Process and device for producing (NH4)2SO4 fertilizer by using ammonium sulfite solution

A technology of ammonium sulfite and 2SO4, applied in fertilization devices, ammonium salt fertilizers, nitrogen fertilizers, etc., can solve the problems of low oxidation rate, high temperature, long reaction time, etc., and achieve sufficient mass transfer, improved mass transfer efficiency, and production environment Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

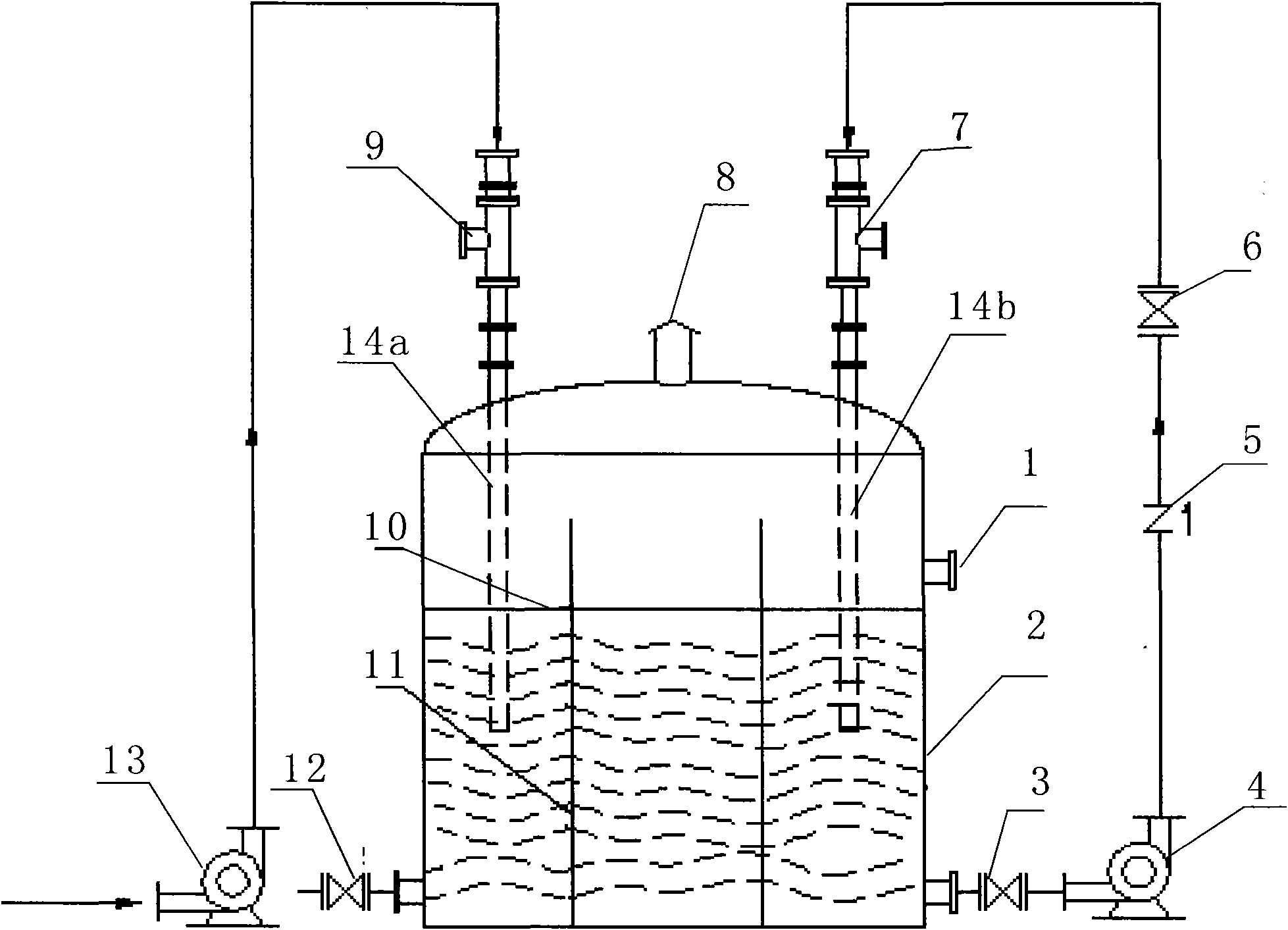

[0021] Such as figure 1 Shown: a preparation with ammonium sulfite solution (NH 4 ) 2 SO 4 The process of chemical fertilizer is to absorb SO with ammonia liquid in the ammonia flue gas desulfurization device 2 The resulting ammonium sulfite solution (NH 4 ) 2 SO 3 , produced by self-inhalation air oxidation (NH 4 ) 2 SO 4 The process of chemical fertilizer, its steps are as follows:

[0022] 1. Using self-absorption air oxidation, the ammonium sulfite (NH 4 ) 2 SO 3 After the solution is pressurized by the liquid inlet pump 13, it is input into the liquid inlet ejector 9 on the top of the oxidation tank 2. While the solution is sprayed into the oxidation tank 2 at a high speed, the liquid inlet ejector 9 utilizes the vacuum formed when the high-speed liquid flow passes through the vacuum chamber. Inhale the atmosphere directly from the suction port, and the high-speed liquid flow cuts the air into extremely fine air particles, which greatly increases the gas-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com