Complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units

A flat-link, closed-loop technology, applied in wing adjustment and other directions, can solve the problems that the basic unit structure cannot be changed, the degree of freedom of the basic unit is not 1, and stays in theoretical analysis, so as to avoid early separation and reduce the risk of failure. , the effect of improving the cruising ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

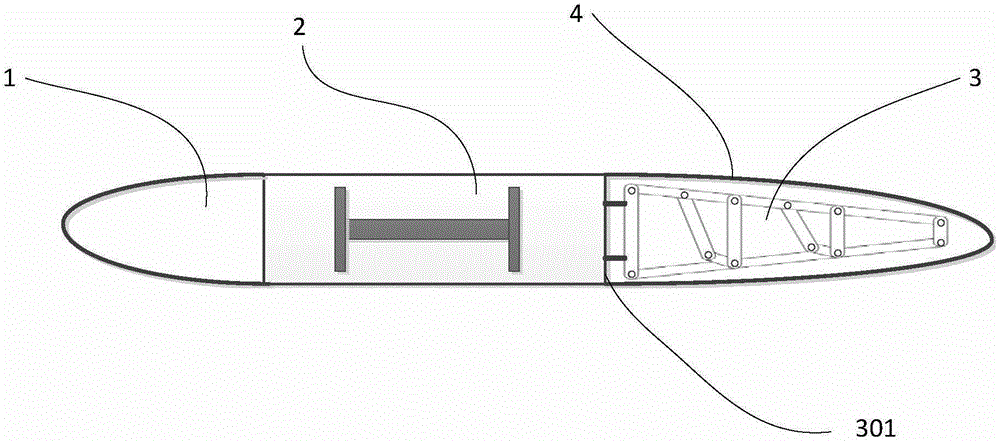

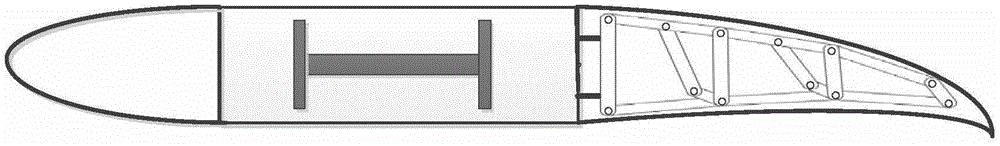

[0032] Such as Figure 1-Figure 4 As shown, the present embodiment provides a kind of aircraft wing, and this aircraft wing comprises wing leading edge 1, wing middle part 2, wing trailing edge 3, wing skin 4; Wherein, wing middle part 2 camber cannot Change, the camber of the wing trailing edge 3 is variable.

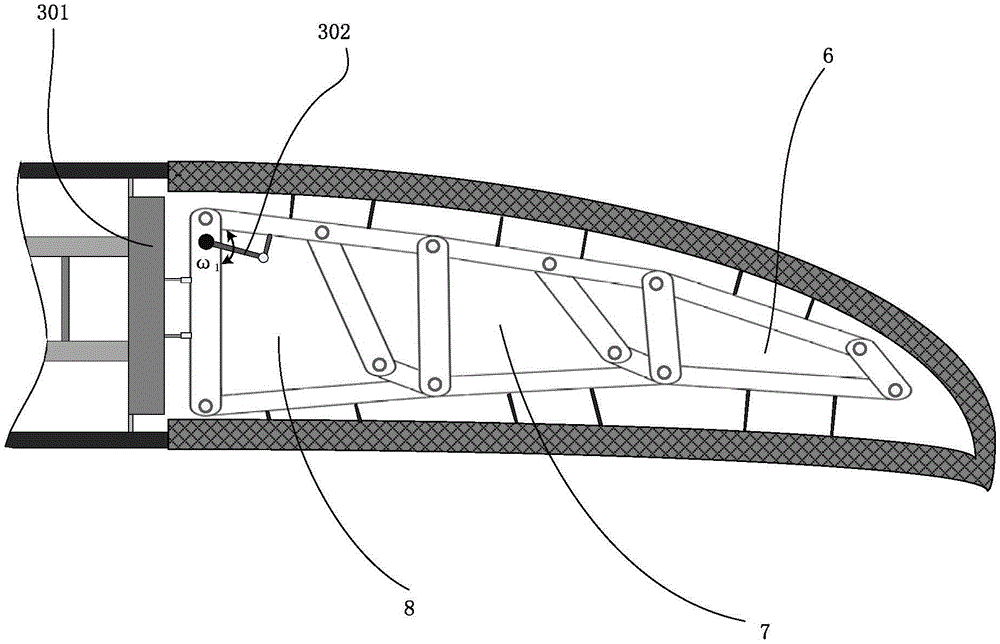

[0033] The wing trailing edge 3 includes a rear beam 301, three sets of closed-loop rod group units, and a drive mechanism 302; the rear beam 301 is connected to the rear end of the main beam; the closed-loop rod group unit is a planar rod group structure based on a 6R closed-loop unit, which has one degree of freedom;

[0034] Among them, such as Figure 4 As shown, three groups of closed-loop rod group units include a group of end units 6, a group of intermediate units 7, and a group of starting units 8; between end units 6;

[0035] The end unit 6 includes a first upper rail 601, a first lower rail 602, a right vertical bar 603, a first middle vertical bar 604, a...

Embodiment 2

[0043] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that: the first lower cross bar is a straight bar, and the second lower cross bar is also a straight bar.

Embodiment 3

[0045] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the upper end point of the first diagonal bar is hinged to the right end point of the second upper cross bar; the upper end point of the second inclined bar is hinged to the right end point of the third upper cross bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com