Patents

Literature

72results about How to "Realize flexible adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

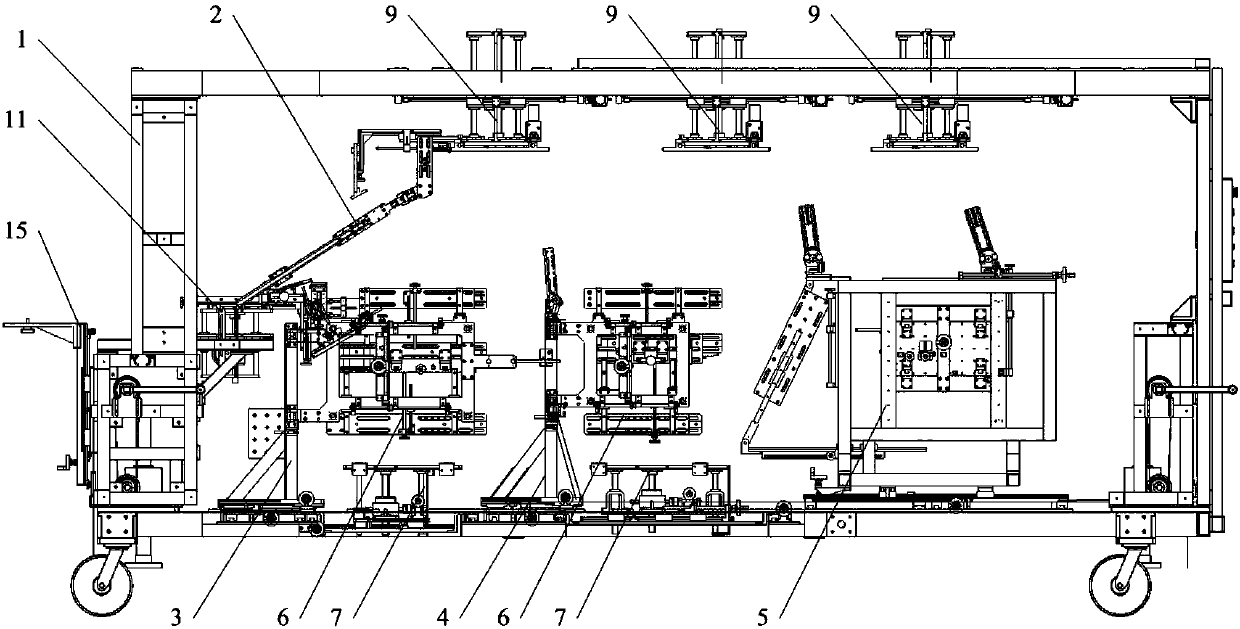

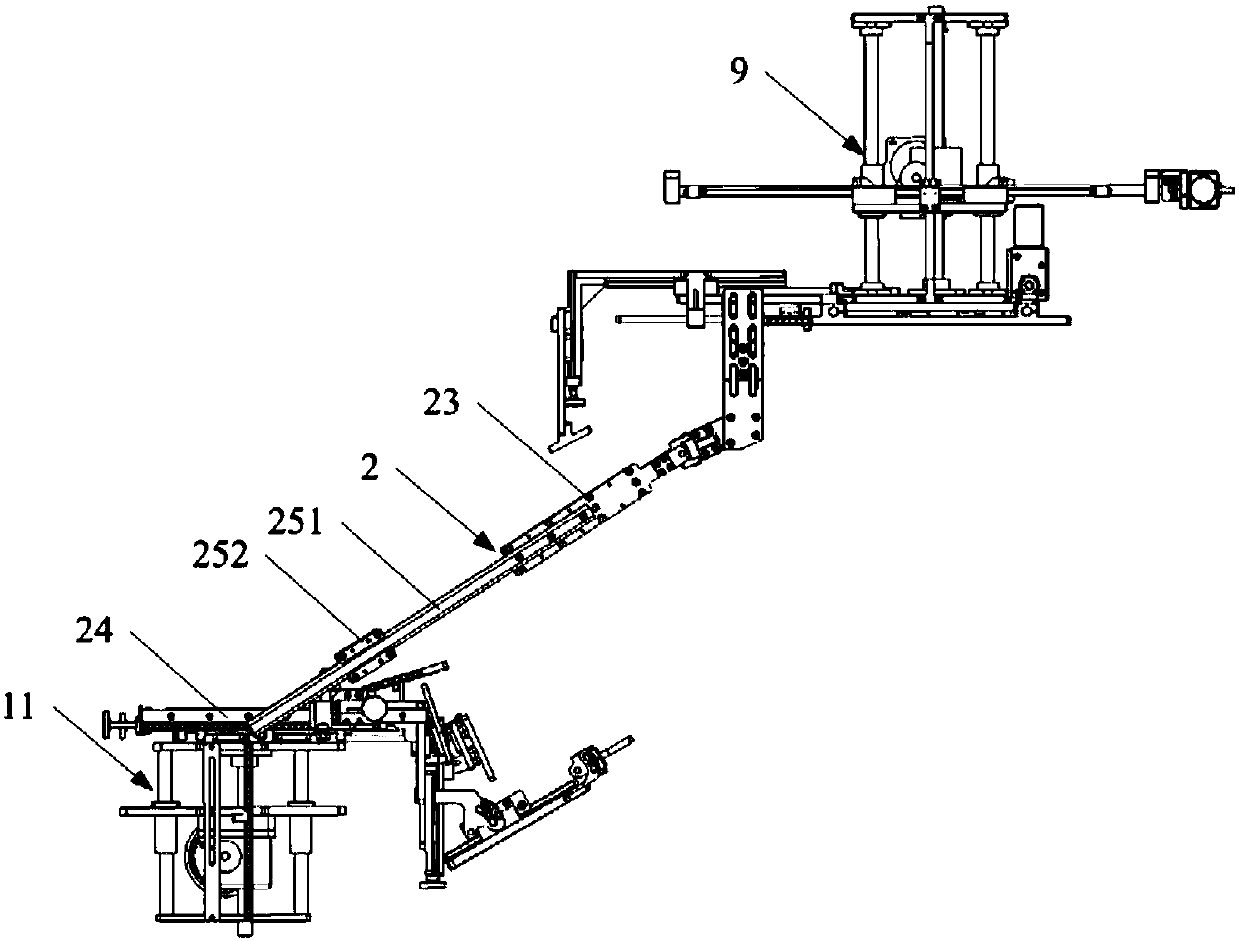

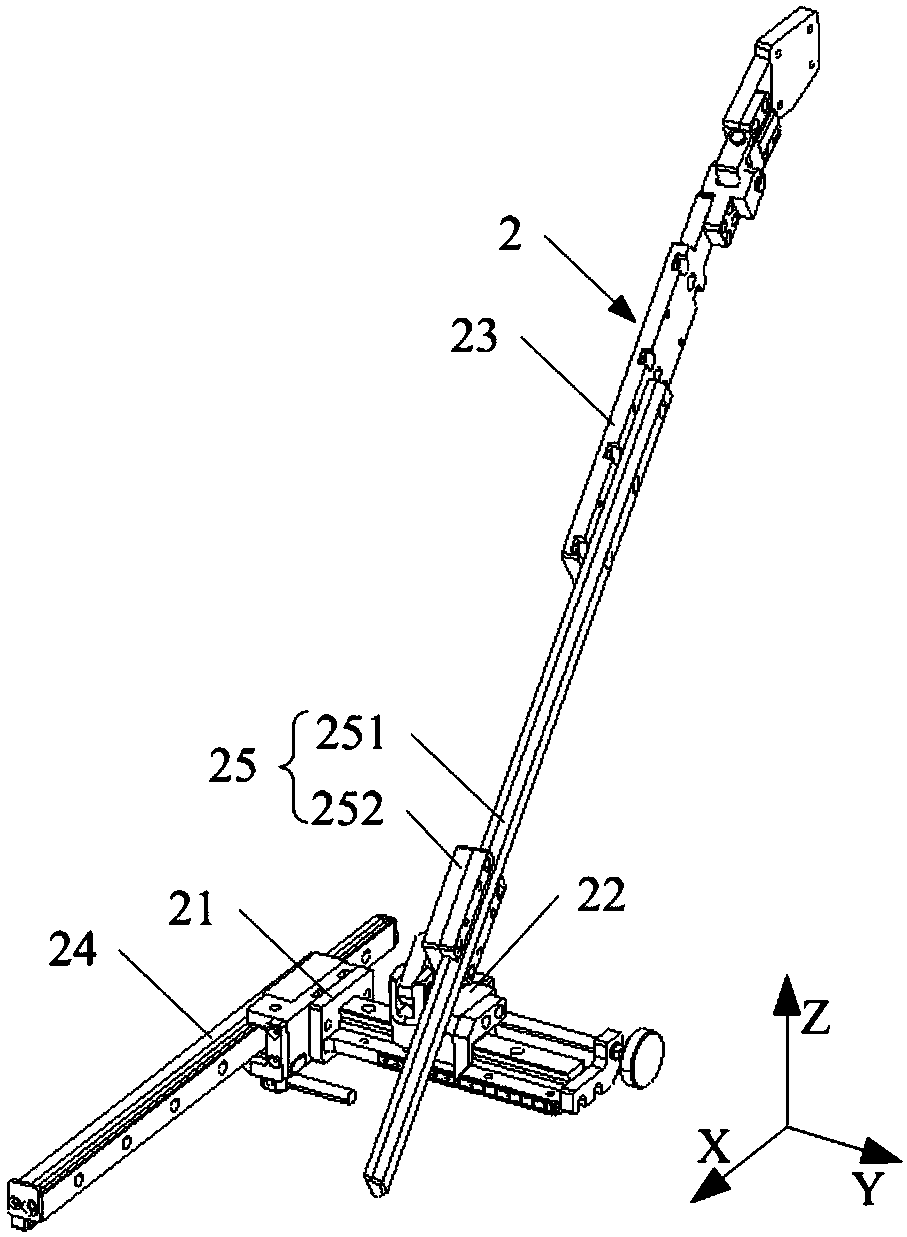

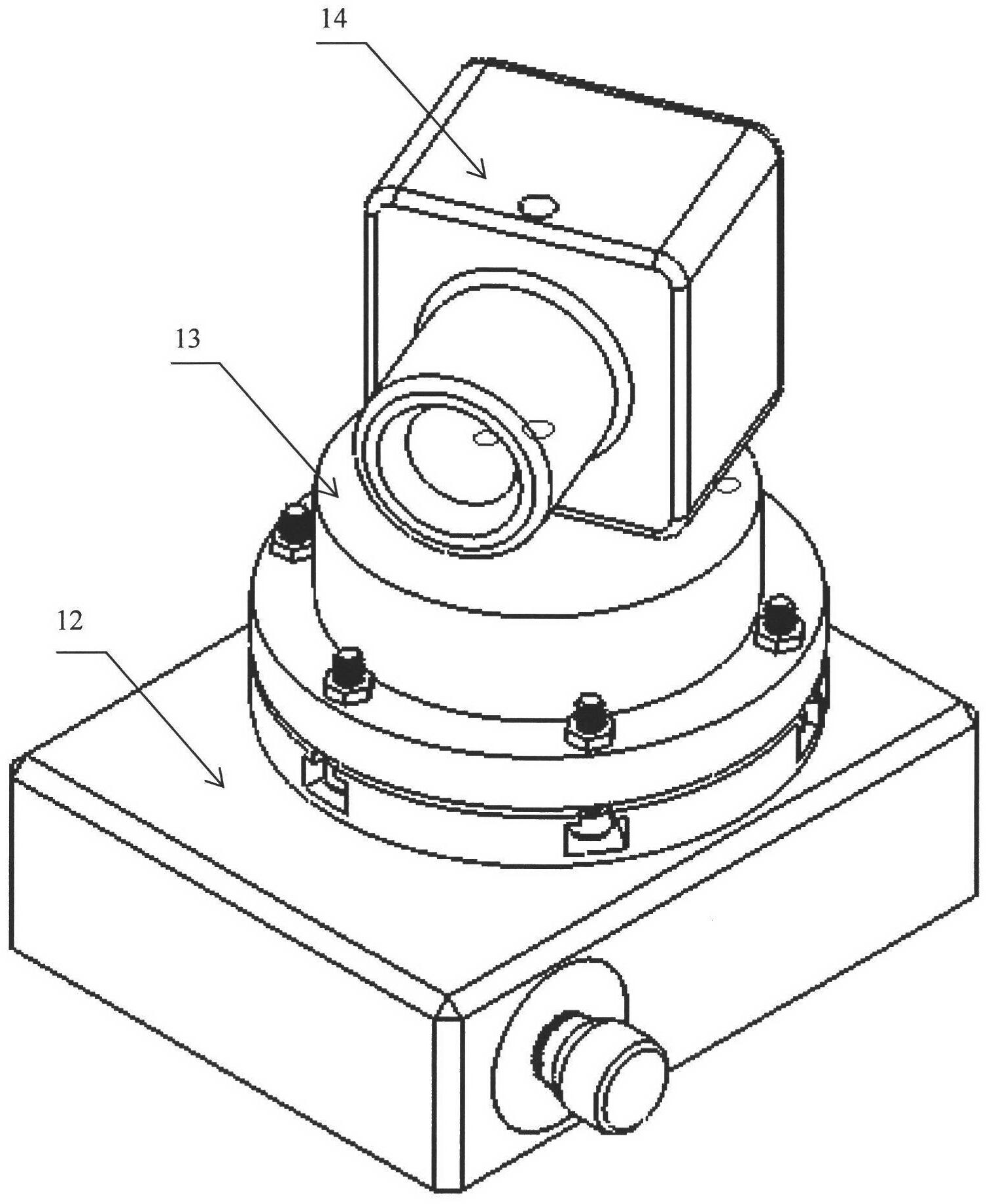

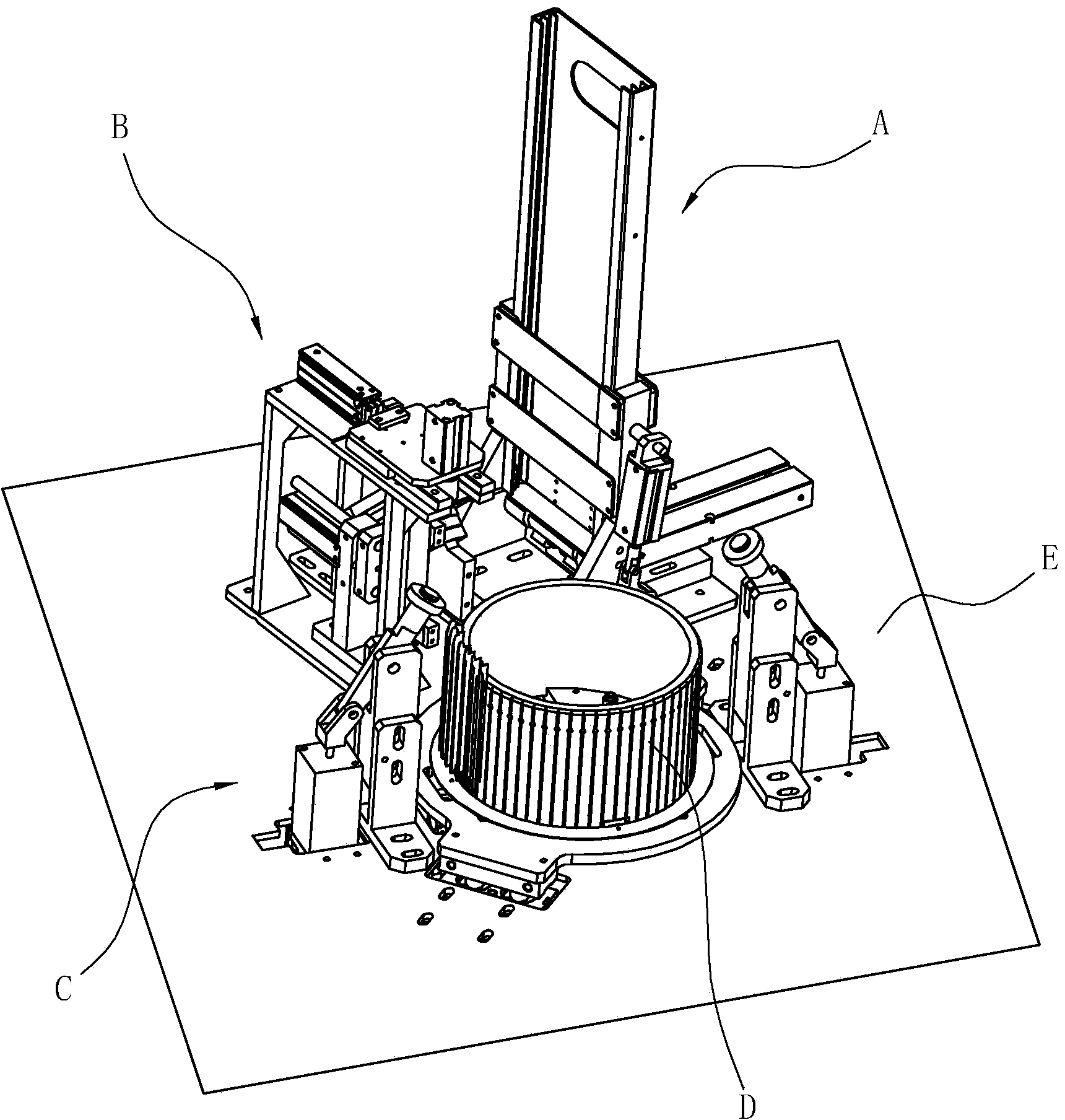

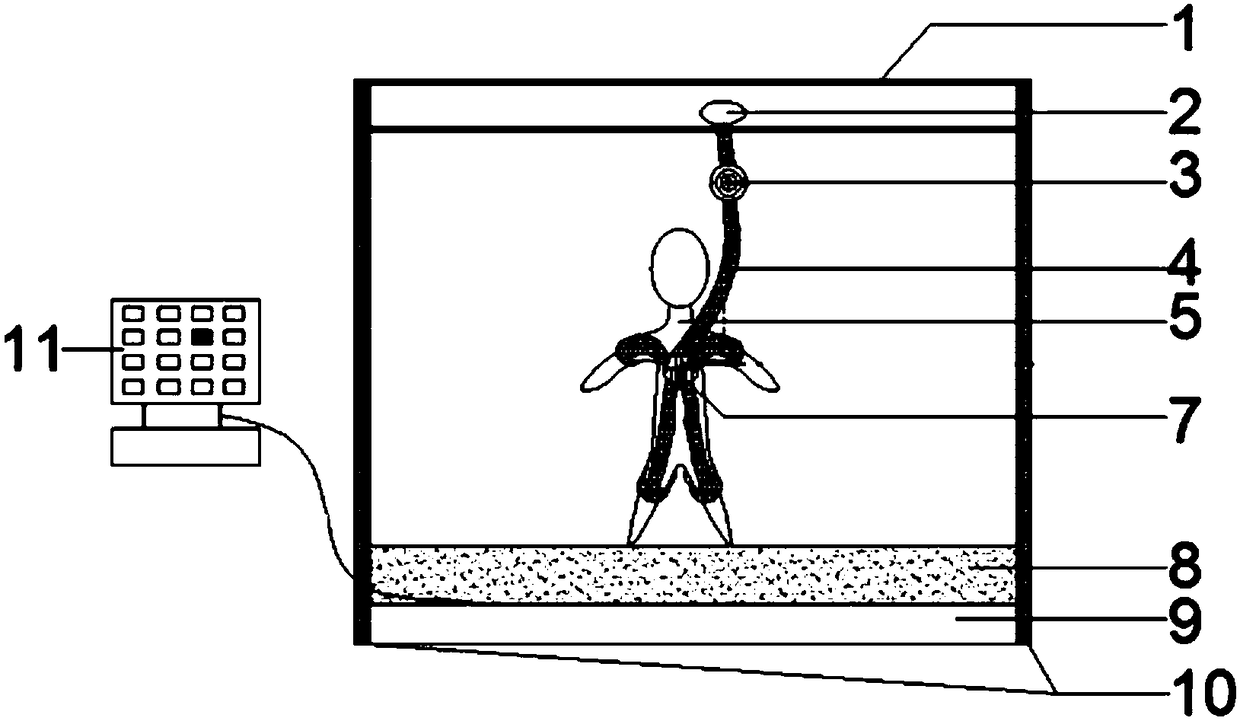

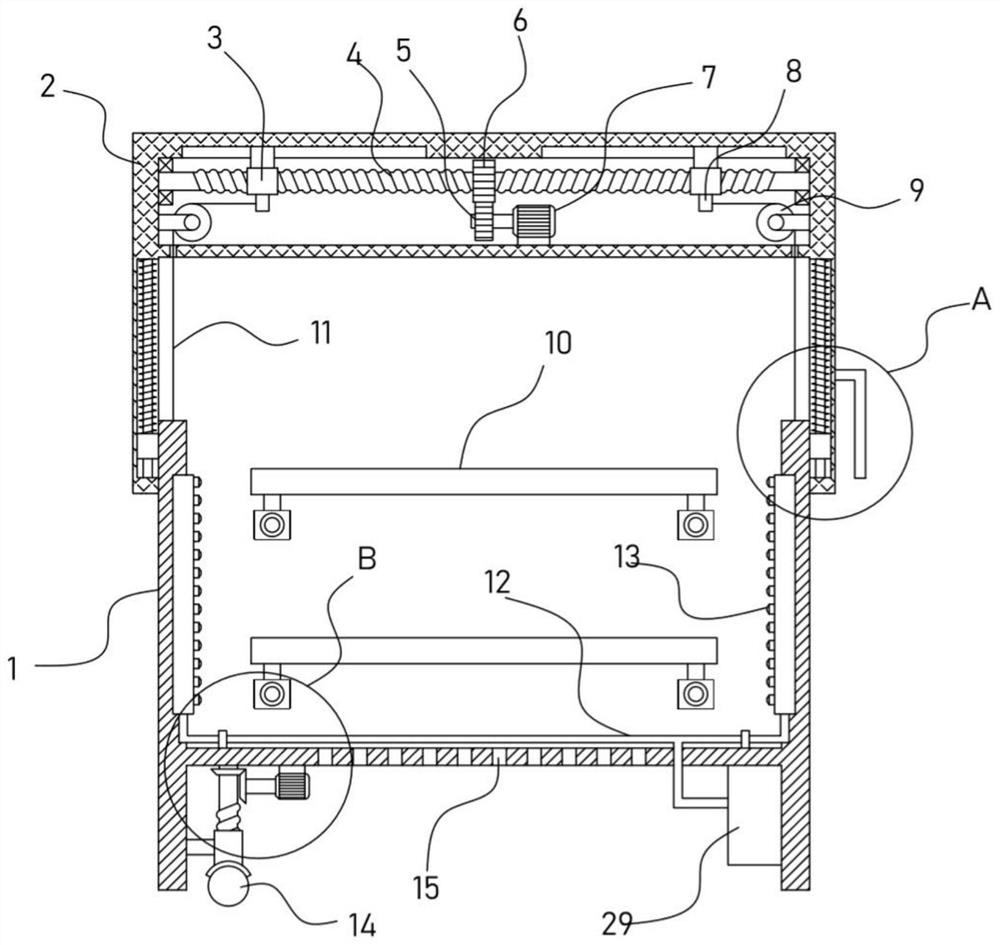

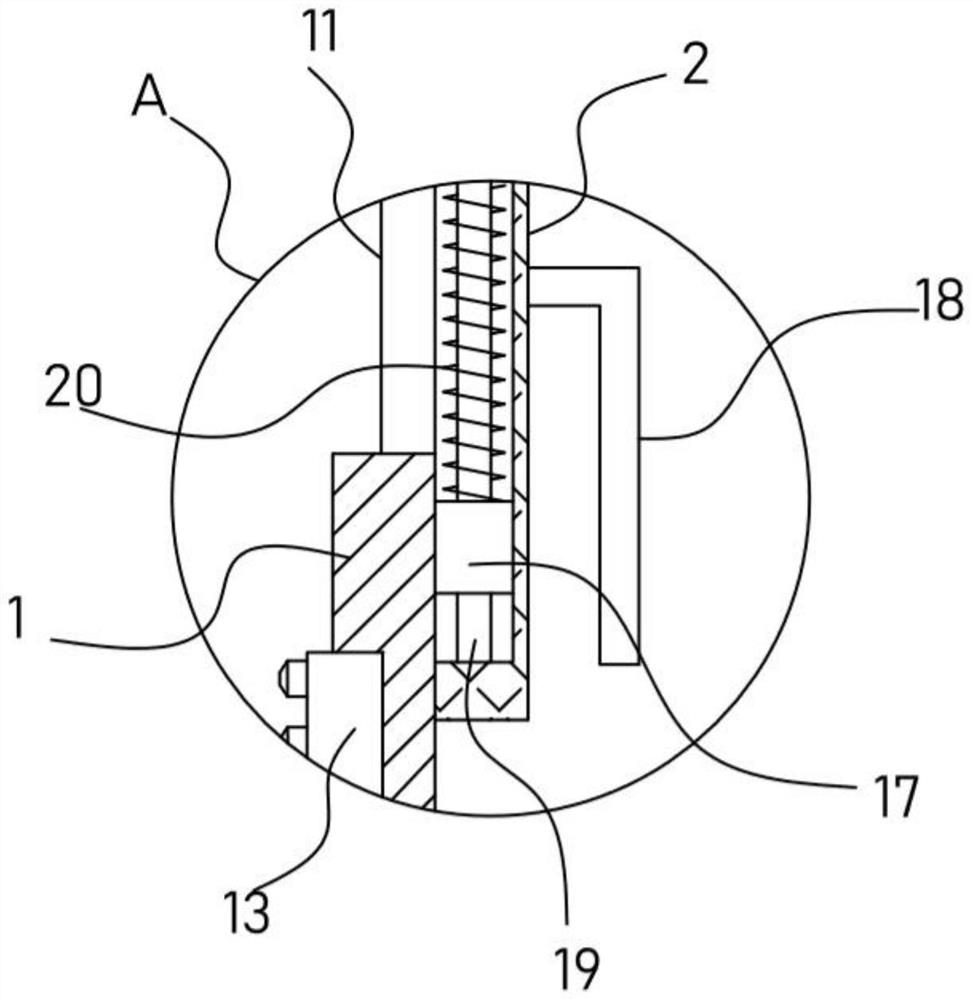

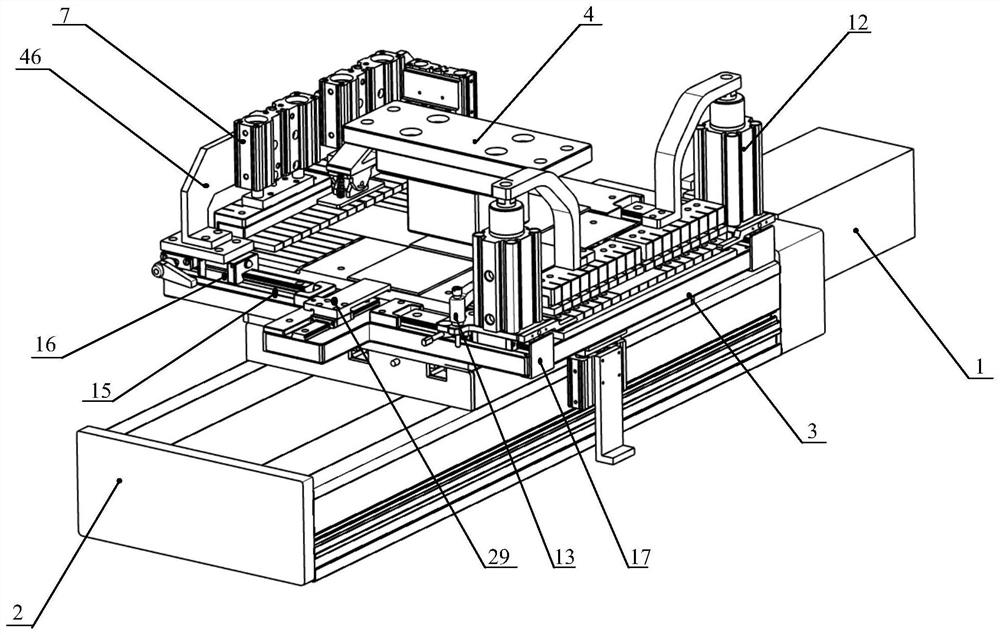

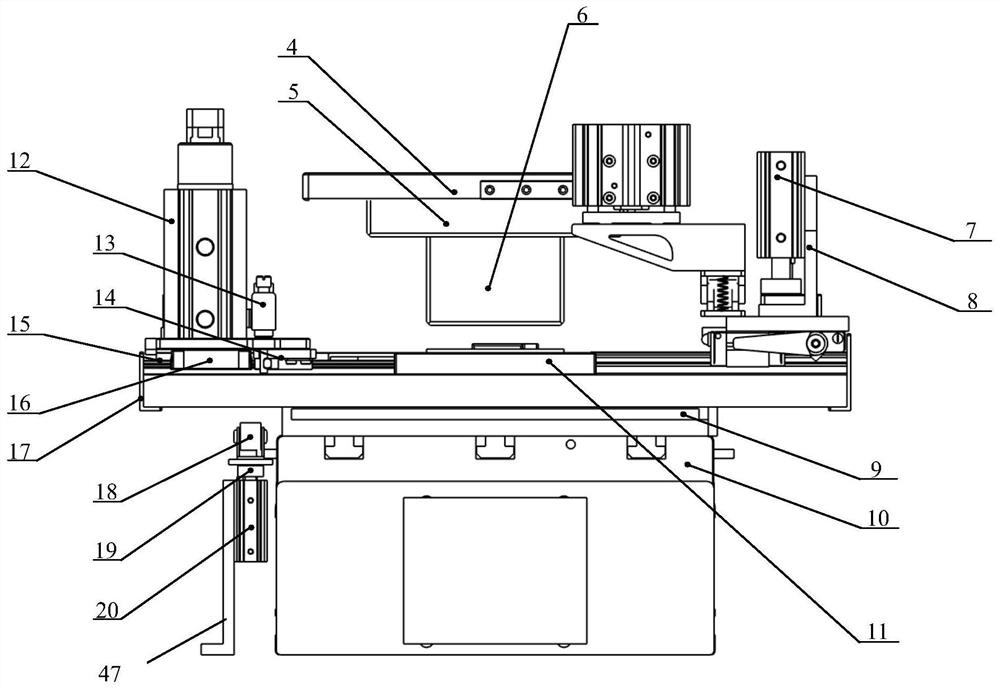

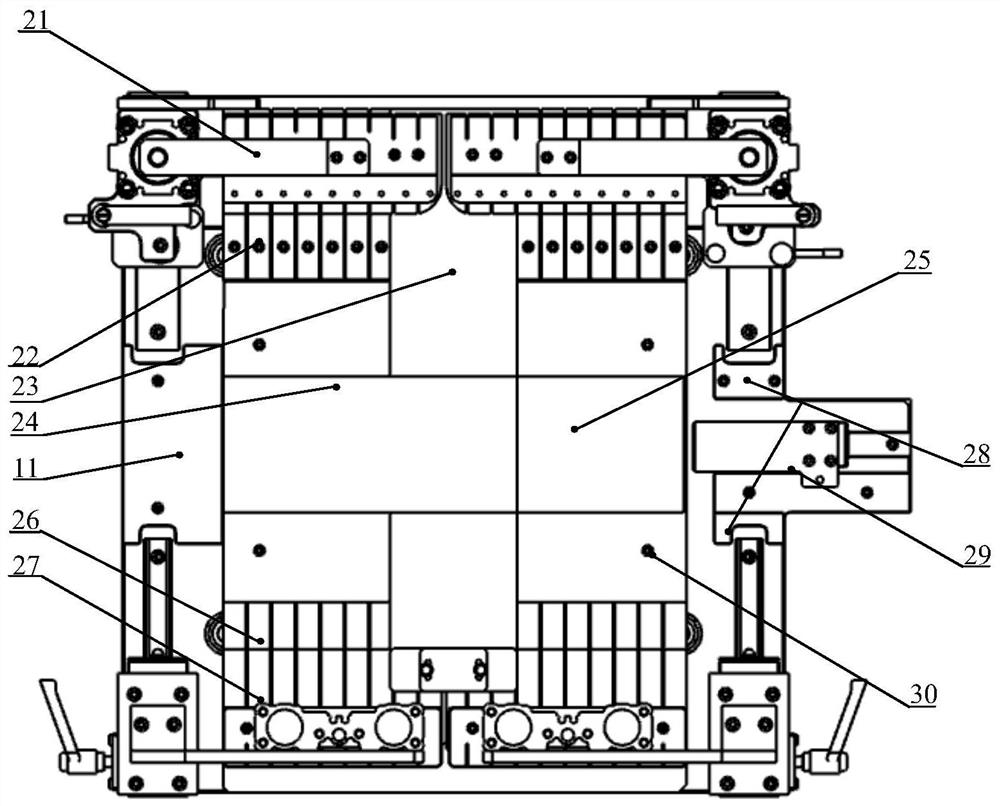

Verification device for automobile ergonomics

ActiveCN109545063ARealize flexible adjustmentReduce riskVehicle testingEducational modelsEngineeringChassis

The invention relates to a verification device for automobile ergonomics. The device comprises a basic frame, and the base frame comprises a chassis and a top frame connected to the chassis; the top frame is provided with a ceiling adjusting mechanism, and the chassis is provided with an engine hood adjustment mechanism, an instrument panel adjustment mechanism, an auxiliary instrument panel adjustment mechanism, a pedal adjustment mechanism, a seat adjustment mechanism, a floor adjustment mechanism, a threshold adjustment mechanism, a door panel adjustment mechanism, an A-column adjustment mechanism, a B-column adjustment mechanism and a C-D-column adjustment mechanism; the A-column adjustment mechanism, the B-column adjustment mechanism and the C / D-column adjustment mechanism respectively correspond to adjust an A-column, a B-column and a C / D-column to move in the front, back, left, right and up and down directions of the basic frame, the A-column, the B-column and the C / D column areadjusted to rotate in the front, back, left and right directions of the basic frame so that an ergonomic scheme can be performed in the ergonomic setting stage, and the rationality verification of the ergonomics scheme can be conducted to reduce the risk of an entire automotive develop and research project.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

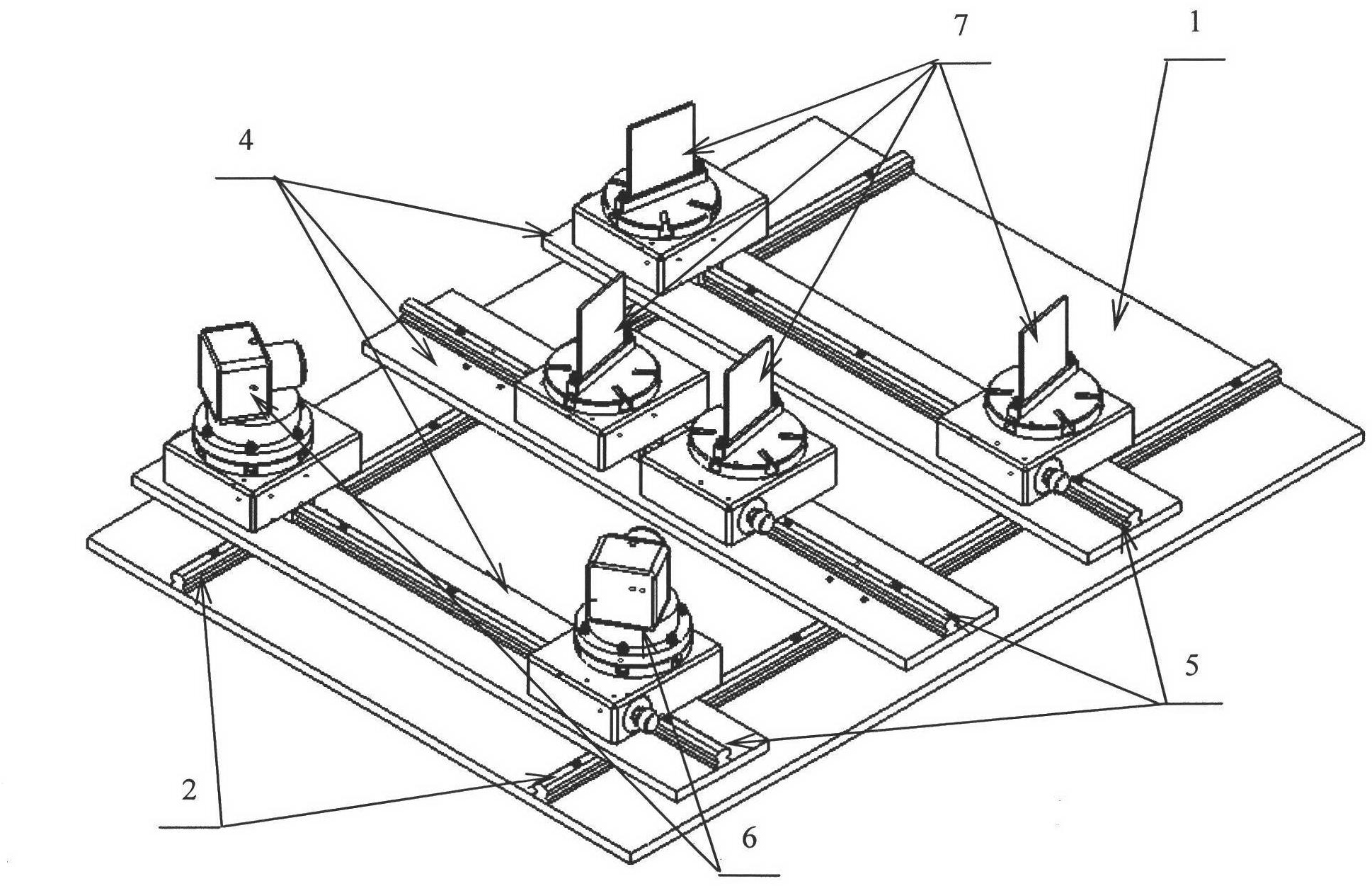

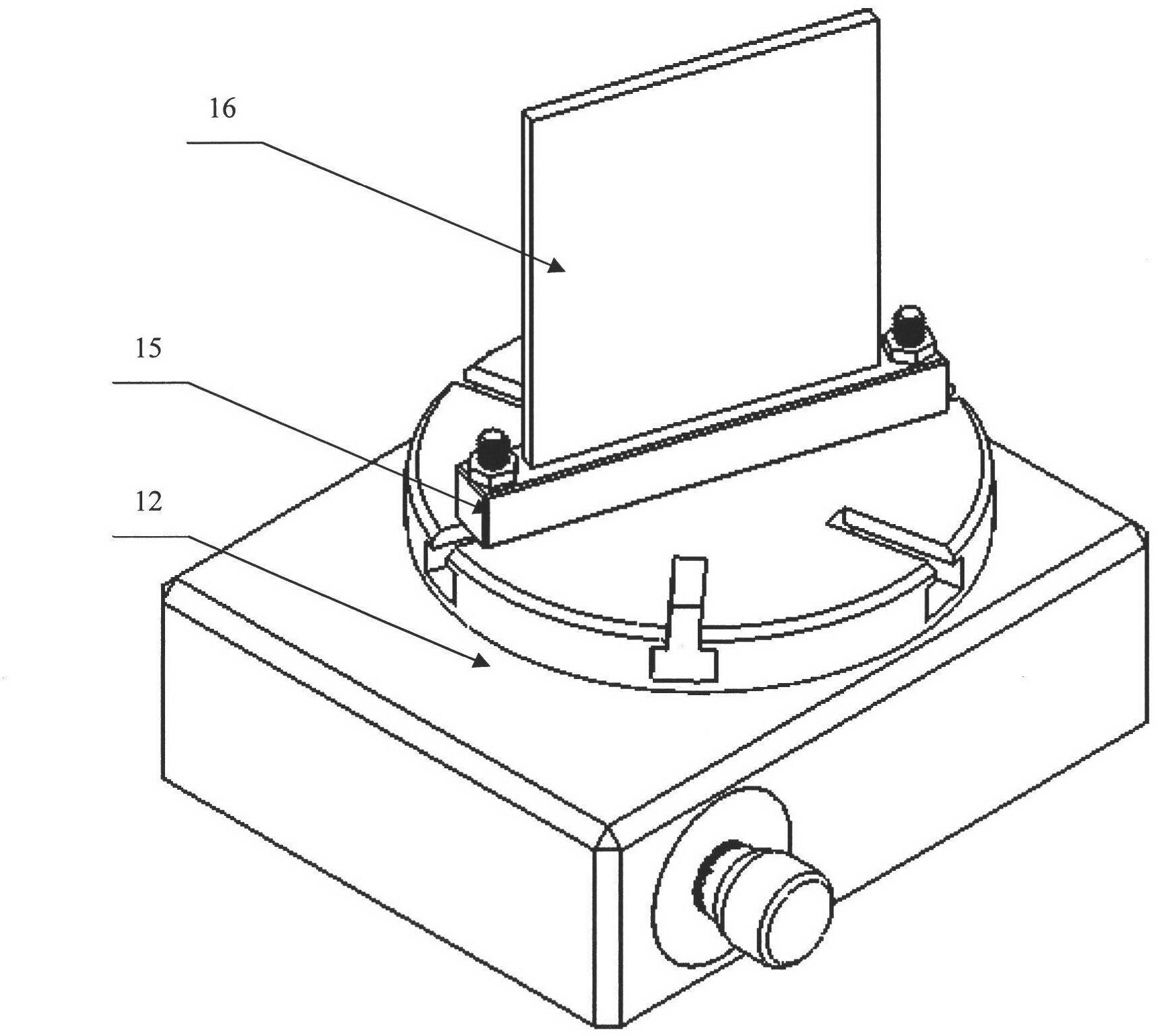

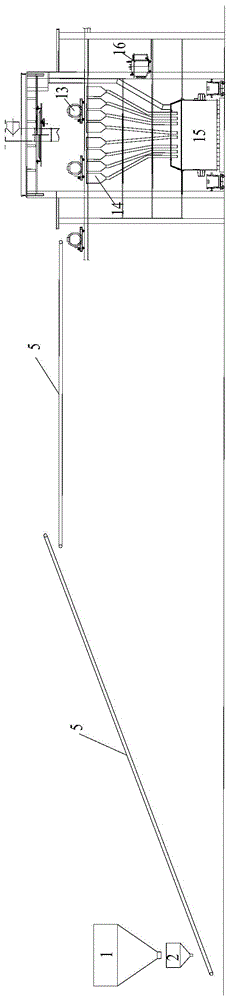

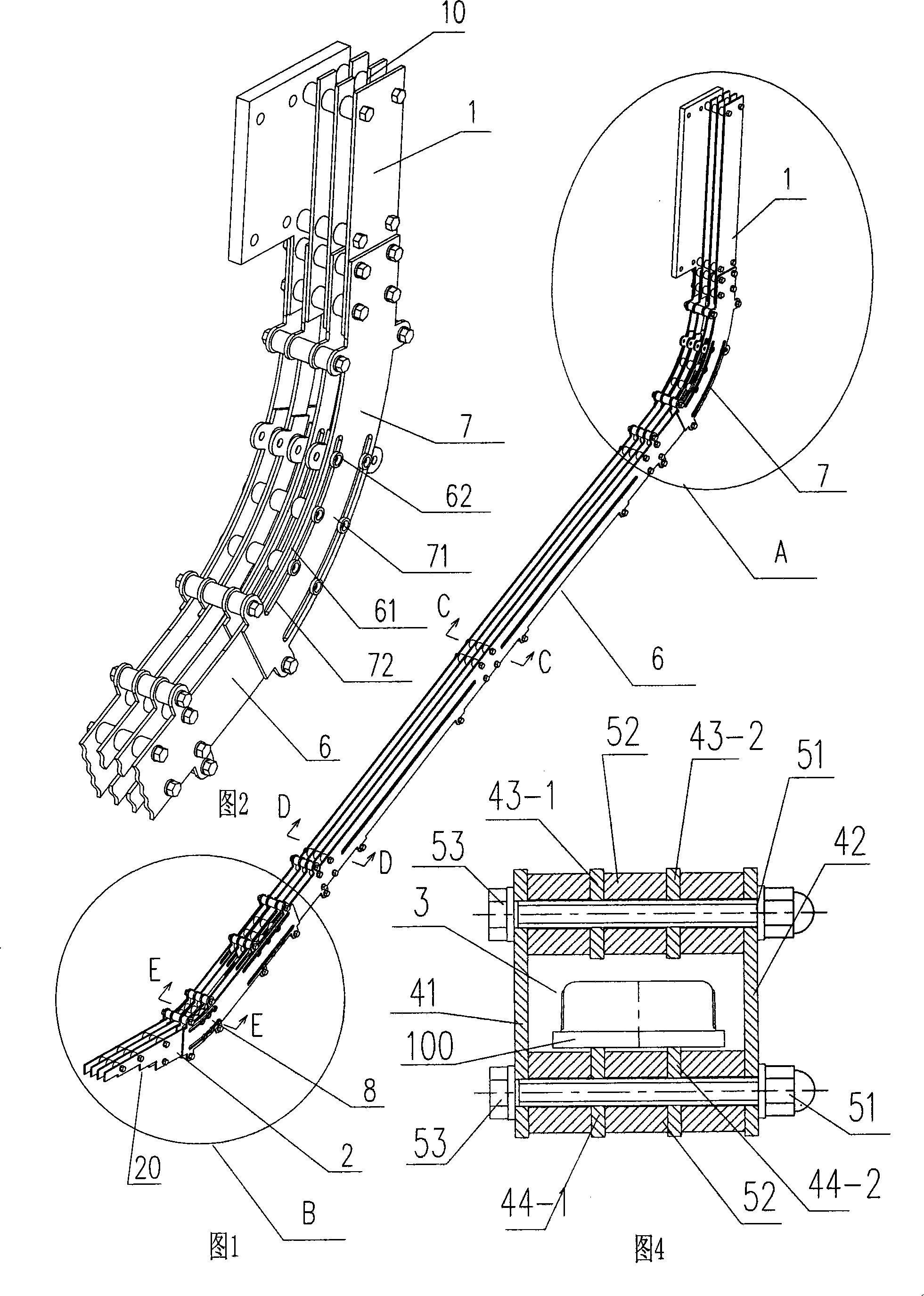

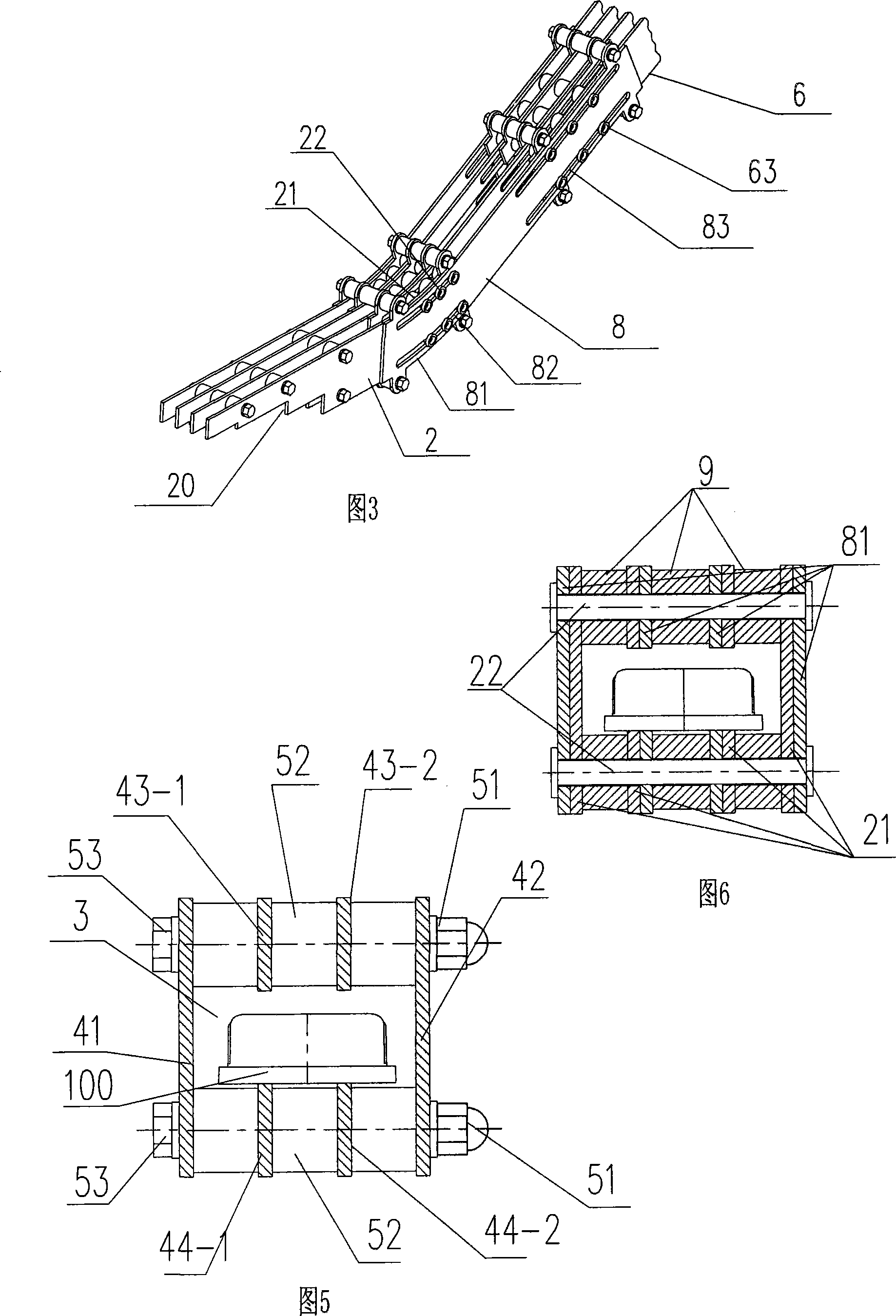

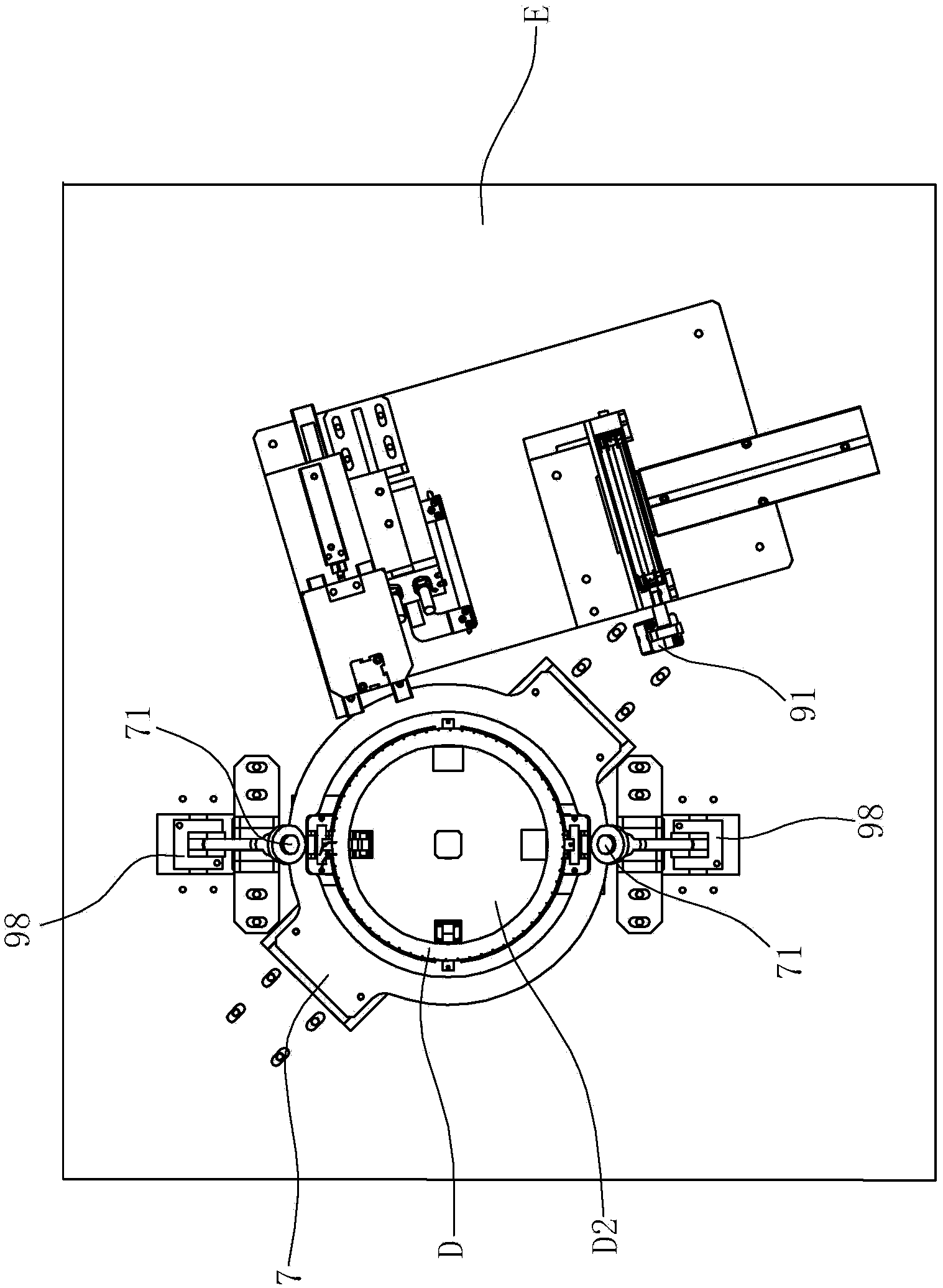

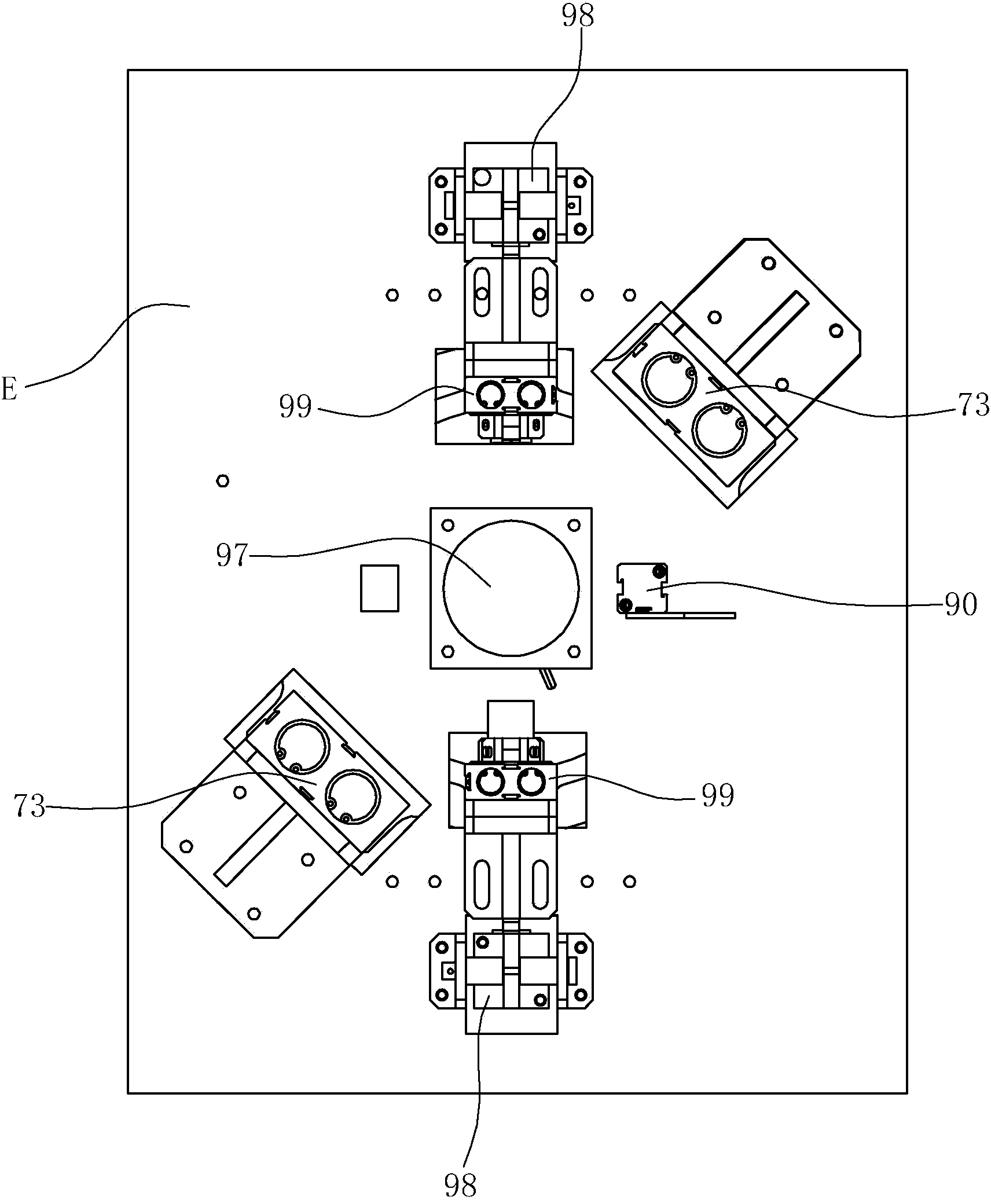

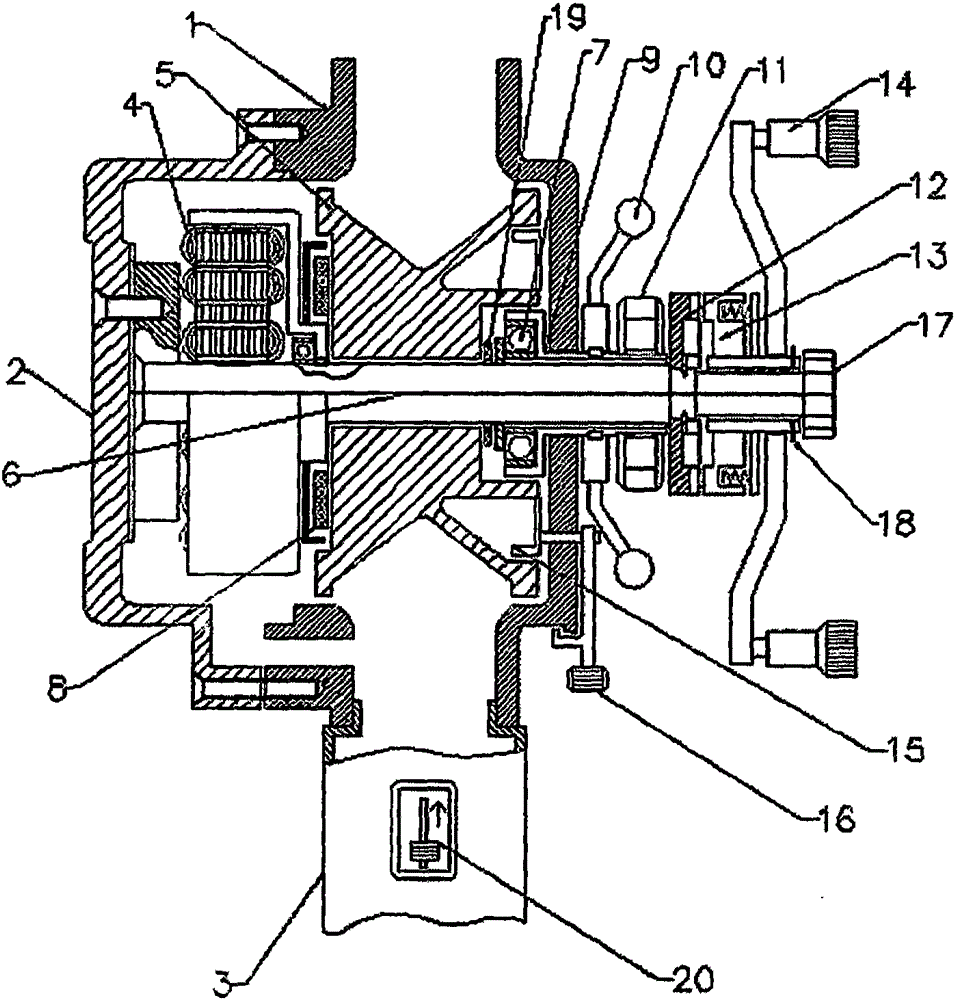

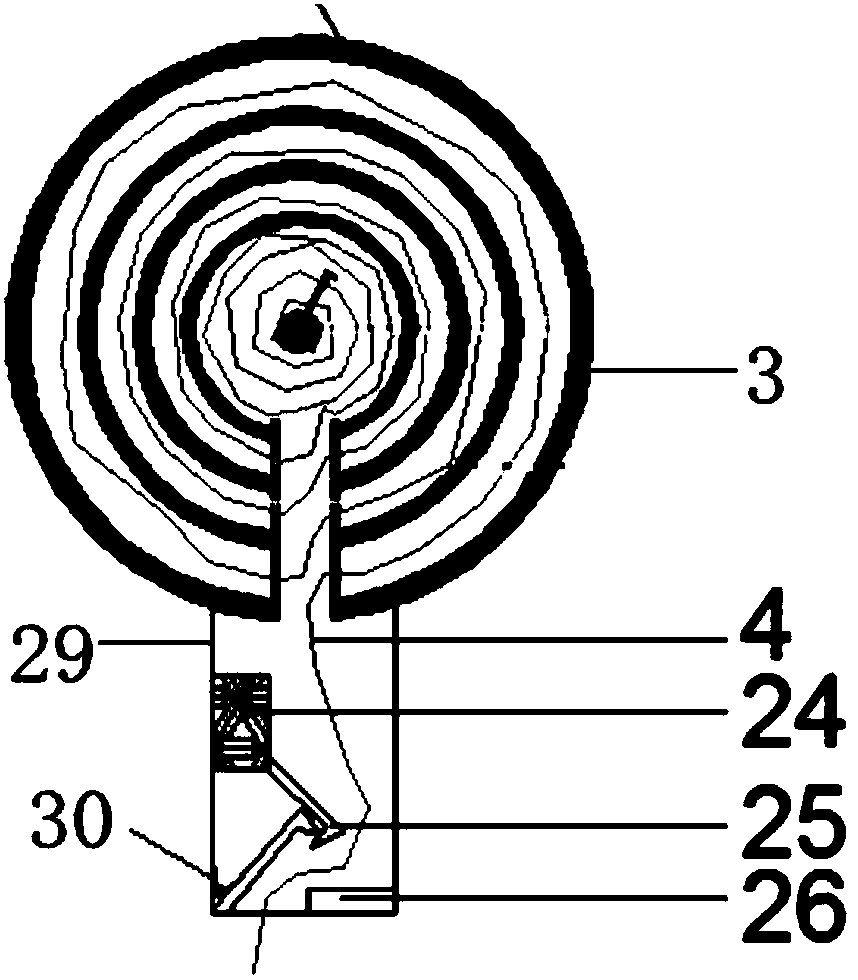

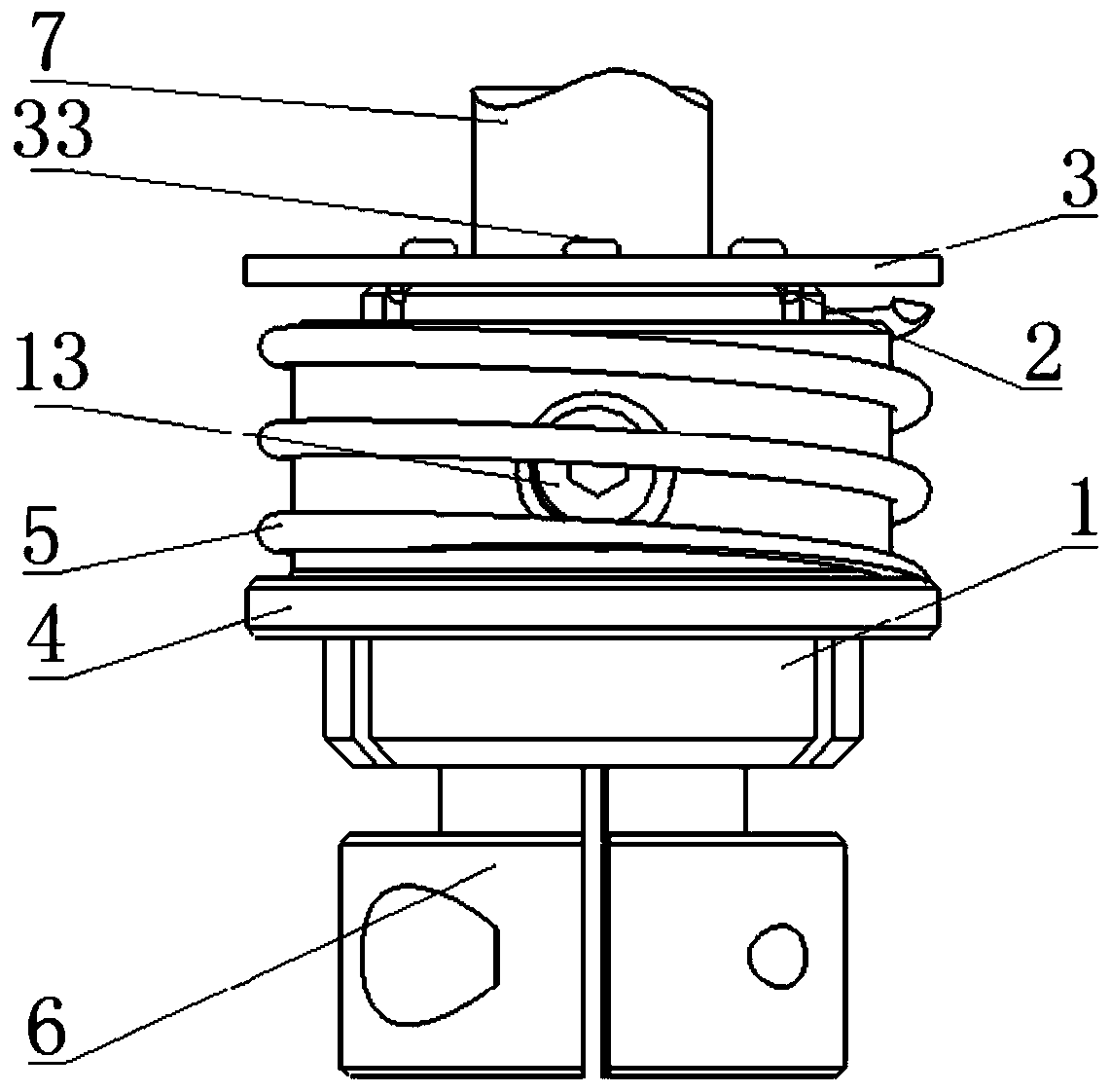

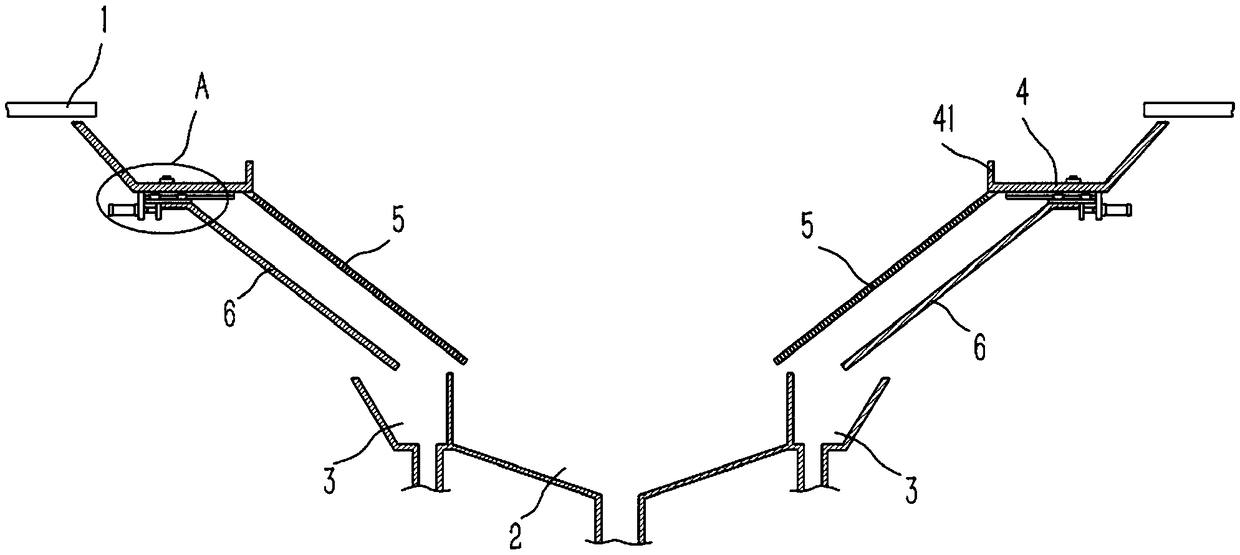

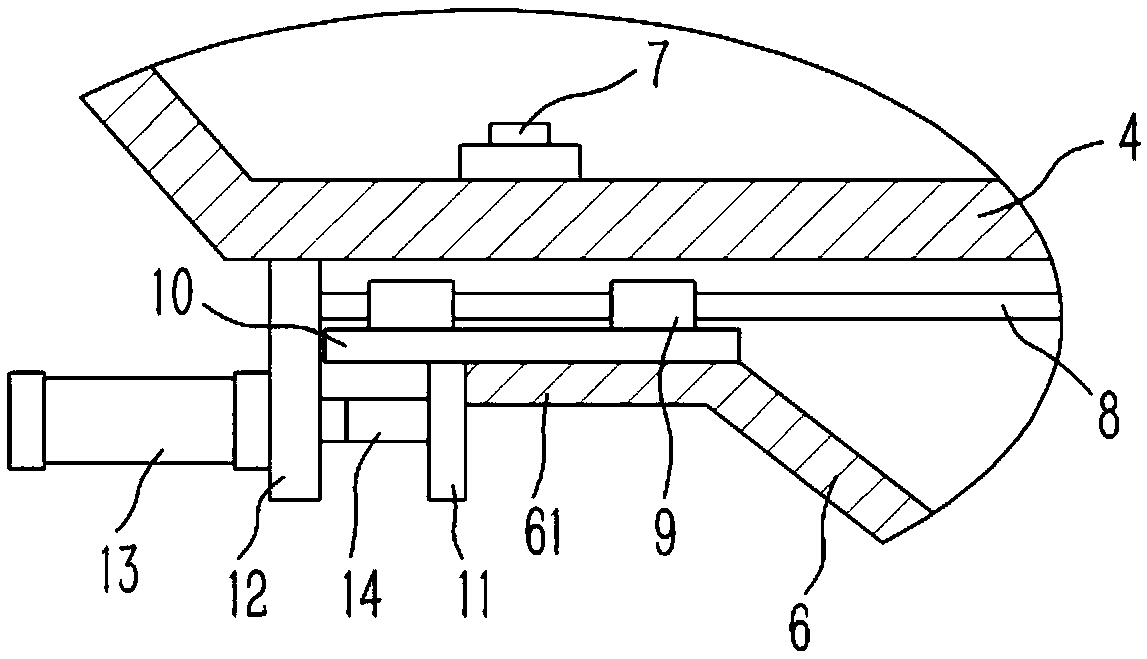

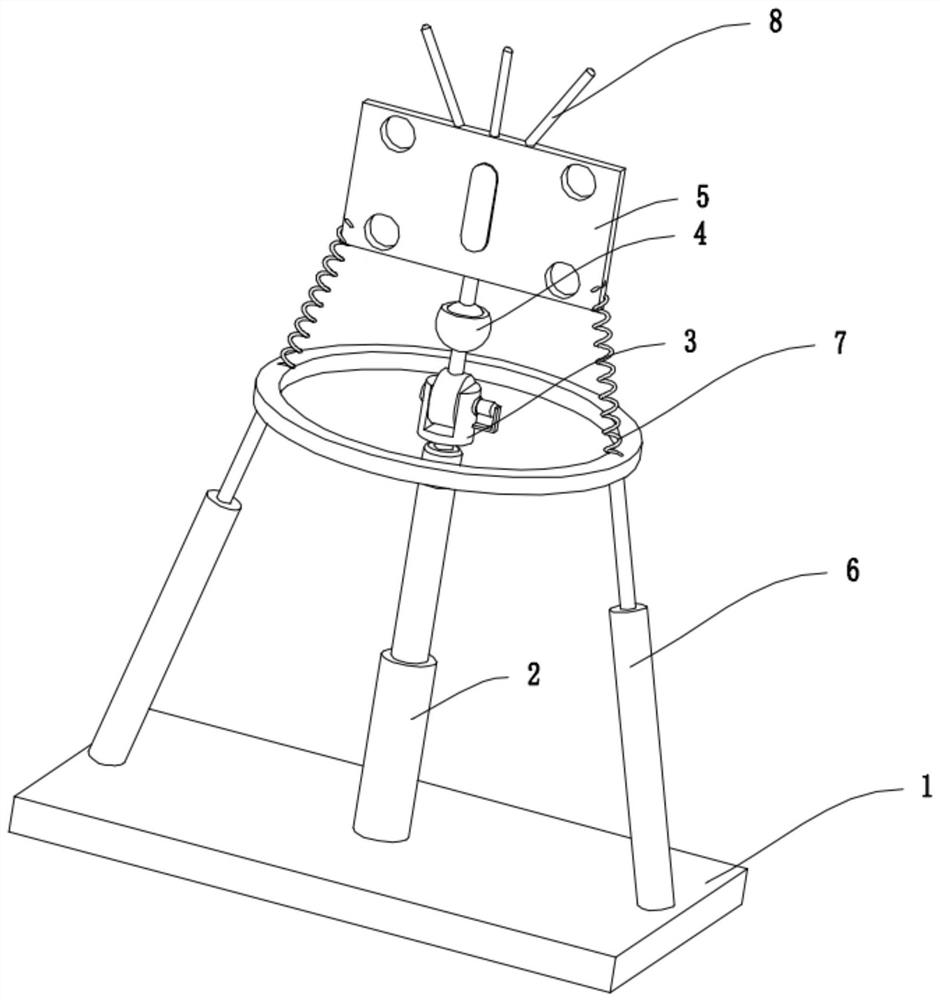

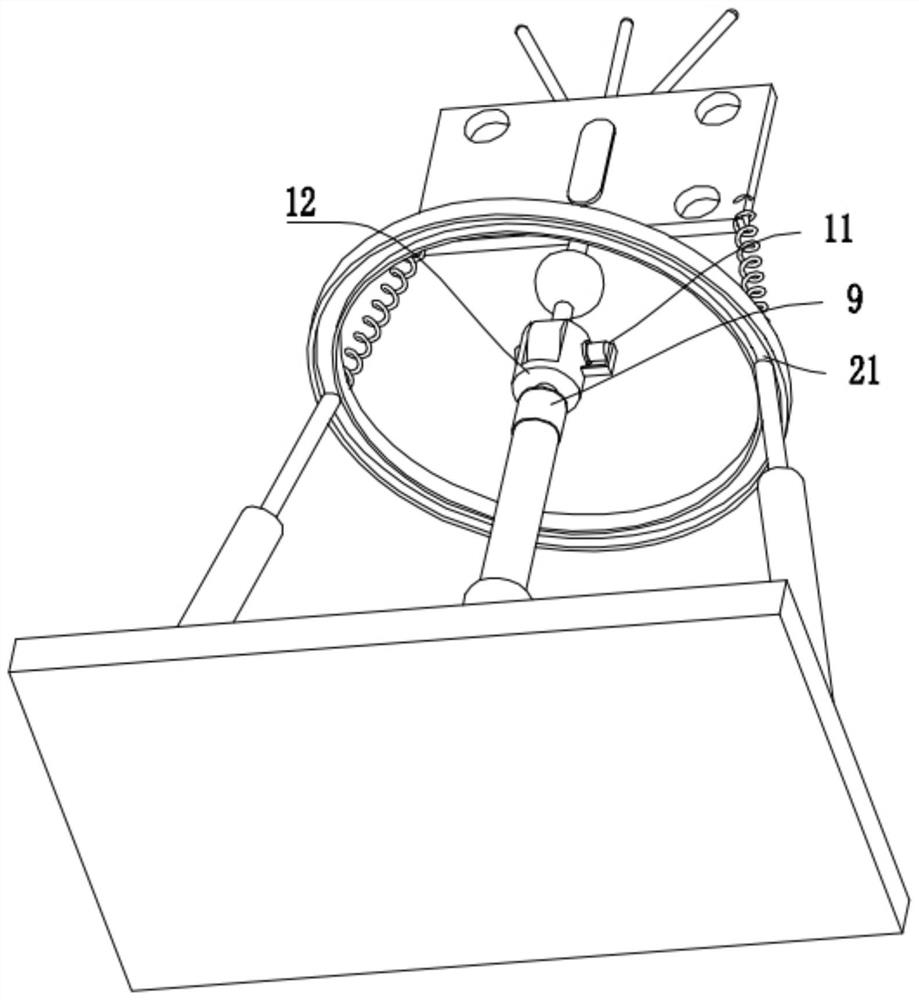

Three-freedom-degree automobile wheel positioning parameter three-dimensionalal visual flexible detection system

InactiveCN102322797ARealize flexible adjustmentLarge measuring rangeUsing optical meansVehicle wheel testingPlane mirrorVisual perception

The invention discloses a three-freedom-degree automobile wheel positioning parameter three-dimensionalal visual flexible detection system, which aims at overcoming the problem that the three-freedom-degree regulation of an automobile wheel positioning parameter three-dimensional visual detection system can not be realized. The system comprises a bottom plate (1), a vertical guide rail (2), a slide block (3), a transverse connecting plate (4), a transverse guide rail (5), a camera assembly (6) and a plane mirror assembly (7). The system can complete the three-freedom-degree regulation of system elements in the automobile wheel positioning parameter visual detection process.

Owner:JILIN UNIV

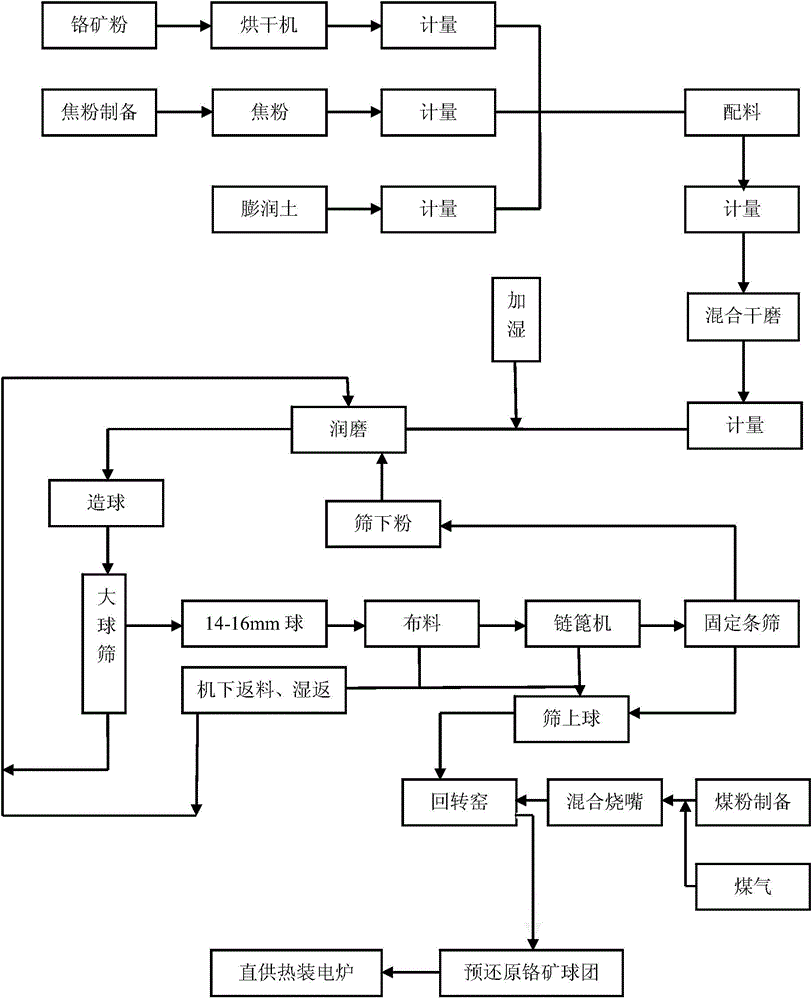

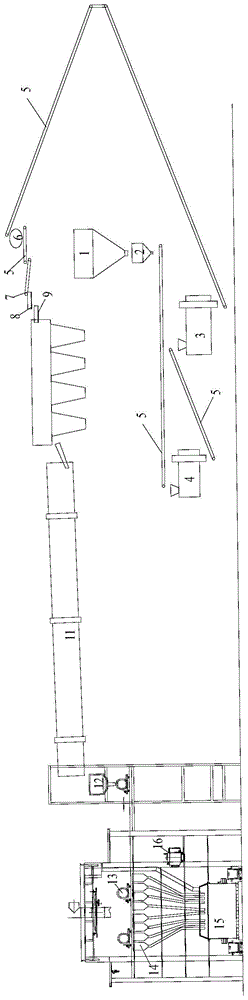

Chromium ore pellet pre-reduction direct-supply submerged arc furnace system and pre-reduction direct-supply method

The invention belongs to the field of metallurgy, and provides a chromium ore pellet pre-reduction direct-supply submerged arc furnace system, which comprises a pelletizer, a chain grate and a pre-reduction rotary kiln, wherein the material inlet of the pelletizer is connected with a material preparing unit through a belt, the material outlet of the pelletizer is connected with the material inlet of the chain grate, the material outlet of the chain grate is connected with the material inlet of the pre-reduction rotary kiln, the material outlet of the pre-reduction rotary kiln is connected with a submerged arc furnace, and the pelletizer, the chain grate and the pre-reduction rotary kiln are arranged on the place 30-50 m far away from the ground. According to the method of the present invention, the cooling process during the oxidized pellet production process is eliminated, and the direct hot material feeding-into-furnace process is adopted, such that the secondary energy source consumption is reduced, and the hot charging direct-supply can be achieved; the pelletizer, the chain grate and the pre-reduction rotary kiln are arranged by adopting the high frame, the highest place is 50 m, and the hot material is directly supplied to the submerged arc furnace; and the hot material-cold material exchange can be achieved, the whole production achieves the flexible regulation, and the passive situation that the furnace stops along with the kiln stopping and the kiln stops along with the furnace can be avoided.

Owner:丰镇市新太新材料科技有限公司

Bottle cap slideway

ActiveCN101100276ASimple manufacturing processReduce frictional resistanceThreaded caps applicationEngineeringBottle cap

The present invention provides one kind of bottle cap slide way, which consists of one upper connecting rail section with bottle cap inlet, one lower connecting rail section with bottle cap outlet, and middle rail sections connected through linear telescopic connection and arc sliding connection. All the sections are made with sheet material. The present invention has the advantages of capacity of regulating the angles and length easily for fitting caps of different sizes, low manufacture cost, small friction resistance, high reliability, and ability of observing the sliding of bottle caps in the slide way.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

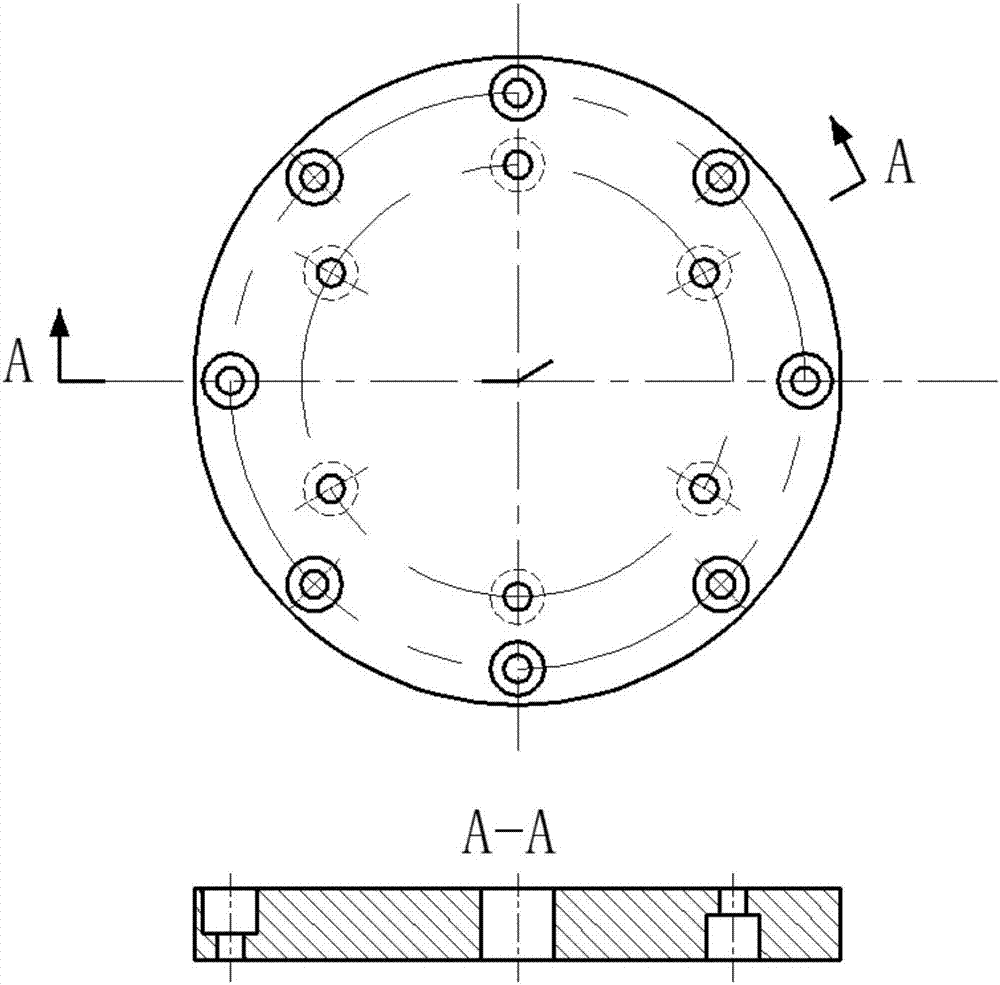

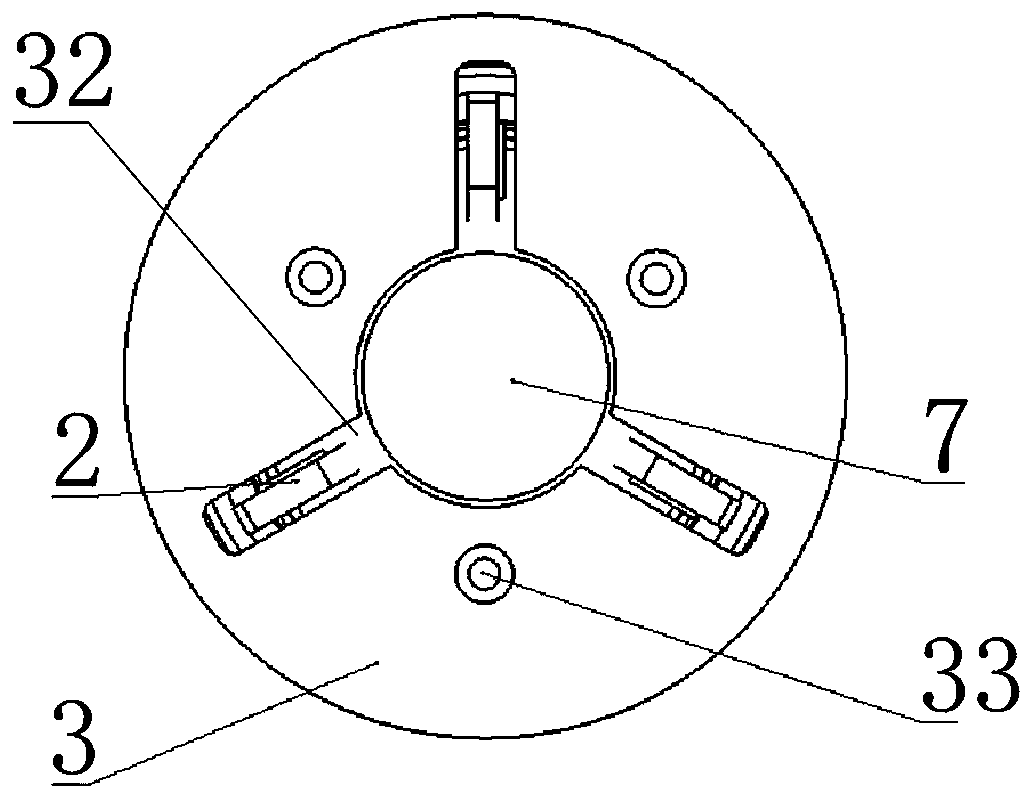

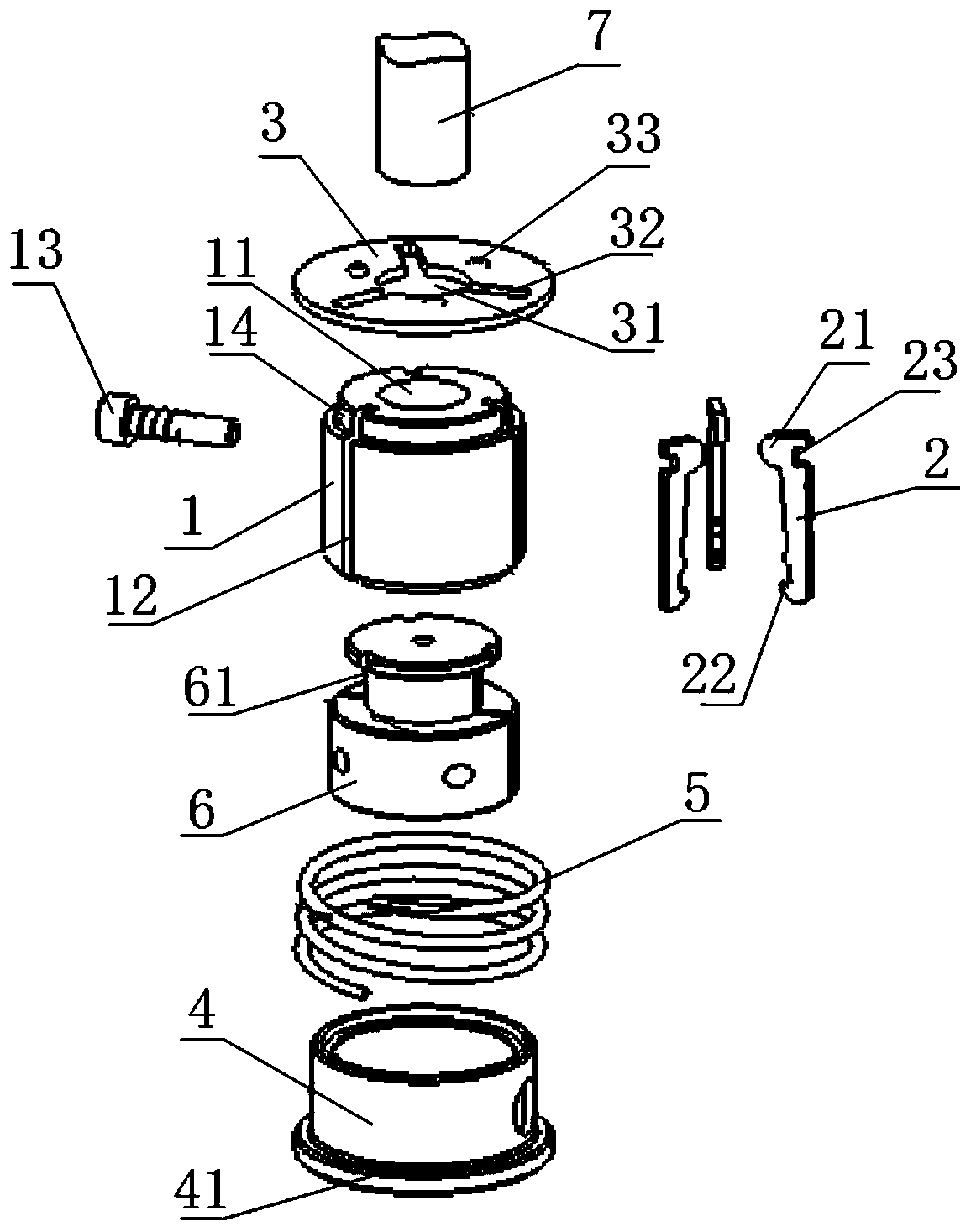

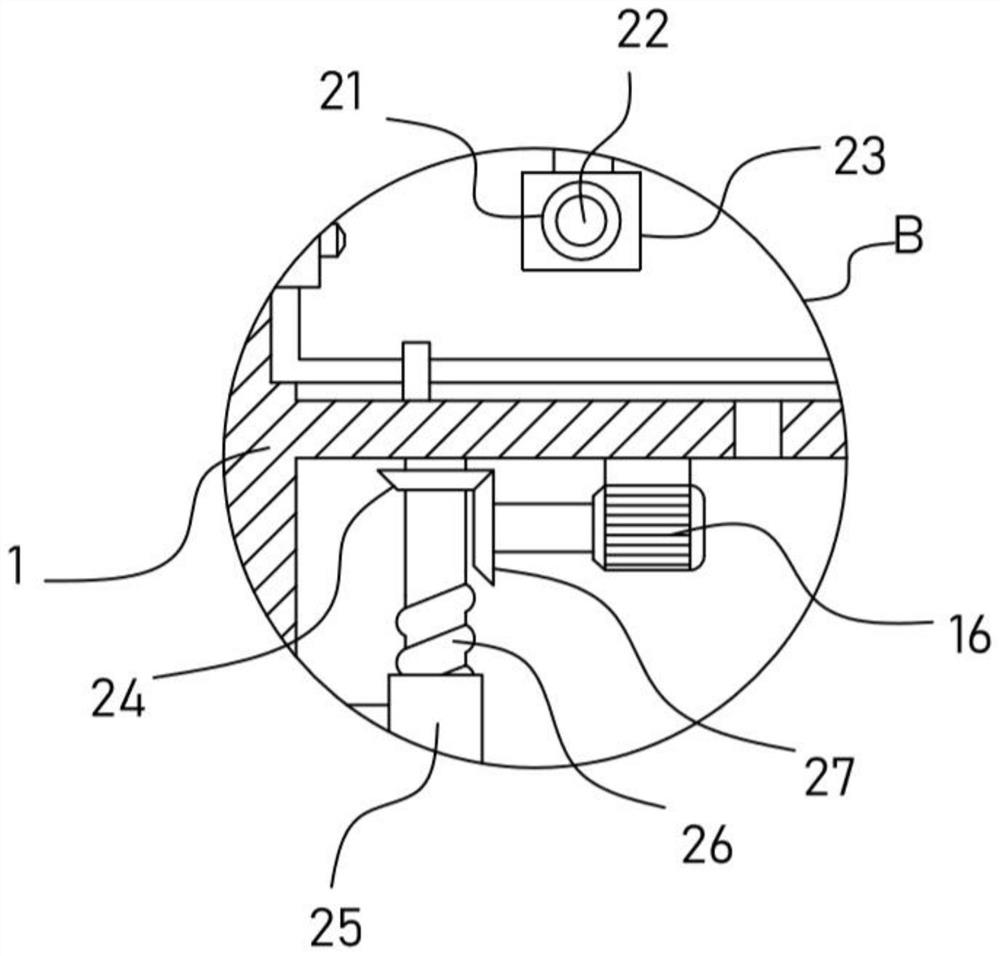

Positioning device of insertion piece type impeller forming machine

ActiveCN104139356ASimple structurePrecise positioningAssembly machinesWork holdersImpellerLocking mechanism

The invention discloses a positioning device of an insertion piece type impeller forming machine. The positioning device is arranged on a base of the insertion piece type impeller forming machine and is characterized by further comprising locking mechanisms, a linkage ring, first cylinders and push heads, wherein each locking mechanism comprises a rocking bar, a first fixing block and a second fixing block, one end of the rocking bar is movably hinged and connected with the first fixing block which is fixedly connected with the linkage ring, a positioning column which can be inserted into a positioning hole of a lower gland of an impeller for positioning is arranged at the other end of the rocking bar, a convex shaft is arranged in the middle of the rocking bar, the rocking bar is hinged and connected with the second fixing block through the convex shaft, the second fixing block is fixedly connected with the bottom of a mold, the push heads are arranged below the linkage ring, and the first cylinders drive the push heads to move up and down. The positioning device has the advantages as follows: the structure is simple, the operation is convenient, accurate positioning between a slotted hole of the lower gland and an inserted slot of the mold can be guaranteed, the precision and the accuracy of the insertion piece are improved, the product quality is guaranteed, and the rejection rate is reduced.

Owner:嘉兴笼列电子商务有限公司

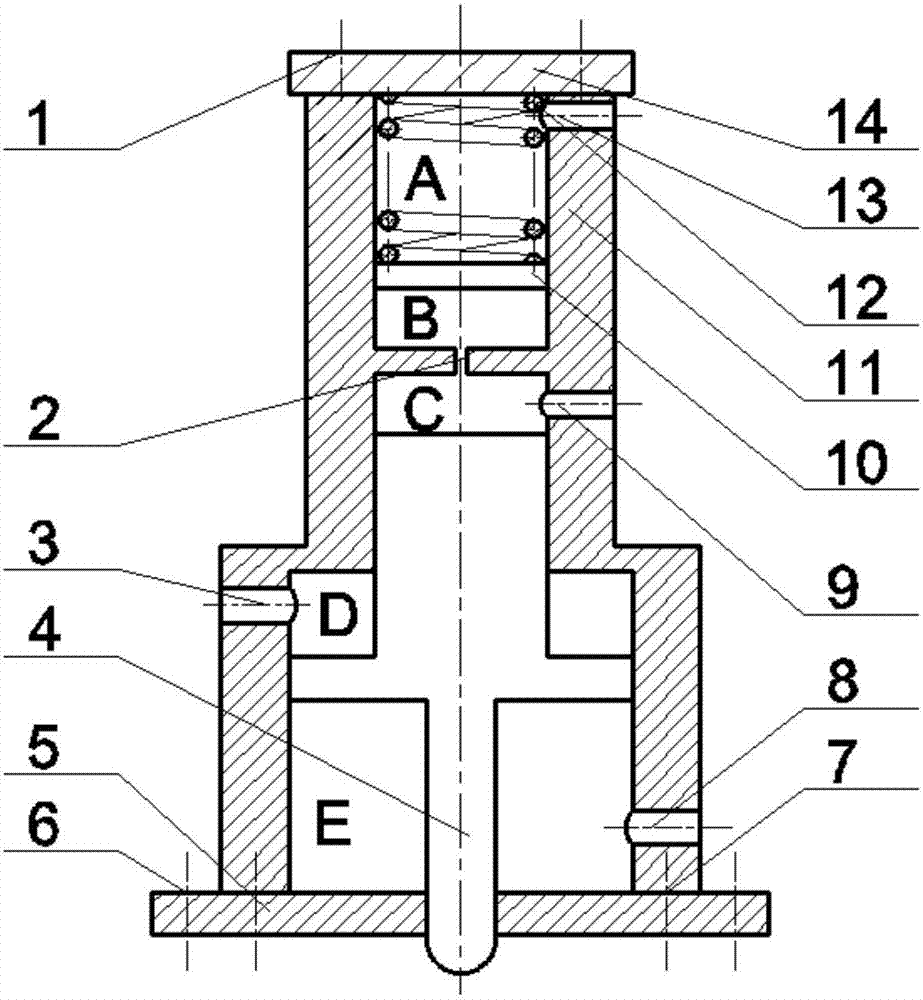

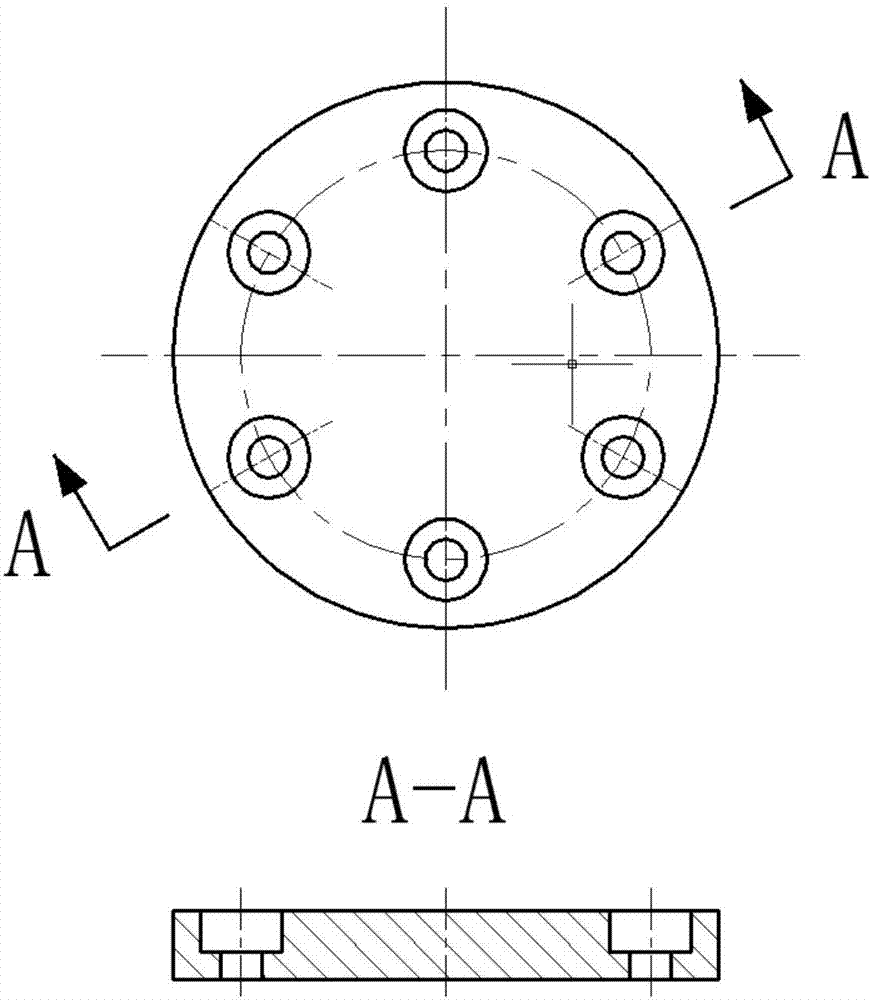

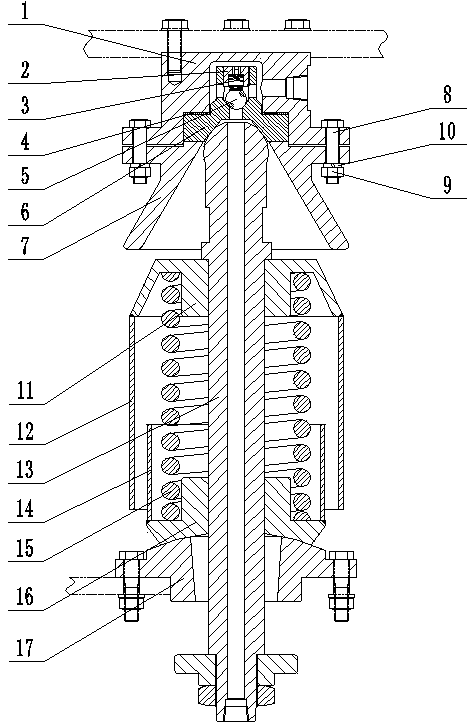

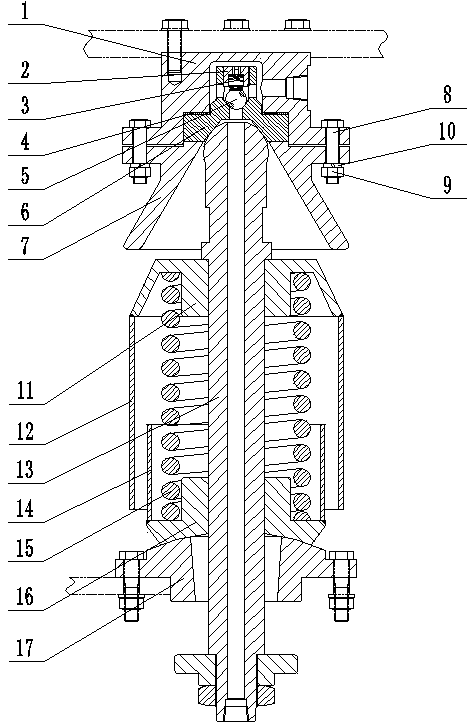

Electro-hydraulic fully variable air distribution device and control method

ActiveCN107327329ASimple structureReduce processing difficultyMachines/enginesNon-mechanical valveHydraulic motorElectronic control system

The invention discloses an electro-hydraulic fully variable air distribution device and a control method, and belongs to the technical field of engine air valves. The electro-hydraulic fully variable air distribution device comprises a buffer control valve, a lift range control valve, a low-pressure oil box, a filter, a hydraulic motor, an energy accumulator, an overflow valve, a solenoid directional valve, an electro-hydraulic fully variable air distribution executor, an electronic control system, and attached components like an oil pipe. A high-pressure oil port, a lift range control port, a buffer control oil port, a cylinder body orifice and five hydraulic cavities (A, B, C, D and E) are formed in the electro-hydraulic fully variable air distribution executor, and by controlling pressure of hydraulic oil in the five hydraulic cavities, movement like the opening and seating of one engine air valve can be realized. By changing power losing and power obtaining hours of a two-position three-way valve, the lift range control valve and the buffer control valve, the opening phase and the opening lift range of the engine air valve can be changed, and soft adjustment on the lift range and the phase of the air valve, and the duration of the opening of the air valve are realized, so that fully variable movement of the air valve is realized.

Owner:HARBIN ENG UNIV

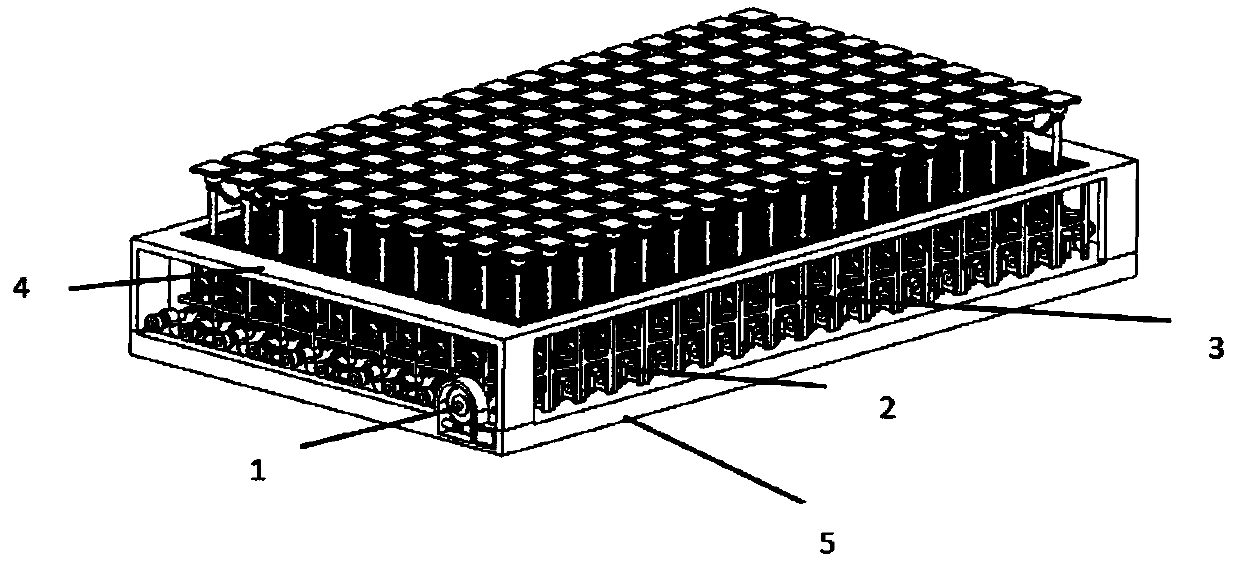

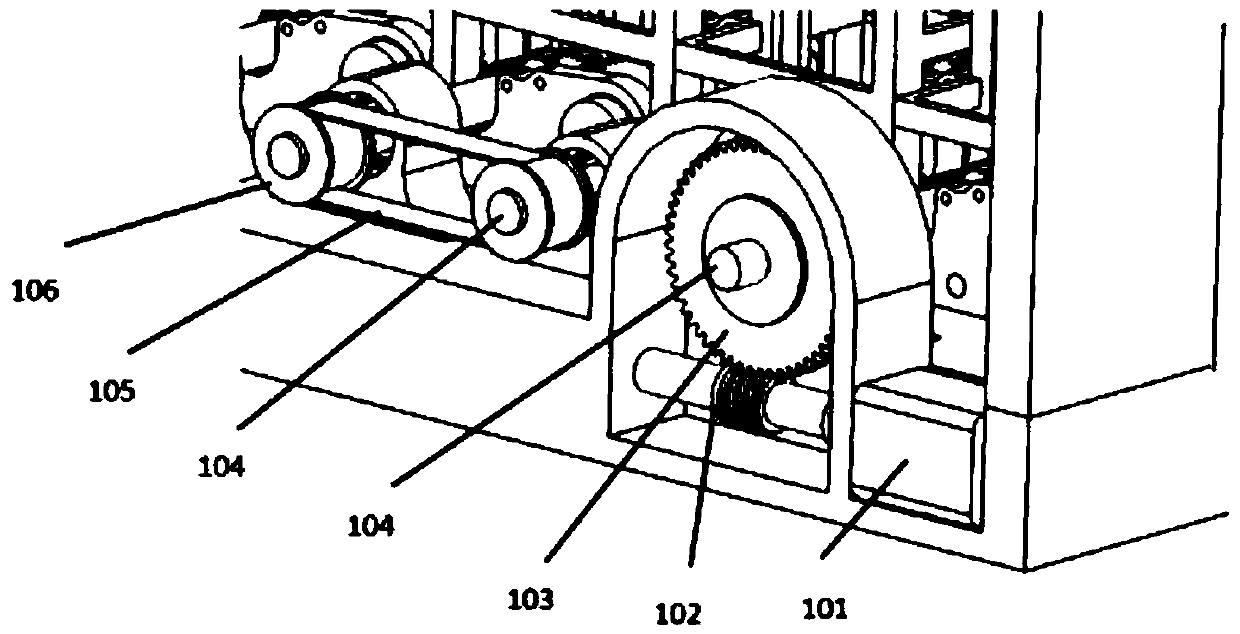

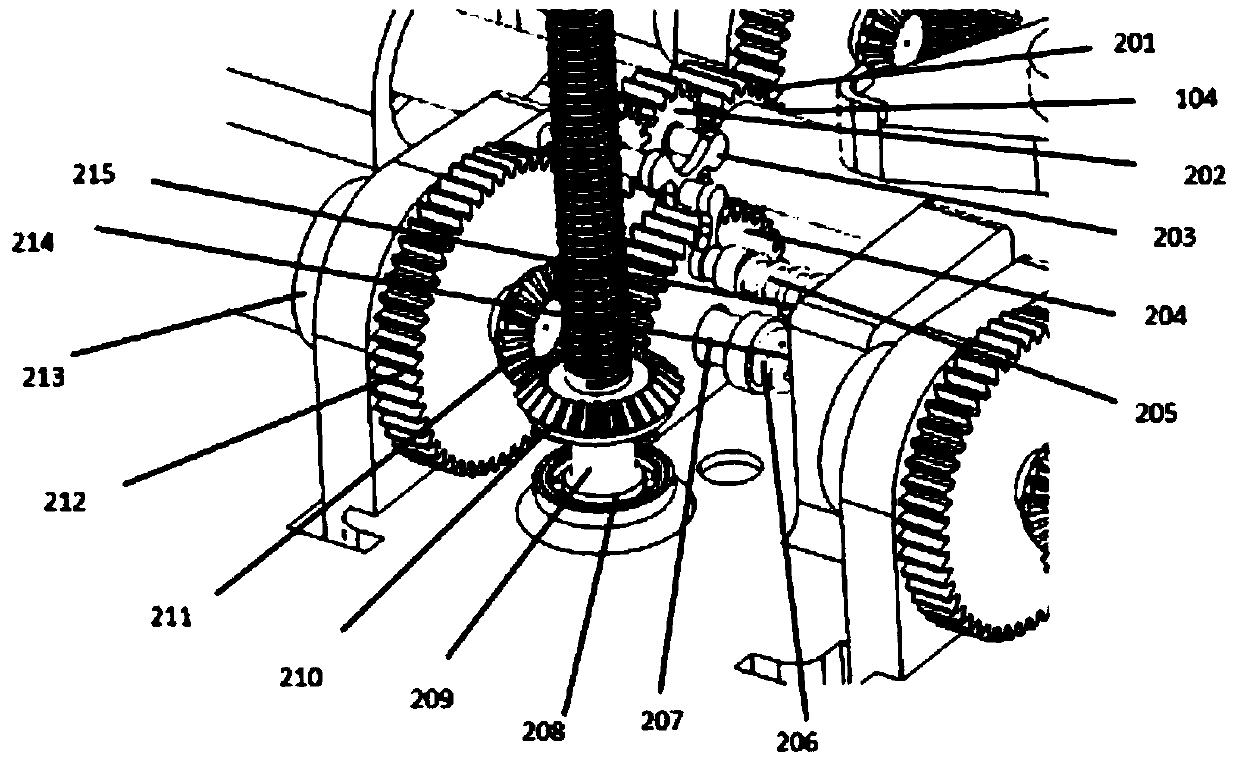

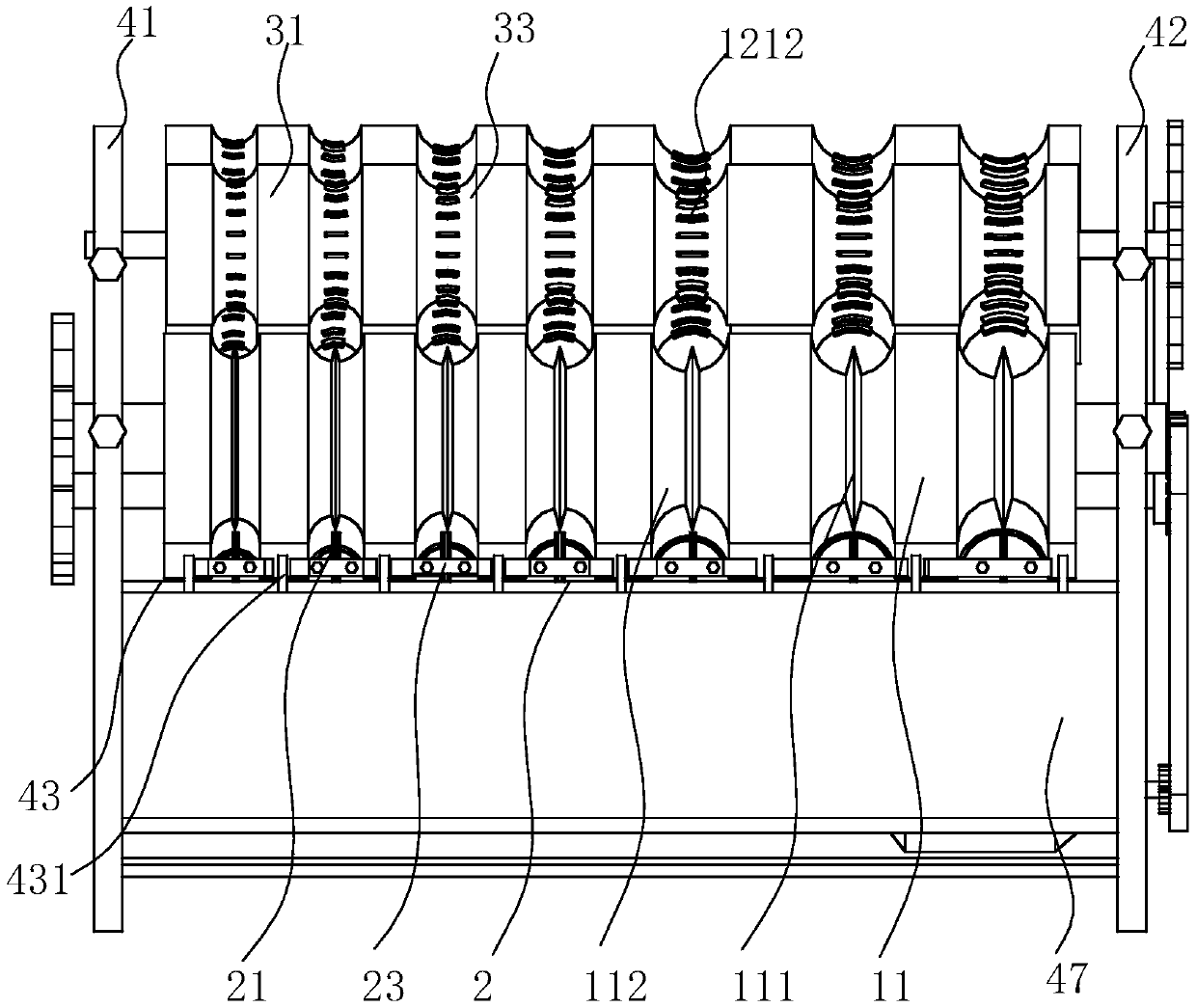

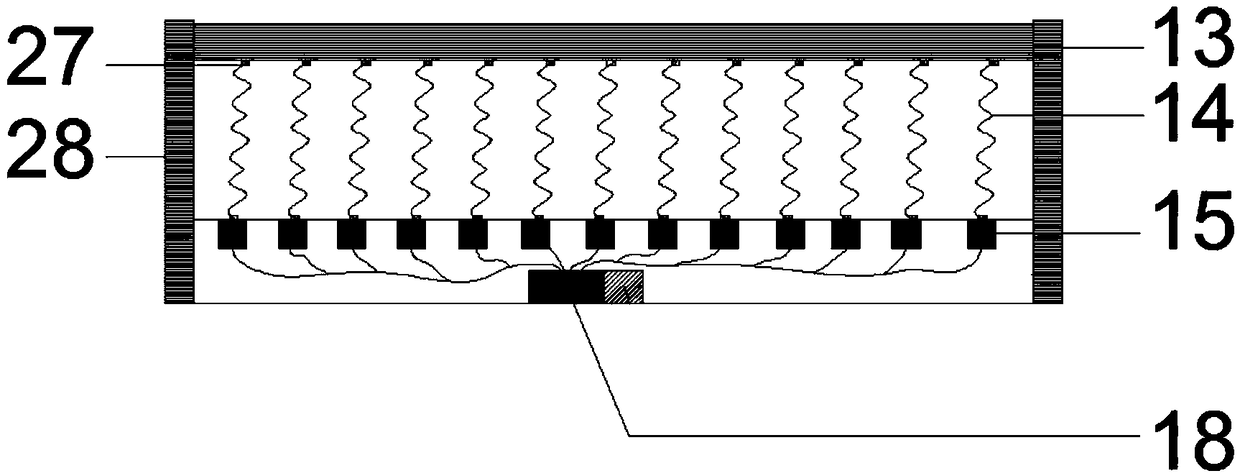

Flexible intelligent nursing bed with adjustable bed top

A flexible intelligent nursing bed with an adjustable bed top comprises a power and transmission mechanism, a plurality of reserving mechanisms, a plurality of lifting mechanisms, a frame and a base;the power and transmission mechanism, the reversing mechanisms, and the lifting mechanisms are mounted on the frame and the base; the power and transmission mechanism and the reversing mechanisms enable the lifting mechanisms to move up and down so as to adjust the change of the bed top, so that a body posture adjusting function and a massaging function are achieved. The flexible intelligent nursing bed herein allows adjustment for complex postures; posture adjustment is highly flexible, and good comfort is provided.

Owner:西安佰优智能科技有限责任公司

Stacked gear structure with side clearance removal through elasticity

InactiveCN102506150AReduce working noiseImprove the lubrication effectPortable liftingGearing elementsEngineeringSelf locking

The invention discloses a stacked gear structure with side clearance removal through elasticity, which aims to provide a gear structure, which has the advantages that: side clearance in gear transmission can be removed, cold / heat stress generated internally can be removed, the service life of gears is improved, and the noise generated when gears are meshed is reduced. A conical surface is arranged on a main gear; a gear with side clearance removal is connected with the main gear in a self-locking way through a taper hole matched with the conical surface; the outer side of the conical surface on the main gear is in thread connection with a compression nut of the gear with side clearance removal; positioning pin holes forming positioning zero points in peripheral directions of the main gear and the gear with side clearance removal are arranged on the main gear and the gear with side clearance removal; an adjusting pin is arranged on the main gear; an arc-shaped adjusting slot hole is arranged at a position on the gear with side clearance removal, corresponding to the adjusting pin; adjusting brackets are respectively arranged on two sides of the arc-shaped adjusting slot hole; each adjusting bracket is provided with an adjusting screw vertical to an axial line of the adjusting pin; and weight balancing blocks are respectively arranged on positions on the gear with side clearance removal, which respectively have intervals of 180 degrees with each adjusting bracket.

Owner:TIANJIN UNIV OF COMMERCE

Peony root processing device and method

ActiveCN107823277AAvoid scratchesReduce frictionPlant ingredientsEngineeringTraditional Chinese medicine

The invention relates to a peony root processing device and method and belongs to the technical field of traditional Chinese medicine processing equipment. The peony root processing device comprises acutting part for cutting peony roots in the length direction and a rejecting part for picking out wooden cores of peony roots, wherein the cutting part comprises cutting wheels and support wheels matched with the cutting wheels, and annular blades for splitting epidermis of the peony roots are arranged on the cutting wheels; first annular slots corresponding to the blades on the cutting wheels inposition are formed in the support wheels. By means of strip-shaped cuts, the wooden cores are pulled out of the cuts, and the condition that peony root bark is split by transverse thorns during axial pulling out is avoided; the sharp ends of the peony roots are inserted into gaps between the wooden cores and the peony root bark by means of sharp end structures at the lower part of the cutting part, the wooden cores are picked out of the gap split along the peony root bark, and the inner wall of the peony root bark is not scratched to the greatest extent.

Owner:黄青青

Large-torque electric fish wire wheel

The invention relates to a large-torque electric fish wire wheel, wherein a main shaft, a motor, a wire winding wheel and a bearing are disposed inside a shell body, a clutch plate is disposed between the motor and the wire winding wheel, the bearing which can move horizontally along the main shaft is disposed inside the right end of the wire winding wheel, and adjustment bearing screw rods sleeve the bearing and the main shaft on the right end of the bearing; and a clutch adjustment handle and a fixation nut are disposed in sequence on the adjustment bearing screw rod outside a shaft hole in the right end face of the shell body, and a driving combining part, a driven combining part, a manual handle, a push force spring, a clamp spring and a fastening nut are disposed in sequence on the main shaft on the right end of the fixation nut. The large-torque electric fish wire wheel provided by the invention has the beneficial effects that the large-torque electric fish wire wheel has a small volume and a light weight, can be operated conveniently, generates huge torque force, will not generate self-twisting, can realize automatic wire winding quickly, realizes double functions including manual operations and electric operations, and can realize flexible adjustment of the torque force of the wire winding wheel.

Owner:TENGZHOU AOKE ELECTRICAL APPLIANCE CO LTD

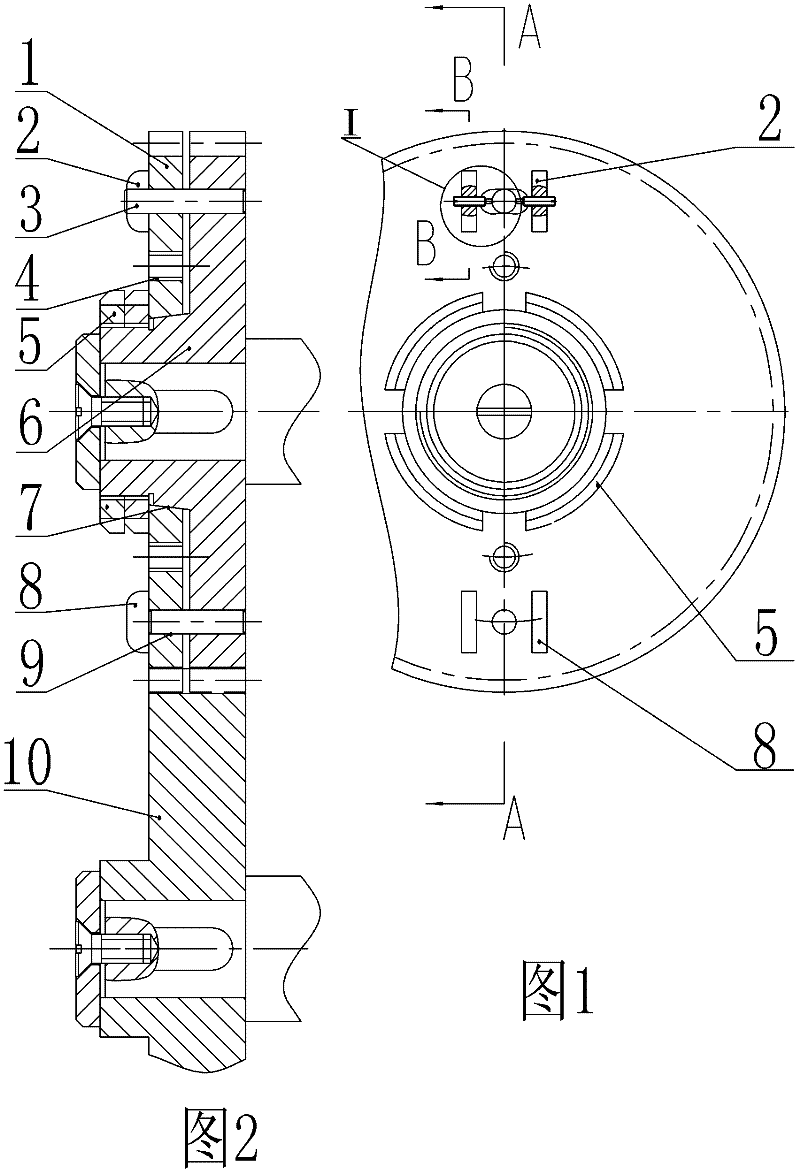

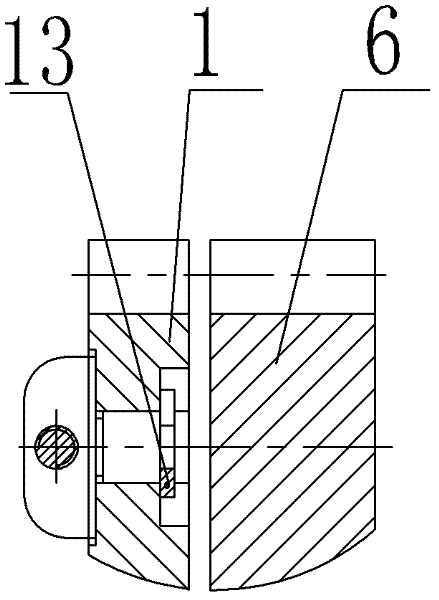

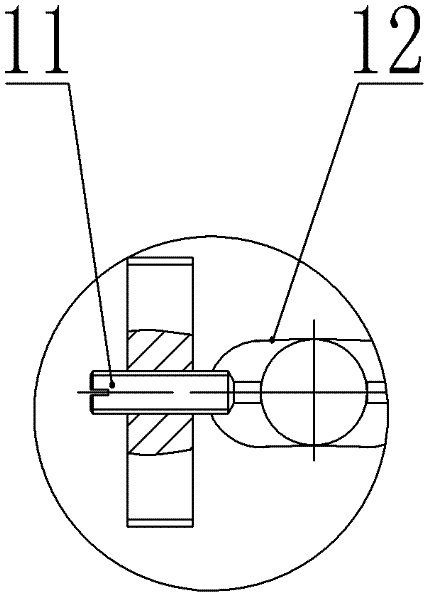

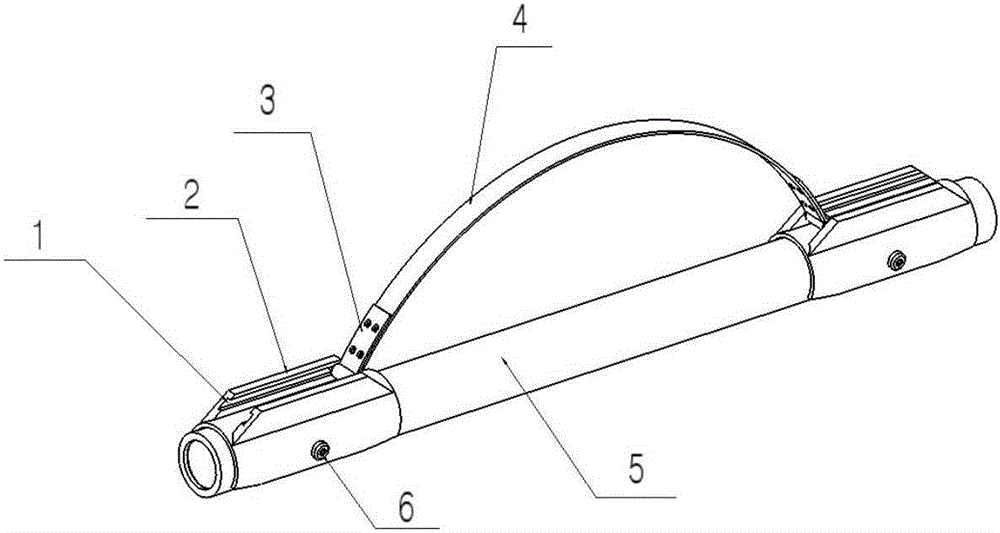

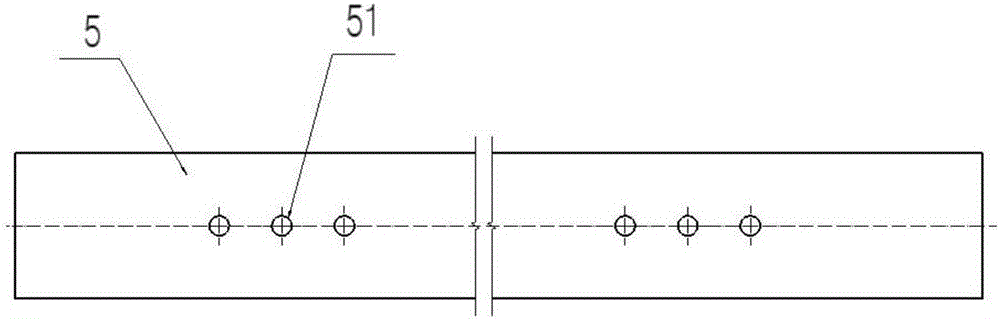

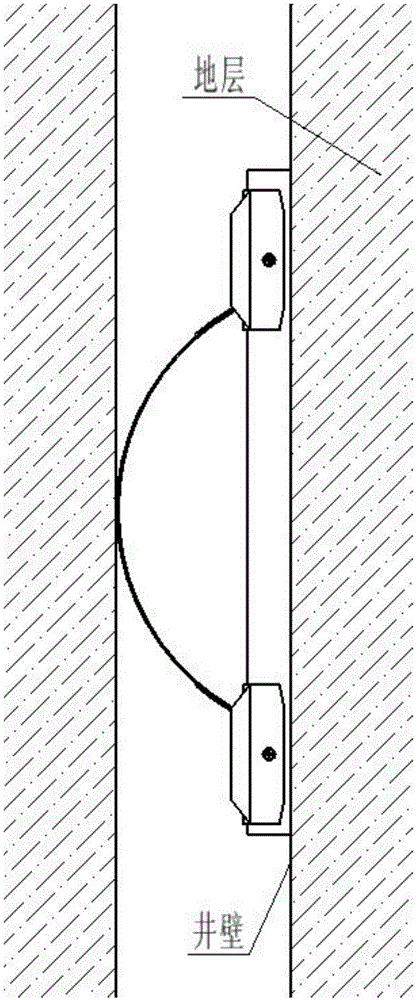

Eccentric centralizer for element logging instrument

InactiveCN106285510ARealize flexible adjustmentAdjustable pushing forceSurveyDrilling rodsMechanical engineeringInstrumentation

The invention belongs to the technical field of logging and particularly relates to a centralizer for an element logging instrument. The eccentric centralizer for the element logging instrument comprises shaft sleeves and an elastic bow, and the shaft sleeves are installed at the two ends of a logging instrument shell. Each shaft sleeve is provided with a slide way with the open outer side and closed inner side. The two ends of the elastic bow are each provided with a connecting sleeve, and a sliding block is arranged at the bottom of each connecting sleeve and located in the corresponding slide way. When the eccentric centralizer is applied inside a well, the logging instrument shell and the face of a well wall are attached, the elastic bow makes contact with the face of the well wall in an abutting mode, and when the well diameter is changed, the two ends of the elastic bow move in the slide ways so that adjustment can be achieved. The eccentric centralizer can adapt to the change of the well diameter, then the instrument can continue to carry out logging by keeping attached to the well wall, and the logging quality is ensured; and the eccentric centralizer is simple in structure and convenient to use.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Automatic argon-blowing butt-joint device

The invention discloses an automatic argon-blowing butt-joint device. The automatic argon-blowing butt-joint device comprises a male head and a female head, wherein the male head is in blocking connection to the female head; the female head is fixed on the outer wall of a steel ladle; the male head is fixed on a base; the female head comprises a joint, and a cavity is arranged in the joint; the cavity in the joint communicates with a pass-through hole in the side wall of the joint; a regulating screw plug is arranged on the outer wall of the joint at the top end of the cavity; the regulating screw plug passes through the joint and is tightly combined with a regulating spring in the cavity; a steel ball is arranged below the regulating spring; a copper sleeve is arranged below the steel ball; a gas hole is formed in the middle of the copper sleeve; the copper sleeve is embedded into the joint; a sealing cushion is arranged between the copper sleeve and the joint; the lower portion of the joint is connected to a conical flange; and the joint and the conical flange are connected through a fixed bolt and a fixed nut. The conical flange is arranged, so that an argon-gas tube can slide to the copper sleeve after being in contact with the inner wall of the conical flange while the argon-gas tube is in butt joint to the copper sleeve, and therefore, fuzzy butt-joint can be realized, butt-joint precision is high, labor intensity of a worker is relieved, and the argon-gas tube is conveniently butt-jointed by the worker.

Owner:江苏博壹重工有限公司

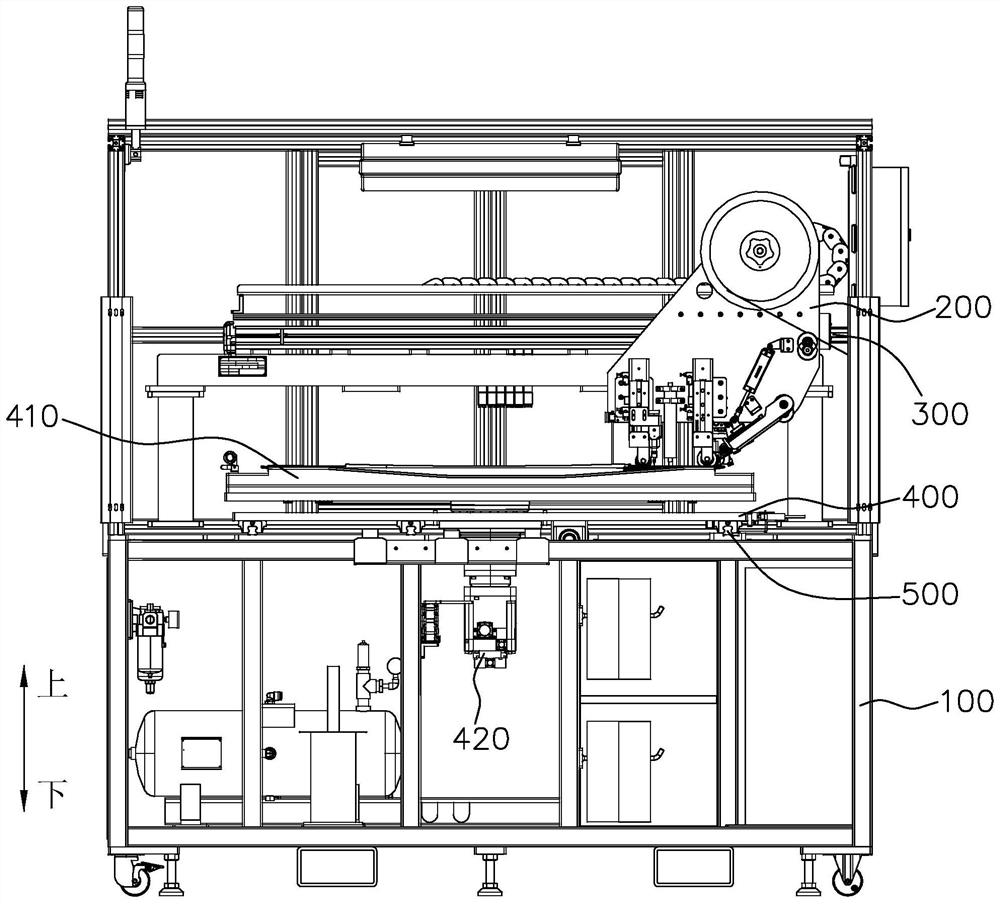

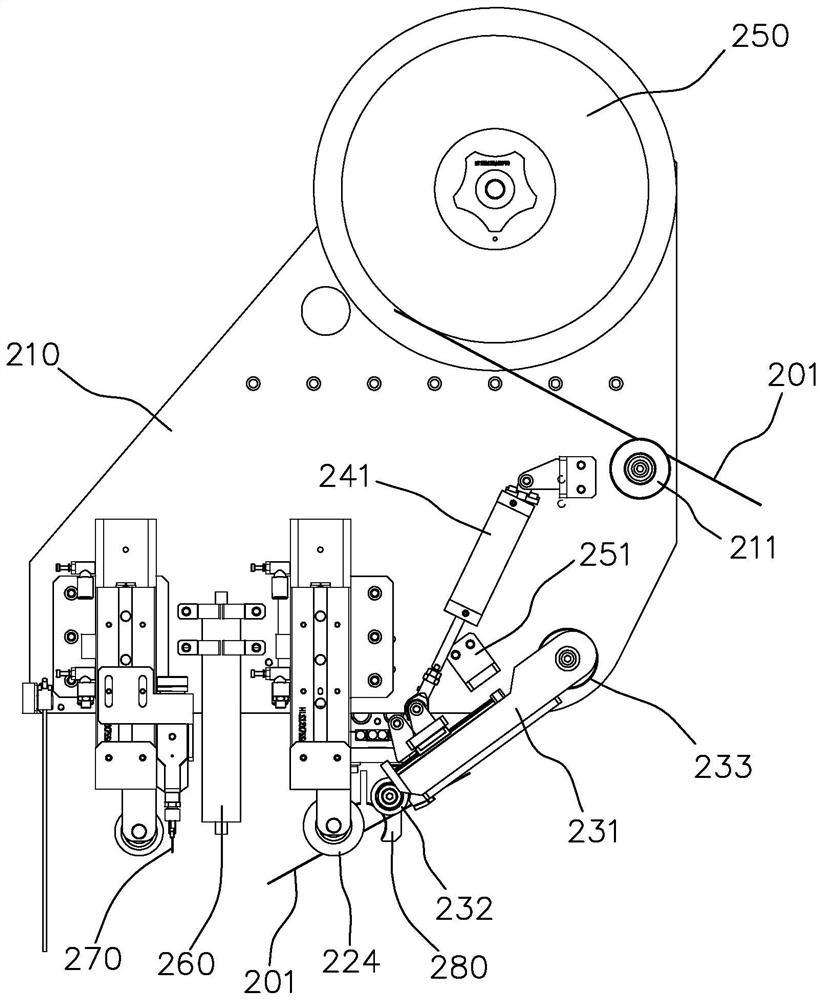

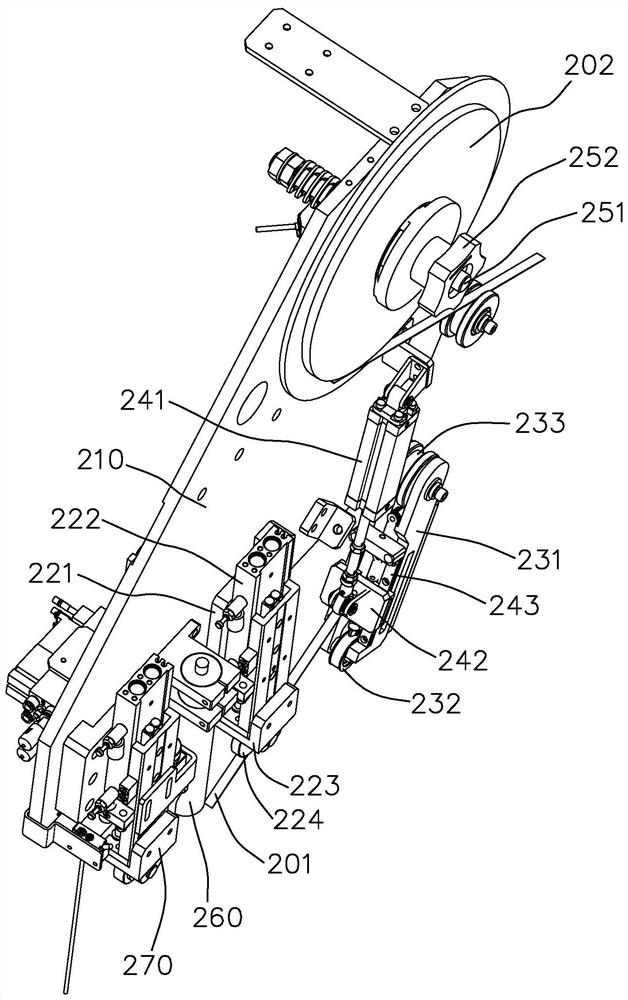

Taping mechanism and taping equipment

ActiveCN112249789AAvoid situations where the bond is not strong enoughRealize flexible adjustmentFinal product manufactureArticle deliveryAdhesive beltEngineering

The invention discloses a taping mechanism and taping equipment, and relates to the technical field of taping. The taping mechanism comprises a base plate; an adhesive tape carrying part used for carrying an adhesive tape roll; a compressing part which comprises a compressing seat, wherein one end of the compressing seat is hinged to the base plate, a first guide wheel is installed at the other end of the compressing seat, the first guide wheel presses the adhesive tape downwards to enable the adhesive tape to be tightly attached to a workpiece, a second guide wheel is installed at the end, hinged to the base plate, of the compressing seat, the compressing seat is hinged to the base plate through a rotating shaft, and the second guide wheel is installed on the rotating shaft; a connectingpart which comprises a telescopic connecting piece and a sliding seat hinged to the lower end of the connecting piece; a pressing wheel part which comprises a pressing wheel capable of moving up and down; and an adhesive tape shearing part which comprises a pair of scissors and is used for shearing the adhesive tape located on a passing path. The taping mechanism can avoid the situation that bonding is not firm enough after empty bonding is formed or bonding is not pressed due to the fact that the adhesive tape is not pressed in place.

Owner:GUANGZHOU MINHUI AUTOMOBILE PARTS

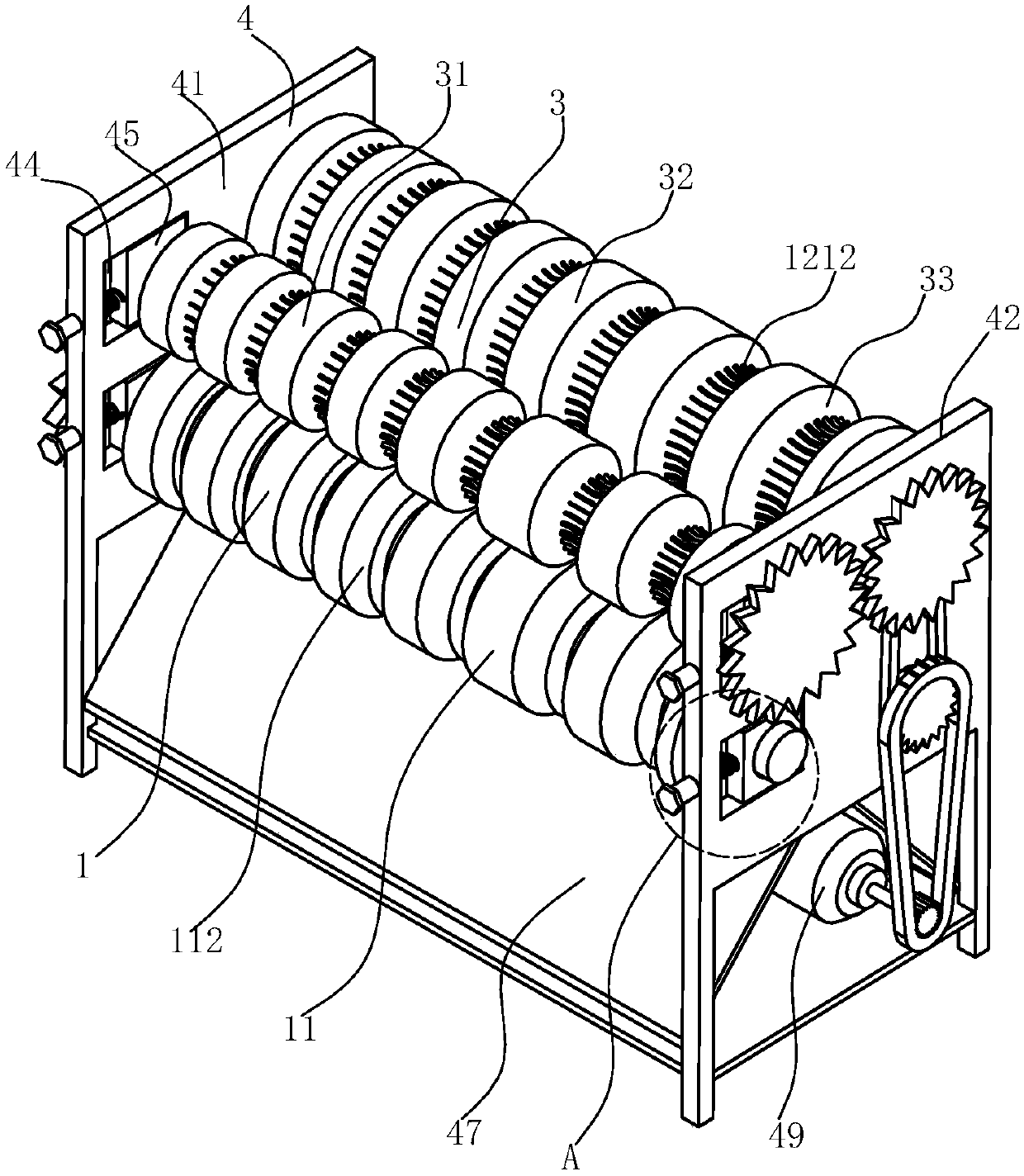

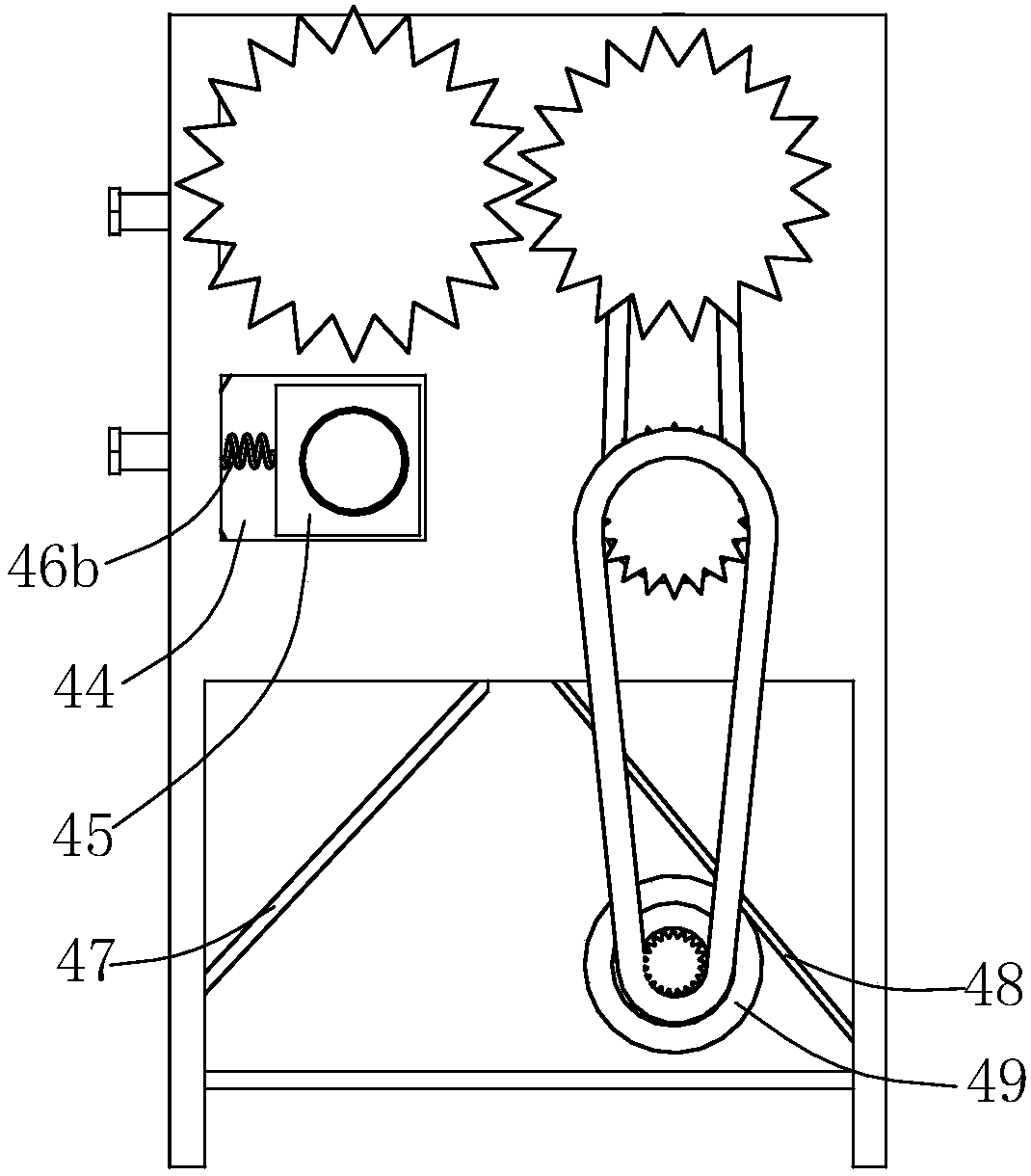

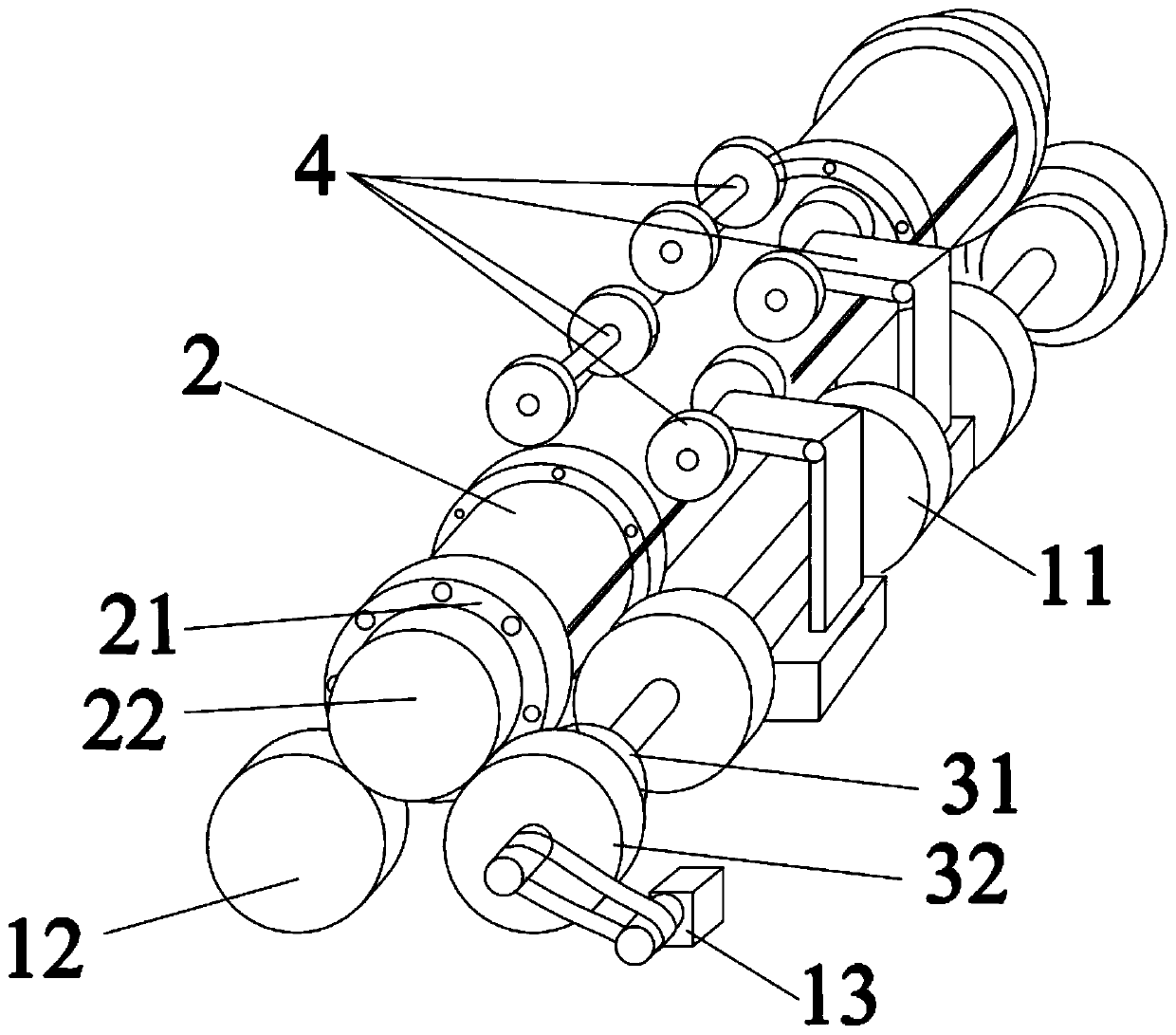

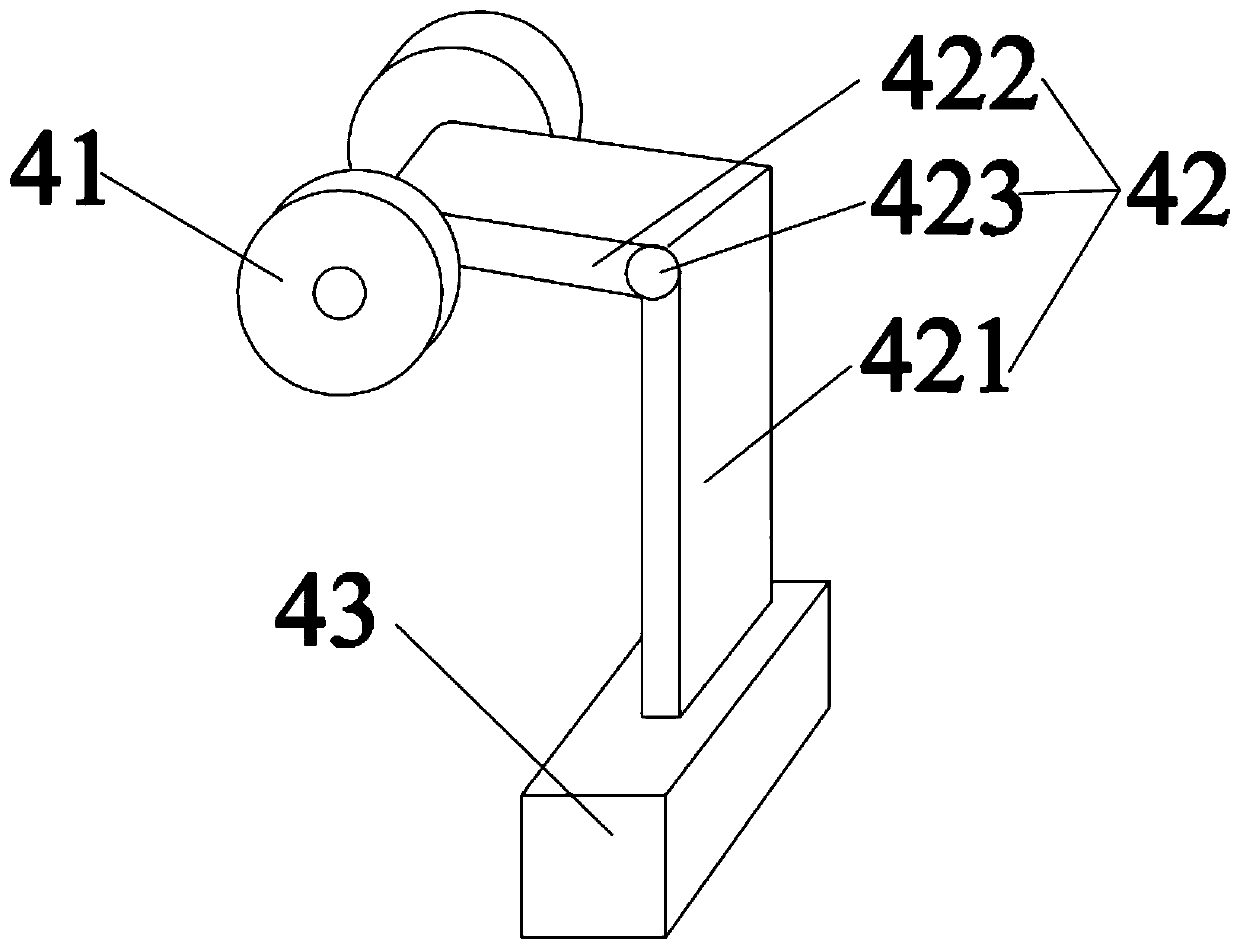

Concrete centrifuge

The invention discloses a concrete centrifuge. The concrete centrifuge comprises a base frame, a drive mechanism arranged on the base frame, and damping mechanisms. The drive mechanism is provided with drive units and supporting units. The drive units drive the supporting units to rotate, and the supporting units are rotationally supported on the rotary peripheral surface of a die. The damping mechanisms comprise damping units rotationally abutting against the rotary peripheral surface of the die, and the damping units apply acting force for limiting the die from being separated from an initial rotary position to the die. The supporting units and the damping mechanisms are arranged along the two sides of the outer surface of the die. One damping mechanism is arranged between any two supporting units. According to the concrete centrifuge of the structure, when the die is driven by the drive mechanism to rotate, if the die has a jump trend, the damping units apply the acting force for limiting the die from being separated from the initial rotary position to the die, in other words, the damping units abut against the peripheral surface of the wall face die to prevent jump generated when the die rotates, and then the purpose that finished pipe piles are uniform is guaranteed.

Owner:盐城市双强管桩有限公司

Safety protection device for high-altitude construction operation

InactiveCN108532976AEasy to operateWith multiple protection measuresBuilding material handlingFixed frameRemote control

The invention discloses a safety protection device for high-altitude construction operation. The safety protection device comprises a fixed frame, a sliding rail fixedly connected with the upper end of the fixed frame, a sliding head capable of sliding back and forth on the sliding rail, and a safety protection belt connected with the sliding head, wherein a wire coil is arranged on the safety protection belt to control the length of a safety protection belt body; the wire coil is provided with a locking mechanism for locking the safety protection belt so that the safety protection belt cannotbe extended continuously; and a working platform is arranged at the lower end of the fixed frame, and a pressure sensing device and a control device are arranged on the working platform. When a worker falls from the working platform, the pressure sensing device detects that the threshold value on the working platform is lower than the set threshold value, and the control device controls the locking mechanism to lock the protection belt to avoid continued falling of the worker; the safety protection device is provided with a remote control terminal, and the remote control terminal is used formonitoring the multiple safety protection devices; and the safety protection device is simple to install and operate, has multiple protection measures, and improves the safety and reliability of high-altitude operation construction.

Owner:张丕拓 +2

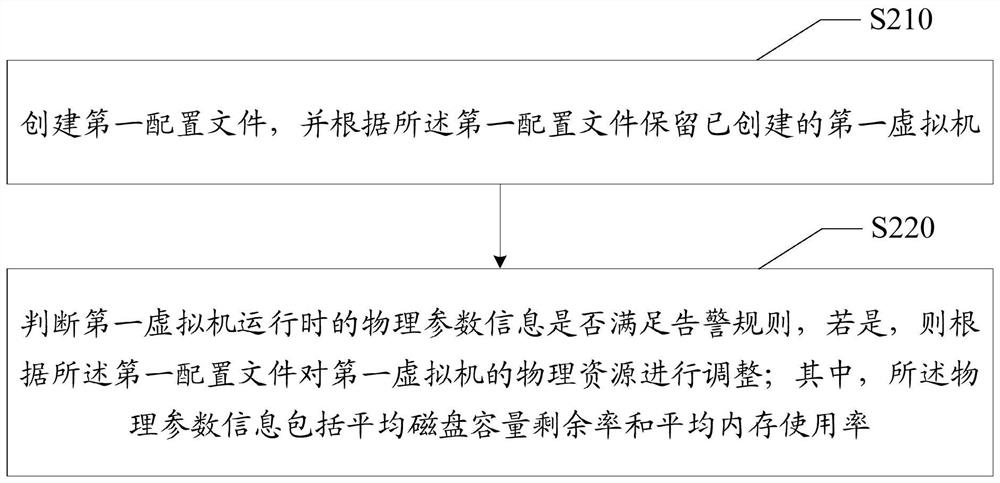

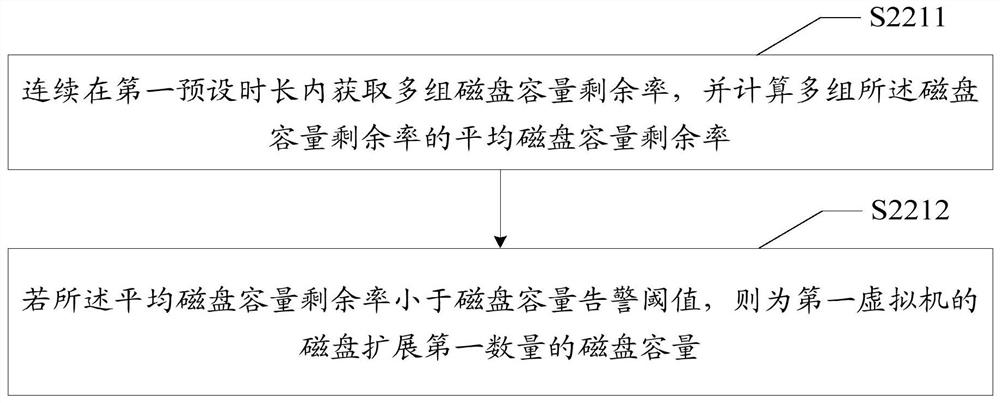

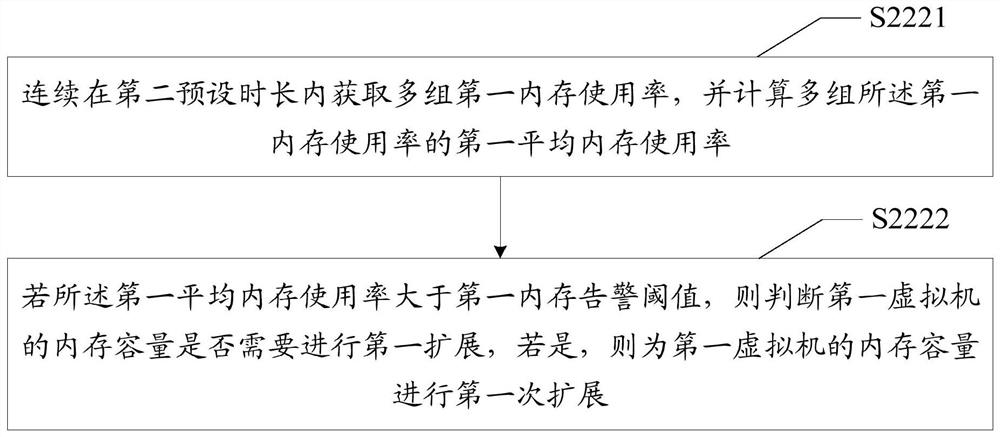

Virtual machine recovery and resource adjustment method

PendingCN112395045ASolve wasteEnable recyclingResource allocationSoftware simulation/interpretation/emulationIndustrial engineeringVirtual machine

The invention discloses a virtual machine recovery and resource adjustment method, and the method comprises the steps of building a first configuration file, and reserving a built first virtual machine according to the first configuration file; judging whether the physical parameter information of the first virtual machine during running meets an alarm rule or not, and if yes, adjusting physical resources of the first virtual machine according to the first configuration file; the virtual machine recovery method comprises the following steps: executing a target task on a created second virtualmachine; monitoring whether the task state of the target task executed on the second virtual machine is completed or not; and if so, deleting the second virtual machine of which the task state of thetarget task is completed. According to the invention, the problem of waste of slave node resources in a software project is solved, not only is recycling of idle slave nodes realized, but also elasticadjustment of physical resources of the slave nodes is realized, and the utilization rate of the slave node resources is increased to a great extent.

Owner:SHENZHEN ZTE NETVIEW TECH +1

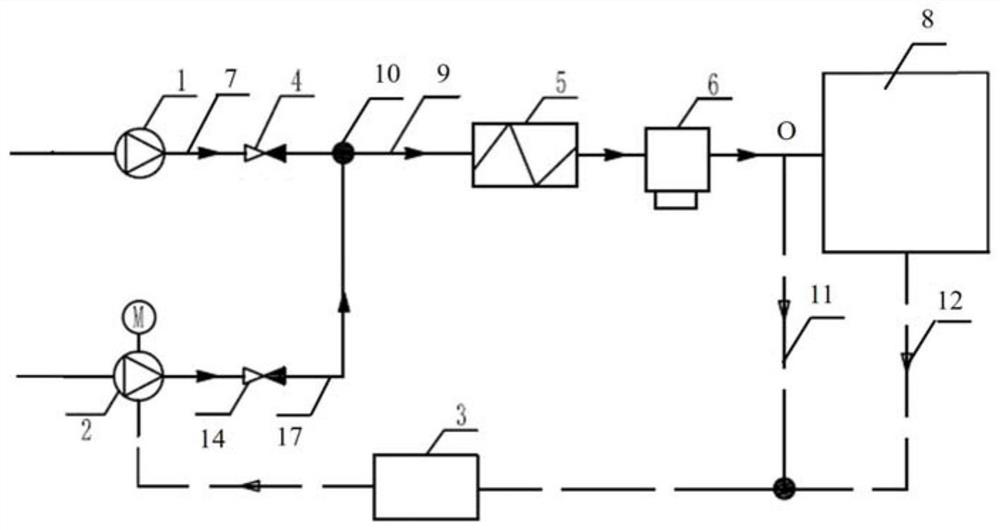

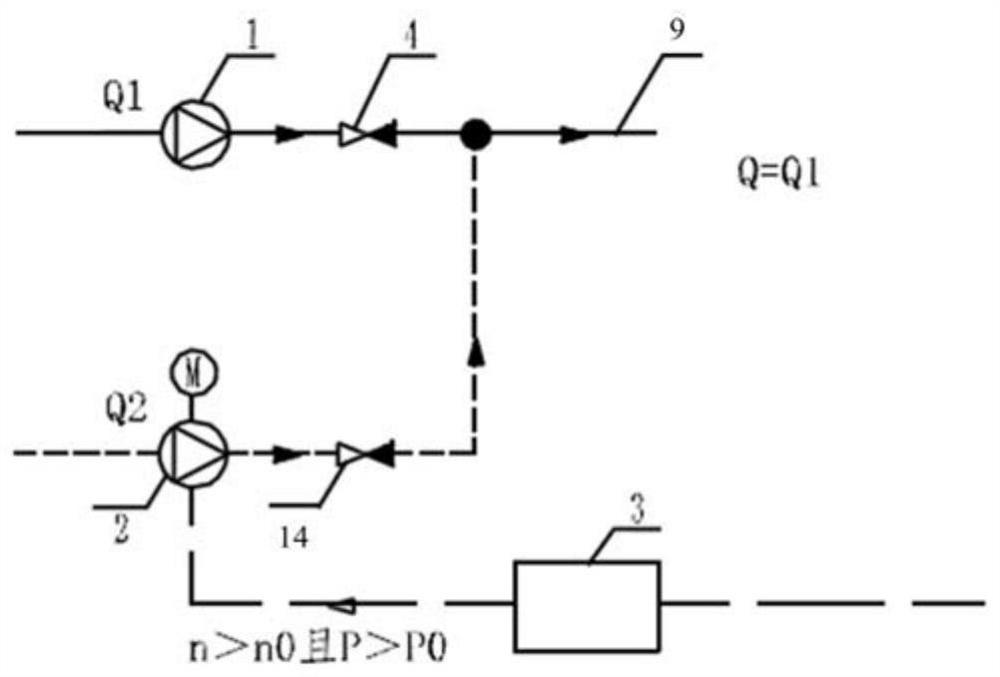

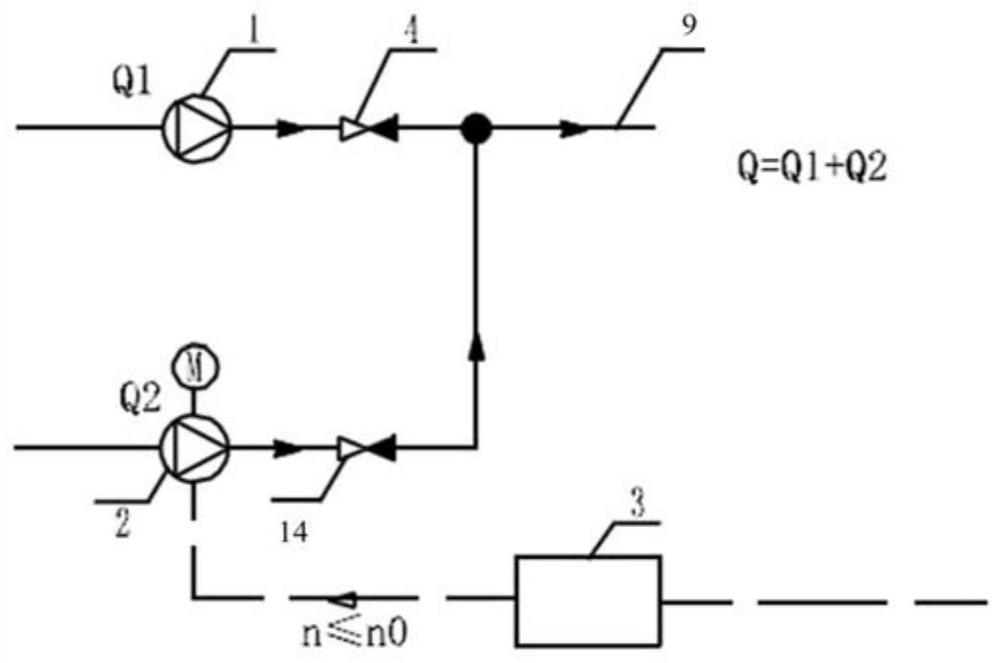

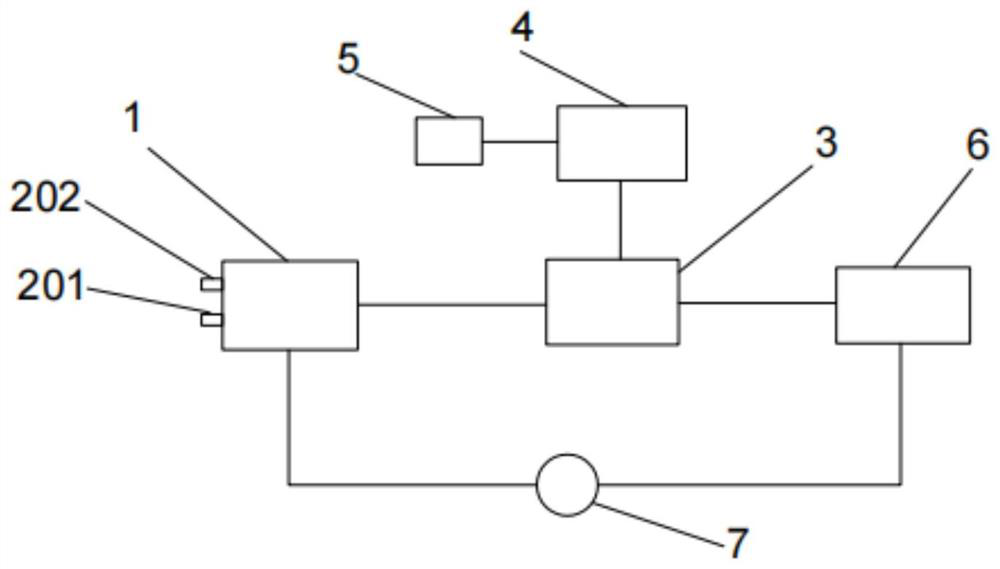

Diesel engine lubricating oil supply system and supply control method

ActiveCN113153482ARaise the inlet pressureImprove reliabilityMachines/enginesClosed-circuit pressure lubricating systemsOil pressureOil supply

The invention provides a diesel engine lubricating oil supply system and a supply control method. The supply control method comprises the steps that when a diesel engine is standby, an auxiliary pump is started, and a main pump is kept closed; after the diesel engine is started, the main pump is started, when an electric controller judges that the inlet pressure of lubricating oil is larger than an oil pressure threshold value and the rotating speed of the diesel engine is larger than the rotating speed threshold value, the electric controller closes the auxiliary pump, and the main pump supplies oil to the diesel engine in the high working condition independently; and after the diesel engine is started and the auxiliary pump is closed, when it is judged that the rotating speed of the diesel engine is smaller than or equal to the rotating speed threshold value or the inlet pressure is smaller than or equal to the safety threshold value, the auxiliary pump is restarted. Independent oil supply of the main pump and the auxiliary pump and cooperative oil supply of the main pump and the auxiliary pump are achieved through independent opening and closing of the main pump and the auxiliary pump, on the premise that an existing lubricating oil pump structure is not changed, the low-energy-consumption design of the diesel engine under the high working condition and intelligent pressure supplementing under the low working condition can be achieved, lubricating oil inlet pressure is increased through common oil supply of the main pump and the auxiliary pump under the low working condition, and therefore the reliability of the diesel engine is improved.

Owner:中国船舶集团有限公司第七一一研究所

Flexible structure for quick device

Owner:航天新长征大道科技有限公司

Replaceable multi-heat-source waste heat generator set

ActiveCN113586193AReduce input flowMeeting power generation needsSteam engine plantsEngineeringElectromagnetic valve

The invention relates to a replaceable multi-heat-source waste heat generator set, and relates to the technical field of generators. The replaceable multi-heat-source waste heat generator set comprises an evaporator used for evaporating an input heat source and transmitting high-temperature and high-pressure gas formed after the evaporation to an expansion machine, the evaporator is provided with a first input port and a second input port, the first input port is used for inputting a flue gas heat source into the evaporator, the second input port is used for inputting a hot water heat source into the evaporator so as to ensure multi-heat-source input, each input port is provided with an electromagnetic valve so as to accurately control heat source input, the expansion machine is used for conducting adiabatic expansion on input gas and transmitting internal energy generated by acting of the gas into a power generator, the power generator is used for converting the input internal energy into electric energy, the power generator is connected to a controller, and the controller is used for controlling the waste heat power generation process. According to the replaceable multi-heat-source waste heat generator set, the power generation efficiency is effectively improved by accurately controlling the input state of the heat source.

Owner:重庆国贵赛车科技股份有限公司

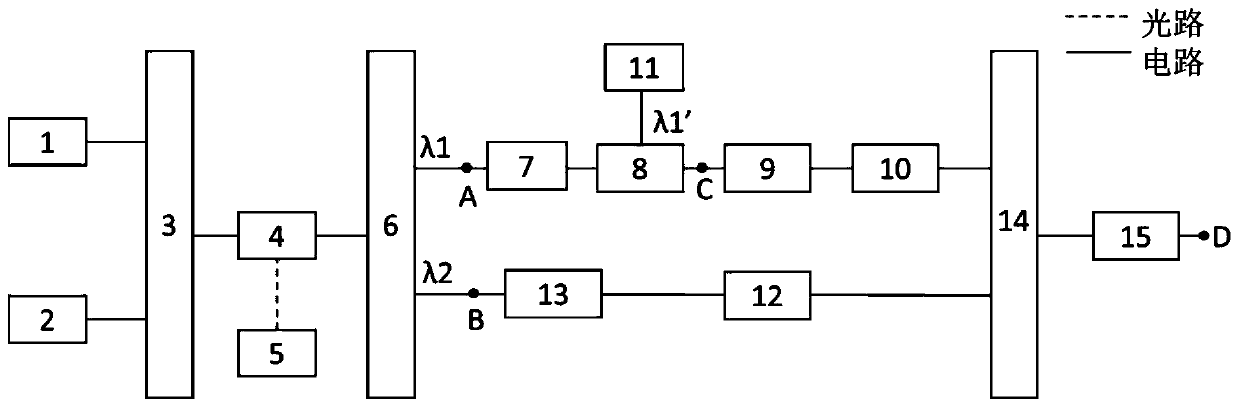

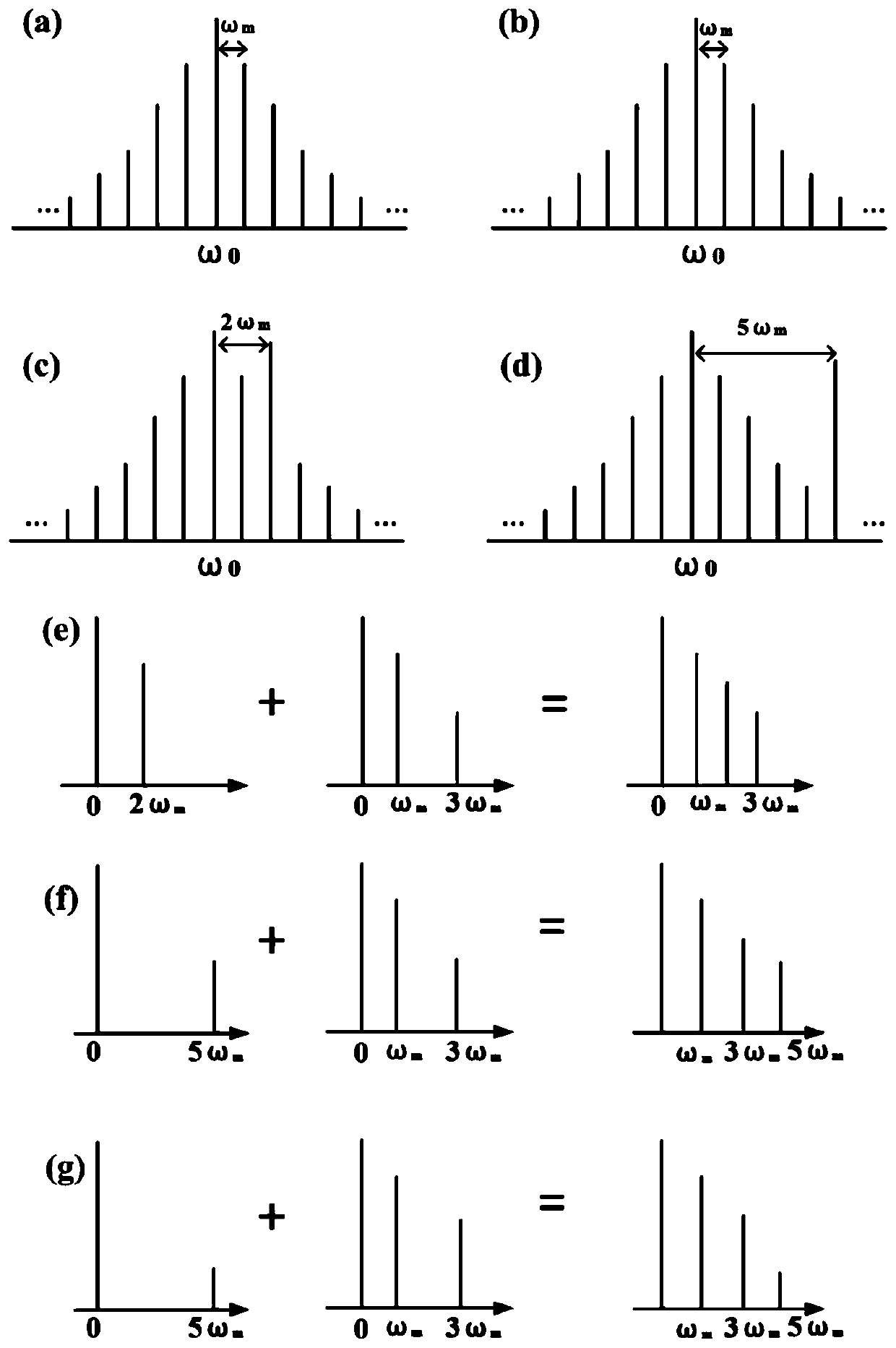

Arbitrary waveform generation method based on injection locking and nonlinear modulation

ActiveCN110572213ARealize flexible adjustmentStrong scalabilityElectromagnetic transmittersPhysicsArbitrary waveform generator

The invention discloses an arbitrary waveform generation method based on injection locking and nonlinear modulation. According to the method, injection locking is achieved through a first laser deviceand a DFB laser device with the wavelengths being lambda 1 and lambda 1' and with the wavelengths being lambda 1 and lambda 1' adjustable so as to generate higher harmonics and even harmonics; and the generation and polarization delay of odd harmonics are realized through the nonlinear modulation of light with the wavelength of lambda 2 generated by the second laser. Time domain superposition iscarried out on harmonic components generated by the lambda 1 branch and the lambda 2 branch, and phases and amplitudes are matched, so that one of triangular waves, square waves, sawtooth waves and anti-sawtooth waves with high-order components can be generated. The complexity of a previous multi-waveform generation scheme is reduced by adopting an external modulation mode, higher harmonics are amplified and enhanced through injection locking, and flexible adjustment of frequency components and accurate generation of fixed spectrum components are realized, so that high-order approximate waveforms are obtained. Theoretically, more approximate waveforms can be obtained by adding injection locking branches.

Owner:TIANJIN UNIV

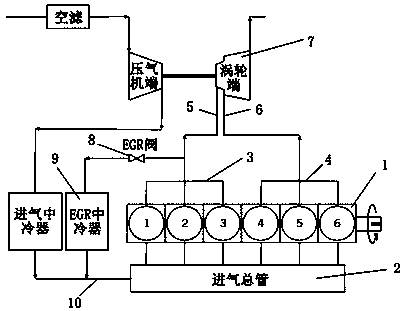

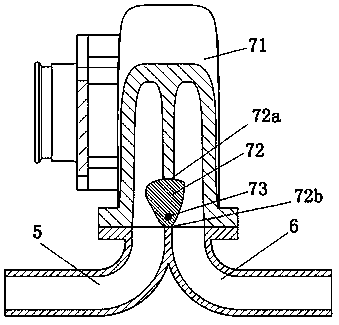

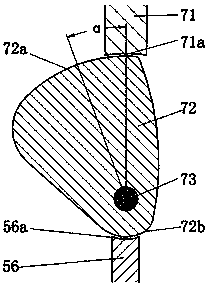

Flow area variable turbosuperchager

ActiveCN107795374AImport smoothlyChange pressureInternal combustion piston enginesExhaust gas recirculationTurbochargerHigh pressure

The invention relates to a flow area variable turbosuperchager, and belongs to the field of diesel engine equipment. A six-cylinder supercharged diesel engine of the flow area variable turbosuperchager is connected with an intake manifold, and every three cylinders in the six-cylinder supercharged diesel engine are connected with a first exhaust manifold and a second exhaust manifold; and each first exhaust manifold is connected with the turbine end through a first runner, and each second exhaust manifold is connected with the turbine end through a second runner. The flow area variable turbosuperchager is characterized in that the first runners and the second runners are arranged side by side, the first runners and the second runners are connected with a turbine shell and correspond to airways in the turbine shell, and a valve is arranged between each first runner and the corresponding second runner; and the valve controls waste gas pressure of the first runners and the second runners. The flow area variable turbosuperchager is suitable for the supercharged diesel engine adopting the high pressure EGR scheme. The flow area of the runners inside the supercharger is adjusted throughthe valve, the pressure of the corresponding exhaust manifolds is accordingly achieved, and EGR smooth guiding-in is achieved; meanwhile, the low average pumping loss is kept; and the turbosuperchager can be matched with an EGR valve to achieve flexible adjustment on the EGR rate.

Owner:CHINA FIRST AUTOMOBILE

Filtering device for paper pulp water filtering

ActiveCN108797179ASimple structureRealize flexible adjustmentPulp de-wateringWater filterPulp and paper industry

The invention discloses a filtering device for paper pulp water filtering. The filtering device comprises a pulp delivery pipe, an oblique filtering net and a pulp collecting tank, wherein a buffer hopper is arranged at the lower side of a pulp outlet of the pulp delivery pipe, the filtering net is fixedly arranged at the front end of the bottom surface of the buffer hopper, the pulp collecting tank is distributed at the lower side of the lower end of the filtering net, and a concentration detector is fixedly arranged at the bottom surface of the inner side of the buffer hopper; an oblique flow guide plate is arranged at the back side of the filtering net, a water collecting tank is arranged at the lower side of the lower end of the flow guide plate and is fixedly arranged at both side walls of the pulp collecting tank, the upper end of the flow guide plate is bent to form a horizontal connecting plate, and the connecting plate is fixedly arranged on a slide plate; a plurality of slideblocks are fixedly arranged at the upper end surface of the slide plate, and are inserted and sleeved onto a guide rail; the guide rail is fixedly arranged at the bottom surface of the buffer hopper;an air cylinder collecting plate is fixedly arranged on the slide plate; a horizontal air cylinder is fixedly arranged at the bottom surface of the buffer hopper through an air cylinder installationplate; a piston rod of the air cylinder penetrates through the air cylinder installation plate and is fixedly arranged on the air cylinder connecting plate. The filtering device has the advantages that the effect of elastic adjusting is realized, and the paper pulp reaching the saturation concentration is not subject to the water filtering by the filtering net.

Owner:山东仁合新材料科技有限公司

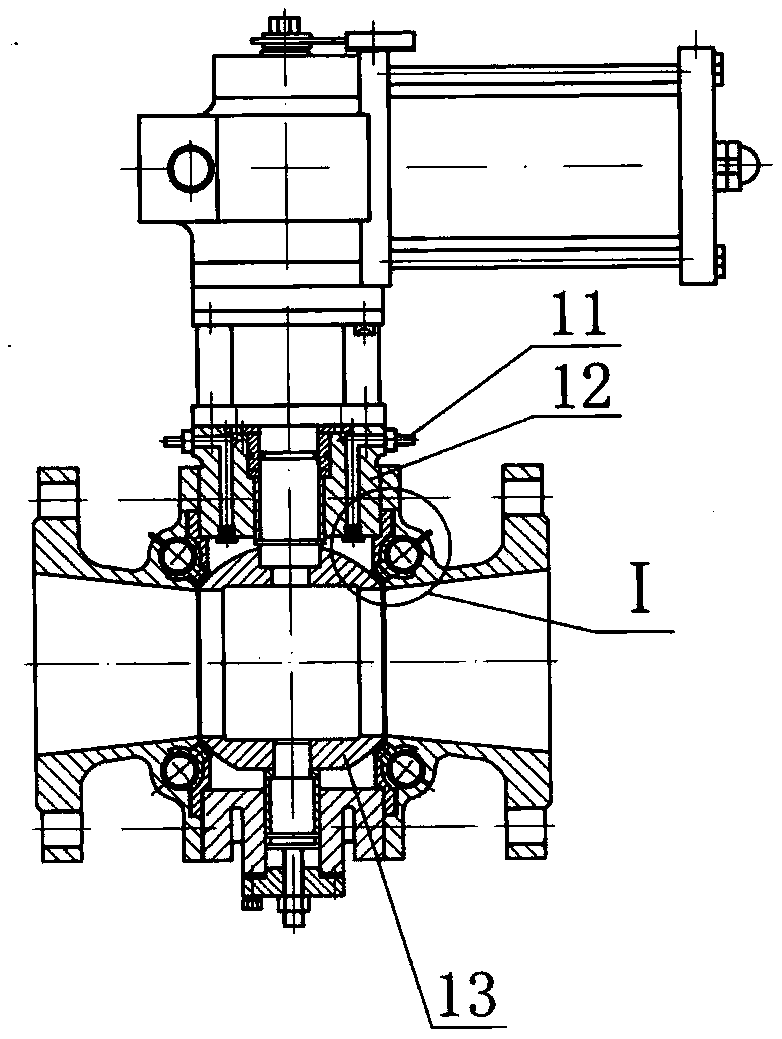

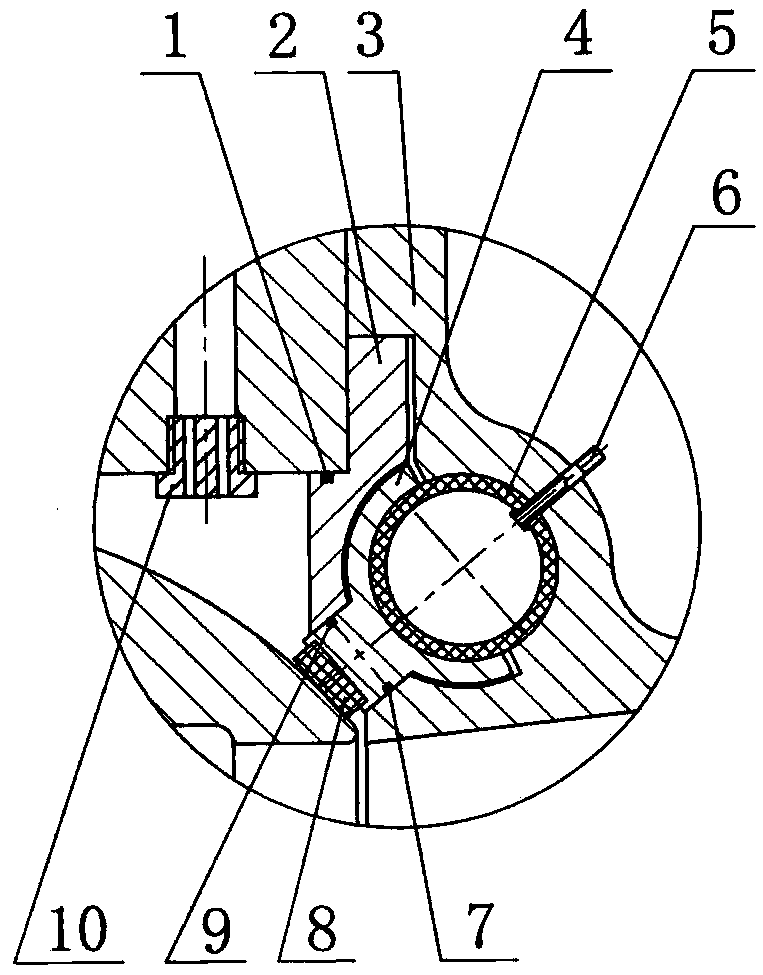

Flexible seal coal powder injection ball valve

PendingCN109404557AChange the tightnessRealize flexible adjustmentPlug valvesValve housingsEngineeringCoal

The invention discloses a flexible seal coal powder injection ball valve. The ball valve comprises a valve body, a valve cover and a sphere, and further comprises an insert, a sealing ring supportingring, an air bag, an air valve and a sealing ring. The insert comprises a concave torus, and the concave torus is of the step structure and integrated with a step-shaped structure. One end of the step-shaped structure is in contact with the valve body. The concave torus is in contact with the inner side surface of the valve cover. The sealing ring supporting ring is a circular annular half-ring surface, the outer sphere surface of the sealing ring supporting ring is in contact with the insert and the valve cover in a sliding mode, the head of the sealing ring supporting ring is loaded with thesealing ring, and the side surface of the sealing ring supporting ring is loaded with an O-shaped sealing ring. The sealing ring is opposite to the sphere. The air bag is a ring type sealing body made of rubber, the air bag is loaded with the air valve, and the air bag is loaded between the valve cover and the sealing ring supporting ring. The valve cover and the valve body are connected to forma valve inlet and outlet end face. The valve body is provided with a structure for removing dust accumulation in a valve body cavity, and the structure is through holes arranged on the left and rightbodies of the valve body. The flexible seal coal powder injection ball valve has the advantages of simple structure, reliable operation and long service life.

Owner:QIDONG METALLURGICAL MASCH CO LTD

Interface display processing method and device

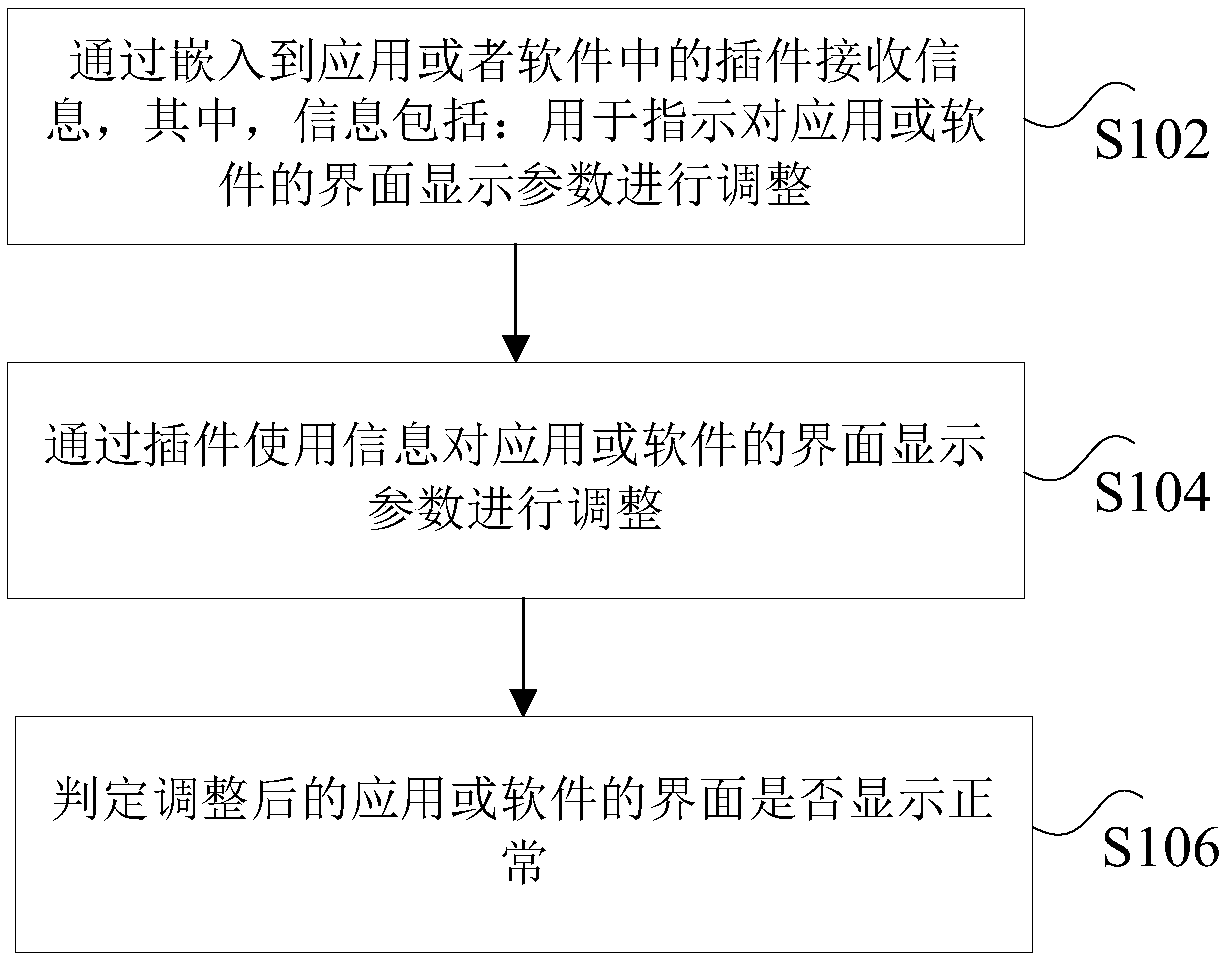

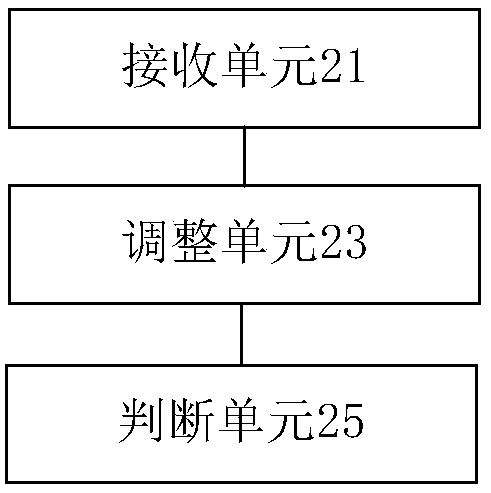

ActiveCN110968377ARealize flexible adjustmentSolve the technical problem that the display size of the interface cannot be flexibly adjustedProgram loading/initiatingExecution for user interfacesEngineeringHuman–computer interaction

The invention discloses an interface display processing method and device. The interface display processing method comprises the steps that information is received through a plug-in embedded into an application or software, and the information comprises information used for indicating adjustment of interface display parameters of the application or the software; adjusting interface display parameters of the application or the software through the plug-in use information; whether the adjusted interface of the application or software is displayed normally or not is judged, the purpose of adjusting the interface display size according to the interface display parameters is achieved, and therefore the technical effect of flexibly adjusting the interface display parameters is achieved, and thetechnical problem that in the prior art, the interface display size cannot be flexibly adjusted is solved.

Owner:BEIJING GRIDSUM TECH CO LTD

Intelligent monitor case of distribution transformer

ActiveCN111668721ARealize relative vertical slidingRealize flexible adjustmentAnti-seismic devicesInterior spaceDistribution transformer

The invention discloses an intelligent monitor case of a distribution transformer, and relates to the technical field of cases. The intelligent monitor case comprises a fixed box body, wherein a horizontally-arranged bearing plate is installed in the fixed box body through a damping mechanism, an elastic guide mechanism is in transmission connection between the fixed box body and a movable box body, a servo motor is in driving connection with a lifting mechanism, universal wheels are rotatably installed at the bottom of the lifting mechanism, and a holding rod is fixed to the side wall of themovable box body. According to the invention, the translation mechanism can drive the connecting block to move transversely to adjust the effect; the connecting block can pull a steel wire rope to achieve relative vertical sliding of the movable box body and the fixed box body under the action of an elastic guide mechanism. The flexible adjusting effect on the internal space of the device is achieved, the arranged damping mechanism can play an elastic damping and supporting role on system components on the bearing plate, the arranged universal wheels can stretch out of the bottom of the fixedbox body under driving of the lifting mechanism, and the flexible moving effect of the position of the device is facilitated.

Owner:HANGZHOU FENGHENG ELECTROMECHANICAL

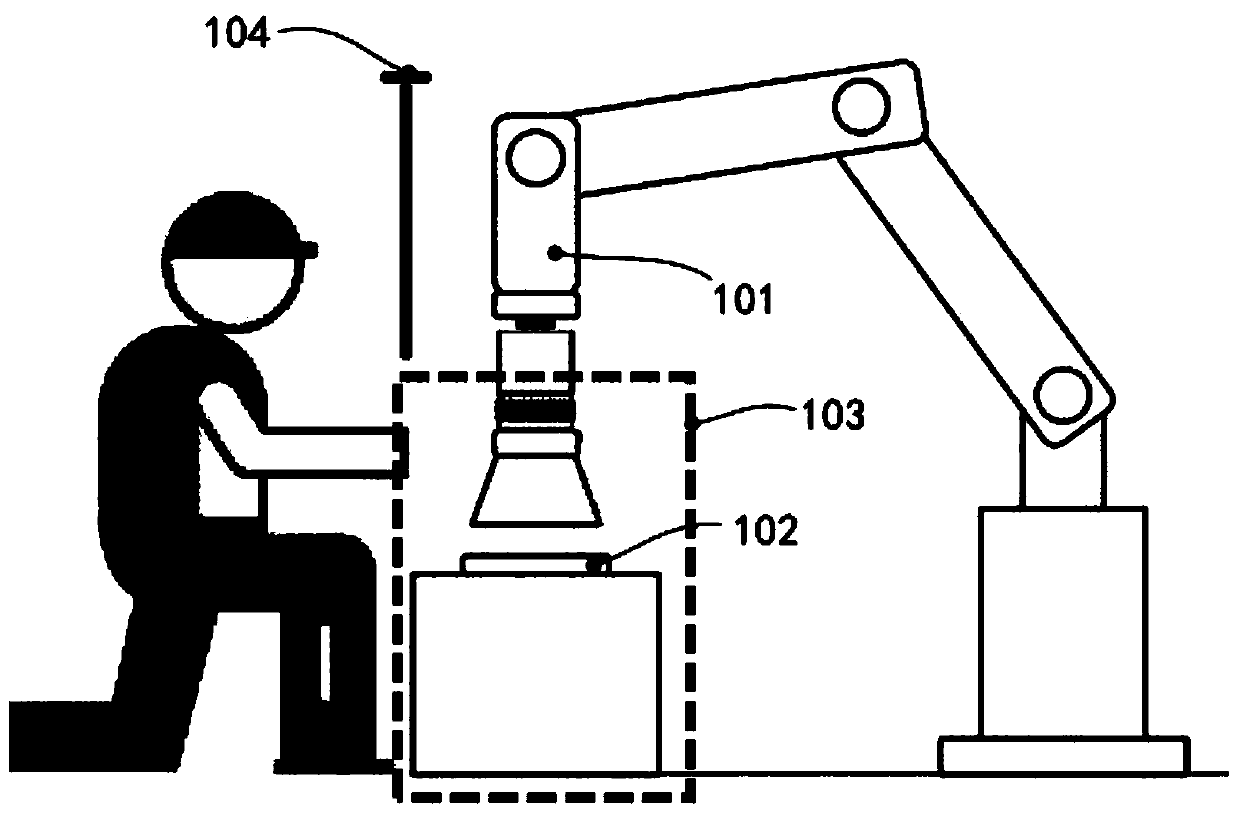

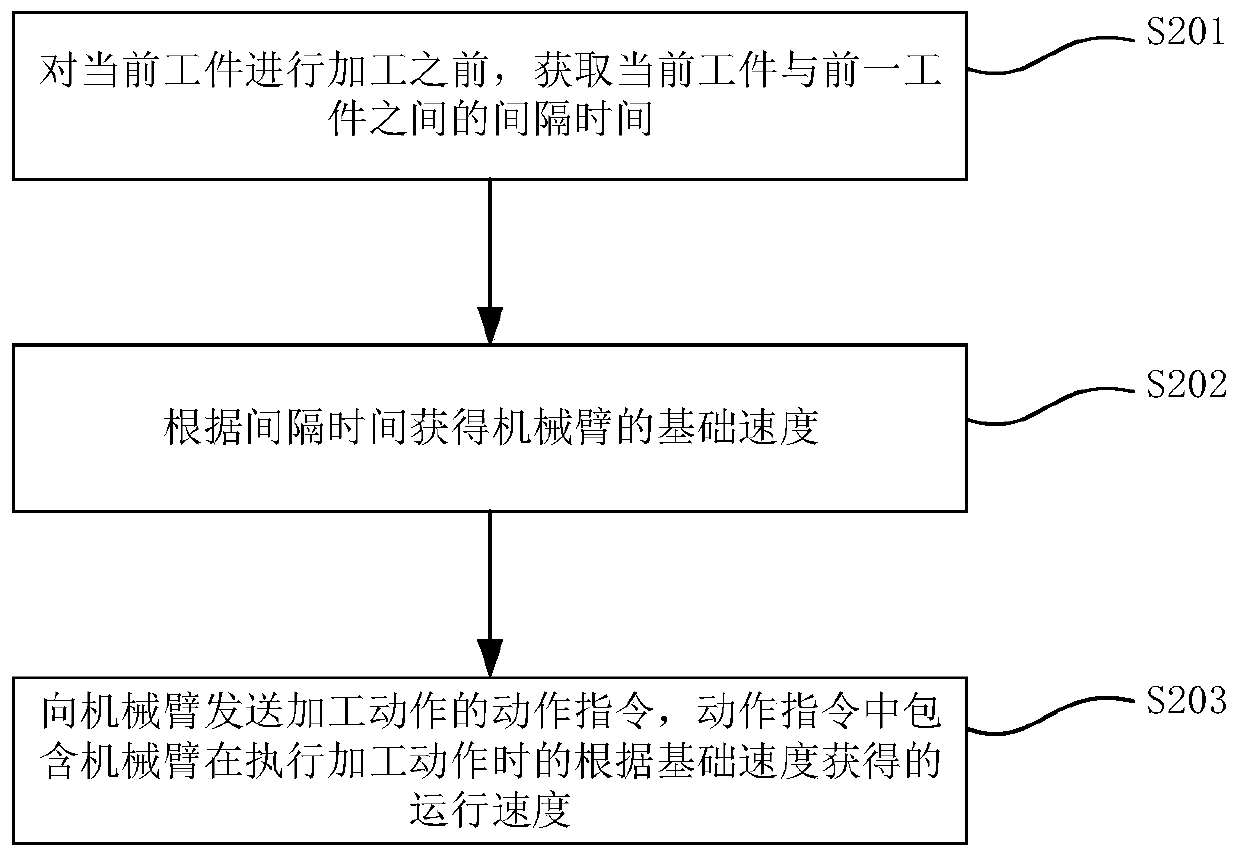

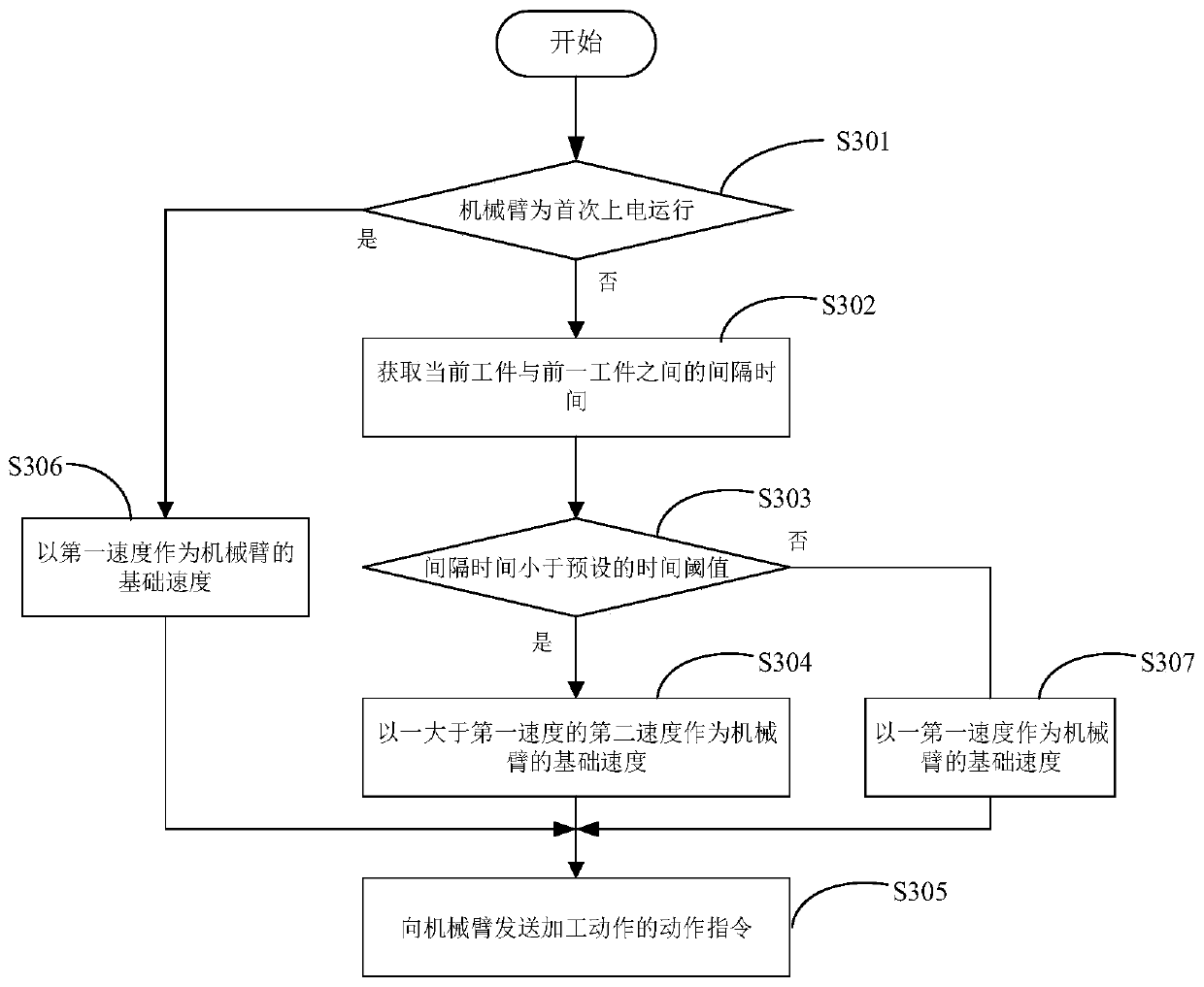

Mechanical arm speed regulation method, system and device and medium

ActiveCN109732602ASlow downReduce information pressureProgramme-controlled manipulatorControl theoryOverall efficiency

The invention discloses a mechanical arm speed regulation method, system and device and a medium. The mechanical arm speed regulation method comprises the steps that interval time of a current workpiece and a previous workpiece is obtained before machining of the current workpiece; according to the interval time, a base speed of a mechanical arm is obtained; and a motion command of machining motions is transmitted to the mechanical arm, and the motion command comprises an operation speed obtained according to the base speed of the mechanical arm during machining motions. The flexible regulation of the operation speed of the mechanical arm is achieved, and the overall efficiency of a production system is improved.

Owner:上海英医达医疗器械用品有限公司

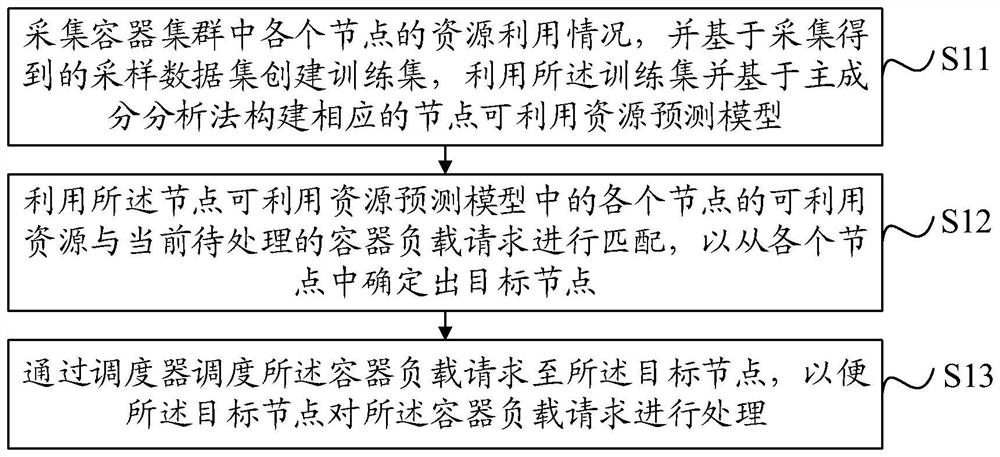

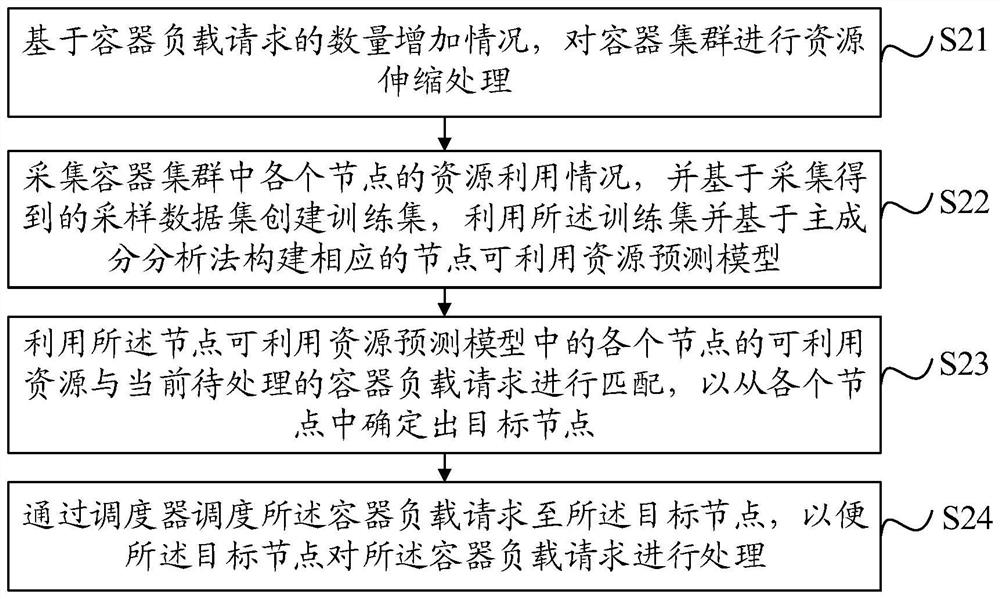

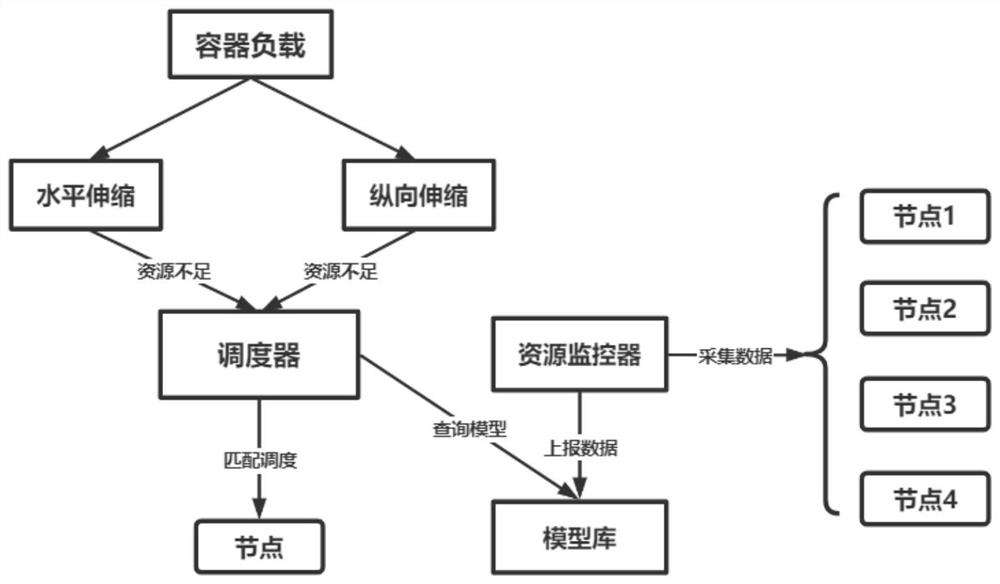

Container cluster scheduling method and device, equipment and storage medium

PendingCN114675933AMaximize utilizationIncrease profitProgram initiation/switchingCharacter and pattern recognitionData setPrincipal component analysis

The invention discloses a container cluster scheduling method and device, equipment and a storage medium, and the method comprises the steps: collecting the resource utilization condition of each node in a container cluster, creating a training set based on a collected sampling data set, and constructing a corresponding node available resource prediction model based on a principal component analysis method through employing the training set; matching available resources of each node in the node available resource prediction model with the current to-be-processed container load request to determine a target node from each node; and scheduling the container load request to the target node through the scheduler, so that the target node processes the container load request. According to the method, the node of which the available resources are most similar to the current container load request is determined from the nodes by using the constructed node available resource prediction model, and the node is used as the target node to process the container load request, so that the elastic adjustment of the allocation of the container load request is realized, and the node resource utilization rate is improved.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

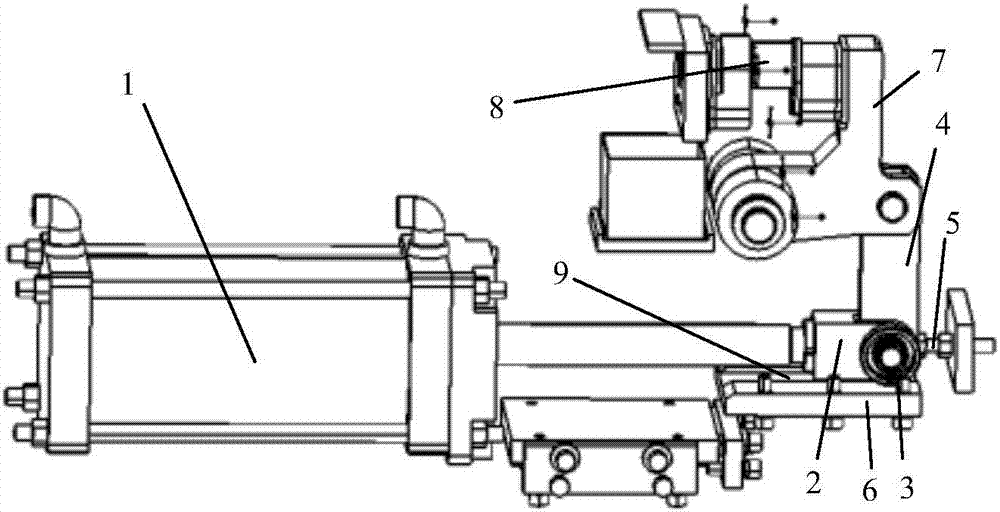

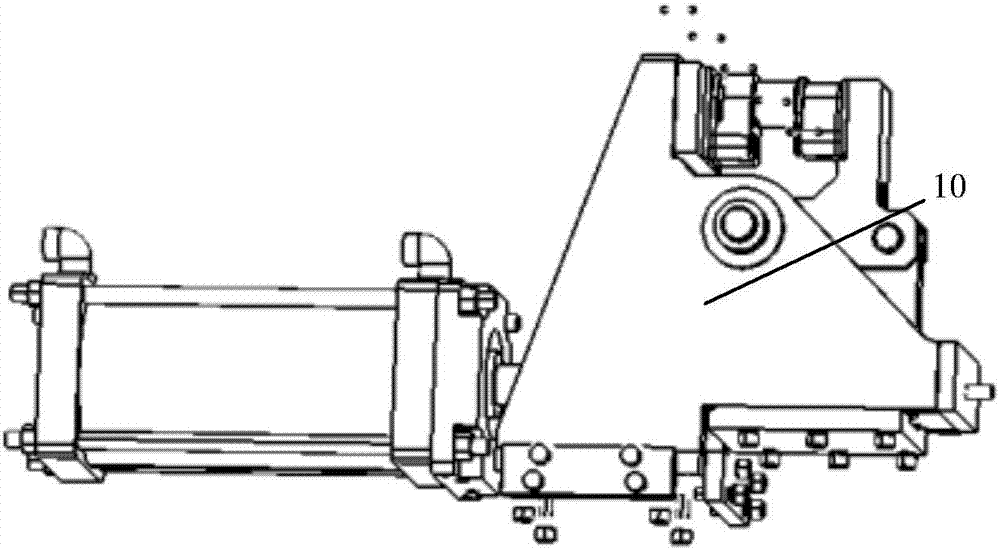

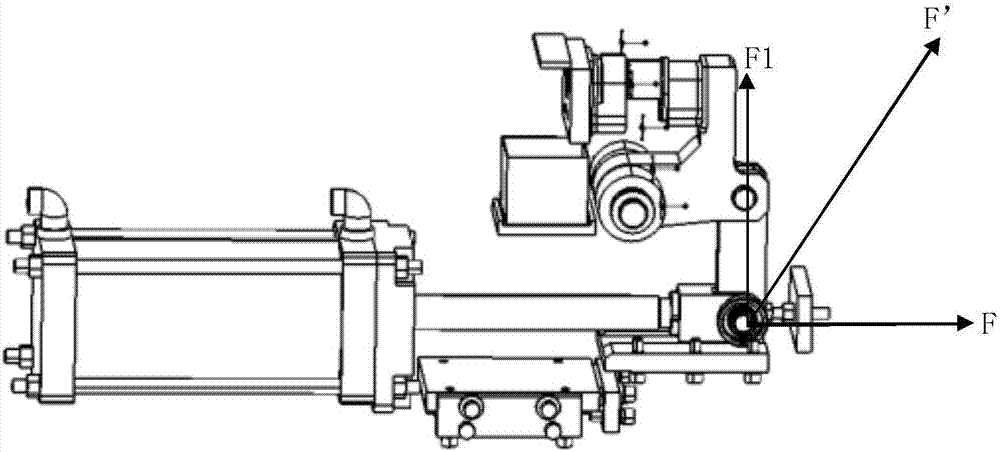

A flexible resistance welding device for thermoplastic composite materials

ActiveCN109940897BGuarantee welding qualityEnsure welding stabilityDomestic articlesElectric machineryElectric resistance welding

The invention discloses a thermal plastic composite material flexible resistance welding device. The device comprises a servo driving motor, a precision roller guiding rail linear movement system anda thermal plastic composite material resistance welding platform, wherein the precision roller guiding rail linear movement system is of a rectangular structure, the top face is provided with a rack in the length direction, and power output is provided by the servo driving motor; the thermal plastic composite material resistance welding platform can be installed on the precision roller guiding rail linear movement system by moving along the rail on the precision roller guiding rail linear movement system. The device has the advantages that welding lower pressure is provided through the servo pressure system, a to-be-welded part is positioned and resistance heating are conducted by a key type flexible electrode module, welding current is guided by connecting the electrode module, and therefore the purpose of thermal plastic composite material static and continuous dynamic flexible resistance welding is achieved.

Owner:CIVIL AVIATION UNIV OF CHINA

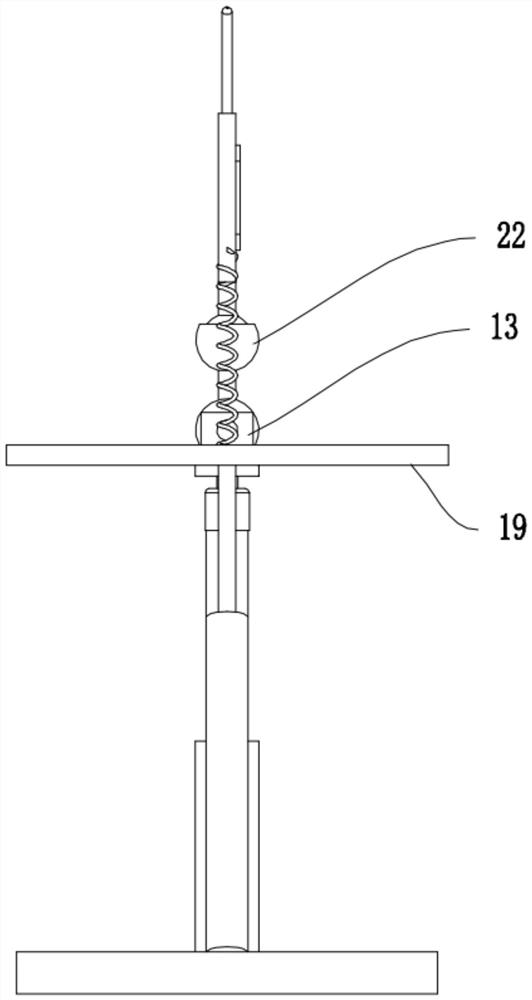

Roof communication base station supporting structure

InactiveCN112727222ARealize flexible adjustmentImprove communication effectTowersStructural engineeringMechanical engineering

The invention discloses a roof communication base station supporting structure. The roof communication base station supporting structure comprises a supporting bottom plate, a height adjusting piece, a rotary angle adjusting device, a universal rotation adjusting device, a mounting fixing plate, a follow-up telescopic supporting piece, a clamping rotary elastic pulling device and a lightning rod. The invention belongs to the technical field of base station supporting structures, and particularly relates to the roof communication base station supporting structure. The mode of combining height adjustment and various angle adjustment is adopted, the technical effect of flexibly adjusting the height and the angle while efficiently fixing the supporting structure is achieved, and the communication effect of a communication base station is further enhanced; and the mode of clamping rotary elastic pulling is adopted, the effect of elastic pulling limiting of the base station is achieved, the situation that communication signals of the base station are poor due to wind power shaking is prevented, and the problems that roof communication base station supporting structures in the current market are poor in effect, complex in structure and inconvenient to maintain are effectively solved.

Owner:中宏航天(北京)技术有限公司

Mechanical booster cylinder punching device

The invention discloses a mechanical booster cylinder punching device. The device comprises a cylinder, a cylinder pushing head, a deep groove ball bearing, a connecting rod, a limiting nut, a groove booster plate, a clamp arm, a punching mechanism, a guide groove and a booster mechanism bracket. The device can amplify the force finally reflected on a punch by 4-5 times under the condition of equal size of the cylinder, realizes punching of a high-torque plate, can obviously reduce the size of the cylinder to reduce the size of a blanking device, and saves public energy.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com