Patents

Literature

59results about How to "Reduce production noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

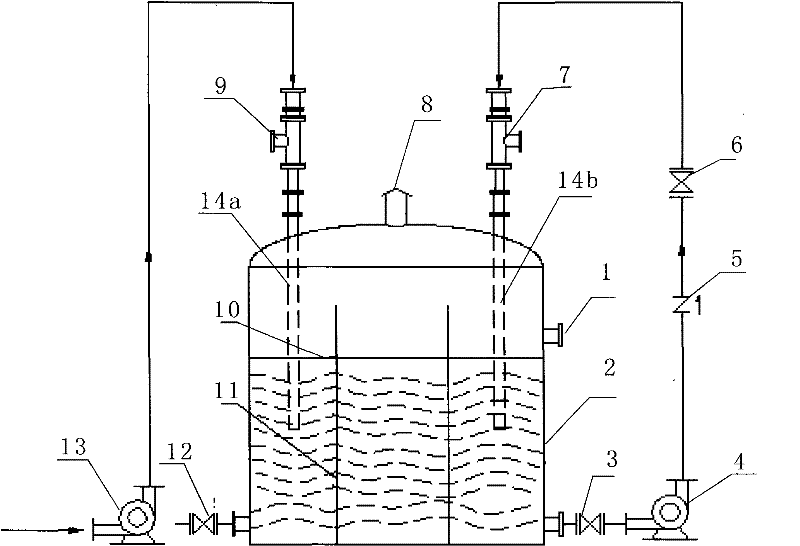

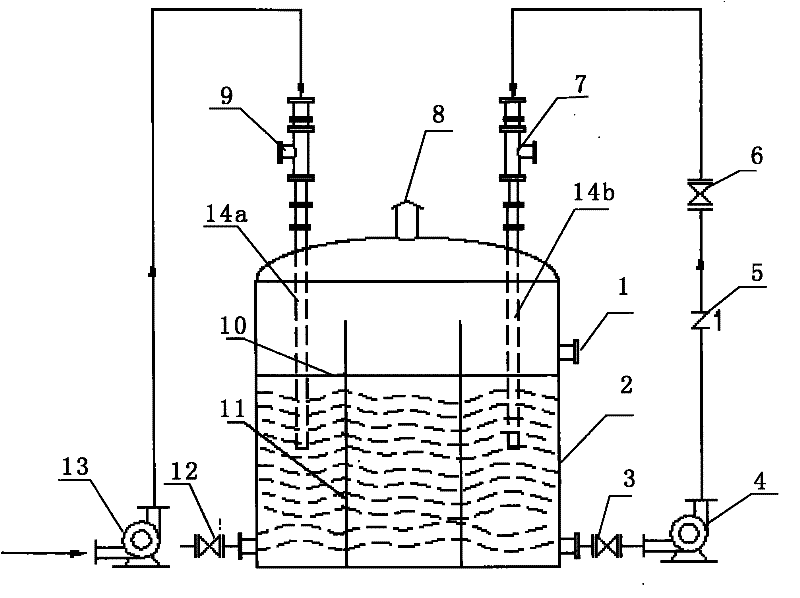

Process and device for producing (NH4)2SO4 fertilizer by using ammonium sulfite solution

InactiveCN101643369AIncrease contact areaAdequate mass transferAmmonium salt fertilisersThree stageSelf-absorption

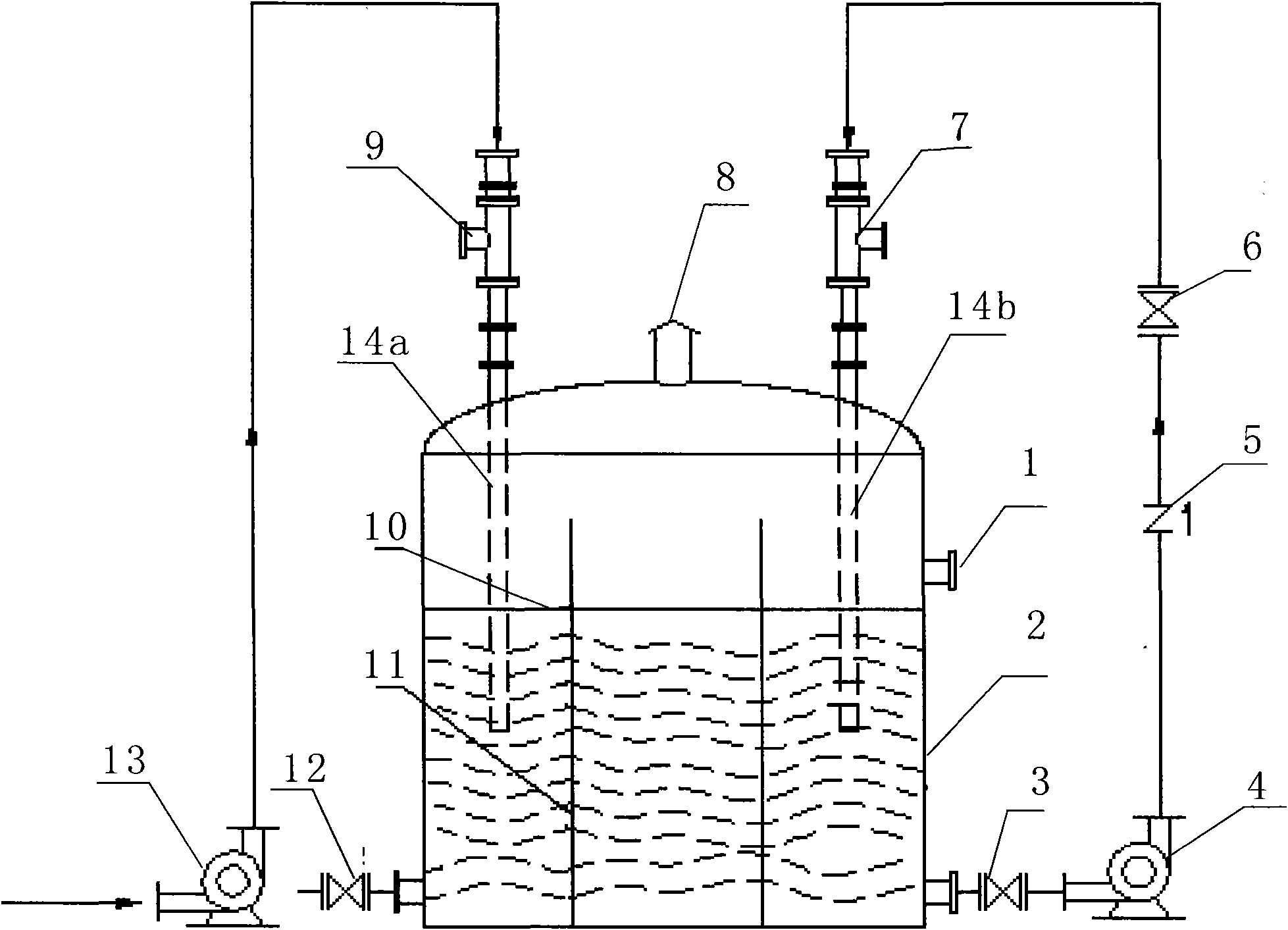

The invention discloses a process and a device for producing a (NH4)2SO4 fertilizer by using an ammonium sulfite solution. In an ammonia-process flue gas desulfurization device, by using the ammoniumsulfite solution (NH4)2SO3 produced after ammonia absorbs SO2, the outlet of a liquid inlet ejector (9) is led into the solution at the middle lower part of an oxidation tank (2) by a downcomer through a oxidization preparation process of (NH4)2SO4 fertilizer by self-absorption of air so as to increase the reaction time; and the medium is fully oxidized through the three-stage cyclic oxidation. The cyclic oxidation procedure comprises liquid at the lower part of the oxidation tank (2), a recycle pump (4), a recycle liquid ejector and the middle lower part of the oxidation tank. Air is absorbedin the liquid inlet ejector, and sheared by liquid flows and dispersed into tiny air particles, so that the contact specific area of the gas and the liquid is increased by tens of times compared withthe bubbling oxidization, thereby fully utilizing the oxygen in the air. Therefore, the process enhances the reaction efficiency, shortens the reaction times and increases the conversion rate.

Owner:洛阳市天誉环保工程有限公司

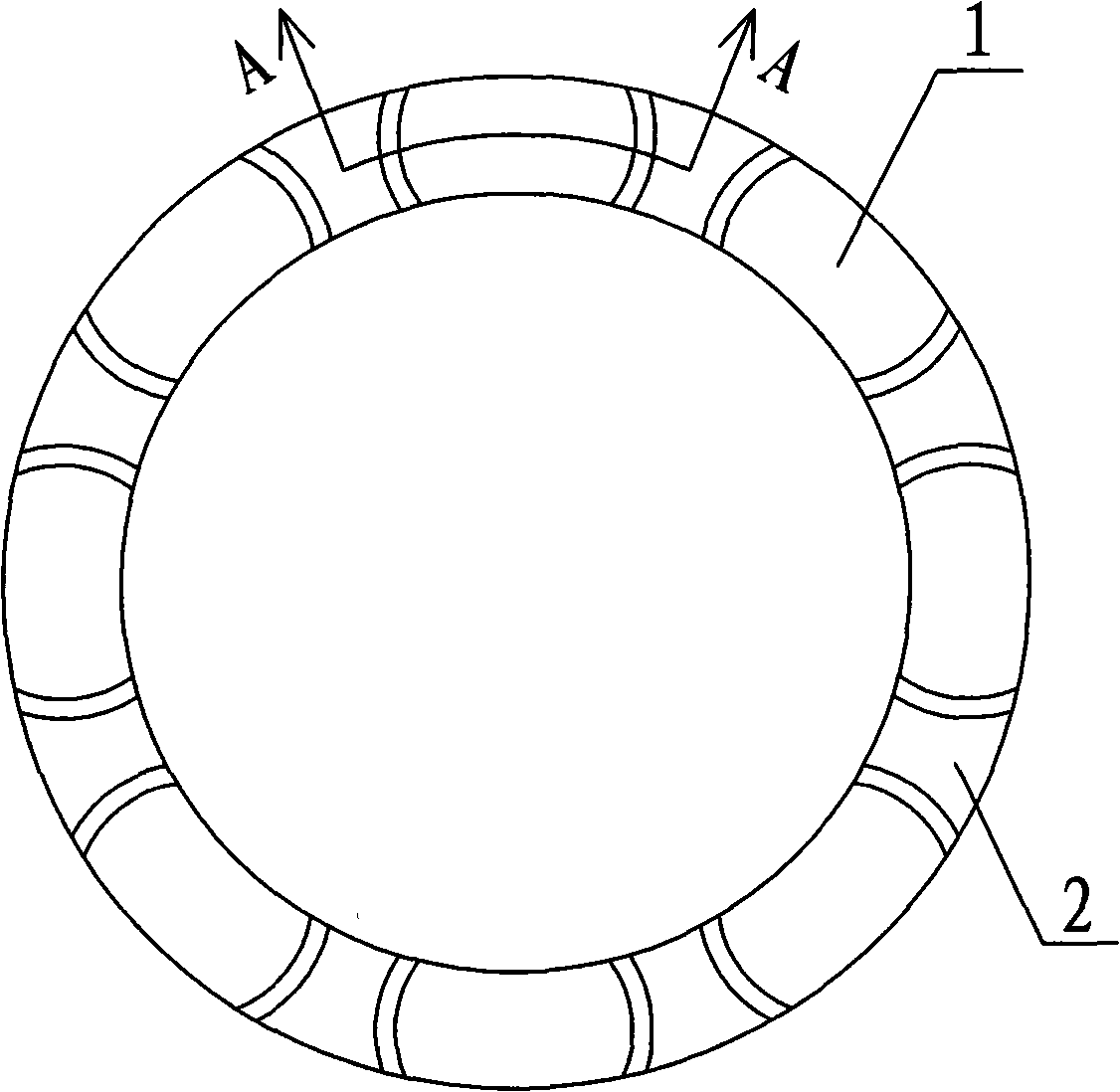

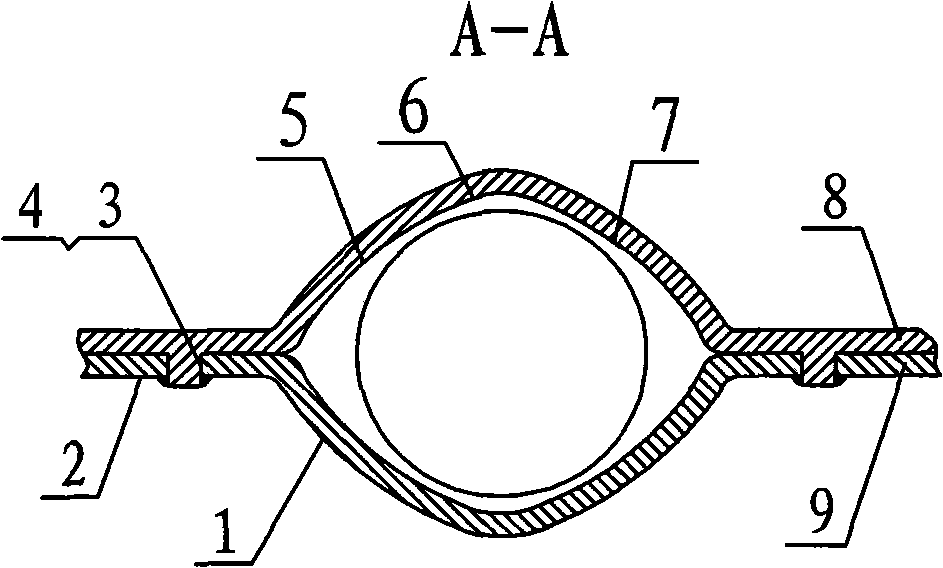

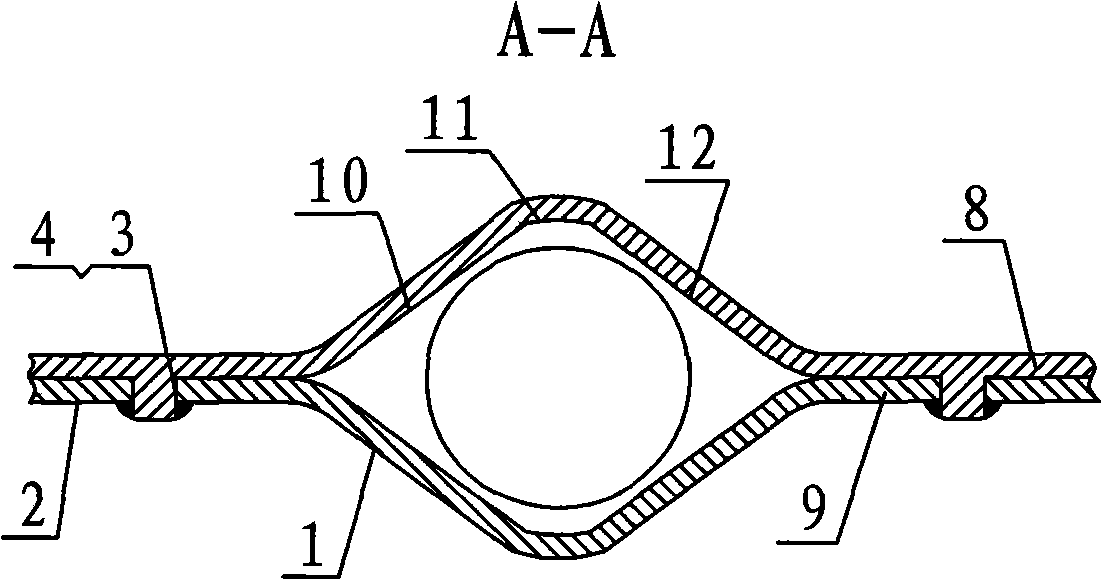

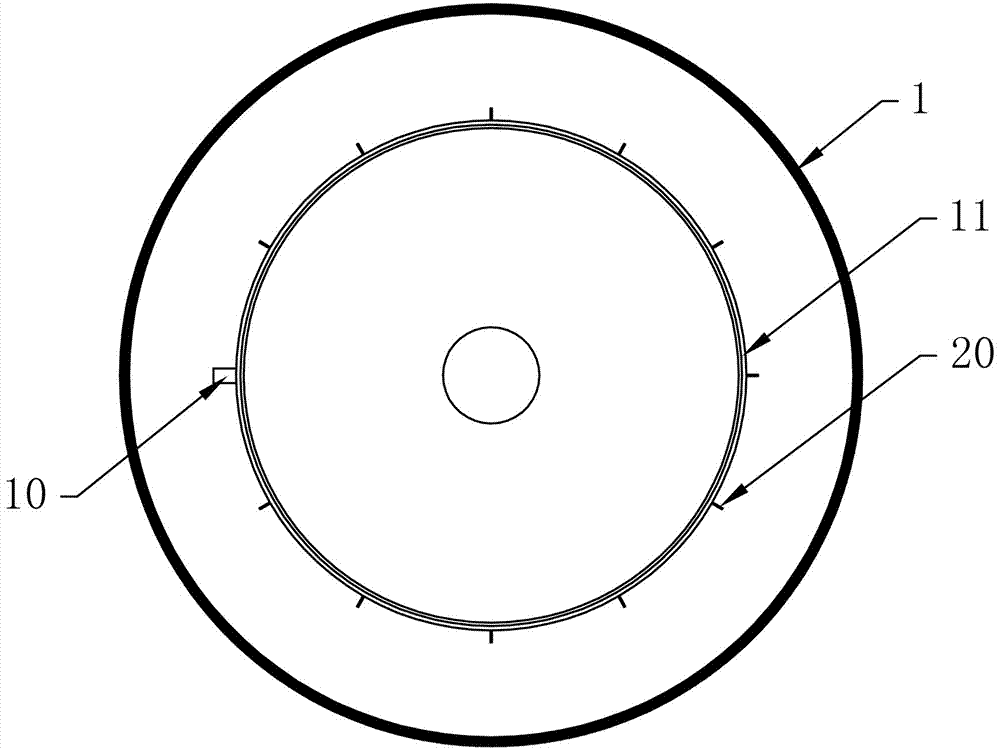

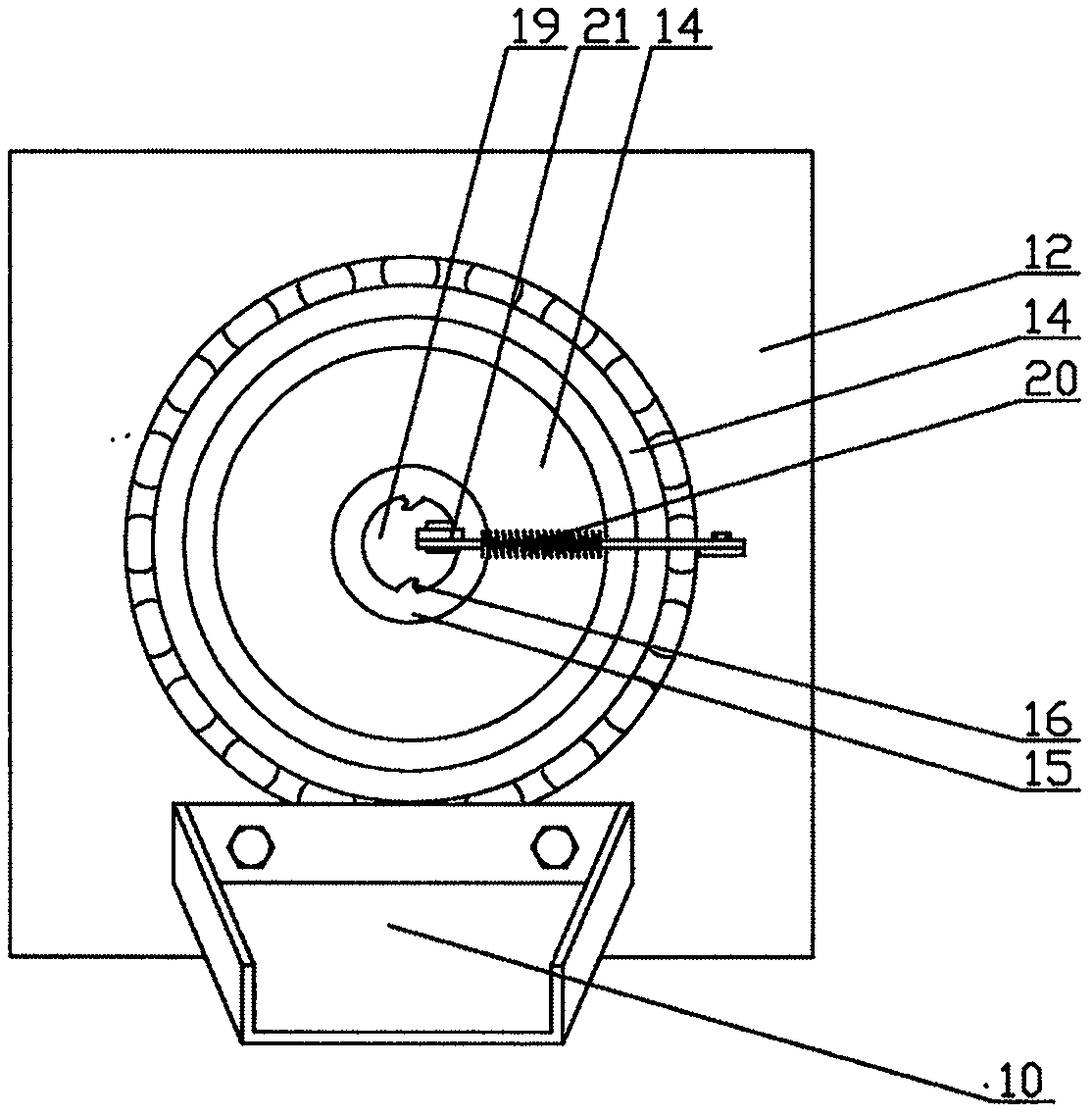

Deep groove ball bearing retainer and bearing

InactiveCN101592190AAvoid radial playInhibit sheddingBall bearingsBearing componentsBall bearingBiomedical engineering

The invention relates to a deep groove ball bearing retainer and a bearing using the retainer. The retainer comprises a retainer body I and a retainer body II which are mutually butted, the retainer body I and the retainer body II consist of ball pockets and planes for connecting the ball pockets into ring shape, at least three planes on the retainer body I are provided with protrusions, the corresponding planes of the retainer body II are provided with positioning holes corresponding to the protrusions, and the passing-out parts of the protrusions are welded with the retainer body II together after the protrusions pass through the positioning holes. The bearing retainer with the structure can realize firm welding between the retainer body I and the retainer body II, avoid rivet connection, reduce the production cost and noise, and avoid radial wandering of the retainer body I and / or the retainer body II and release of rivets.

Owner:郑广辉

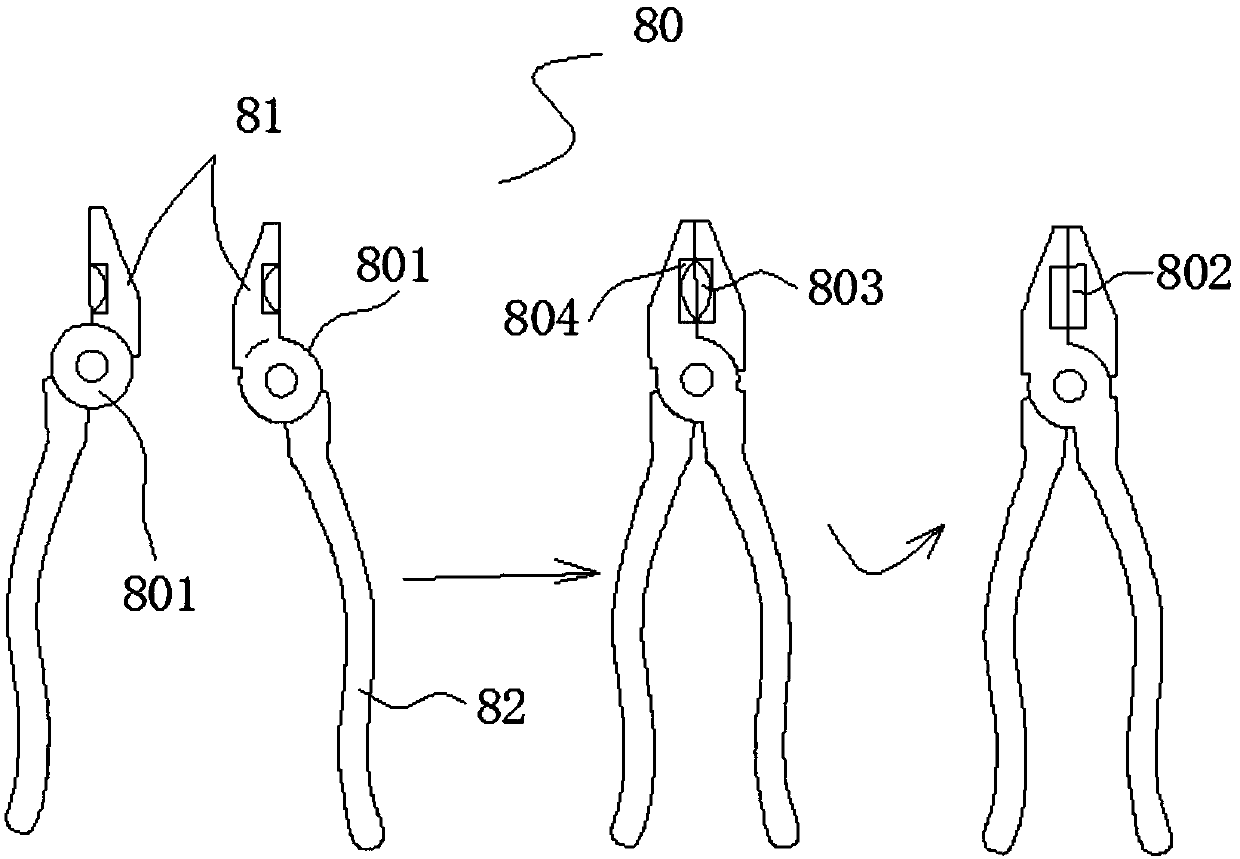

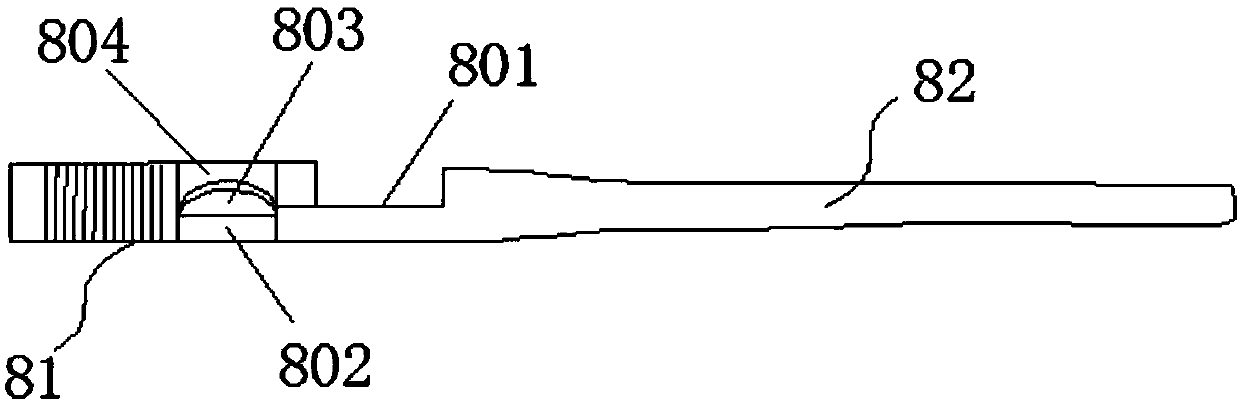

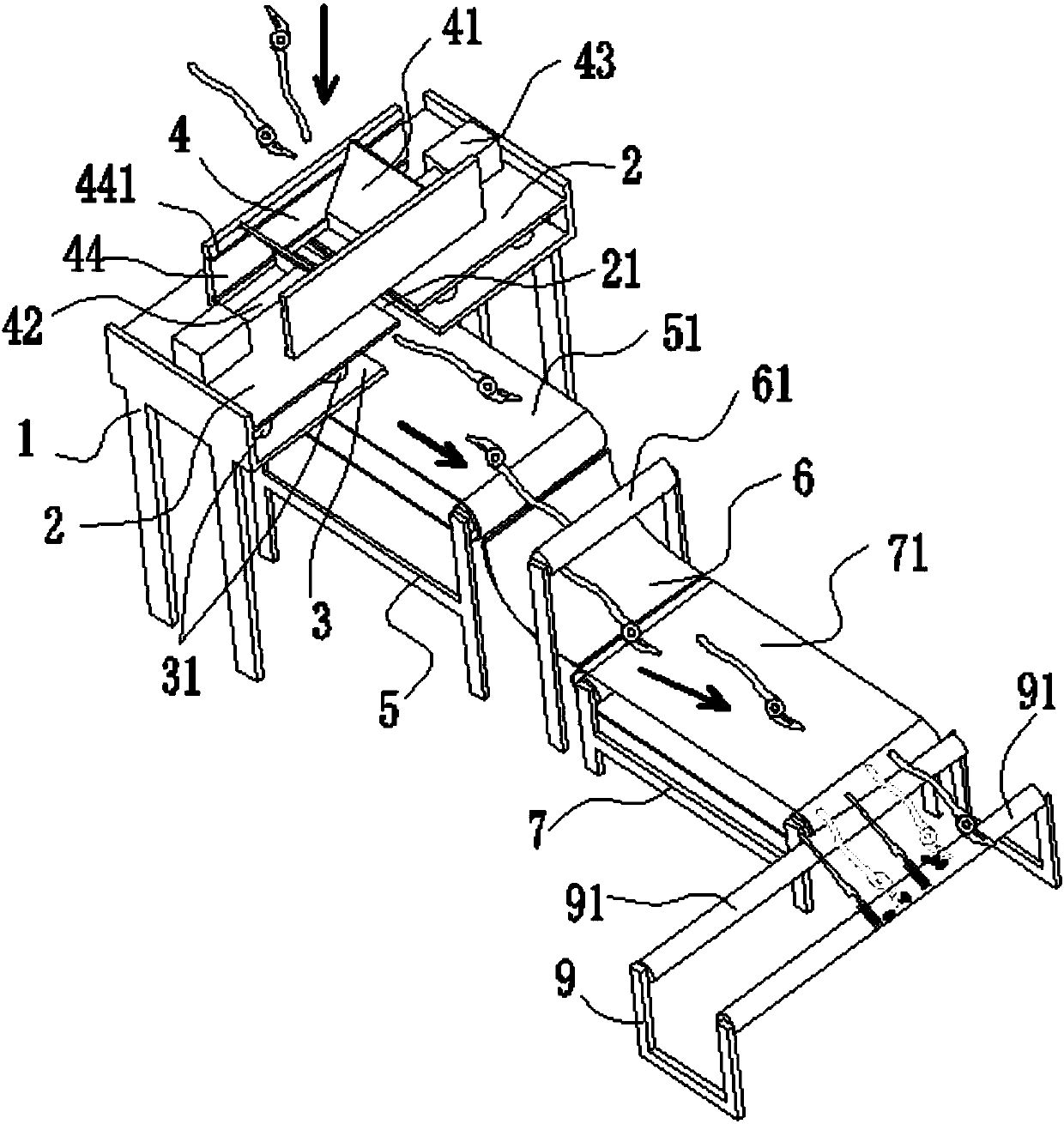

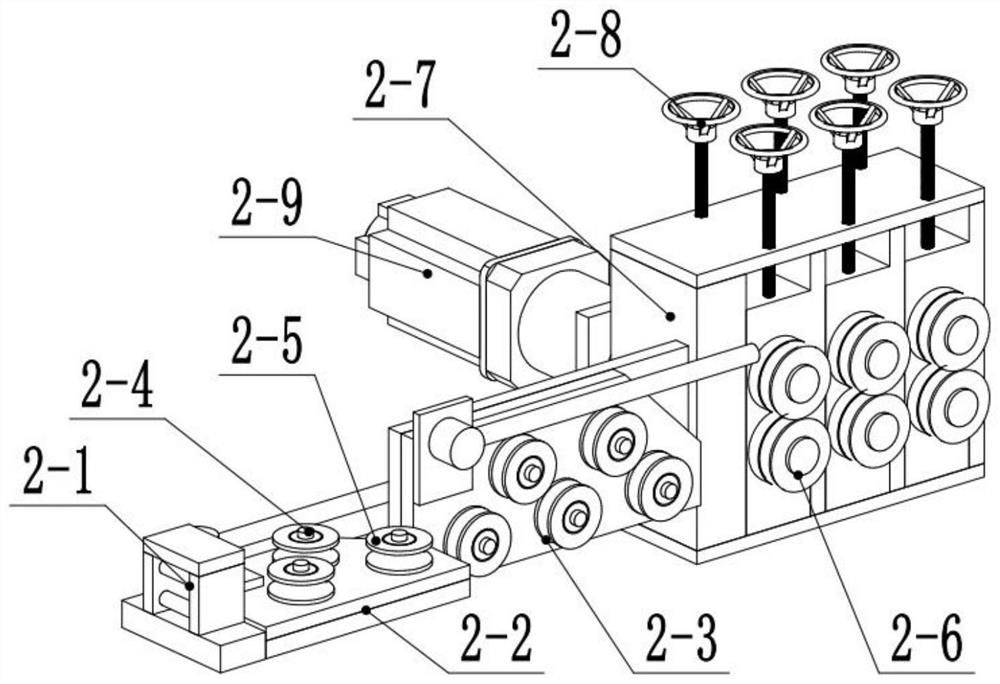

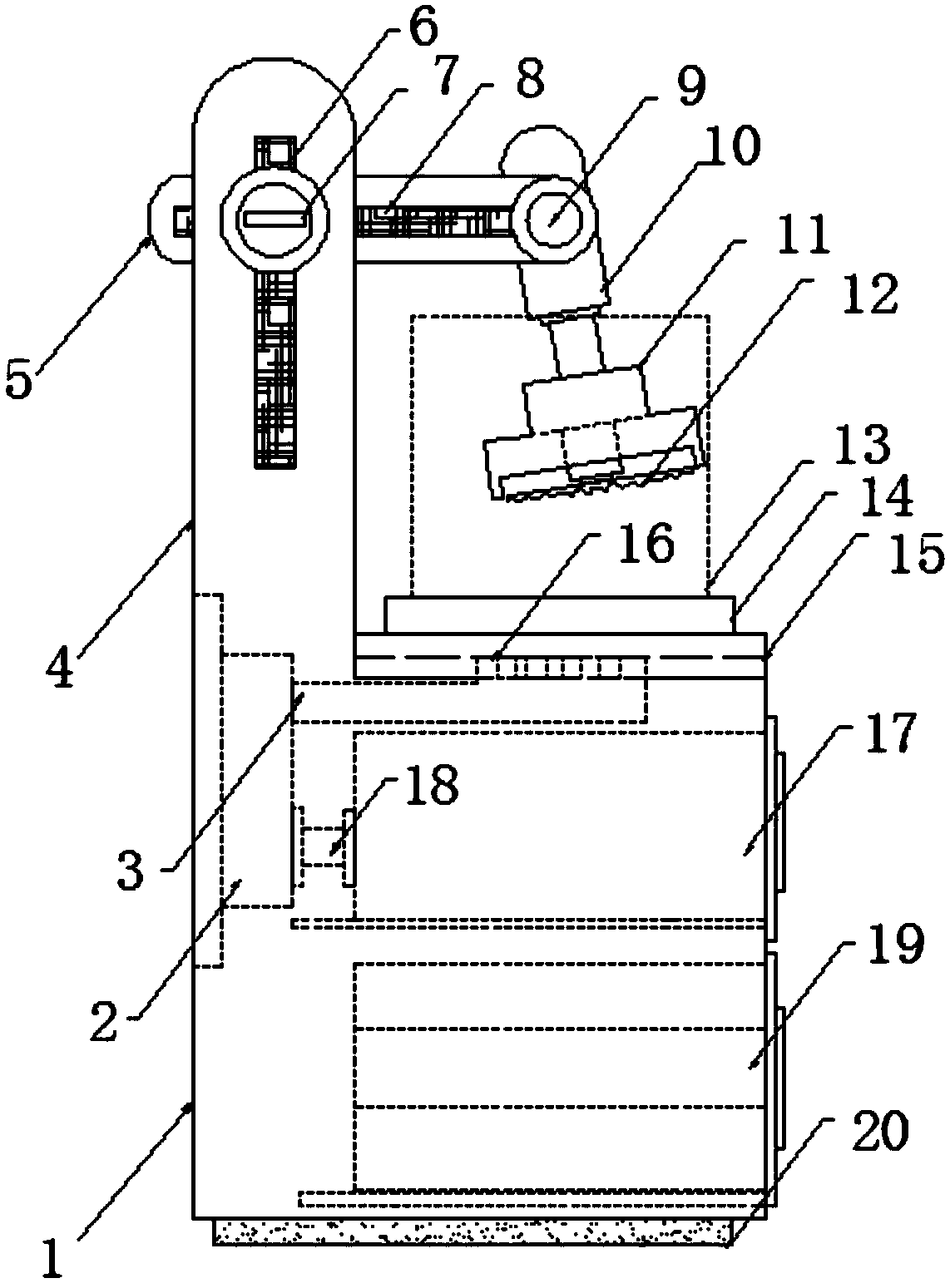

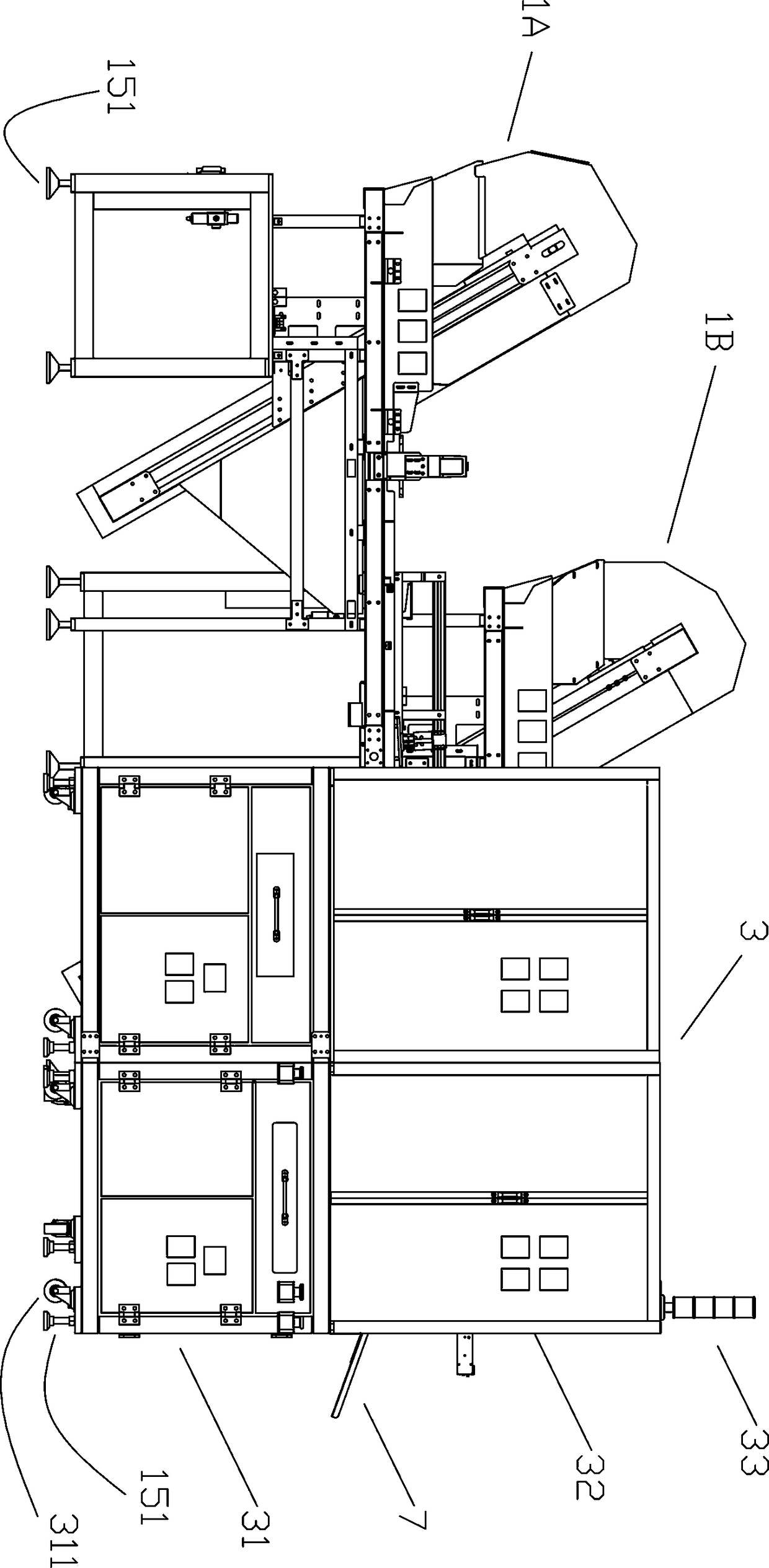

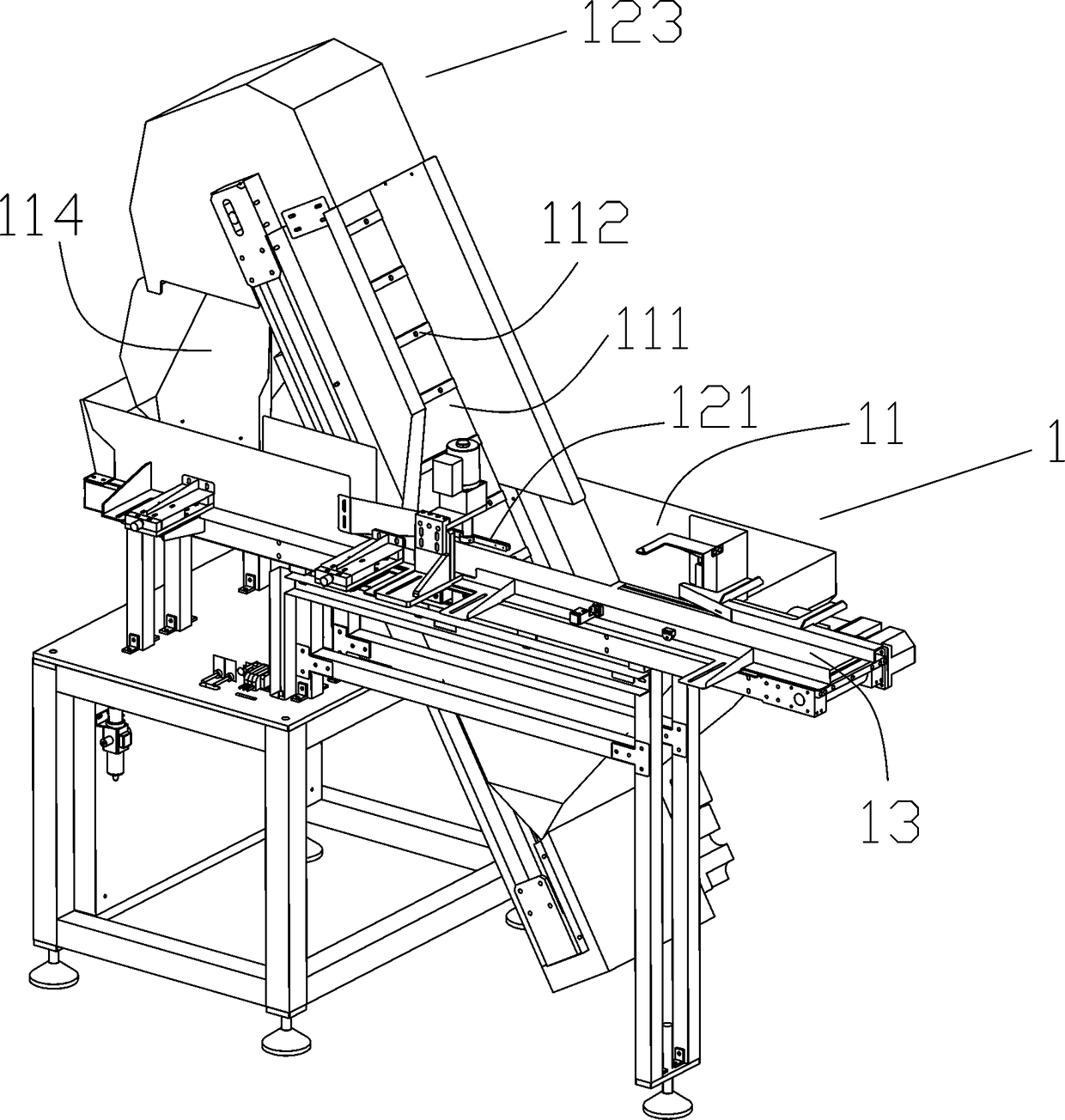

Low-noise blanking and feeding device for automatic sorting of clamps

PendingCN107777306AConvenient to arrange in rowsReduce usageConveyorsConveyor partsLow noiseAutomatic processing

The invention discloses a low-noise blanking and feeding device for automatic sorting of clamps. The device comprises a rack and a containing plate, a blanking port is formed in the middle of the device, moving push plates and retaining side plates are arranged above the containing plate and around the blanking port in two-two symmetry and jointly form a clamp feeding hopper area, and a push rod and an extensible driver connected with the same are arranged on two sides of each moving push plate respectively; a first feeding platform is arranged below the blanking port, conveying direction of the first feeding platform is perpendicular to horizontal moving direction of each moving push plate, a blanking retaining block for turning the clamps and a blanking arc plate are arranged at the feeding tail end of the first feeding platform, and the lower end of the blanking arc plate is horizontally docked with a second feeding platform. A material falling form is utilized ingeniously, so thatusing of a vibration disc is avoided, and production noise of a workshop is lowered; deadweight characteristics and gravity action of the clamps are utilized, so that convenience is brought to sequentially placing the clamps in rows, and convenience is brought to subsequent automatic processing and feeding.

Owner:湖南精专自动化技术有限公司

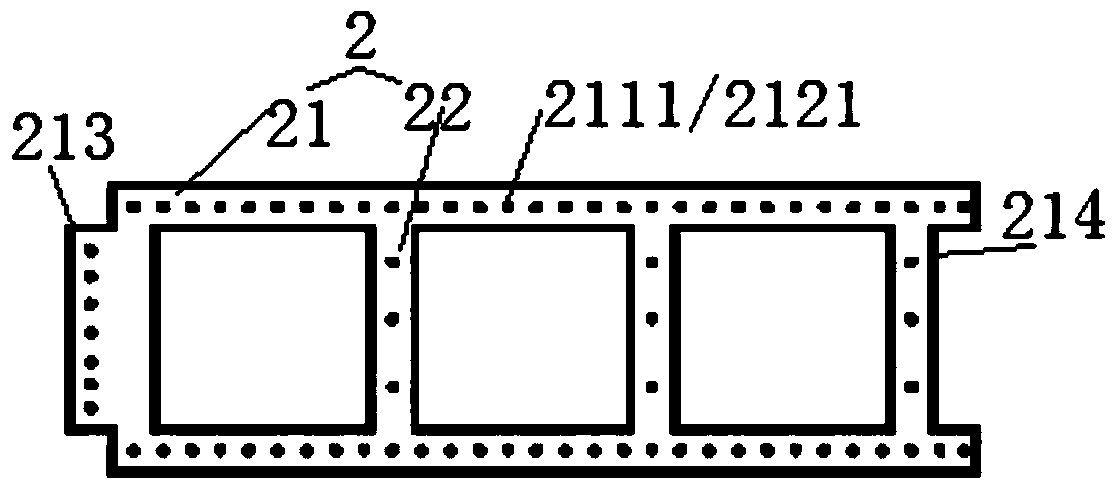

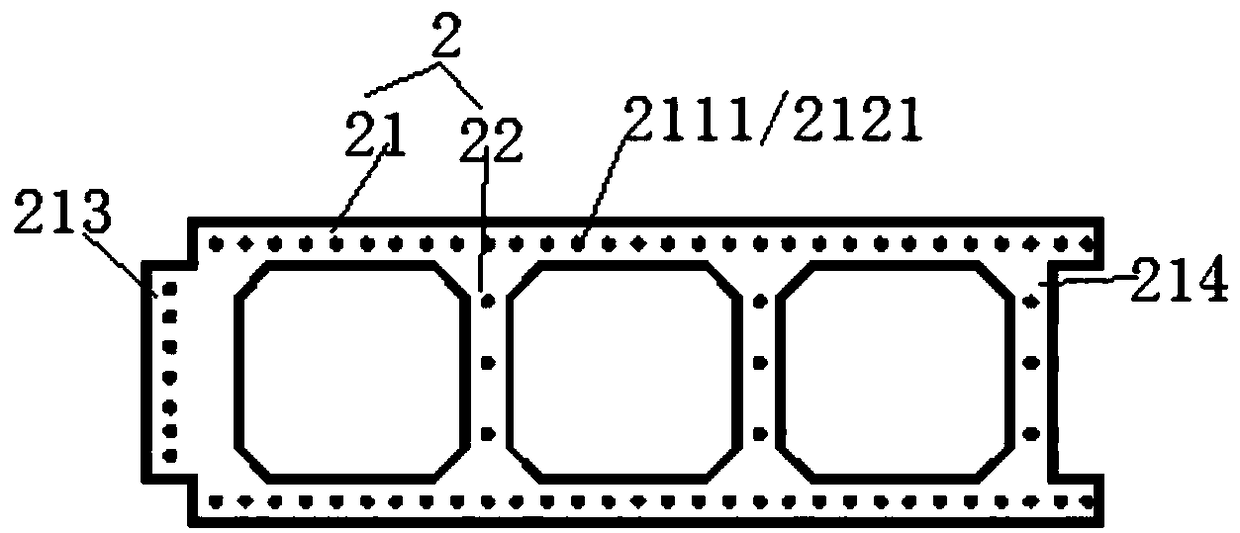

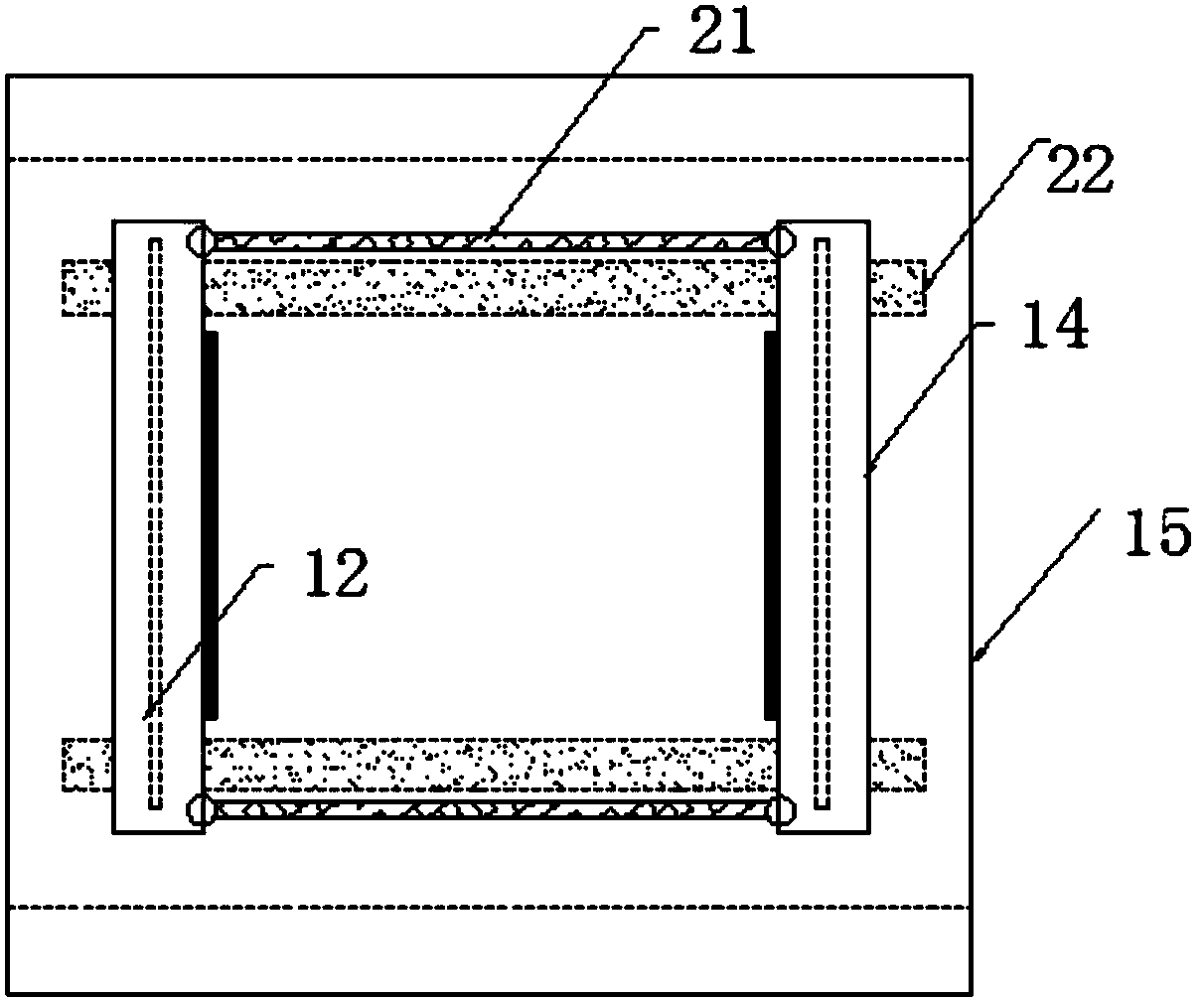

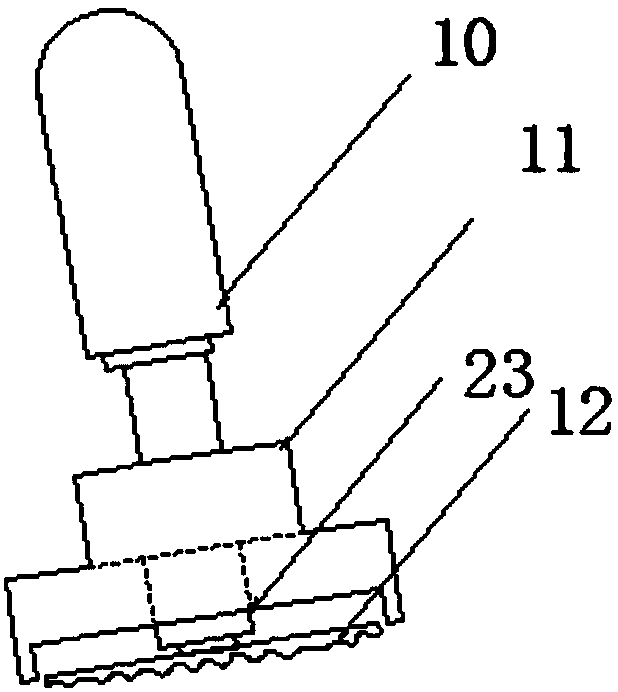

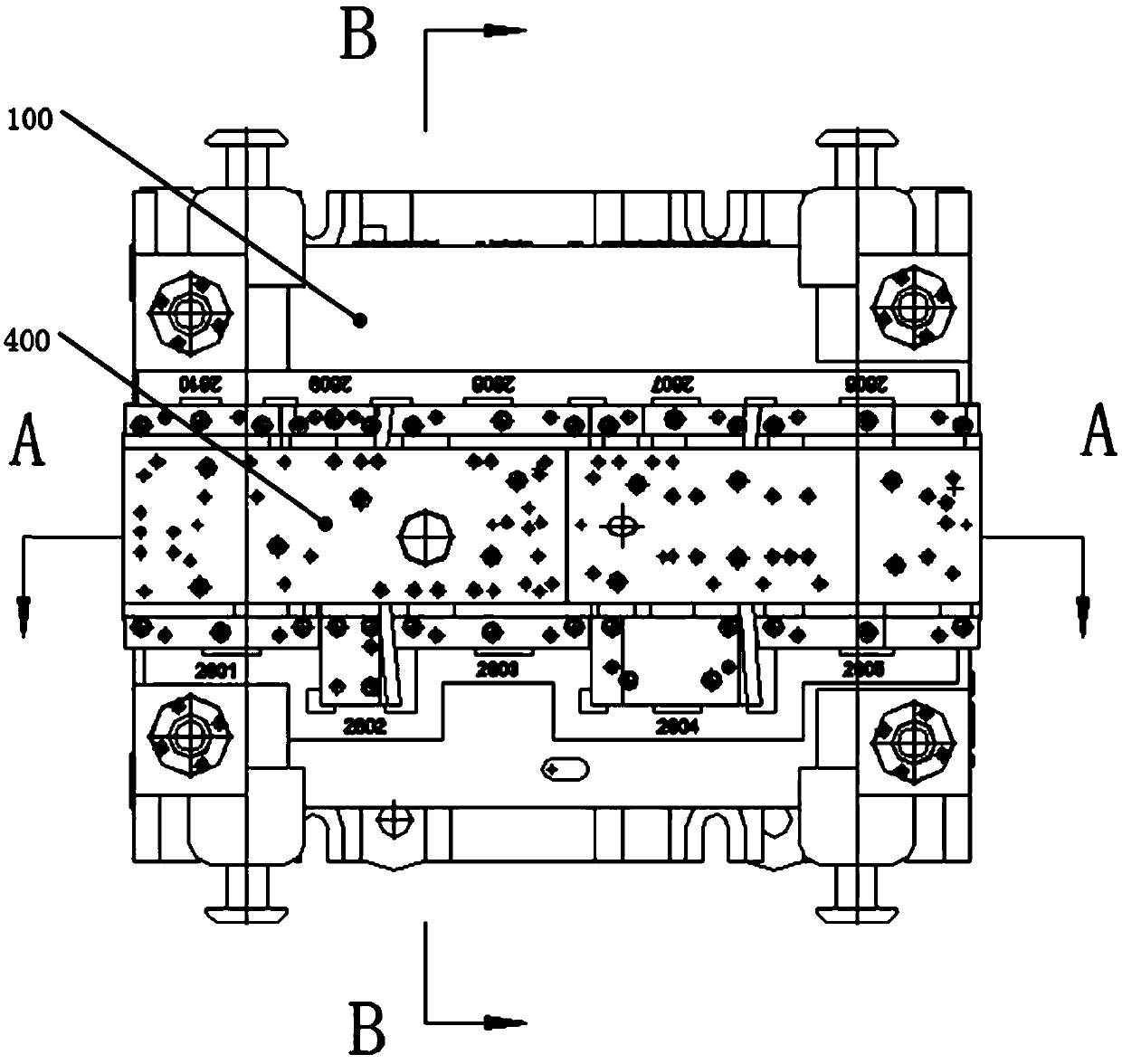

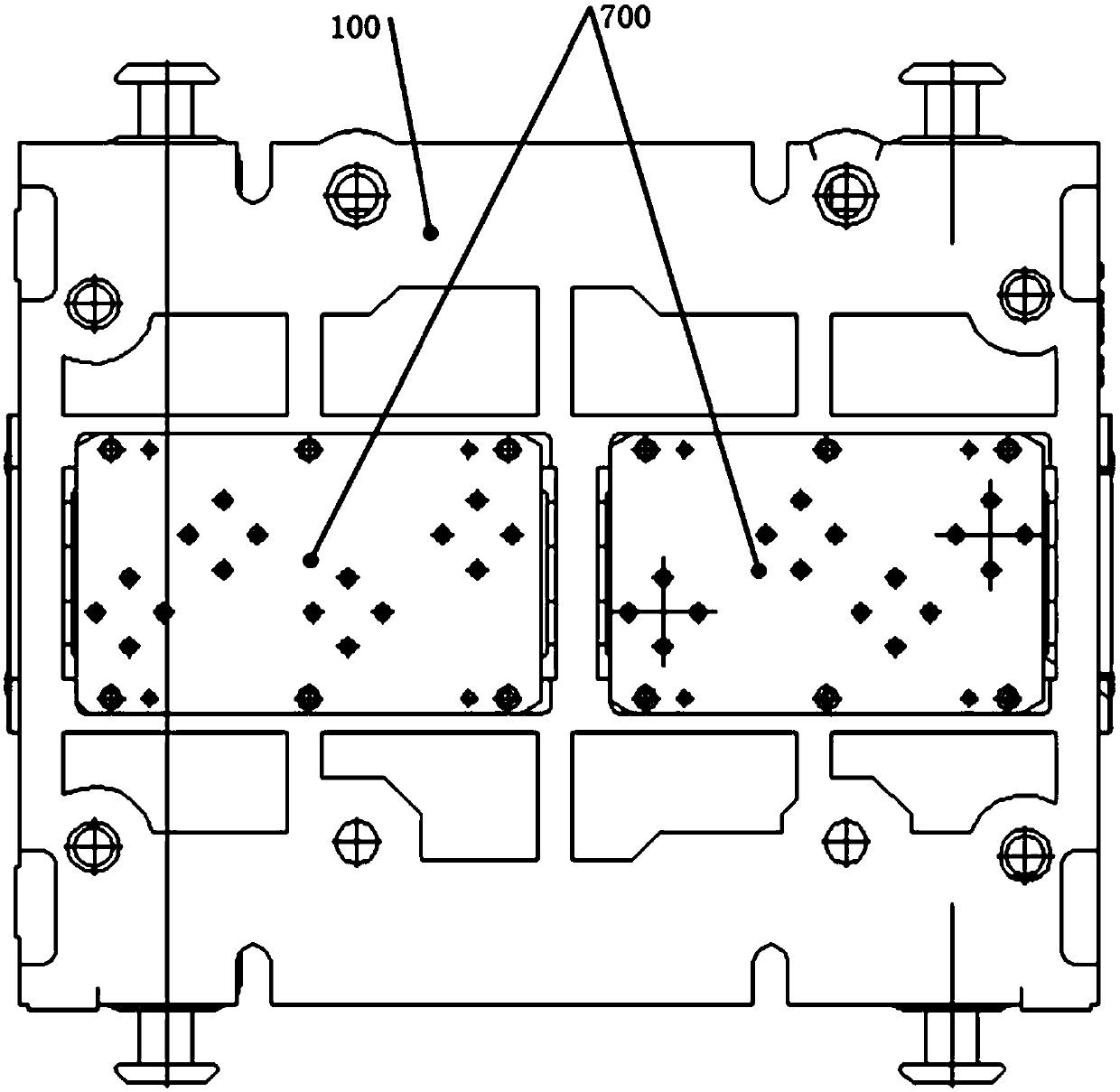

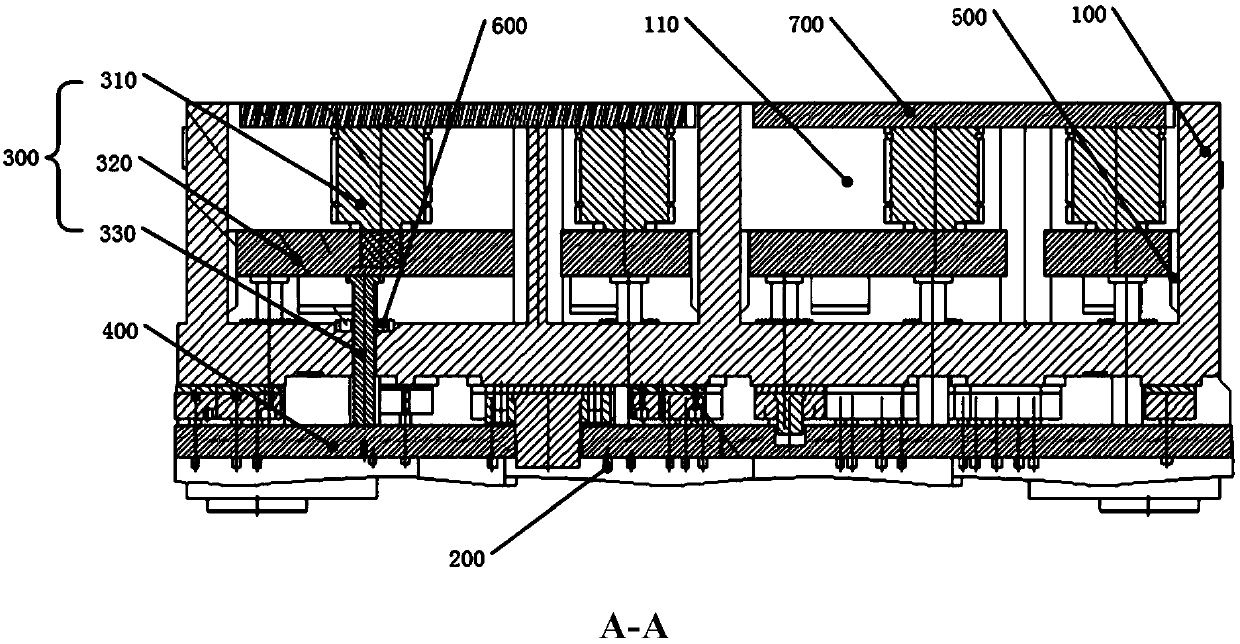

Prefabrication combined box type underground diaphragm wall and construction method thereof

PendingCN109281313ASafety and civilized construction optimizationLabor savingBulkheads/pilesConstrictionSlurry wall

The invention discloses a prefabrication combined box type underground diaphragm wall comprising prefabrication box type underground diaphragm wall components as foundation pit retaining structures. Each prefabrication box type underground diaphragm wall component comprises a box provided with a hollow part, and a web arranged in the box, wherein the vertical two ends of the box are provided withfirst tenons or first mortises, and the transverse two ends of the box are provided with second tenons or second mortises. Adjacent prefabrication box type underground diaphragm wall components are connected through mortise-tenon structures to form a combined box type underground diaphragm wall body. The invention further discloses a construction method of the prefabrication combined box type underground diaphragm wall. For the prefabrication combined box type underground diaphragm wall and the construction method thereof, the box type underground diaphragm wall components made through factory-like concentrated prefabrication are adopted for plane and vertical combined assembly of a foundation pit, any foundation pit plane forms can be formed, flexibility is achieved, prefabrication quality is high, constriction quality is stable, stress participation can be conducted in time, a large amount of labor force is saved, and cost is reduced.

Owner:GUANGZHOU METRO DESIGN & RES INST

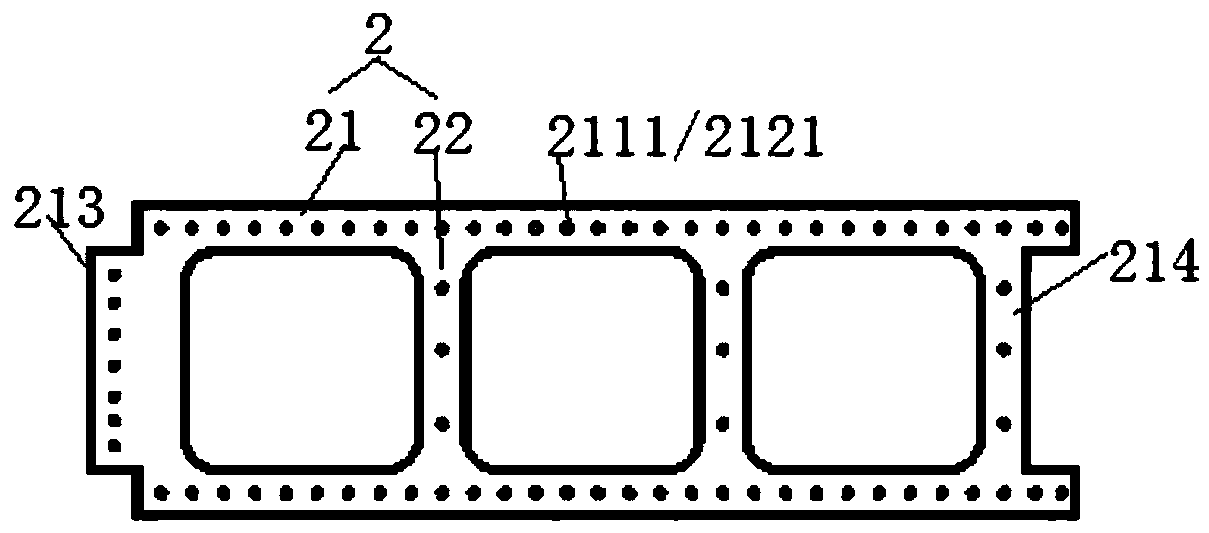

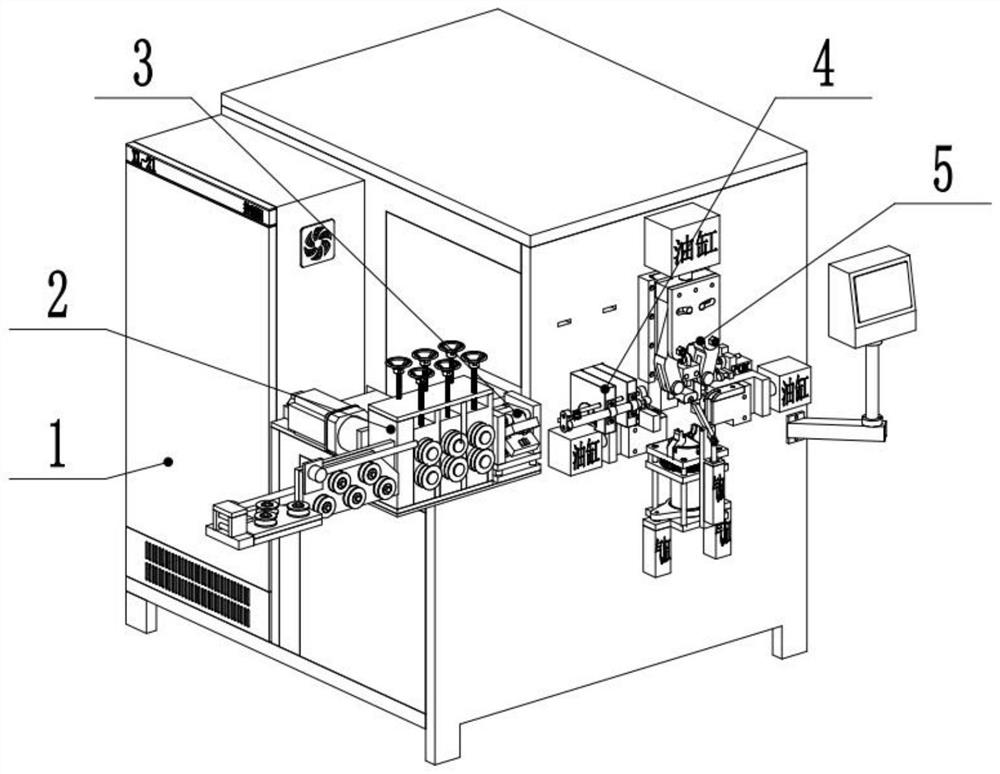

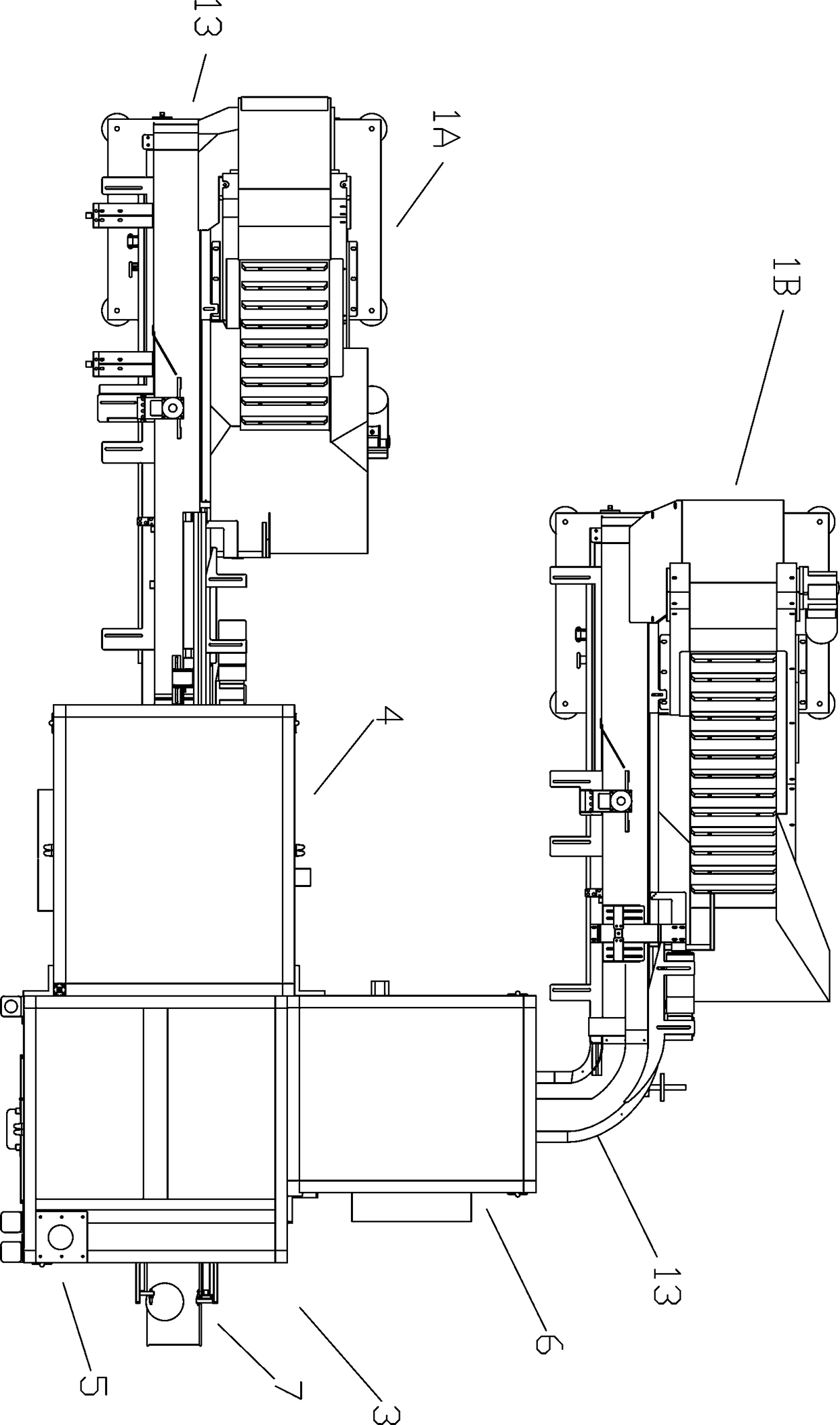

Full-automatic slitting machine

ActiveCN105502068AFully automatic withSimple structureArticle deliveryWebs handlingProduction effectEngineering

The invention relates to the technical field of mechanical equipment, in particular to a full-automatic slitting machine. The full-automatic slitting machine comprises a feeding device, a main slitting device, a discharging device and a control box. One end of the main slitting device is connected with one end of the feeding device, and the main slitting device is arranged on one side of the feeding device; the discharging device is connected with the other end of the main slitting device; the control box is connected with the other end of the feeding device. The main slitting device comprises a frame, a first feeding mechanism, a rotating mechanism and a manipulator device. The first feeding mechanism is arranged in the frame, the rotating mechanism is arranged on the frame, and the manipulator device is rotatably arranged on the inner side wall of the frame. The full-automatic slitting machine has the advantages of simple and compact structure, high production efficiency, full automation, low production noise, excellent production effects and the like.

Owner:东莞市大道精密智能装备有限公司

Low self-noise stainless steel wire

The invention discloses a low self-noise stainless steel wire. The diameter of the low self-noise stainless steel wire is 5.9-6.1 mm. The low self-noise stainless steel wire comprises, by mass percentage, 0.01-0.03% of carbon, 13-17% of chromium, 4-8% of nickel, 0.1-0.12 % of copper, 0.4-0.5 % of magnesium, 1-1.2% of manganese, and the balance iron. The prepared low self-noise stainless steel wire greatly improves the abrasion resistance and corrosion resistance performance, is easy to machine and form, has certain vibration reducing performance, is low in self-noise, better solves the problems that steel wires are likely to be corroded, rusted and abraded and large in noise, and prolongs the service life.

Owner:唐山智新科技有限公司

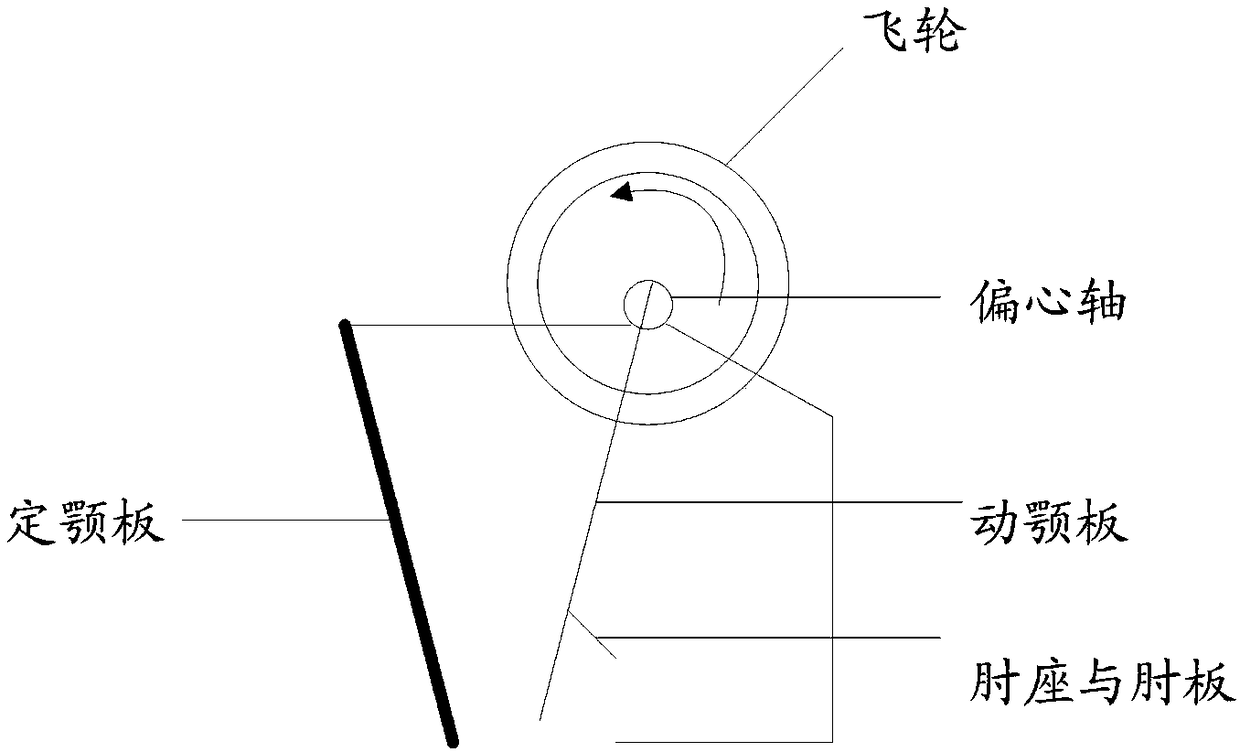

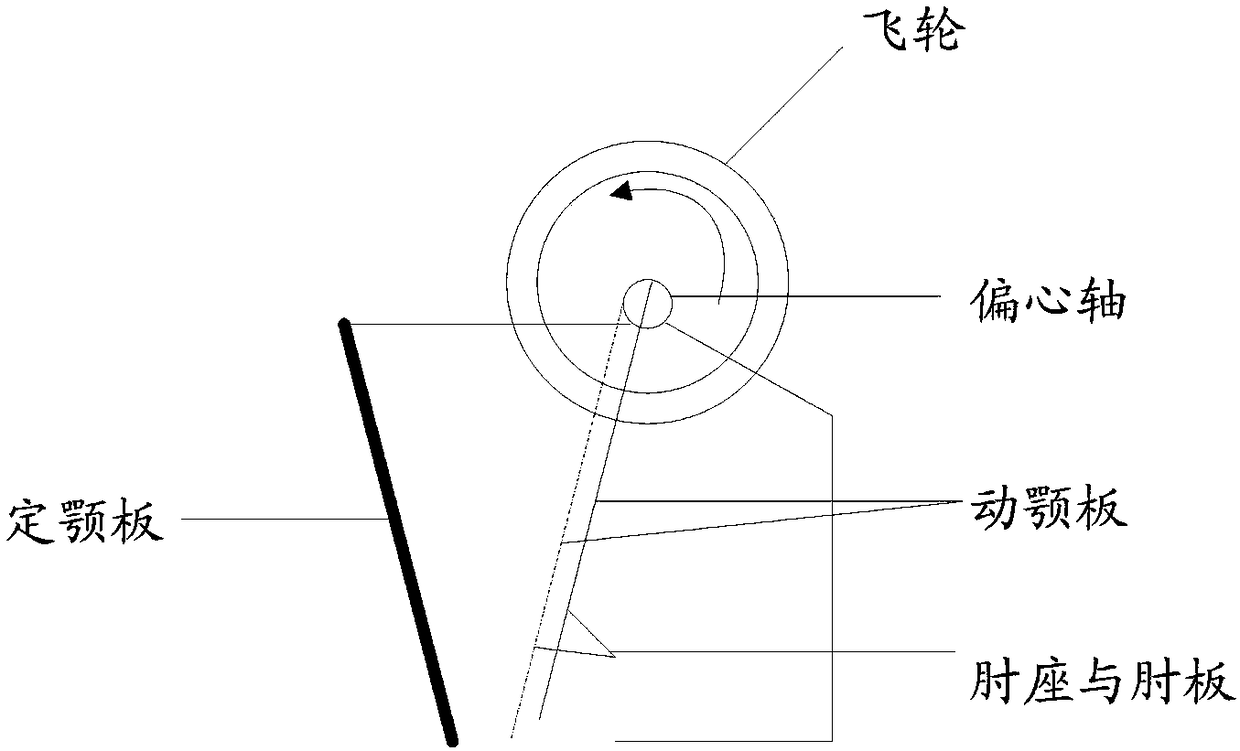

Hydraulic jaw crusher unit

The invention discloses a hydraulic jaw crusher unit. The hydraulic jaw crusher unit comprises a feeding device, a screening device, a jaw crusher, a conveying device, a hydraulic station and an integrated frame, wherein the feeding device, the screening device, the jaw crusher, the conveying device and the hydraulic station are arranged in the integrated frame; the jaw crusher adopts a crusher jaw plate structure adopting deep cavity as a double-curved cavity form; the hydraulic station is used for supplying working oil pressure to the feeding device, the screening device, the jaw crusher andthe conveying device; materials enter the screening device through the feeding device and enter the jaw crusher for being crushed after passing through the screening device; the crushed materials enter the conveying device. In-factory pre-installing debugging can be realized by all parts of equipment of the whole unit, integrated transportation is realized, assembling is not required during a production site, and civil construction is not required.

Owner:北京博岳恒科技发展有限公司 +1

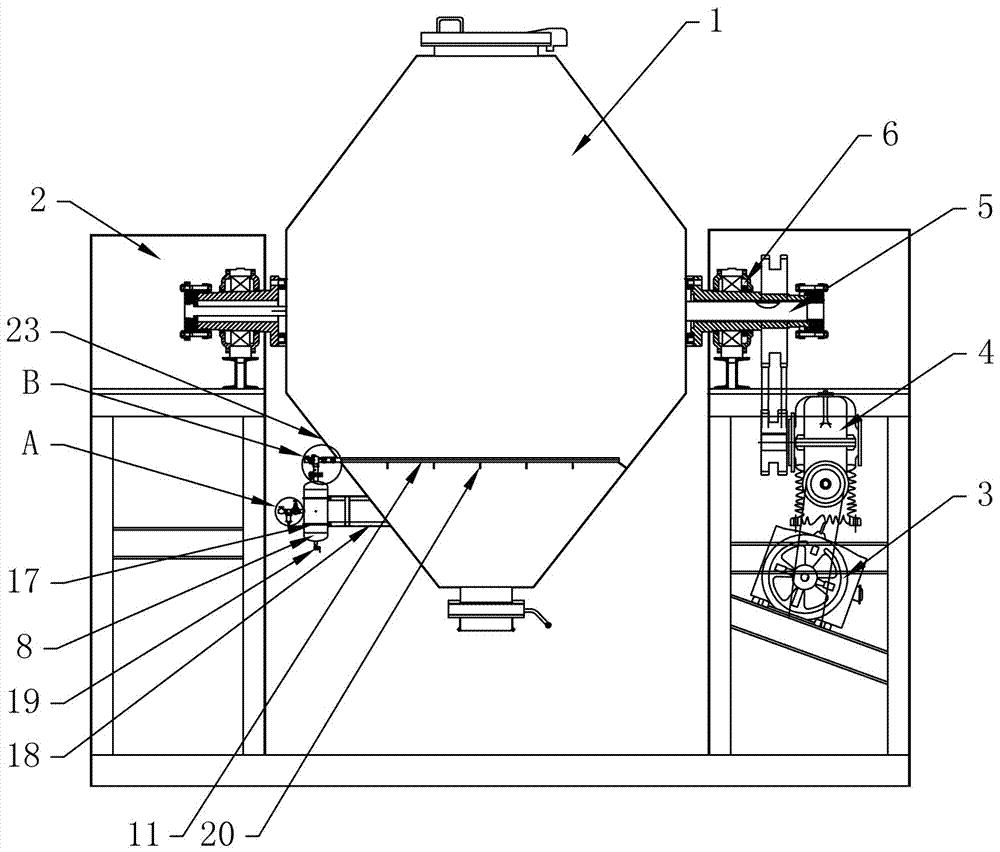

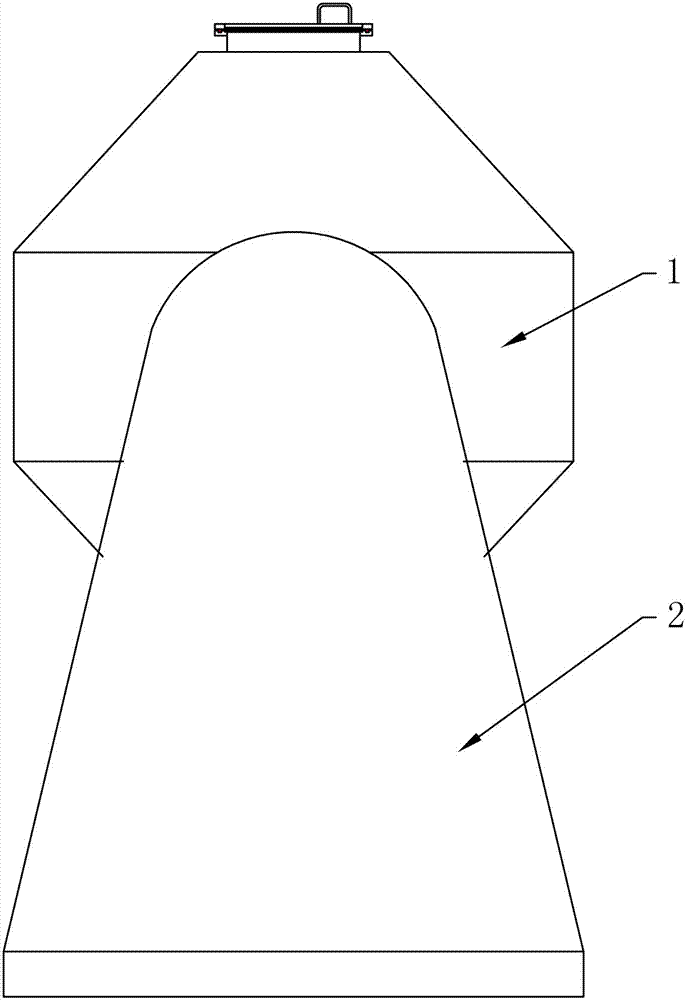

Double-cone mixer

PendingCN107243281AExtended service lifeEnsure safetyRotating receptacle mixersTransportation and packagingAutomatic controlMotor drive

The invention relates to a double-cone mixer which comprises a mixing cylinder, a machine frame for supporting the mixing cylinder and a mixing cylinder driving mechanism, wherein the mixing cylinder driving mechanism comprises a motor, a worm gear reducer, a rotating shaft and a bearing carrier; the motor drives the worm gear reducer to operate, the worm gear reducer is connected with the rotating shaft in a transmission mode, and the rotating shaft penetrates through the bearing carrier and drives the mixing cylinder to rotate; the double-cone mixer is also provided with a cut-off valve, an air bag, an explosion-proof electromagnetic pulse valve, an injection pipe and an air cannon stirring bracket which are contained in an air cannon unblocking device; the inside of the air cannon stirring bracket is hollow; an air outlet of the cut-off valve is connected with an air inlet of the air bag; an air outlet of the air bag is connected with an air inlet of the explosion-proof electromagnetic pulse valve; one end of the injection pipe is connected with an air outlet of the explosion-proof electromagnetic pulse valve; the other end of the injection pipe communicates with the air cannon stirring bracket; and a plurality of air holes are arranged outside the air cannon stirring bracket. The double-cone mixer implements automatic control, is convenient to operate, enhances the production efficiency, lowers the noise, prolongs the service life of the mixing cylinder and ensures the safety of operators.

Owner:NINGBO SONGKE MAGNETIC MATERIAL

Preparation method for low-self-noise stainless steel wire

The invention discloses a preparation method for a low-self-noise stainless steel wire. The diameter of the low-self-noise stainless steel wire is 5.9-6.1 mm. The low-self-noise stainless steel wire comprises, by mass, 0.01%-0.03% of carbon, 13%-17% of chrome, 4%-8% of nickel, 0.1%-0.12% of copper, 0.4%-0.5% of magnesium, 1%-1.2% of manganese and the balance iron. According to the low-self-noise stainless steel wire prepared through the preparation method, the abrasion resistance and the corrosion resistance of the stainless steel wire are greatly improved; machining and forming are easy; a certain damping performance is achieved; the self noise is low; the problems that a steel wire is prone to being corroded, rusted and abraded and large in noise are well solved; and the service life of the low-self-noise stainless steel wire is prolonged.

Owner:唐山智新科技有限公司

Dust removing system for plant safety production

ActiveCN105382007AAchieve absorptionReduce production noiseDirt cleaningSound proofingPlant safetyEngineering

The invention provides a dust removing system. The dust removing system comprises a fixing plate and a plurality of dust suction assemblies arranged on the fixing plate. A plurality of sound absorbing assemblies are arranged on the dust suction assemblies. The dust suction assemblies absorb dust in various spaces of a plant. The production noise in the plant is lowered through the sound absorbing assemblies. By means of the dust removing system, absorption of the dust in various spaces of the plant can be achieved, the production noise in the plant can be effectively lowered, and cleanliness and safety of the production environment of the plant are guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

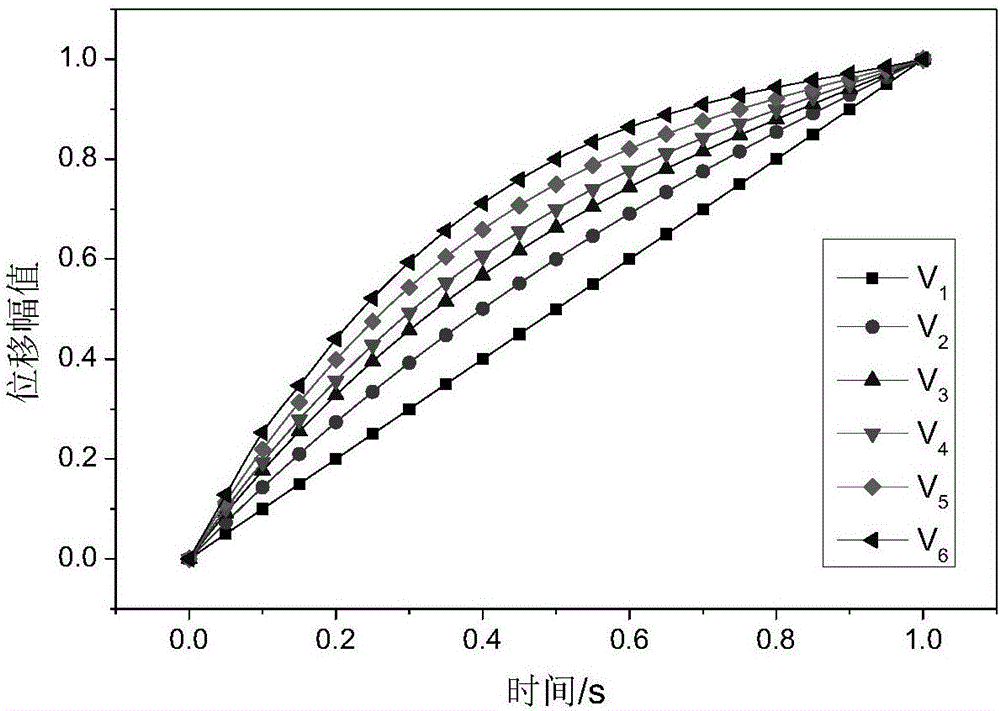

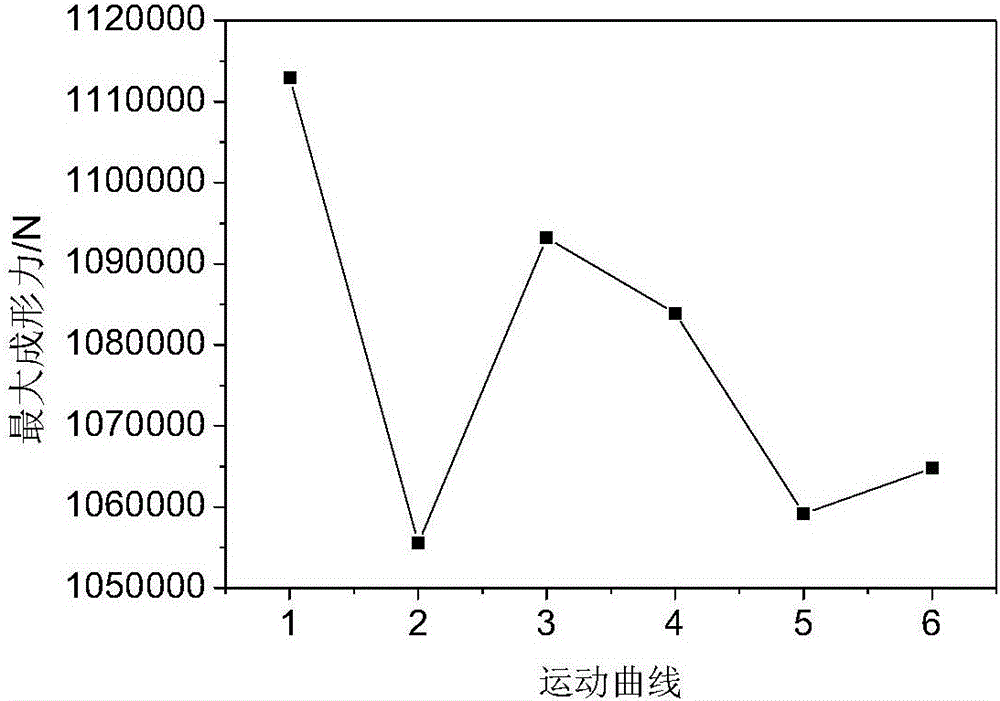

Servo stamping speed control method based on jerking movement degree

ActiveCN106739128AImprove forming qualityExtend your lifePressesFinite element analysis softwareFinite element analyse

The invention discloses a servo stamping speed control method based on a jerking movement degree. The method comprises the following steps of S1, building a three-dimensional model of a component to be stamped and introducing the model into finite element analysis software; S2, setting a material parameter, a boundary condition and a contact condition, and dividing grids; S3, setting a displacement amplitude mathematical expression to be X=At3+Bt2+Ct+D, and determining an initial value range of A to be 0 to 1, the initial value range of B to be 0 to -3, the initial value range of C to be 1 to 3, and the initial value of D to be 0; S4, selecting different values within the initial value ranges of A, B and V to set different displacement amplitude curves, and submitting for computation; and S5, extracting data from computation results for comparative analysis, and determining the optimized value ranges of A, B and C. According to the method provided by the invention, the displacement, speed, acceleration jerking movement degree can be continuously adjustable, and shaping quality of the complex components and the components difficult to shape is enhanced.

Owner:WUHAN UNIV OF TECH

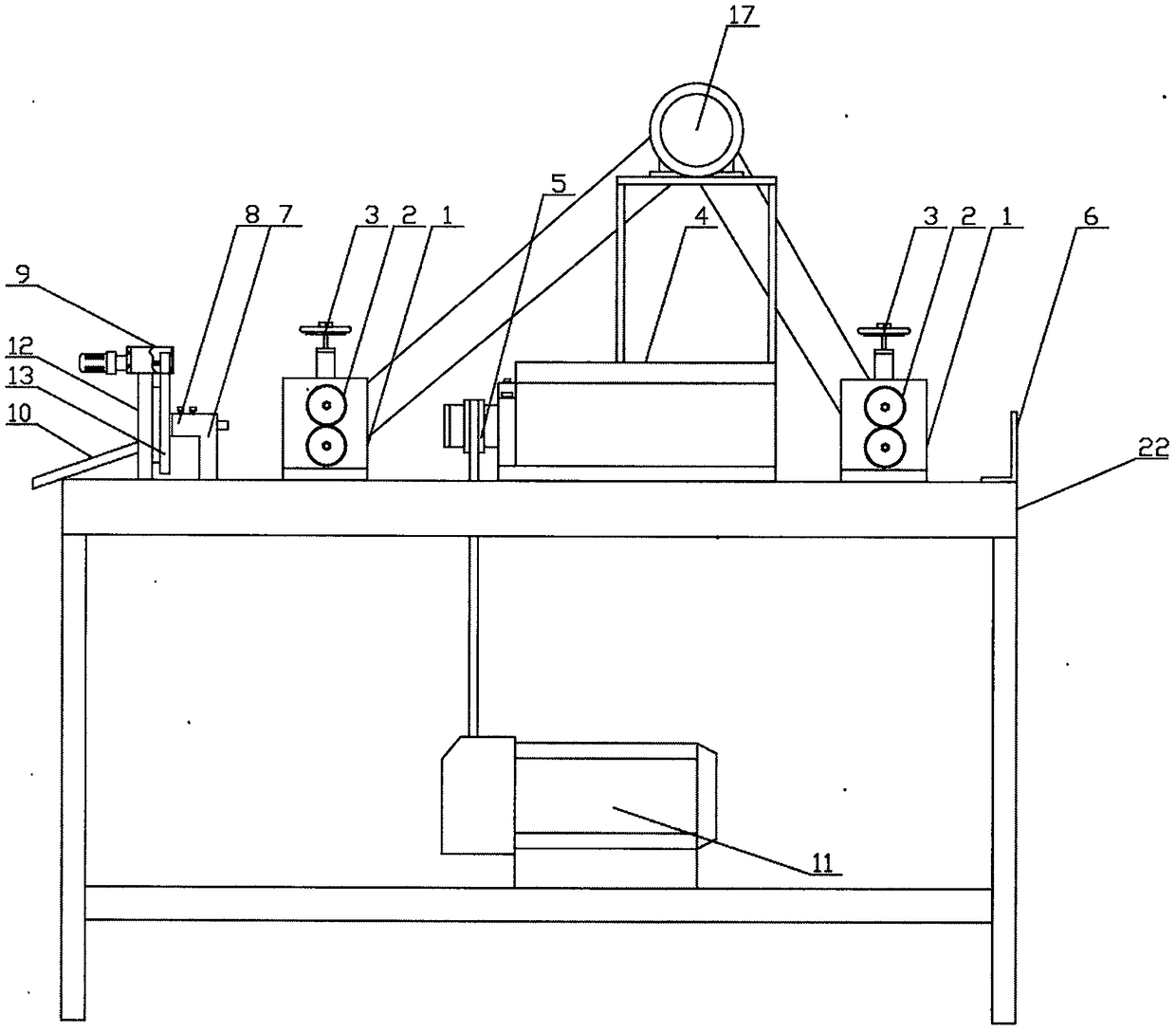

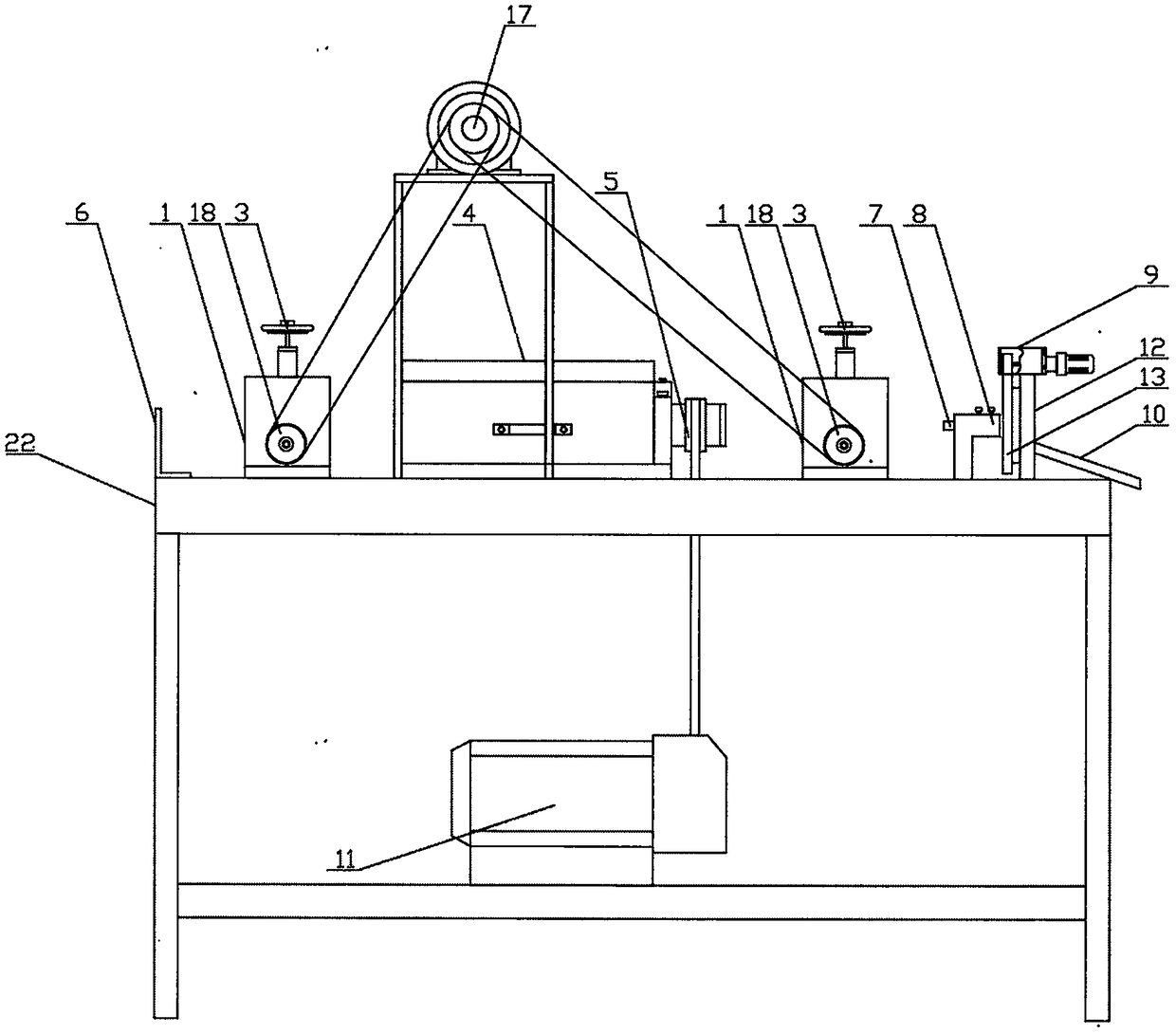

High-speed and low-noise wire twisting-off machine

The invention relates to a high-speed and low-noise wire twisting-off machine. The high-speed and low-noise wire twisting-off machine comprises an operation platform, a fixed cutter assembly, a movable cutter assembly, a straightening device assembly and at least one set of traction box; the fixed cutter assembly, the movable cutter assembly, the straightening device assembly and the traction boxes are linearly distributed on the operation platform with a metal wire as the center; the straightening device assembly is located on the front side of the fixed cutter assembly; the traction boxes are arranged on the input side and / or the output side of the straightening device assembly; and the movable cutter assembly is located on the rear side of the fixed cutter assembly. The high-speed and low-noise wire twisting-off machine is reasonable in structural design, devices needed for machining of the metal wire are integrated into one operation platform, so that the devices continuously convey, straighten and twist off the metal wire, the working efficiency is improved, production noise is lowered, and the twisting-off quality of the metal wire is ensured at the same time.

Owner:德州市八骏焊割设备附件有限公司

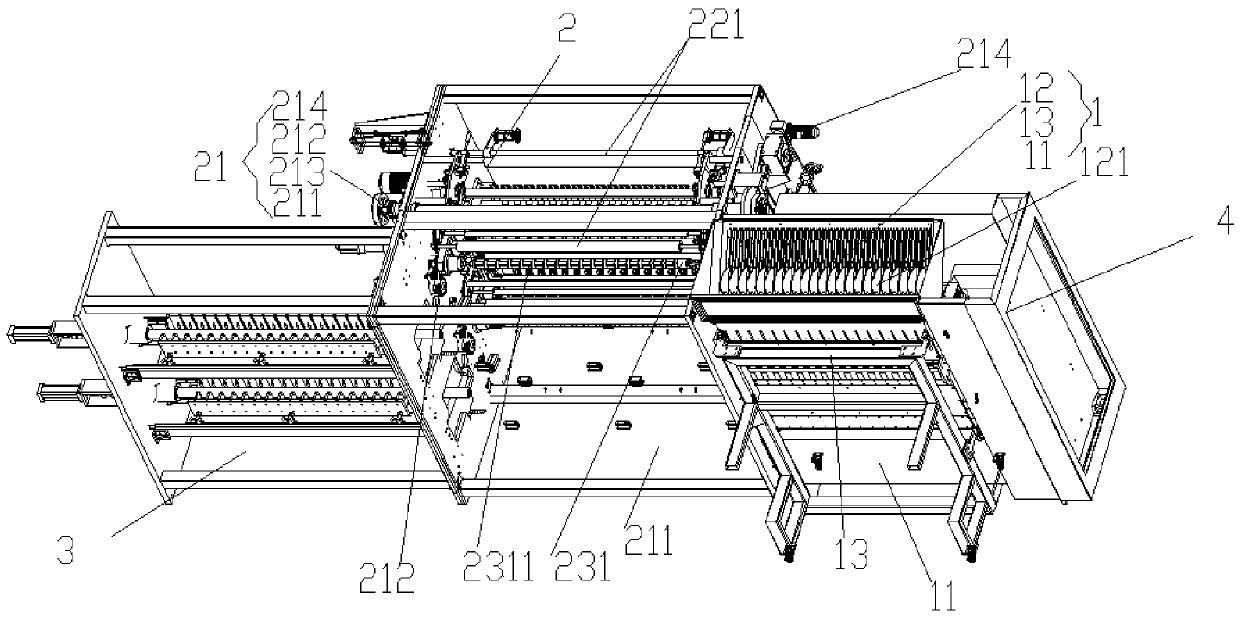

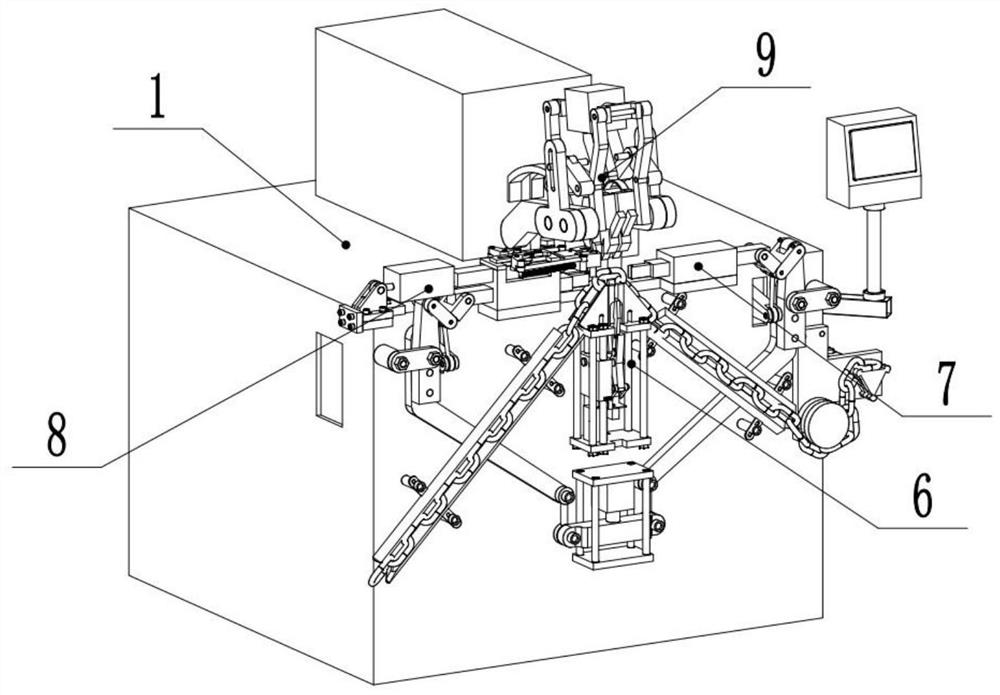

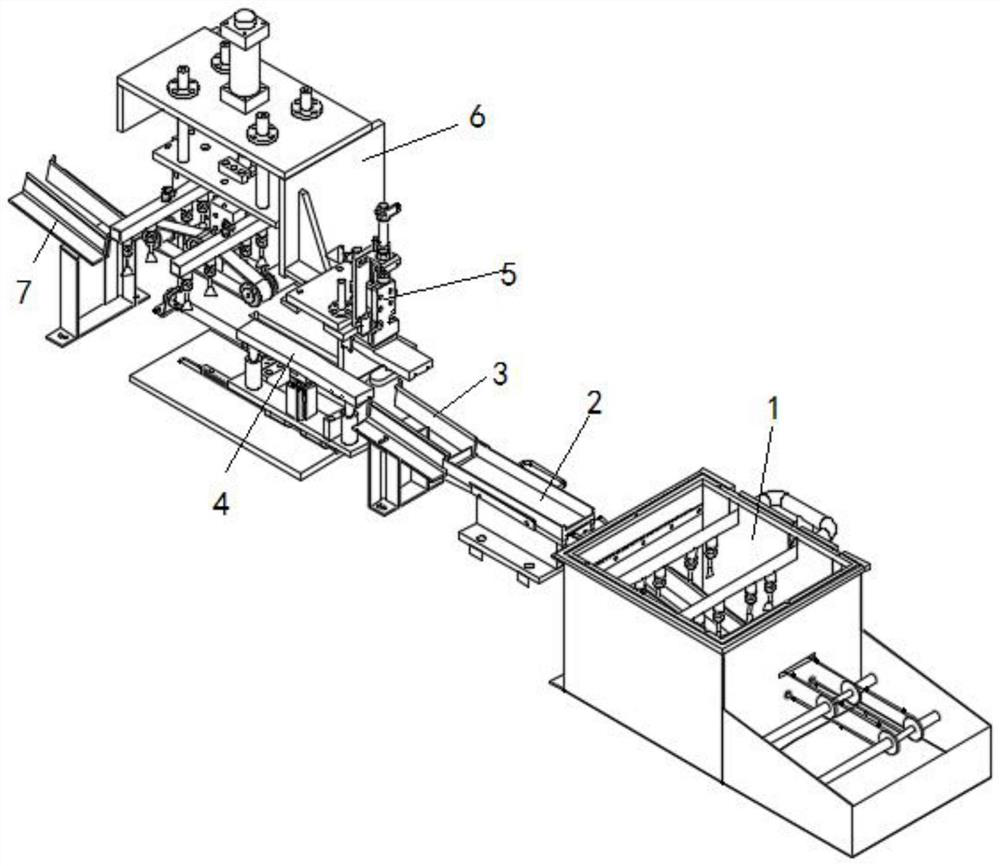

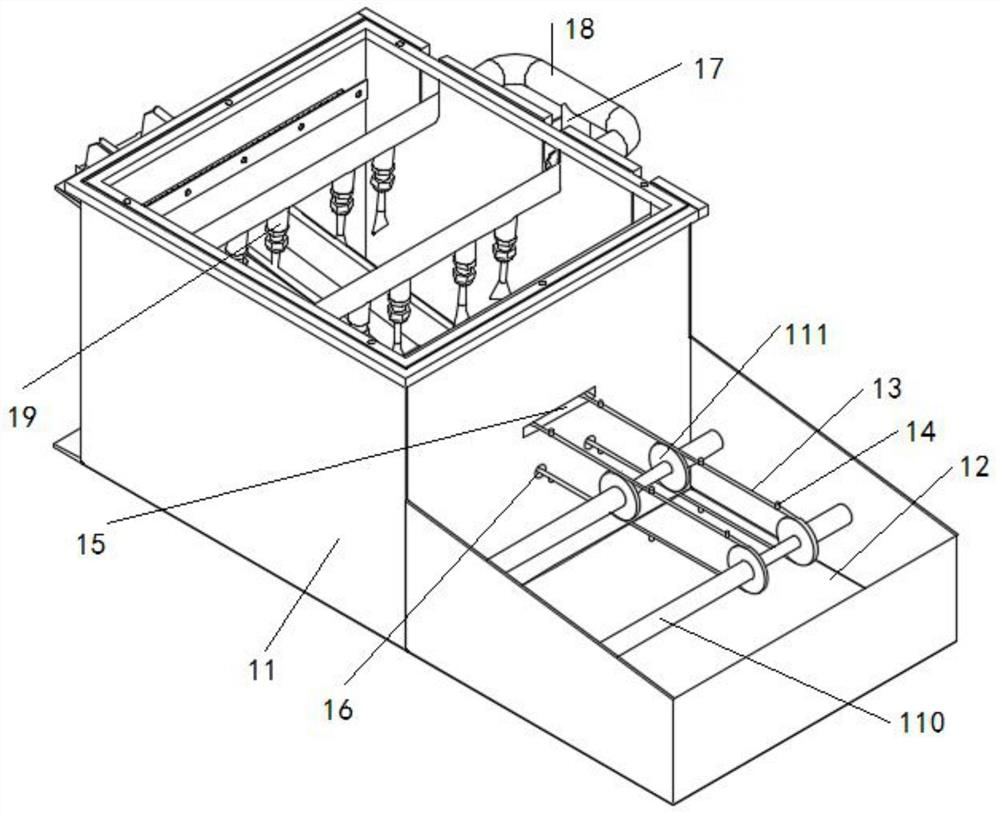

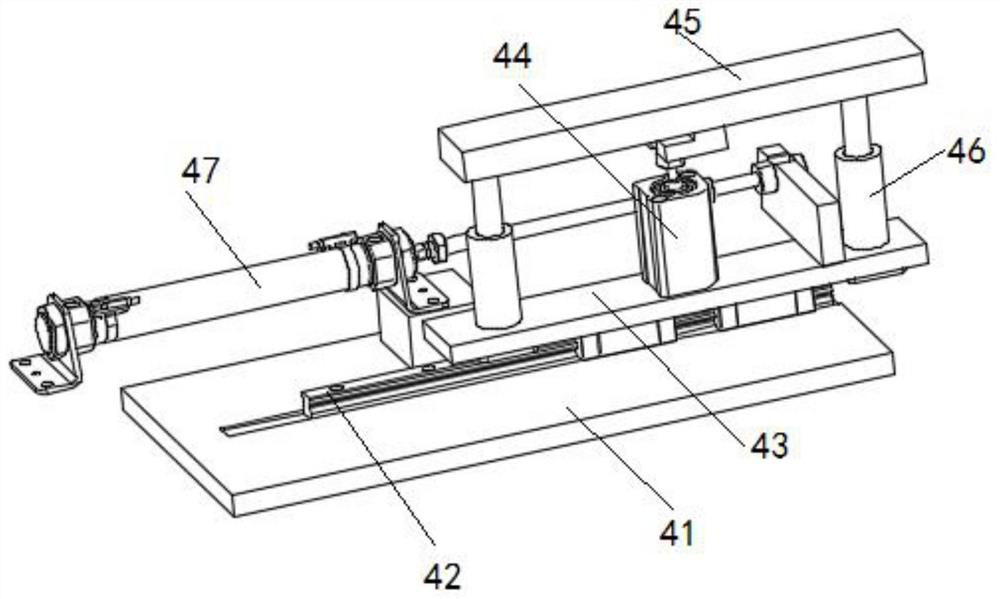

Automatic chaining and welding all-in-one machine for antiskid chains and chain machining method

PendingCN113770728AImprove working environmentReduce production noiseOther manufacturing equipments/toolsDrive wheelMolding machine

The invention discloses an automatic chaining and welding all-in-one machine for antiskid chains. The design of a novel chaining and welding all-in-one machine which can complete processes of chaining and welding and overcome the defects of a traditional chaining and welding machine has become the urgent demand for development of the chain machining field in China. According to the machine, a feeding device adopts horizontal and vertical straightening, a servo motor drives a plurality of driving wheels to feed intermittently, a cutting device breaks a mouth in advance and then cuts materials, the materials are conveyed to a forming station through the feeding device, and preforming, ring sleeving and complete forming are achieved through a forming mechanism. According to the machine, the chain rolling servo motor is matched with a triangular chuck and a fixed pulley to achieve routing control of the chains, the welding with different sizes is achieved by controlling the rotation angle, and a deburring mechanism achieves that annular burrs fall off twice in a semi-annular welding scrap mode in the one-time deburring process.

Owner:JINHUA HUANAN MACHINERY MFG

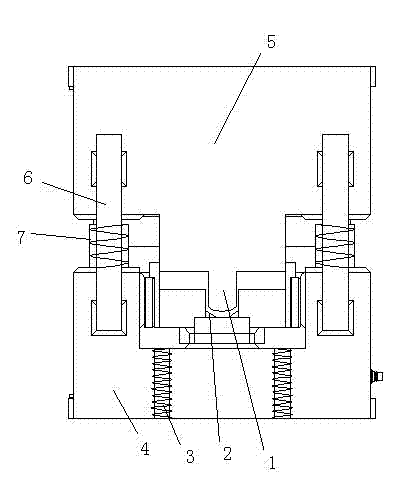

Gasket processing device

The invention relates to a gasket processing device. The gasket processing device is characterized in that the gasket processing device includes a lower die seat, an upper die seat, a guiding mechanism and a punching mechanism; the guiding mechanism includes guiding pillars arranged symmetrically at two ends of the top surface of the lower die seat, guiding sleeves arranged at the ends, away fromthe lower die seat, of the guiding pillars in a sleeving mode and springs arranged between the inner parts of the guiding sleeves and the lower die seat, and the guiding sleeves can move up and down in the perpendicular direction of the guiding pillars; the punching mechanism includes a material ejecting rod, a material ejecting disc, an upper die plate, a female die, a male die, an upper discharging plate, a lower discharging plate, a discharging rod, a lower die and a rubber blanket; and the punching mechanism is guided by the guiding mechanism to reciprocate in the vertical direction, and punching is finished through the action of the female die, the male die and the lower die. The device is used for processing gaskets, the blanking-punching process can be finished at the same positionof a die at the same time, and the production efficiency is high.

Owner:NINGXIA KOCEL MOLD

Wedge cross-rolling two cycle roll-forming method for train shaft blank

InactiveCN1947884AImprove productivityIncrease profitTemperature control deviceRollsRoll formingEngineering

A technology for forming the axle bank of train by using wedge dies to roll it by two-turns includes such steps as heating a circular blank to 1000-1200 deg.C, feeding it between two die sets with at least one pair of internal wedges and one pair of external wedges, rotating the die sets by one turn while rolling it by internal wedges, and rotating the die sets by another turn while rolling it by external wedges.

Owner:UNIV OF SCI & TECH BEIJING

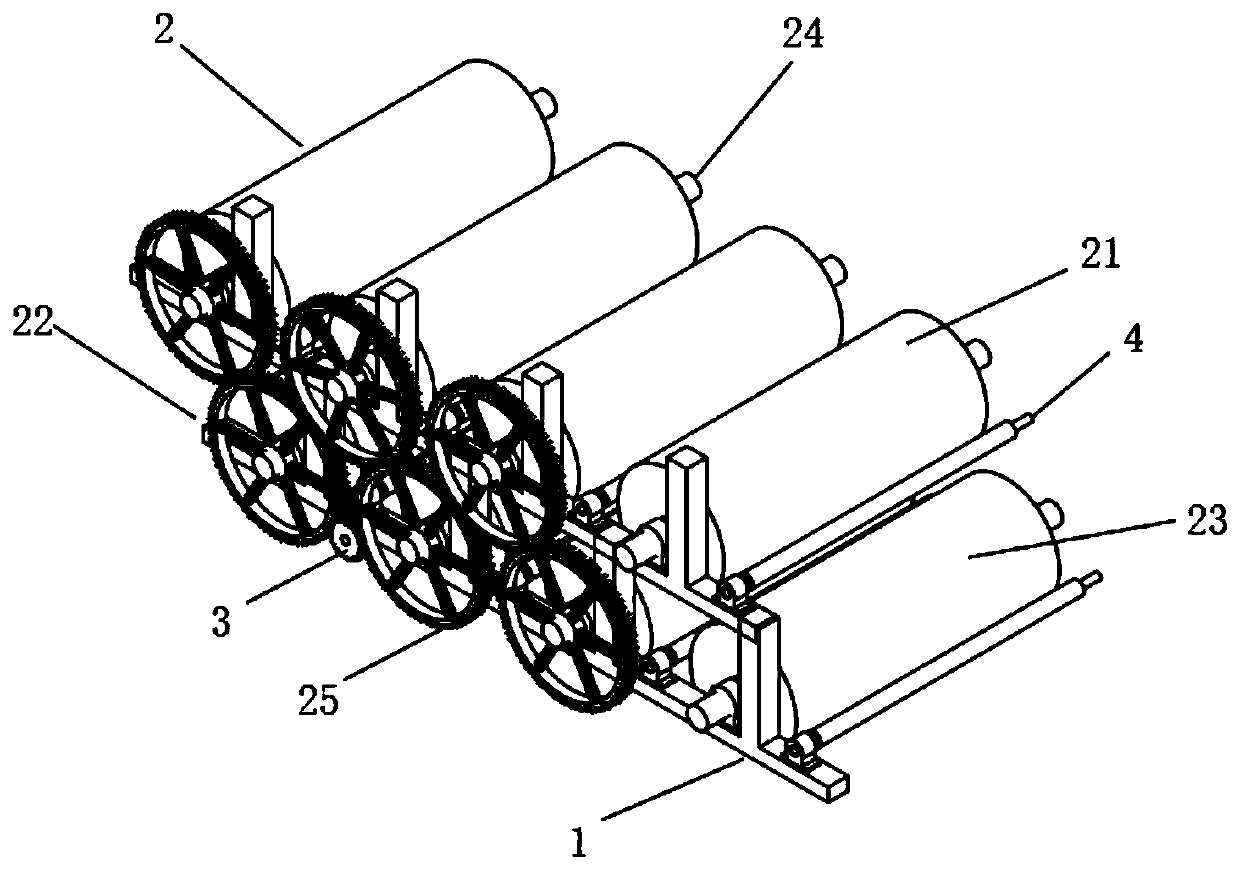

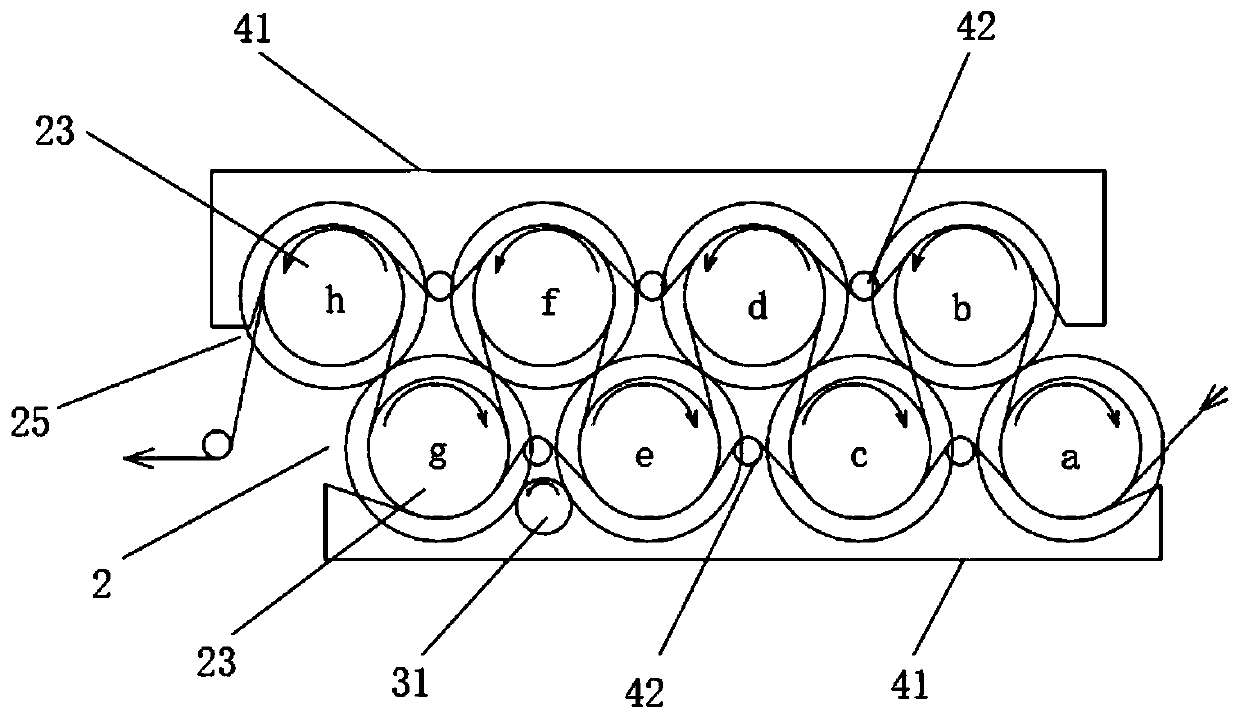

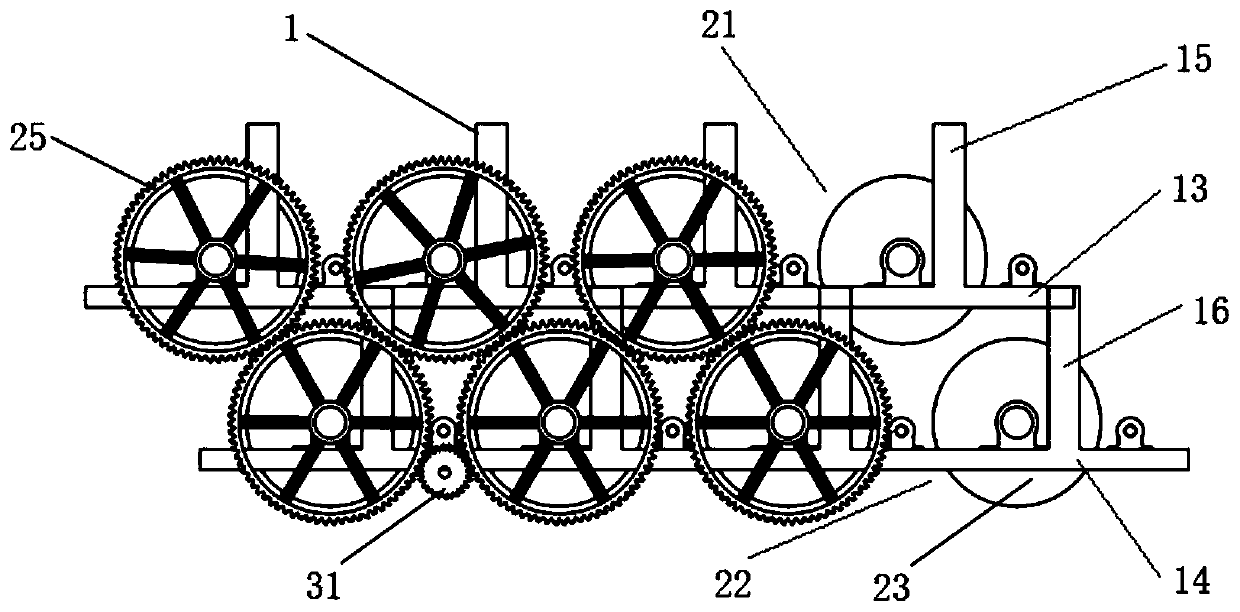

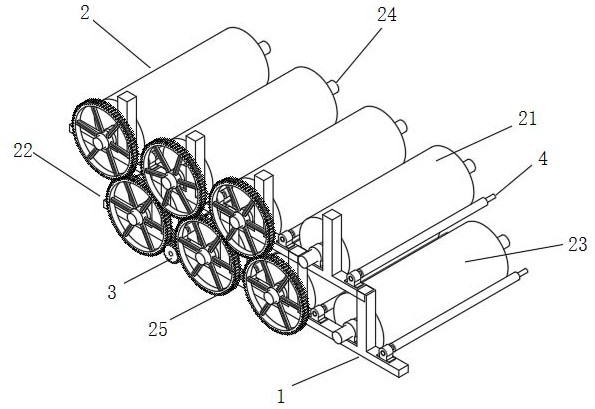

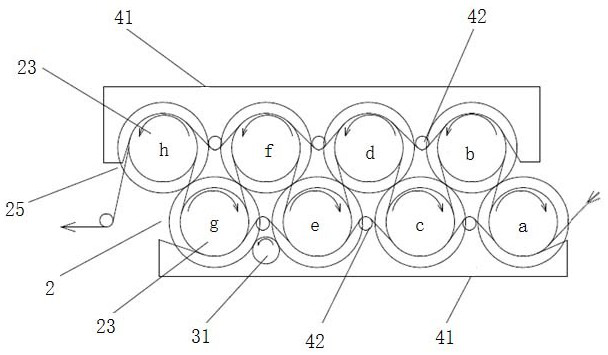

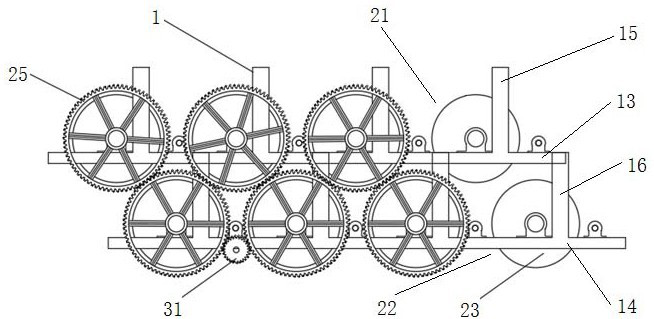

Papermaking drying cylinder mechanism

ActiveCN111501394AExtended run lengthImprove drying effectDryer sectionPaper sheetElectric machinery

The invention relates to the technical field of papermaking, and specifically relates to a papermaking drying cylinder mechanism that comprises a machine frame; a plurality of drying cylinder assemblies installed on the machine frame; a driving assembly is in transmission connection with any drying cylinder assembly, a bearing assembly is installed on the periphery of the whole drying cylinder assembly, and a brake assembly is installed on the driving assembly, wherein the drying cylinder assemblies comprise the upper drying cylinder assembly and the lower drying cylinder assembly which are arranged in an up-down staggered mode. The upper drying cylinder assembly and the lower drying cylinder assembly each comprise a drying cylinder body, a center shaft axially penetrating through the drying cylinder body and a transmission gear installed at the front end of the center shaft. The driving assembly comprises a motor, a driving shaft fixedly connected with the output end of the motor anda driving gear fixedly connected with the other end of the driving shaft, and the driving gear is in meshing transmission with any transmission gear; the driving shaft is sleeved by the brake assembly. According to the papermaking drying cylinder mechanism, a paper web can be dried and conveyed stably, the tension of paper can be better adjusted, and the production quality of the paper is improved.

Owner:DONGGUAN JINTIAN PAPER CO LTD

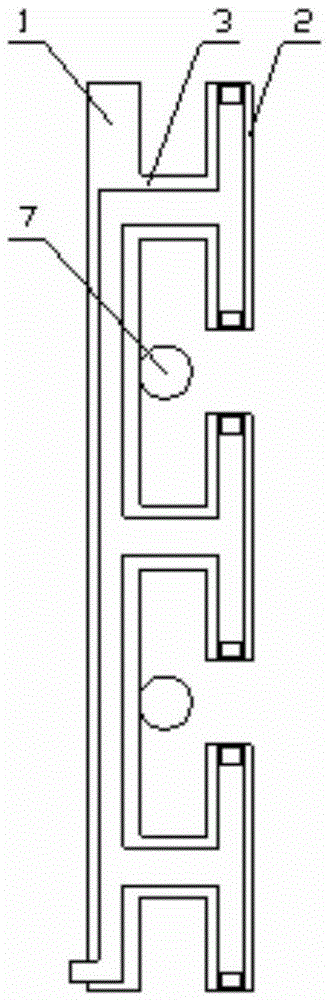

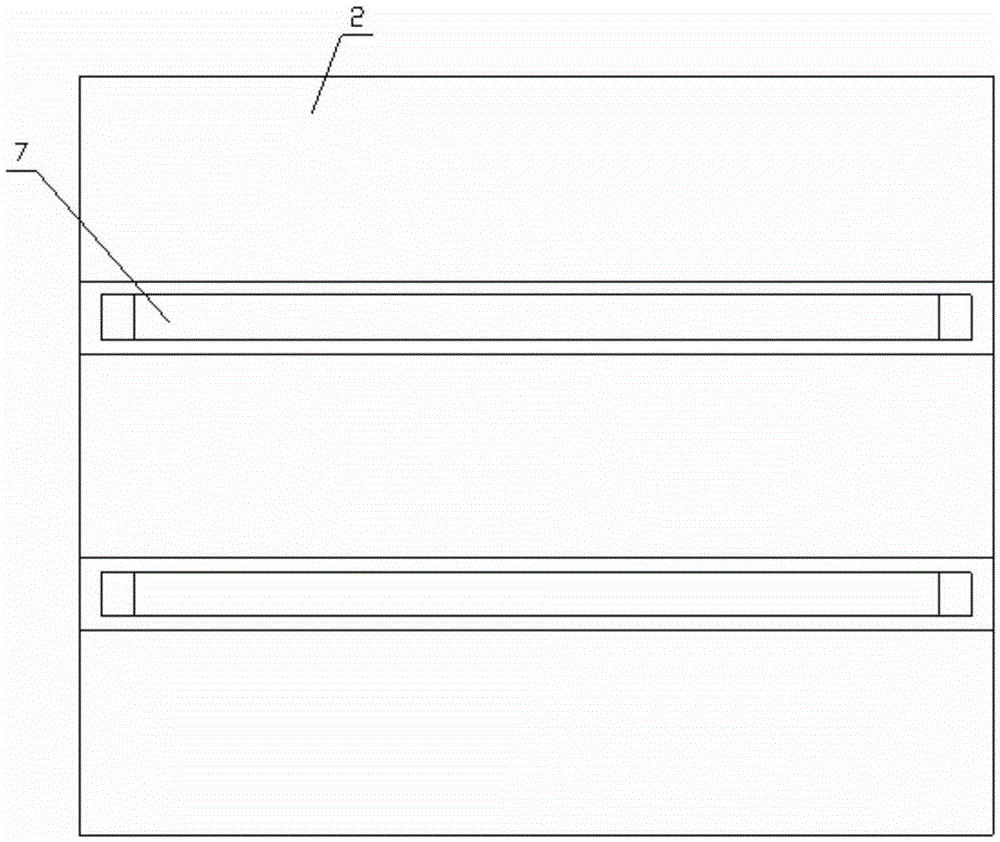

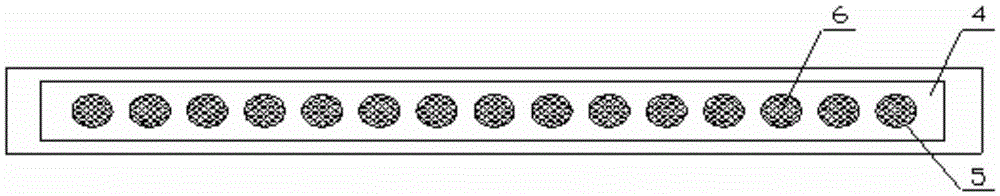

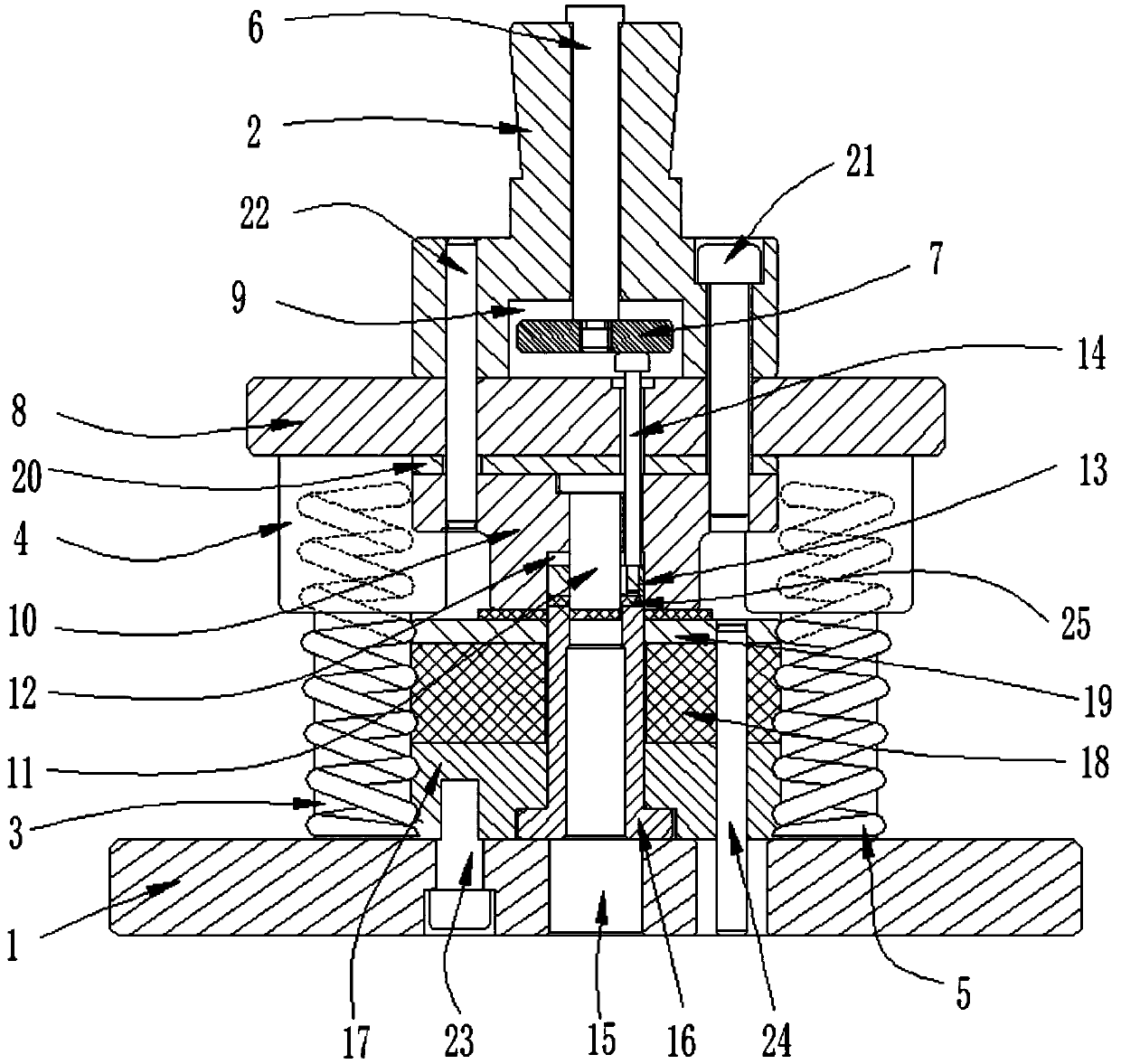

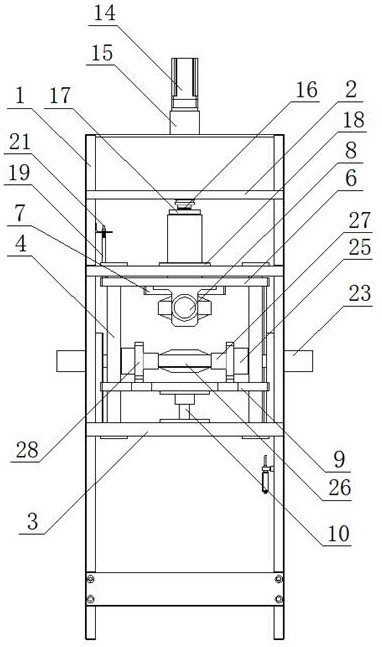

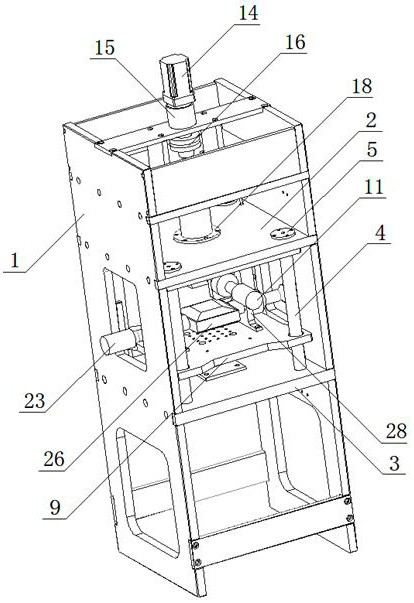

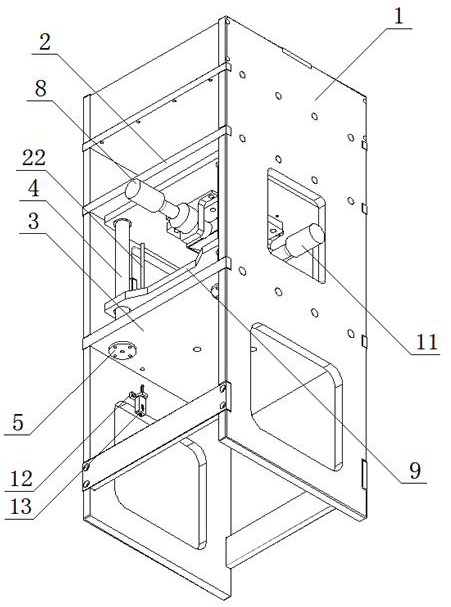

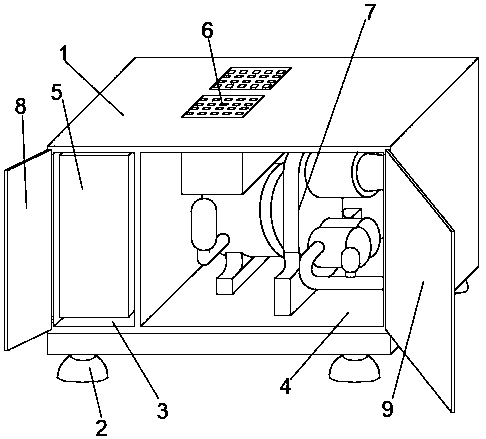

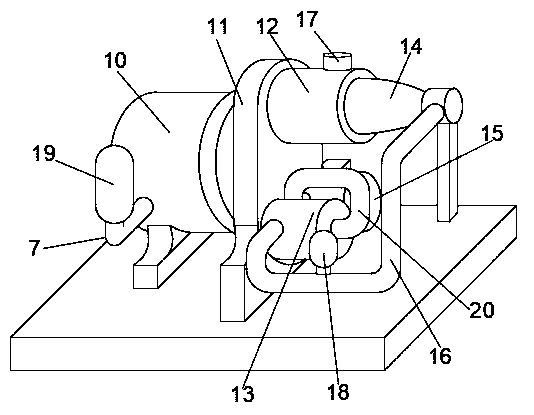

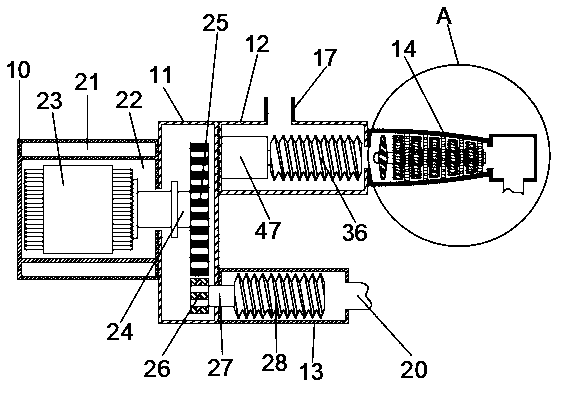

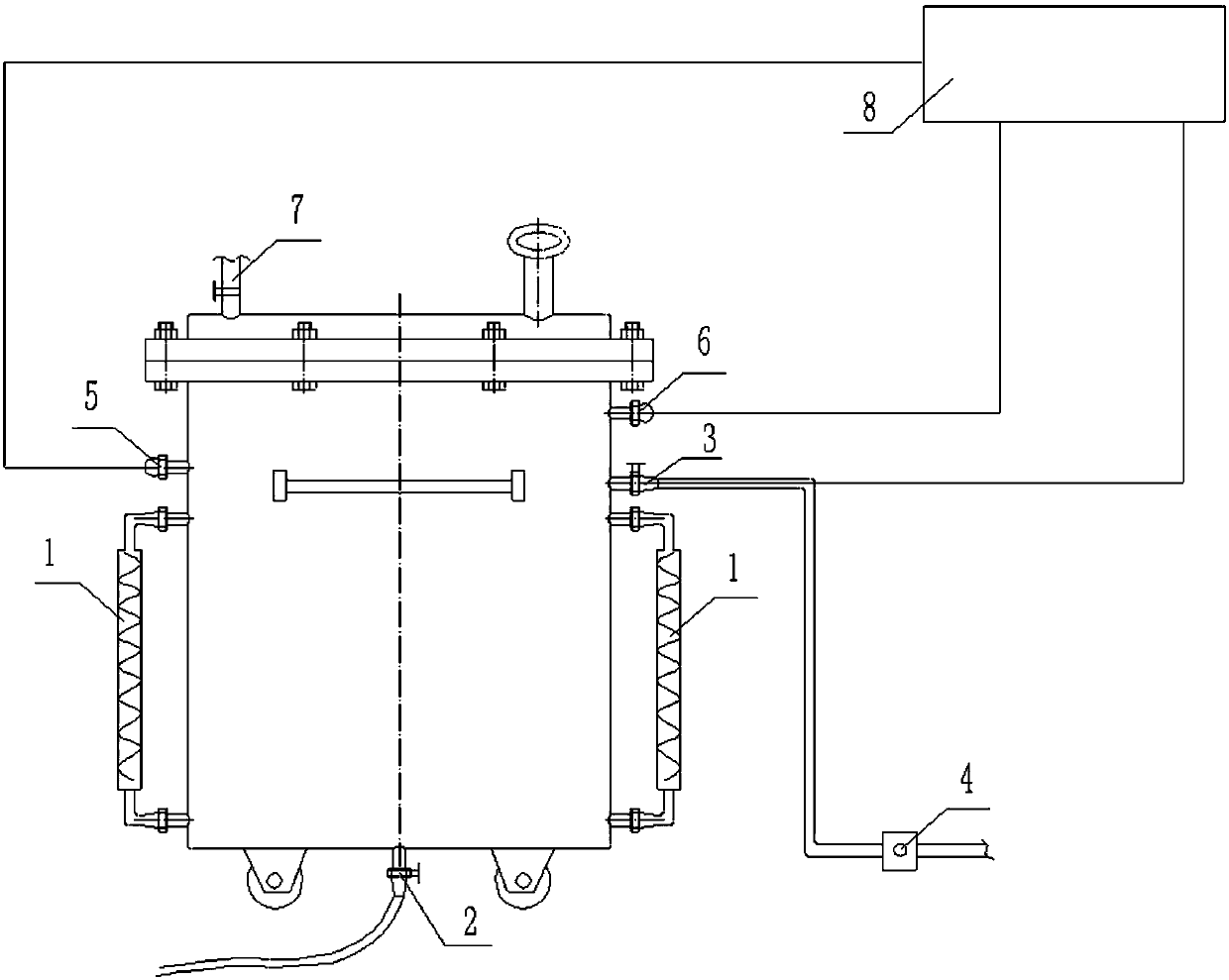

Ultrasonic servo press device

ActiveCN112296112ARealize closed-loop regulation controlRealize ultrasonic vibration extrusion moldingEngineeringUltrasonic vibration

An ultrasonic servo press device comprises a machine frame (1) and is characterized in that an upper fixing plate (2) is horizontally fixed to the upper portion of an inner cavity of the machine frame(1), a plurality of guide rods (4) are vertically arranged between the upper fixing plate (2) and a lower fixing plate (3), and a sliding lifting plate (6) is movably installed on the guide rods (4);and a first ultrasonic vibration instrument (8) is installed at the bottom of an upper pressing plate (7), a pair of ultrasonic vibration instrument installation supports (28) are installed on the upper surface of a lifting lower pressing plate (9), and a second ultrasonic vibration instrument (11) is installed on the ultrasonic vibration instrument installation supports (28). The ultrasonic servo press device is compact in structure, the controllable forming operation is conducted on a workpiece through ultrasonic vibration, the accurate extrusion forming operation is achieved, a transmission structure is simplified, the maintenance cost and the operation cost are quite low, the production noise is low, and the forming quality and the forming precision of products are greatly improved.

Owner:HUBEI UNIV OF TECH

Notching press for U-shaped workepiece

The invention relates to the field of machining, in particular to a notching press for a U-shaped workepiece. The notching press is provided with an upper die and a lower die which are arranged longitudinally, wherein the bottom of the upper die is connected with a plurality of positioning rods and provided with a cylindrical punch; the lower die is provided with a plurality of spring sleeves matched with the positioning rods; the middle of the lower die is provided with a U-shaped female die; and two sides of the bottom of the U-shaped female die are provided with annular runners. The notching press for the U-shaped workpiece is reasonable in structural design; the notching machining accuracy is improved by the design of the positioning rods and the spring sleeves; and by the design of the annular runners, echoes generated by stamping can be effectively lowered, and production noises can be obviously lowered.

Dust removing metal grinding device

InactiveCN108145564AAvoid allergic reactionsAvoid infectionGrinding machinesGrinding work supportsEngineeringAllergic reaction

Provided is a dust removing metal grinding device. Mechanical grinding is used for replacing handholding of a grinder, it is only needed that a worker operates a machine, fatigue caused by long-time work is avoided, and the work efficiency is improved; a fragment dust collecting device and a square dustproof sound insulating cover are arranged, influences of fragment dust generated during production on the environment are eradicated, and it is prevented that after fragments make contact with human bodies, an allergic reaction happens to the human bodies; a particle sensor inducts the degree ofparticles in air, a dust sucking draught fan is controlled by a control chip itself to work, and respiratory tract infection caused after dust is inhaled into the respiratory tract is prevented; andby arranging a containing frame, a metal workpiece after being ground can be conveniently placed. The dust removing metal grinding device is compact in structure, convenient to use and practical in function, dust pollution generated during production is eliminated, the production noise is lowered, and the defects in the prior art are overcome.

Owner:重庆精高金属结构制造有限公司

Photographing recognition system of clamp assembling machine

InactiveCN108655700AAutomateImplement initial detectionMetal working apparatusMechanical engineeringRecognition system

The invention discloses a photographing recognition system of a clamp assembling machine. The photographing recognition system is arranged on a conveying mechanism of the clamp assembling machine. A conveying table for conveying materials is arranged in the conveying mechanism. The photographing recognition system is arranged above the conveying table and comprises a photographing device arrangedabove the conveying table and a material removing device which is arranged above the conveying table and located below the photographing device. The photographing recognition system comprises the photographing device and the material removing device electrically connected with the photographing device. Once it is found that fastening screws on clamps are located below the clamps, the clamps are removed to return into a hopper, and finally, clamps with upward fastening screws are sequentially conveyed to the next assembling procedure. The photographing recognition system of the clamp assemblingmachine is provided and is simple in structure and more accurate and rapid in material screening.

Owner:JIANGSU BVM INTELLIGENT TECH

Wedge cross-rolling two cycle roll-forming method for train shaft blank

InactiveCN100389901CImprove productivityIncrease profitTemperature control deviceRollsRoll formingEngineering

A technology for forming the axle bank of train by using wedge dies to roll it by two-turns includes such steps as heating a circular blank to 1000-1200 deg.C, feeding it between two die sets with at least one pair of internal wedges and one pair of external wedges, rotating the die sets by one turn while rolling it by internal wedges, and rotating the die sets by another turn while rolling it by external wedges.

Owner:UNIV OF SCI & TECH BEIJING

Magnetic levitation air compressor

ActiveCN109209842AEfficient productionImprove compression efficiencyPositive displacement pump componentsPump installationsAir compressionFrequency changer

The invention discloses a magnetic levitation air compressor, and belongs to the field of air compressors. The magnetic levitation air compressor comprises a fan shell and support legs, wherein the periphery of the lower surface of the fan shell is fixedly connected with the support legs; a frequency conversion cavity and a fan system cavity are arranged inside the fan shell; a frequency converteris fixedly arranged in the frequency conversion cavity; a heat-dissipation device and a blowing system are fixedly arranged in the fan system cavity; a control box door is arranged at an opening in the front side of the frequency conversion cavity; the front side of the control box door is provided with a regulating and controlling panel for controlling and regulating the frequency converter, theheat-dissipation device and the blowing system; a system box door which can be opened and closed conveniently for rapid overhauling is arranged at the opening in the front side of the fan system cavity. By adopting the magnetic levitation air compressor, multi-stage air compression is designed, and boosting of compressed air is improved further through an air cylinder, so that the producing efficiency of the compressed air is improved effectively. Meanwhile, magnetic levitation support rotation centrifugal compression is adopted, so that noise pollution is lowered, the service life is prolonged, and the fan production efficiency is improved.

Owner:LINAN PAIQI AIR PURIFYING TECH CO LTD

Continuous automatic blanking and punching composite die and stamping process

InactiveCN109570330ADoes not cause movementWill not cause return tripPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a continuous automatic blanking and punching composite die and a stamping process. The continuous automatic blanking and punching composite die comprises a plurality of material pressing mechanisms and material pressing plates, each material pressing mechanism comprises a driving part, a force transmission plate and a plurality of force transmission rods; and the material pressing plates are fixed to driving ends of the driving parts through the force transmission plates and the force transmission rods. When the device is in the using process, an upper die base drives amale die to move downwards to be in contact with the upper surface of a blank in a lower die base, firstly, the driving ends of the driving parts drive the material pressing plates to carry out material pressing through the force transmission plates and the force transmission rods, then, the male die further descends to finish stamping, then the male die moves upwards to complete the stripping, then the driving parts release the material pressing, and the stamping process is completed. In the process, in the stamping and stripping process of the male die, the independent material pressing plates are arranged for material pressing, so that the problems that in the prior art, the material pressing is not stable and the quality of the stamped products is not consistent due to the fact that only the upper die base depending on self weight is used for pressing materials can be solved, the noise can be reduced, and the production efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Process and device for producing (NH4)2SO4 fertilizer by using ammonium sulfite solution

InactiveCN101643369BTake advantage ofImprove reaction efficiencyAmmonium salt fertilisersThree stageSelf-absorption

The invention discloses a process and a device for producing a (NH4)2SO4 fertilizer by using an ammonium sulfite solution. In an ammonia-process flue gas desulfurization device, by using the ammonium sulfite solution (NH4)2SO3 produced after ammonia absorbs SO2, the outlet of a liquid inlet ejector (9) is led into the solution at the middle lower part of an oxidation tank (2) by a downcomer through a oxidization preparation process of (NH4)2SO4 fertilizer by self-absorption of air so as to increase the reaction time; and the medium is fully oxidized through the three-stage cyclic oxidation. The cyclic oxidation procedure comprises liquid at the lower part of the oxidation tank (2), a recycle pump (4), a recycle liquid ejector and the middle lower part of the oxidation tank. Air is absorbed in the liquid inlet ejector, and sheared by liquid flows and dispersed into tiny air particles, so that the contact specific area of the gas and the liquid is increased by tens of times compared with the bubbling oxidization, thereby fully utilizing the oxygen in the air. Therefore, the process enhances the reaction efficiency, shortens the reaction times and increases the conversion rate.

Owner:洛阳市天誉环保工程有限公司

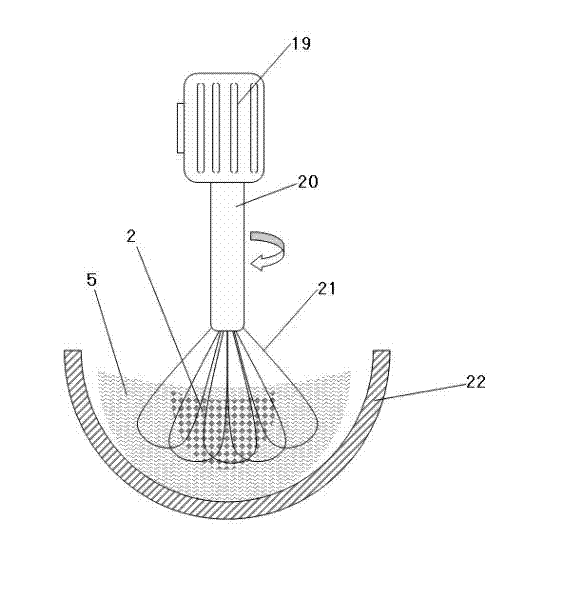

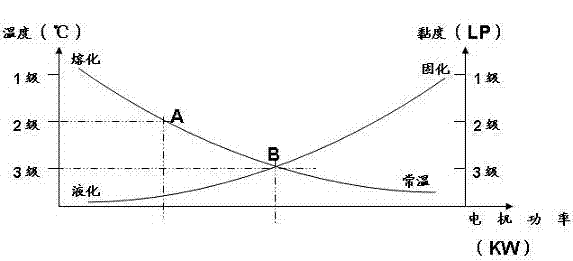

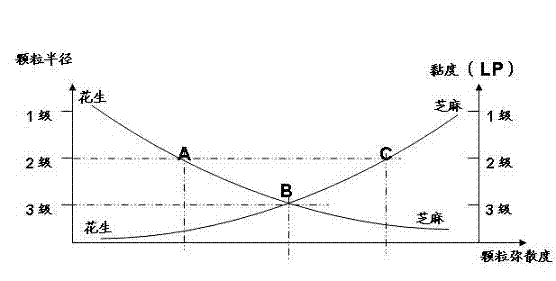

Slurry turnover tank and method avoiding viscosity difference of slurry in turnover tank

InactiveCN108016764AConsistent viscosityGuarantee statusLarge containersRotary piston pumpsSlurryVolumetric Mass Density

The invention discloses a slurry turnover tank and a method avoiding the viscosity difference of slurry in the turnover tank. The slurry turnover tank comprises a tank body. The upper portion of the tank body is connected with a slurry feeding pipe, and the bottom of the tank body is connected with a slurry discharging pipe. A plurality of circulation pipes are evenly distributed on the circumference of the outer portion of the tank body and provided with pumps. The circulation pipes are vertically arranged, and the upper ends and the lower ends of the circulation pipes communicate with the interior of the tank body. The slurry turnover tank and the method avoiding the viscosity difference of slurry in the turnover tank have the beneficial effects that up-down circulation of slurry in theturnover tank can be achieved, it is guaranteed that slurry at the top and slurry at the bottom are consistent in viscosity, and a foundation is laid for coating face density stability; bubbles can beeffectively prevented from being guided into the slurry, and the slurry state is guaranteed; and production noise can be effectively lowered through usage of screw pumps.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

An electroplating solution adding injection device for pcb circuit board electroplating

The invention discloses an electroplating solution adding and spraying device for electroplating of a PCB. The electroplating solution adding and spraying device comprises an electroplating device, acleaning device, a draining track, a material fixing device, a grinding device and a feeding conveyor belt, wherein a material transferring device is fixedly arranged on the grinding device and arranged above the position between the material fixing device and the draining track; the cleaning device is used for cleaning an electroplated substrate; the material transferring device transfers drainedmaterials to the material fixing device; the material fixing device is used for fixing the substrate and conveying the fixed substrate to the position below the grinding device; and the grinding device is used for grinding the substrate. According to the electroplating solution adding and spraying device, in the whole electroplating process, a material conveying rope moves continuously, the wholeelectroplating process is conducted continuously, and the production efficiency is improved; and the material fixing device achieves the effect of fixing the substrate and also achieves the effect oftransferring the materials, a large-span transferring device is avoided, the number of transferring devices used in the process is decreased, and the complexity of a production line is reduced.

Owner:深圳市金辉展电子有限公司

A papermaking dryer mechanism

Owner:DONGGUAN JINTIAN PAPER CO LTD

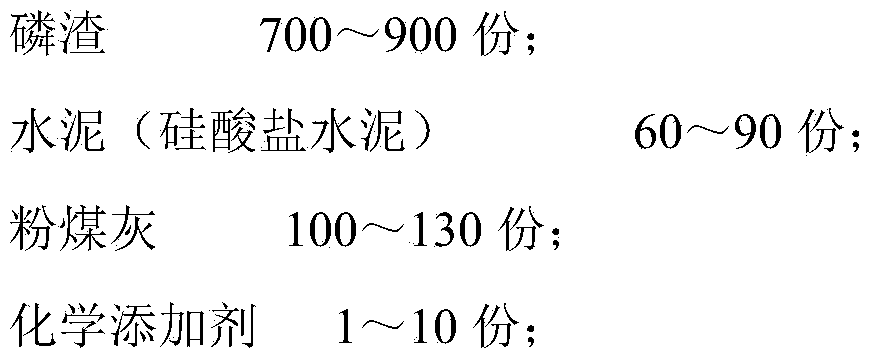

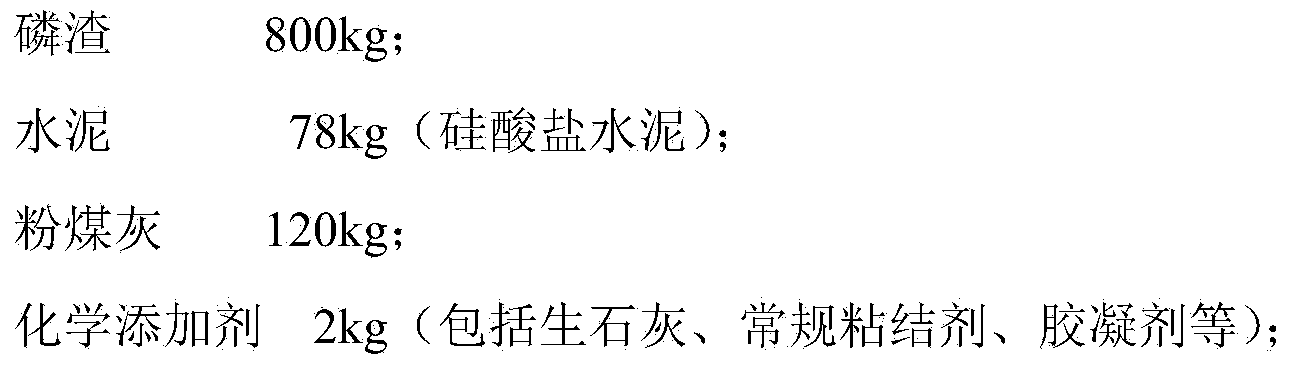

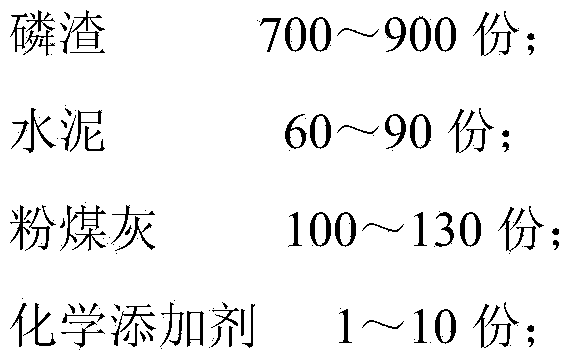

Phosphorus slag silicate building block and production process

The invention discloses a phosphorus slag silicate building block and a production process therefor. The process comprises the following steps: main raw materials are first prepared, and the main raw materials comprise 700-900 parts of phosphorus slags, 60-90 parts of cements, 100-130 parts of fly ash and 1-10 parts of chemical additives; the prepared raw materials are sent to a hopper, and automatic batching is carried out by utilization of a batching system according to the set ratio; after the batching, the raw materials are sent to a stirring system, and water is added in the stirring system and the mixture is stirred and mixed fully; then the mixture is transported to a storage bunker of a molding system, and after the mixture is subjected to pressure forming in a mold of the molding system, the formed intermediate products are subjected to truck loading by a loading transport system, and sent to a steam curing device; the intermediate products are subjected to normal pressure and temperature steam curing until the early stage intensity of the green bricks meets the requirement; after the products after curing are sent to a conveying device, and a brick pushing machine pushes the products to a package zone, and the production is finished. The production process has advantages of energy saving, environmental protection, consumption reduction, various functions of products, good quality of products and the like.

Owner:瓮安县日升新型环保建材有限责任公司

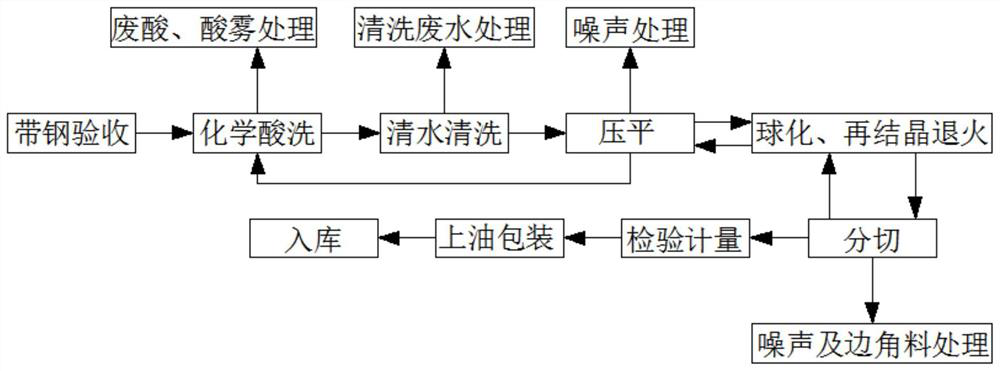

Special steel belt production process

PendingCN112442698ASimple production processAvoid pollutionFurnace typesHeat treatment furnacesWastewaterStrip steel

The invention provides a special steel belt production process. The special steel strip production process comprises the following steps that S1, strip steel is checked and accepted, specifically, purchased strip steel raw materials are checked, and checking and accepting are conducted after no quality problem exists; S2, chemical acid pickling is conducted, specifically, the strip steel raw material obtained after checking and accepting is put into an acid pickling tank, acid pickling is conducted through a hydrochloric acid dilute solution, and waste acid and acid mist generated by acid pickling are treated; S3, cleaning is conducted with clear water, specifically, after acid pickling is finished, residual acid liquor on the surface of the strip steel raw materials is washed away with clear water, and cleaning wastewater washed with clear water is treated; and S4, flattening is conducted, specifically, the strip steel raw materials washed with the clear water are mechanically flattened through a flattening machine. According to the special steel belt production process provided by the invention, the detailed production process of a special steel belt is systematically shown, theprocess is simple and easy to operate, meanwhile, detailed and systematic treatment is conducted on pollution sources easily generated in the process, environmental pollution is avoided, the production noise is lowered, and the production environment is optimized.

Owner:浙江恒震特种材料股份有限公司

Method for mixing solid granules and syrup uniformly

ActiveCN102524488AImprove qualityImprove securityConfectionerySweetmeatsFood safetyWorking environment

The invention discloses a method for mixing solid granules and syrup uniformly. The method comprises a syrup blanking device, a solid granule blanking device and a mixing device, wherein after mixing with the pneumatically-jetted solid granules in a three-way pipeline through which the syrup flows without stirring, the syrup naturally flows, cools and cures, so that the solid granules are dispersed optimally. According to the method, different from the conventional stirring mixed mode of the solid granules and the syrup, a new field of the swing type mixing of the syrup is developed, so that the processing means of multiple series of the syrup in food processing industry can be improved, the quality of food processing is improved, the food safety performance is improved, the development of new series of products is promoted, and the method has advantages in reduction of energy consumption and production noise and improvement of work environment of workers.

Owner:SHANGHAI GUANSHENGYUAN FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com