Photographing recognition system of clamp assembling machine

A technology of identification system and assembly machine, applied in the field of machinery, can solve the problems of easy clamping, low efficiency, and inability to place the robot smoothly, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

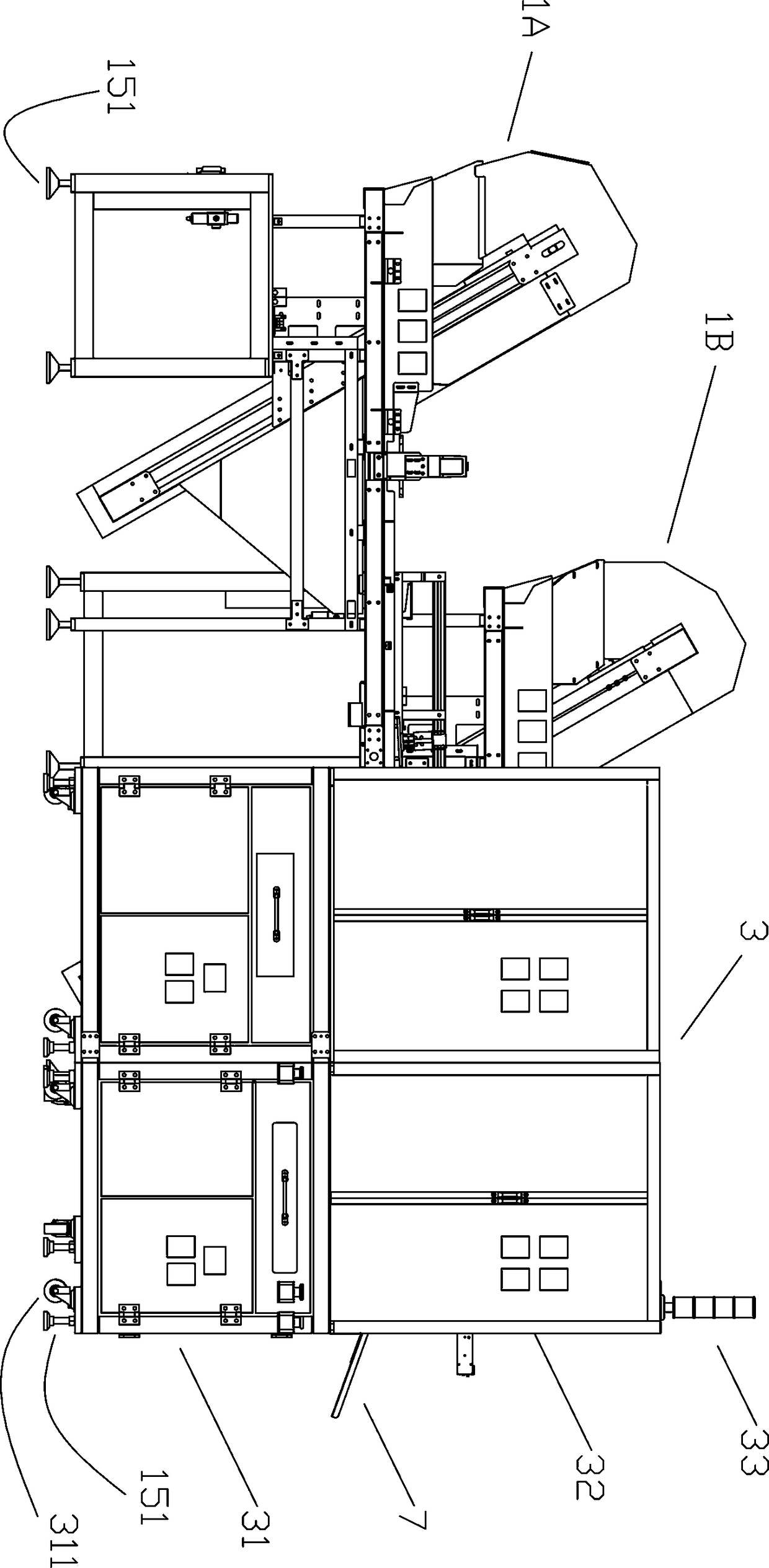

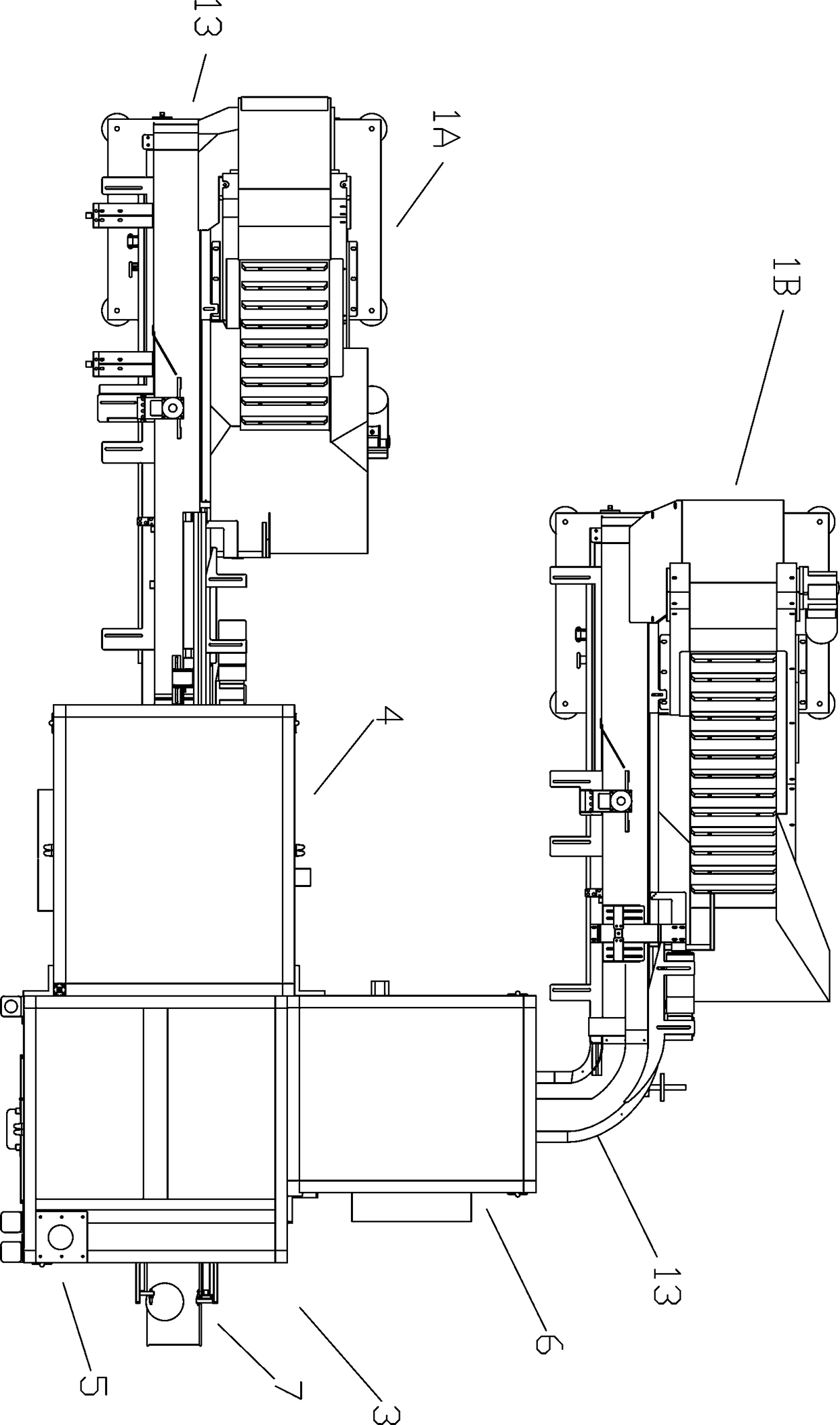

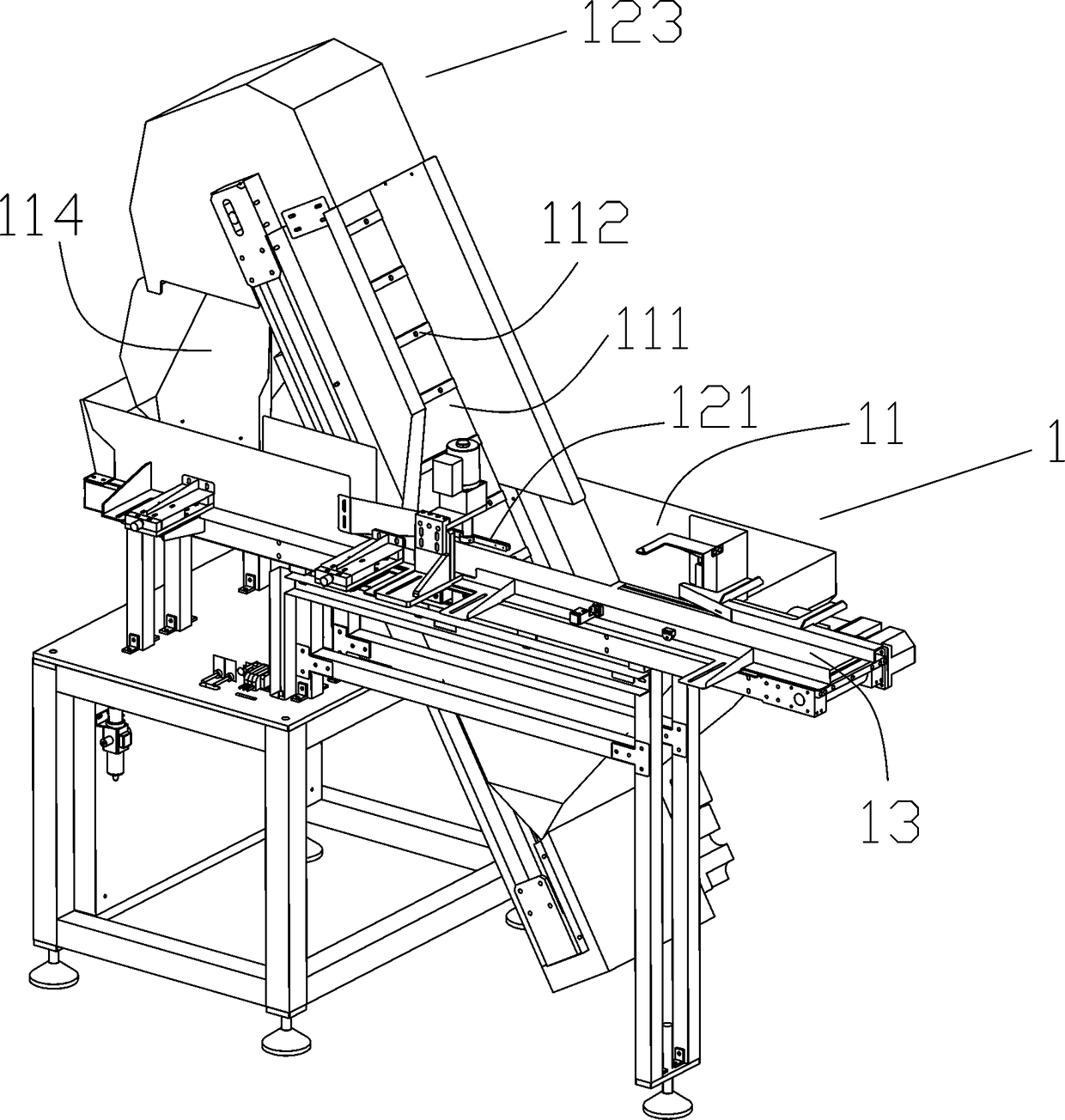

[0028] Such as Figure 1~Figure 9 As shown, a hoop assembly machine includes a feeding mechanism 1, the feeding mechanism 1 is divided into an inner hoop feeding mechanism 1B and an outer hoop feeding mechanism 1A, a transmission mechanism 13 connected with the feeding mechanism 1, and a transmission mechanism 13 is provided with a blocking mechanism 12 and a photographic identification system 14 in sequence, and the feeding mechanism 1 is connected with the operating mechanism 3 through a transmission mechanism 13;

[0029] In a preferred embodiment of the present invention, as Figure 1~Figure 4 As shown, the feeding mechanism 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com