Novel wet type oily fume purifier and application thereof

An oil fume purifier and oil fume technology, applied in the application, removal of oil fume, household stoves and other directions, can solve the problems of low oil fume purification efficiency, noise pollution, easy blockage of filter materials, etc., to achieve high oil fume purification efficiency, prevent secondary pollution, Avoid easy clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and through examples. The following examples are only illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following descriptions.

[0029] Structures, connections, etc. that are not described in detail in the present invention can be understood as conventional technical means in the art.

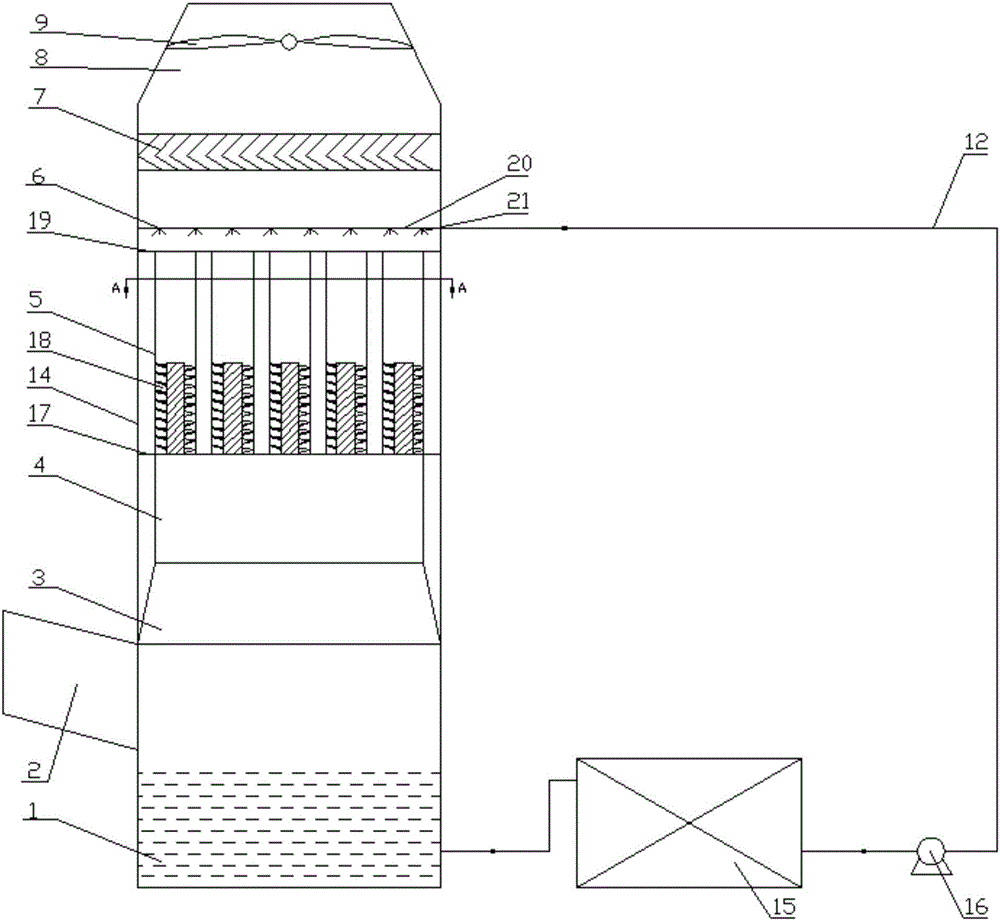

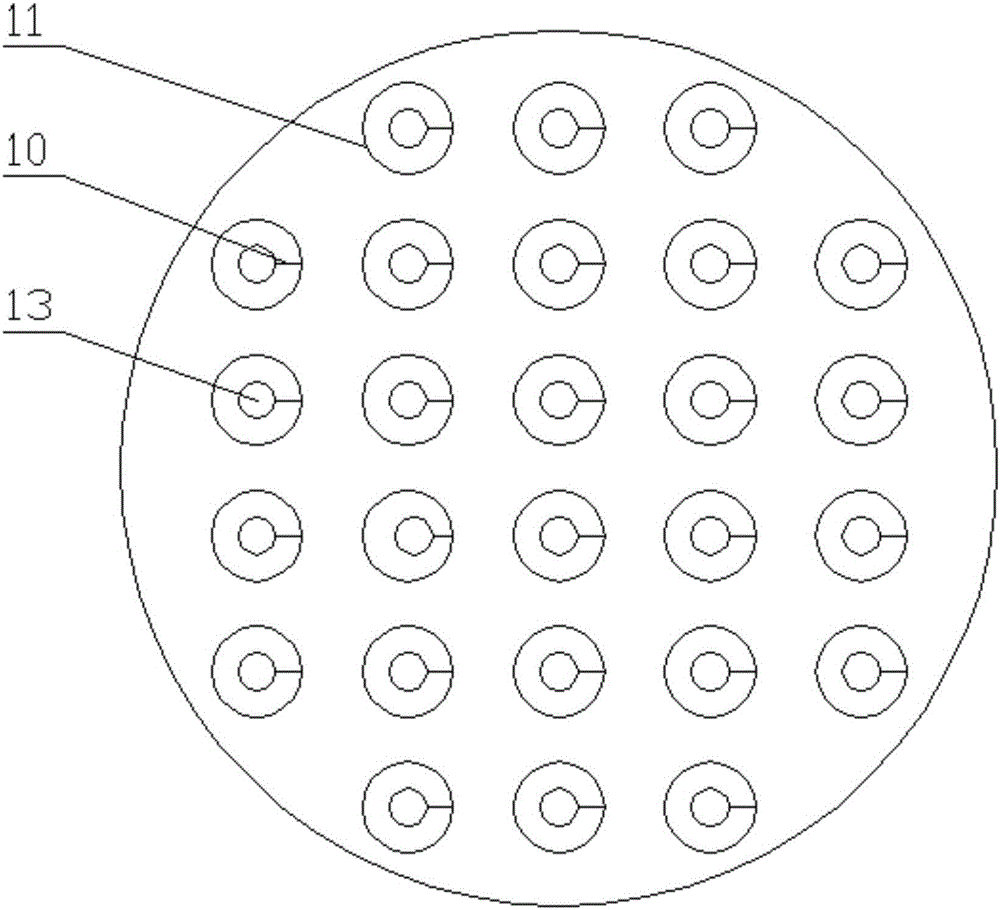

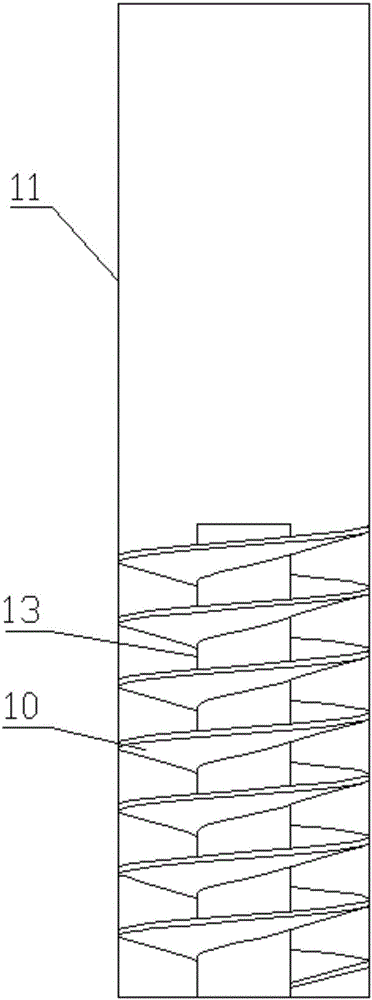

[0030] A new type of wet fume purifier, such as figure 1 As shown, the purifier includes a housing 14, a circulating water tank 1, an oil fume inlet 2, an oil fume discharge port 8, an exhaust fan 9, a rectification section, a purification section 5, a spray section 6 and a defogging section 7. The top of the casing communicates with the inside of the casing to set a fume discharge port, and the purified flue gas is discharged into the atmosphere through the fume discharge port, and the exhaust fan is connected to the fume discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com