Concrete centrifuge

A centrifuge and concrete technology, applied in the direction of molds, etc., can solve the problems of uneven finished pipe piles and easy jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

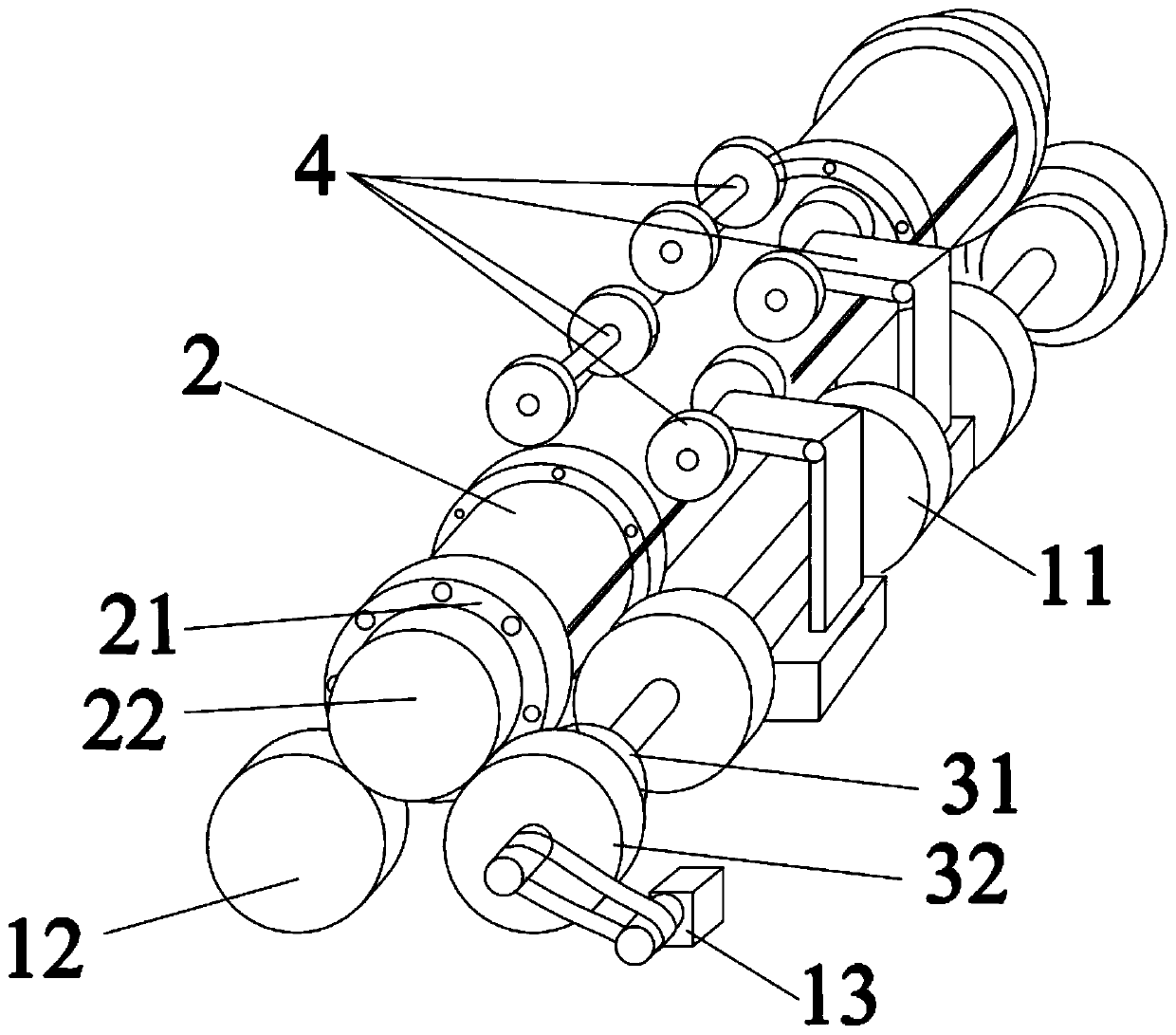

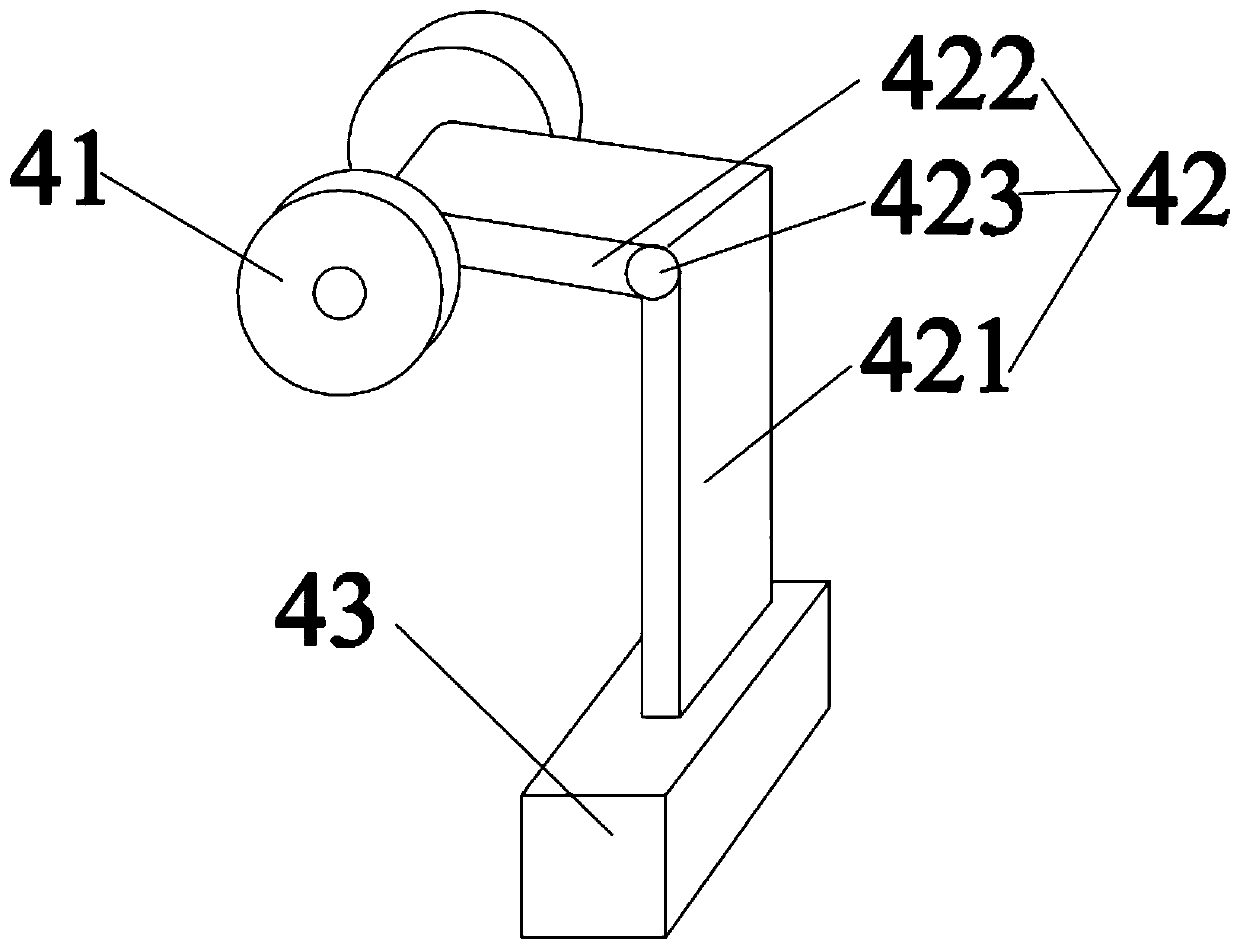

[0037] This embodiment provides a concrete centrifuge, such as Figure 1 to Figure 2 As shown, it includes a base frame and a driving mechanism and a shock absorbing mechanism 4 arranged on the base frame. Wherein, the driving mechanism has a driving unit 13 and a supporting unit, the driving unit 13 drives the supporting unit to rotate, and the supporting unit is rotatably supported on the rotating outer peripheral surface of the mold 2; Rotate the damping unit 41 on the outer peripheral surface, and the damping unit 41 applies a force to the mold 2 to limit its departure from the initial rotation position; the supporting unit and the damping mechanism 4 are along both sides of the outer surface of the mold 2; the damping mechanism 4 is set between any two supporting units. The force exerted by the damping mechanism 4 on the mold 2 partially offsets the force exerted by the supporting unit on the mold 2 . Such as figure 1 As shown, two groups of shock absorbing units 4 are...

Embodiment 2

[0046] This embodiment provides a concrete centrifuge, which differs from the concrete centrifuge provided in Embodiment 1 in that the structure of the driving mechanism is different:

[0047] In this embodiment 2, when the main body wheel 31 is not considered to cause the wheel body structure to burst due to the different pressure bearing capacity, the supporting unit of the driving mechanism may not be provided with the explosion-proof wheel 32, and the mold 2 can be adjusted by setting a plurality of main body wheels 31. load bearing.

Embodiment 3

[0049] This embodiment provides a concrete centrifuge, which differs from the concrete centrifuge provided in Embodiment 1 or Embodiment 2 in that multiple driving units 13 can be provided, and the active support of the supporting unit The number of wheels 11 and driven supporting wheels 12 changes:

[0050] For example, two driving units 13 are provided, and the two driving units 13 are respectively arranged at both ends of the mold 2 in the axial direction. 2. At both ends of the axial direction, multiple groups of driven supporting rollers 12 can be set on the left or right side of the bottom of the mold 2, as long as they avoid the driving supporting rollers 11. When the driving supporting rollers 11 drive the mold 2 to rotate, from The movable support roller 12 can rotate under the drive of the mold 2 to get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com