Denitration method for FCC (Fluid Catalytic Cracking) device regenerated fume

A technology for regenerating flue gas and denitrification, applied in the field of flue gas denitrification, can solve the problems of low utilization rate of reactors, achieve stable reaction effect, reduce cost, and achieve good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

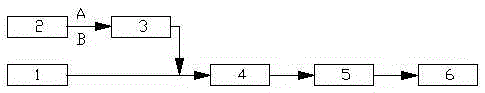

Method used

Image

Examples

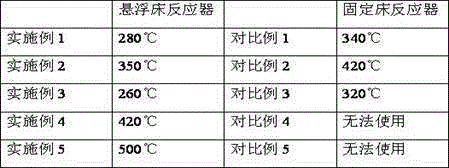

Embodiment 1

[0040] FCC regeneration flue gas flow rate is 150,000 Nm 3 / h, temperature is 650°C, pressure is 10kPa, NOx concentration is 600mg / Nm 3 , SO 2 The concentration is 1000mg / Nm 3 , SO 3 The concentration is 20mg / Nm 3 , the dust content is 200mg / Nm 3 . NOx emission standard is 200 mg / Nm 3 .

[0041] The active components of granular catalyst particles are V oxides, Ti oxides, W oxides and Mo oxides. The active components are calculated as oxides. The catalyst is a microsphere carrier, and the mass ratio is as follows: V is 0.01 wt%, Ti is 99wt%, W is 0.1wt%, Mo is 0.02wt%; the catalyst particle size is 0.1-0.6mm, preferably 0.5mm; the bulk density is 0.4-0.8g / cm 3 , the specific surface area is 40~60m 2 / g, the adsorption capacity is 0.2~0.3g / g.

[0042] First, the FCC regenerated flue gas passes through the boiler to take heat, and the temperature is lowered from 650°C to the SCR denitrification reaction temperature of 280°C; the flow rate of the mixed gas containing am...

Embodiment 2

[0044] FCC regeneration flue gas flow rate, temperature and pressure are the same as in Example 1, and the NOx concentration is 600mg / Nm 3 , SO 2 The concentration is 2000mg / Nm 3 , SO 3 The concentration is 200mg / Nm 3 , the dust content is 200mg / Nm 3 . NOx emission standard is 100 mg / Nm 3 .

[0045] Catalyst composition is the same as embodiment 1.

[0046] First, the FCC regenerated flue gas passes through the boiler to obtain heat, and the temperature is lowered from 650°C to the SCR denitrification reaction temperature of 350°C; the flow rate of the mixed gas containing ammonia provided by the raw material supply area is 1000 Nm 3 / h, where the ammonia concentration is 3v%, and the concentration of the catalyst in the gas-solid mixture is 450ppm; the catalyst and the mixed gas containing ammonia pass through the mixing zone, and the mixing time is 0.5s; the present embodiment adopts an upflow reactor, preferably 4m / h s, the residence time of the reactor is 2s, and t...

Embodiment 3

[0048] FCC regeneration flue gas flow rate, temperature and pressure are the same as in Example 1, and the NOx concentration is 400mg / Nm 3 , SO 2 The concentration is 600mg / Nm 3 , SO 3 The concentration is 10mg / Nm 3 , the dust content is 100mg / Nm 3 . NOx emission standard is 200 mg / Nm 3 .

[0049] Catalyst composition is the same as embodiment 1.

[0050] First, the FCC regenerated flue gas passes through the boiler to obtain heat, and the temperature is lowered from 650°C to the SCR denitrification reaction temperature of 260°C; the flow rate of the mixed gas containing ammonia provided by the raw material supply area is 2000 Nm 3 / h, wherein the ammonia concentration is 2.8v%, and the concentration of the catalyst in the gas-solid mixture is 450ppm; the catalyst and the mixed gas containing ammonia pass through the mixing zone, and the mixing time is 0.2s; the present embodiment adopts an upflow reactor, preferably 12m / s, the residence time of the reactor is 1s, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com