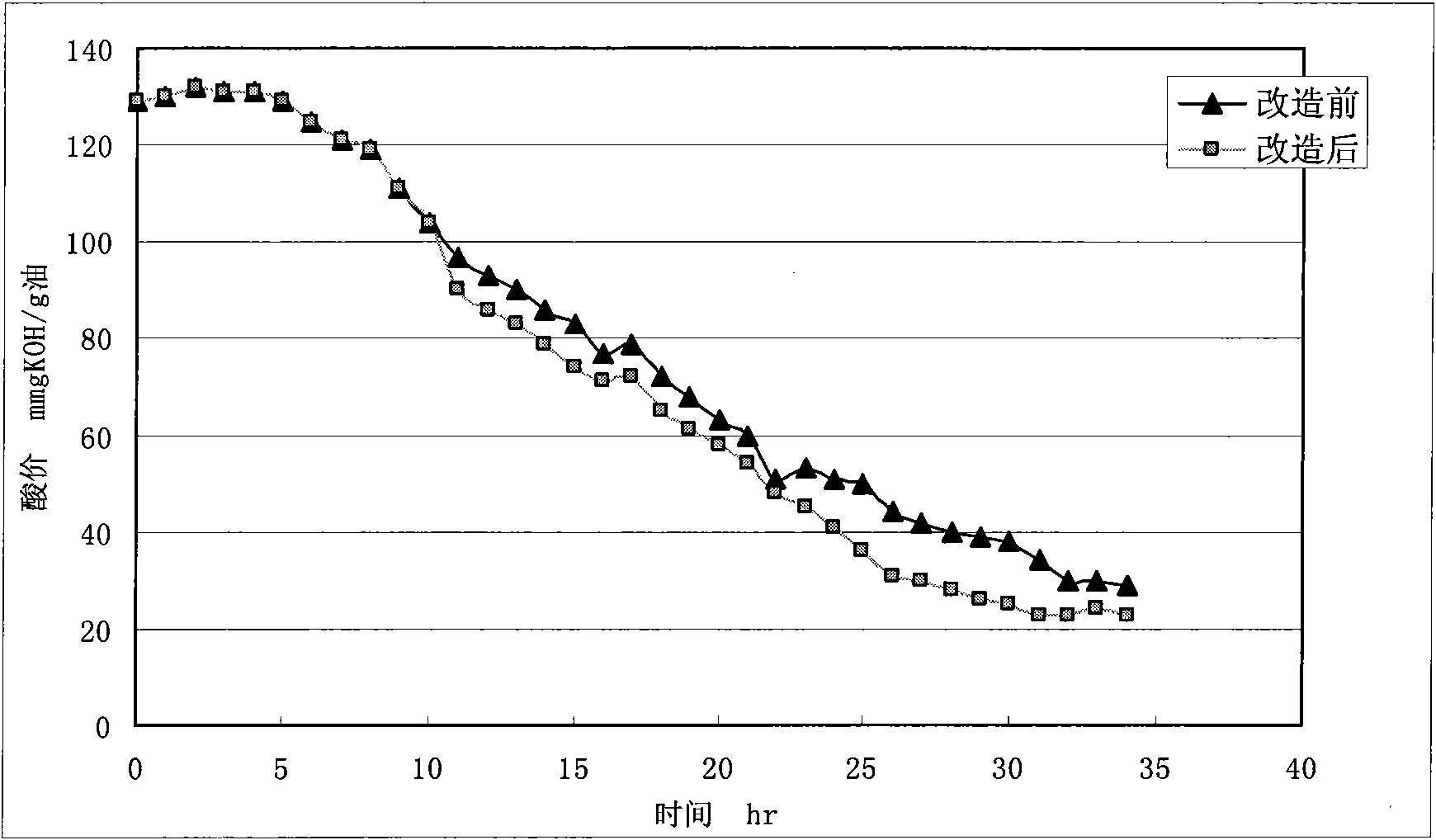

Method for improving fermentation capability of slurry dry process

InactiveCN102020404APromote decompositionImprove anaerobic degradabilityBiological sludge treatmentMass ratioSludge

The invention provides a method for improving the fermentation capability of a slurry dry process, belonging to the field of solid waste recycling, which can be used for solving the problems that reacted intermediate products and energy are difficult to transmit and diffuse in a medium resulted from the large viscosity of reaction matrix and high total solid (TS) concentration; slow hydrolysis acidification and low aerogenesis speed are caused by that a large amount of substances difficult to degrade exist in slurry and the further biotransformation is limited by the microbial residue cell-wall structure. In the method, dewatered slurry is placed in microwave of which the frequency is 915MHz and the power is 10-60kW for carrying out pretreatment for 3-10 minutes; the pretreated dewatered slurry is cooled to the selected fermentation temperature, and then mixes with seed slurry uniformly based on the mass ratio of 5: 1-3:1 to obtain a mixture which is placed in an anaerobic fermentation tank for standing for 3-5 days in a sealing and non-stirring state; a stirring motor is started, and the stirring speed is controlled to 10-30r / min; and materials are fed and discharged continuously so as to ensure the materials to stay in the anaerobic fermentation tank for 40-60 days. The method for improving the fermentation capability of the slurry dry process can be used to reduce the slurry viscosity and improve the dry fermentation rate and gas production rate; and in addition, the method for improving the fermentation capability of the slurry dry process can be used to save equipment investment and land occupancy compared with the wet fermentation.

Owner:TONGJI UNIV

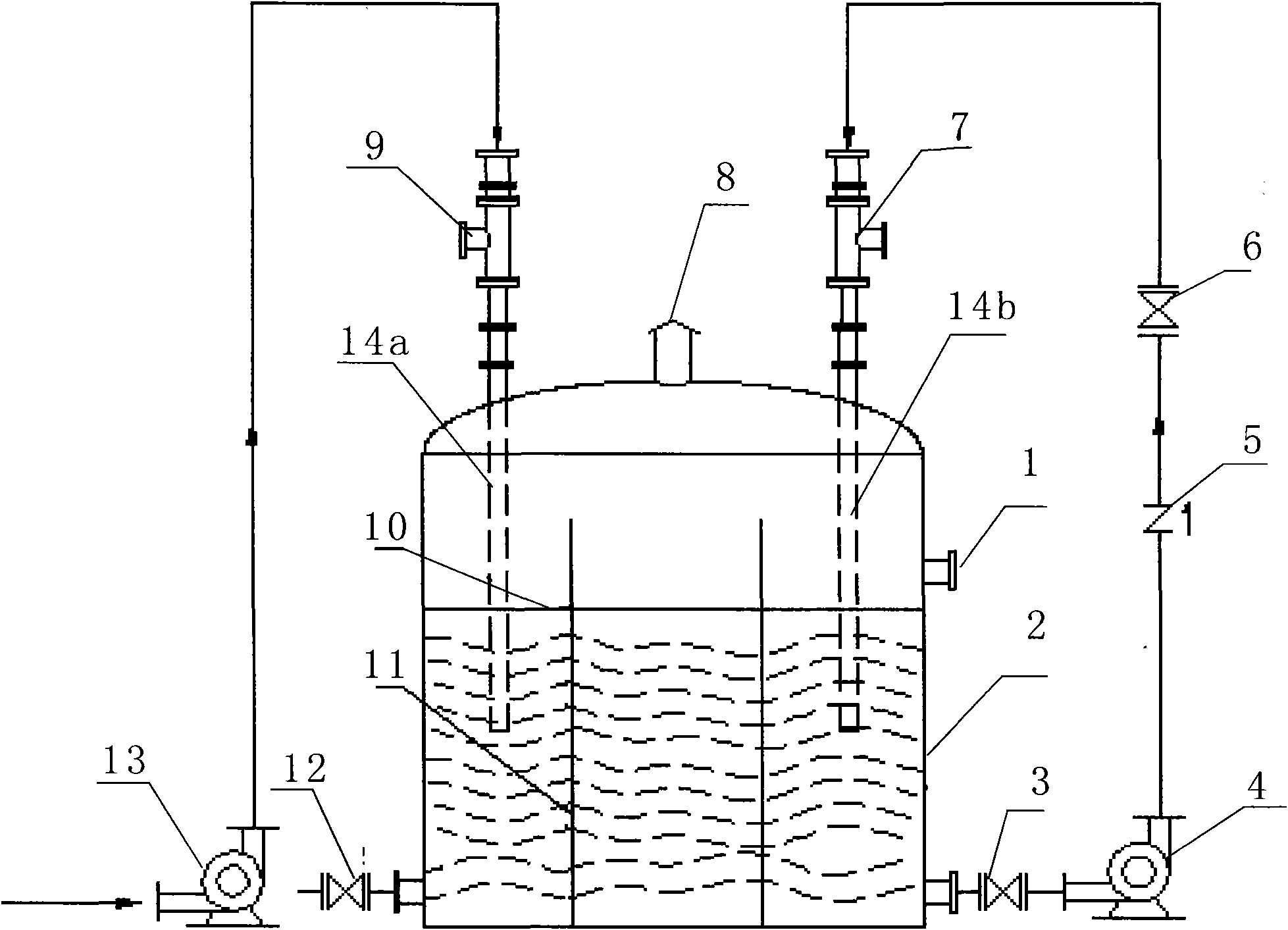

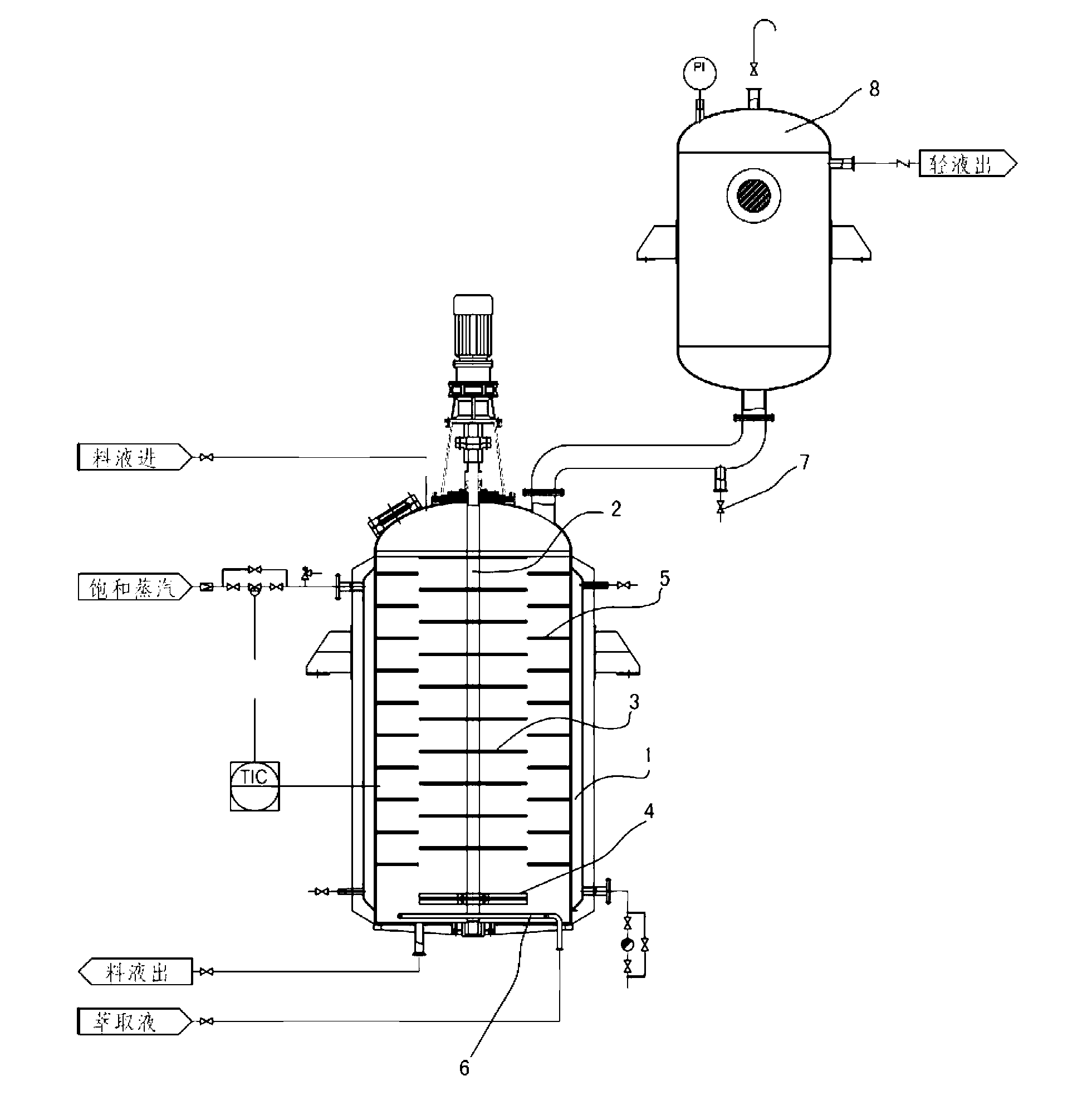

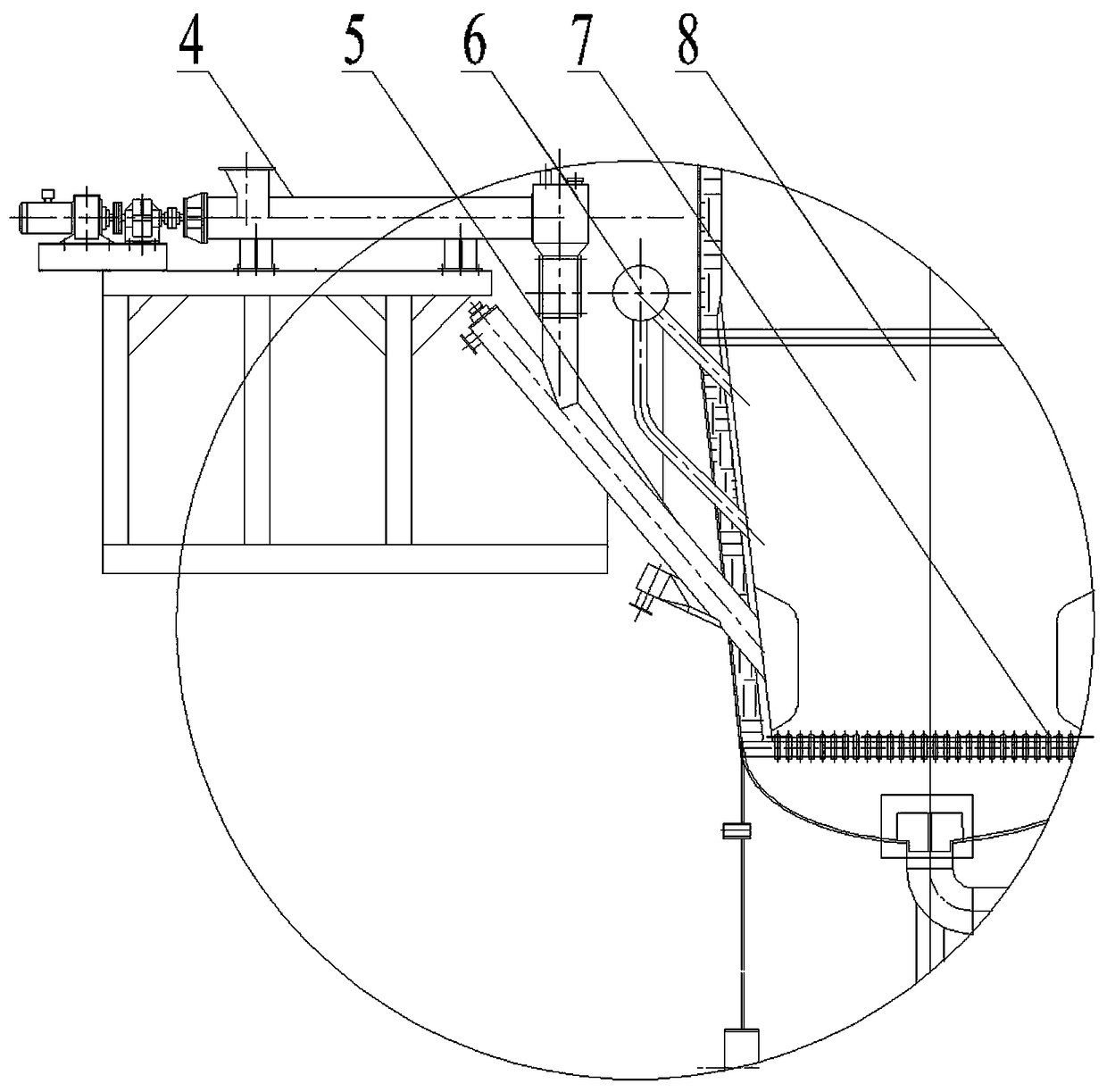

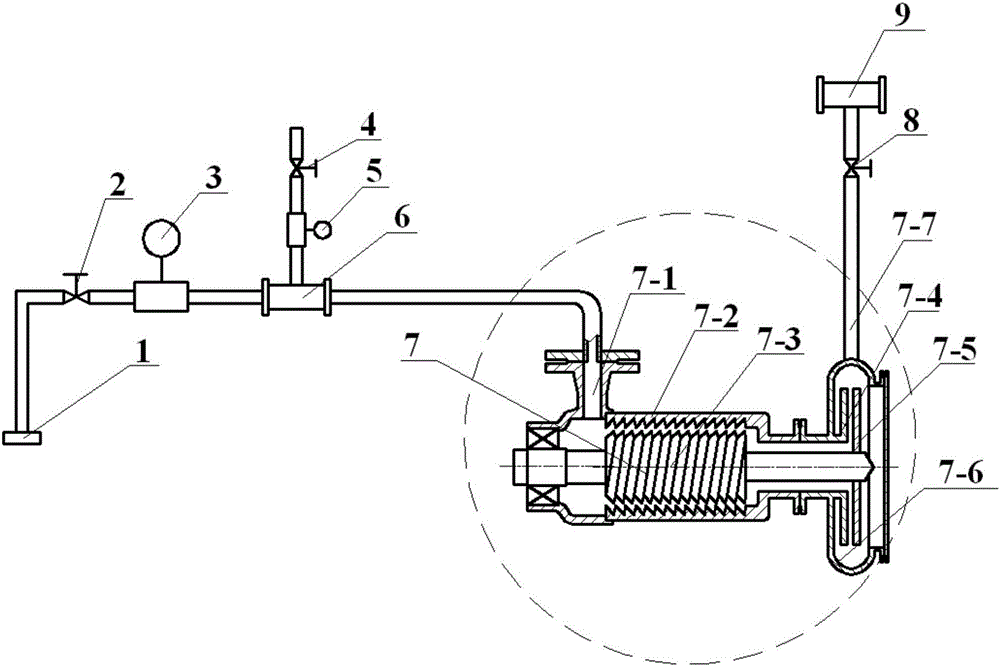

Process and device for producing (NH4)2SO4 fertilizer by using ammonium sulfite solution

InactiveCN101643369AIncrease contact areaAdequate mass transferAmmonium salt fertilisersThree stageSelf-absorption

The invention discloses a process and a device for producing a (NH4)2SO4 fertilizer by using an ammonium sulfite solution. In an ammonia-process flue gas desulfurization device, by using the ammoniumsulfite solution (NH4)2SO3 produced after ammonia absorbs SO2, the outlet of a liquid inlet ejector (9) is led into the solution at the middle lower part of an oxidation tank (2) by a downcomer through a oxidization preparation process of (NH4)2SO4 fertilizer by self-absorption of air so as to increase the reaction time; and the medium is fully oxidized through the three-stage cyclic oxidation. The cyclic oxidation procedure comprises liquid at the lower part of the oxidation tank (2), a recycle pump (4), a recycle liquid ejector and the middle lower part of the oxidation tank. Air is absorbedin the liquid inlet ejector, and sheared by liquid flows and dispersed into tiny air particles, so that the contact specific area of the gas and the liquid is increased by tens of times compared withthe bubbling oxidization, thereby fully utilizing the oxygen in the air. Therefore, the process enhances the reaction efficiency, shortens the reaction times and increases the conversion rate.

Owner:洛阳市天誉环保工程有限公司

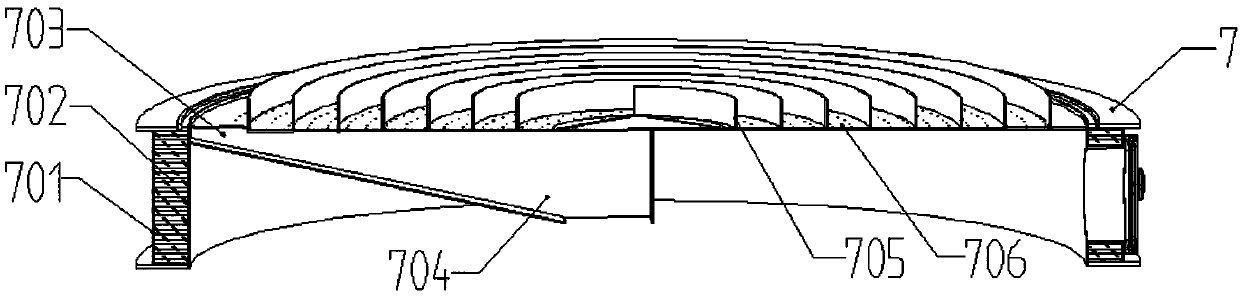

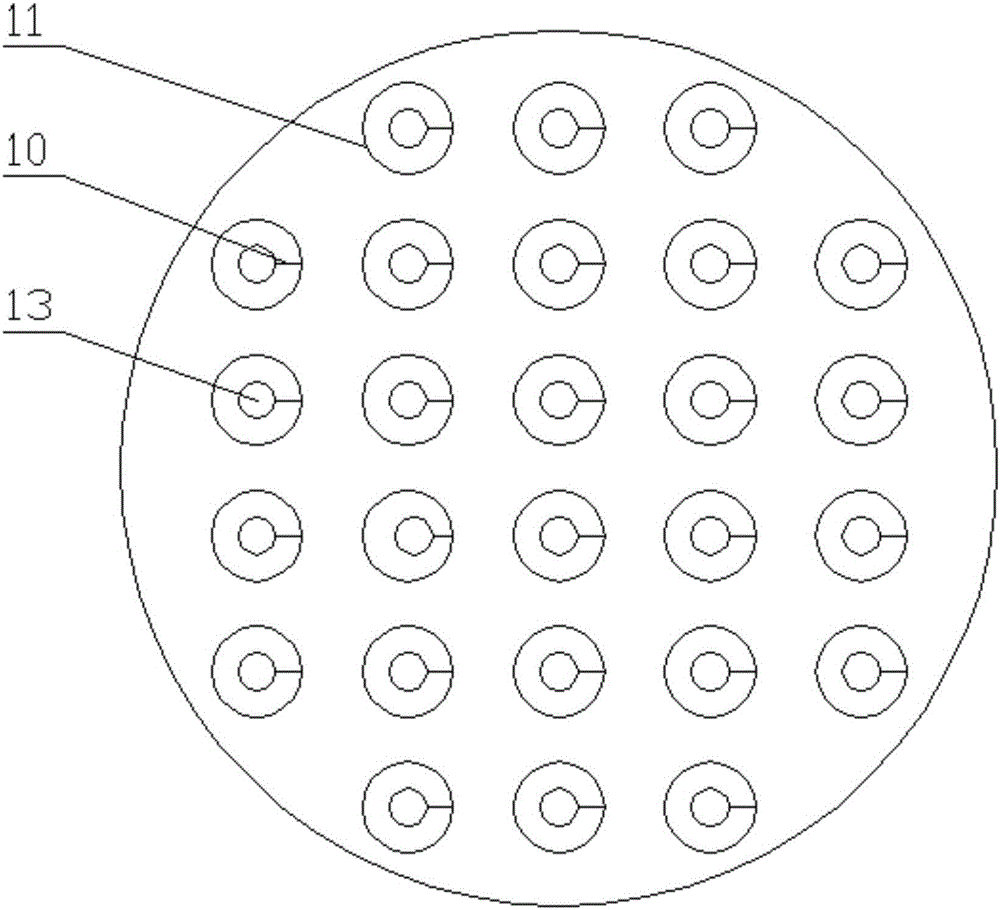

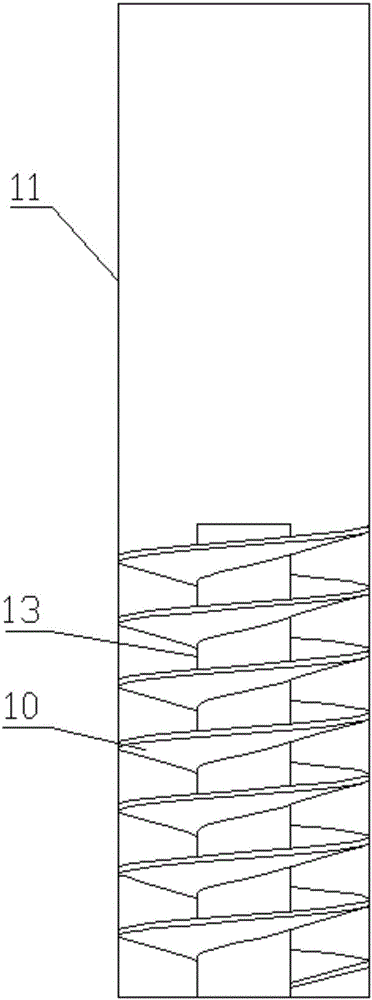

A rotary bed and a recovery method of hydrocarbon-containing exhaust gas

ActiveCN103789000AEffective prolapseEfficient removalLiquid hydrocarbon mixture recoveryDispersed particle separationRecovery methodKerosene

The invention discloses a rotary bed. The rotary bed comprises a cylinder, a bed layer assembly, an upper head and a lower head. A spiral plate is fixed to the inner wall of the cylinder. The spiral plate and a bed layer are in a clearance fit. The bed layer assembly is an integrated structure formed by an upper cover plate, the bed layer, a lower cover plate and a rotating shaft. The upper cover plate and the lower cover plate are respectively fixed to the upper part and the lower part of the rotating shaft. The bed layer is sandwiched between the upper cover plate and the lower cover plate. The lower cover plate is provided with a through hole. The part of the rotating shaft in the bed layer and the part of the rotating shaft above the bed layer are hollow tubular structures. The tube wall of the rotating shaft, in the bed layer, is provided with a plurality of through holes, namely, the part of the rotating shaft is also a liquid distributing tube. The invention relates to a recovery method of hydrocarbon-containing exhaust gas. Crude diesel or crude kerosene is pretreated by utilization of the rotary bed. Materials discharged from a liquid phase outlet of the rotary bed are adopted as an absorbent and used for adsorption treatment of the hydrocarbon-containing exhaust gas. The recovery method is simple in process, economic, reasonable, and free of secondary pollution, and is suitable for adsorption recovery processes of the hydrocarbon-containing exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

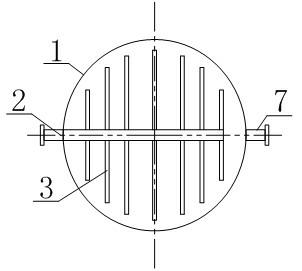

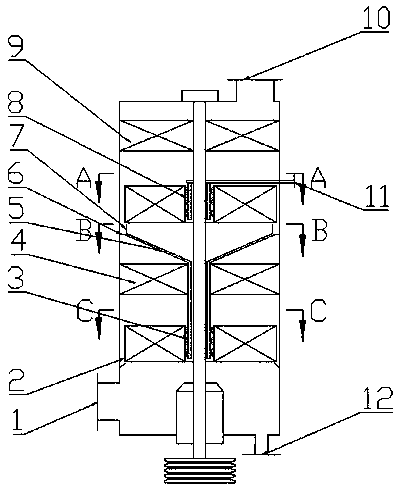

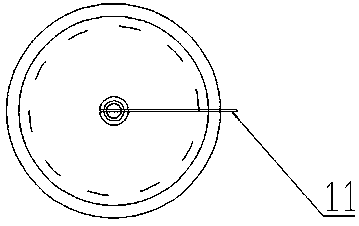

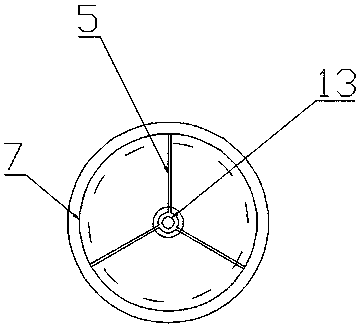

Device and method for removing methanol from methyl tert-butyl ether cracking product

InactiveCN108159844AEvenly distributedAdequate mass transferDispersed particle separationProduct gasMethyl tert-butyl ether

The invention discloses a device and a method for removing methanol from a methyl tert-butyl ether cracking product. The MTBE cracking product and absorption liquid undergo cross flow-counterflow contact in a multistage airflow shear cross-flow bed; under the shear action of high-speed rotating filler, cracked gas and the absorption liquid are dispersed, coalesced and redispersed for multiple times, so that multistage absorption is realized; cracking gas is introduced to a gas inlet in the side bottom of a multistage airflow shear cross flow bed; a gas outlet in the top of the multistage airflow shear cross flow bed is connected with a purified gas section; the absorption liquid is introduced to a liquid inlet in the side top of the multistage airflow shear cross flow bed; a liquid outletin the bottom of the multistage airflow shear cross flow bed is used for draining the absorption liquid; the liquid inlet is connected with a pump; the liquid outlet of the multistage airflow shear cross flow bed is connected with a liquid-rich tank; the multistage airflow shear cross flow bed comprises a liquid distributor, a liquid collecting and redistributing device, a rotor, a stator, a driving device and a casing. According to the equipment, the gas and the absorption liquid generally make counterflow contact, so that a gas-liquid mass transfer propulsion force is greater, the purification degree of the cracking gas is improved, and the concentration of methanol in the rich solution and the utilization rate of the absorption liquid are improved.

Owner:ZHONGBEI UNIV

Novel wet type oily fume purifier and application thereof

InactiveCN106422616ALow costImprove removal efficiencyCombination devicesDomestic stoves or rangesFiltrationWaste management

The present invention relates to a novel wet type oily fume purifier. The purifier comprises a housing, a circulation water tank, an oily fume inlet port, an oily fume discharge port, an air exhaust fan, a rectification section, a purification section, a spraying section and a demisting section. The top of the housing is provided with the oily fume discharge port while being in communication with the interior of the housing. The air exhaust fan is connected with the oily fume discharge port. The air exhaust fan provides the negative-pressure power for the oily fume discharge port. The bottom of the housing is provided with the circulation water tank. Above the circulation water tank, the housing is provided with the oily fume inlet port in communication with the interior of the housing. Between the oily fume discharge port and the oily fume inlet port, the rectification section, the purification section, the spraying section and the demisting section are sequentially and coaxially arranged from bottom to top inside the housing. The purification section, the spraying section and the demisting section are arranged at intervals. According to the invention, the removal efficiency of the purifier for oily fume particles with the diameters thereof larger than 2 mum is up to over 90%. Therefore, the purifier is high in oily fume purification efficiency and low in cost. The defect in the prior art that the filter section of a conventional filtration type purifier is frequently cleaned to be easily blocked in the prior art can be overcome.

Owner:AEROSPACE ENVIRONMENTAL ENG

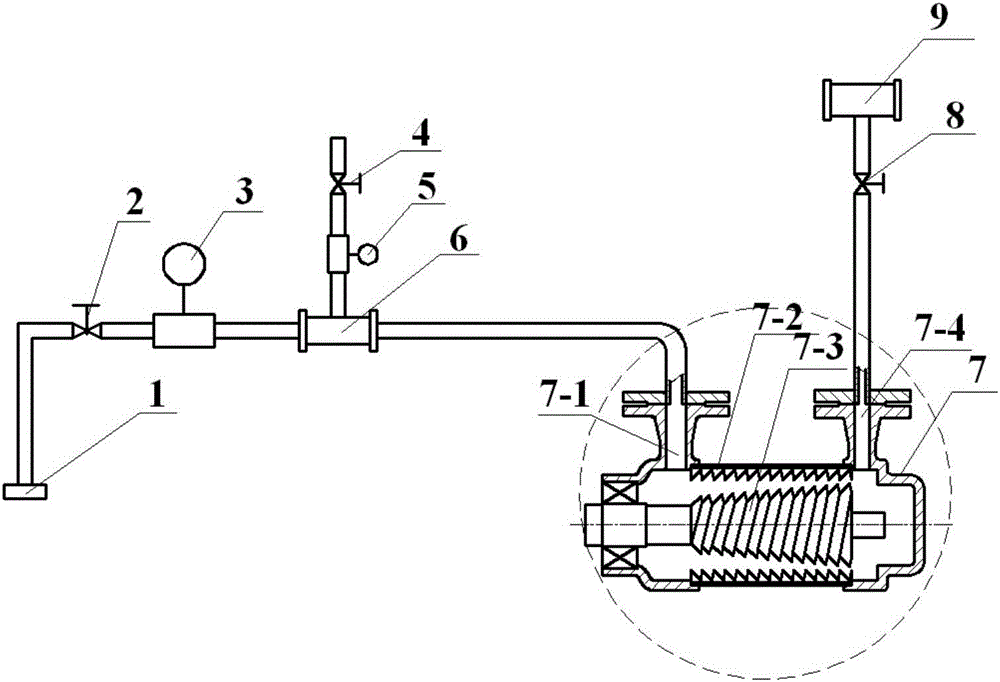

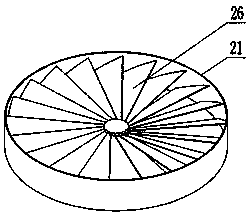

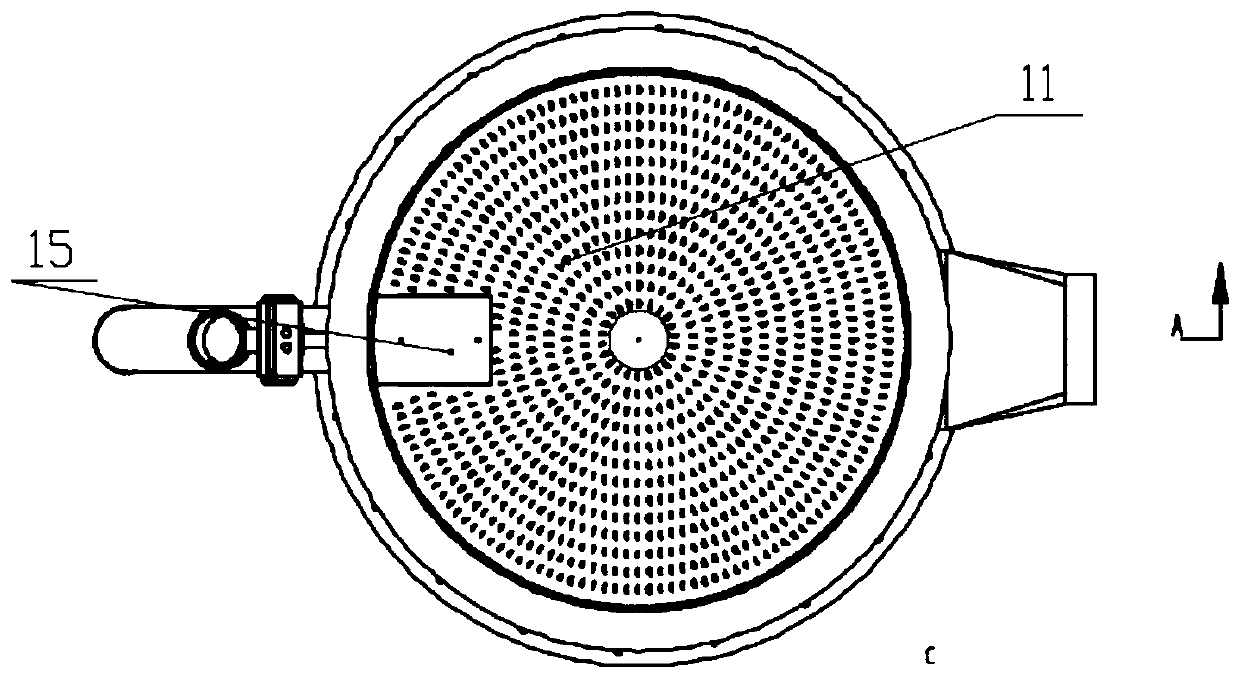

Tubular photobioreactor CO2 aerating device

ActiveCN106434326AAbsorb thoroughlyGood refinement effectBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorEngineering

The invention discloses a tubular photobioreactor CO2 aerating device, comprising a filtering device, a valve, a fluid flowmeter, a valve, a gas flowmeter, a conical rotor labyrinth spiral pump and a tee joint, wherein the conical rotor labyrinth spiral pump comprises a pump inlet, a stator, a conical rotor and a pump outlet. During the working process, the filtering device is placed in a tubular photobioreactor water tank, and the tee joint is connected with a light reacting tube through a thread or a flange; an electric motor drives the conical rotor to rotate at high speed, so as to respectively suck the mixed gas of CO2 and air and fluid in the water tank to the conical rotor labyrinth spiral pump; gas-fluid two-phase fluids perform circling motion and axial motion along with the conical rotor along with a working cavity body formed by the conical rotor and the stator; the mixed gas is gradually scrubbed and sheared at high speed continuously, and finally, massive trace bubbles are formed and mixed in the fluid, and then flowed into a light reaction pipeline. The tubular photobioreactor CO2 aerating device is good in bubble refining effect, high in pump efficiency; the microalgae can absorb CO2 completely and well perform the photosynthesis.

Owner:BEIJING UNIV OF CHEM TECH

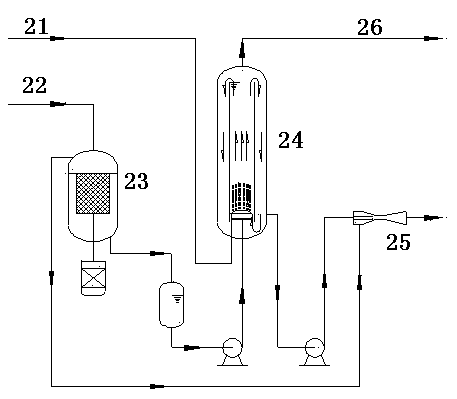

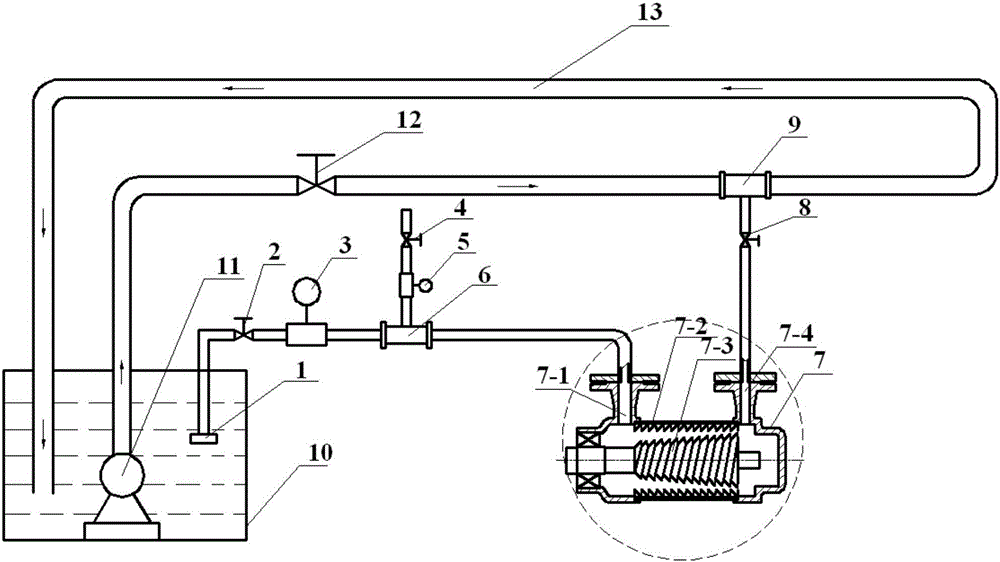

Reactor for producing biodiesel in presence of solid catalyst

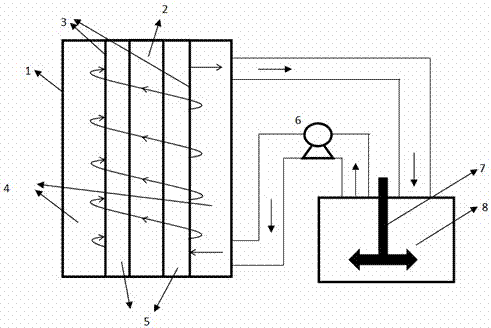

InactiveCN101927144AAdequate mass transferGood transesterification reactionChemical/physical processesBiodieselControl valves

The invention relates to a reactor for producing biodiesel in the presence of a solid catalyst. The reactor comprises a stirring tank, a filter, a circulating pump, a methanol storage tank and a discharging pump, wherein the filter is internally arranged at the bottom of the stirring tank; the outlet of the filter is connected with the inlet of the circulating pump; the outlet of the circulating pump is connected with the feed inlet of the stirring tank; the stirring tank is connected with the outlet of the circulating pump through a pipeline with a control valve; and the methanol storage tank is directly connected with the feed inlet of the stirring tank or the inlet of the circulating pump. Compared with the prior art, the reactor has the advantages of conveniently recovering the solid catalyst, prolonging the service life of the catalyst, reducing the cost, and the like.

Owner:上海绿铭环保科技股份有限公司

A rotary bed and an adsorption method of hydrocarbon-containing exhaust gas

ActiveCN103785343APromote prolapseIntegrated structure realizationDispersed particle separationChemical/physical/physico-chemical stationary reactorsRecovery methodGas phase

The invention discloses a rotary bed. The rotary bed comprises a cylinder, a bed layer assembly, an upper head and a lower head. A gas-phase outlet is disposed in the lower part of the cylinder and a liquid phase outlet is disposed in the lower head. A spiral plate is fixed to the inner wall of the cylinder. The spiral plate and a bed layer are in a clearance fit. The bed layer assembly is an integrated structure formed by an upper cover plate, the bed layer and a lower cover plate. The upper end of the bed layer assembly is fixed in a rotatable manner to the upper part in the cylinder through a support. The bed layer is sandwiched between the upper cover plate and the lower cover plate. The middle part of the bed layer is a cylindrical cavity. A liquid distributing tube stretches from the upside into the cylindrical cavity in the middle part of the bed layer. The invention relates to a recovery method of hydrocarbon-containing exhaust gas. Crude diesel or crude kerosene is pretreated by utilization of the rotary bed. Materials discharged from the liquid phase outlet of the rotary bed are adopted as an absorbent and used for adsorption treatment of the hydrocarbon-containing exhaust gas. The recovery method is simple in process, economic, reasonable and free of secondary pollution, and is suitable for adsorption recovery processes of the hydrocarbon-containing exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

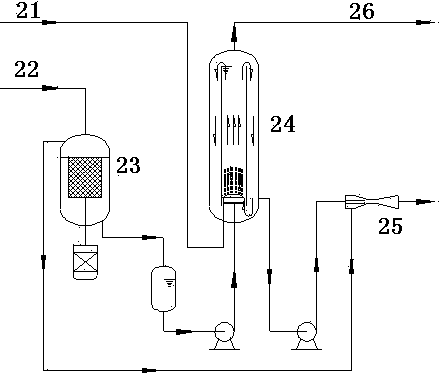

Method for extracting rare earth elements and rare earth extraction system

InactiveCN102936664AReduce dosageImprove work efficiencyProcess efficiency improvementRare-earth elementSolvent

The invention relates to a method for extracting rare earth elements and a rare earth extraction system. The method comprises the following steps: inputting quantitative water solution or suspension, as heavy liquid, of rare earth elements into an extraction tank via a heavy liquid inlet at the top of the extraction tank; starting a stirring shaft; filling an extraction solvent as light liquid into the extraction tank uniformly from a liquid distributor at the bottom of the extraction tank, ensuring step-by-step mixing and mass transfer from bottom to top between the light liquid and the heavy liquid in the stirring process and enabling the light phase liquid completing mass transfer to overflow into a decanting tank from the top of the extraction tank; after the light phase liquid is decanted in the decanting tank, discharging the light components via a light liquid outlet at the top of the decanting tank; judging whether extraction is completed by detecting the concentrations of the needed rare earth elements in the light component solution discharged from the decanting tank; after extraction is completed, stopping input of the light liquid and starting an emptying valve below the decanting tank to empty the decanting tank; and discharging the heavy liquid in the extraction tank via a heavy liquid outlet at the bottom of the extraction tank.

Owner:陆文光

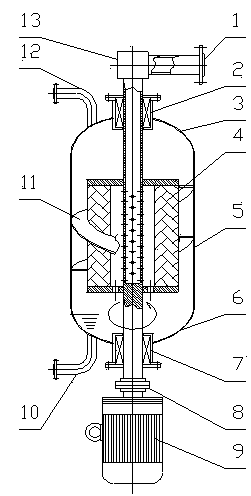

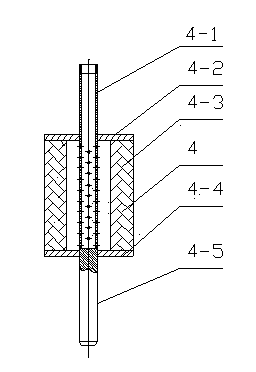

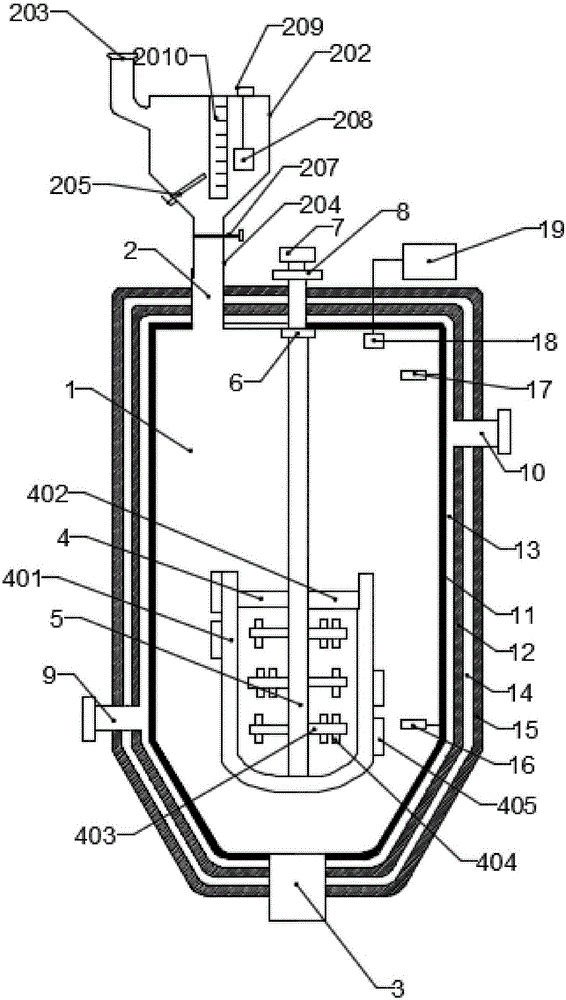

Reaction kettle

InactiveCN105148825AEasy outflowAccurate heating controlChemical/physical/physico-chemical stationary reactorsAtmospheric pressureHeating temperature

The invention discloses a reaction kettle which comprises a kettle body, wherein a material inlet is formed in the top of the kettle body; a material outlet is formed in the bottom of the kettle body; the kettle body comprises an inner layer and an outer layer; a heat preservation layer is arranged at the outer side of the outer layer; a temperature detection device is arranged at the lower side wall of the kettle body; a bearing in the top of the kettle body is in tight connection with a stirring shaft; a motor and a speed reducing machine are arranged above the stirring shaft; the stirring shaft positioned at the lower part of the kettle body is connected with a stirring device blew the stirring shaft. The reaction kettle can be used for improving the heat exchange efficiency, and the heating temperature is easy to control; the whole kettle body is heated, so that liquid materials can be uniformly heated; the stirring effect is good, and the flowing directions of the materials are changed in a stirring process, so that the reaction of the materials is relatively full; an air valve is adopted for controlling the output of gas generated in a reaction process; parameters such as the temperature, air pressure and stirring speed can be controlled; a temperature sensor in a feeding device can effectively sense the temperature of the materials.

Owner:成都米戈科技有限公司

Method for treating nickel-cobalt alloy waste

ActiveCN106893859AEfficient deliveryOvercome the problem of "slurry depletion zone"Process efficiency improvementResource utilizationSizing

The invention discloses a method for treating nickel-cobalt alloy waste. The dilute sulfuric acid system nickel-cobalt alloy waste is put into a sizing groove, a mechanical stirring paddle is arranged in the sizing groove, and therefore sizing is maintained in an evenly-mixed state; and the sizing enters a rotary flow electrolyzing system through a pneumatic pump according to the certain speed, is electrolyzed and then discharged from an electrolyzing device and enters the sizing groove continuously, circulation is conducted in this way, and nickel and cobalt in minerals are extracted efficiently after certain time. The technology conditions include that the concentration of dilute sulfuric acid in the sizing ranges from 180 g / L to 200 g / L, the temperature ranges from 55 DEG C to 85 DEG C, the liquid-solid ratio ranges from 6-12:1, and the cathode current density ranges from 100 A / m<2> to 200 A / m<2>. The method is short in process, high in reaction speed, and even in mass transfer in the reaction process. Compared with a traditional acid wet process technology, the acidity is low, no extra oxidizing agent needs to be added, the nickel and the cobalt in the alloy waste can be comprehensively and efficiently extracted, and the resource utilization rate is increased.

Owner:CENT SOUTH UNIV

Anhydrous hydrogen fluoride preparation process

ActiveCN108946668AImprove heat transfer efficiencyExtend your lifeHydrogen fluorideHydrogen fluorideFluidized bed

The invention relates to the technical field of fluorine chemicals and in particular relates to an anhydrous hydrogen fluoride preparation process. The process is characterized by comprising the following steps: circulating fluidized bed reaction, granular moving bed filtration, washing and condensing, circulating fluidized bed distillation, circulating fluidized bed degassing and environmental-friendly tail gas treatment.

Owner:FUJIAN LONGFU CHEM

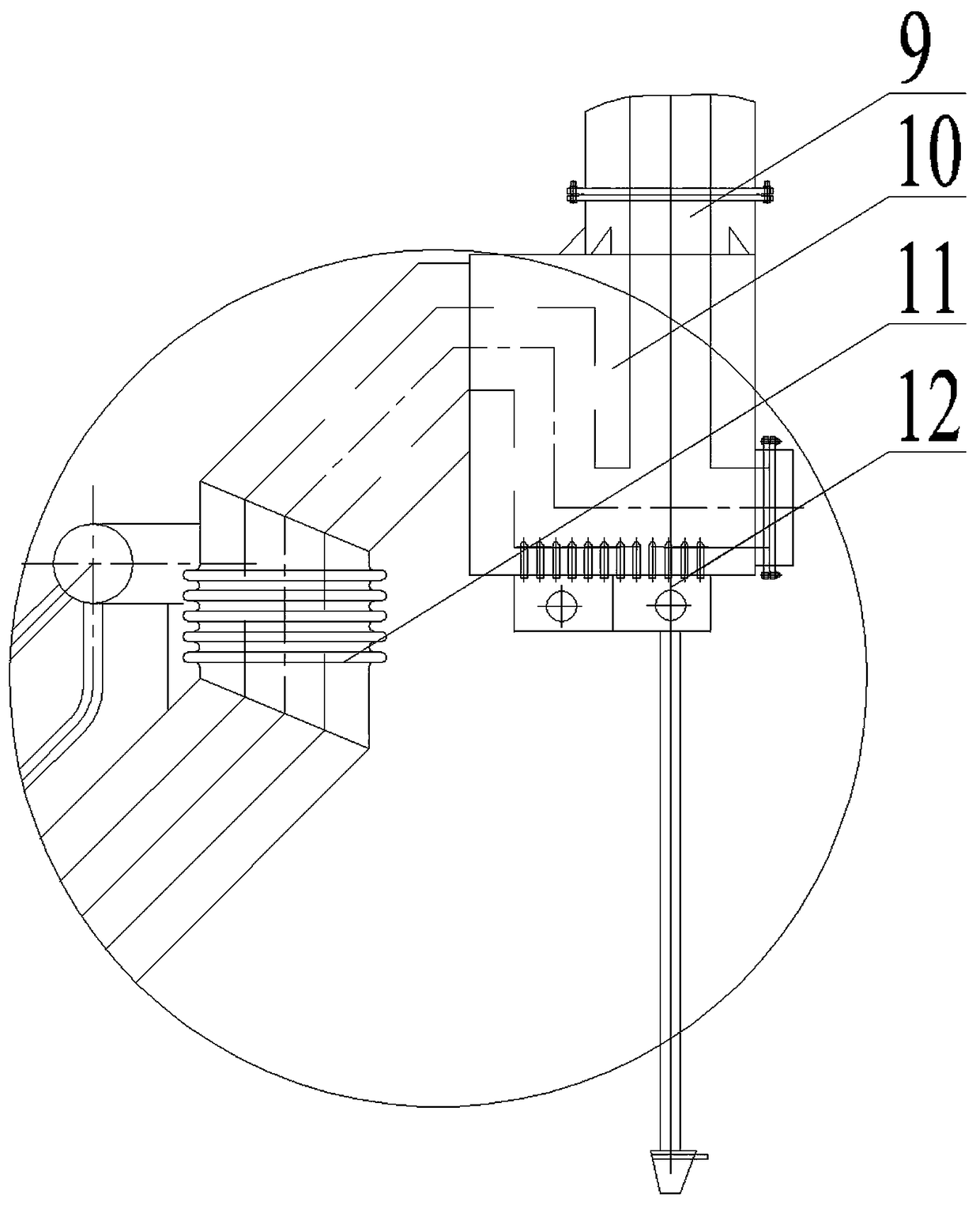

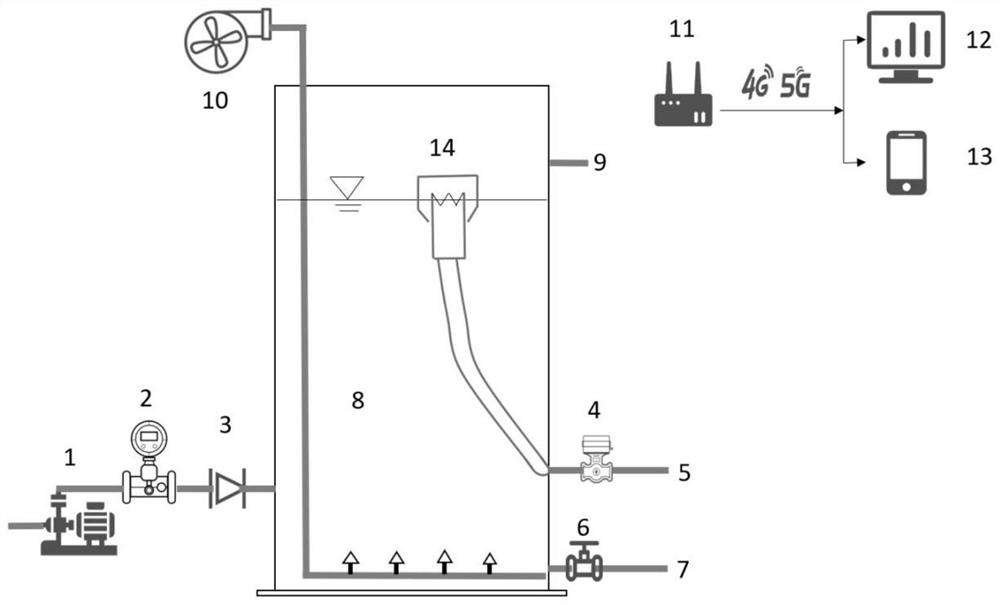

Device and method for desulfurizing waste gas of ship engine

PendingCN109821366ARealize the effect of secondary desulfurizationImprove desulfurization efficiencyDispersed particle separationWaste water treatment from gaseous effluentsSeawaterFlue gas

The invention discloses a device and method for desulfurizing waste gas of a ship engine.Seawater or fresh water and alkaline substances are used as an absorbent, and wastewater of a secondary desulfurization technology combining a primary washer and a main tower can be directly discharged into the ocean after treatment; the device comprises a flue gas system, a desulfurization system, a seawatersupply system, a wastewater treatment system and a control system, wherein the flue gas system comprises a booster fan and a connecting pipeline; waste gas from an engine chimney outlet is supercharged by a supercharged fan and then enters a desulfurization tower; the desulfurization system comprises the desulfurization tower, a circulating pump, a flow meter, and a circulating water tank; the seawater supply system comprises a filter, a seawater detector 1 and a seawater pump; the wastewater treatment system comprises a replacement pump, an aeration tank, an aeration fan, an exhaust pump, a rotary vacuum filter, a sludge tank, a seawater detector 2. The device and methodachieve the combination of dual-mode and two-stage desulfurization, thetechnological process is simple, the system adjustability is high and the operation cost is low, the device and methodare suitable for desulfurizing waste gas of the ship engine.

Owner:WEIHAI ZHENGDA ENVIRONMENTAL PROTECTION EQUIP LTD BY SHARE LTD

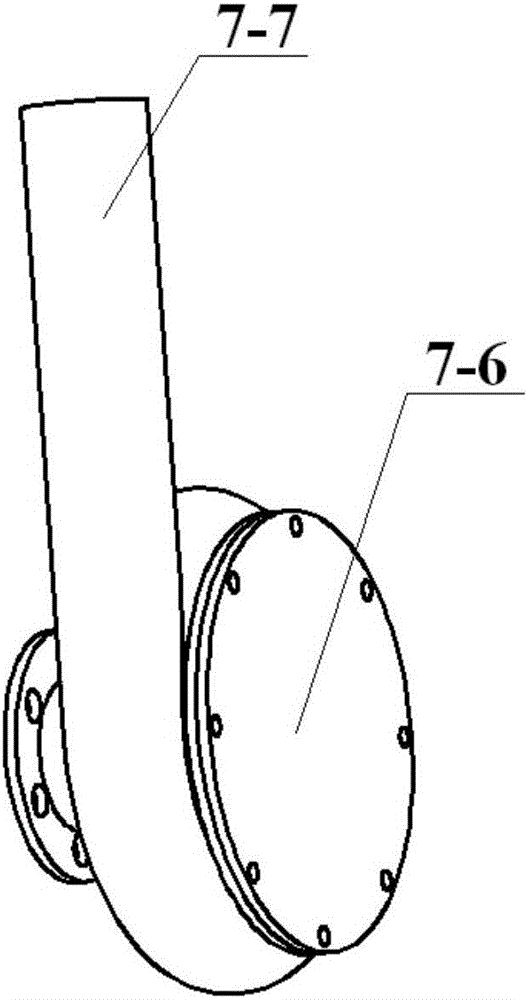

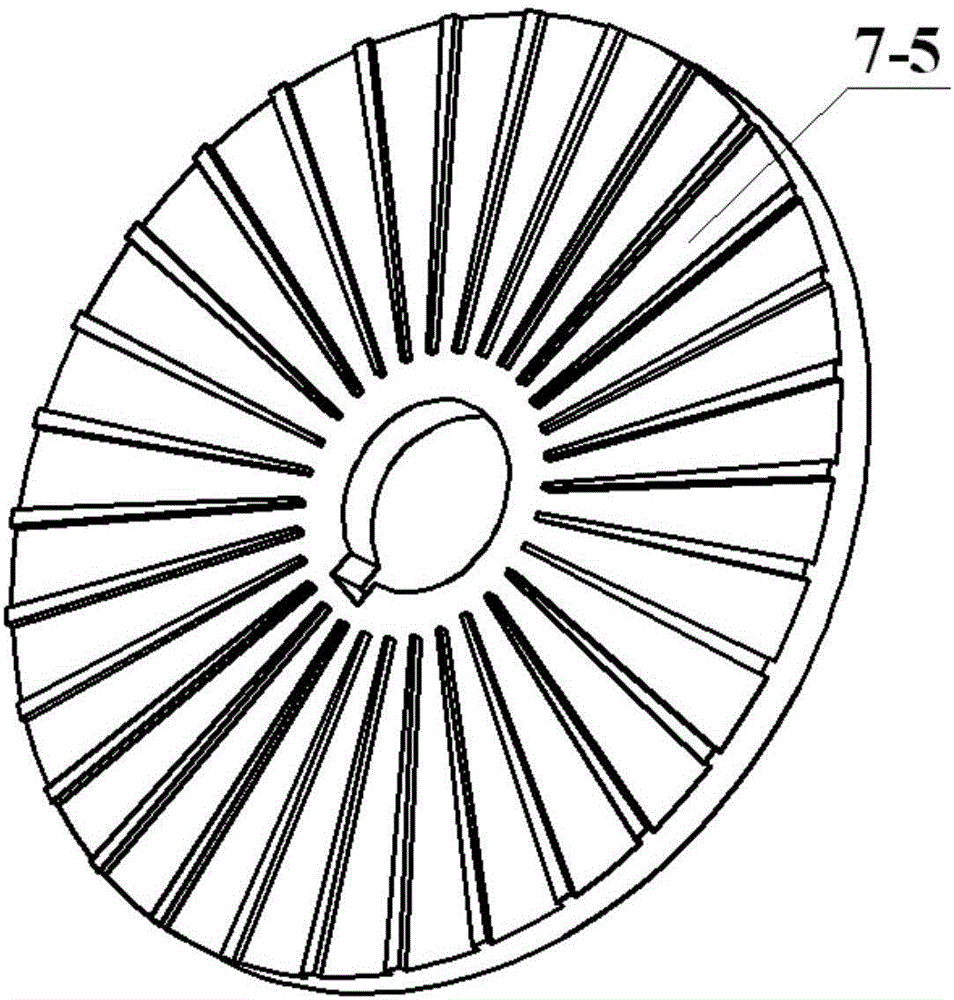

Tubular photo-biological reactor CO2 refining device

ActiveCN106367333AGood refinement effectExtended stayBioreactor/fermenter combinationsBiological substance pretreatmentsPhotosynthesisPhotobioreactor

The invention discloses a tubular photo-biological reactor CO2 refining device. The tubular photo-biological reactor CO2 refining device mainly comprises a filter device, a liquid valve, a liquid flowmeter, a gas valve, a gas flowmeter, a gas-liquid mixed tee, an axial flow and radial flow composite labyrinth screw pump, a microbubble liquid valve and a microbubble liquid tee, wherein the axial flow and radial flow composite labyrinth screw pump comprises a pump inlet, a stator, a rotor, a fixed disc, a refining disc, a volute and a pump outlet. The rotor and the stator form an axial flow working cavity, and the fixed disc and the refining disc form a radial flow working cavity. According to the axial flow and radial flow composite labyrinth screw pump CO2 refining device disclosed by the invention, CO2 gas can be pumped into a tubular photo-biological reactor in a micron-order scale, the problems that the requirment on installation accuracy of the rotor and the stator is high is avoided, the bubble refining effect is good through two-stage refining of gas, the residence time of microbubbles in pipelines is long, the microbubbles are unlikely to float to the top of a pipe quickly, gas-liquid two-phase mass transfer and mixing are more sufficient, and the absorption of microalgae for CO2 is more thorough, so that photosynthesis is carried out preferably.

Owner:BEIJING UNIV OF CHEM TECH

Novel method for terminating allyl alcohol irregular polyether methyl

InactiveCN106565949AIncrease mass transfer rateIncreased mass transfer rates over conventional stirred tank reactorsEther preparation by ester reactionsIsomerizationKinetic control

The invention discloses a novel method for terminating allyl alcohol irregular polyether methyl. The novel method comprises the following steps of: adding allyl alcohol irregular polyether raw materials through a material inlet in a jetting loop reactor based on Venturi effect, deoxidizing and introducing inert gases for replacement and protection, and starting an external circulating pump to carry out high-speed jetting mixing; and at a control temperature ranging from 20 DEG C to 70 DEG C, slowly adding a methane chloride raw material and an alkali raw material into the jetting loop reactor through a methane chloride raw material feeding hole and a material feeding hole separately, and the like. According to the novel method disclosed by the invention, this system belongs to a dynamic control system, side reactions are restrained sufficiently, a low-temperature method is further adopted to carry out dynamic reaction control according to the characteristic that activation energy of side reactions is high, hydrolysis reaction of methane chloride is restrained, and isomerization reaction of allyl is further restrained, and therefore, selectivity of a reaction system is higher. Finally obtained allyl alcohol irregular polyether methyl terminated product has color and luster smaller than 30, and has a terminating rate greater than 98%.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Gas-liquid contact type residual heat recovery device

ActiveCN103884203AImprove heat exchange efficiencyImprove heat transfer efficiencyDispersed particle separationTrickle coolersFlue gasEngineering

The invention discloses a gas-liquid contact type residual heat recovery device for recovering residual heat from flue gas and low-pressure steam. The residual heat recovery device is characterized in that a gas inlet pipe is arranged at the lower part of a shell and is connected with a gas input pipe; a plurality of spray heads are mounted in the shell and are connected with a cold liquid inlet pipe and a cold liquid conveying pipe; a plurality of annular liquid baffles are mounted in the shell; a liquid on the wall of the shell is intercepted and flows back to gas ascending space; a gas screw-out pipe is arranged at the upper part of the shell and is connected with a gas screw-in pipe; a gas distribution cone and a foam remover are mounted in the upper part of the shell, gas rotates at a high speed after entering a cyclone separator and then enters the foam remover through the gas distributor to separate the liquid from foam in gas flow; a liquid backflow outlet pipe is connected with a liquid backflow inlet pipe; a gas outlet pipe is connected with a gas emptying pipe; and a hot liquid outlet pipe is arranged at the lowest part of the shell and is connected with a hot liquid tank. The residual heat recovery device has the advantages of high heat exchange efficiency, capability of purifying flue gas, simple structure, reliability in working, convenience in mounting and the like.

Owner:GUANGXI DETIAN CHEM CYCLE CO LTD

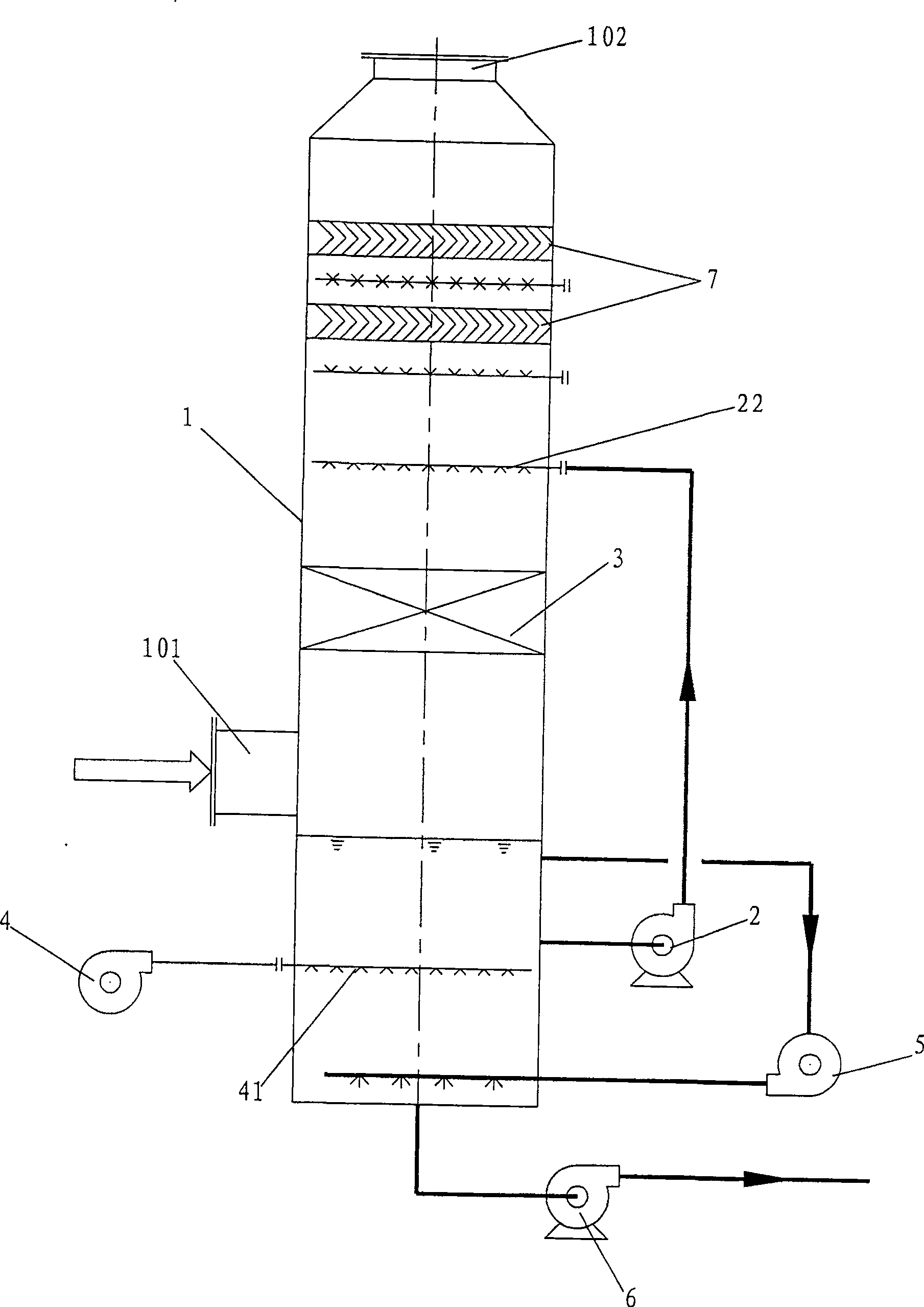

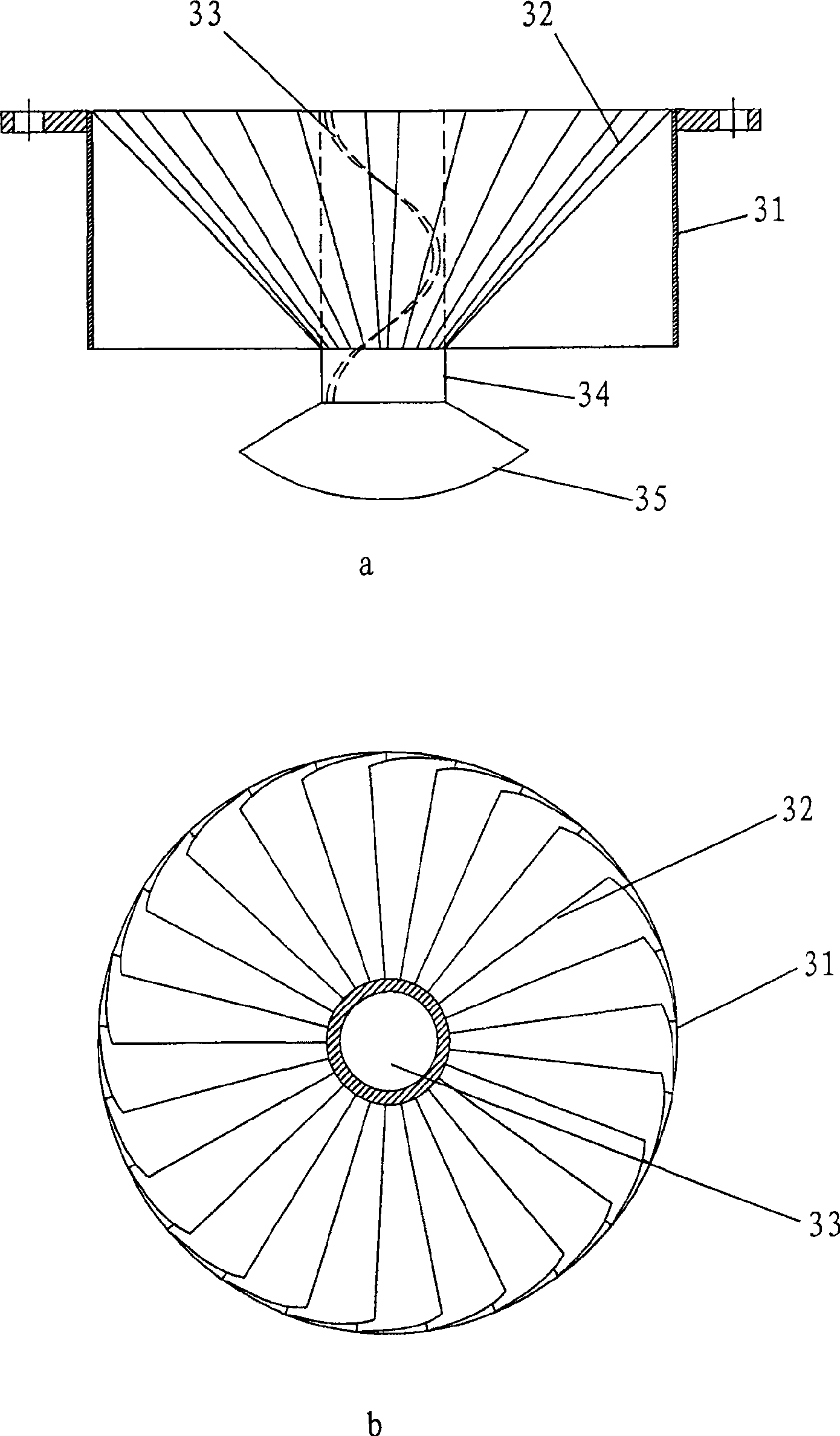

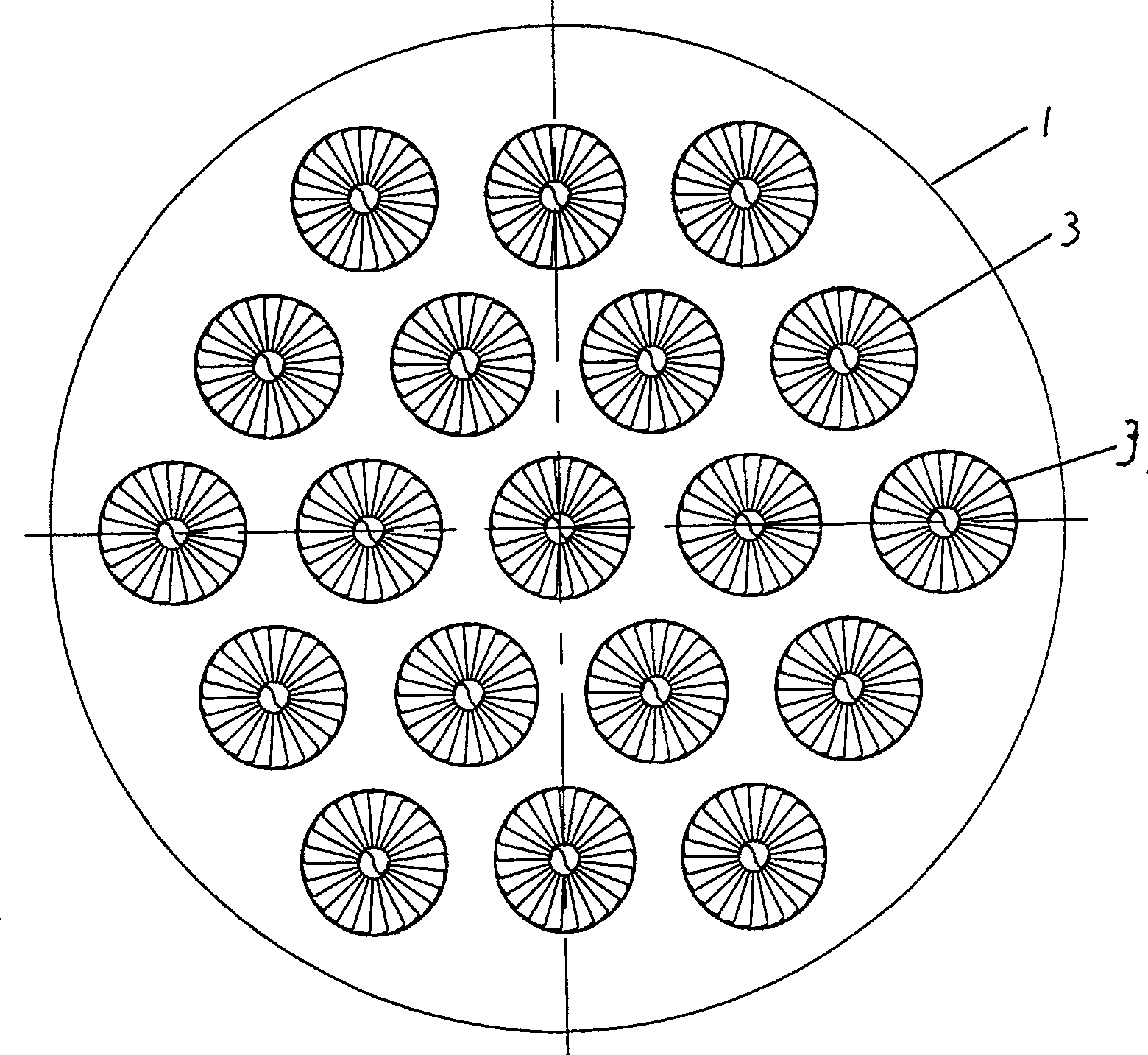

Turbine type pressure charging acceleration fuel gas desulfurization gas wash tower

InactiveCN100525885CIncrease contact timeIncrease contact spaceDispersed particle separationLiquid gasDust abatement

The invention relates to a turbine typed turbocharged accelerating flue gas desulfurization dust abatement tower, belonging to the field of gas purification technique, which includes a spray pump tower body, a slurry pump that is arranged on the tower from bottom to top and is connected with a slurry outlet at the bottom of the tower, a roots blower that is connected with a fall trachea and is arranged in a liquid storage district at the bottom in the tower, a spray pump pipe arranged over the liquid storage district, a circulating pump that is connected with and arranged in a circulating pipeline communicated with the spray pump pipe, and a demister arranged on the spray pump pipe; a flue gas inlet, a flue gas outlet and a slurry outlet are arranged on the lateral wall, on the top and at the bottom of the lower part of the spray pump tower body; a disturbance pump and a turbine typed turbocharged accelerating flue gas desulfurization dust abatement system are also included, wherein, the disturbance pump is connected with and arranged in the circulating pipeline communicated with the liquid storage district at the bottom of the tower, and the desulfurization dust abatement apparatus is arranged under the spray pump pipe in the tower and over the flue gas inlet. The invention has the advantages that sufficient connection of gas and liquid can be realized and high speed mass transfer can be carried out within the shortest time, in the smallest space and with the minimum liquid-gas ratio, thus improving high dust abatement and desulfurization efficiency with minimum energy consumption.

Owner:北京紫光威肯环保工程技术有限公司

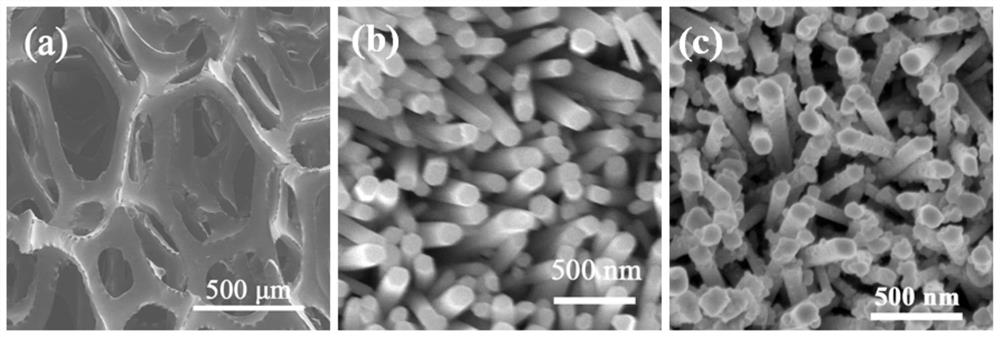

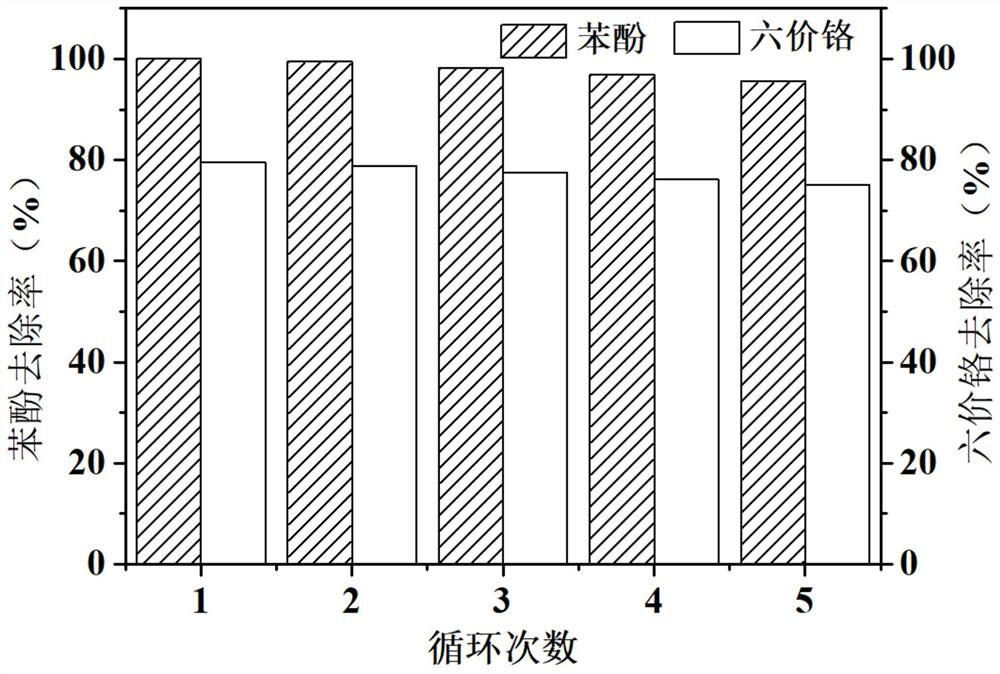

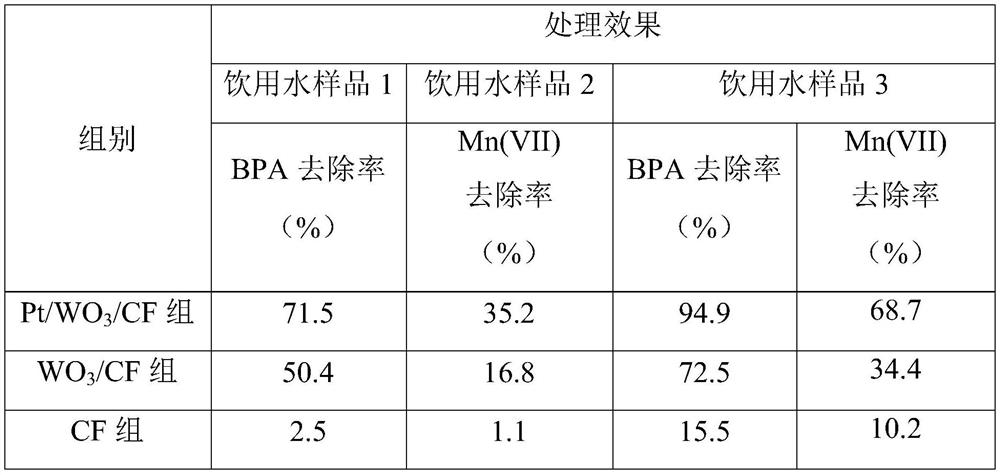

Composite photocatalytic material and preparation method and application thereof

ActiveCN113634250AModerate pore structureFast mass transferWater/sewage treatment by irradiationWater treatment compoundsIndustrial waste waterChemical reduction

The invention provides a composite photocatalytic material and a preparation method and application thereof, and relates to the field of water treatment. The composite photocatalytic material comprises foamy carbon, a metal oxide nano array and noble metal nano particles. A metal oxide nano array is grown on a foamy carbon substrate in situ through an impregnation method-hydrothermal method, and then noble metal nanoparticles are loaded on the metal oxide nano array through a chemical reduction method, so that the three-dimensional porous hierarchical structure composite photocatalytic material with high specific surface area, moderate pore structure and rich active sites is formed. The material is used for carrying out photocatalytic oxidation treatment on heavily-polluted wastewater containing high-valence heavy metals and organic pollutants, the high-valence heavy metals and organic matters can be removed at the same time, the operation process is simple, the material price is low, other sacrificial agents do not need to be added, the treatment cost is low, the catalytic performance is relatively high, and the stability is good; the material can be applied to advanced treatment engineering of high-valence heavy metal and organic matter combined pollution in drinking water, industrial wastewater and natural water.

Owner:TSINGHUA UNIV

Denitration method for FCC (Fluid Catalytic Cracking) device regenerated fume

InactiveCN106669419AReduce concentrationSuppress generationGas treatmentUsing liquid separation agentReaction temperatureSide reaction

The invention discloses a denitration method for FCC (Fluid Catalytic Cracking) device regenerated fume. The denitration method comprises the following steps of (1) mixing a granular denitration catalyst with a mixed gas containing an ammonia gas, so as to obtain a mixed product, namely a gas-solid mixture; and (2) feeding the gas-solid mixture obtained in the mixing step into a bottom area of a denitration reaction area, mixing with fluid catalytic cracking device regenerated fume which is generated from a boiler and comprises NOx, Sox and impurities, suspending the granular denitration catalyst in the fume, enabling the granular denitration catalyst to adsorb NOx in the fume, performing a selective catalytic reduction reaction, discharging out a material flow obtained after the reaction from a top area of the denitration reaction area, implementing a desulfuration dust collection step so as to obtain purified fume, and discharging the fume to a chimney. By adopting the denitration method, side reactions can be reduced, the reaction temperature range can be widened, the utilization rates of the catalyst and a reactor can be increased, the denitration rate can be increased, and besides, the production cost can be lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-concentration village and town sewage treatment method

ActiveCN111747527ASimple structureSmall structureWater treatment parameter controlWater contaminantsBatch operationSewage

The invention relates to the technical field of biological sewage treatment, in particular to a low-concentration village and town sewage treatment method. The low-concentration village and town sewage treatment method provided by the invention comprises the following steps: inoculating flocculent sludge into a reactor, culturing aerobic granular sludge by adopting a sequencing batch operation mode of water feeding, pulse aeration stirring, anaerobic treatment, aerobic treatment, standing, pulse aeration stirring, precipitation and drainage, and purifying low-concentration village and town sewage at the same time. By adopting pulse aeration stirring, sludge and sewage can be fully mixed, the problem of non-uniform water distribution is solved, and a complex water distribution structure anda stirring device or a reflux device are saved, so that the reactor is simple in structure, less in equipment and low in investment and operation cost. Pulse aeration stirring is adopted, it can be guaranteed that sludge is in a suspended state all the time in the stirring process, and it is guaranteed that the good effluent quality of the system is always kept from the granular sludge culture stage to the stable operation stage.

Owner:北京益科赛斯科技有限公司

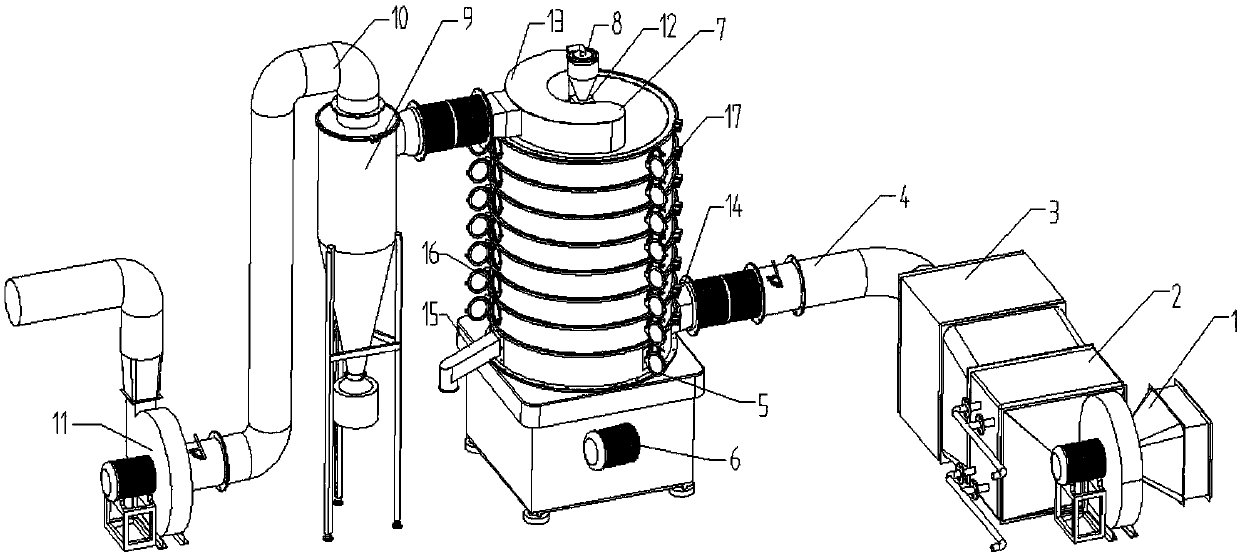

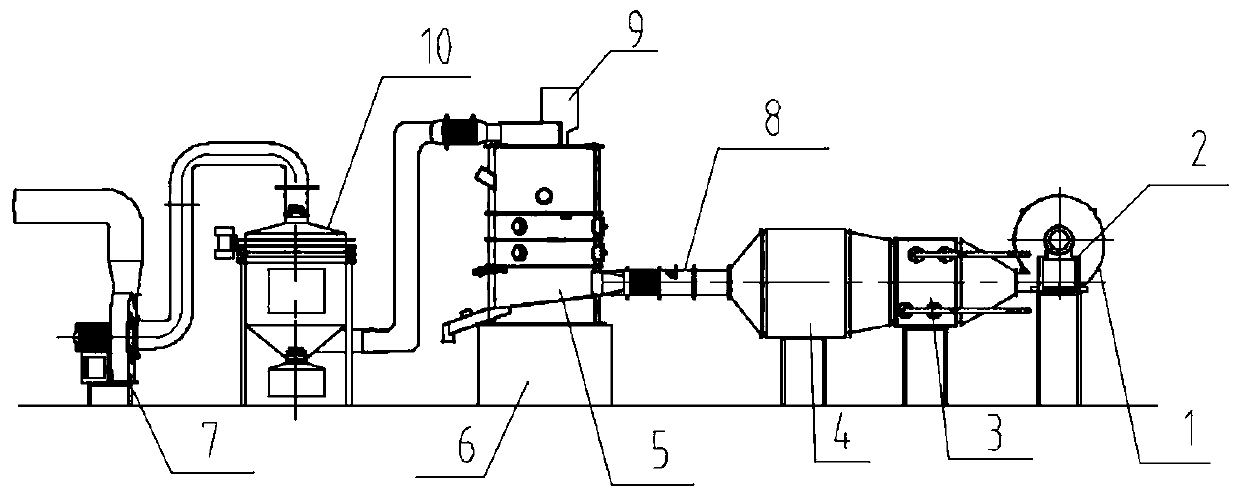

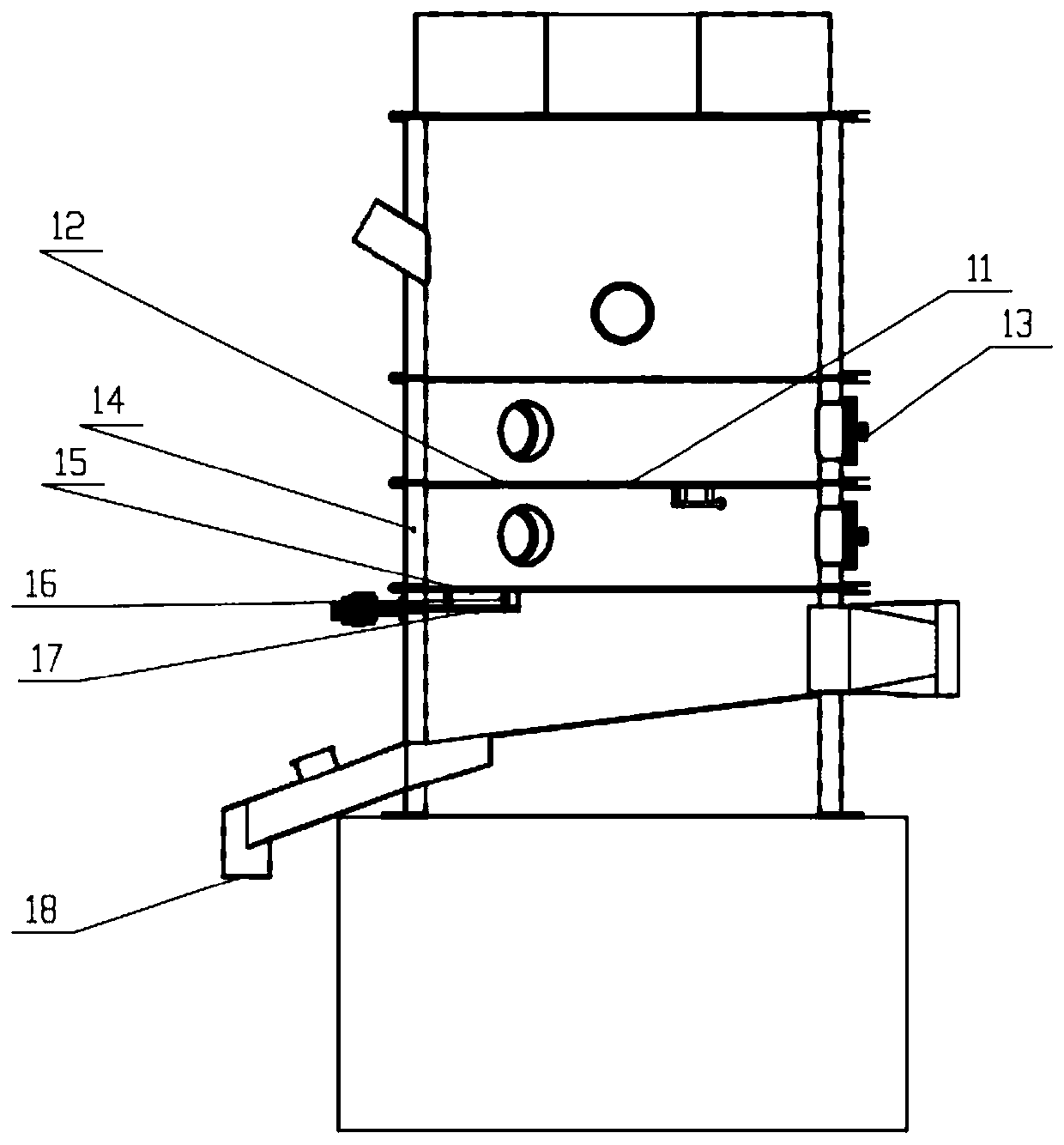

Multifunctional composite type centrifugal vibration adverse-flow solid dryer and method

PendingCN110345713AUniformity can achieve boiling dryingAdequate mass transferDrying solid materials with heatDrying solid materials without heatTowerDust collector

The invention discloses a multifunctional composite type centrifugal vibration adverse-flow solid dryer. The multifunctional composite type centrifugal vibration adverse-flow solid dryer comprises a drying tower and a vibrating platform, wherein the inner part of the drying tower is of a multi-layer structure, a plurality of layers of drying discs are arranged inside the drying tower; a cowl flapand a screen are arranged on the drying disc at each layer, the screen is arranged on the cowl flap, air holes are uniformly distributed in the cowl flap, air caps for changing outlet air of the air holes into the horizontal direction from the vertical direction are arranged on the air holes, the edge of the cowl flap and the edge of the screen are equipped with dropping holes, and dropping mechanisms are arranged in the dropping holes; the drying tower is mounted on the vibrating platform, an air inlet of the drying tower is connected to an air inlet tube, and then is connected to an air inlet end filter device, an air valve is arranged on the air inlet tube, the air inlet end filter device is connected to an air inlet mechanism, an air outlet of the drying tower is connected to a dust collector, and the dust collector is connected to an induced draft fan. The multifunctional composite type centrifugal vibration adverse-flow solid dryer disclosed by the invention protects the screen through the cowl flap, facilitates air introduction, boils and dries through cooperative action of vibration and hot air to realize drying of particle materials, powdered materials, blocked materials and spherical materials.

Owner:江西赫柏康华制药设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com