Using method of reactivation drying rotary furnace for preparing activated clay

A technology of secondary activation and activated clay, which is applied in the field of environmental protection and circular economy, can solve the problems that the drying process is not mentioned, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

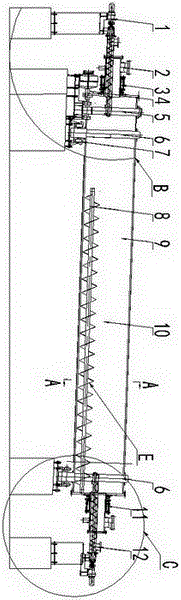

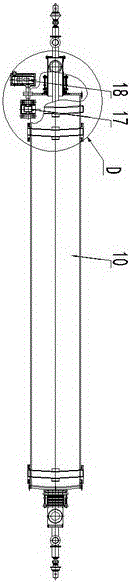

[0022] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a method for using a secondary activation and drying rotary kiln for preparing activated clay is characterized in that it includes a secondary activation and drying rotary kiln 10, a roller assembly 7, a driving gear assembly 4, a screw feeder 1, a screw How to use the discharger 12.

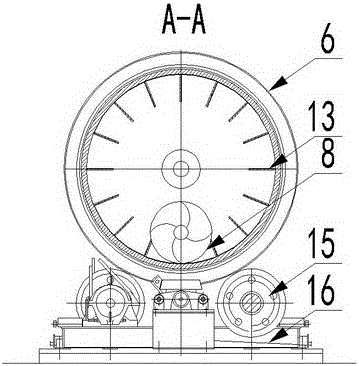

[0023] Step 1: The use method of the idler assembly 7 and the drive gear assembly 4 is as follows: the idler assembly 7 includes a roller set 15 and a base 16, two sets of roller assembly 6 are set in the front and rear of the secondary activation drying rotary furnace body 9, and the positioning Erected on the roller assembly 7, the ring gear is set on the secondary activation drying rotary furnace body 9, driven by the drive gear assembly 4 to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com