Notching press for U-shaped workepiece

A technology for notching machines and workpieces, which is applied in the field of U-shaped workpiece notching machines, and achieves the effects of reasonable structural design, improved precision, and reduced production noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

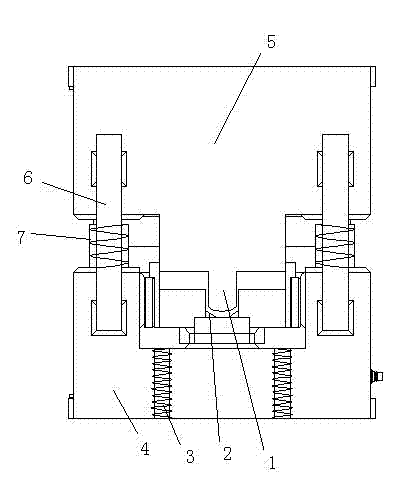

[0011] see figure 1 , U-shaped workpiece notching machine, with an upper die 5 and a lower die 4 arranged longitudinally.

[0012] The bottom of the upper die 5 is connected with several positioning rods 6, and the bottom of the upper die 5 is provided with a cylindrical punch 1.

[0013] The lower die 4 is provided with several spring sleeves 7 that cooperate with the positioning rod 6, the middle part of the lower die 4 is provided with a U-shaped die 2, and both sides of the bottom of the U-shaped die 2 are provided with annular runners 3.

[0014] The above content is only an example and description of the structure of the present invention. Those skilled in the art make various modifications or supplements to the described specific embodiments or replace them in similar ways, as long as they do not deviate from the structure of the invention or Anything beyond the scope defined in the claims shall belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com