Patents

Literature

106results about How to "Reduce echo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

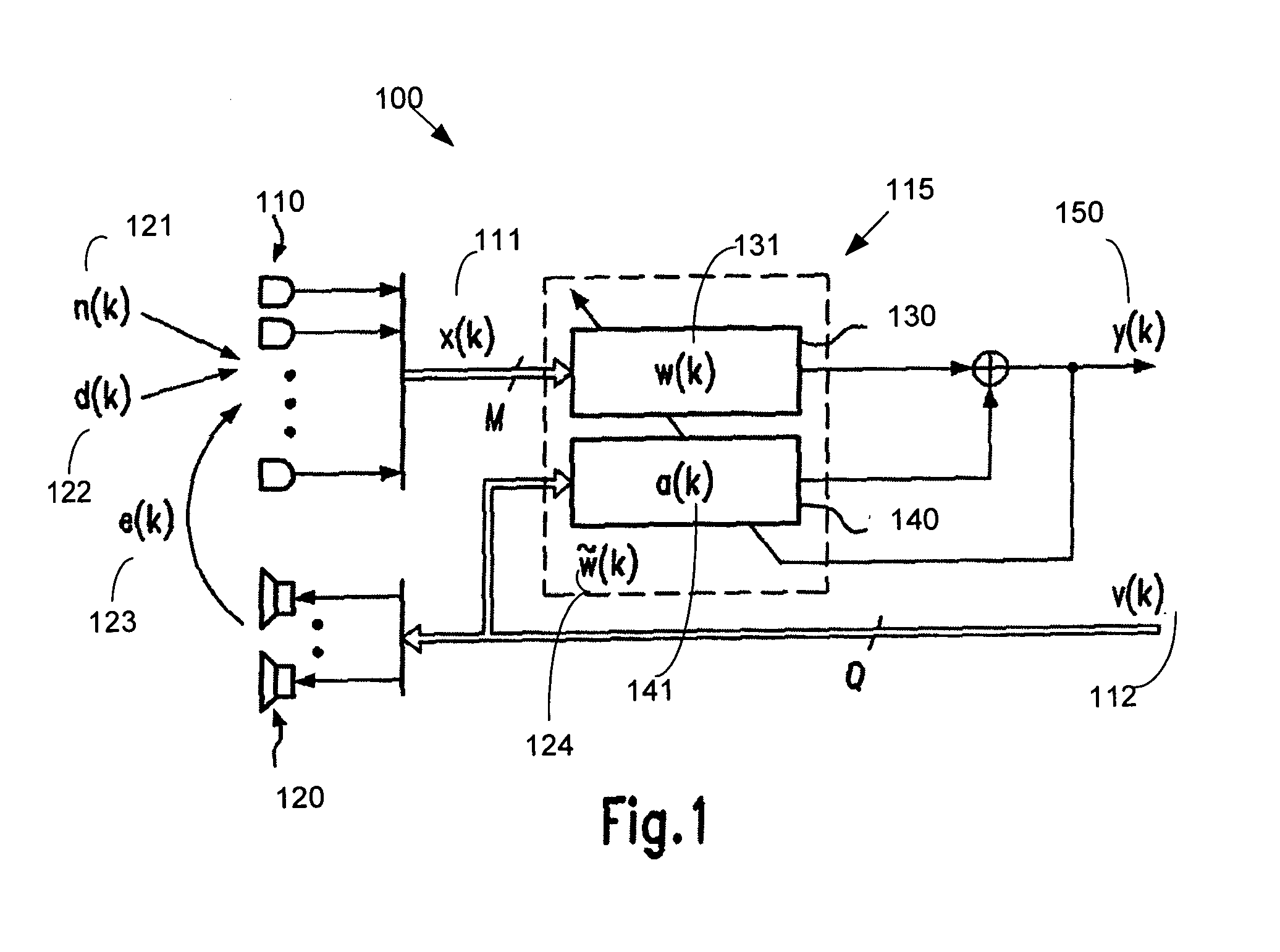

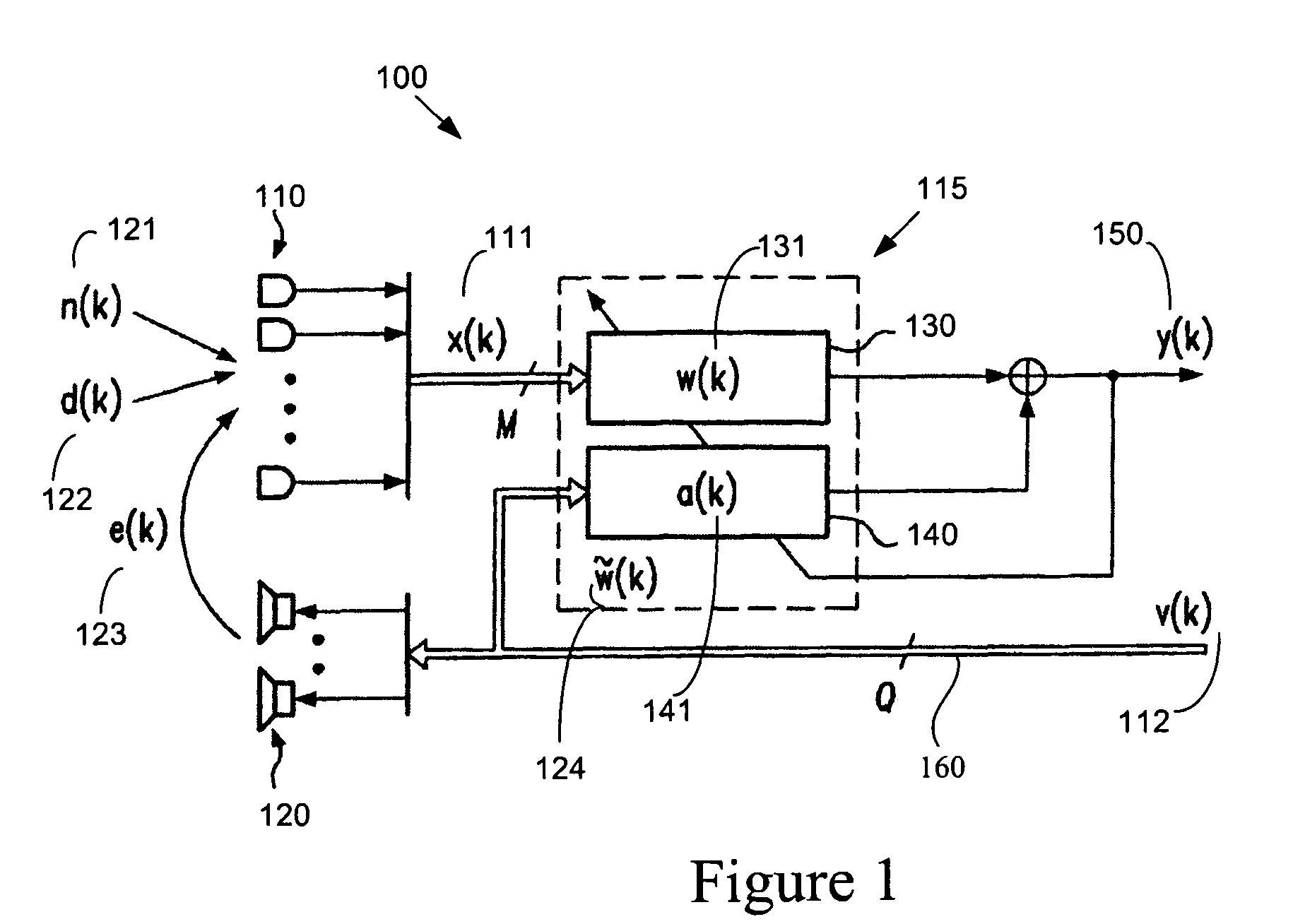

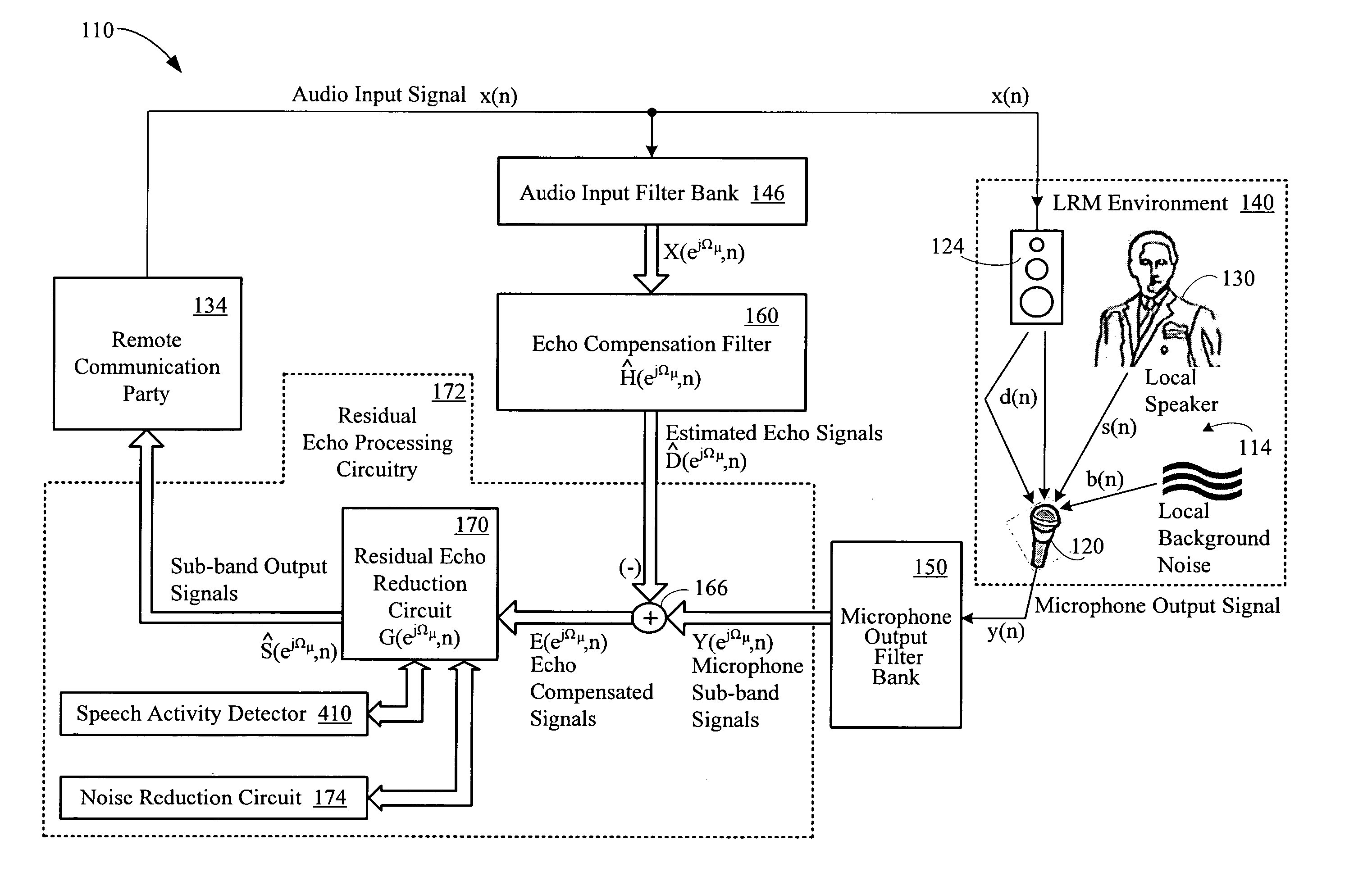

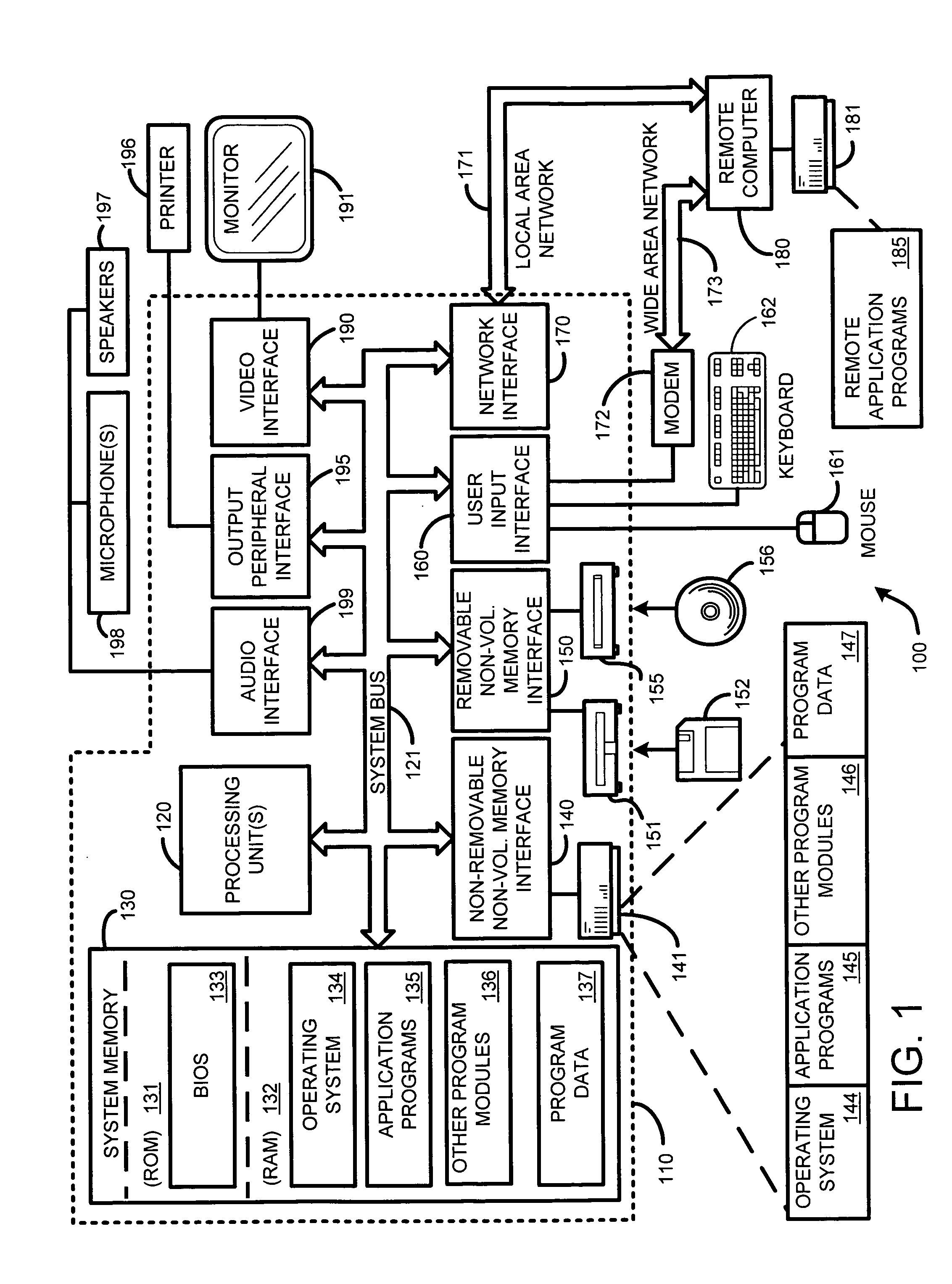

Speech signal processing with combined noise reduction and echo compensation

ActiveUS20060153360A1Improve acoustic performanceReduce echoTwo-way loud-speaking telephone systemsSpeech recognitionAcoustic noise reductionIn vehicle

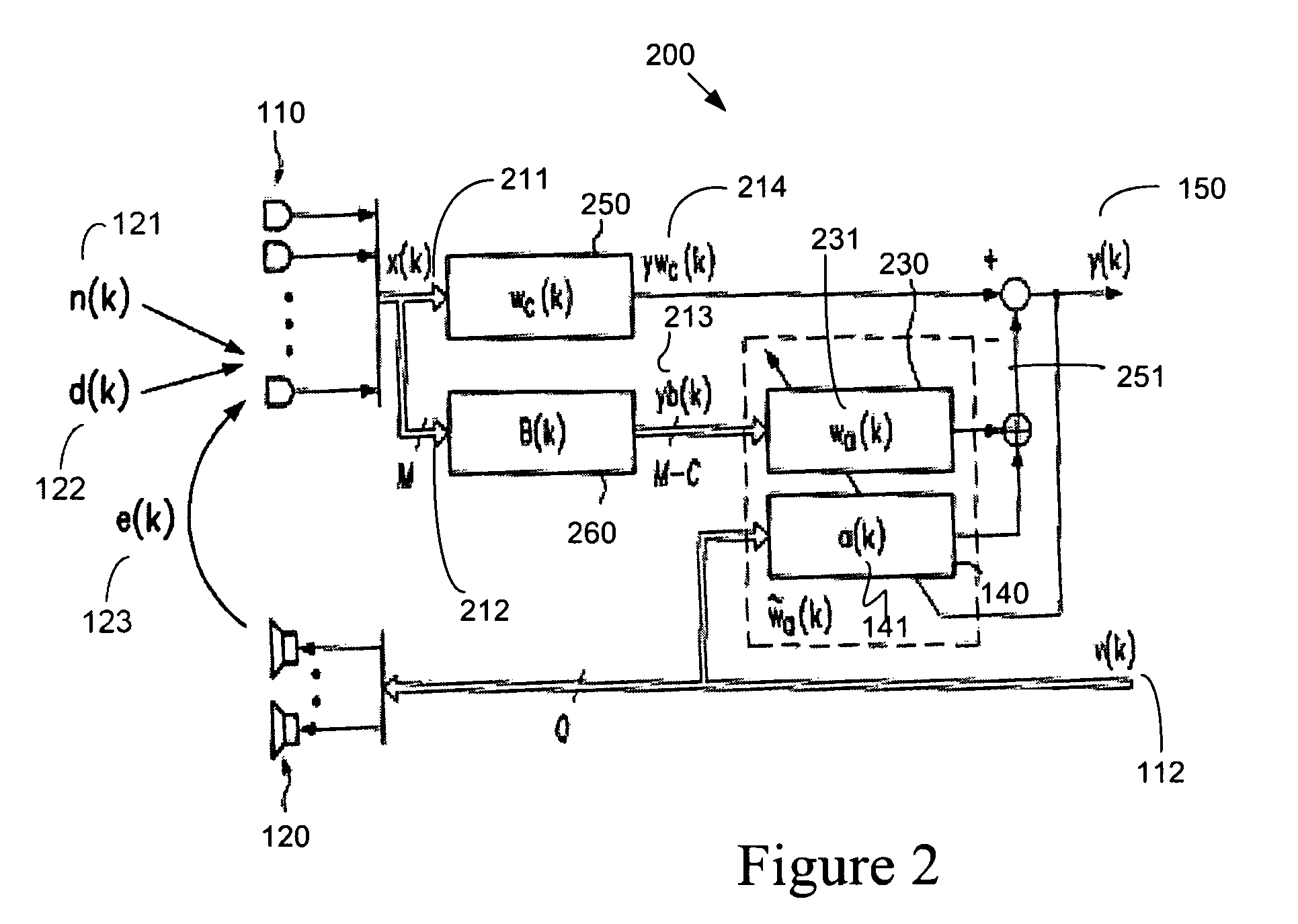

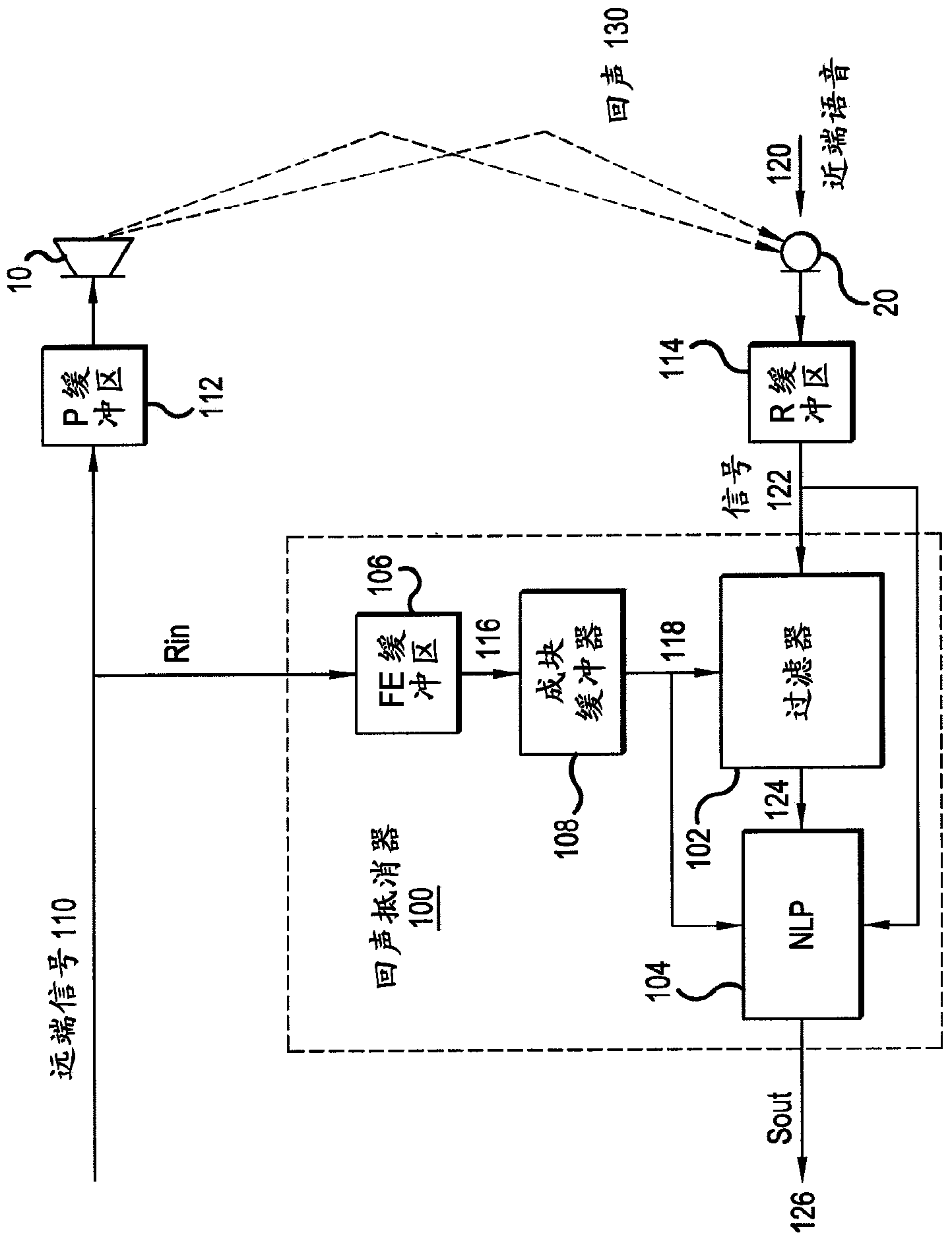

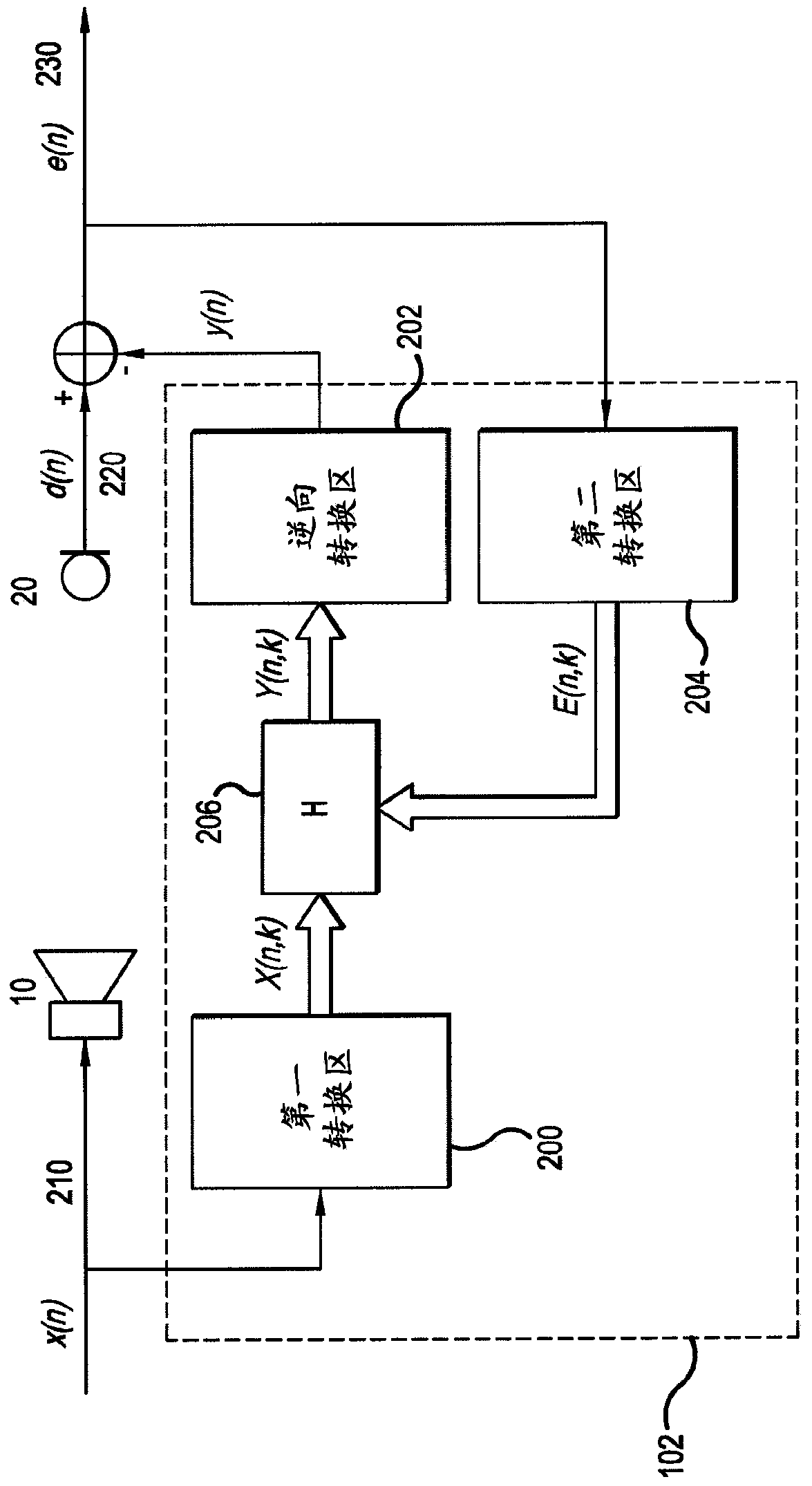

A speech signal processing system combines acoustic noise reduction and echo cancellation to enhance acoustic performance. The speech signal processing system may be used in vehicles or other environments where noise-suppressed communication is desirable. The system includes an adaptive beamforming signal processing unit, an adaptive echo compensating unit to reduce acoustic echoes, and an adaptation unit to combine noise reduction and adaptive echo compensating.

Owner:NUANCE COMM INC

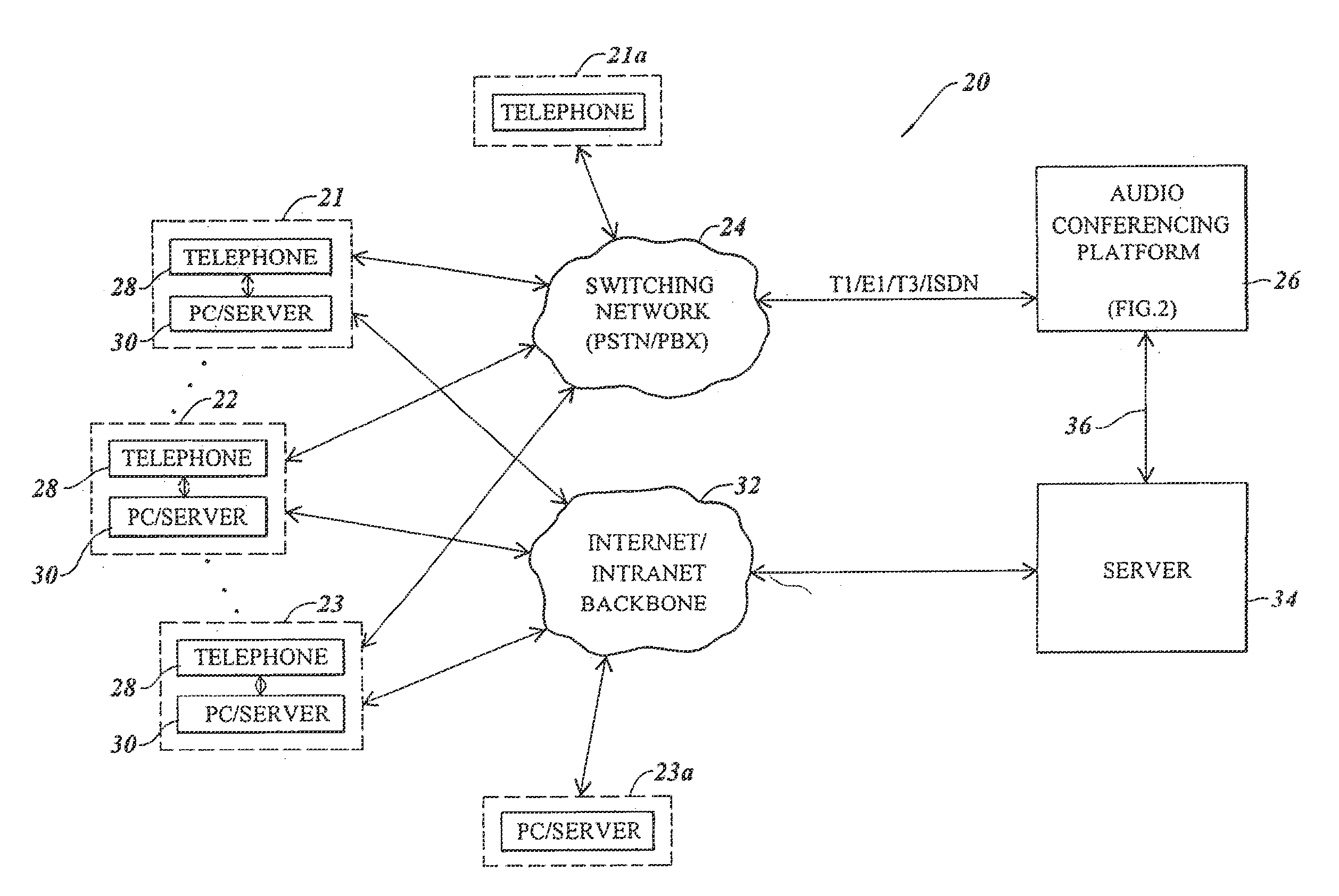

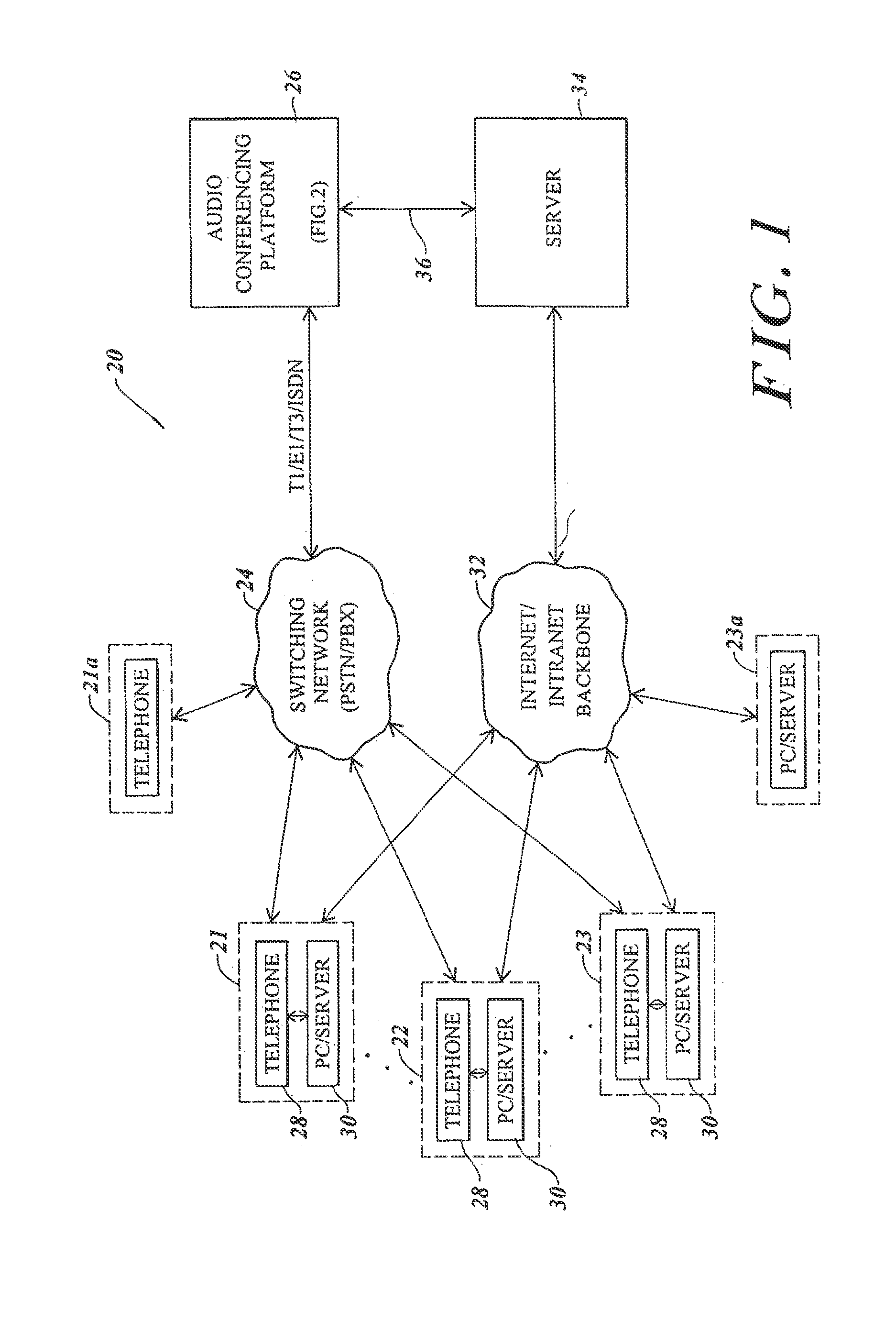

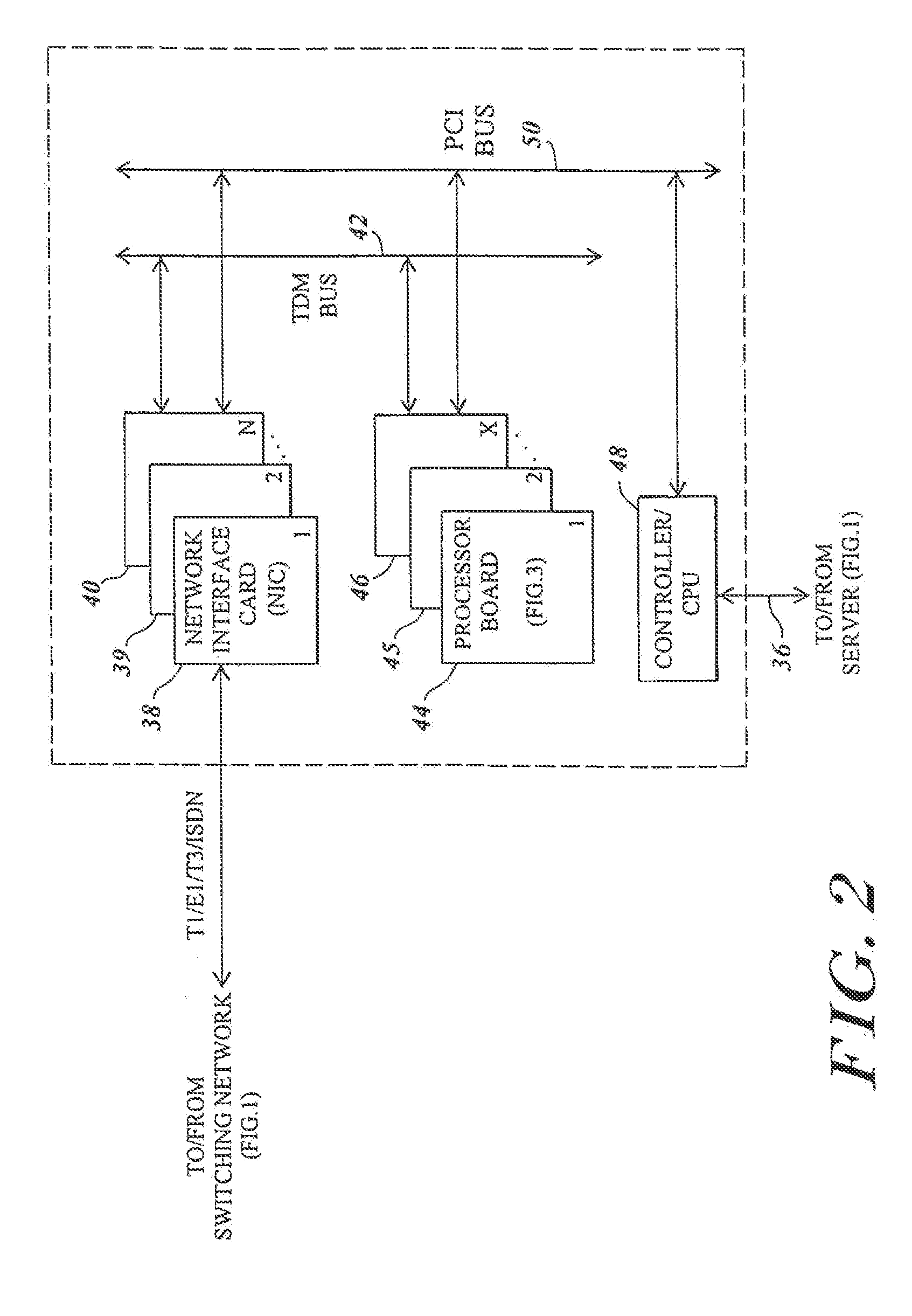

Audio conference platform with dynamic speech detection threshold

InactiveUS20130028404A1Improve conferencingReduce echoSpecial service provision for substationTwo-way loud-speaking telephone systemsEngineeringSpeech sound

The present invention comprises a method for audio / video conferencing. In a preferred embodiment, the method comprises using a dynamic threshold value to determine whether there is speech on a line. One aspect, the method comprises determining a dynamic threshold value based on one or more characteristics of signals received on a port, associating that dynamic threshold value with the port; and comparing one or more characteristics of signals subsequently received on the port to the dynamic threshold value. Signals received over a plurality of ports are summed, but for ports whose signal characteristics have a specified relationship to the dynamic threshold value associated with that port, signals are not contained in the sum.

Owner:HEWLETT PACKARD DEV CO LP

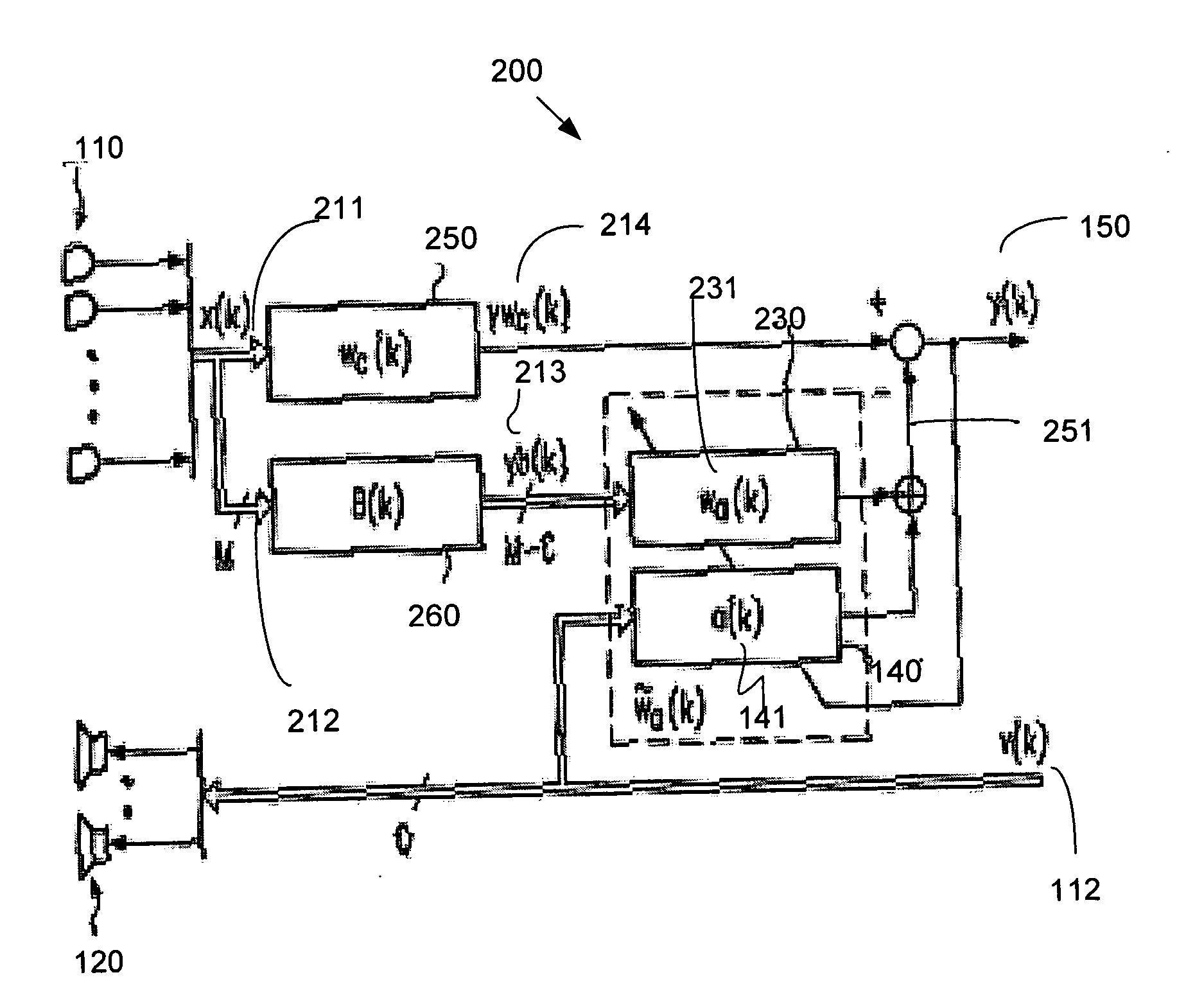

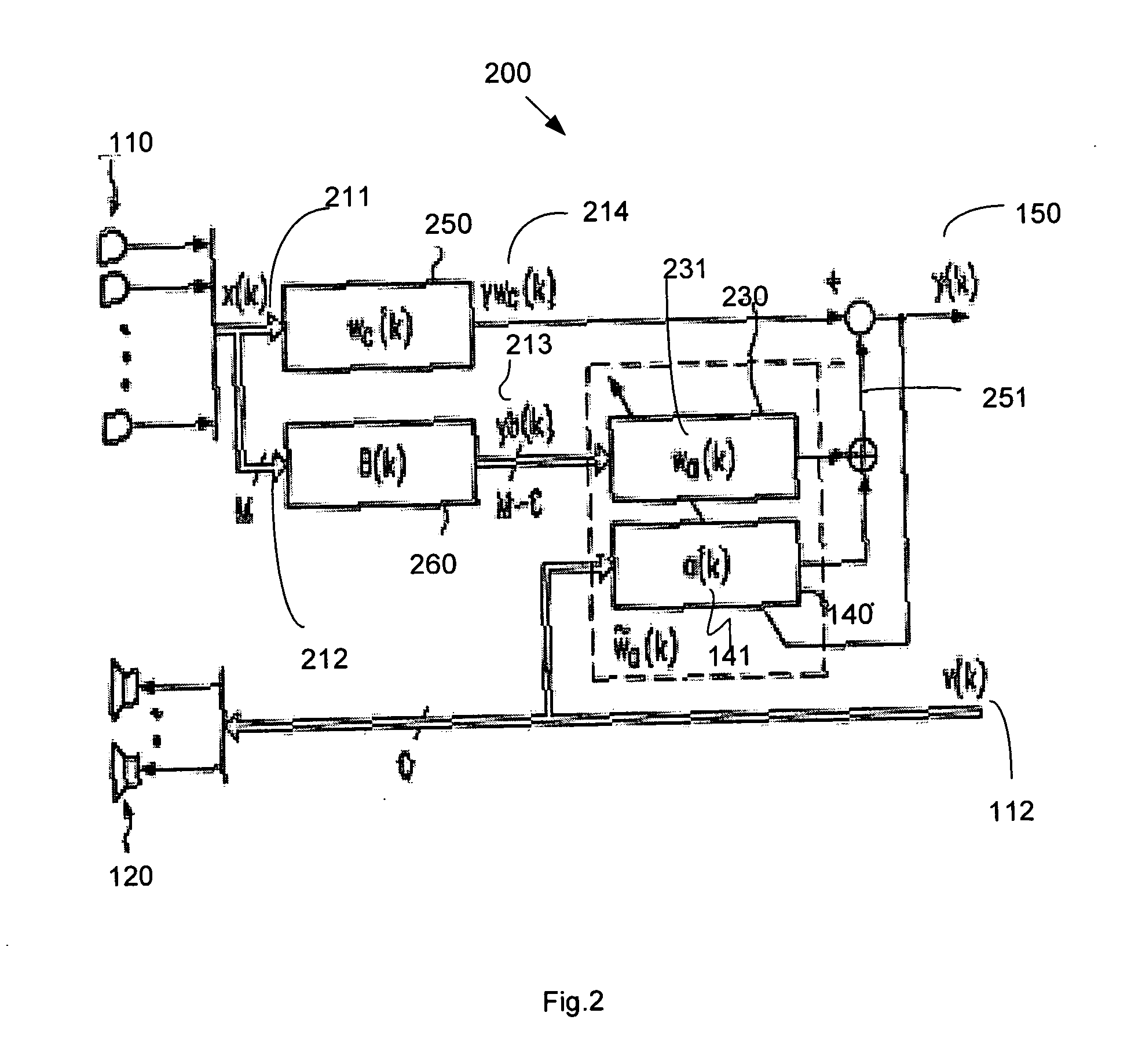

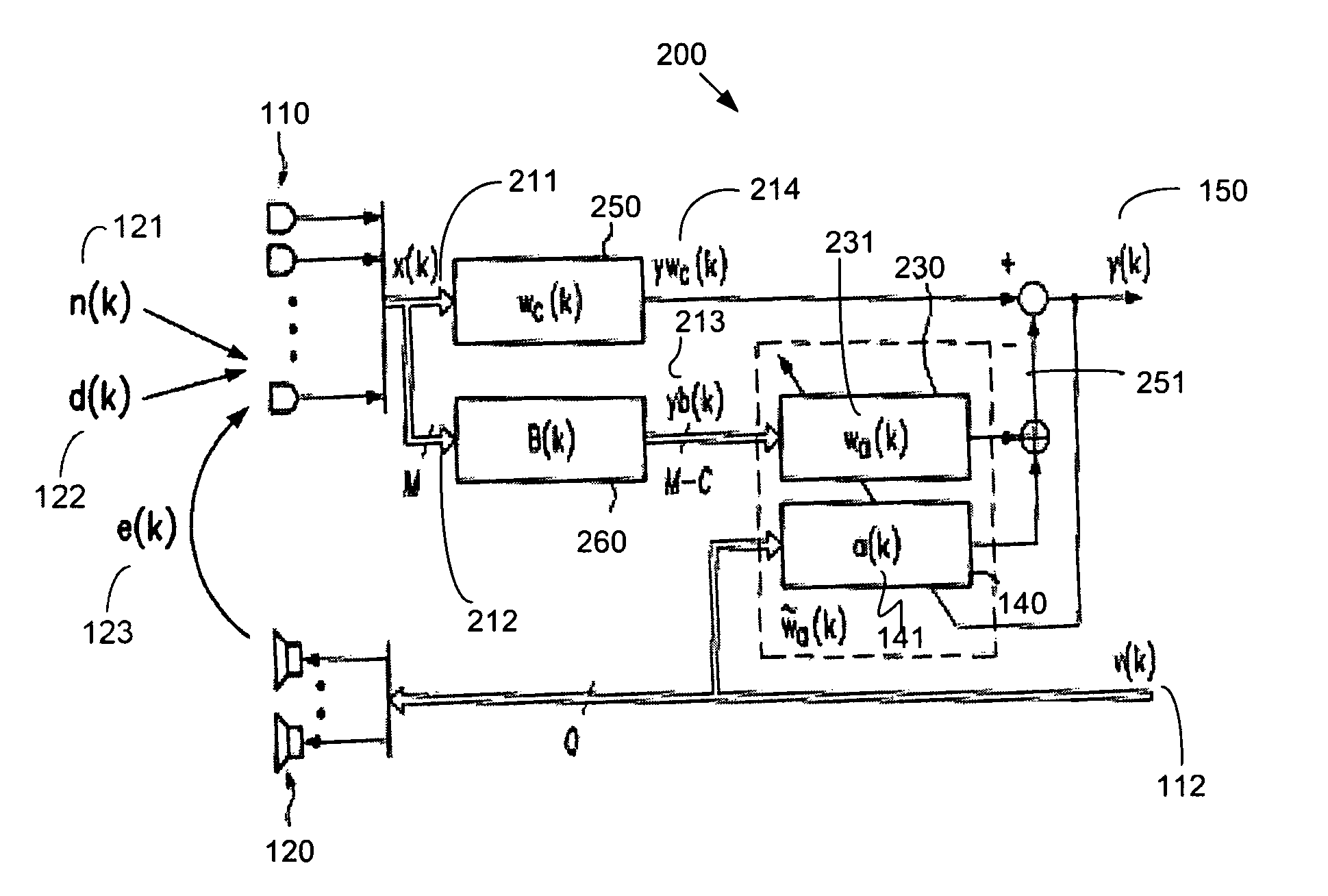

Speech signal processing with combined noise reduction and echo compensation

ActiveUS7747001B2Improve acoustic performanceReduce echoTwo-way loud-speaking telephone systemsSpeech recognitionAcoustic noise reductionIn vehicle

A speech signal processing system combines acoustic noise reduction and echo cancellation to enhance acoustic performance. The speech signal processing system may be used in vehicles or other environments where noise-suppressed communication is desirable. The system includes an adaptive beamforming signal processing unit, an adaptive echo compensating unit to reduce acoustic echoes, and an adaptation unit to combine noise reduction and adaptive echo compensating.

Owner:NUANCE COMM INC

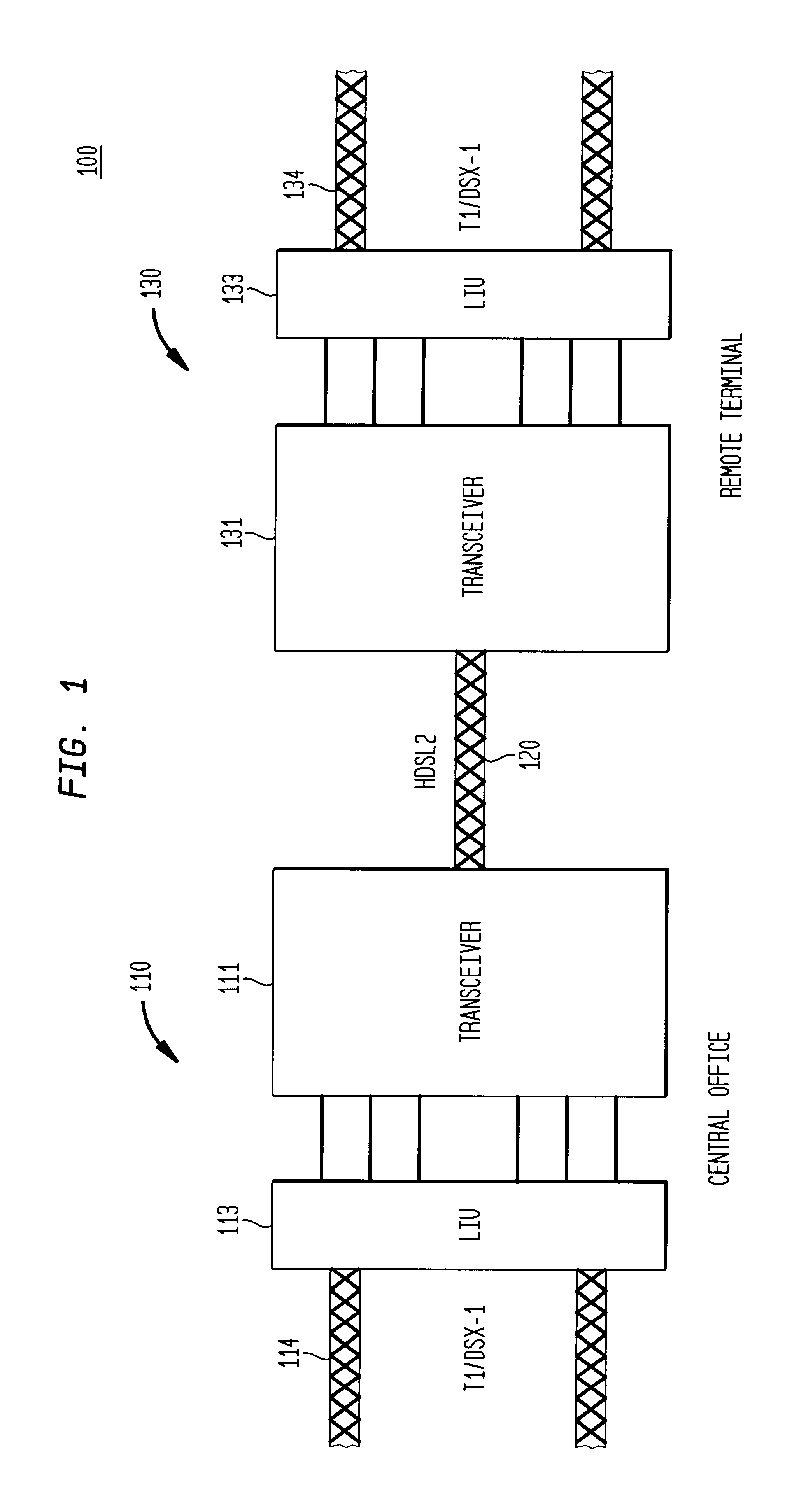

Method and system for data rate optimization in a digital communication system

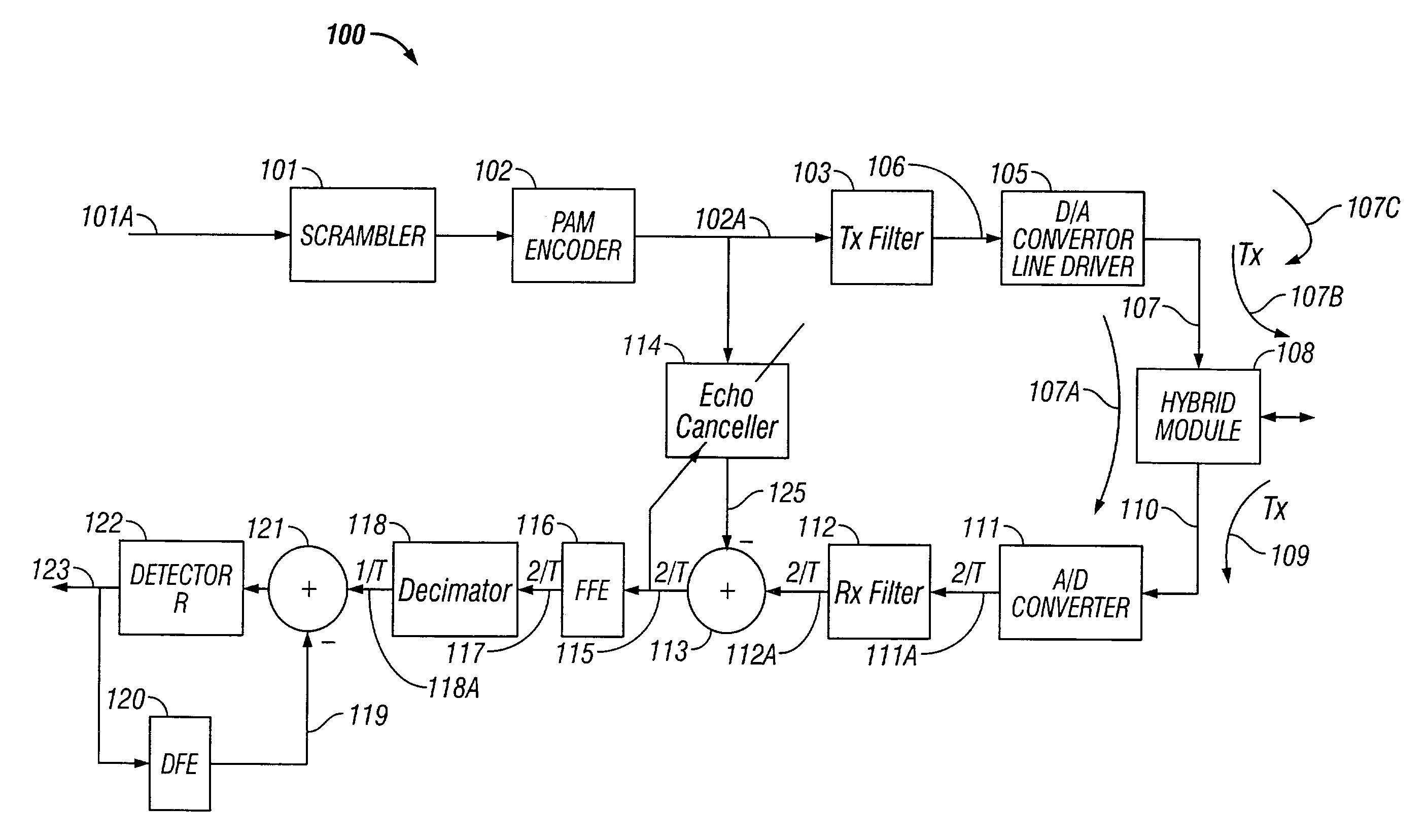

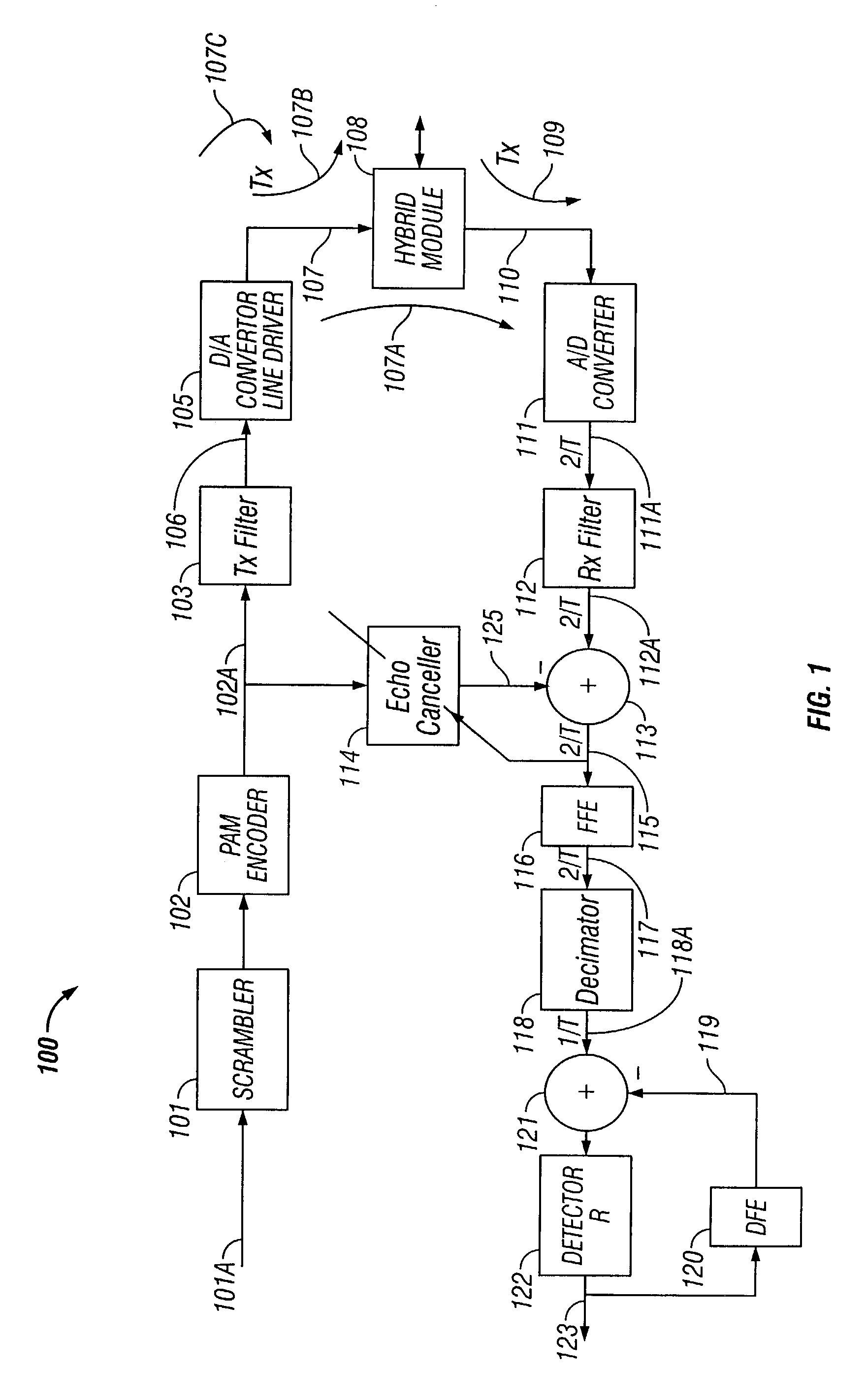

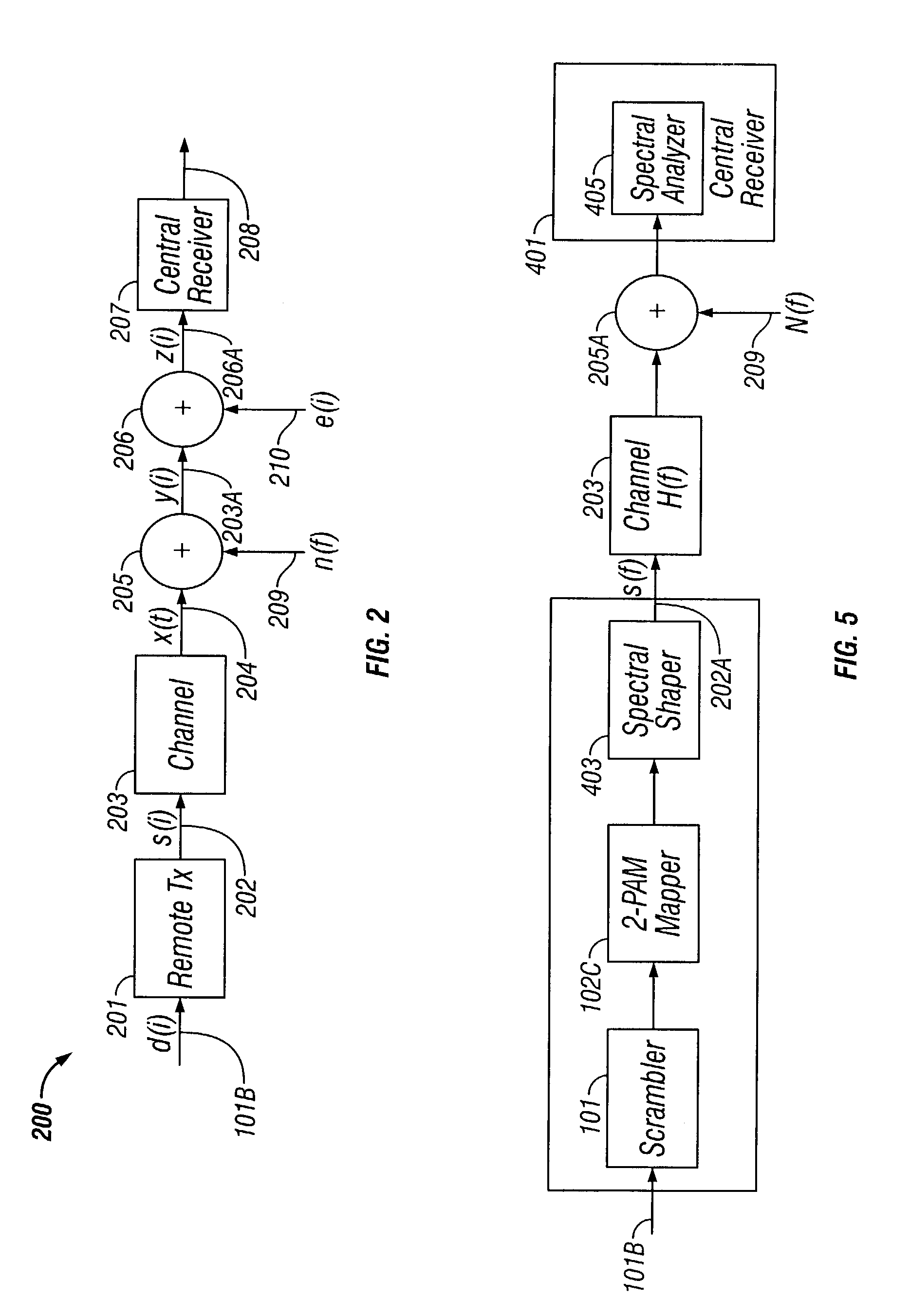

InactiveUS7187719B2Large bit rateEasy to operatePower managementTransmission control/equalisingNoise power spectrumSignal-to-quantization-noise ratio

A method and for optimizing bit rate throughput in a digital communication system is provided. The method includes establishing a relationship between signal to noise ratio and plural symbol rates for a particular constellation size. The method also includes determining noise power spectral density (N(f)), wherein N(f) is determined during a silent period of line probing; determining Xk(f), wherein Xk(f) is determined by turning on a remote station transmit signal, after N(f) has been measured and determining residual echo Ek(f), wherein Ek(f) is determined by turning on a central station echo canceller.

Owner:MACOM TECH SOLUTIONS HLDG INC

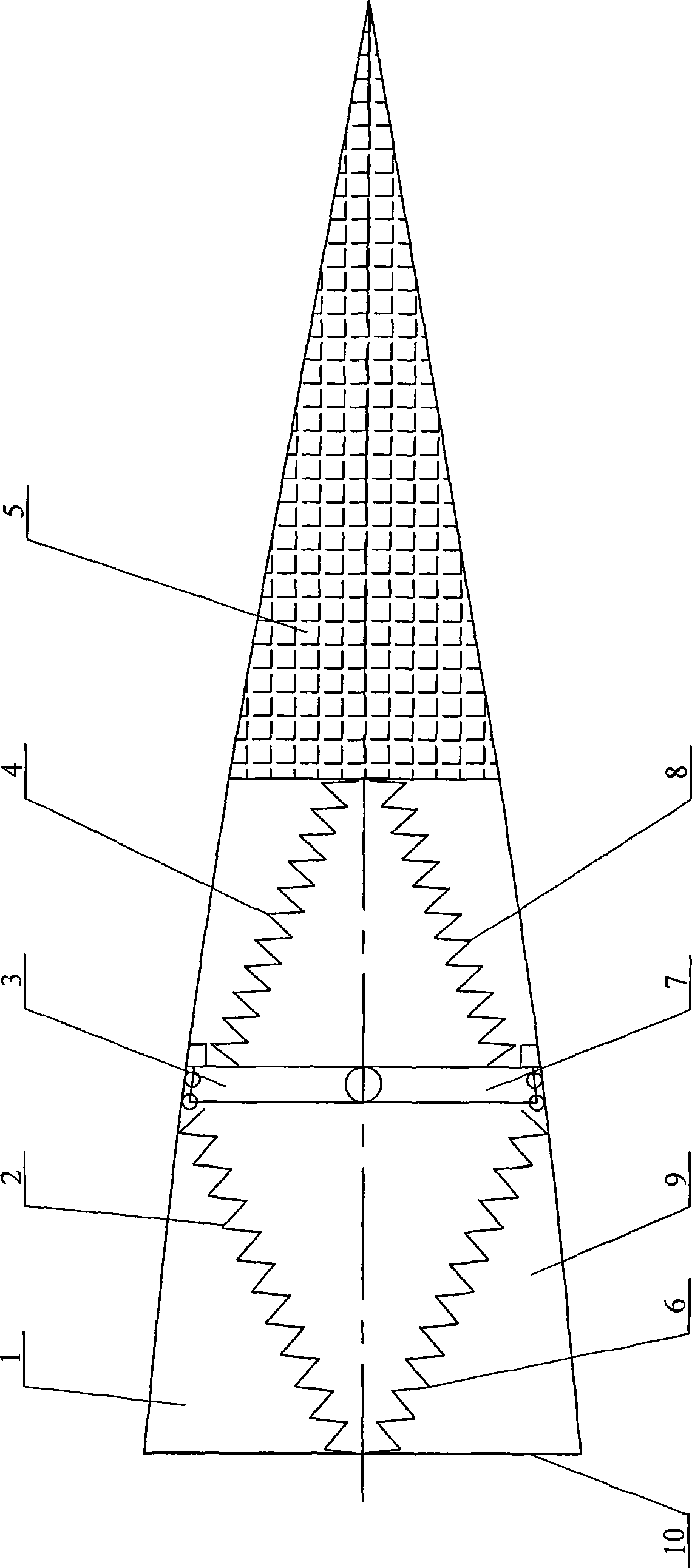

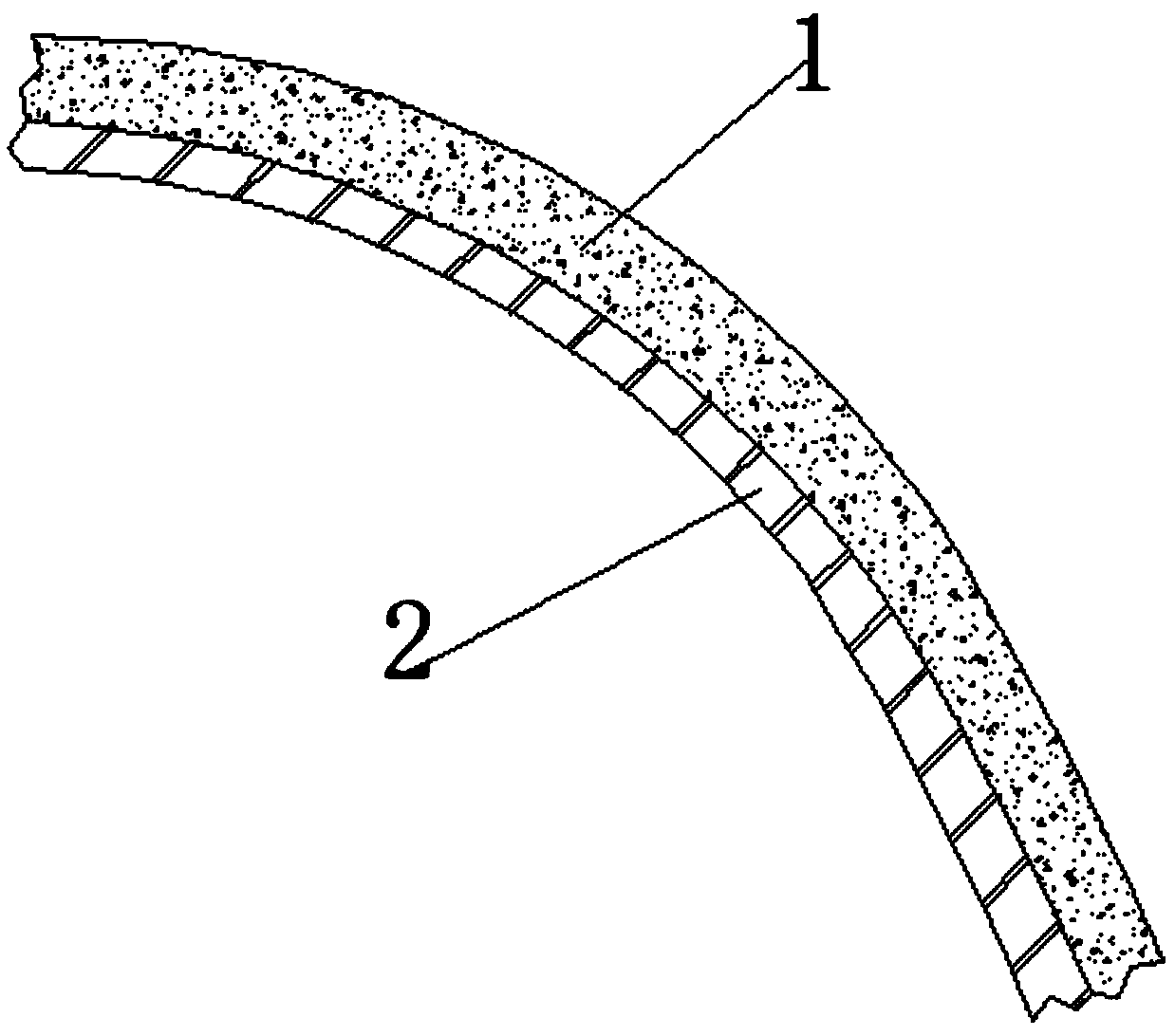

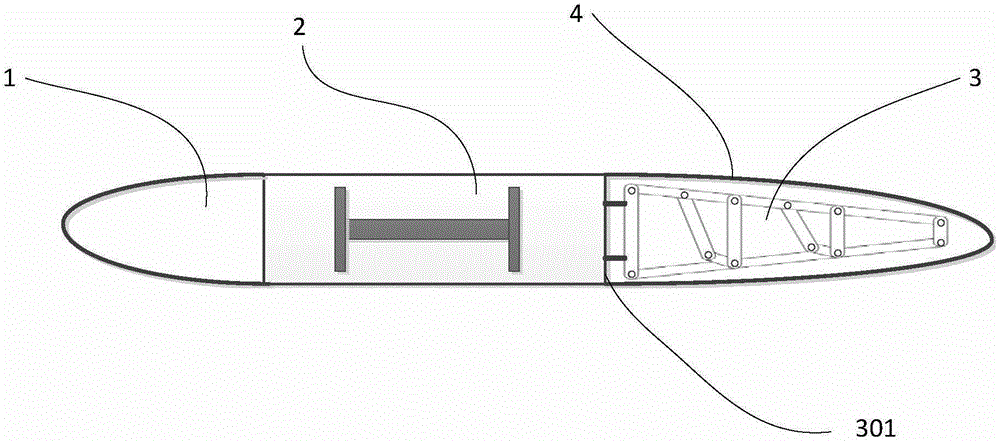

Shape memory spring driven hinder margin camber variable wing

InactiveCN101503113AImprove pressure distributionIncrease lift coefficientWing adjustmentsEngineeringMetal sheet

The invention provides a wing with changeable trailing edge camber driven by a shape memory spring, relating to a wing with a changeable trailing edge camber, and aiming at the problems of traditional airplanes that a mechanism is complex and heavy, airflow breakaway is quite early and aerodynamic efficiency is low. The front end face and the back end face of an upper metal plate are fixedly connected with the front end faces of a connecting plate and the trailing edge; the front end face and the back end face of the lower metal plate are fixedly connected with the front end face of the connecting plate and the trailing edge; the same side surface of the upper metal plate and the lower metal plate are fixed with an upper prop stay and a lower prop stay; the two ends of a first shape memory spring are fixedly connected with a fixed plate and the upper metal plate; the two ends of a second shape memory spring are fixedly connected with the front end faces of the upper prop stay and the trailing edge; the two ends of a third shape memory spring are fixedly connected with the fixed plate and the lower metal plate; and the two ends of a fourth shape memory spring are fixedly connected with the front end faces of the lower prop stay and the trailing edge. The invention has the advantages of light weight, simple structure and high aerodynamic efficiency.

Owner:HARBIN INST OF TECH

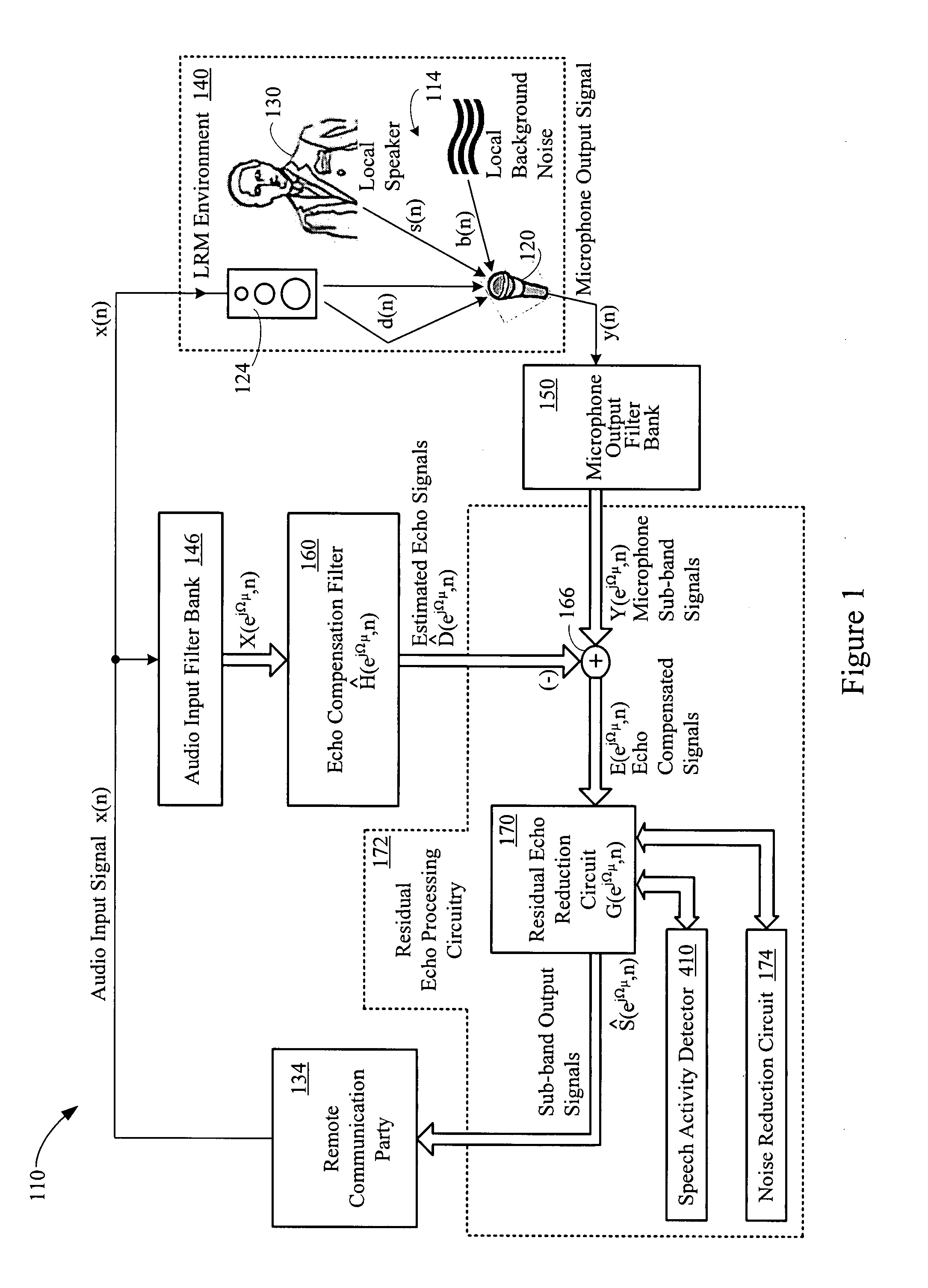

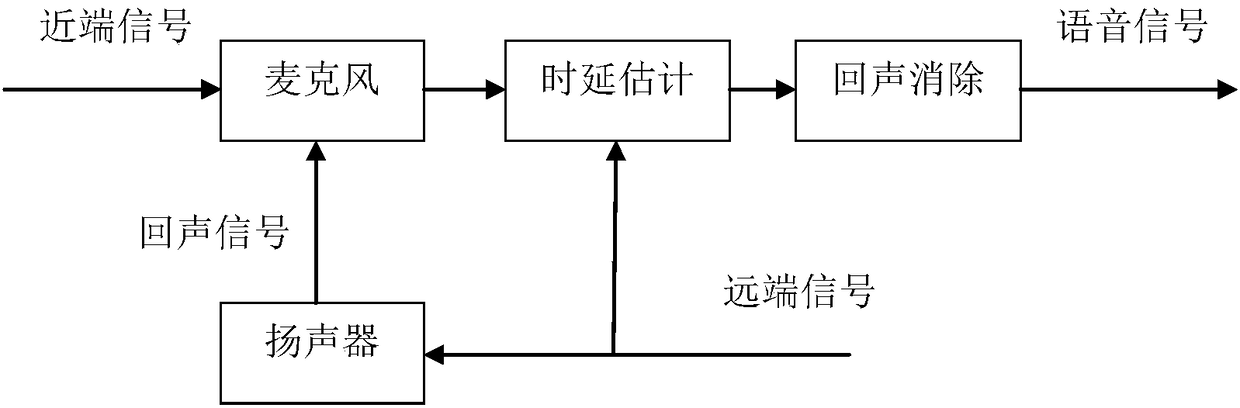

Echo reduction system

ActiveUS20080031467A1Quality improvementReduce echoInterconnection arrangementsPublic address systemsSignal onMicrophone signal

The present invention relates to a method for reducing an echo in a microphone signal generated by a microphone, comprising echo compensating the microphone signal by subtracting an estimated echo signal from the microphone signal to generate an echo compensated signal, detecting a speech activity of a local speaker on the basis of the microphone signal and the estimated echo signal and suppressing a residual echo in the echo compensated signal on the basis of the detected speech activity to obtain an output signal. The invention further relates to a system for processing a microphone signal generated by a microphone, comprising echo compensation filtering means configured to receive and echo compensate the microphone signal to output an echo compensated signal based on the received microphone signal, a speech activity detection means configured to detect speech activity of a local speaker by receiving and analyzing the echo compensated signal and to output a detection signal and a residual echo suppressing means configured to receive the detection signal and to receive and filter the echo compensated signal on the basis of the detection signal to output an output signal.

Owner:CERENCE OPERATING CO

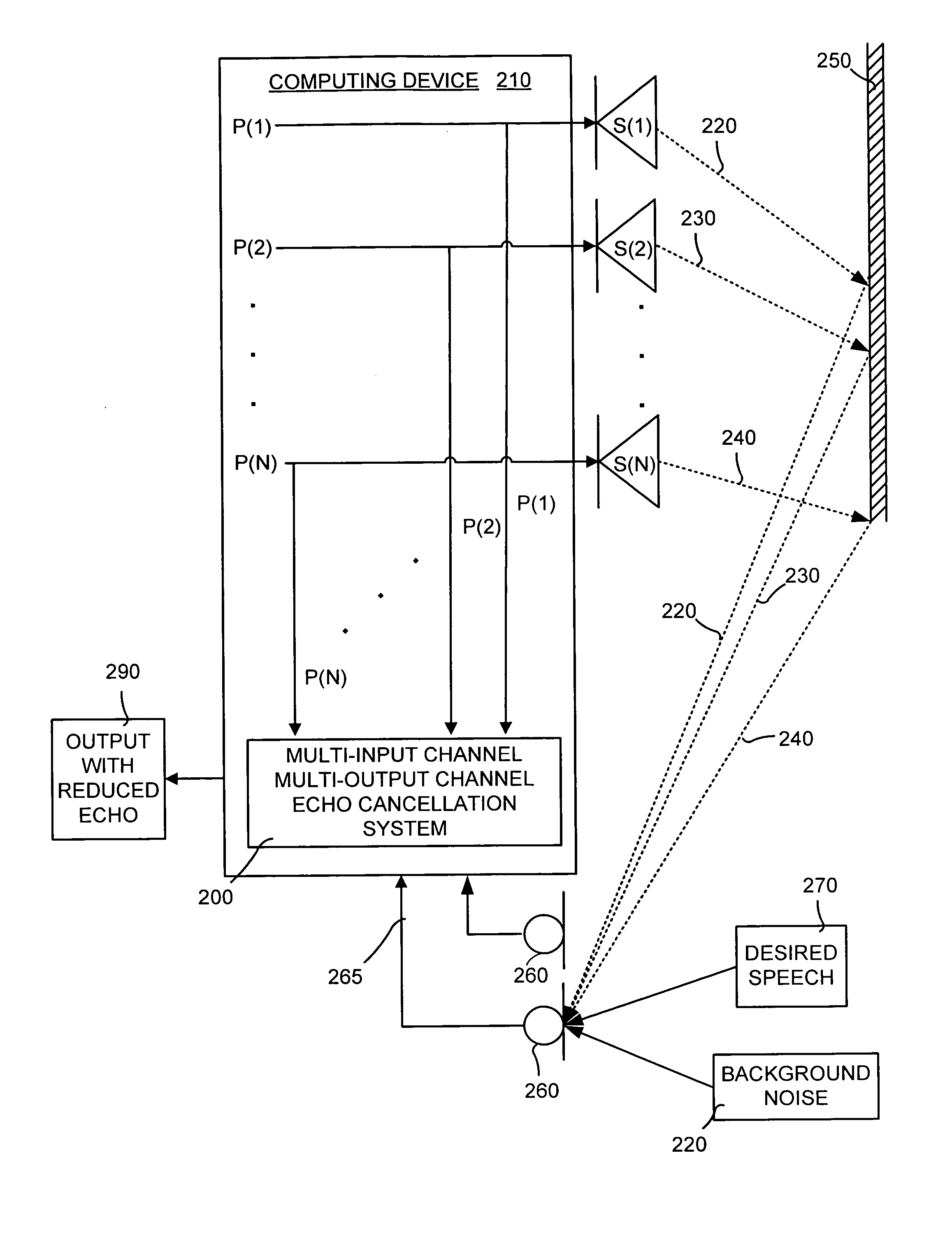

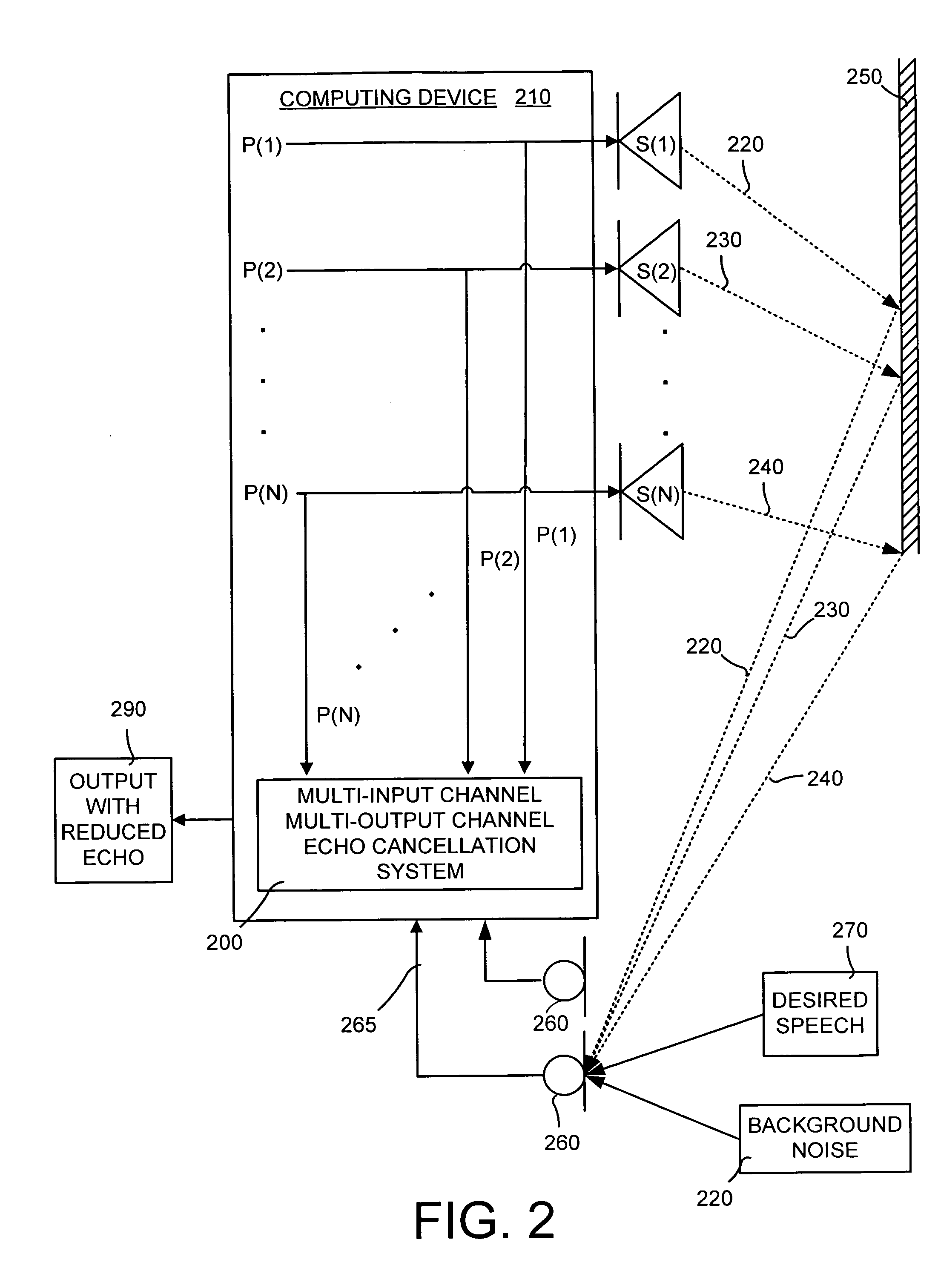

Multi-input channel and multi-output channel echo cancellation

InactiveUS20060002546A1Increase consumptionMinimize the numberTwo-way loud-speaking telephone systemsSpeech analysisMulti inputEngineering

An echo cancellation technique that can process multi-input microphone signals with only a small increase in the overall CPU consumption compared to implementing the algorithm for a single channel microphone signal. Furthermore, the invention provides an architecture that provides for echo cancellation for multiple applications in parallel with only a small increase in CPU consumption compared to a single instance of echo cancellation with a single microphone input and multi-output channel playback.

Owner:MICROSOFT TECH LICENSING LLC

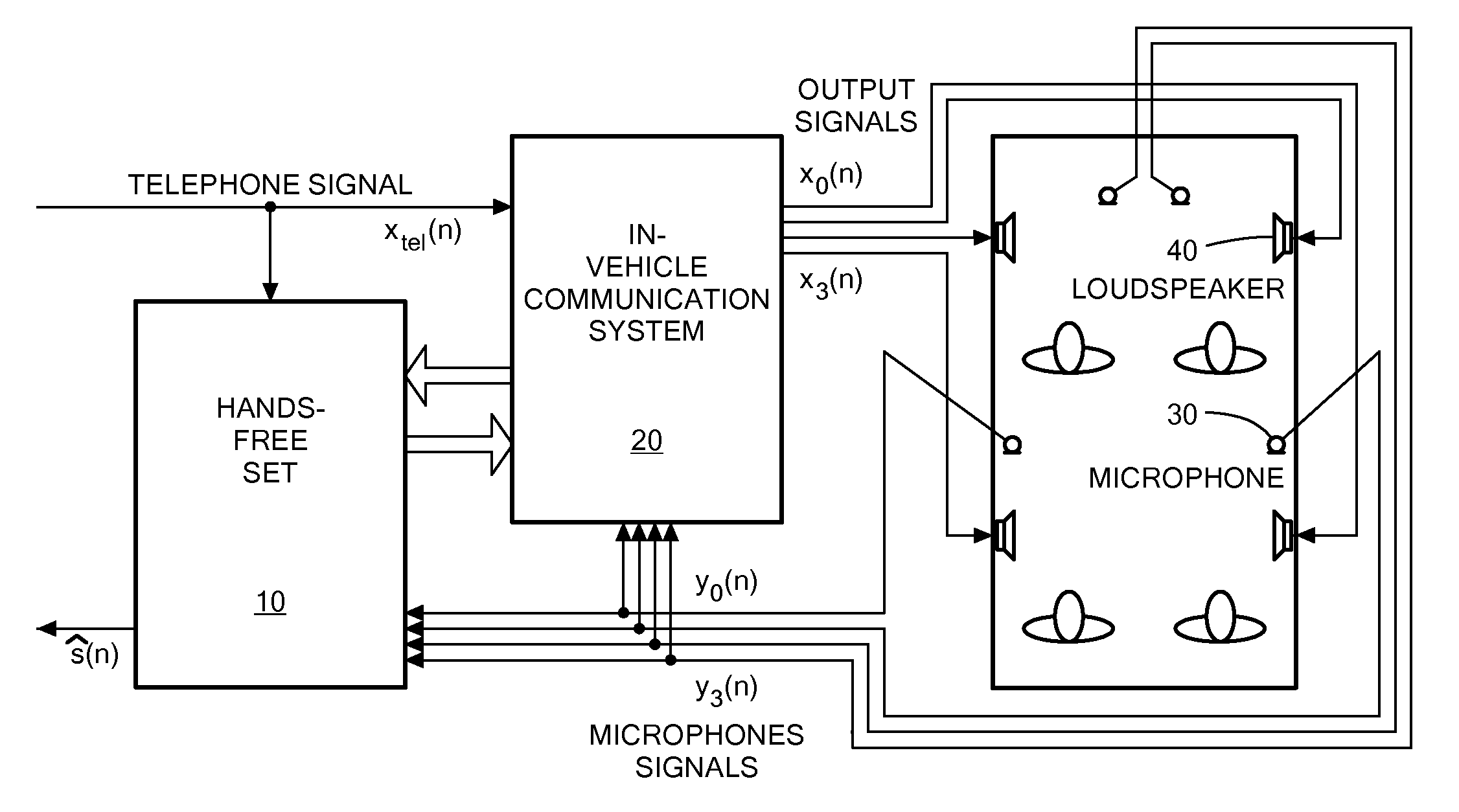

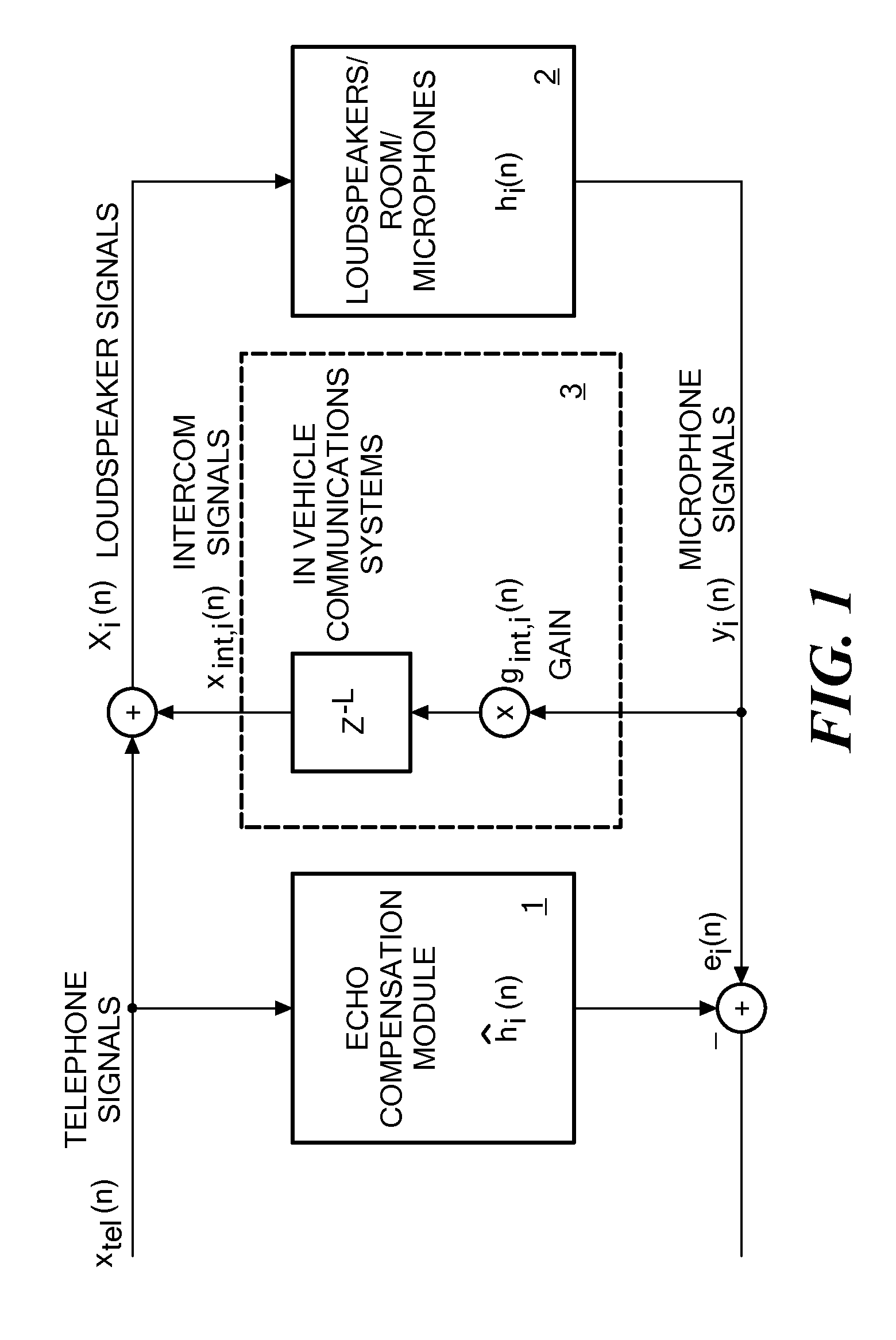

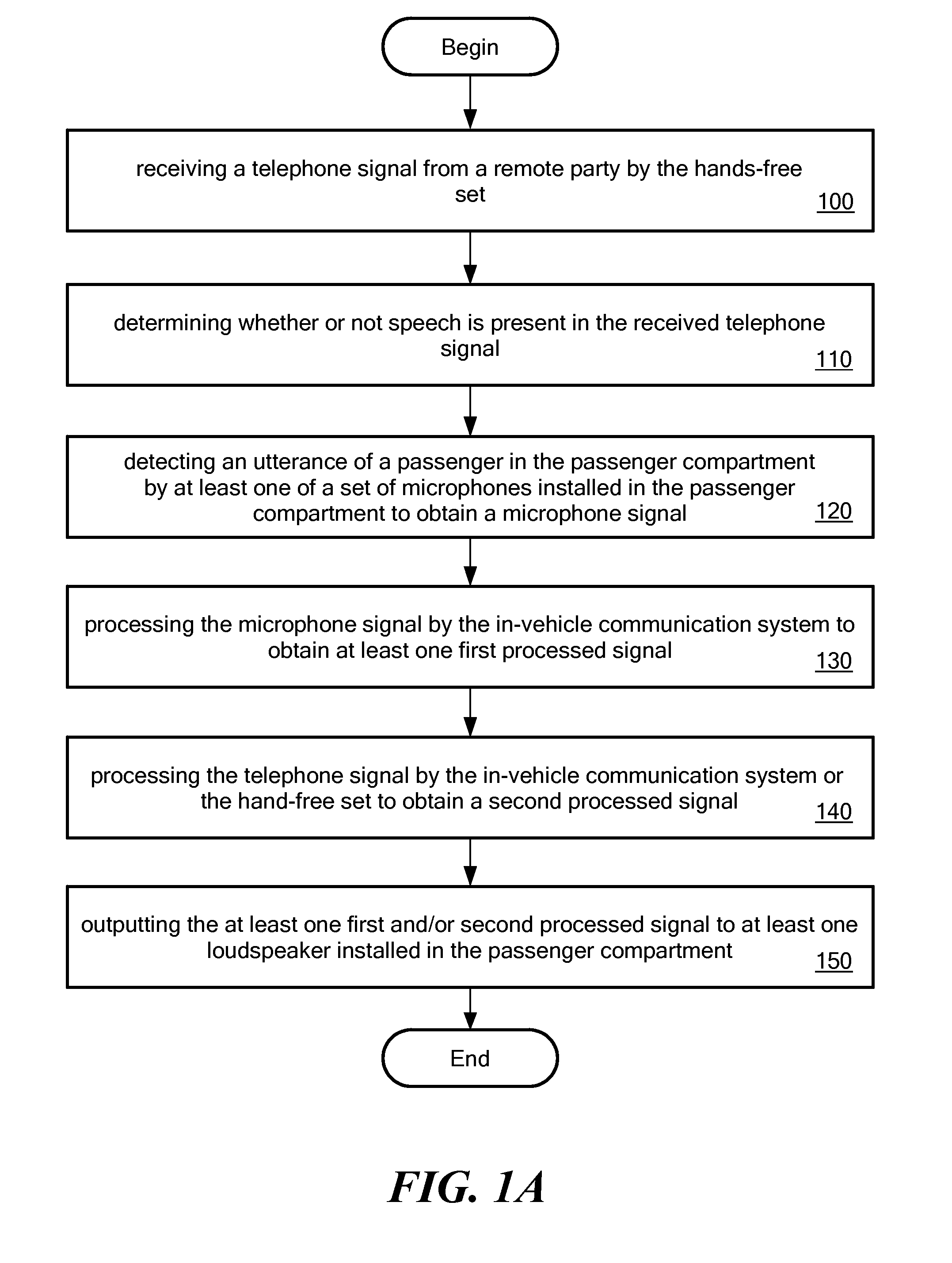

Hands-Free Telephony and In-Vehicle Communication

ActiveUS20100035663A1Efficient and reliable dampingReduce echoInterconnection arrangementsSpeech analysisDamping factorCommunications system

The present invention relates to a signal processing system, comprising a number of microphones and loudspeakers, a hands-free set configured to receive a telephone signal from a remote party and to transmit a microphone signal supplied by at least one of the microphones to the remote party; an in-vehicle communication system configured to receive a microphone signal supplied by at least one of the microphones; receive the telephone signal; amplify the microphone signal to obtain at least one first output signal; output the at least one first output signal and / or a second output signal corresponding to the telephone signal to at least one of the loudspeakers; and wherein the signal processing systems is configured to detect speech activity in the telephone signal and to control the in-vehicle communication system to reduce amplification of the microphone signal by a damping factor, if it is detected that speech activity is present in the telephone signal.

Owner:CERENCE OPERATING CO

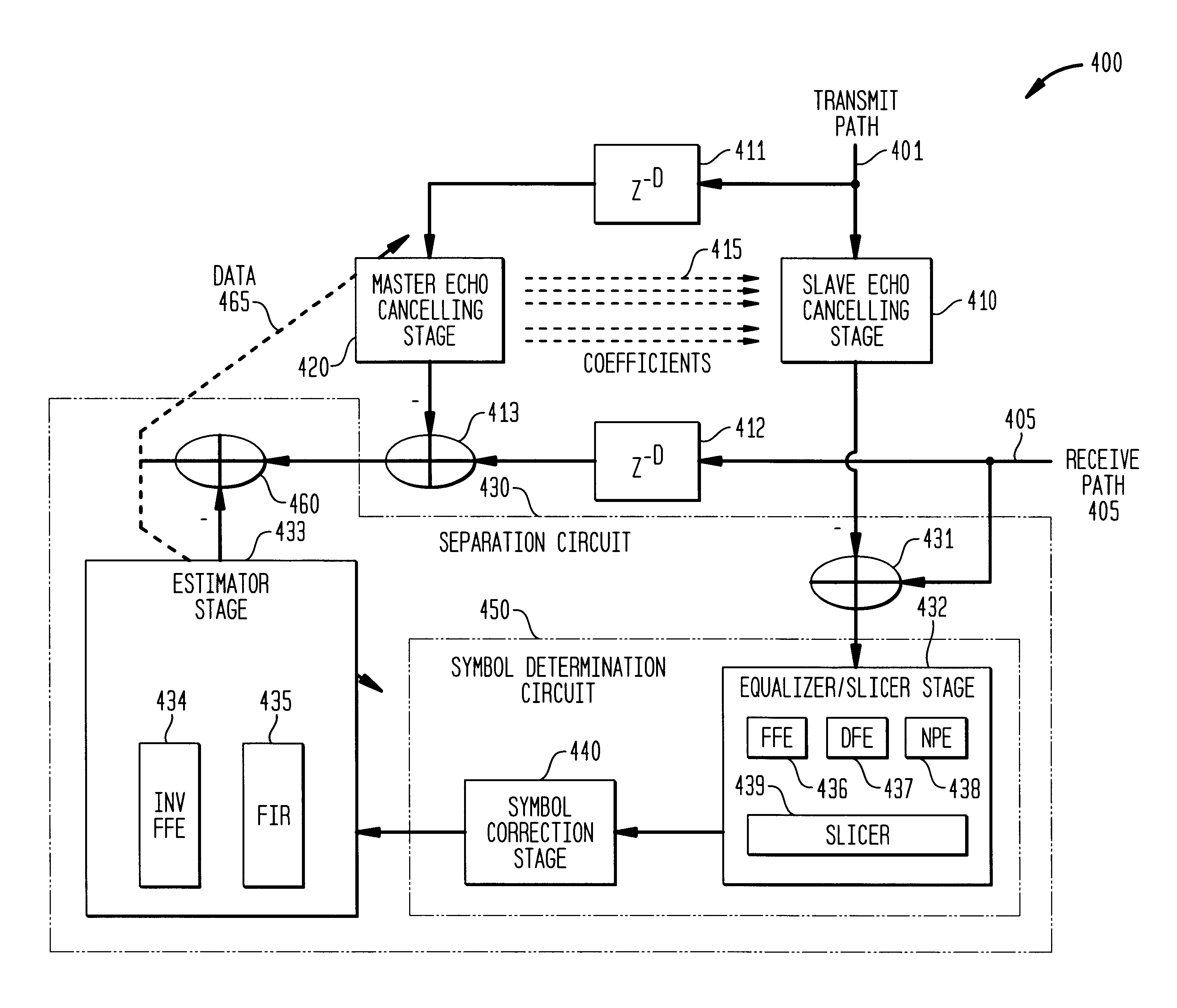

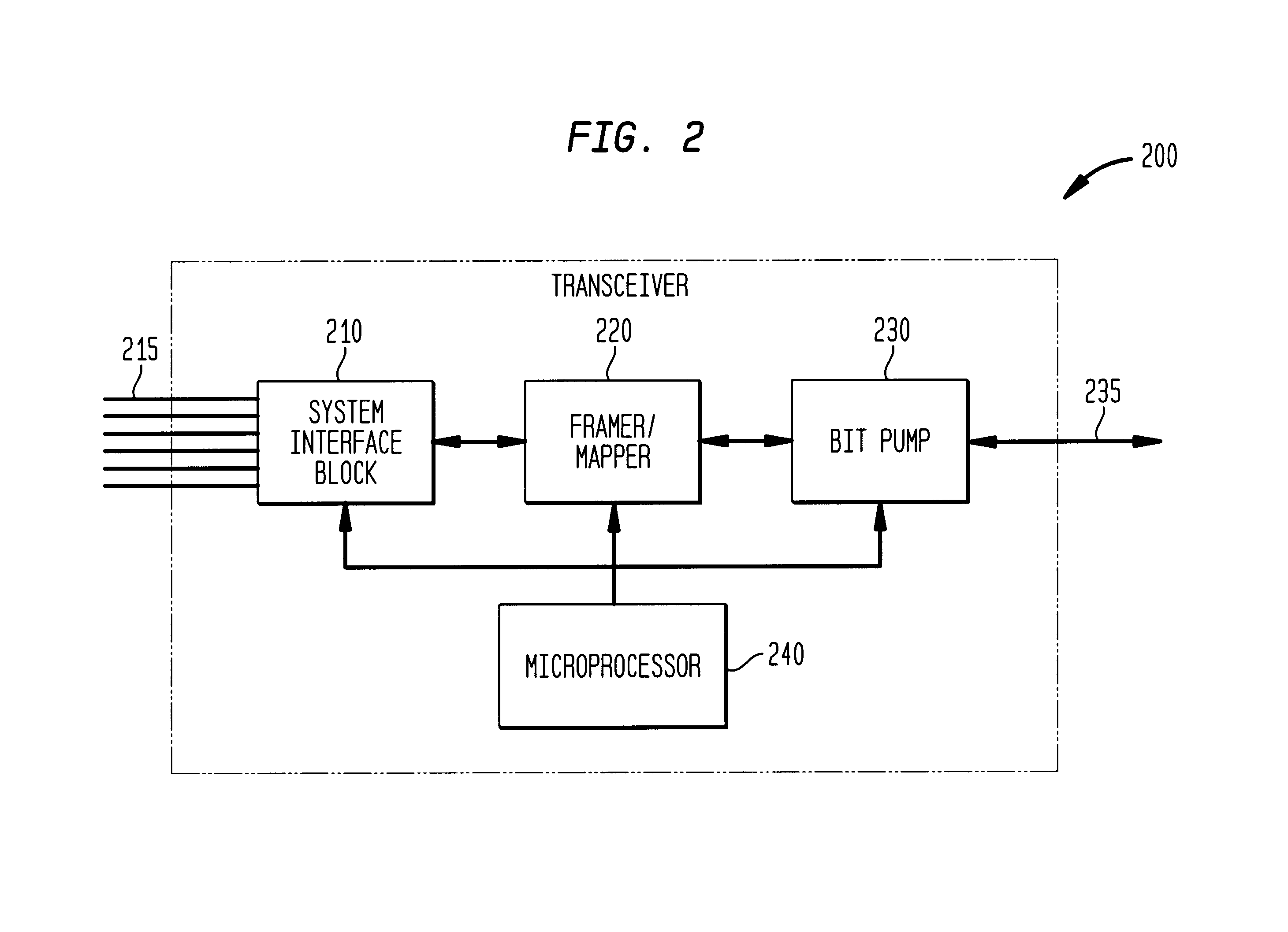

Separation circuit for an echo canceling system and method of operating the same

InactiveUS6894989B1Improve fidelityReduce echoTwo-way loud-speaking telephone systemsSubstations coupling interface circuitsTransceiverEngineering

A separation circuit, method of determining a residual level of an echo, and an echo canceling system, bit pump and transceiver employing the circuit and method. The echo canceling system employing the separation circuit is couplable between a transmit and receive path of the bit pump and generates an echo canceling signal. In one embodiment, the separation circuit includes a symbol determination circuit that accepts a receive signal, propagating along the receive path, substantially free of an echo and determines a symbol associated with the receive signal. The separation circuit also includes an estimator stage, coupled to the symbol determination circuit, that receives the symbol and provides an estimated receive signal. The separation circuit generates data representing a residual level of the echo as a function of the estimated receive signal and the echo canceling signal.

Owner:LUCENT TECH INC

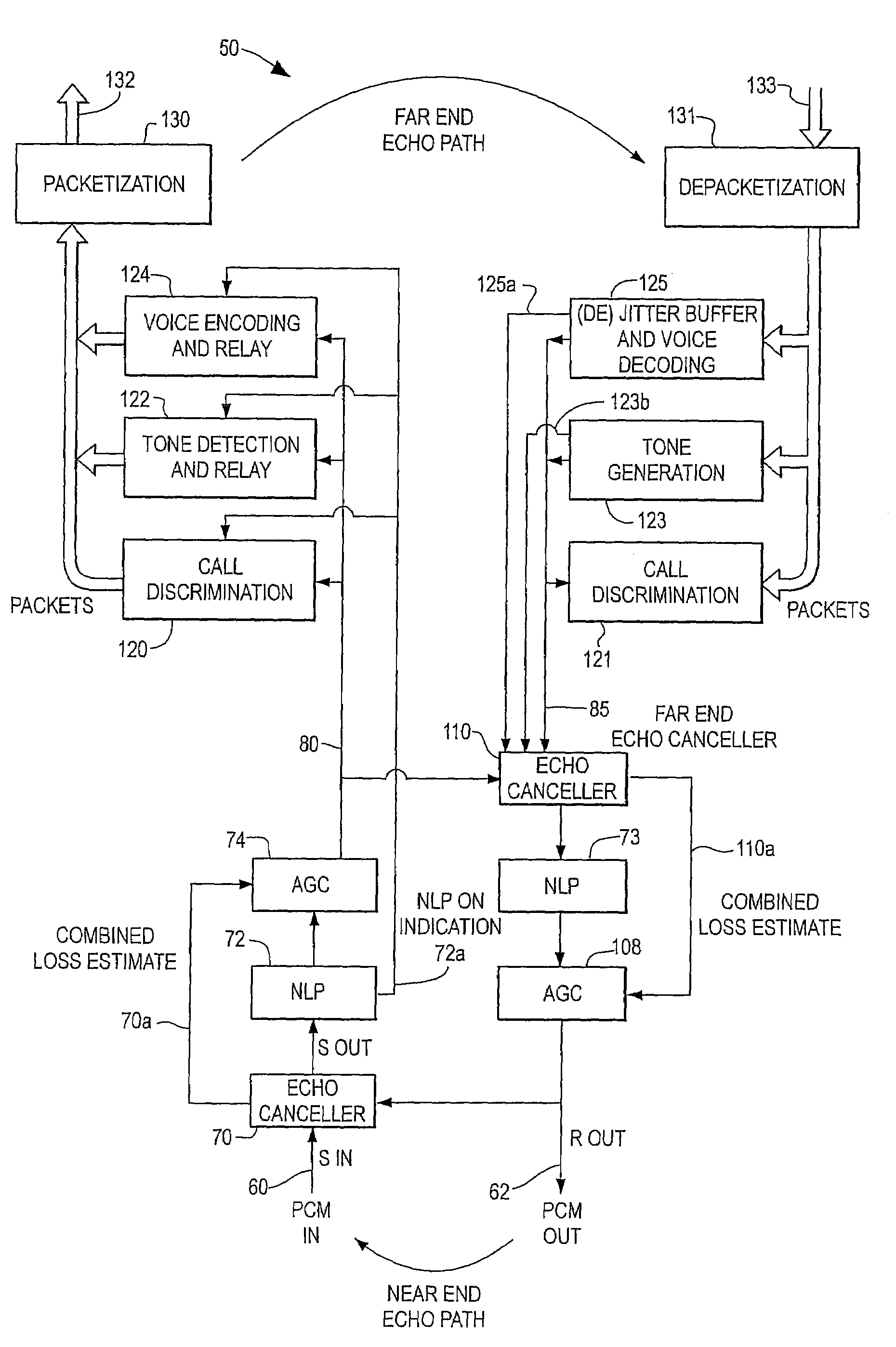

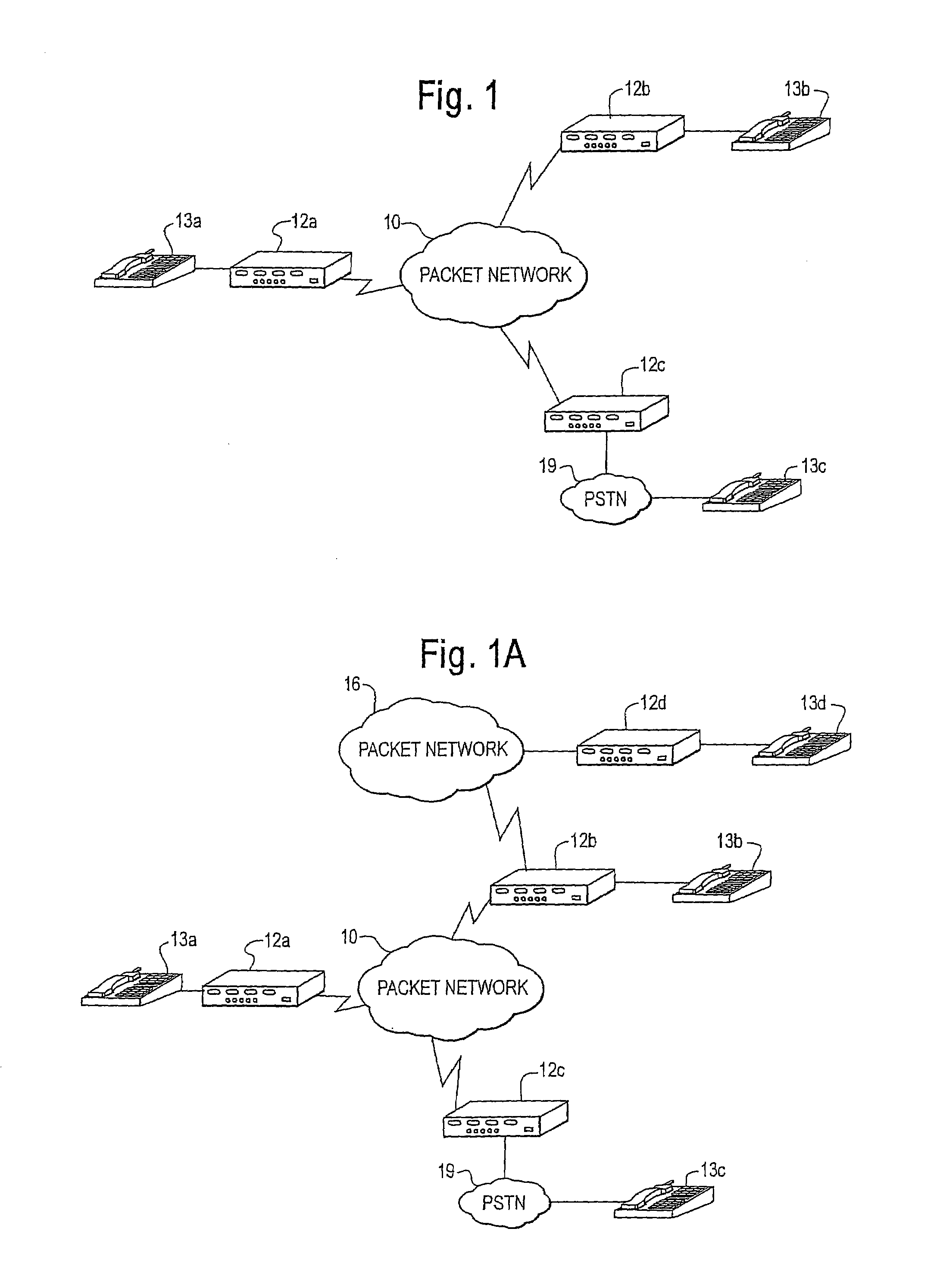

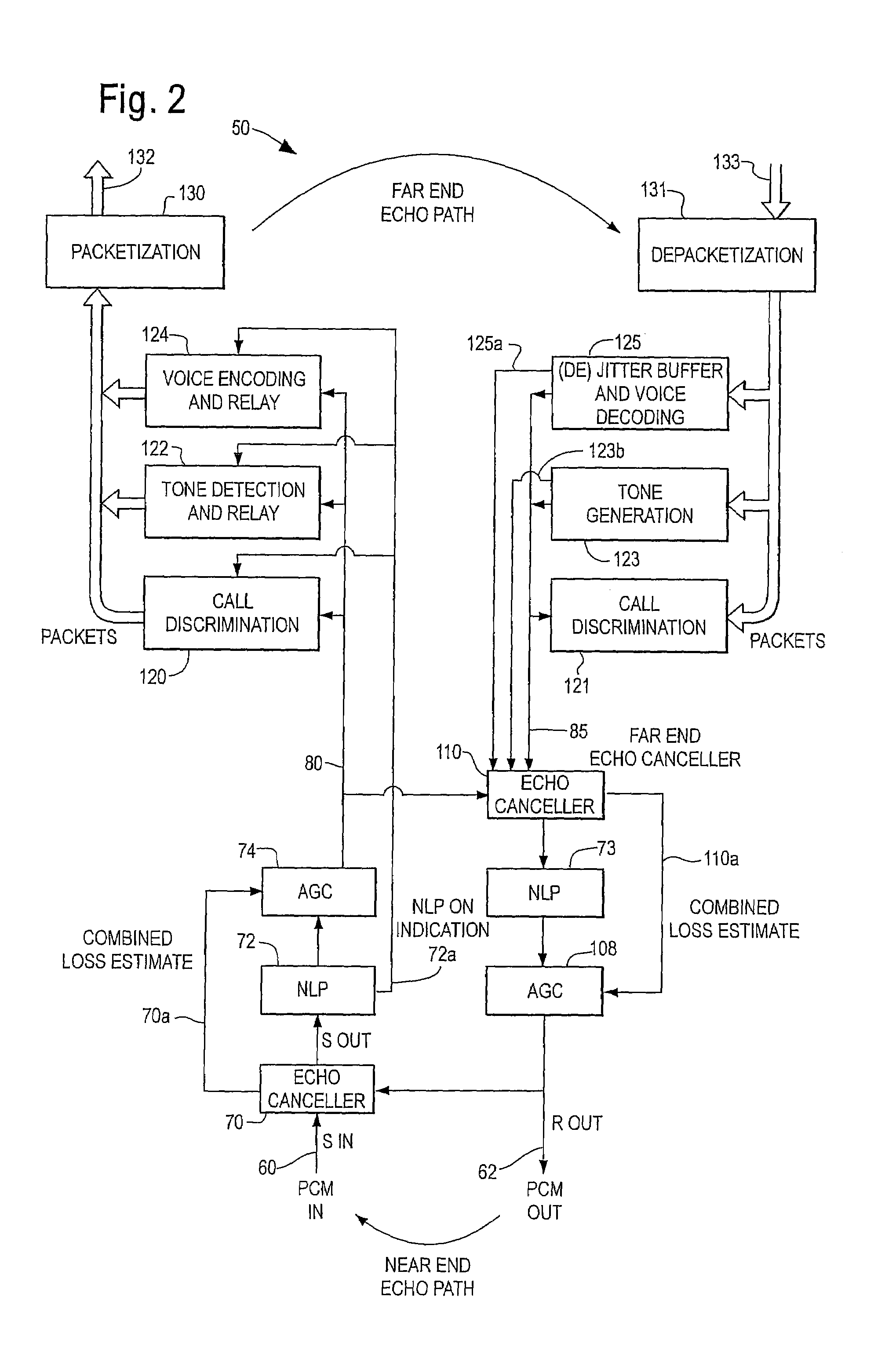

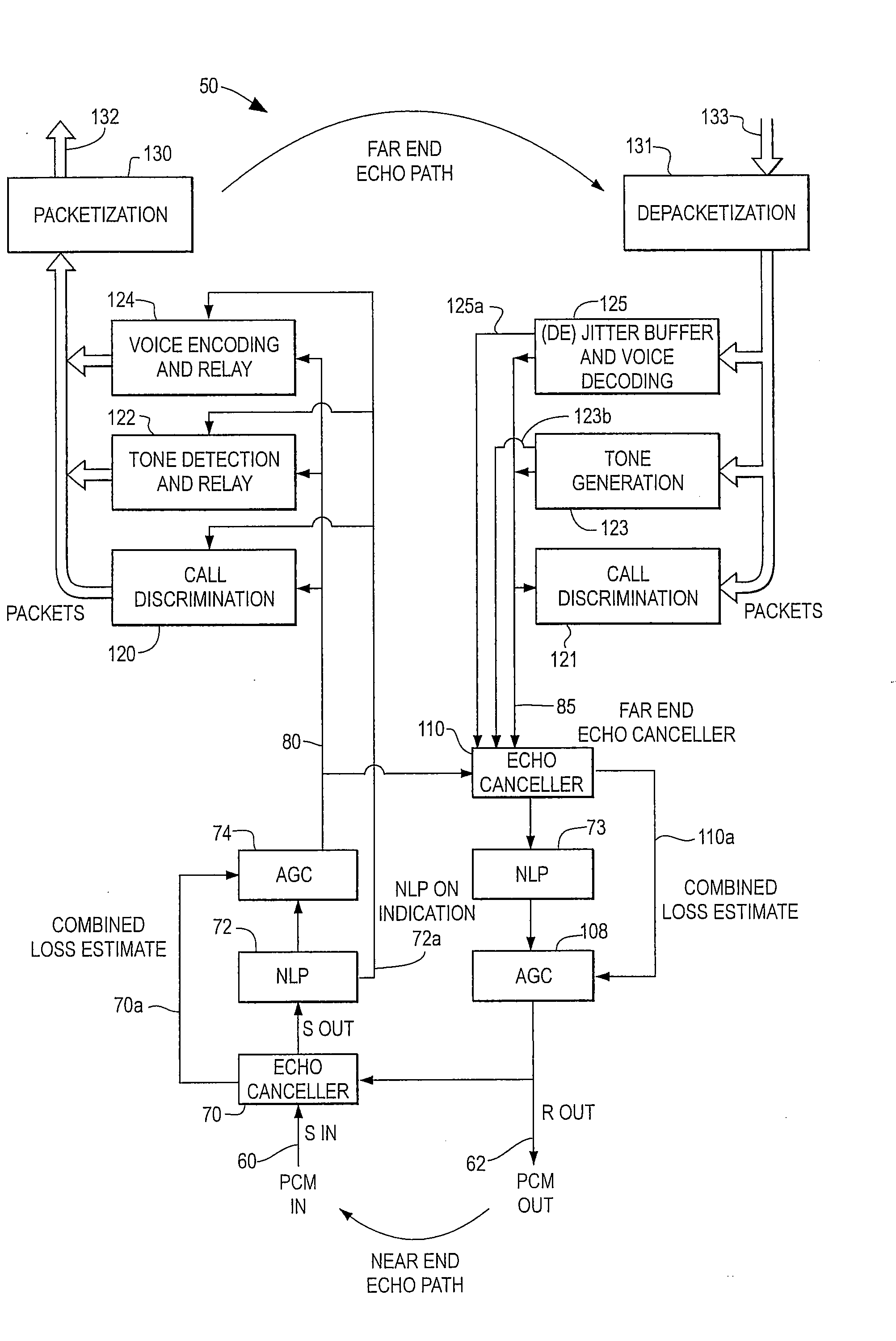

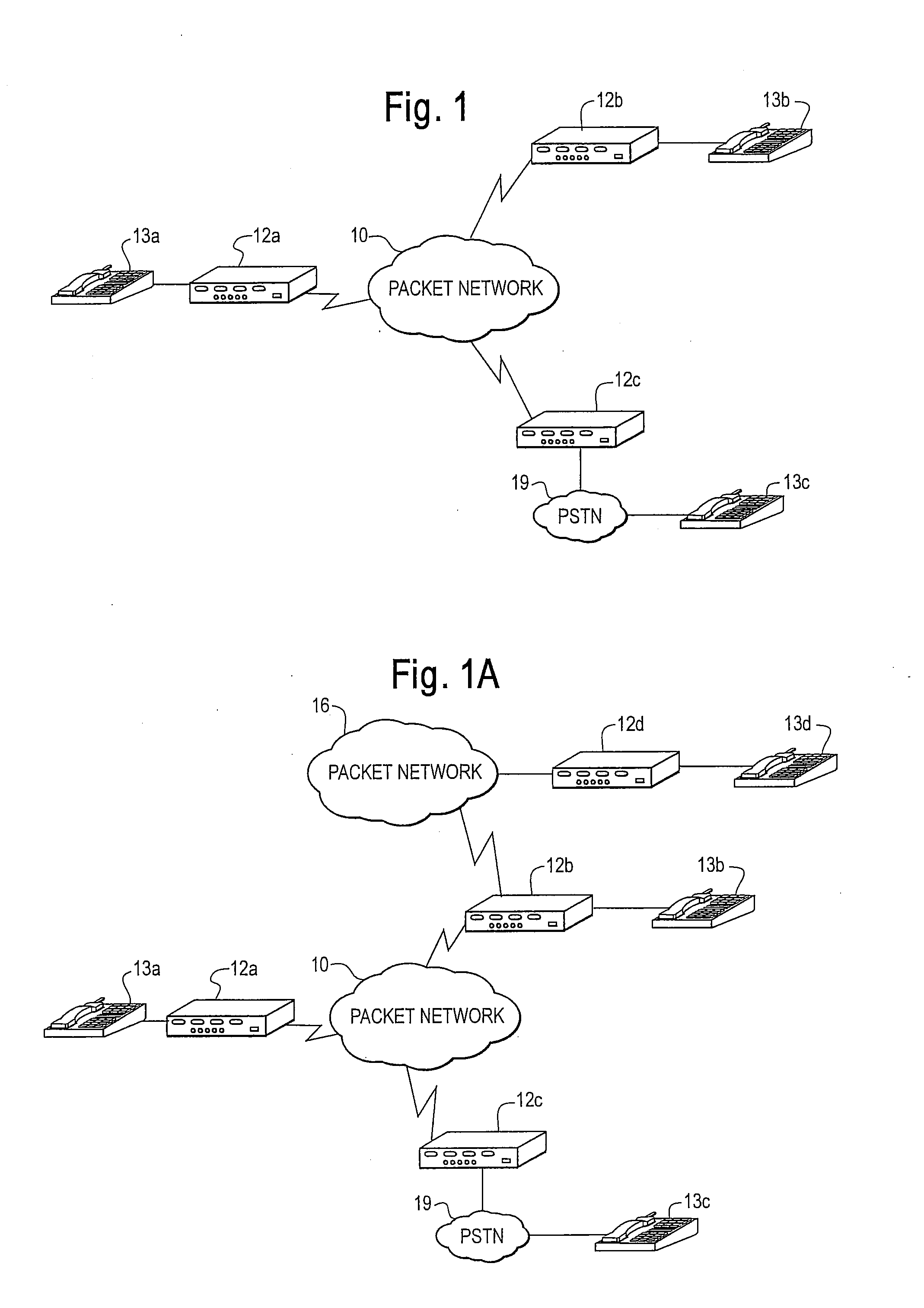

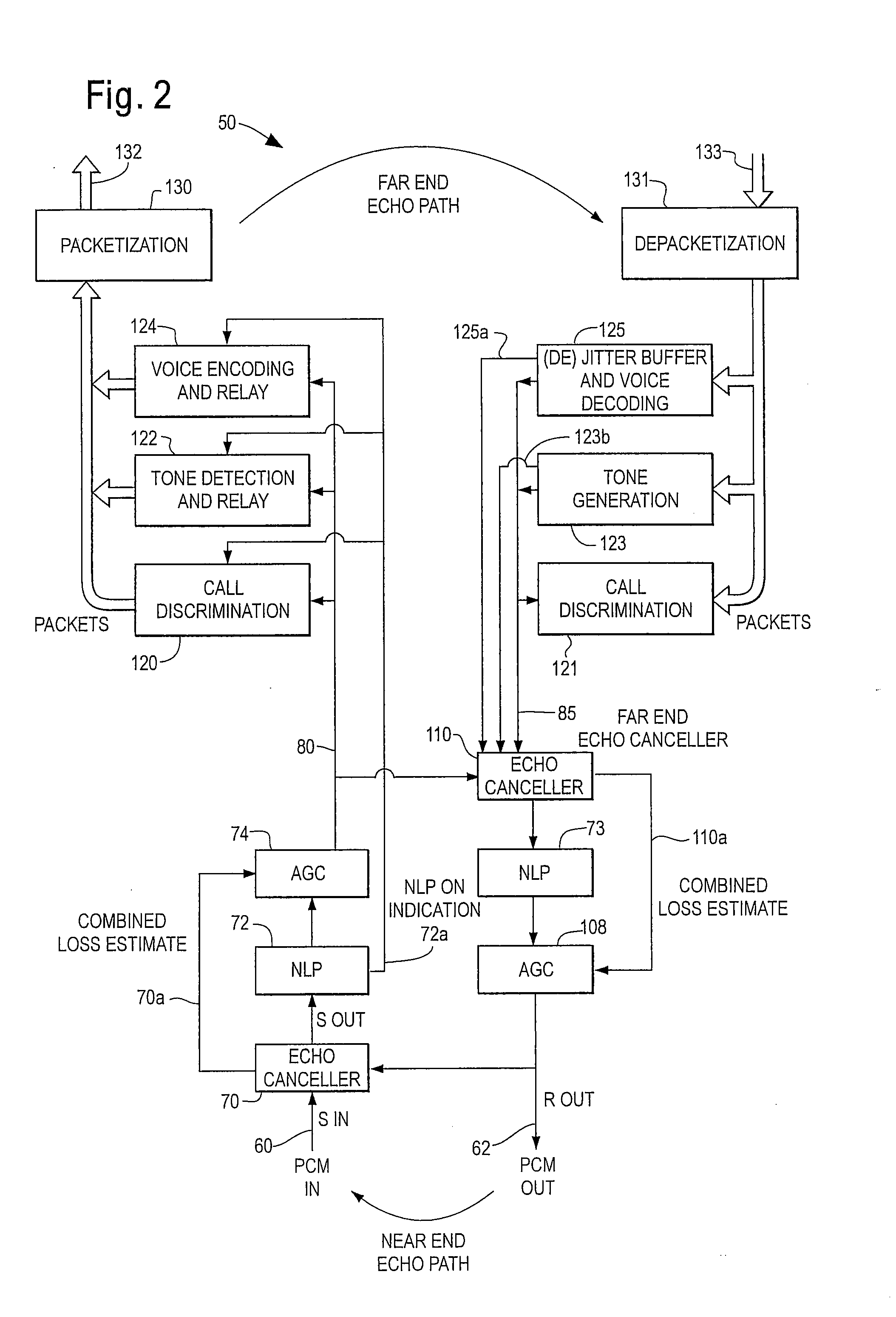

System and method for operating a packet voice far-end echo cancellation system

InactiveUS7333476B2Echo be not reduceReduce echoTwo-way loud-speaking telephone systemsTime-division multiplexTransceiverComputer network

Owner:AVAGO TECH INT SALES PTE LTD

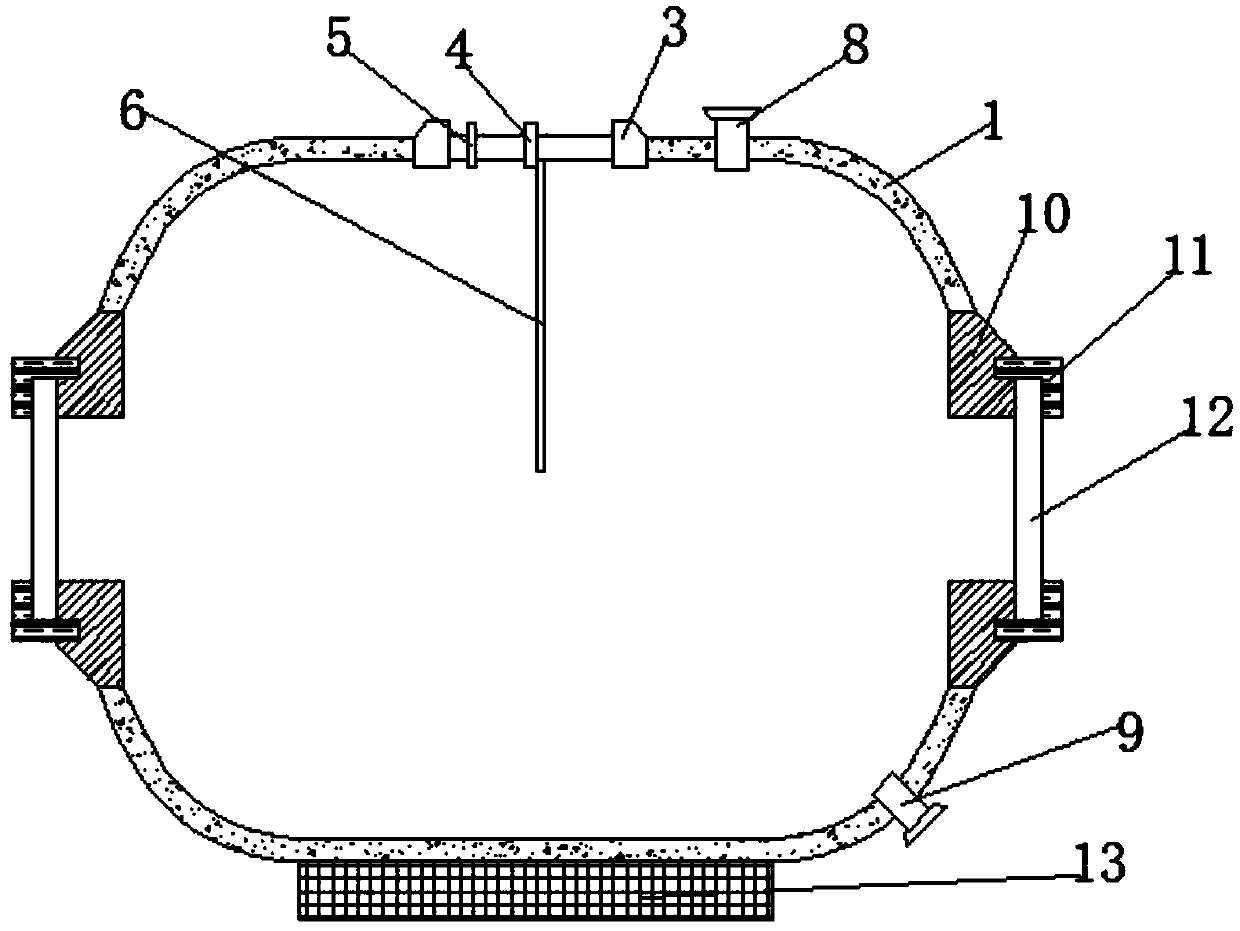

Explosion experimental device for simulating underground free field environment

InactiveCN109596666AReasonable designImprove accuracyMaterial exposibilityDetonationImpedance matching

The invention discloses an explosion experimental device for simulating an underground free field environment. The device comprises a spherical pressure container, an inner wall sprayed layer, an operation sealing head, a detonation line interface, a pressure sensor test interface, an explosive fixing rod, a fixing groove, a water inlet, a water outlet, an installation base, a flange plate, toughened glass and a base support. The explosion experimental device has the beneficial effects that the spherical pressure container is used as a main body, meeting the requirement of certain amount of explosive for many experiments; the device can be pressurized so as to simulate a certain deep water environment; a spherical tank is provided with an observation window which allows an operator to observe shapes of bubbles in the tank in experiment; the interior of the tank is treated by spraying or pasting multiple layers of material better in wave impedance matching, so as to absorb or suppress reflected impulse load to realize an underground free field environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

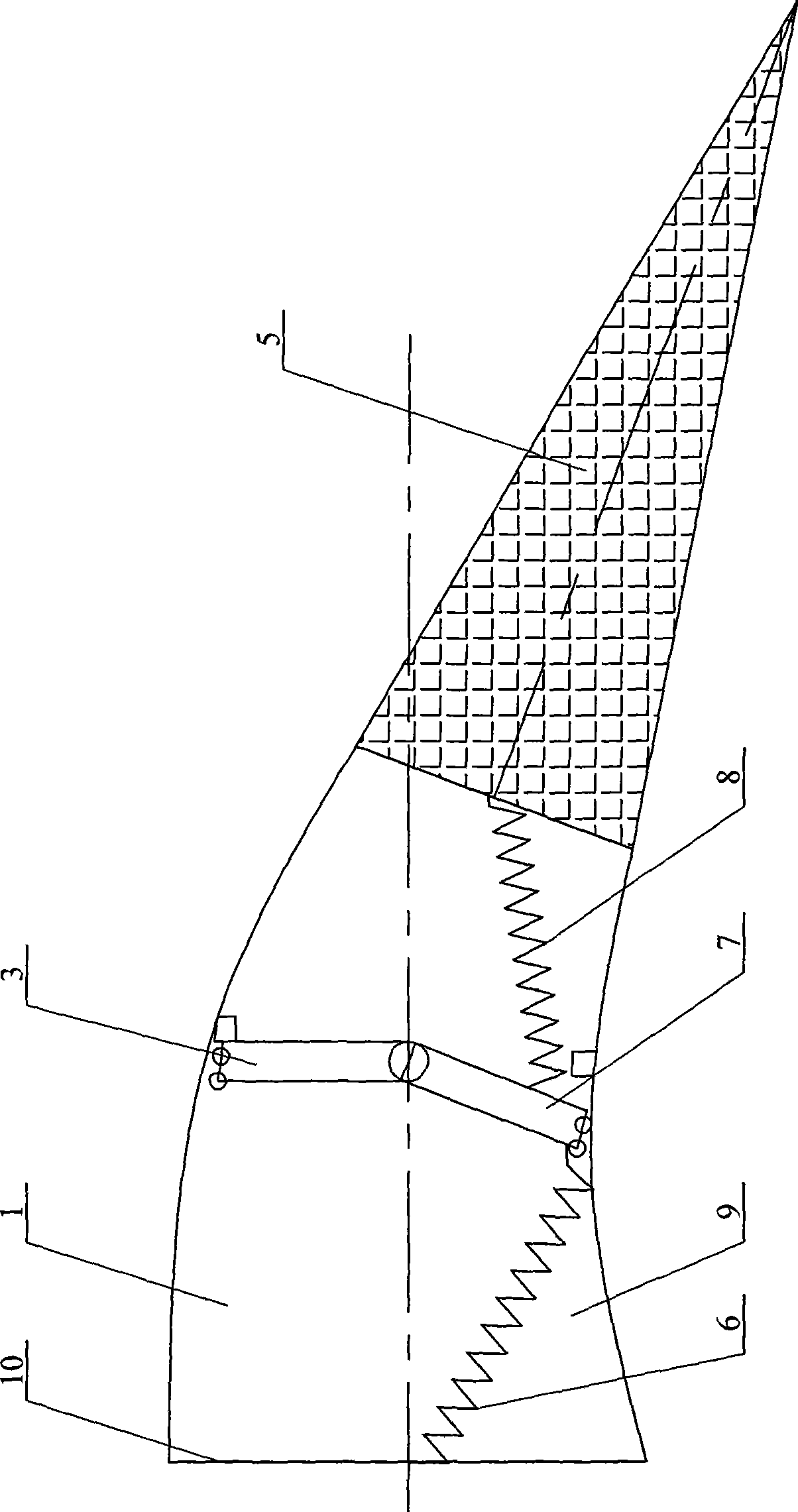

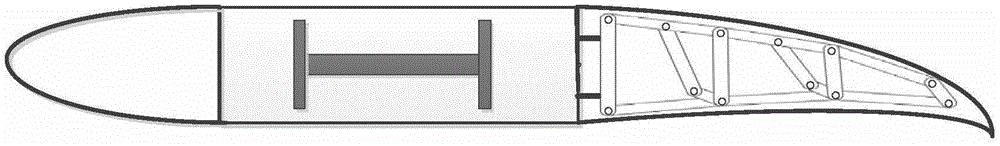

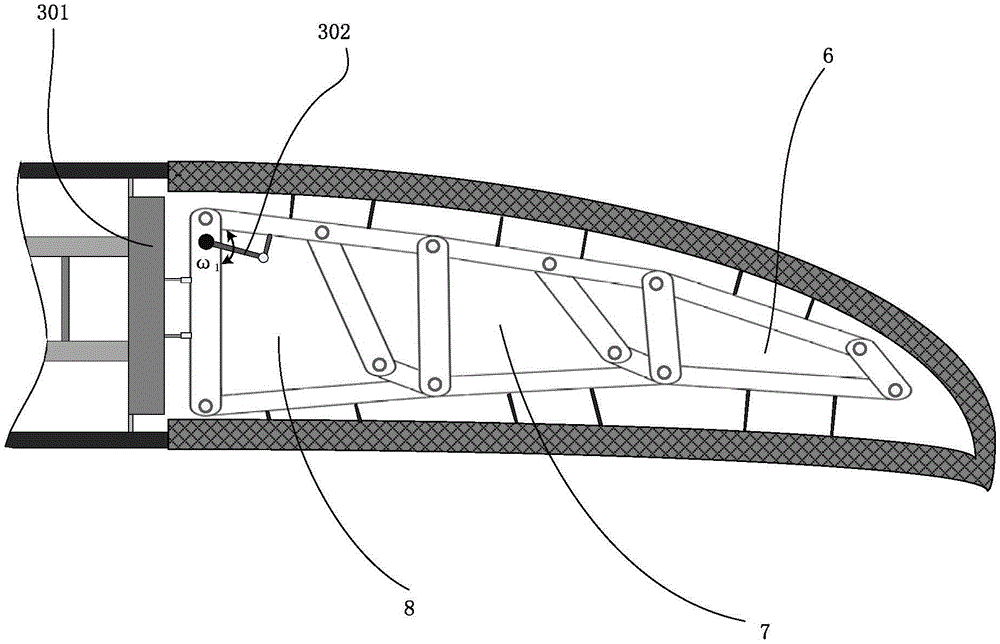

Complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units

ActiveCN106275388AImprove pressure distributionImprove aerodynamic characteristicsWing adjustmentsControl systemClosed loop

The invention provides a complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units. The complex-hinge transformable trailing edge mechanism comprises at least three closed-loop linkage units and a drive mechanism. Each closed-loop linkage unit is a planar linkage structure based on a 6R closed-loop unit and has one freedom degree. The closed-loop linkage units include a tail-end unit, at least one middle unit and a starting-end unit which are parallelly arranged, and the middle units are arranged between the starting-end unit and the tail-end unit. Compared with the prior art, the complex-hinge transformable trailing edge mechanism has the advantages that the basic units of the complex-hinge transformable trailing edge mechanism are independent 6R closed-loop units, the units influence on another, and the output of the previous unit is the input of the next unit; the whole mechanism contains few linkages and is lightweight; the freedom degree of the whole mechanism is 1, the mechanism can be driven by only one drive motor, the weight of the mechanism is reduced, system control difficulty is lowered, and the gradual bending effect of a transformable wing is good due to the fact that multiple basic unit modules are used.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

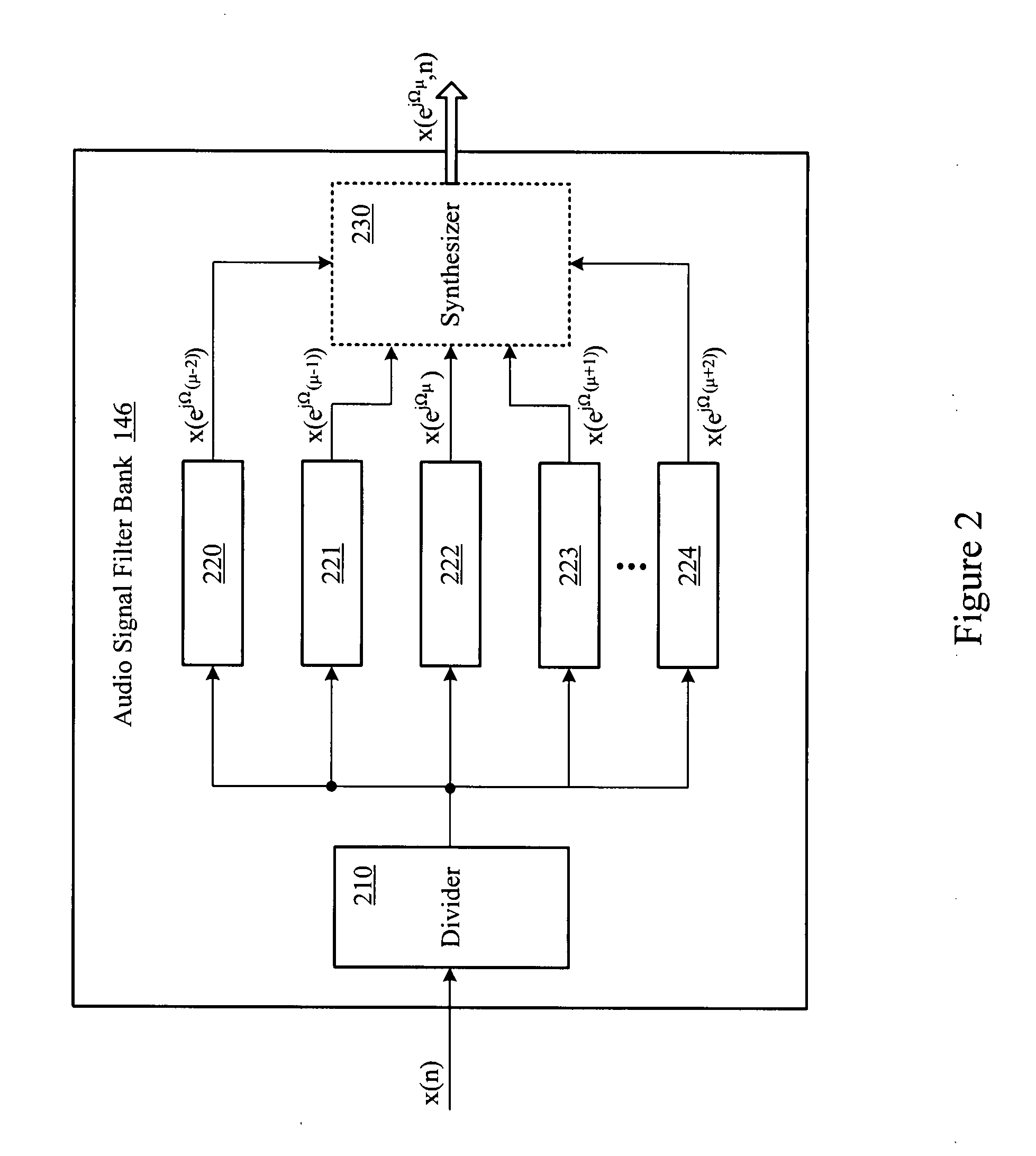

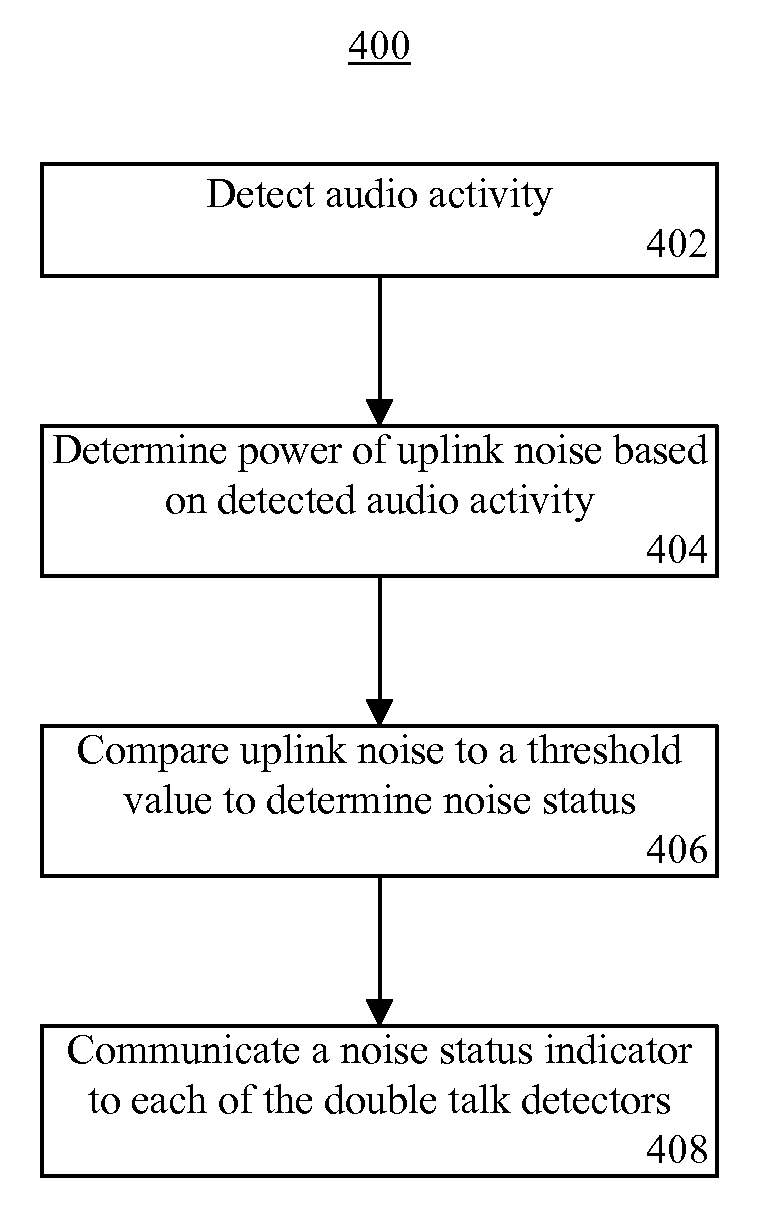

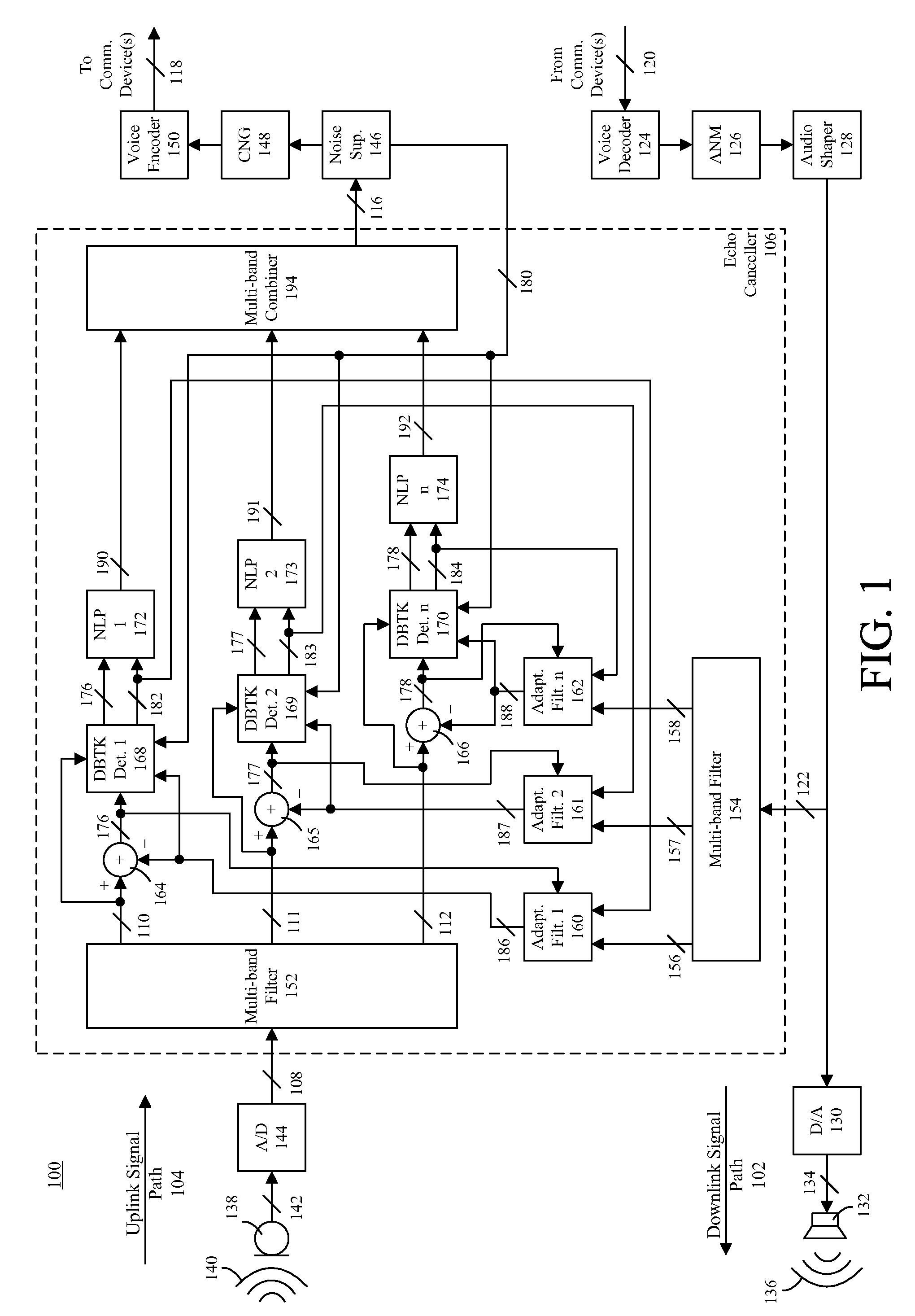

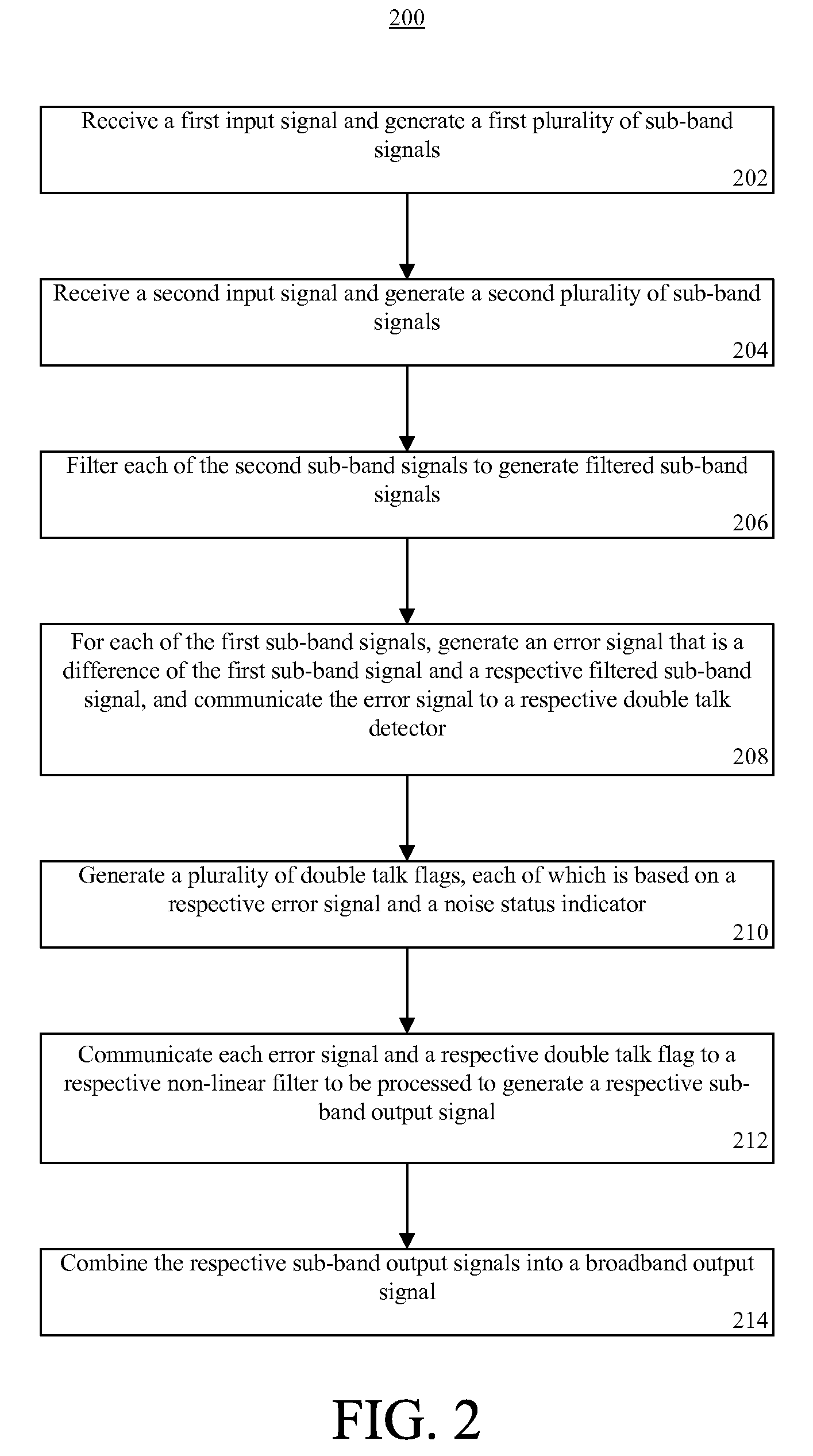

Acoustic echo canceller using multi-band nonlinear processing

InactiveUS20090046847A1Reduce echoTwo-way loud-speaking telephone systemsSupervisory/monitoring/testing arrangementsMulti bandDouble talk detector

An echo canceller (106) can include a first multi-band filter (152) which receives a first input signal (108) and generates a first plurality of sub-band signals (110, 111, 112), and a second multi-band filter (154) which receives a second input signal (122) and generates a second plurality of sub-band signals (156, 157, 158). The echo canceller also can include a plurality of double talk detectors (168, 169, 170) that each generate a double talk flag (182, 183, 184) based on at least a respective one of the first sub-band signals and a respective one of the second sub-band signals.

Owner:GOOGLE TECH HLDG LLC

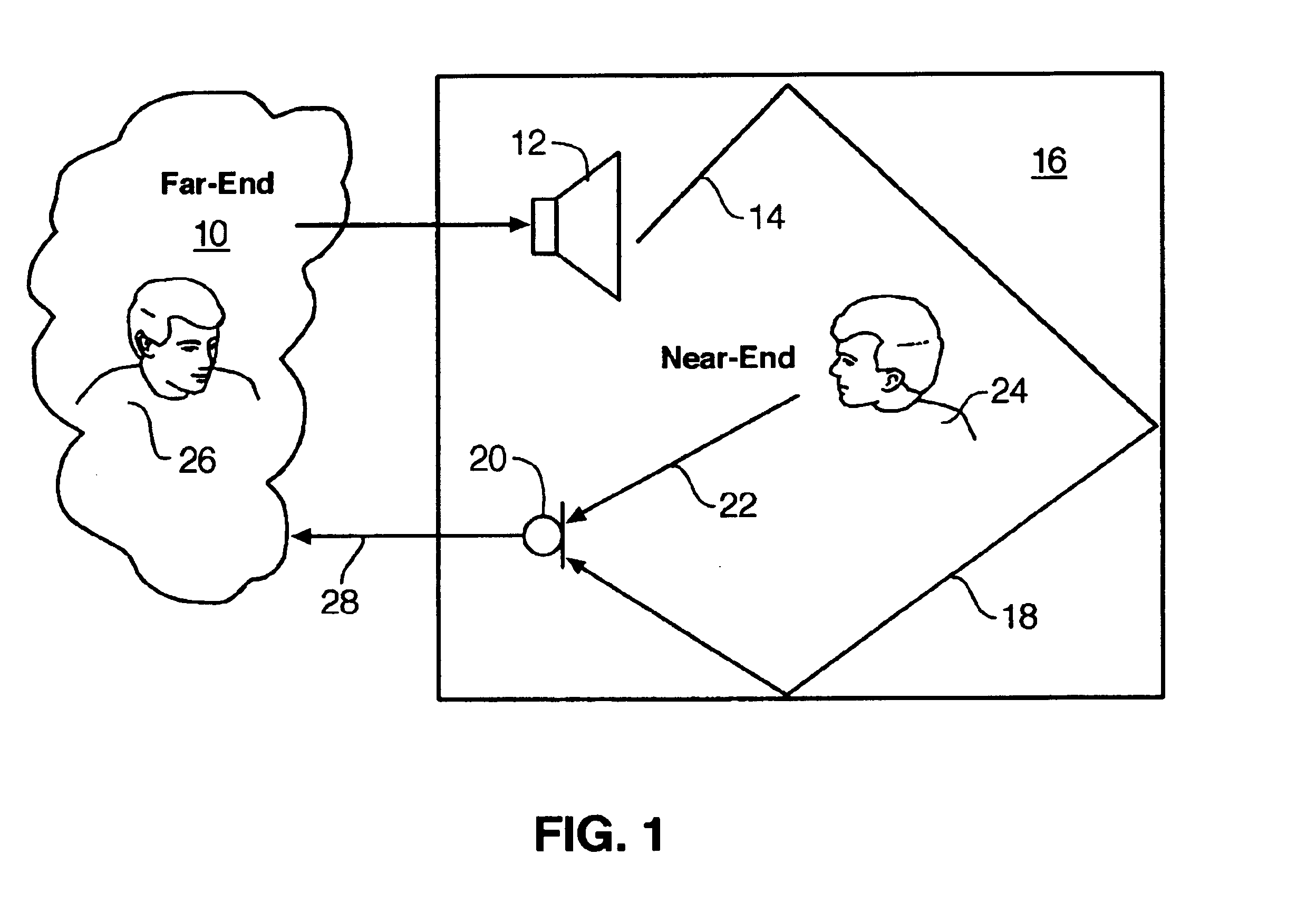

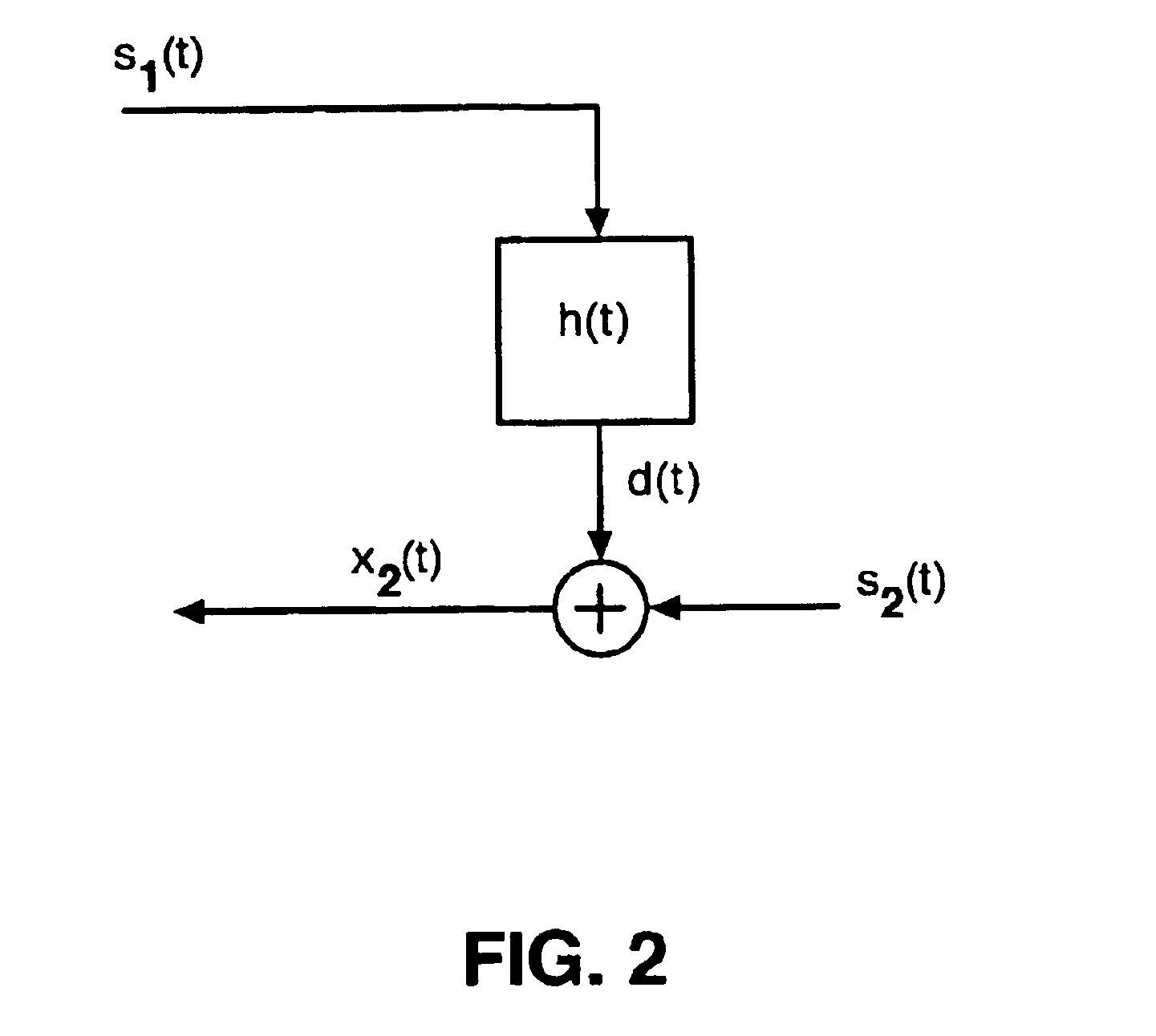

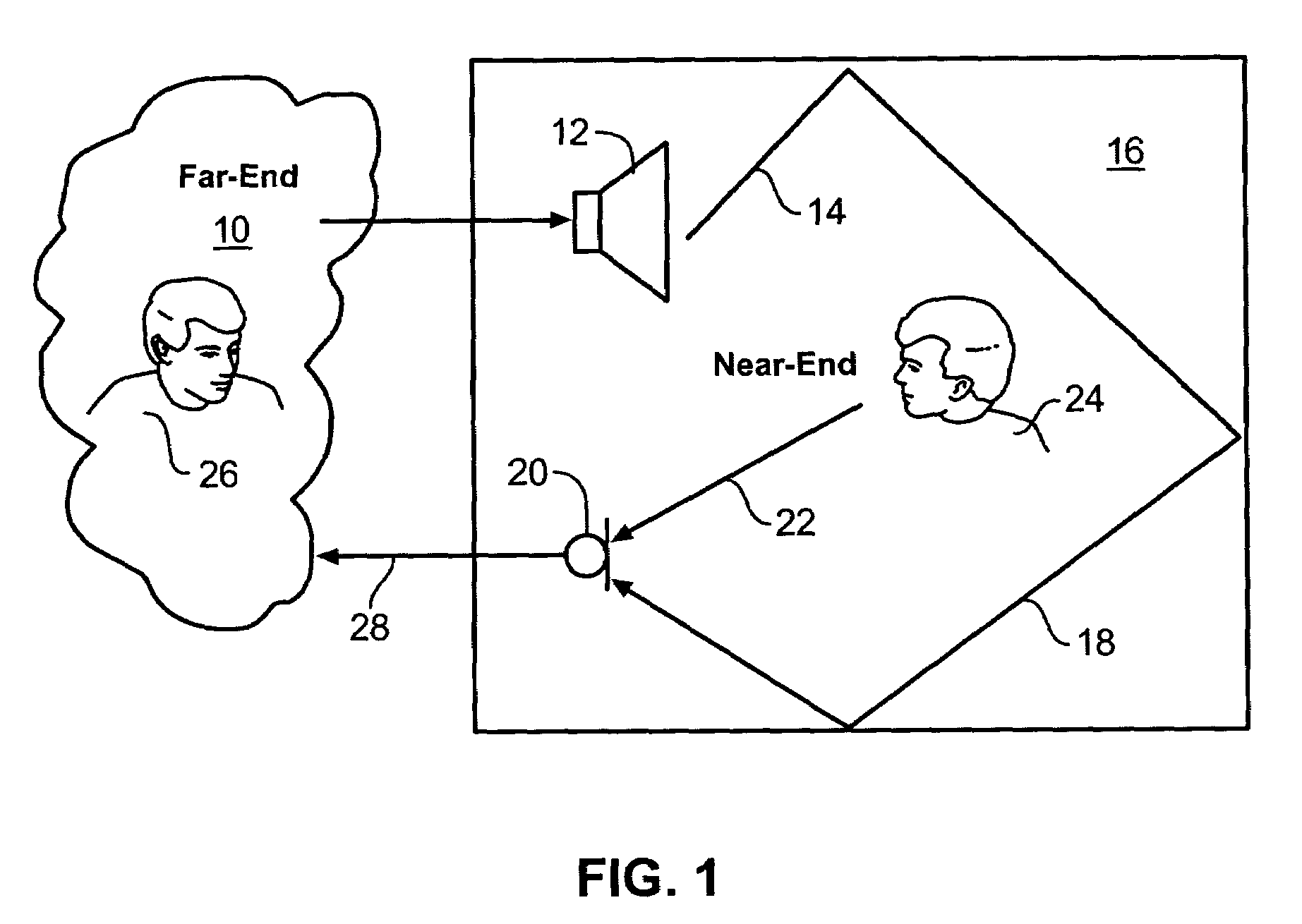

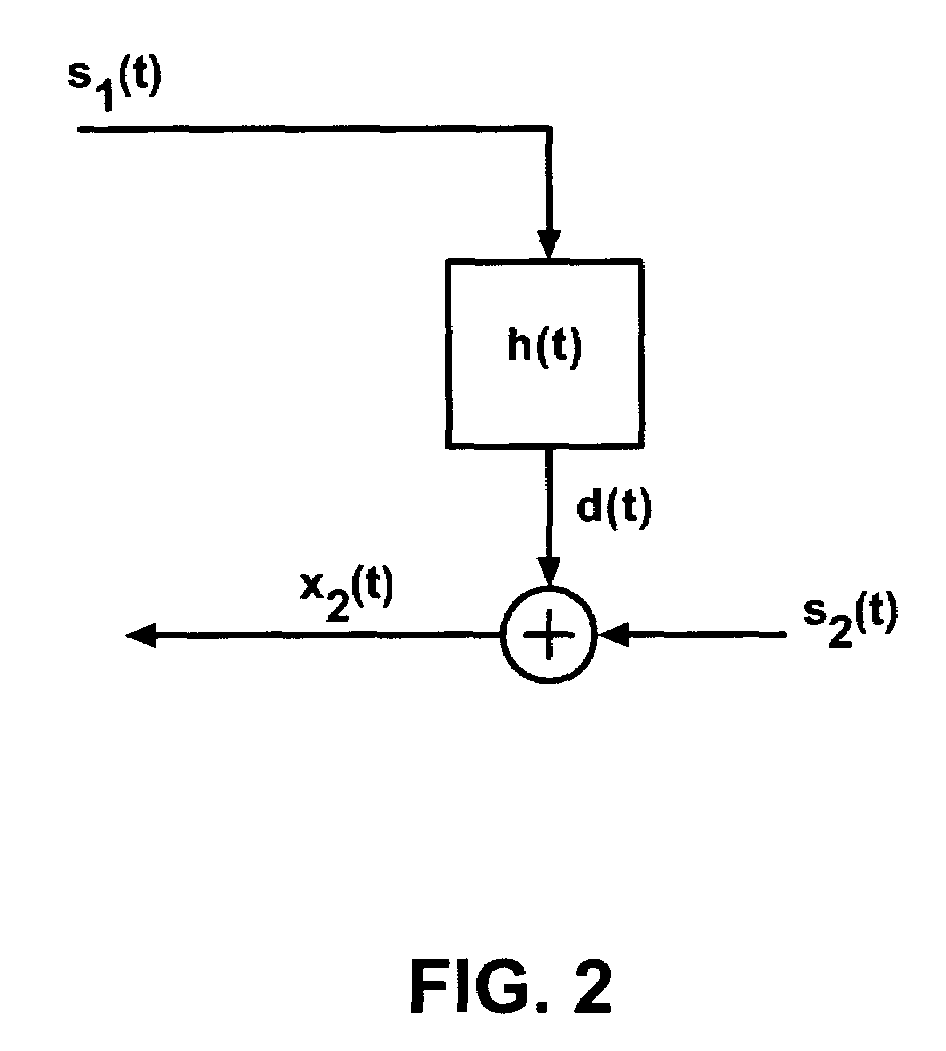

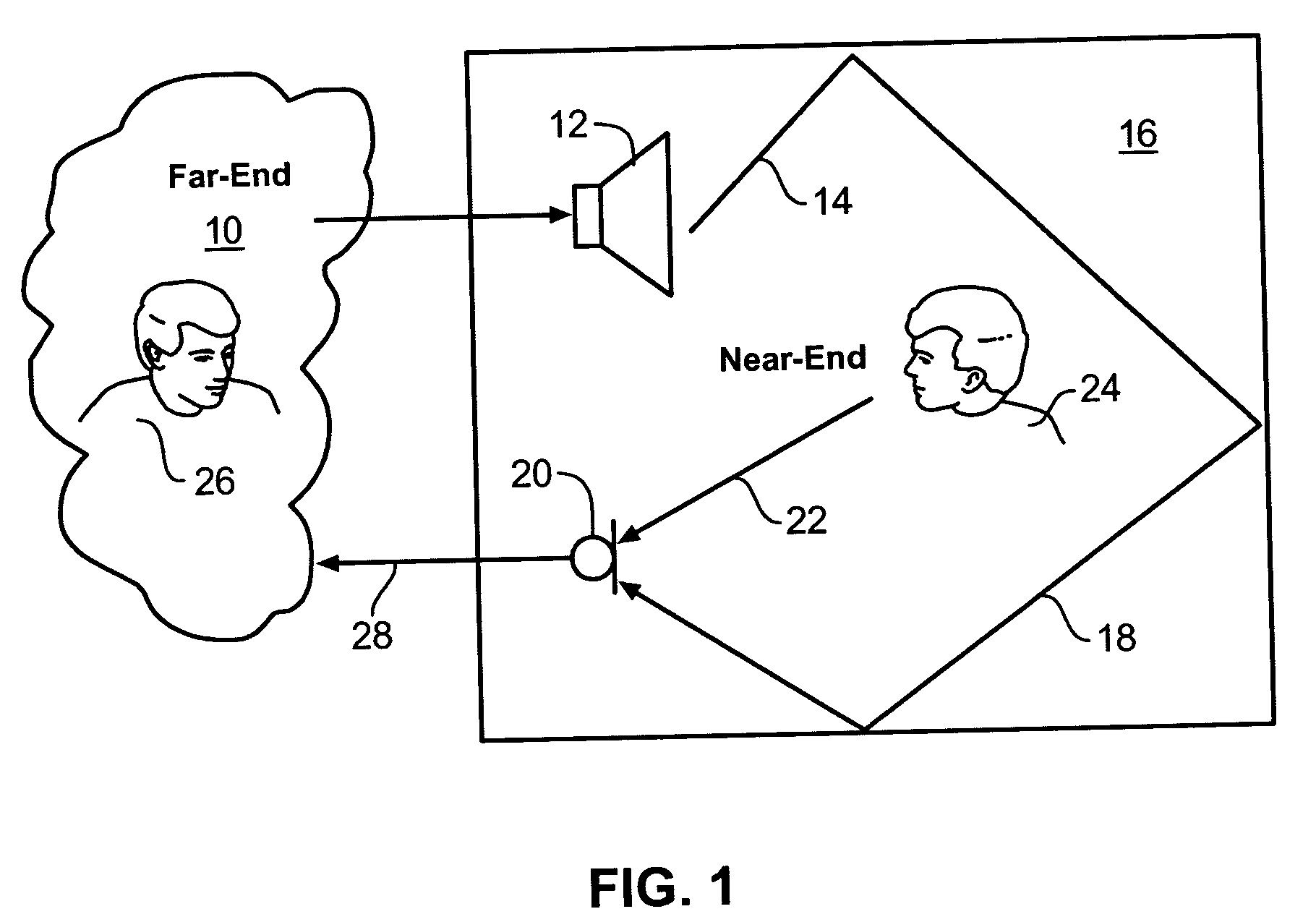

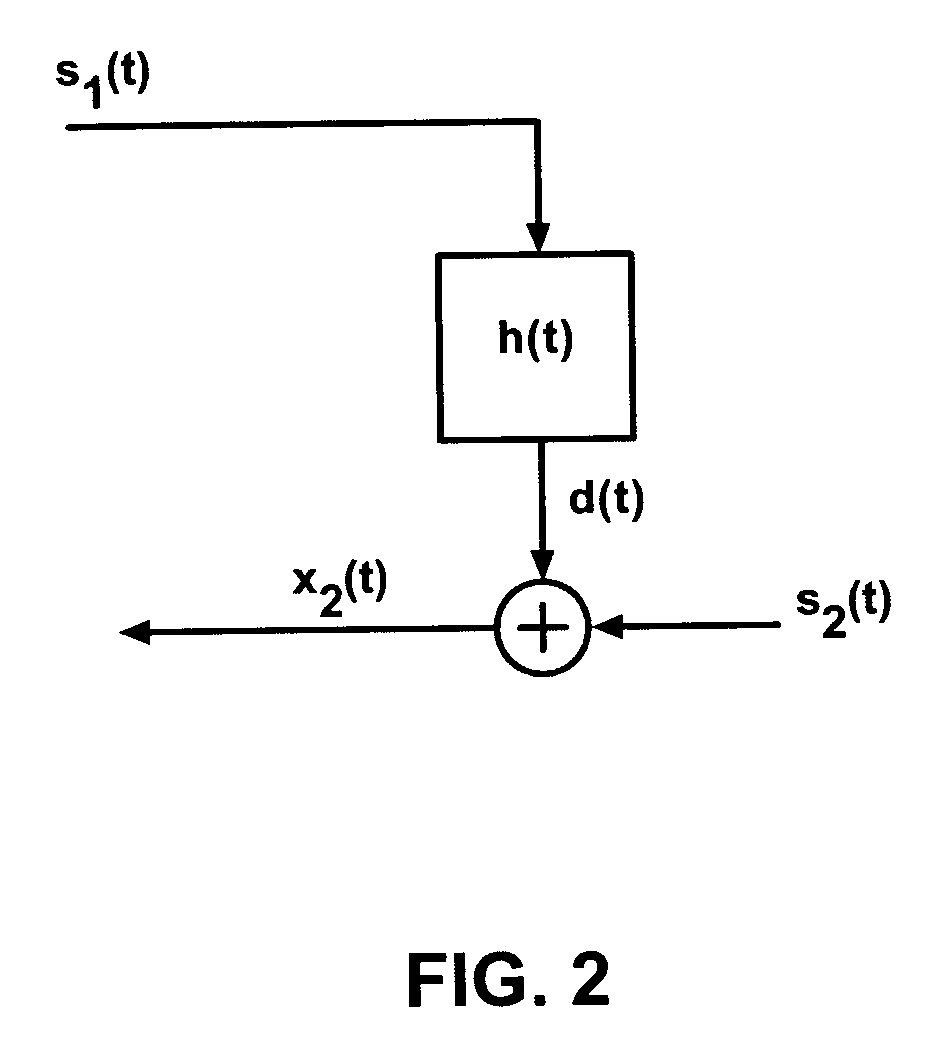

Echo cancellation filter

InactiveUS6954530B2Reduce echoAdaptable to changeTwo-way loud-speaking telephone systemsSubstation equipmentTime delaysDouble talk detector

An echo canceler includes an recursive least squares lattice to whiten a far-end signal s1(t) and provide whitened time delays. The echo canceler further decorrelates a microphone signal based on the whitened time delays to reduce echoes of the far-end signal s1(t) that are contained in the microphone signal x2(t). The echo canceler does not use a double-talk detector and avoids all problems inherent with their use. Thus, speaker phones, and other communication devices, can continuously operate in full-duplex mode of operation thereby providing natural conversational hands-free communication.

Owner:CLEARONCE COMM INC

System and method for operating a packet voice far-end echo cancellation system

InactiveUS20080151791A1Reduce echoTwo-way loud-speaking telephone systemsTime-division multiplexComputer networkTransceiver

A packet voice transceiver adapted to reside at a first end of a communication network and to send an ingress communication signal comprising voice packets to, and receive an egress communication signal comprising voice packets from, a second packet voice transceiver residing at a second end of the communication network. The packet voice transceiver includes a far-end echo canceller that reduces echo that is present in the egress communication signal. The far-end communicates with other functional components of the transceiver system and adapts its behavior based on the activity of the other functional components.

Owner:AVAGO TECH INT SALES PTE LTD

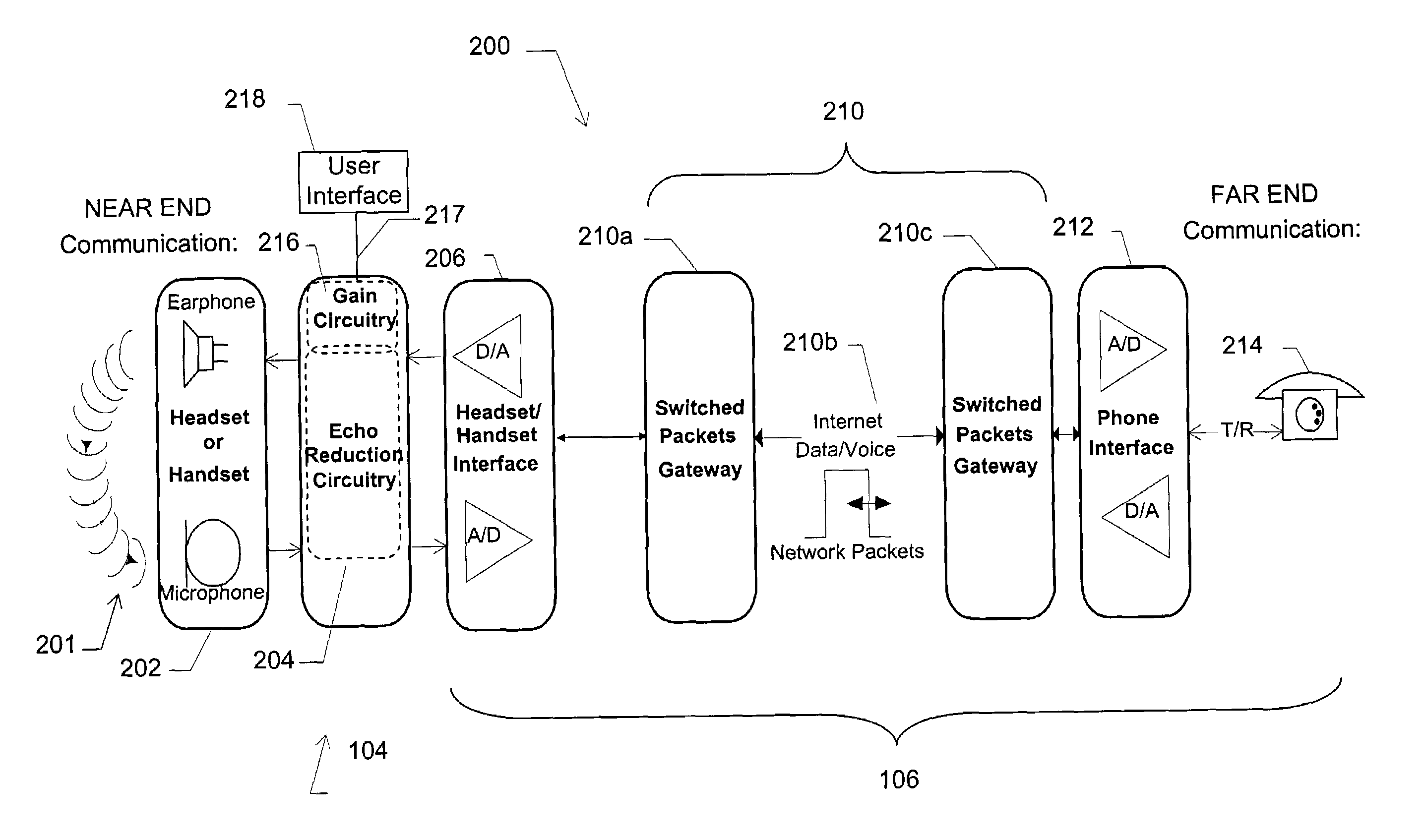

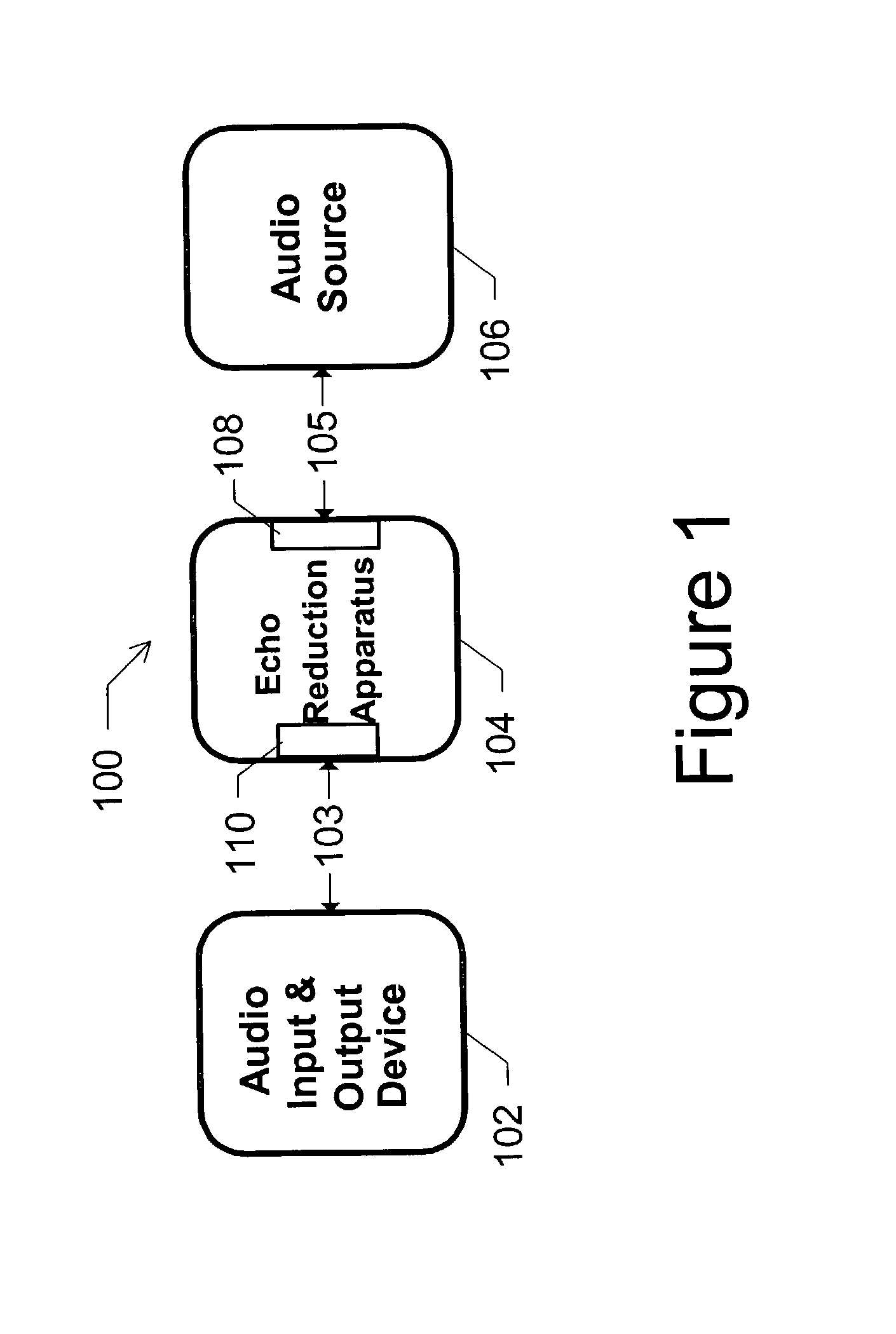

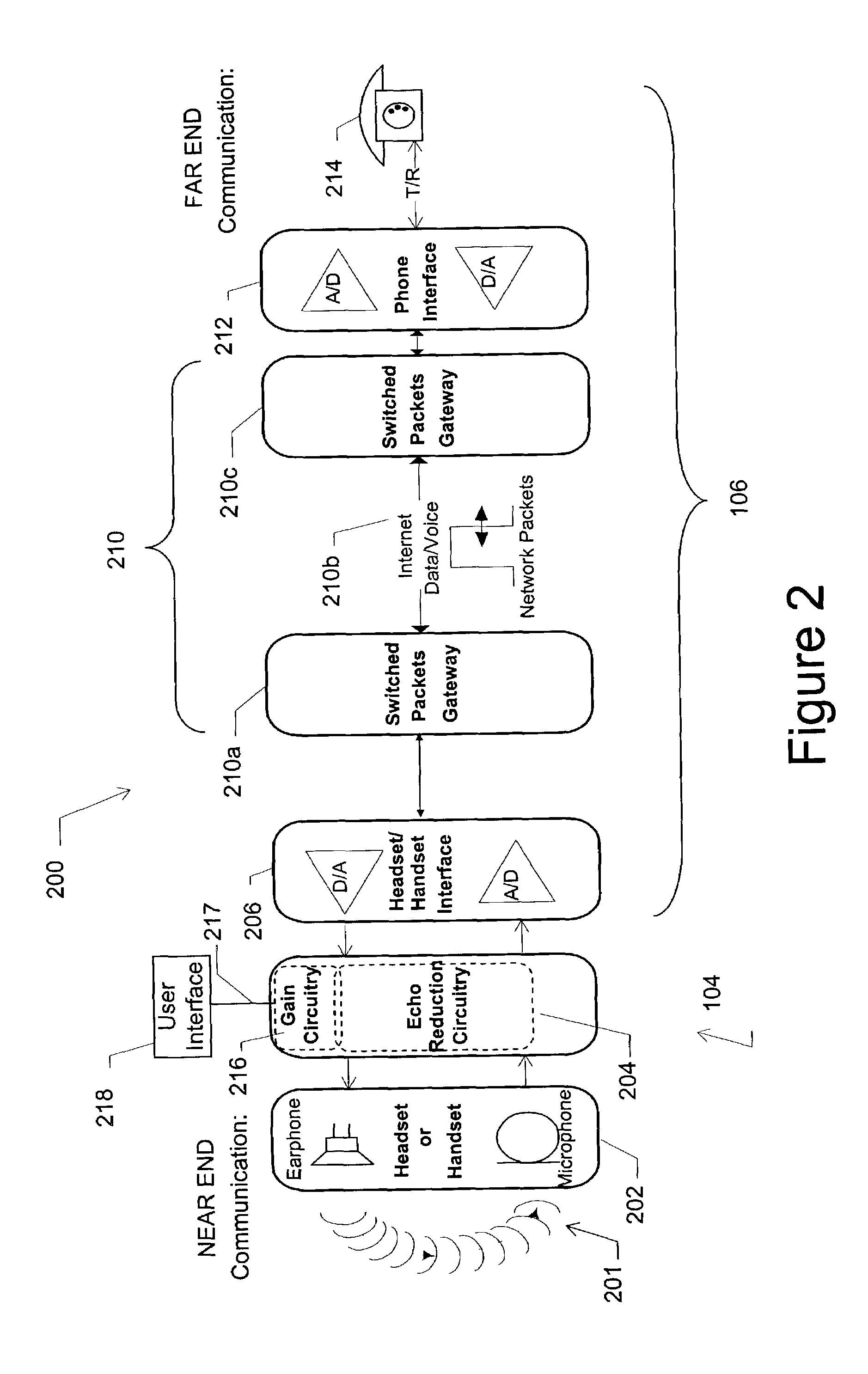

Echo reduction for a headset or handset

ActiveUS7039179B1Reduce echoAdvantageously reduce or suppress caller echo associatedInterconnection arrangementsAnti-side-tone circuitsPacket switchedHeadphones

The present invention provides an echo reduction apparatus, system, and method that advantageously reduces echo when communicating over packet-switched networks. An echo reduction apparatus, including echo reduction circuit, operably couples a headset or handset device to an audio source that is capable of transmitting a sound signal. The echo reduction circuit receives the sound signal from the audio source and a transmit signal from the headset or handset device and provides an adjusted sound signal to the audio source. Advantageously, a variety of headsets and handsets may be used in accordance with the present invention with reduced caller echo and without the need to purchase new headsets or handsets.

Owner:PLANTRONICS

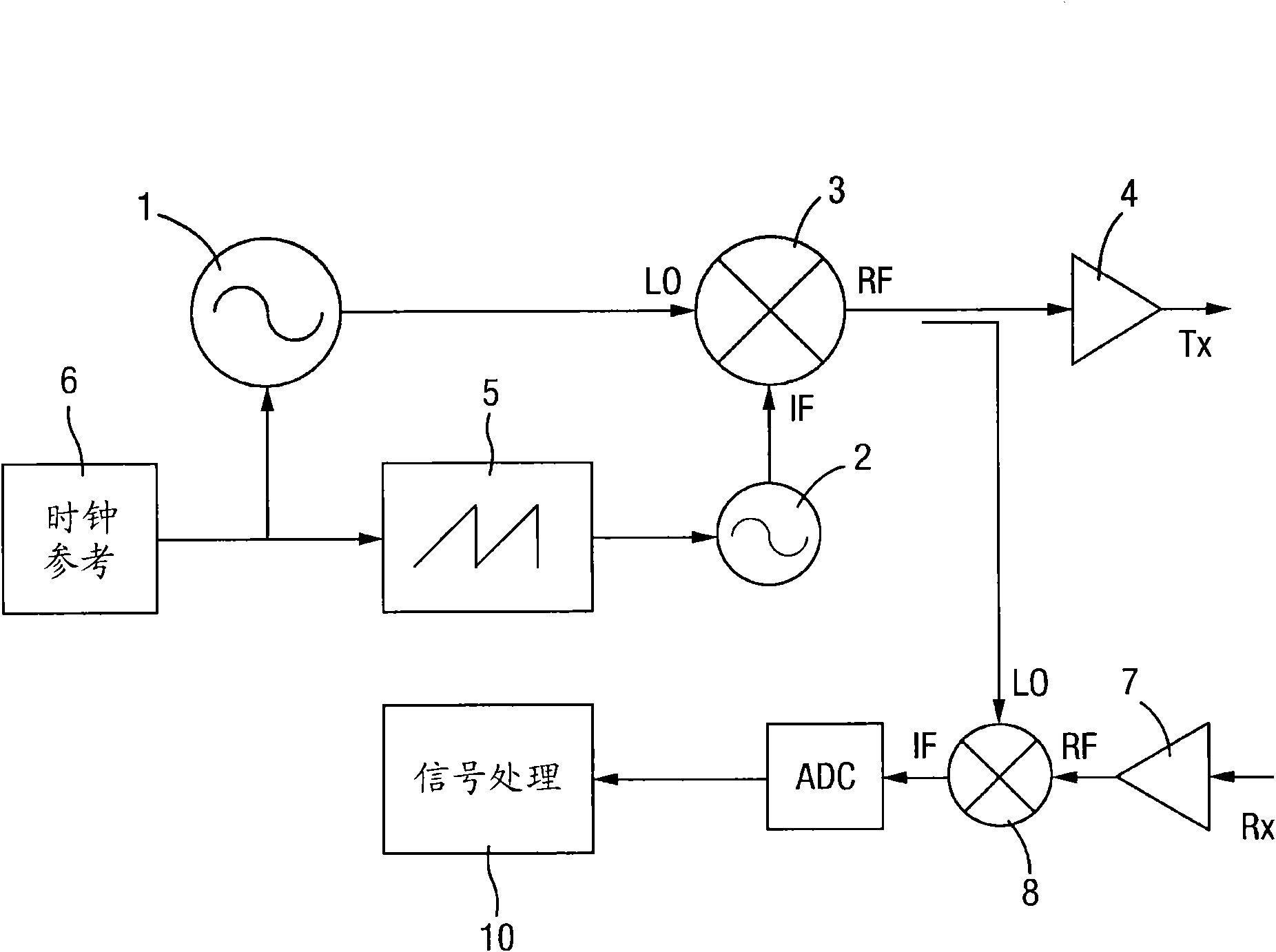

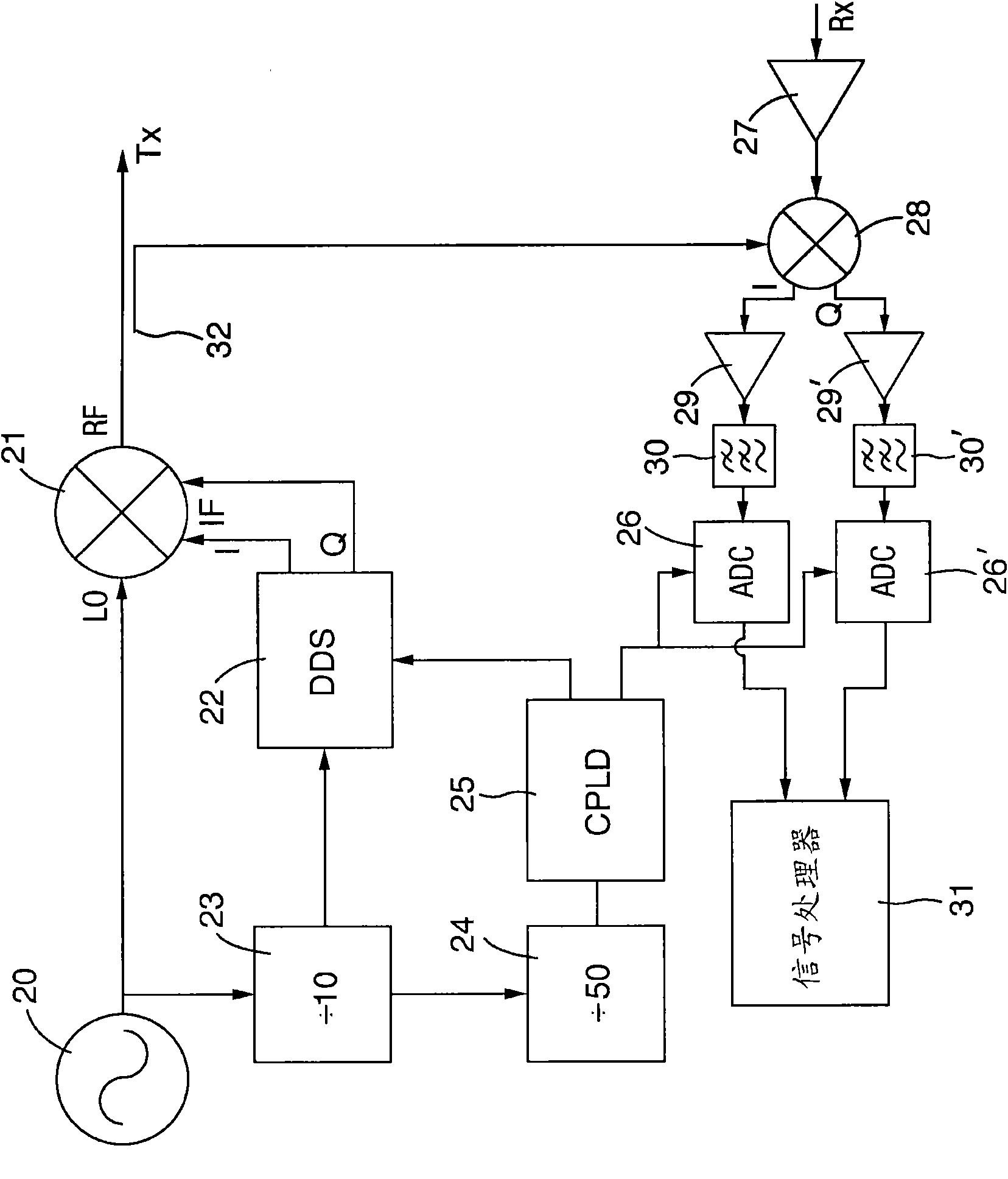

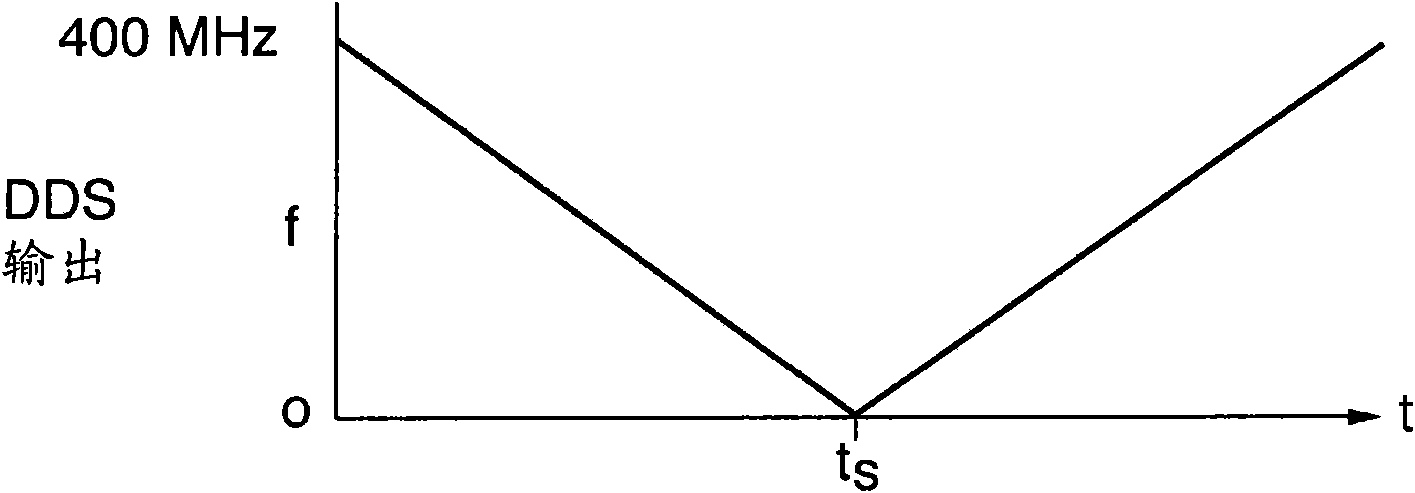

Low noise generator for frequency swept signals

ActiveCN101601183ASimplified filtering arrangementAvoid adding close-in phase noiseParallel-plate/lens fed arraysAntenna detailsLow noiseRadar systems

A signal generation system suitable for use in a radar system comprises a local oscillator (LO) and an intermediate frequency IF oscillator, wherein the IF oscillator is a Direct Digital Synthesiser, and the LO is a free runn ing oscillator not itself locked to another oscillator but which acts as a c lock reference for the DDS and is the highest frequency oscillator in the sy stem. The LO may also act as a reference for a receive chain digitiser. The invention exploits phase noise advantages of a free running oscillator at so me distance from the carrier whilst maintaining coherency with other system components. The system typically finds application in FMCW radars.

Owner:QINETIQ LTD

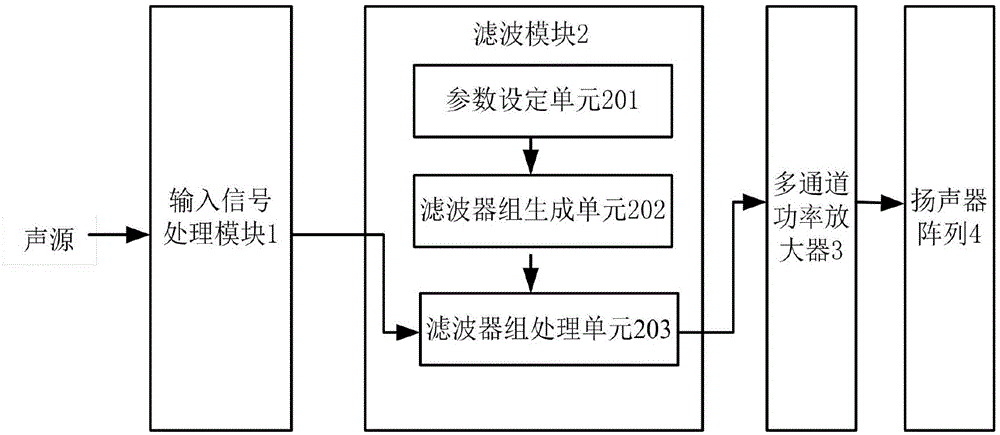

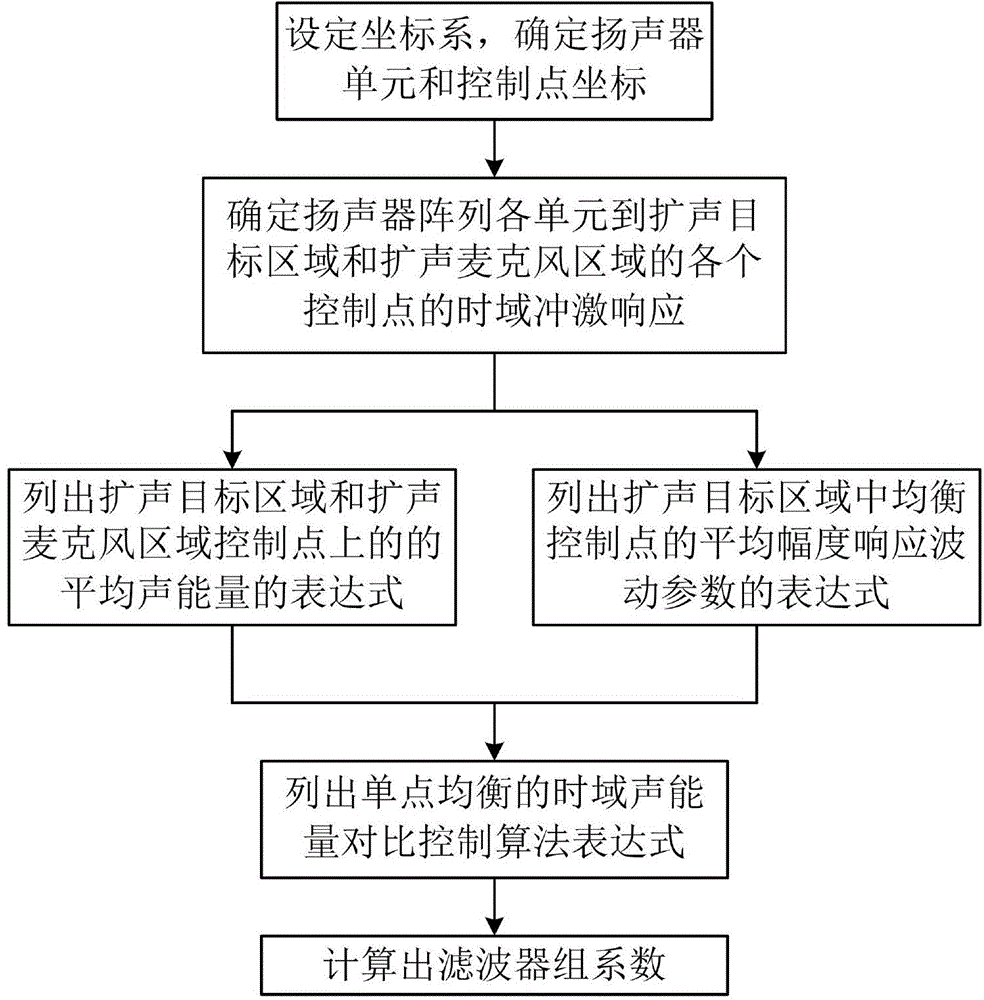

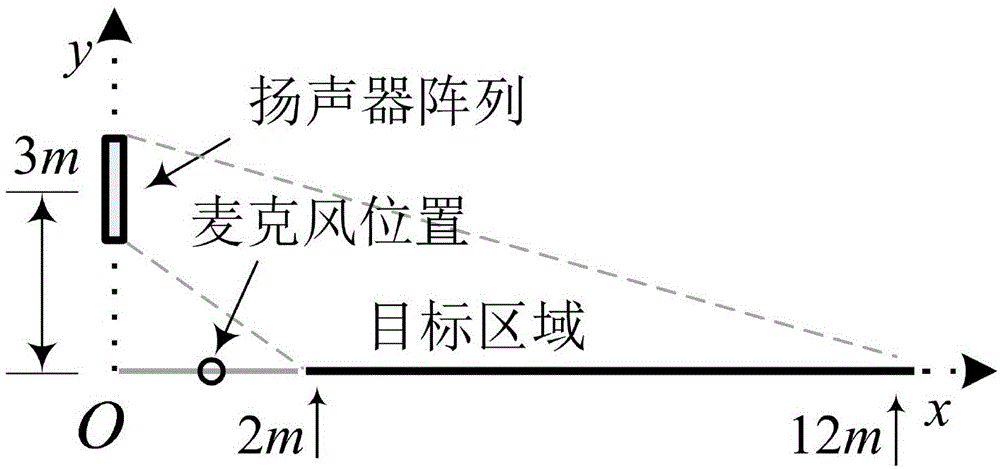

Loudspeaker array sound reinforcement system and method for inhibiting howling

ActiveCN106162482ASound field constraintsReduce echoPublic address systemsAmplitude responseAcoustic energy

The invention provides a loudspeaker array sound reinforcement system for inhibiting howling. The system comprises an input signal processing module (1), a filter module (2), a multichannel power amplifier (3) and a loudspeaker array (4); the filter module (2) comprises a parameter setting unit (201), a filter group generation unit (202) and a filter group processing unit (203); the filter group generation unit (202) is used for calculating convolution matrixes Hm and Hn formed by time domain impulse response at each control point of the loudspeaker array (4) according to parameters set by the parameter setting unit (201); calculating matrixes Rb and Rd accordingly; calculating a matrix Q according to an average amplitude response fluctuation parameter expression of an equilibrium control point in a sound reinforcement target area; solving a vector w according to Rb, Rd and Q to ensure a maximum value of time domain acoustic energy contrast control of single point equilibrium; converting the vector w into a filter form; and acquiring filter parameters of the filter group processing unit (203).

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

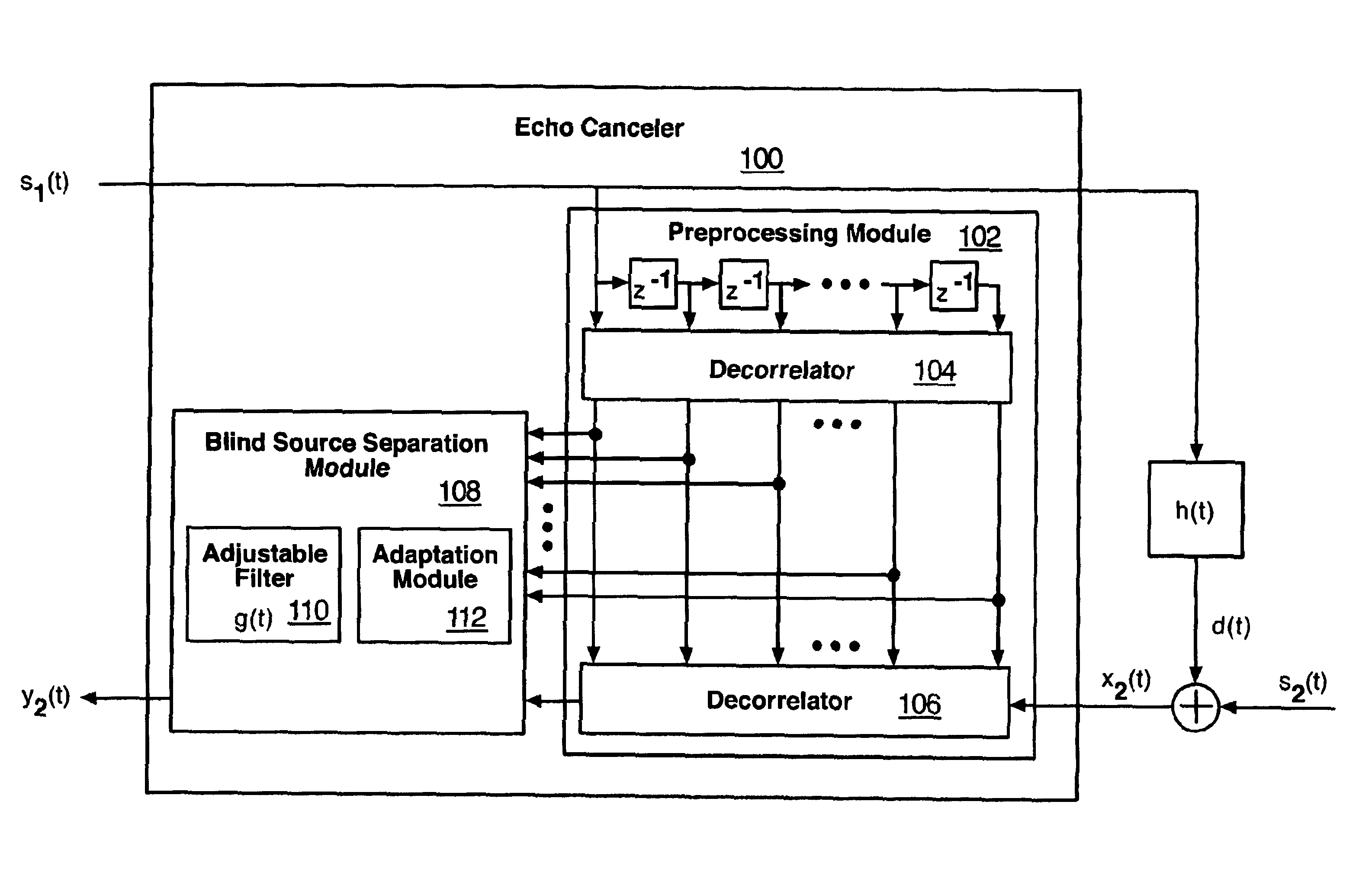

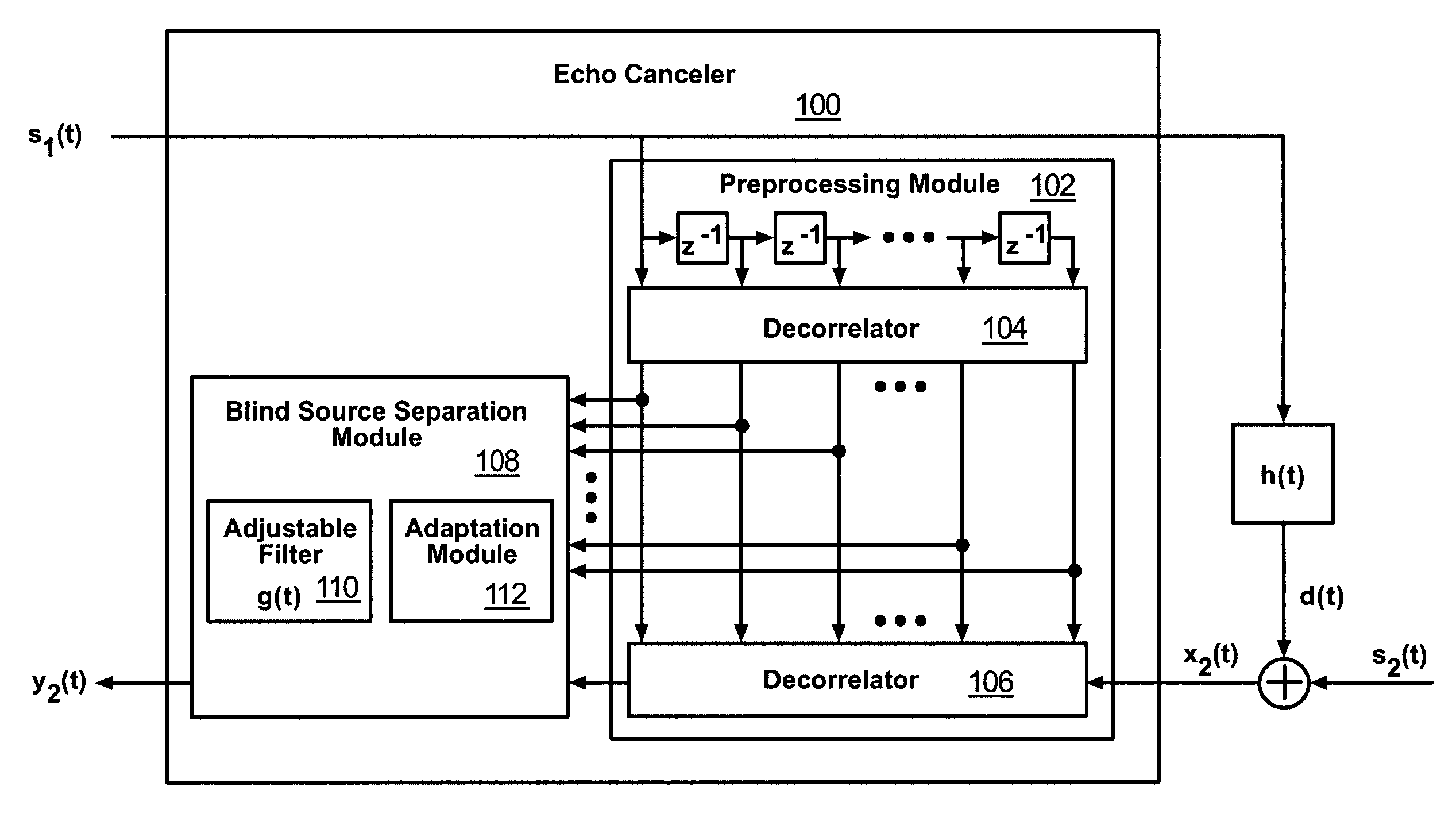

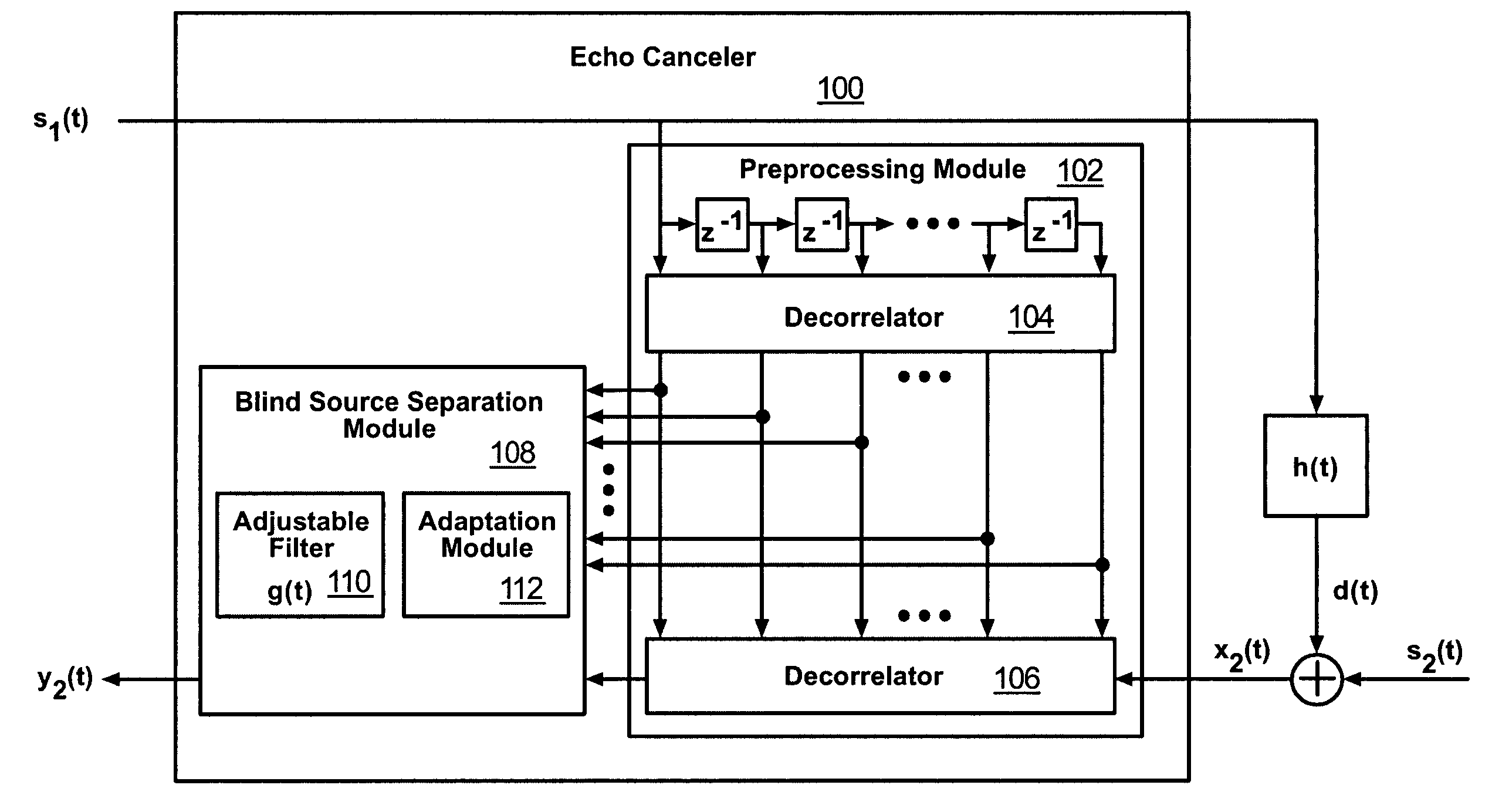

Echo cancellation filter

InactiveUS6996229B2Reduce echoAdaptable to changeTwo-way loud-speaking telephone systemsSubstation equipmentMicrophone signalNegentropy

An echo canceler includes an adaptable filter that is updated during double-talk and far-end talk. The echo canceler receives a microphone signal that includes a near-end signal and echoes resulting from a far-end signal. The echo canceler whitens the far-end signal and decorrelates the microphone signal. The whitening and decorrelating is done as a preprocessing step for the one-unit blind source separation algorithm. A criterion of measure is used to emphasize the statistical independence of the echo canceled signal and the far-end signal. The echo cancellation problem is cast as a one-unit blind source separation problem. A one-unit blind source separation algorithm such as negentropy maximization can be used to extract the echo canceled signal.

Owner:CLEARONCE COMM INC

Fly ash glass bead-ferrite compound microwave absorbing material and preparation method thereof

InactiveCN108949103AImprove absorbing performanceWith sound absorption effectOther chemical processesMagnetic/electric field screeningMicrowaveAbsorption effect

The invention provides a fly ash glass bead-ferrite compound microwave absorbing material and a preparation method thereof. The compound microwave absorbing material comprises fly ash glass beads andferrite coating the surface of the fly ash glass beads, wherein the ferrite is selected from one or more of barium ferrite BaFe12O19, barium cobalt ferrite BaCox1Fe(12-x1)O19, nickel barium ferrite BaNix2Fe(12-x2)O19 and manganese ferrite MnFe12O19, wherein x1 is 0.5-1, and x2 is 0.5-1. The compound microwave absorbing material has excellent microwave absorbing performance by coating the fly ash glass beads with a specific type of ferrite, has light weight and certain sound absorption effect. The compound microwave absorbing material has a density of 0.6-1g / cm<3>, and has a sound absorption coefficient of 0.34-0.66 and echo reduced by 5-8dB in 1-5kHz.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Clock drift compensation method and apparatus

InactiveCN103688522AReduce echoTwo-way loud-speaking telephone systemsSpeech analysisData setClock drift

A method and system to compensate for a drift between a first signal (110) and a second signal (120) is disclosed. The system includes a drift estimator (600) and a resampler (602). The drift estimator (600) receives, as input, for a predetermined amount of time, a first data set containing information related to a sample rate of the first signal (110) and a second data set containing information related to a sample rate of the second signal (120), and produces a one-time estimate of a drift between the first signal (110) and the second signal (120) based on the first data set and the second data set during the predetermined amount of time. The resampler (602) resamples the first signal (110) according to the estimated drift to compensate for the drift between the first signal (110) and the second signal (120).

Owner:GOOGLE LLC

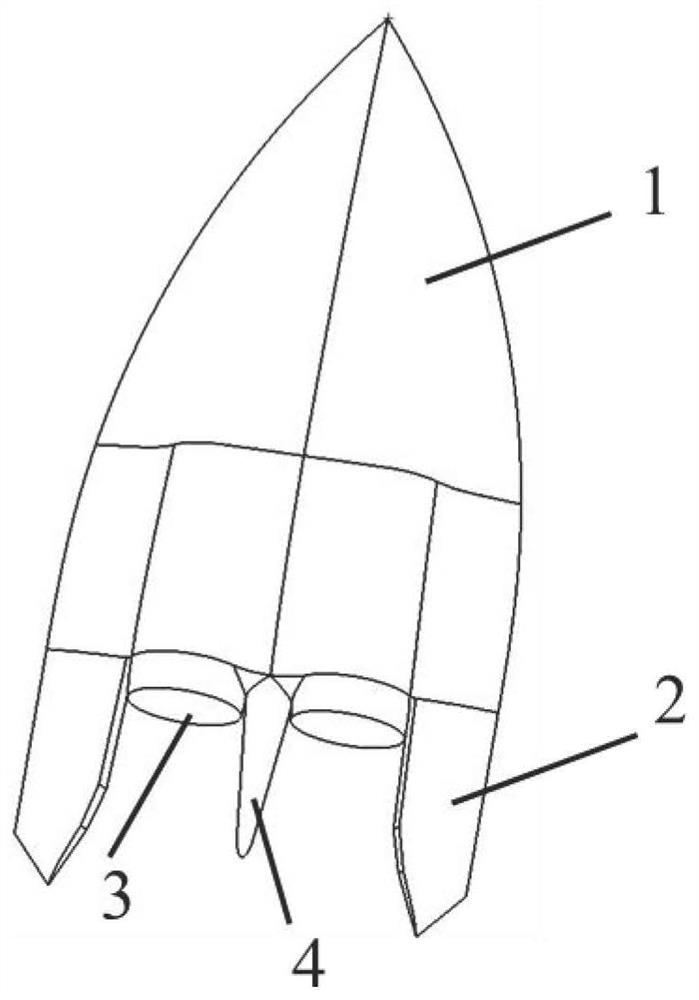

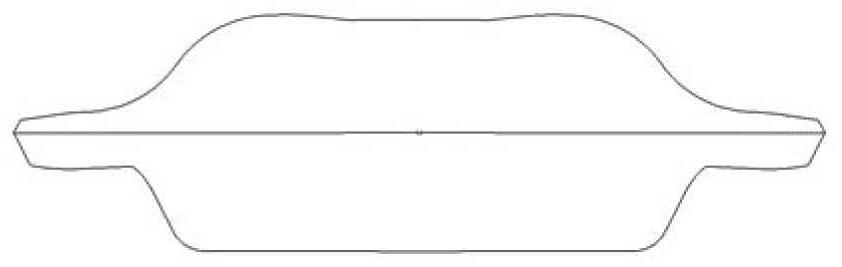

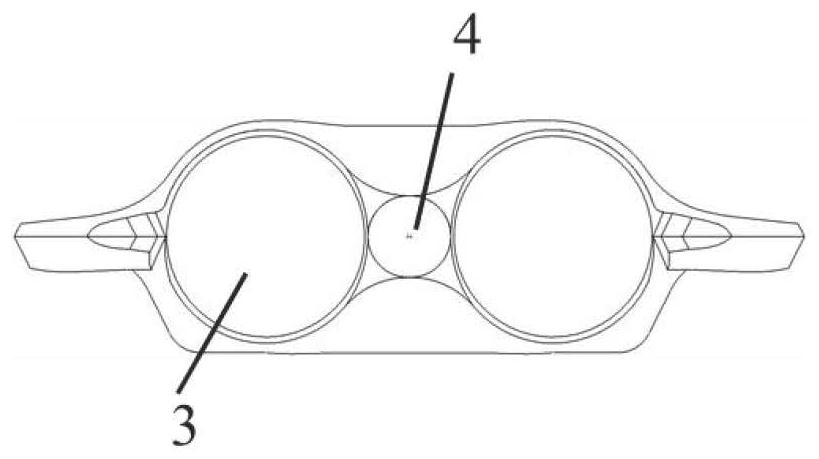

Axisymmetric double-engine low-scattering carrier for RCS testing and application method

The invention discloses an axisymmetric double-engine low-scattering carrier for RCS testing and an application method, and belongs to the field of RCS testing of aero-engines. The axisymmetric double-engine low-scattering carrier comprises a carrier body with a smooth curved surface in appearance, wherein the carrier body is divided into a carrier front half section and a carrier rear half section in the axial direction; the carrier is in the shape of a flat cone; two ports are symmetrically formed in the tail end of the rear half section of the carrier by taking the central axis as the center axis and are used for mounting a double-engine spray pipe during an electromagnetic test; and a tail cone is arranged between the two ports, and horizontal tails are symmetrically arranged on the outer sides of the two ports. Horizontal tails on the two sides and a tail cone in the middle are introduced to simulate the layout of an aircraft afterbody, the interior of a nozzle cavity is shielded when radar waves enter from the side direction, and radar echoes are reduced. In addition, the relation between single-engine and double-engine backward RCSs can be researched by testing the scattering characteristics of the double-nozzle backward radar.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for improving IP phone echo

ActiveCN108076239AReduce latency and dropoutsImprove echo problemTwo-way loud-speaking telephone systemsSpeech analysisAudio frequencyBuffer zone

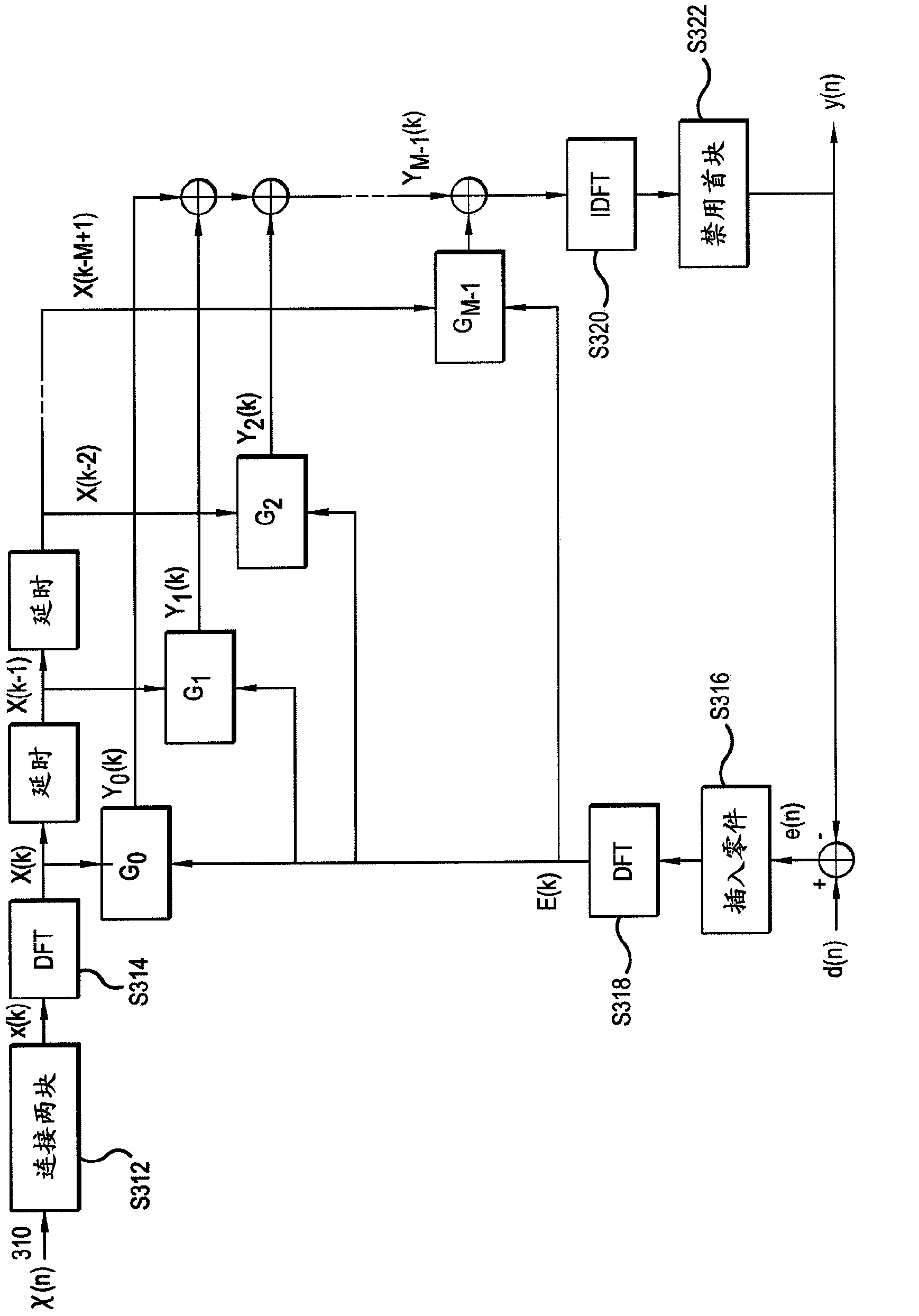

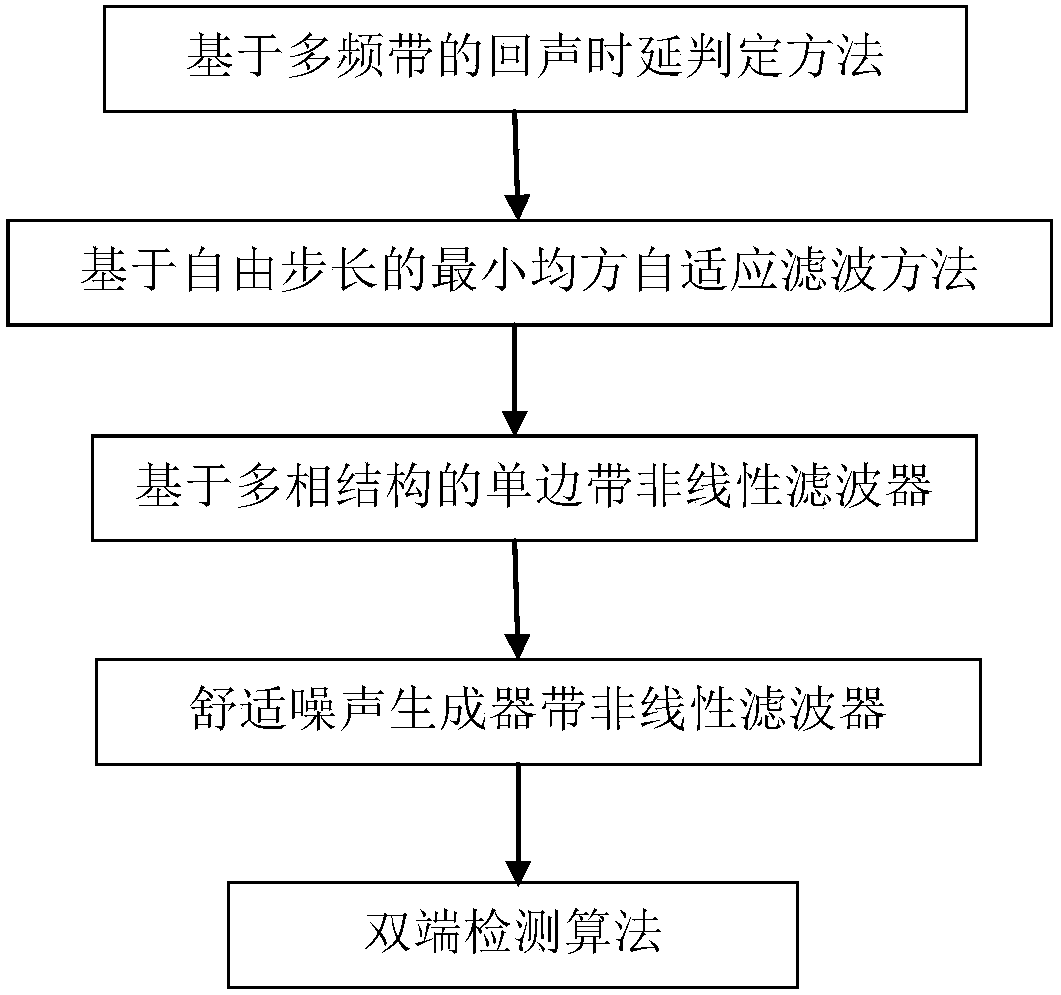

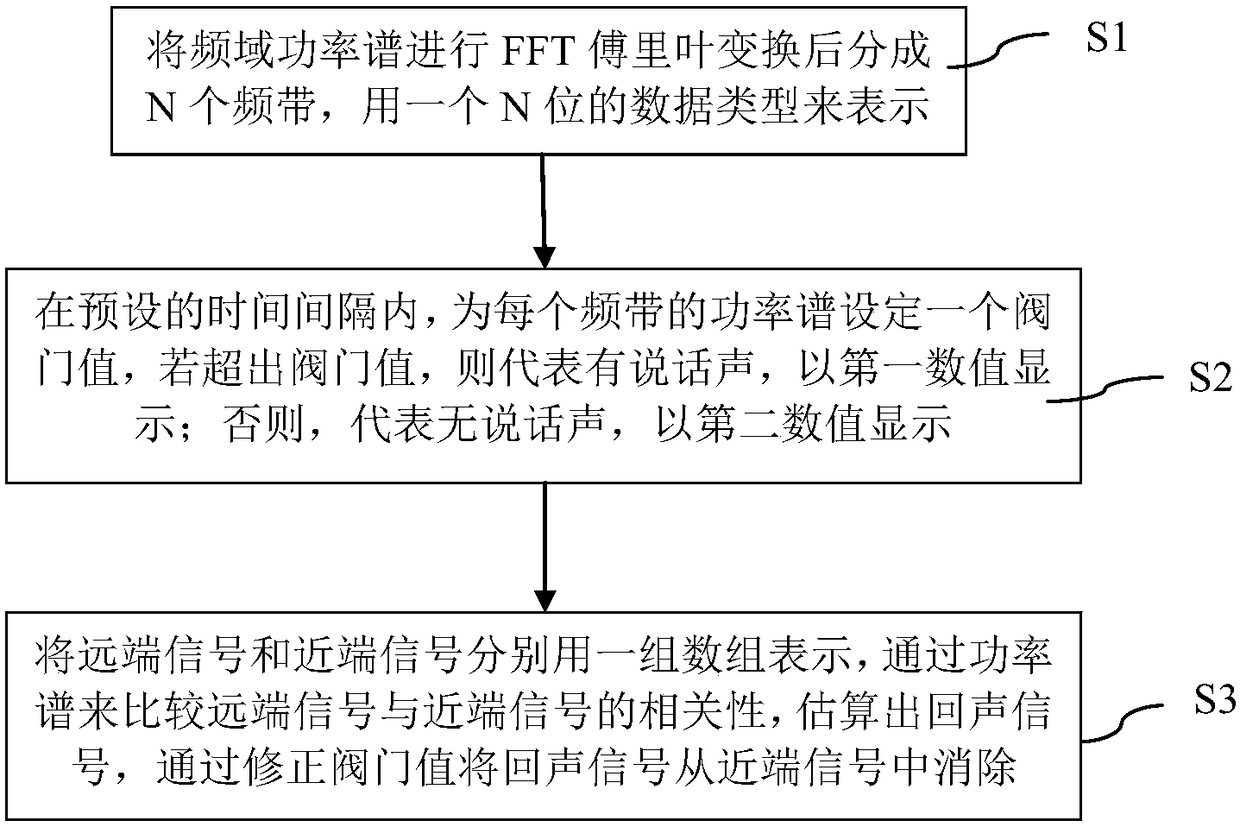

The invention discloses a method for improving IP phone echo. At least one audio channel is contained in the method, wherein each audio channel comprises a recording thread, a receiving thread and a playing thread; the recording thread performs audio processing on microphone sound acquired each time through an echo cancellation module and transmits the processed audio data to the opposite side; the echo cancellation module contains a multiband-based echo delay determination method, a least mean square self-adaptive filtering method based on free step length, a single side band nonlinear filterbased on a multiphase structure, a comfort noise generator and a double-talk detection algorithm; and the receiving thread processes audio data sent by the opposite side and then sends the audio datato a buffer zone, and the playing thread processes the audio data in the buffer zone and plays the processed audio data. The method has the benefits as follows: the voice call quality is improved byreducing the echo phenomenon of an IP phone in a call, the internet phone practicability can be improved, the application range of the internet phone is enlarged, and the enterprise cost is reduced.

Owner:SHENZHEN LAN YOU TECH

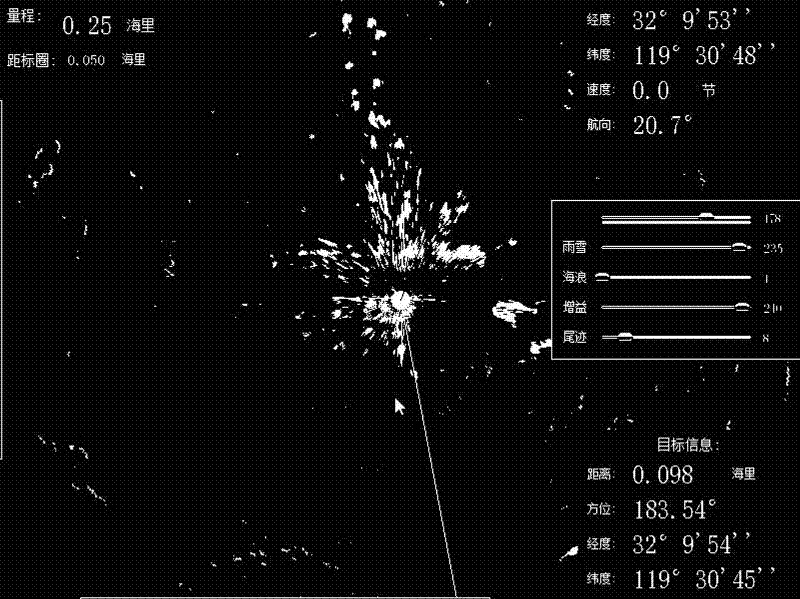

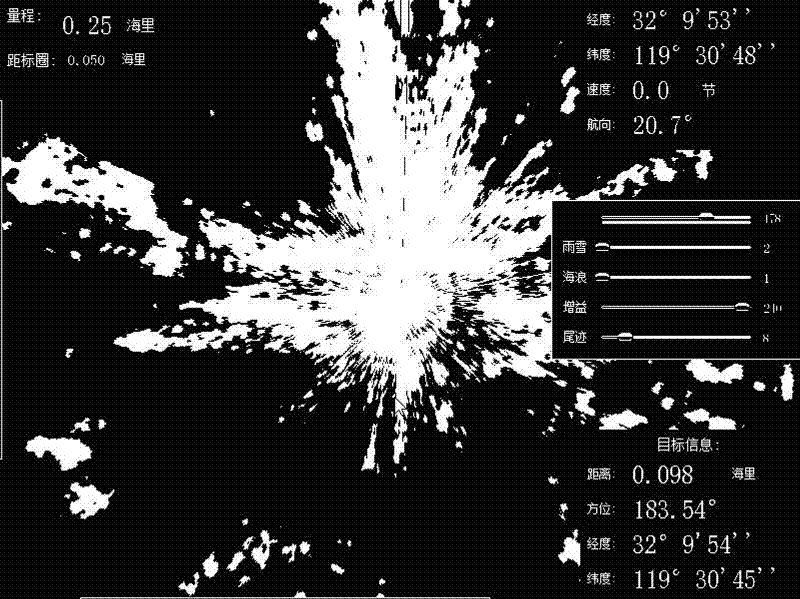

Method for inhibiting precipitation clutter in radar echo

ActiveCN102305930AReduce echoTo achieve the purpose of clutter suppressionWave based measurement systemsRadarTarget signal

The invention discloses a method for inhibiting precipitation clutter in radar echo, which comprises the following steps of: firstly, inputting a radar echo image, carrying out mode matching on the radar echo image according to a precipitation noise distributing formula and recognizing the distributing areas of different signals; secondly, marking a suspected target in a dye spot way according tothe distributing characteristics of clutter in different signal areas; then, separating a suspected precipitation clutter signal by a filter and carrying out precipitation clutter recognition on the separated suspected precipitation clutter signal; after carrying out secondary scanning separation on a hidden small target in the precipitation clutter, transmitting a non-precipitation clutter smalltarget to the radar echo image in which the target signal is located; meanwhile, filtering the recognized precipitation clutter; and finally, after properly strengthening the target signal in the processed radar echo image, inputting the target signal into a display system. The invention can carry out effective clutter removal on the radar echo image in severe weather, such as precipitation, and the like.

Owner:镇江光宁航海电子科技有限公司

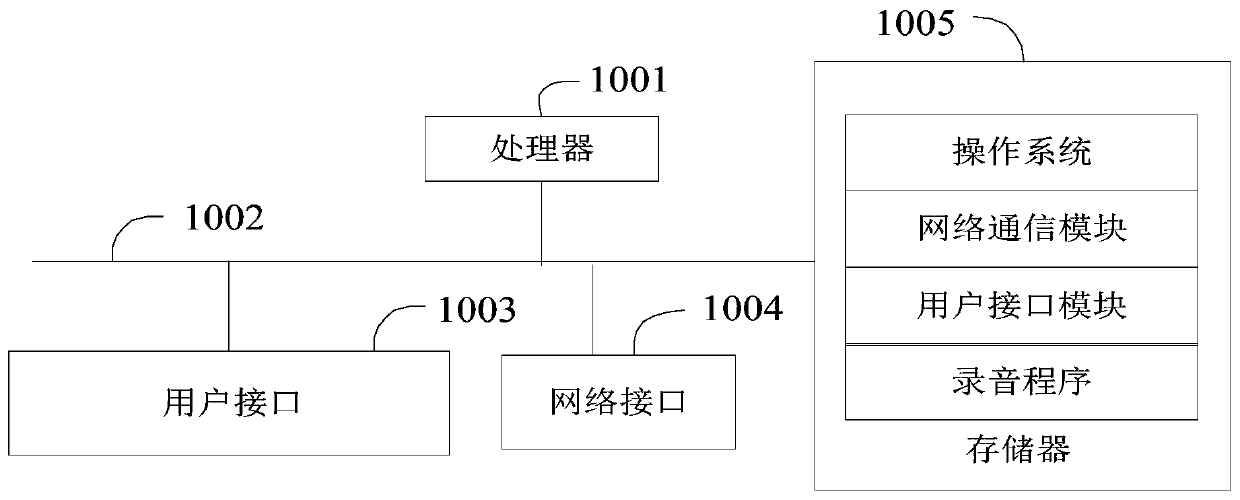

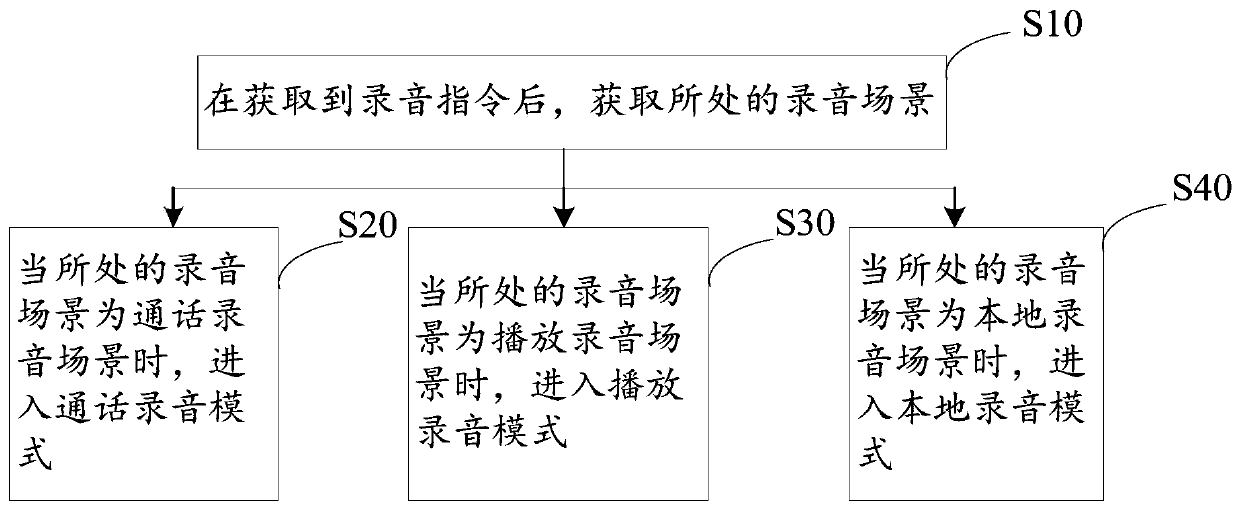

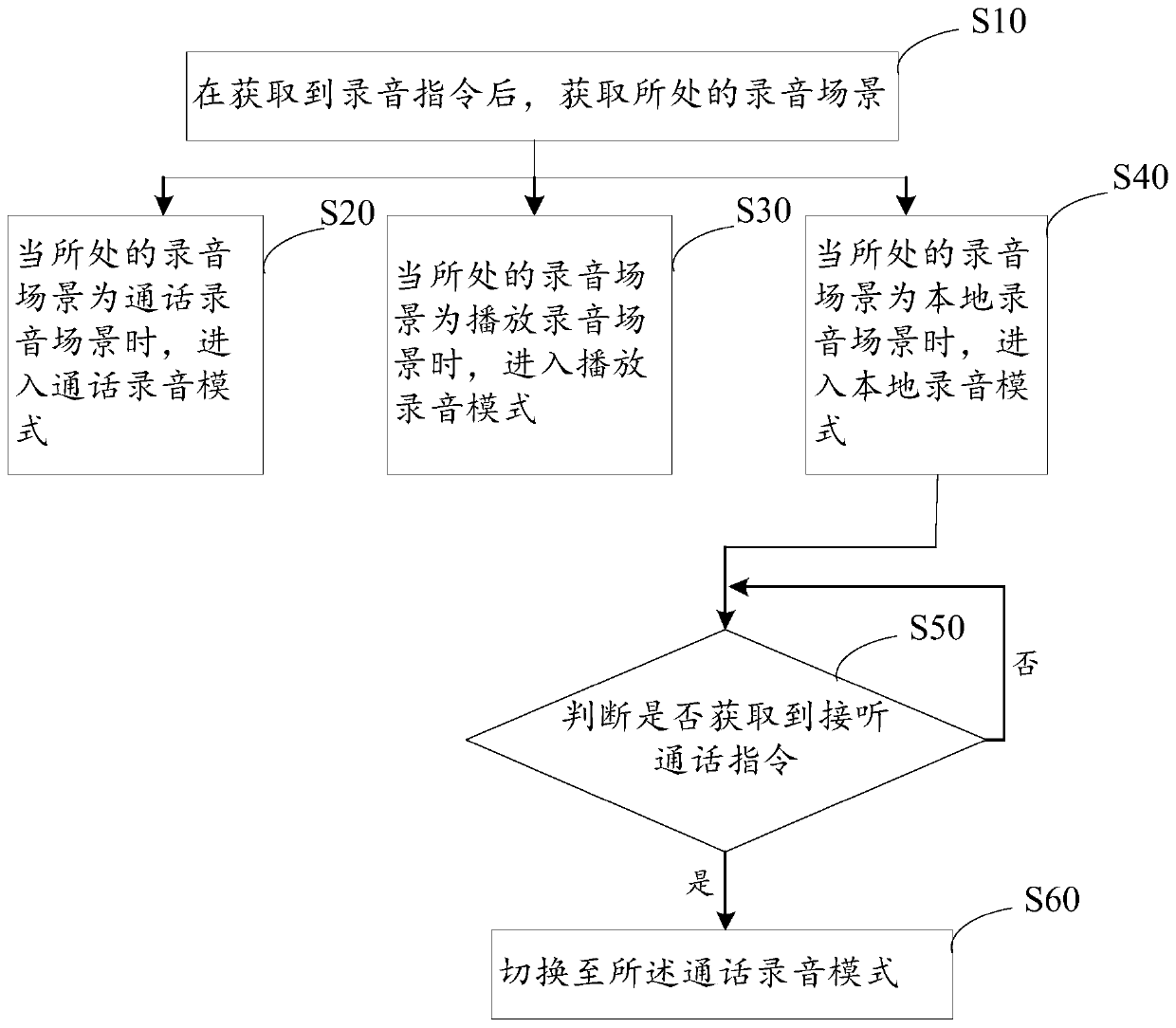

Recording method, terminal and computer readable storage medium

InactiveCN110198375AQuality improvementImprove claritySpeech analysisAutomatic call-answering/message-recording/conversation-recordingComputer terminalSpeech sound

The invention discloses a recording method, a terminal and a computer readable storage medium, and the method comprises the steps: obtaining a recording scene after obtaining a recording instruction;when the located recording scene is a call recording scene, entering a call recording mode; when the located recording scene is a recording playing scene, entering a recording playing mode; and when the located recording scene is a local recording scene, entering a local playing recording mode. The recording method, the terminal and the computer readable storage medium aim to solve technical problems that existing recording equipment cannot be suitable for various recording scenes, and the recording effect is poor. According to the method and the device, the targeted recording modes are designed for different recording scenes, the voice can be differentially recorded based on the characteristics of the recording scenes, the definition and the intelligibility of the voice are improved, incoherent noise and echoes are weakened, and in addition, a basis can be provided for subsequent voice-to-character conversion.

Owner:SHENZHEN EMEET TECH CO LTD

Echo cancellation filter

InactiveUS20050008144A1Reduce echoAdaptable to changeTwo-way loud-speaking telephone systemsEngineeringMicrophone signal

An echo canceler includes an adaptable filter that is updated during double-talk and far-end talk. The echo canceler receives a microphone signal that includes a near-end signal and echoes resulting from a far-end signal. The echo canceler whitens the far-end signal and decorrelates the microphone signal. The whitening and decorrelating is done as a preprocessing step for the one-unit blind source separation algorithm. A criterion of measure is used to emphasize the statistical independence of the echo canceled signal and the far-end signal. The echo cancellation problem is cast as a one-unit blind source separation problem. A one-unit blind source separation algorithm such as negentropy maximization can be used to extract the echo canceled signal.

Owner:CLEARONCE COMM INC

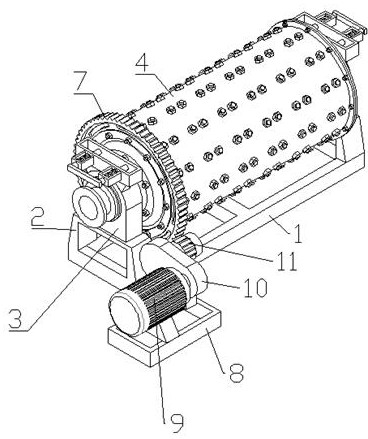

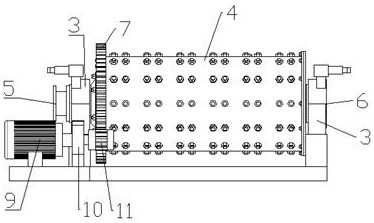

Buffering noise reduction ball mill

The invention discloses a buffering noise reduction ball mill. The buffering noise reduction ball mill comprises a chassis, supporting frames, bearing seats, a cylinder body, a discharge port, a feeding port, a driven gear, a motor seat, a motor, a speed reducer, a driving gear and a sound-proof cover. The supporting frames are vertically welded to the left and right ends of the chassis. The bearing seats are fixed to the tops of the supporting frames. The cylinder body is arranged between the two bearing seats. The discharge port and the feed port are formed in the left and right ends of thecylinder body correspondingly. The driven gear is fixed to the left end of the cylinder body. The motor is mounted at the top of the motor seat. An output shaft of the motor is mounted with the speedreducer. An output shaft of the speed reducer is mounted with the driving gear. The driving gear is engaged with the driven gear. The outer side of the cylinder body is provided with the sound- proofcover. Impact force applied to a lining plate by a steel ball is reduced, the service life of the lining plate is prolonged, the influence of noise in the cylinder body on people is reduced, eardrumsof the people are protected against being damaged, and workers can communicate normally.

Owner:屠文水

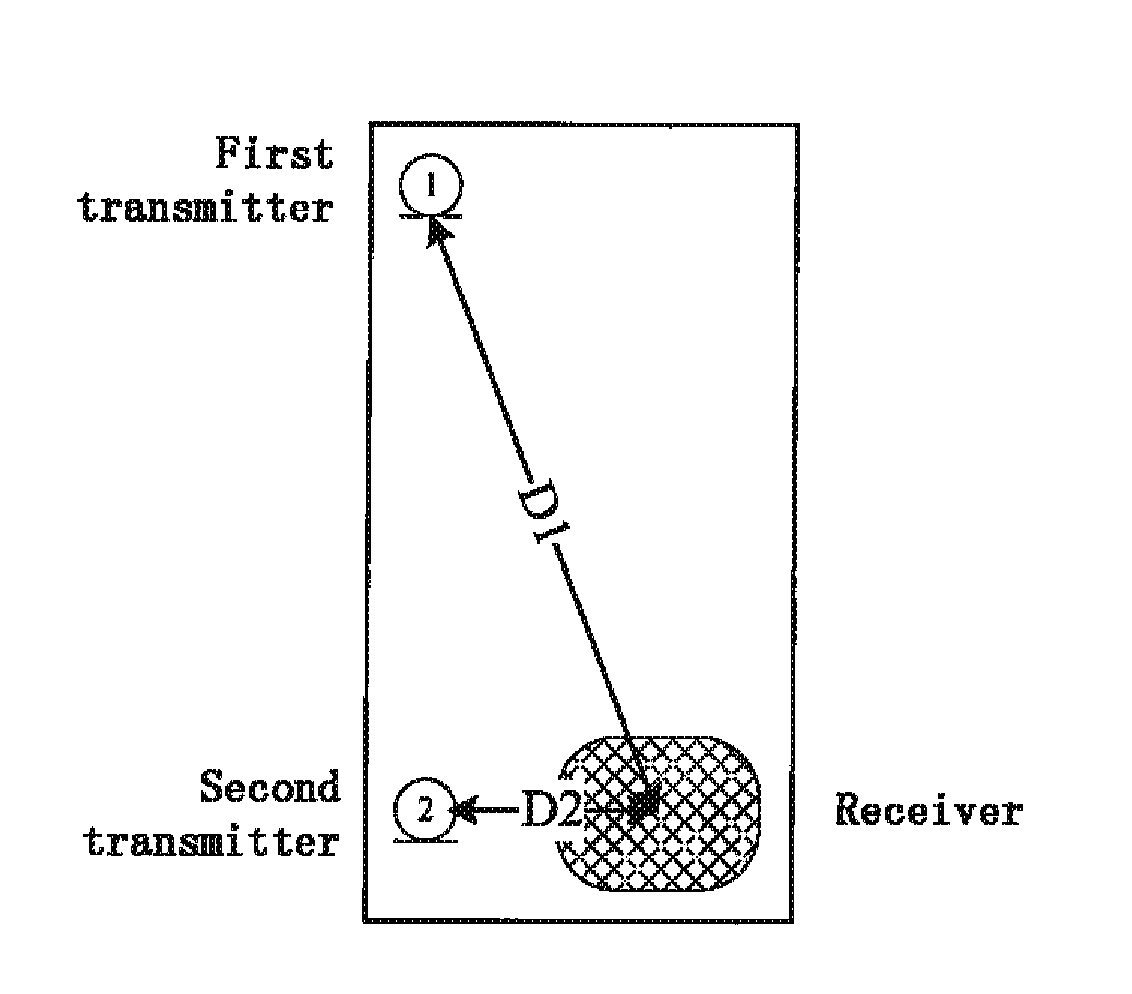

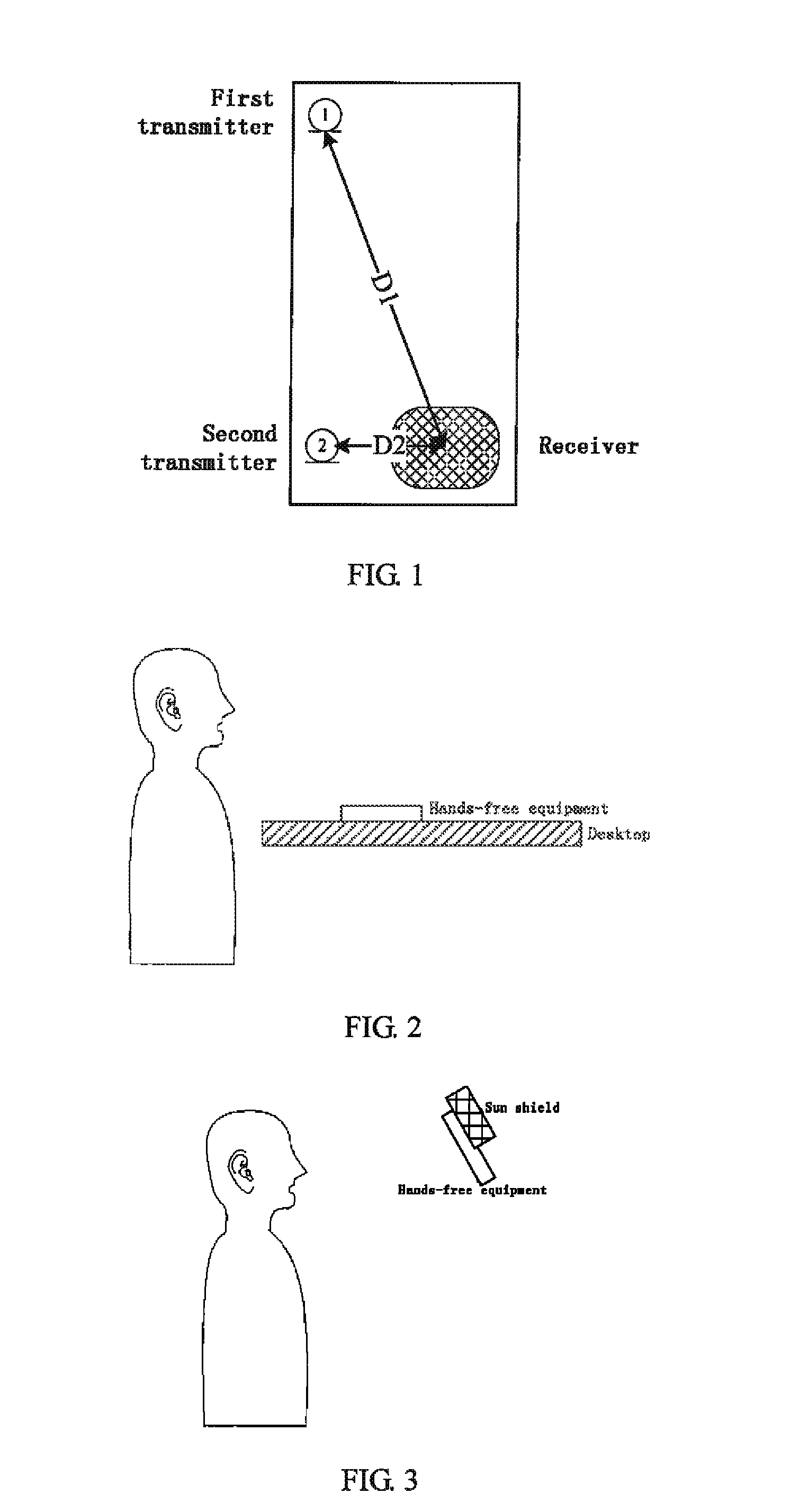

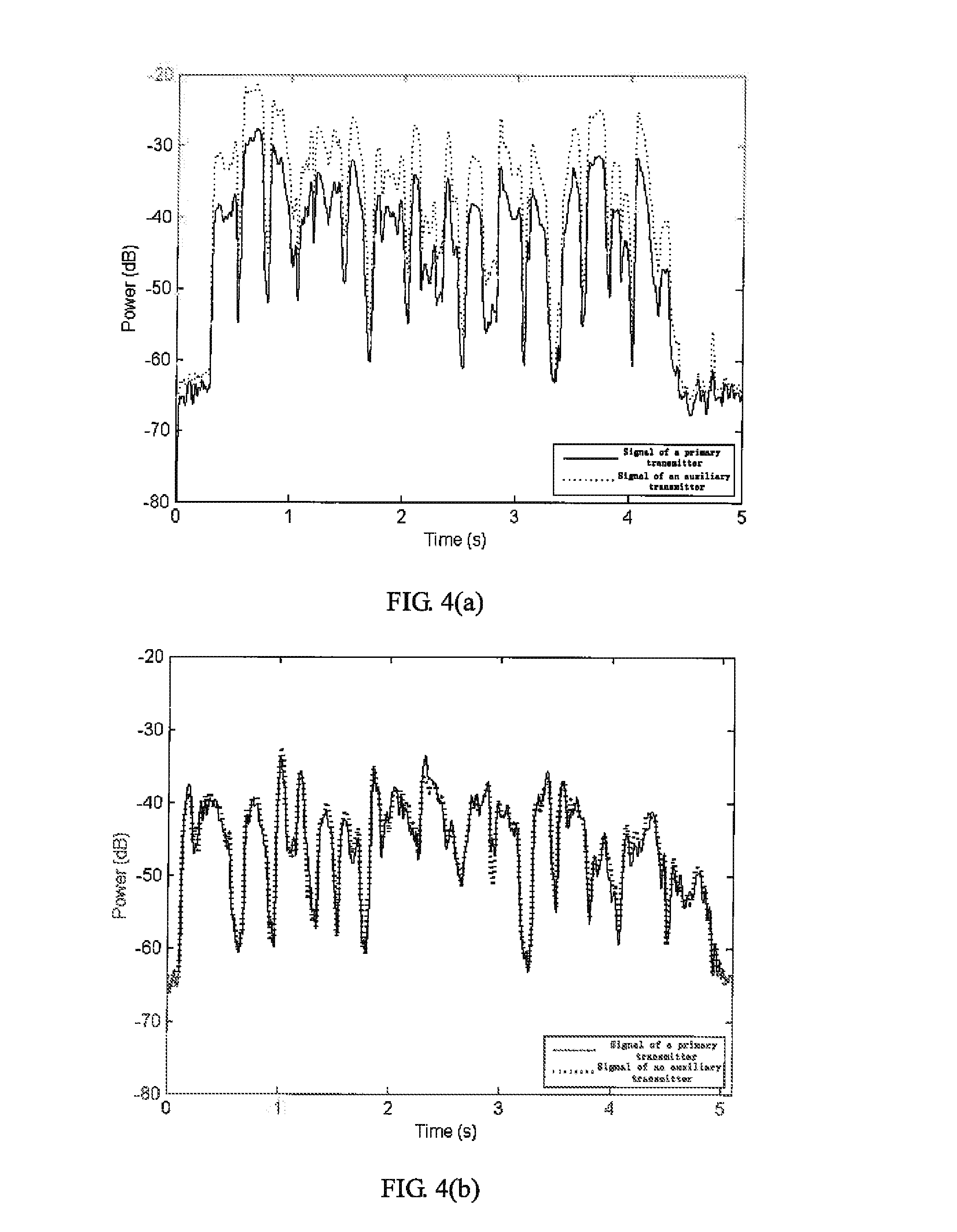

Echo Elimination Device And Method For Miniature Hands-Free Voice Communication System

ActiveUS20150172468A1Improve performanceEfficient removalTwo-way loud-speaking telephone systemsSubstation equipmentProbability estimationVoice communication

The present invention discloses an echo elimination device and method for a miniature hands-free voice communication system. The system comprises a receiver, a primary transmitter and an auxiliary transmitter, a distance from the primary transmitter to the receiver being greater than that from the auxiliary transmitter to the receiver. The device comprises an array echo elimination unit, a self-adaptive echo elimination unit and a residual echo elimination unit, which are structurally cascaded in turn. The array echo elimination unit, with inputs being a signal of the primary transmitter and a signal of the auxiliary transmitter, performs array filtering to obtain one path of output signals; the self-adaptive echo elimination unit, with the input signals being a signal of the receiver, the output signal of the array echo elimination unit and a signal of the auxiliary transmitter, performs self-adaptive filtering to obtain two paths of output signals; the residual echo elimination unit, with the input signals being the two paths of output signals of the self-adaptive echo elimination unit, performs voice probability estimation and echo matching to obtain an echo-eliminated voice signal. Thus, the duplex performance can be enhanced, and the phase consistency of the transmitters is not strictly required.

Owner:GOERTEK INC

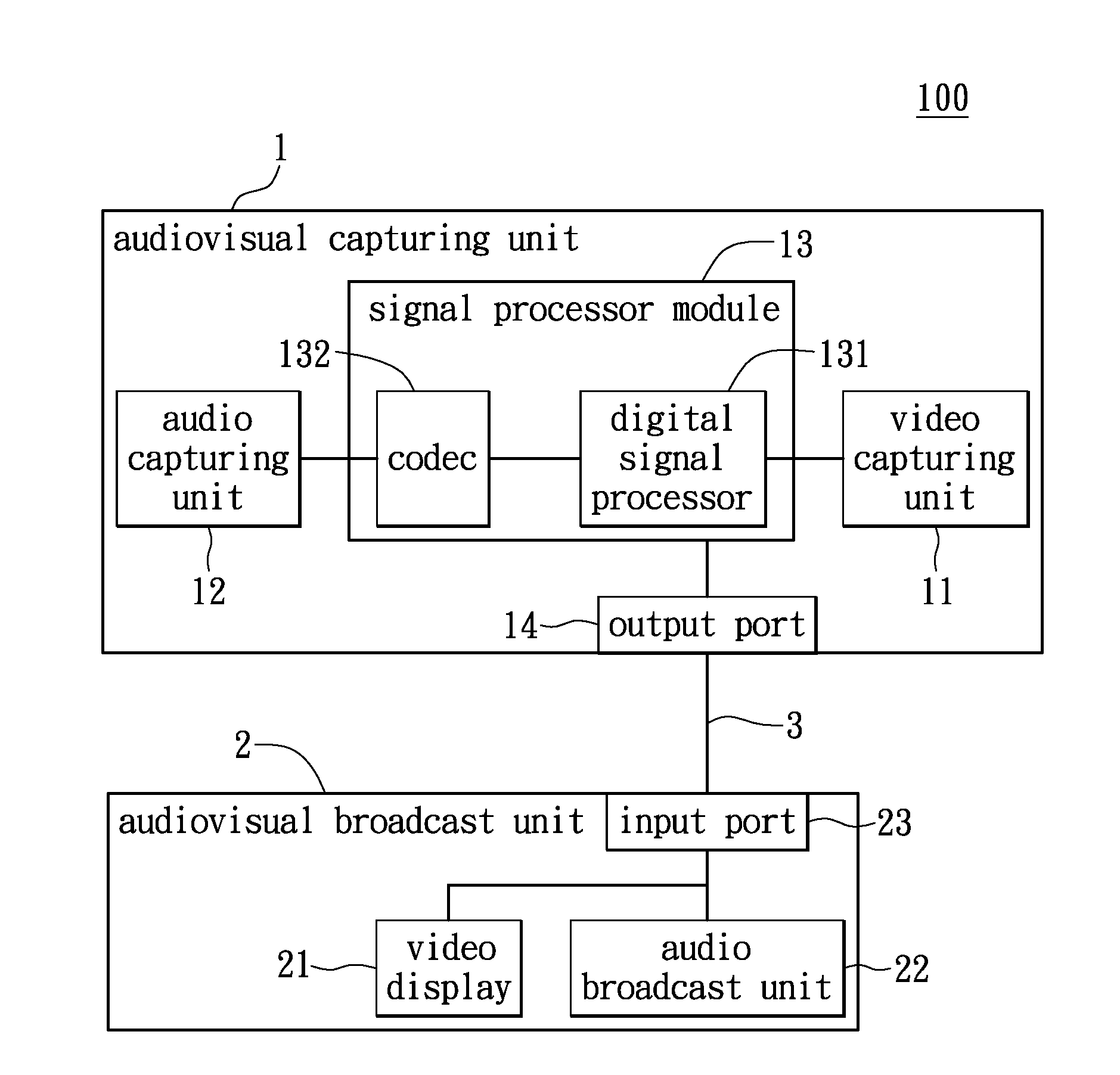

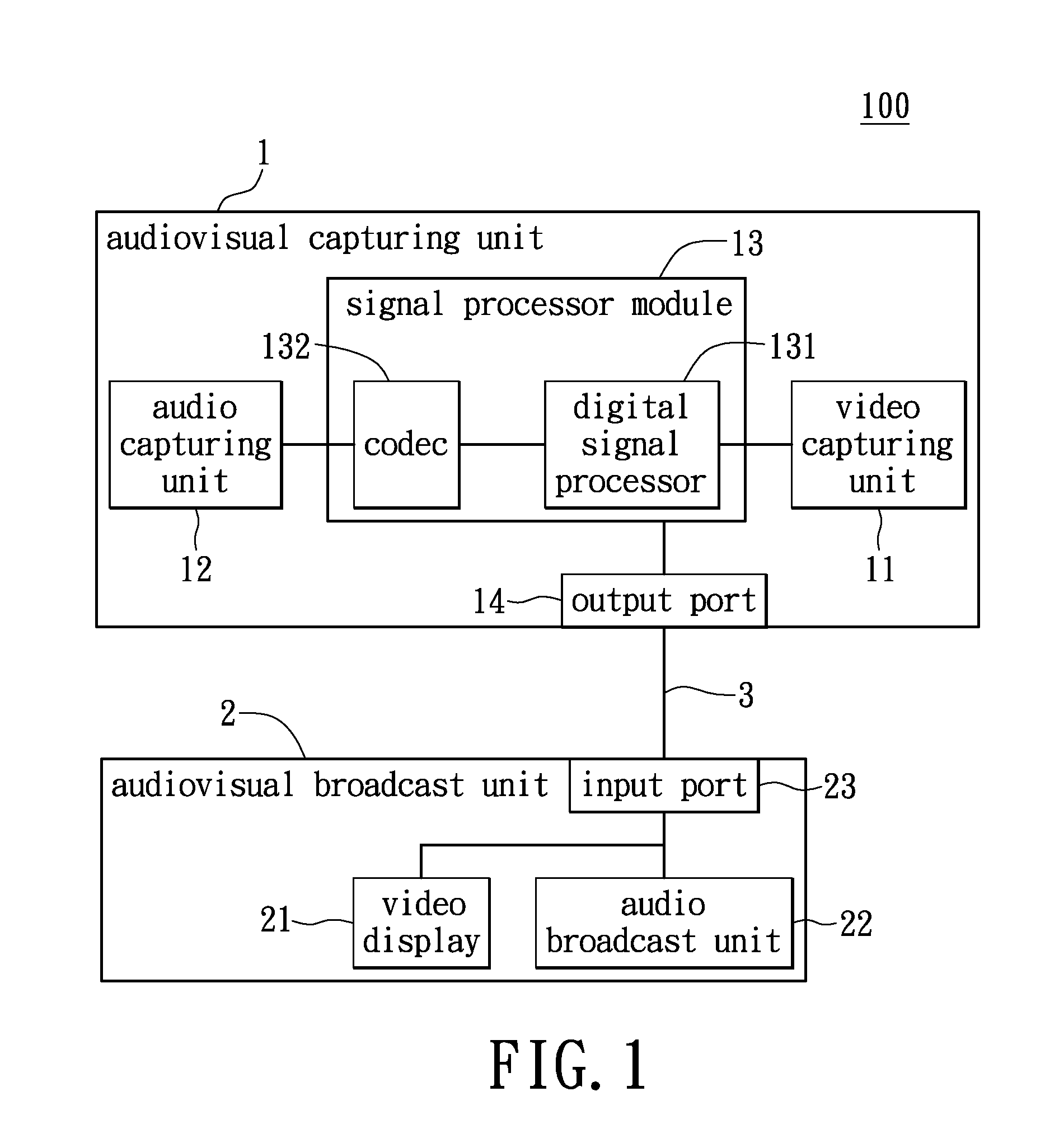

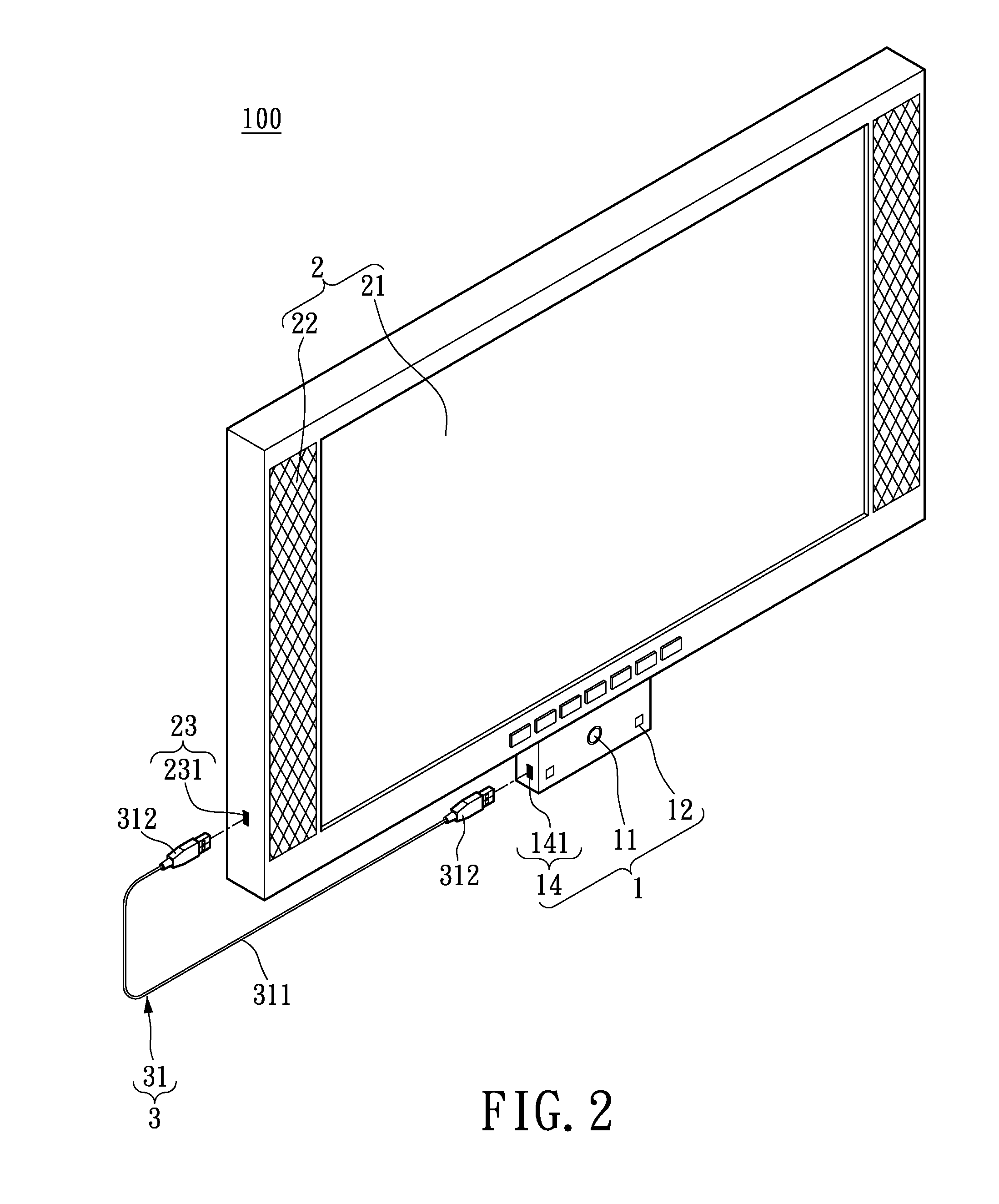

Audiovisual apparatus for reducing echo

InactiveUS20140125756A1Reduce echoTwo-way loud-speaking telephone systemsCathode-ray tube indicatorsDigital clockAudiovisual device

The present disclosure relates to an audiovisual apparatus, which includes an audiovisual capturing unit, an audiovisual broadcast unit, and a transmission cable module. The two ends of the transmission cable module are respectively connected to the audiovisual capturing unit and the audiovisual broadcast unit. The transmission cable module has a video cable group for transmitting video signals and an audio cable group for transmitting audio signals suitable for reducing echo. The audio cable group includes a cable for providing a digital clock for the audio signal, a cable for providing a clock for the left right channel switching audio signal, a cable for inputting serial audio signal, and a cable for outputting serial audio signal. With this arrangement, the audio signals captured by the audiovisual capturing unit and transmitted by the transmission cable module to the audiovisual broadcast unit can be effectively removed of echo.

Owner:ANHUI HAIHUA CHEM

Radar/infrared compatible stealth metasurface

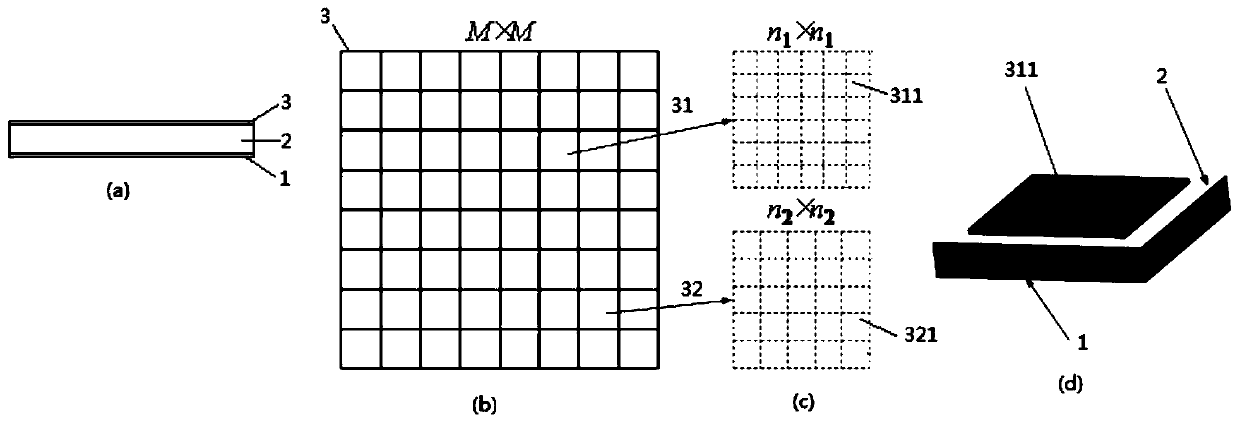

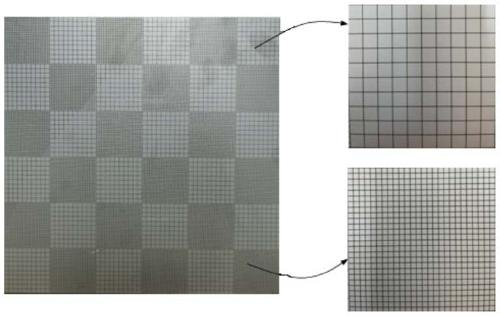

The invention discloses a radar / infrared compatible stealth metasurface, which belongs to the technical field of novel artificial electromagnetic materials. The metasurface comprises a conductive reflection layer, a dielectric layer and a conductor film functional layer which are sequentially arranged from bottom to top; the conductor film functional layer is of an M * M array structure of patch large units I and patch large units II; each patch large unit I is of an n1 * n1 array structure composed of patch small units I, and each patch large unit II is of an n2 * n2 array structure composedof patch small units II; M is an even number; the patch large units I and the patch large units II are the same in size and number; the patch small units I and the patch small units II are different in size. The metasurface is composed of a conductive reflection layer-dielectric layer-conductor film functional layer sandwich structure, the structure is simple, and radar and infrared stealth compatibility of the structure can be achieved at the same time only through one layer of artificial structure unit array.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com