Filtering device for paper pulp water filtering

A filtering device and water filtering technology, applied in the field of papermaking equipment, can solve problems affecting normal production, prolonging process time, high pulp concentration, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

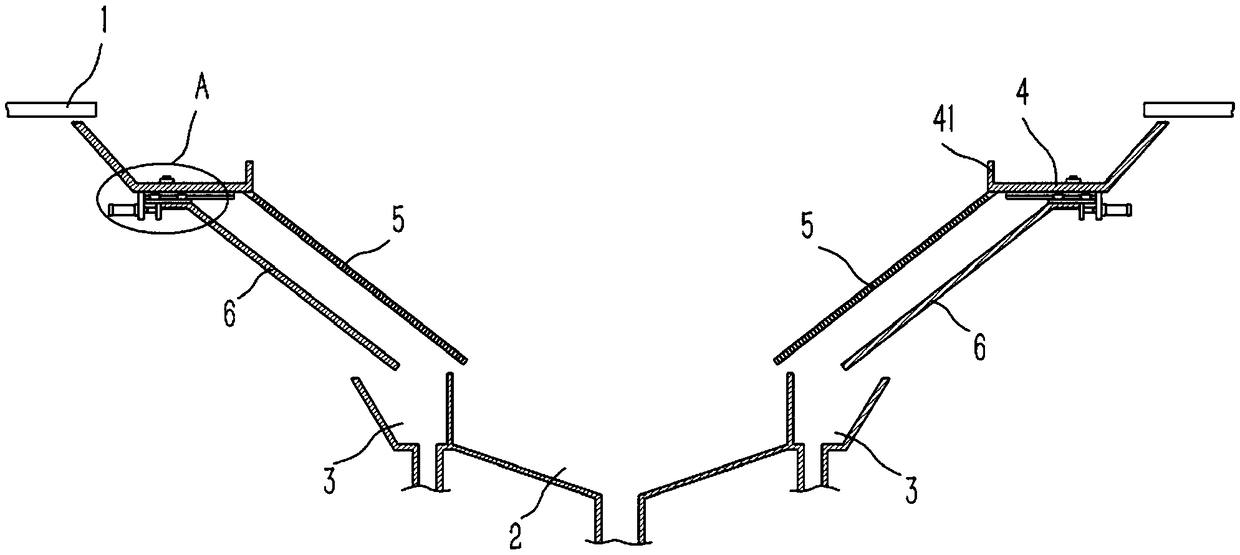

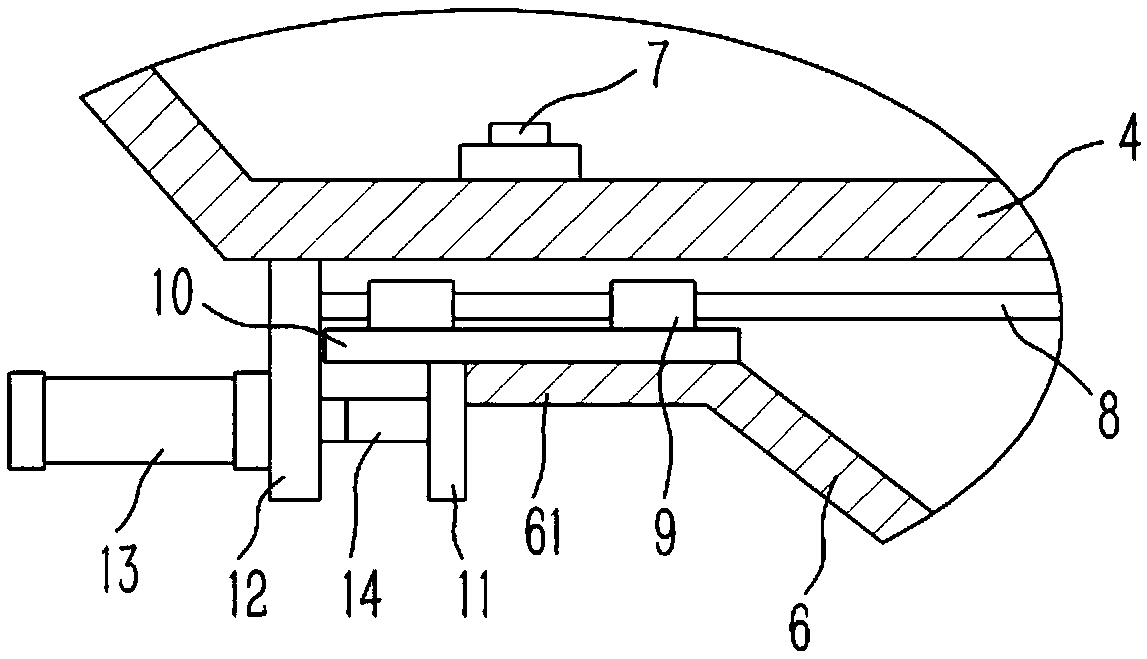

[0015] Example: see figure 1 , 2 As shown, a kind of pulp water filtration device comprises a pulp feeding pipe 1, an inclined filter screen 5 and a pulp collecting tank 2, a buffer bucket 4 is arranged on the lower side of the liquid outlet of the pulp feeding pipe 1, and the bottom surface of the buffer bucket 4 is The front end of the filter screen 5 is fixed with a filter screen 5, the slurry collecting tank 2 is distributed on the lower side of the filter screen 5 lower end, a buffer baffle 41 is provided on the buffer bucket 4 at the upper end of the filter screen 5, and a concentration Detector 7; the rear side of the filter screen 5 is provided with an inclined deflector 6, and the underside of the lower end of the deflector 6 is provided with a water collection tank 3, and the water collection tank 3 is fixed on the two side walls of the slurry collection tank 2, The upper end of the deflector 6 is bent to form a horizontal connecting plate 61. The connecting plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com