Special steel belt production process

A production process and technology for steel strips, applied in the field of special steel strip production processes, can solve problems such as difficult implementation and cumbersome processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

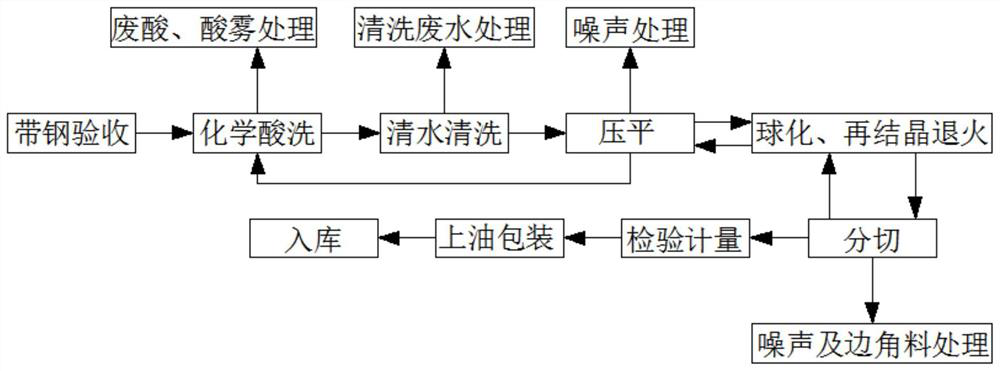

[0026] Please refer to figure 1 , figure 1 It is a flow diagram of a preferred embodiment of the special steel strip production process provided by the present invention. A special steel strip production process, comprising the following steps:

[0027] S1: Strip steel acceptance, check the purchased strip steel raw materials to ensure that there are no quality problems before acceptance;

[0028] S2: Chemical pickling, put the strip steel raw material after acceptance into the pickling tank, pickle with dilute hydrochloric acid solution, and treat the waste acid and acid mist generated by pickling;

[0029] S3: Cleaning with clean water. After pickling, use clean water to rinse off the residual acid solution on the surface of the strip steel raw material, and treat the cleaning wastewater after cleaning with clean water;

[0030] S4: Flattening, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com