Patents

Literature

37results about How to "Play the role of heating and heat preservation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat accumulating type food heat-preservation device with metal porous structure

InactiveCN101773357ASpeed up meltingEfficient deliveryTable equipmentsWarming devicesHeating timeHeat losses

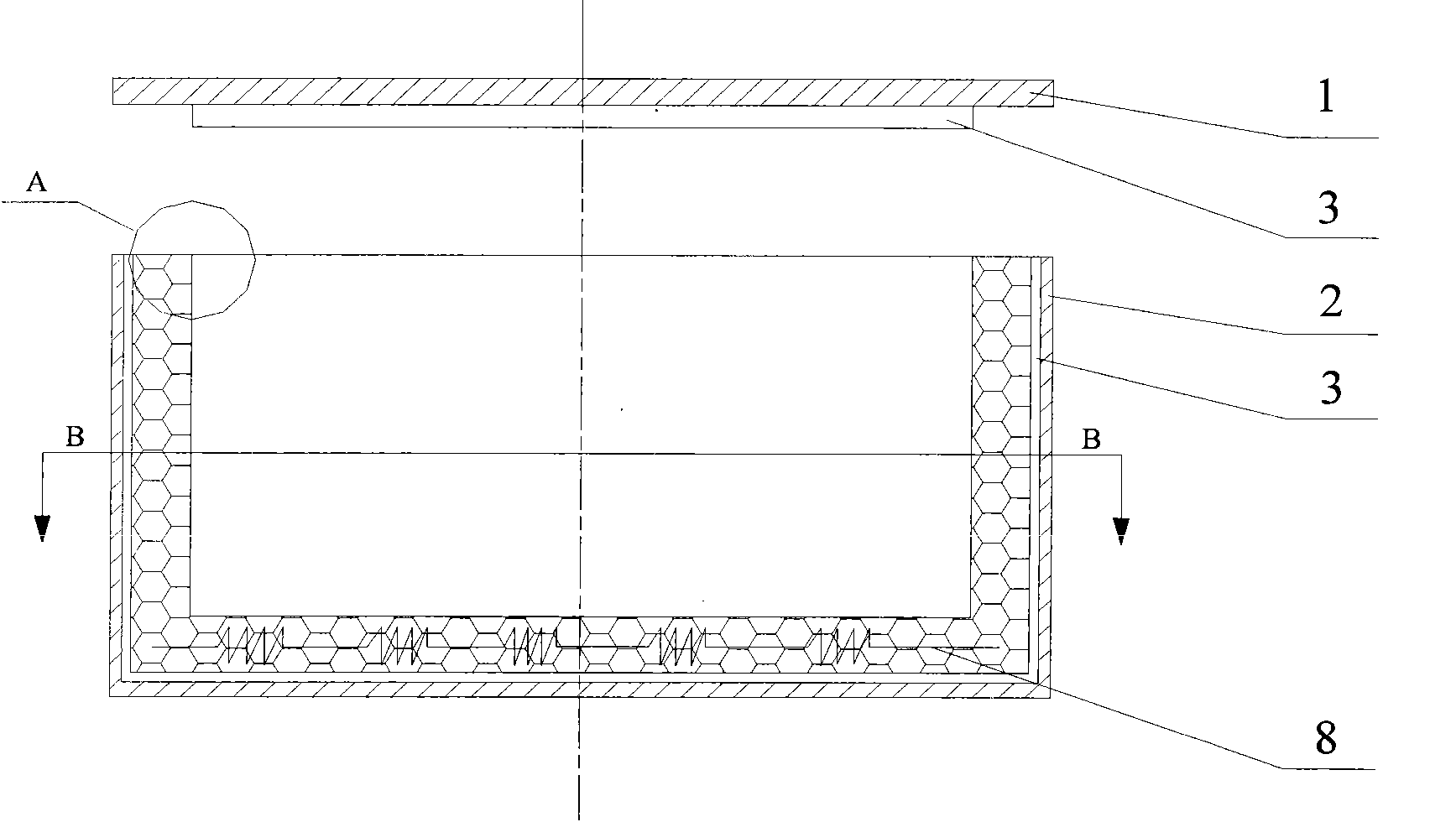

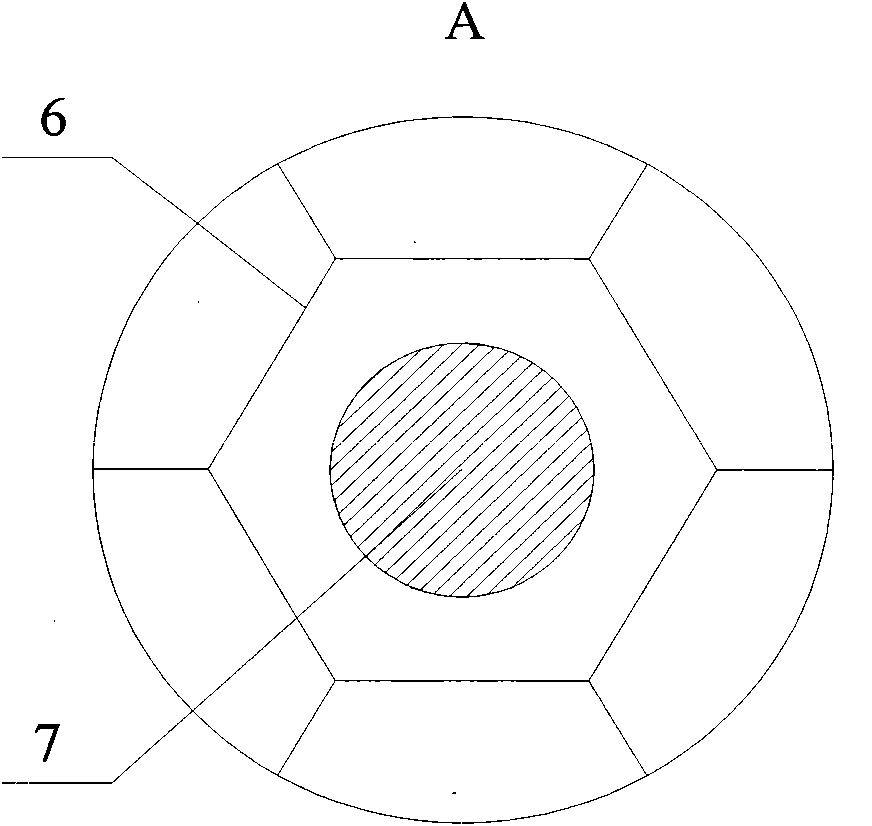

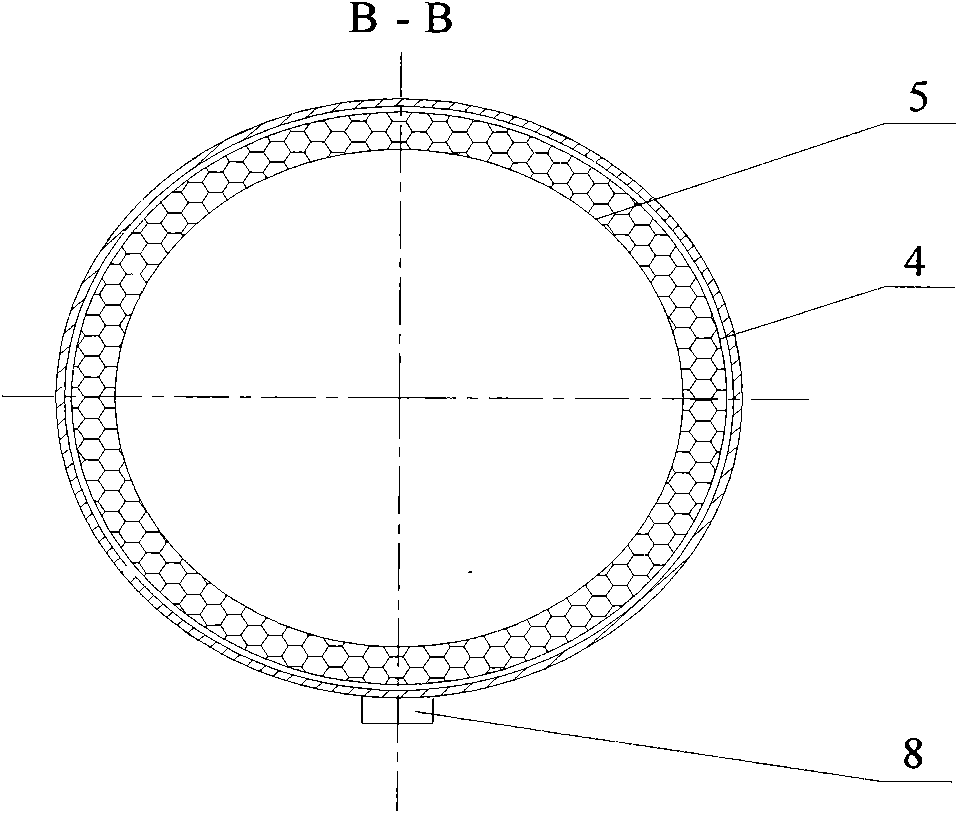

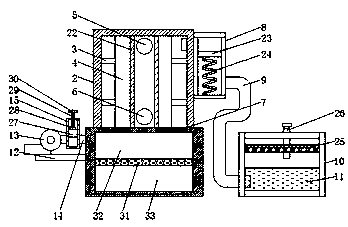

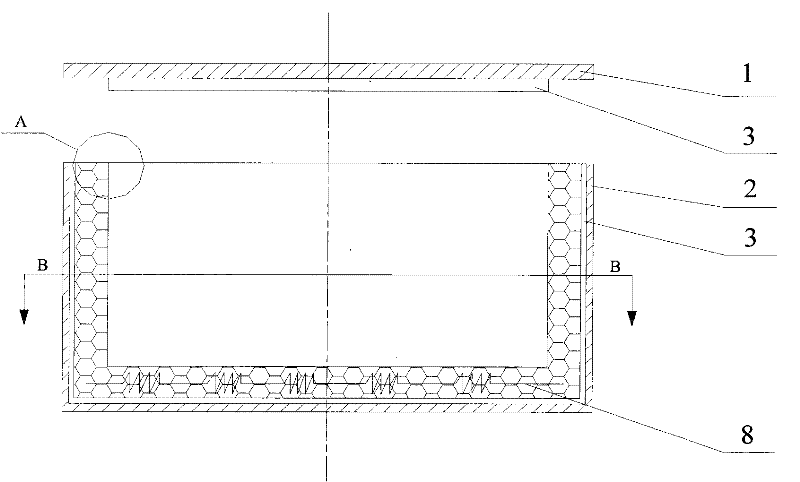

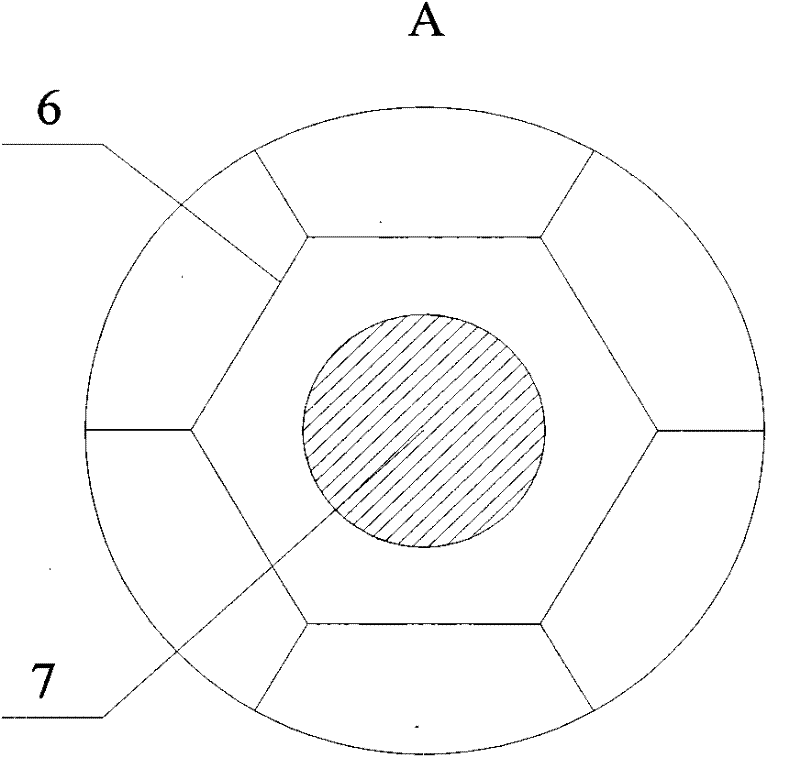

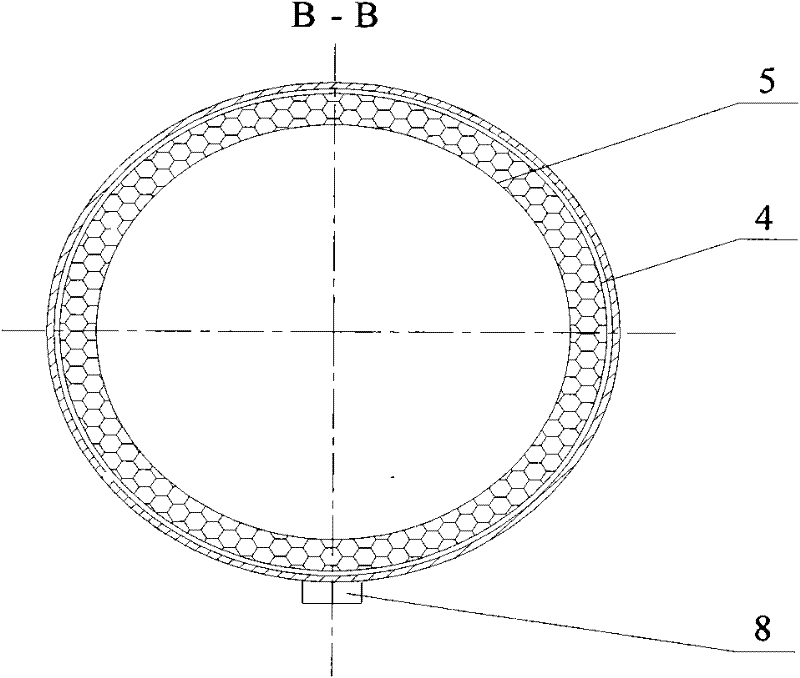

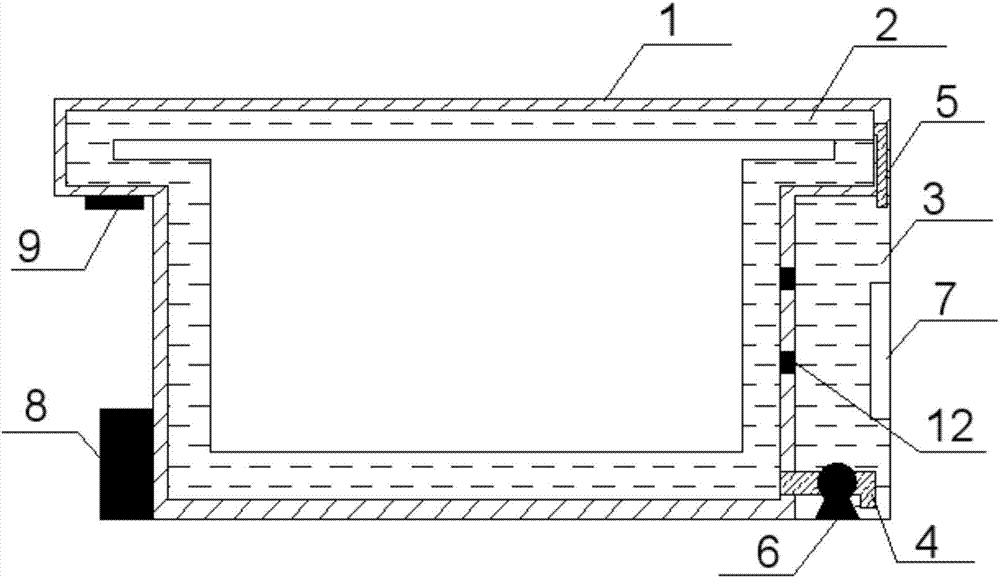

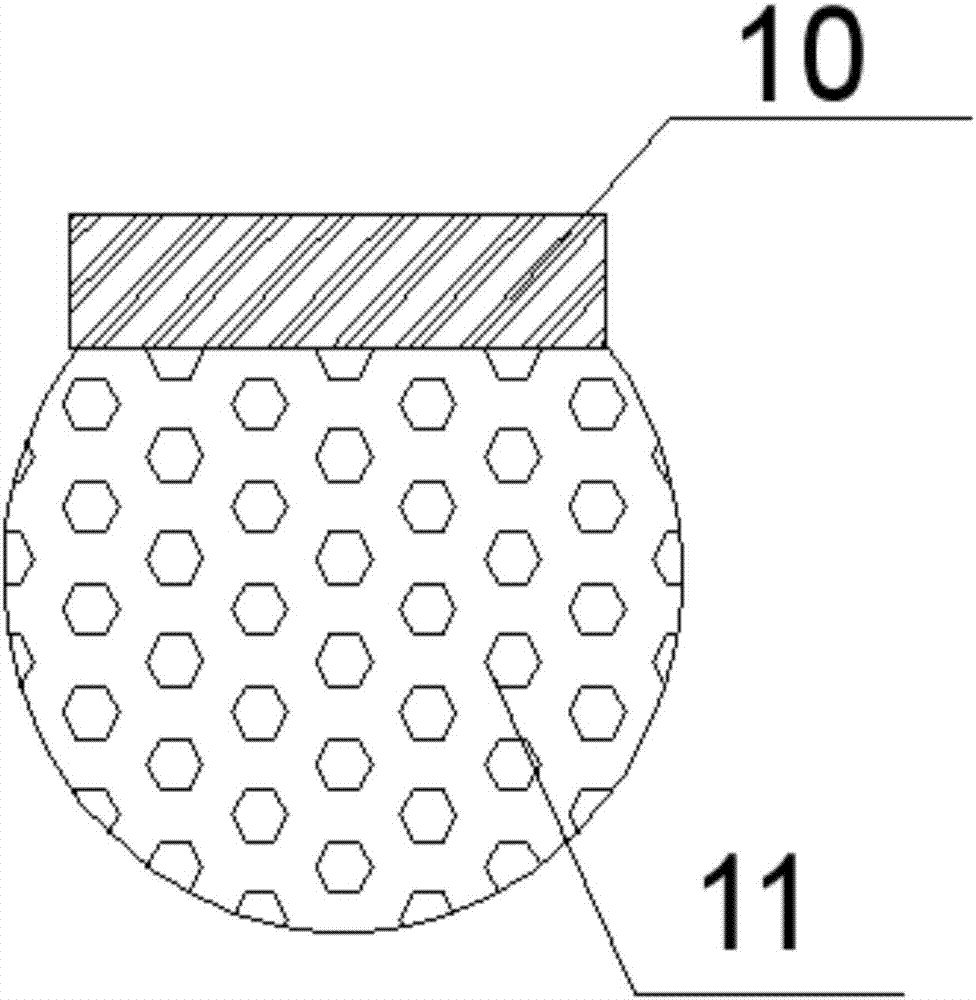

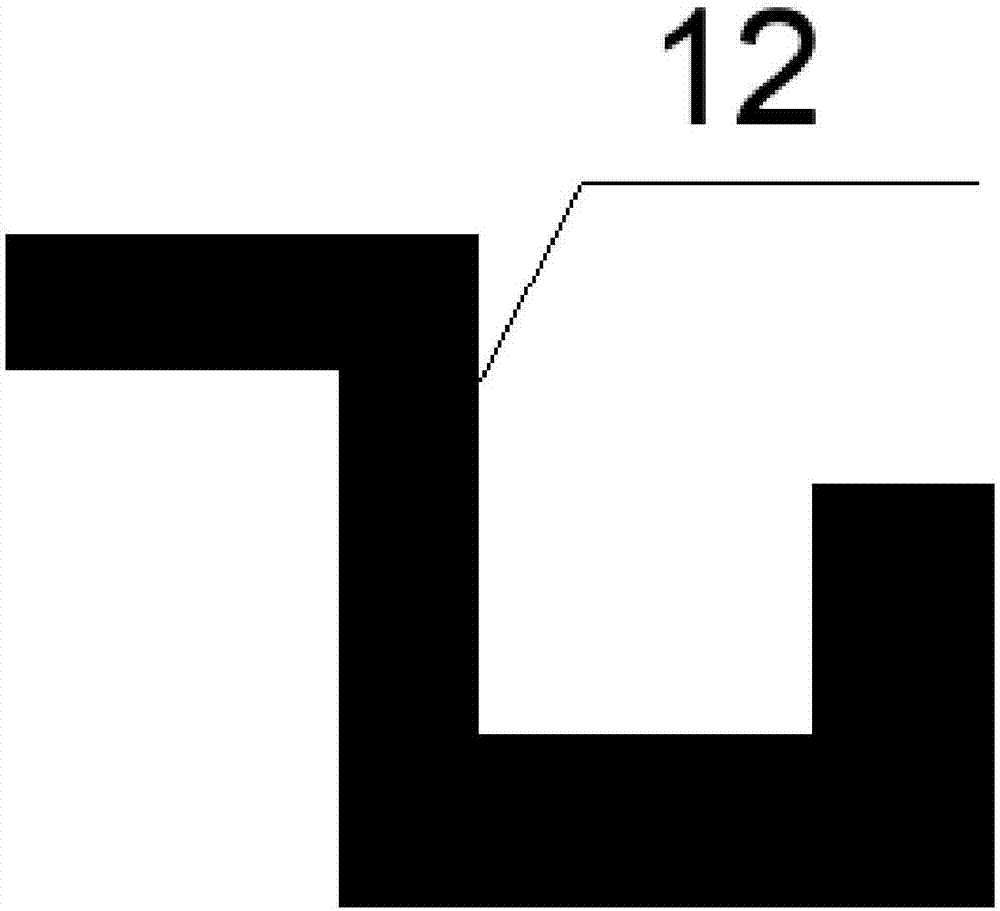

The invention relates to a heat accumulating type food heat-preservation device with a metal porous structure, comprising a top cover, a shell, a vacuum layer, an outer wall, an inner wall, through-hole metal foam, a phase-change material and an electric heating device. In the invention, a through-hole metal foam material is sintered between the inner wall and the outer wall according to an intensifying heat-exchange principle of a phase-change material inside the through-hole metal foam, and the phase-change material is packaged in a through-hole metal foam gap between the inner wall and the outer wall; when the heat accumulating type food heat-preservation device is electrified to be heated, the phase-change material is melted when heated and stores electric energy in a latent heat of fusion way, and the through-hole metal foam has high heat conductivity so as to intensify the melt of the phase-change material and shorten the heating time; the phase-change material is concreted and releases the stored latent heat, and the through-hole metal foam can more efficiently transfer heat to foods by utilizing the high heat conductivity and heat the foods to make up the heat loss of the foods. The heat accumulating type food heat-preservation device preserves the heat by adopting a latent heat heating principle, overcomes the defect of a passive heat insulation technology of the traditional heat-preservation devices and has long heat-preservation time and high efficiency.

Owner:XI AN JIAOTONG UNIV

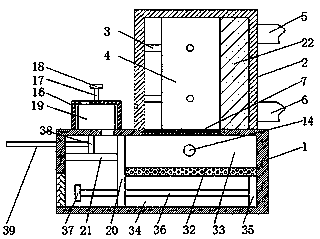

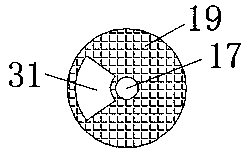

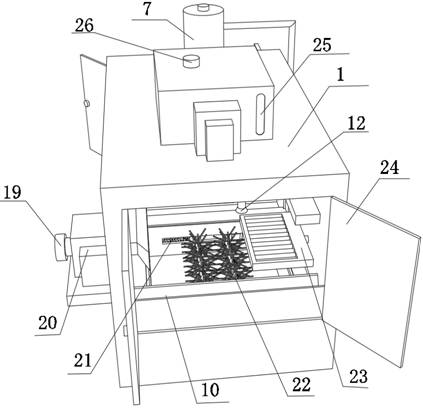

Energy-saving and environment-friendly combustion furnace

ActiveCN108548317AControl flowBurn fullyDamper arrangementSolid fuel combustionCombustion chamberEngineering

The invention relates to the field of boiler equipment, and discloses an energy-saving and environment-friendly combustion furnace. The energy-saving and environment-friendly combustion furnace comprises a bottom furnace, wherein a top furnace is fixedly arranged on the top of the bottom surface; six fixed rods are fixedly arranged on the inner wall of the top furnace; the six fixed rods are pairwise grouped and are symmetrically distributed on the inner walls of the two side surfaces and the back surface of the top furnace; and the end, far away from the top furnace, of each fixed rod is fixedly connected to the same boiler. The energy-saving and environment-friendly combustion furnace has the beneficial effects that a draught fan enables air to enter a combustion chamber so as to ensurethe sufficient combustion of coal, and meanwhile, a sealing plug is adjusted to move up and down by rotating a threaded rod, so that the flow rate of air is controlled, the content of air in the combustion chamber is controlled, the content of oxygen in the combustion chamber is appropriate, the coal is fully combusted, and the problem that as a common boiler cannot control the content of internalair, the coal combustion is insufficient, and the wasting of the coal is caused is solved.

Owner:南通高新工业炉有限公司

Sterilizing method for low temperature steam sterilized traditional Chinese medicine

The invention provides a sterilizing method for low temperature steam sterilized traditional Chinese medicine, and relates to the technical field of traditional Chinese medicine sterilizing methods. The sterilizing method comprises the following steps: placing traditional Chinese medicine into a sterilizing room; vacuuming the sterilizing room; introducing high-temperature and high-pressure steam into the sterilizing room; when the pressure in the sterilizing room reaches a sterilizing pressure, preheating for stabilizing; continually introducing high-temperature and high-pressure steam, so that the temperature in the sterilizing room rises to a sterilizing temperature; starting sterilization; entering a drying process after finishing the sterilization; drying and standing for 24 hours to wait for the growth of spores; sterilizing once again; repeating the waiting and sterilizing processes after finishing the sterilization; finishing the sterilization. The sterilizing method is convenient to run, energy consumption is lowered greatly, and the original efficacy, characteristic and uniformity of the traditional Chinese medicine are kept; meanwhile, a plurality of bacteria such as molds and escherichia coli in traditional Chinese medicinal powder are killed fully, and a large amount of energy and material resource cost is saved; the sterilizing method is a novel and environment-friendly sterilizing method being worthy of wide popularization.

Owner:LIANYUNGANG YOUYUAN MEDICAL EQUIP MFG

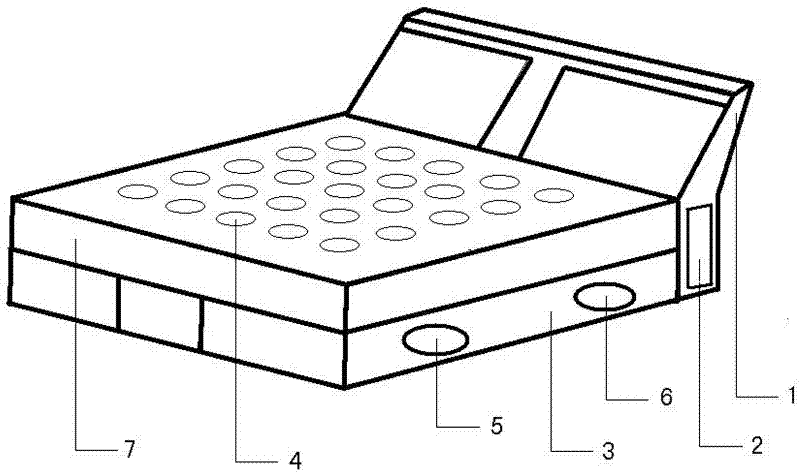

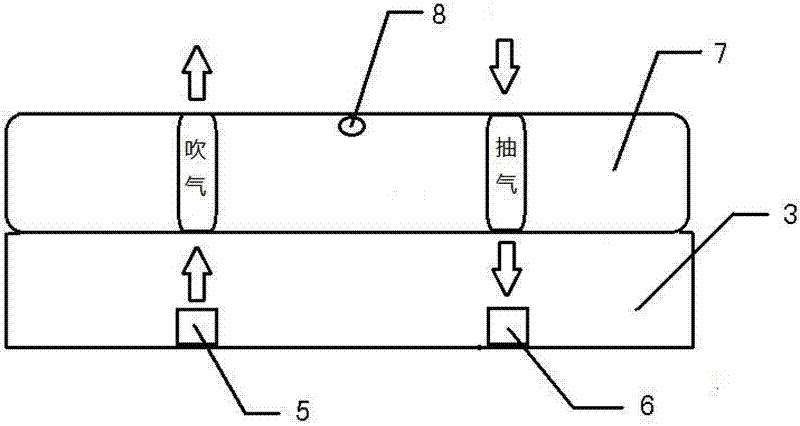

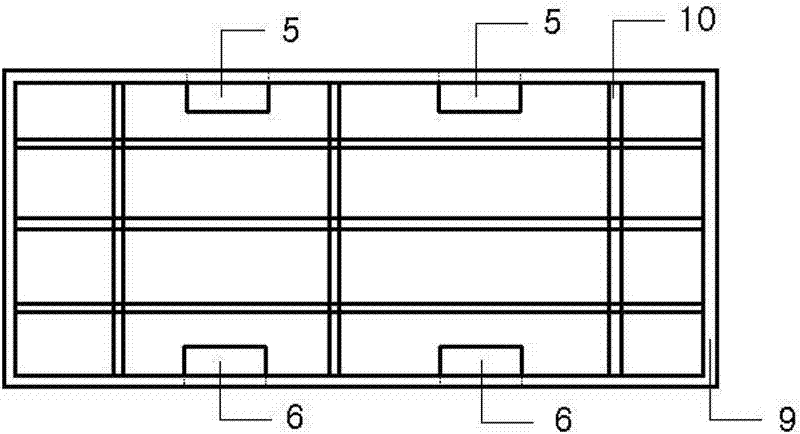

Health care bed

The invention relates to a health care bed. The health care bed comprises a power supply, a mattress (7), a detection circuit, an air exchange chamber (3), a control panel (2) and a control circuit. The mattress (7) is provided with air exchange holes (4). The detection circuit is embedded in an upper surface of the mattress (7). The mattress (7) is covered on an upper surface of the air exchange chamber (3). The control panel (2), the control circuit and the air exchange chamber (3) are connected orderly. The detection circuit is connected to the control circuit. The power supply is connected to the control circuit, the detection circuit and the air exchange chamber (3). The health care bed utilizes the detection circuit to induct a temperature and humidity around a human body, and utilizes the control circuit to control an air-heater and a negative pressure blower fan to carry out automatic adjustment on a temperature of the surface of the health care bed so that a temperature around a human body is maintained in a range of 25 to 35 DEG C and humidity around the human body is maintained in a range of 50 to 60%. The health care bed is rich in high-technology performances, has health care effects on a human body, is comfortable and environmentally friendly, and is beneficial for human health.

Owner:BEIJING UNION UNIVERSITY

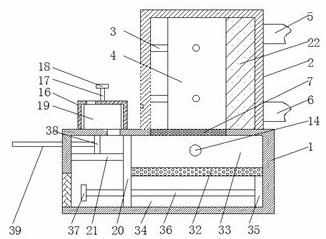

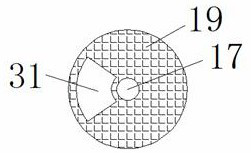

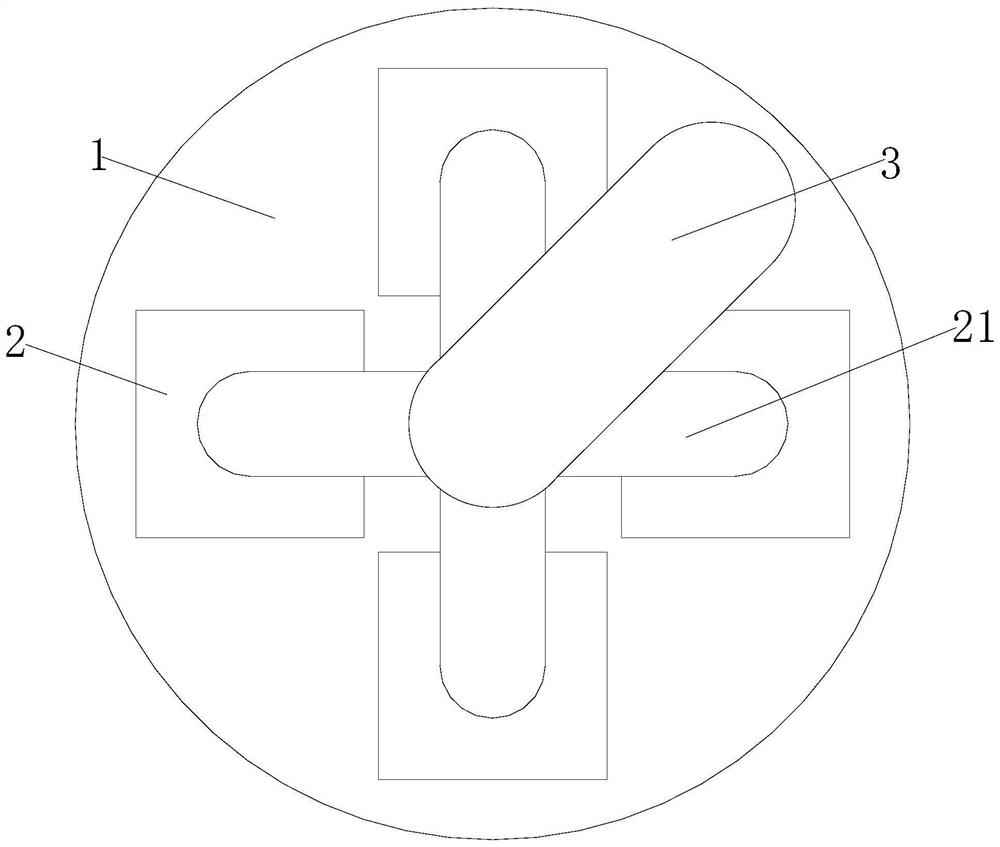

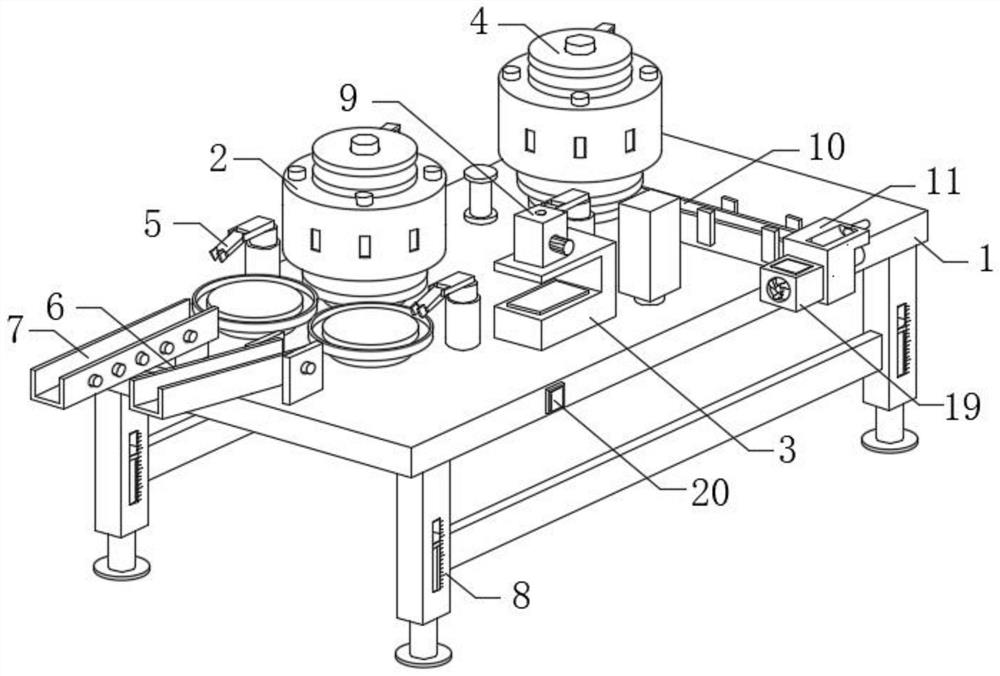

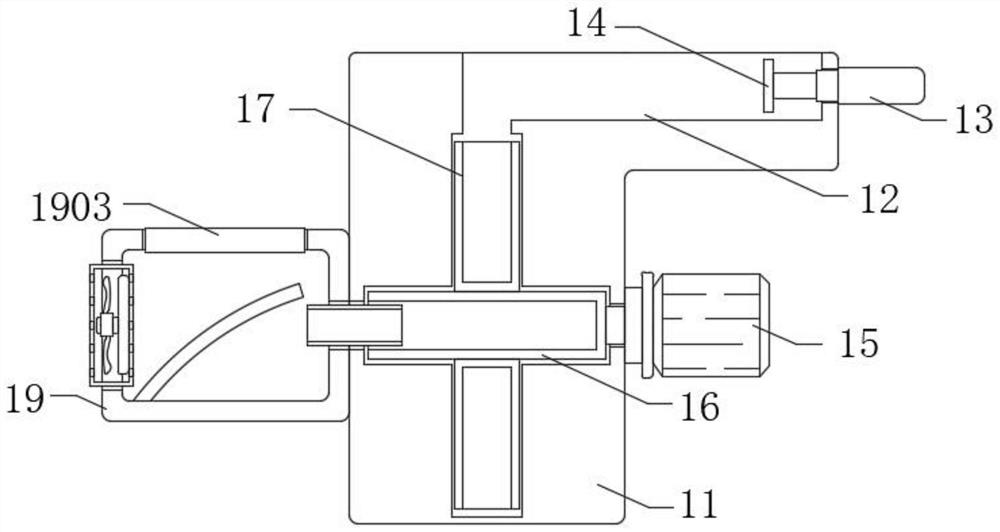

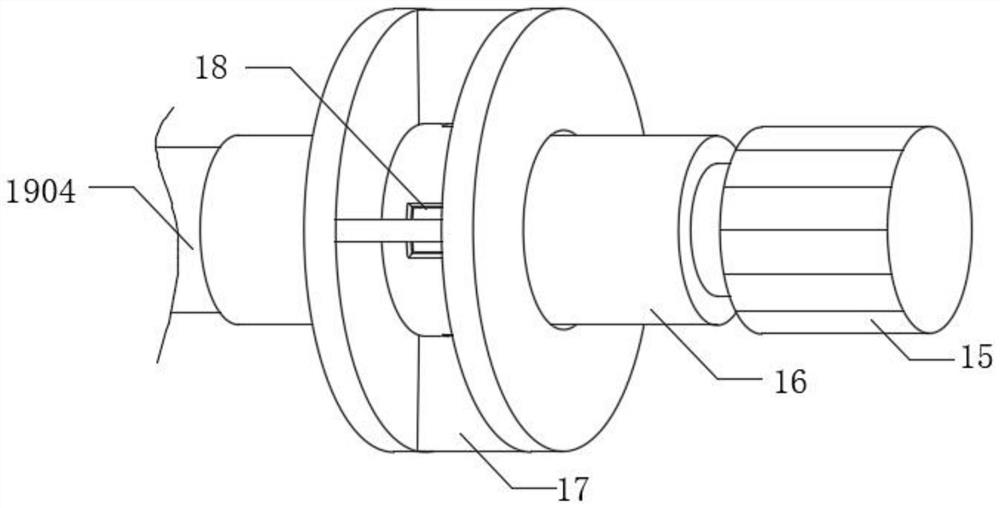

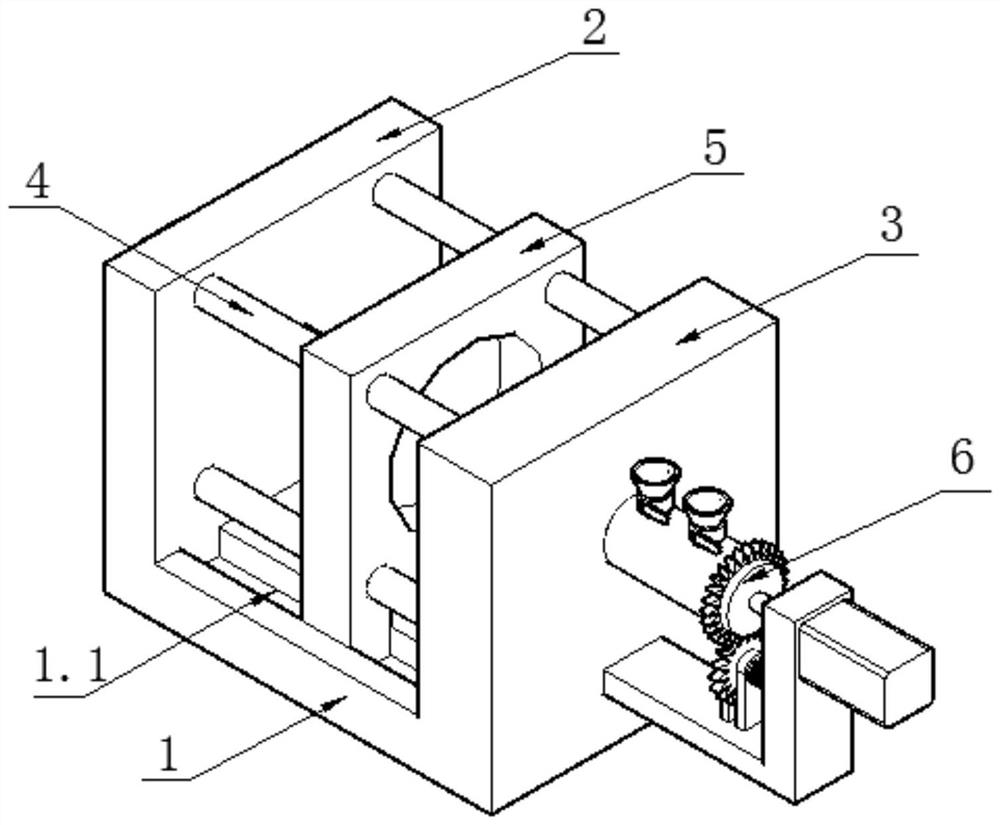

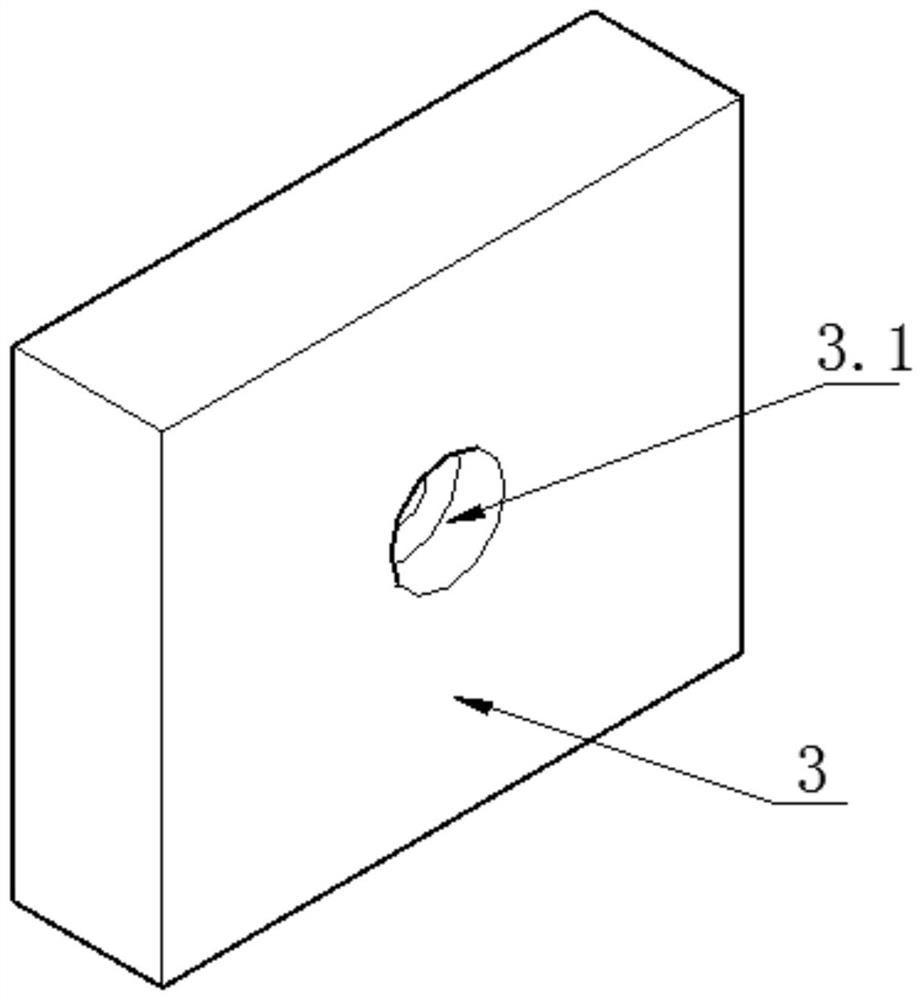

Paint plating device and paint plating method for valve machining

ActiveCN112371428AAccelerate solidificationQuality assurancePretreated surfacesCoatingsHydraulic cylinderGear wheel

The invention discloses a paint plating device and a paint plating method for valve machining, relates to the technical field of valve machining, and aims at solving the problem that paint is easily accumulated at a contact point. The device comprises a machine body; a first electric sliding groove is formed in the inner wall of the top of the machine body; a hydraulic cylinder is arranged on theinner wall of the first electric sliding groove; the extending end of the hydraulic cylinder is rotatably connected with a connecting base through a connecting column; a third motor is arranged on theinner wall of the bottom of the connecting base; and three gears are arranged on the inner wall of one side of the connecting base. The paint plating method for the device comprises the following steps that the paint is added to a first material box; a valve is placed in a net box; and a cleaning spraying member and a second motor are started to drive the net box to complete cleaning and spin-drying in the rotating process. In the air blowing process, the valve rotates continuously at the same time to accelerate solidification of the valve after feeding; and no acting point exists in the solidification period of the feeding position of the valve, and therefore the situation of paint accumulation is avoided, and the quality and efficiency of paint plating are guaranteed.

Owner:林仙夫

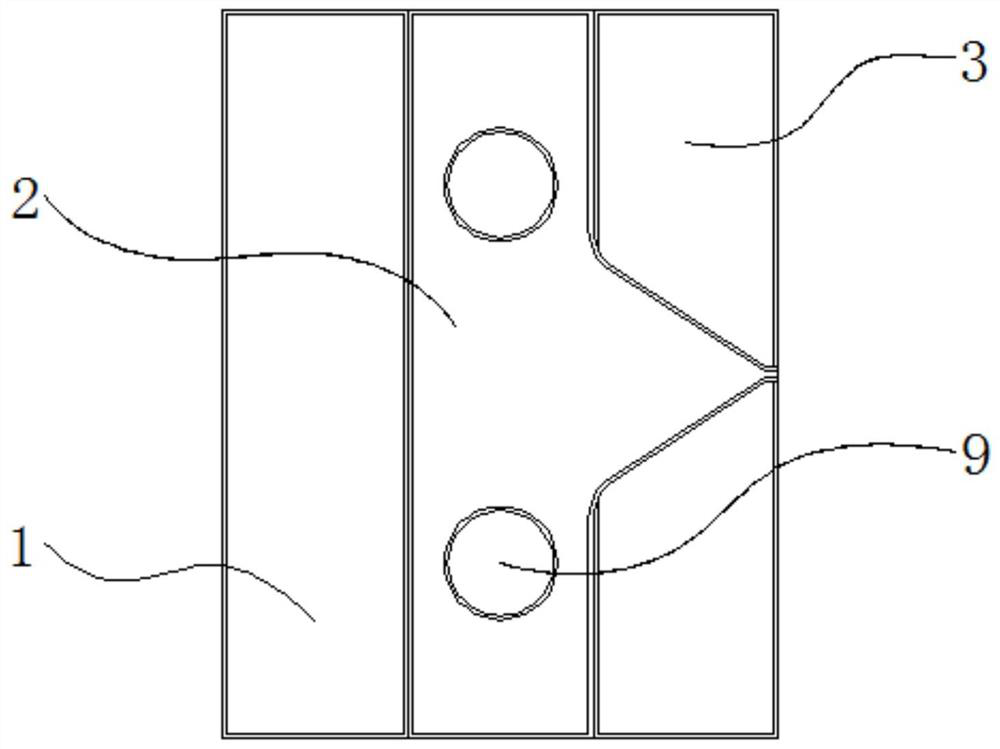

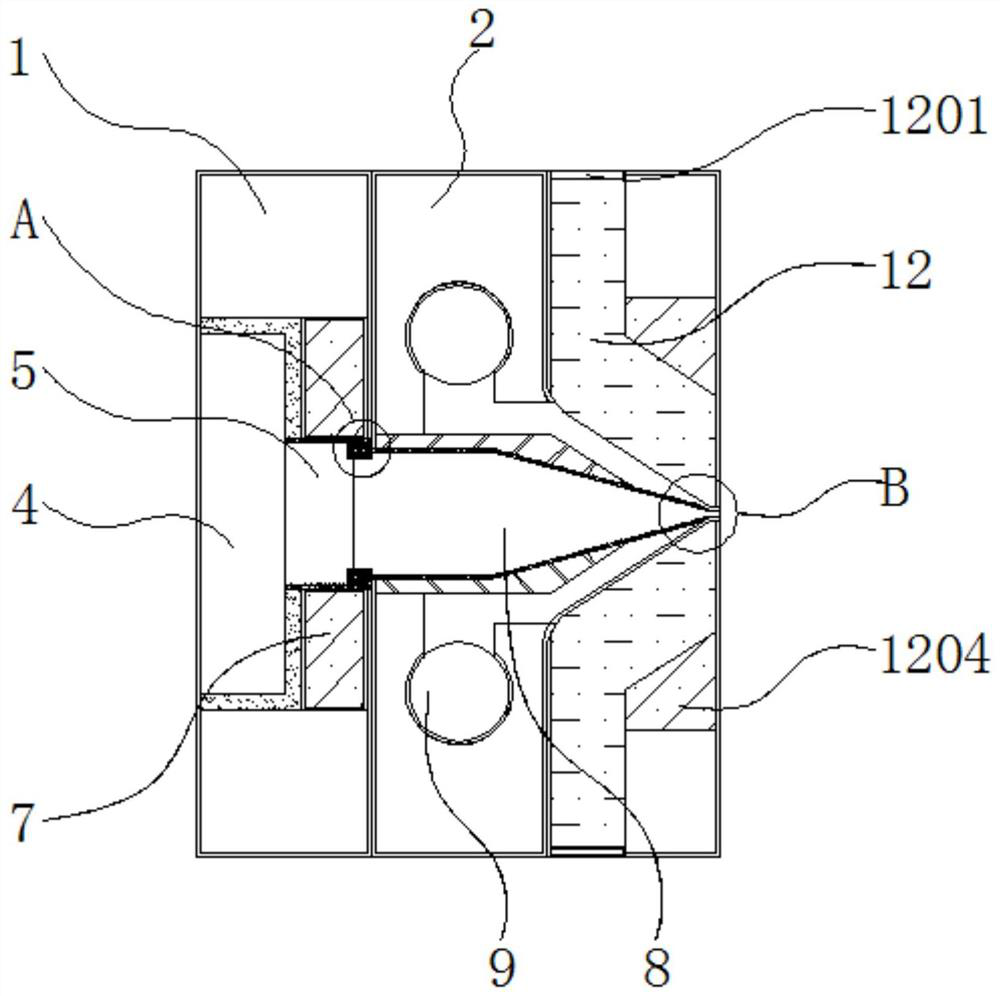

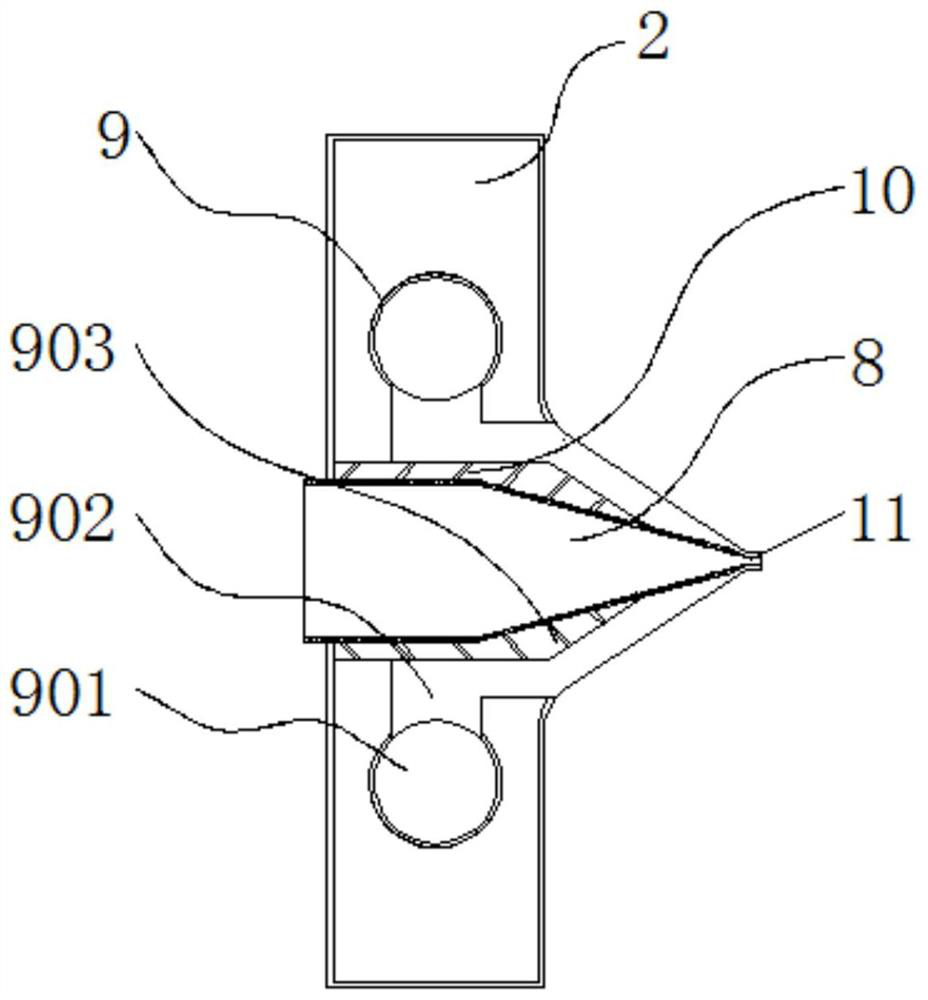

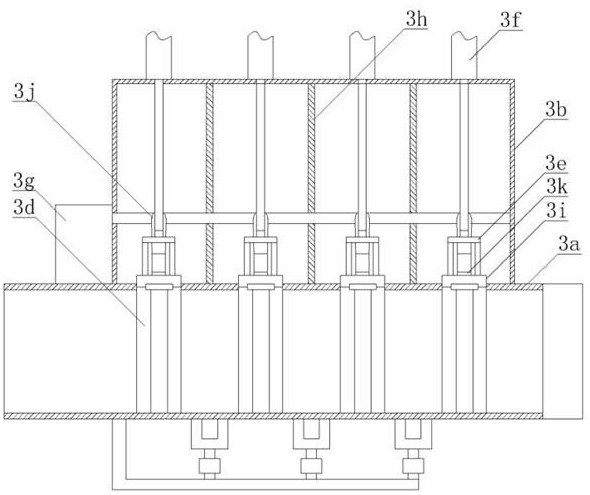

Melt-blown nozzle for melt-blown fabric production device

PendingCN111636151AMelt blown realizationEasy to replaceSpinnerette packsMelt spinning methodsThermodynamicsPolymer melt

The invention discloses a melt-blown nozzle for a melt-blown fabric production device, and relates to the technical field of melt-blown fabric production. The melt-blown nozzle comprises a first nozzle piece, a flow guide pipe and a heating mechanism, wherein a second nozzle piece is arranged above the first nozzle piece, a third nozzle piece is arranged above the second nozzle piece, a material groove is formed in the first nozzle piece, a discharging port is formed in one side, close to the second nozzle piece, of the material groove, a sealing gasket is fixed on the inner side of the discharging port, a first heating block is fixed on the outer side of the discharging port, the flow guide pipe is fixed inside the second nozzle piece, an air flow distribution mechanism is arranged outside the flow guide pipe, a heat preservation layer is fixed on the outer wall of the flow guide pipe, and a nozzle is formed in one side, close to the third nozzle piece, of the flow guide pipe. The melt-blown nozzle has the beneficial effects that the heat preservation layer is arranged on the outer wall of the flow guide pipe, so that the heat preservation of the flow guide pipe is facilitated, the heat loss at the flow guide pipe is reduced, and the solidification of polymer melt is prevented.

Owner:江苏润亿通用装备有限公司

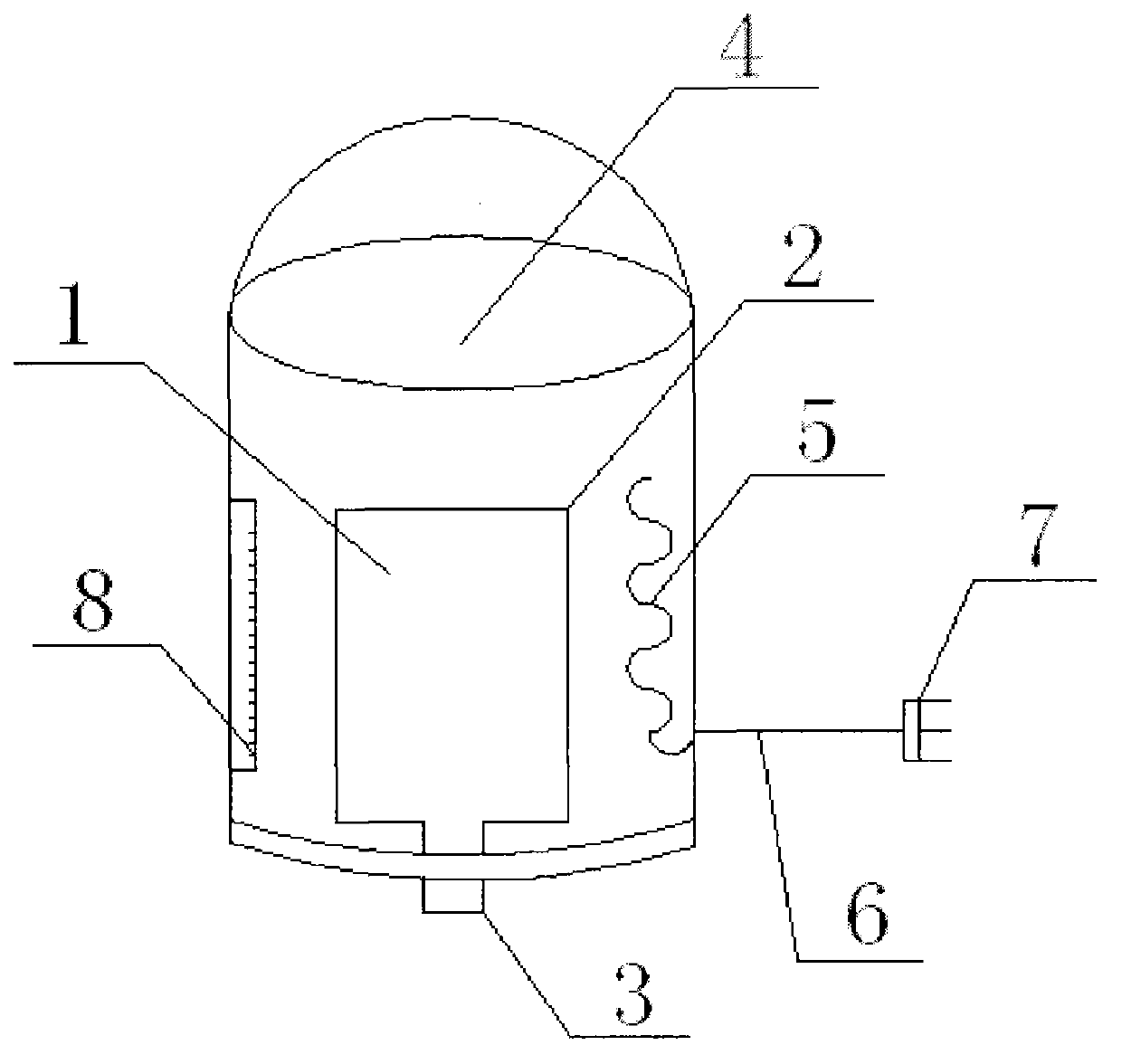

Vertical efficient fermentation equipment for organic fertilizer

InactiveCN108911813AImprove product qualityImprove filtration efficiencyOrganic fertiliser preparationEngineeringOrganic fertilizer

The invention discloses vertical efficient fermentation equipment for an organic fertilizer. The equipment comprises a fermentation tank, a motor and heating wires; a first partition board and a second partition board are welded inside the fermentation tank; the first partition board is located above the second partition board; the first separation plate and the second separation plate divide theinterior of the fermentation tank into a temperature change chamber, a homogenization chamber and a temperature preservation chamber from top to bottom; and a first partition valve and a second partition valve are respectively arranged at the middle positions of the first partition board and the second partition board. The equipment provided by the invention is provided with the temperature preservation chamber, the temperature change chamber, the second partition valve, the first partition valve and the homogenization chamber. When fermentation operation is carried out, materials enter a heating stage and a high-temperature stage in the temperature change chamber; the first partition valve is started after the materials reach a high temperature stage; the obtained compost is introduced into the homogenization chamber; turning and secondary heating are carried out in the homogenization chamber; the compost enters a cooling stage; and finally, the second separation valve is started, sothat the compost enters the heat preservation chamber, and enters a heat-preservation stage.

Owner:重庆市黔江区丰采多有机肥有限公司

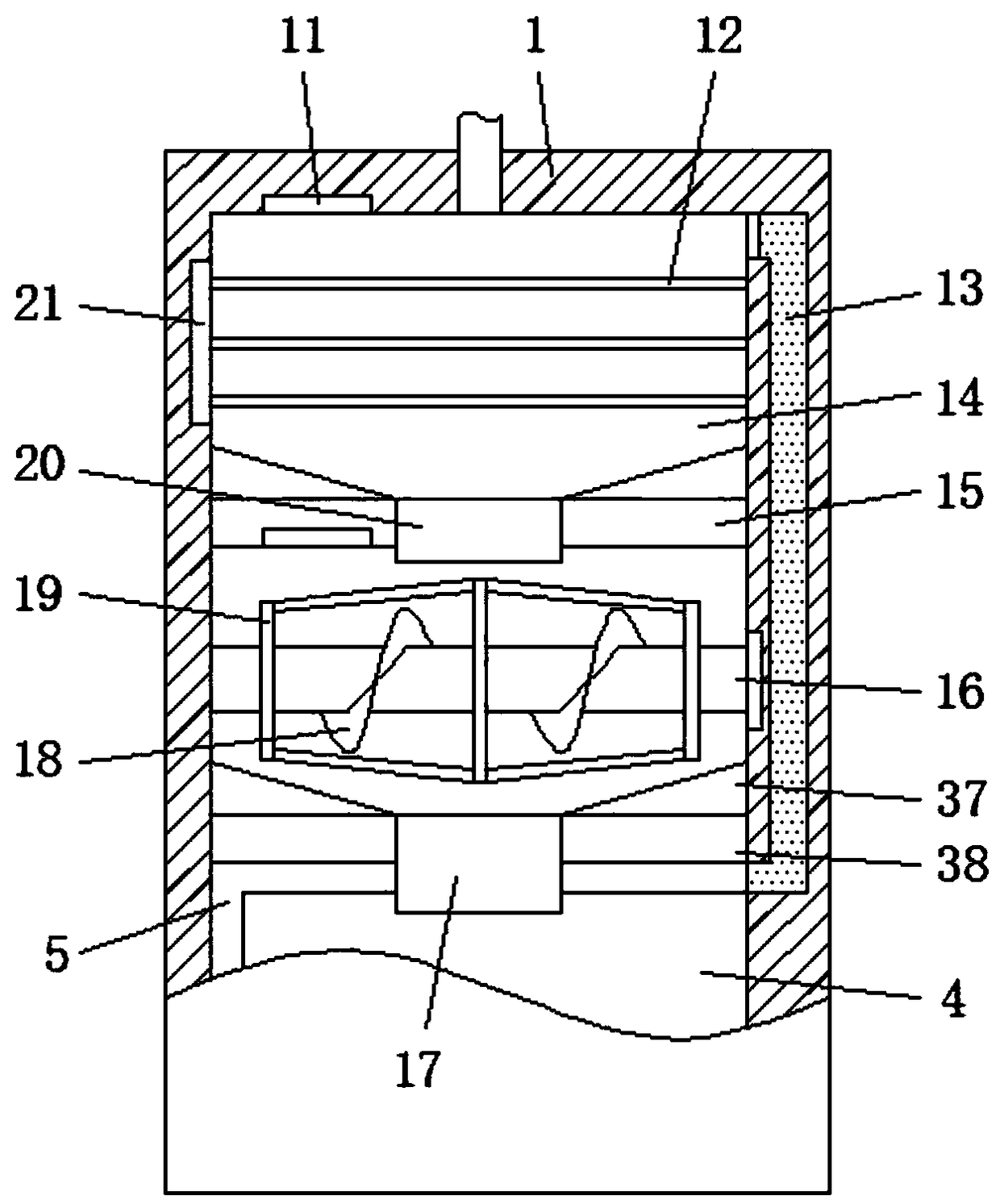

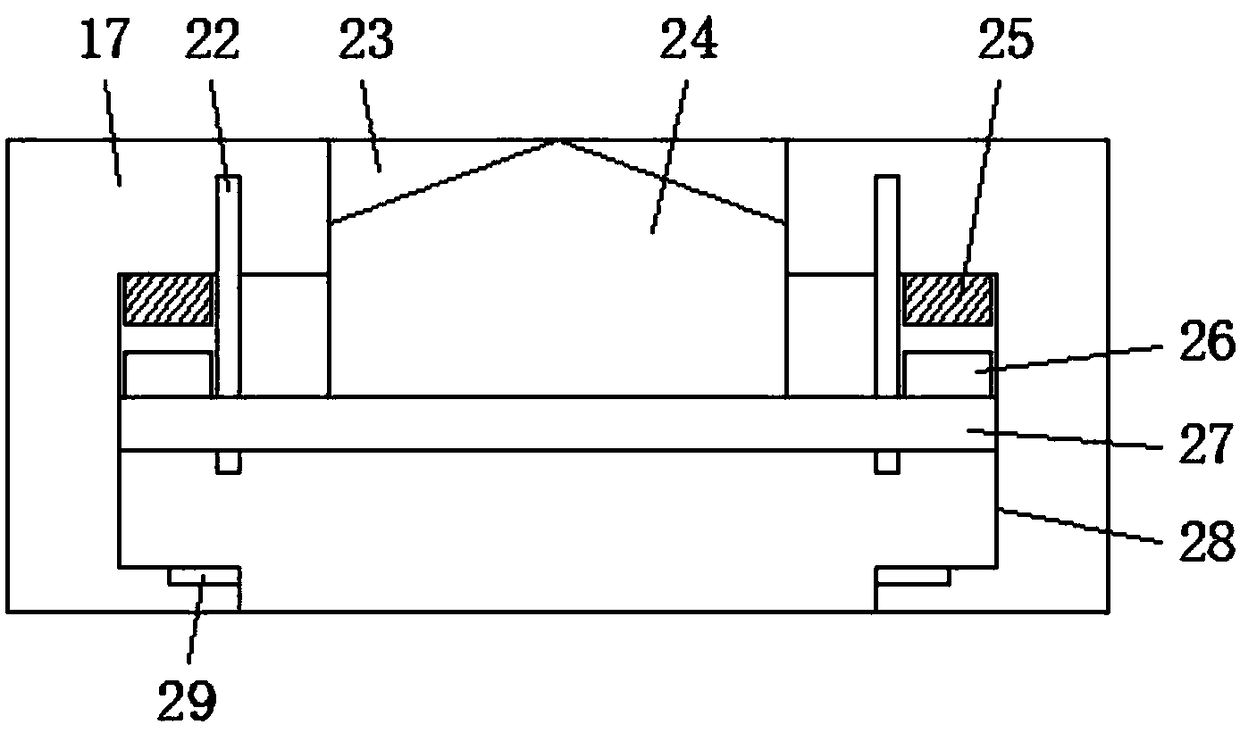

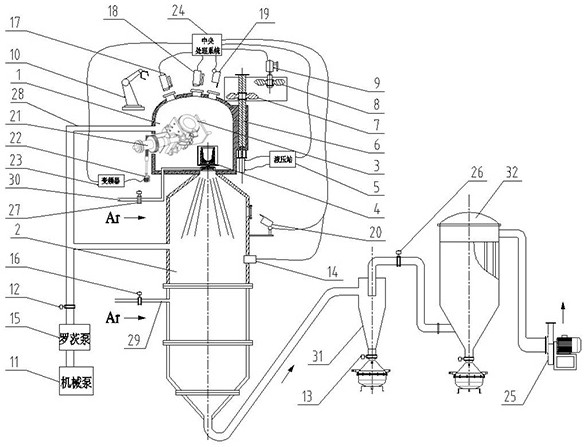

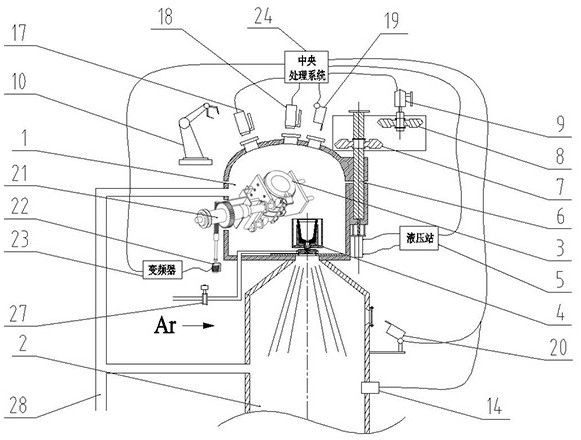

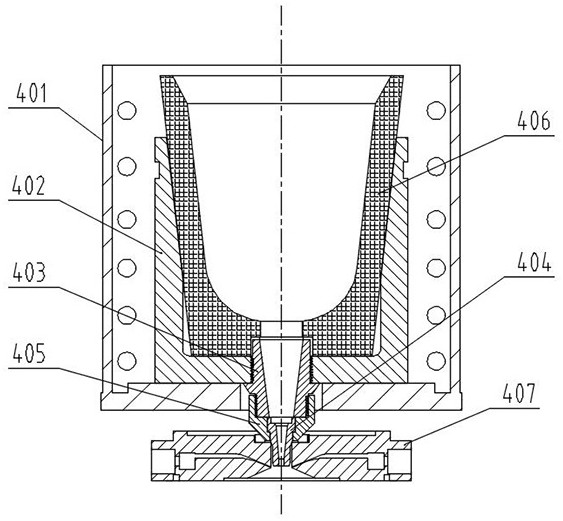

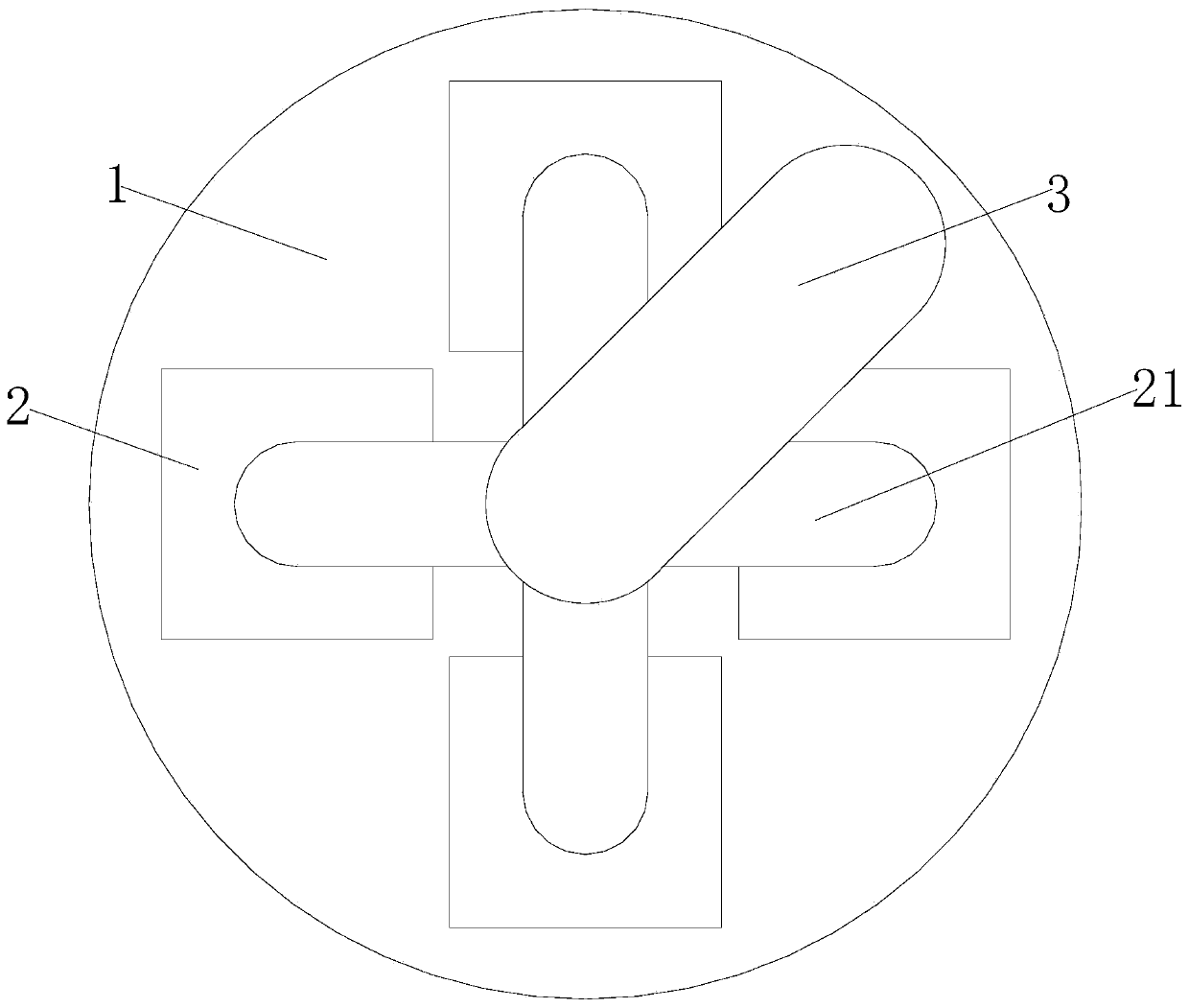

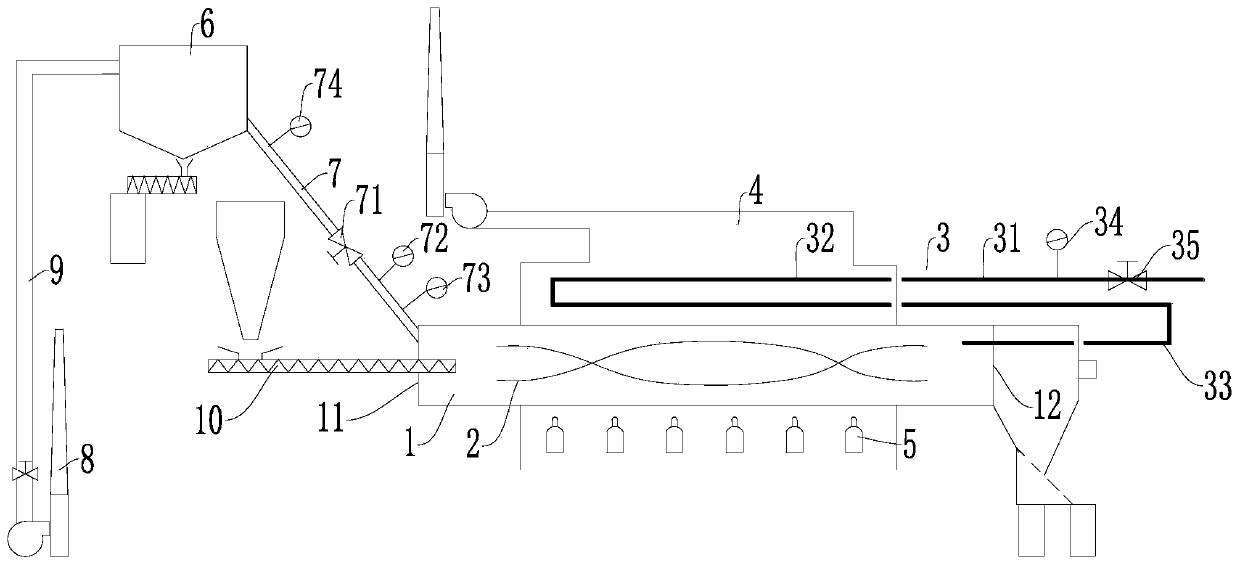

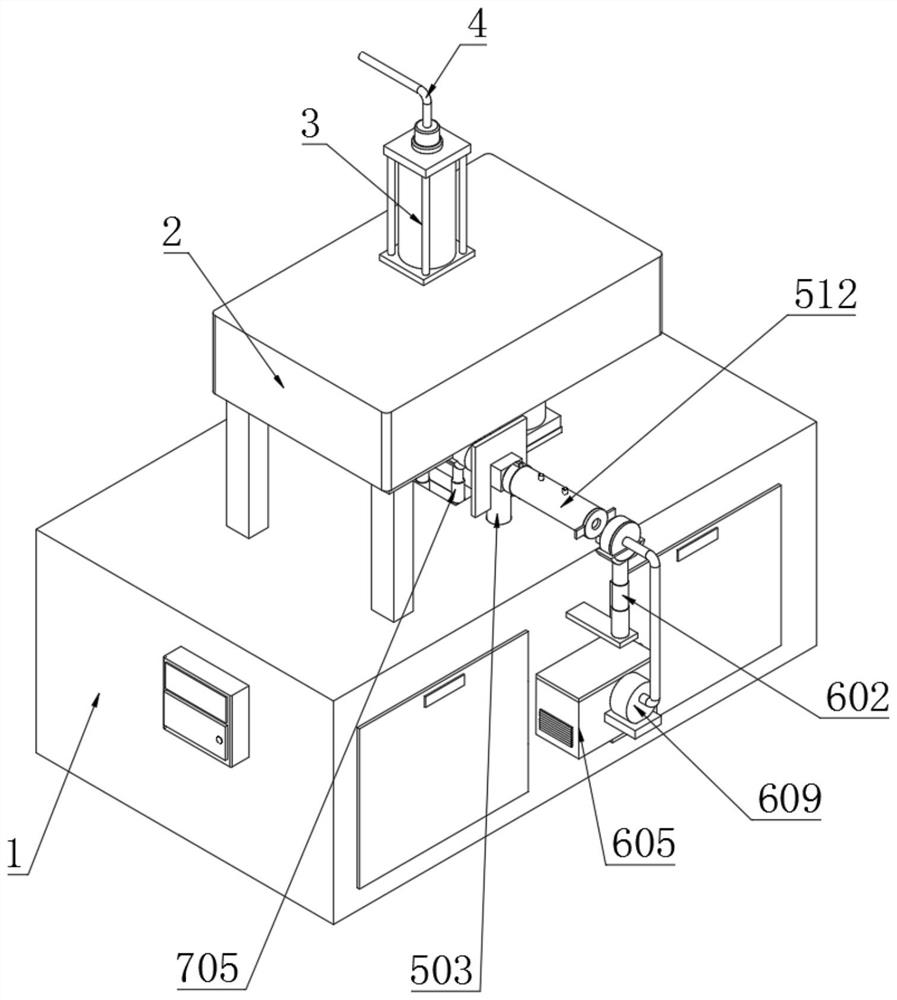

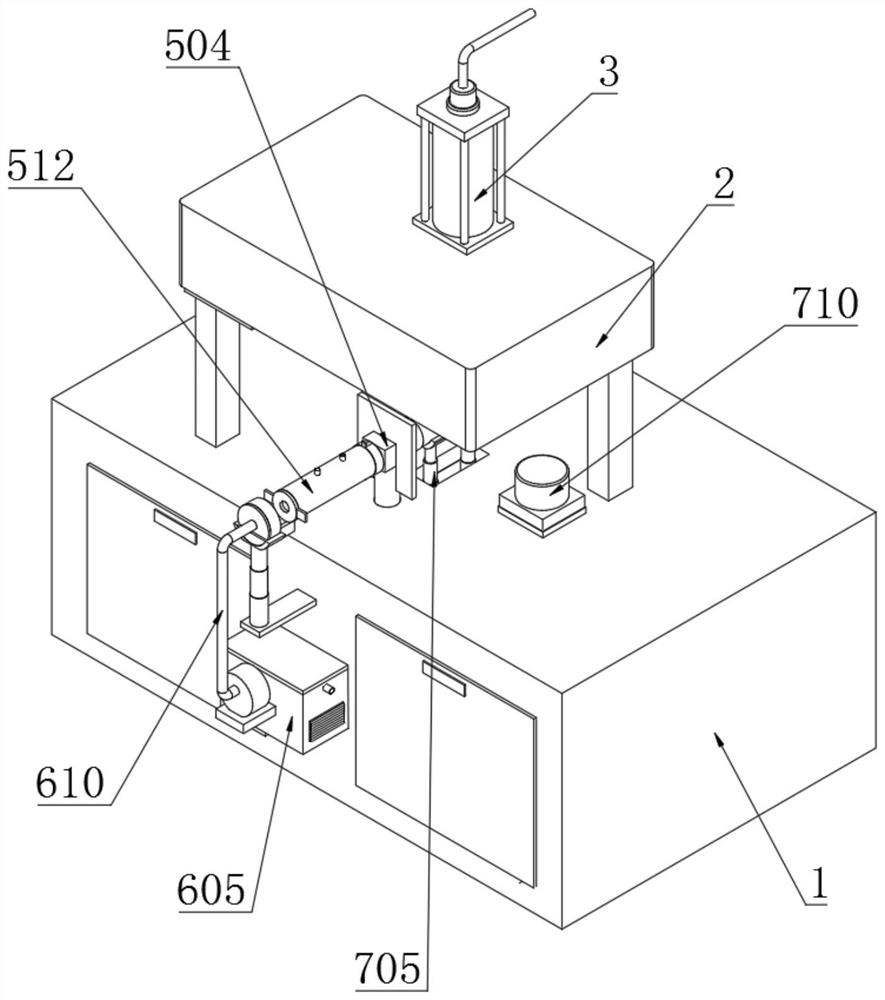

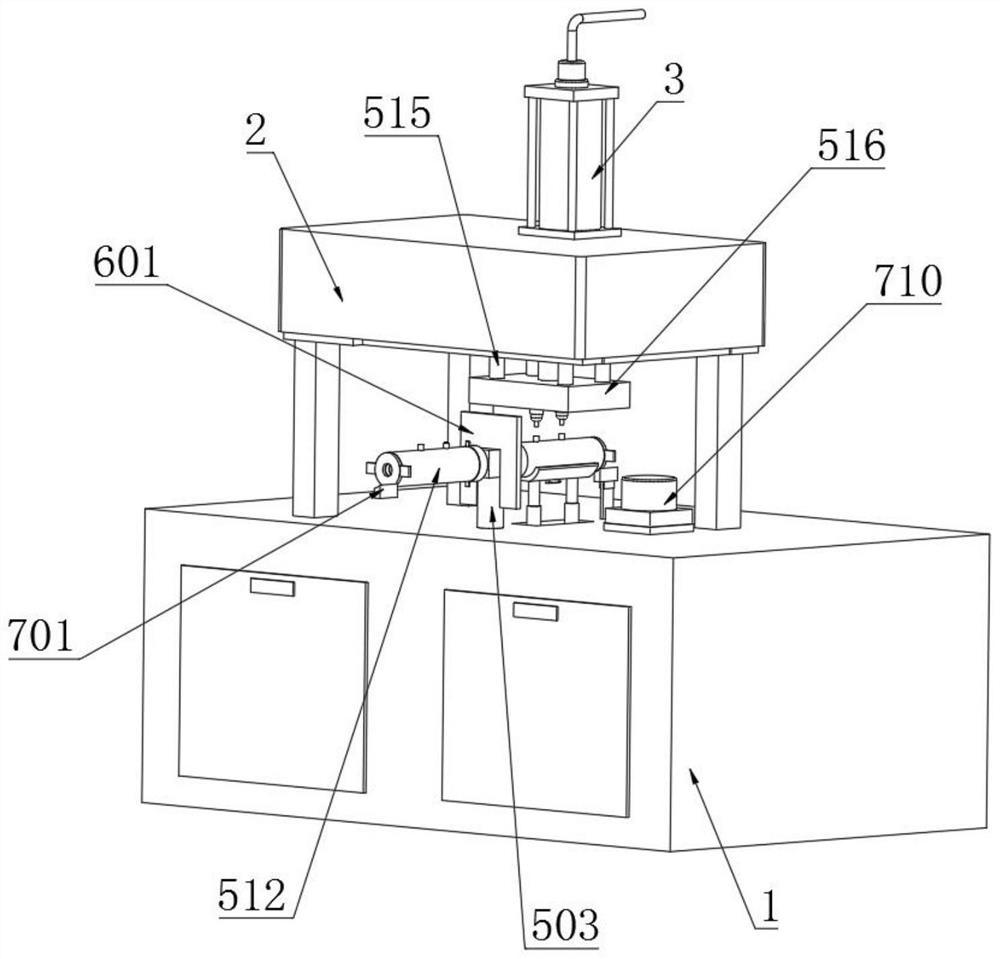

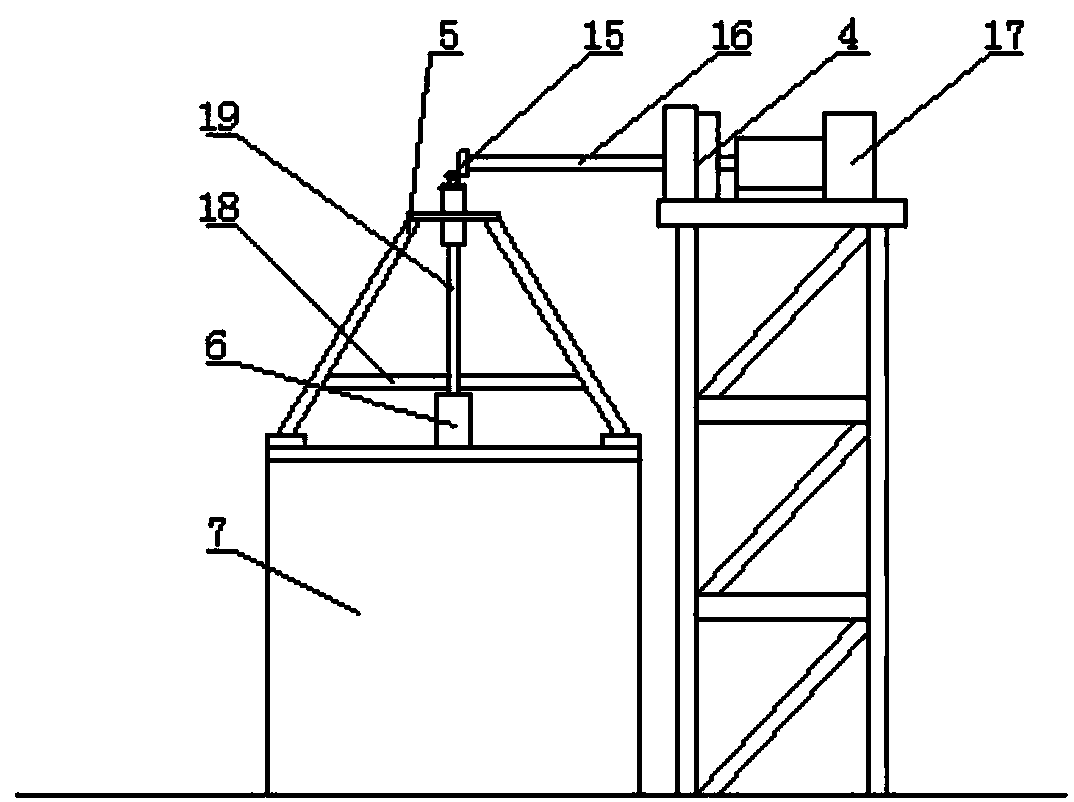

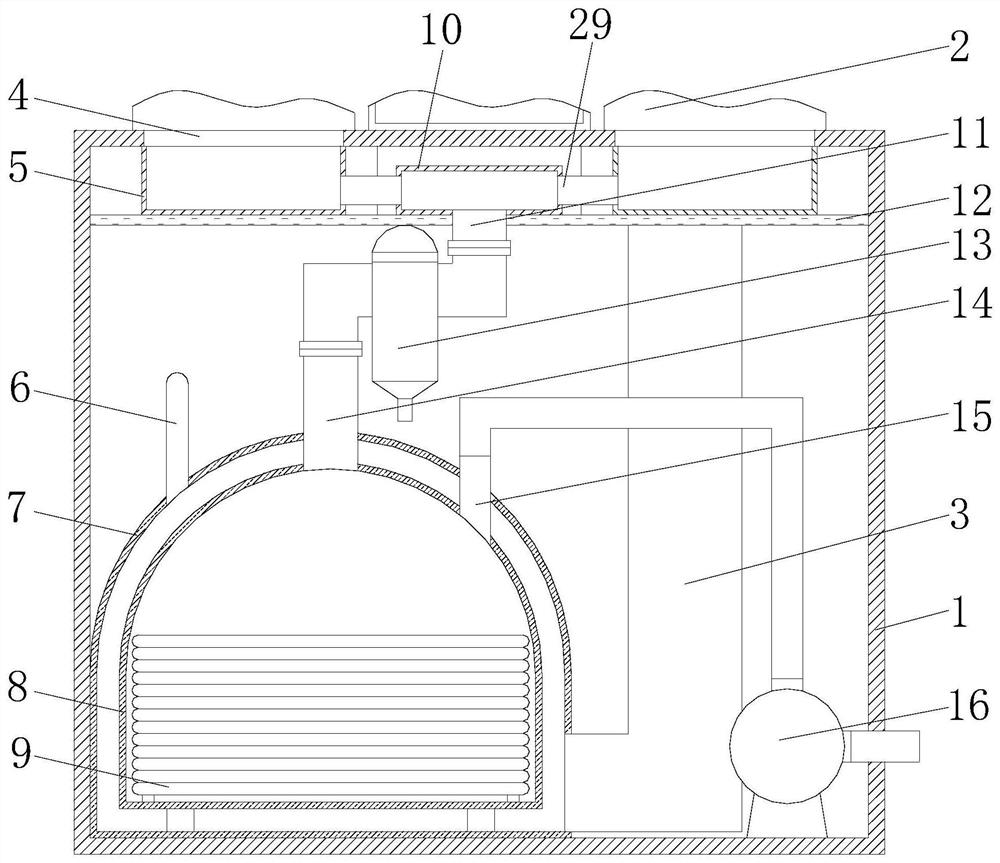

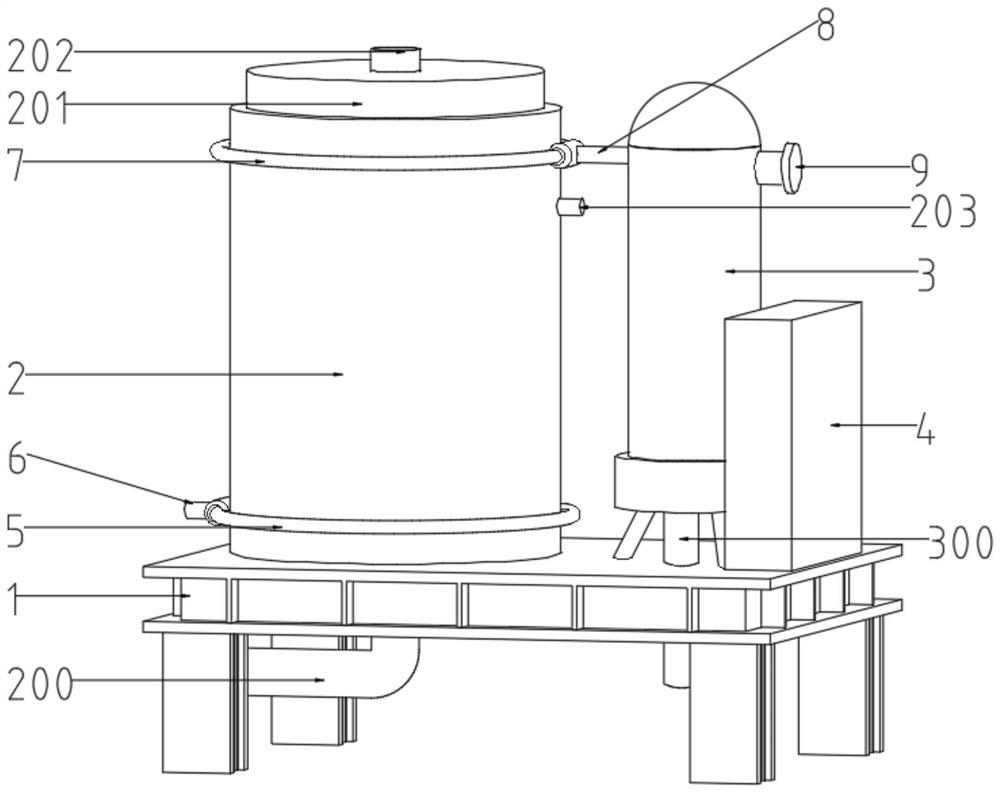

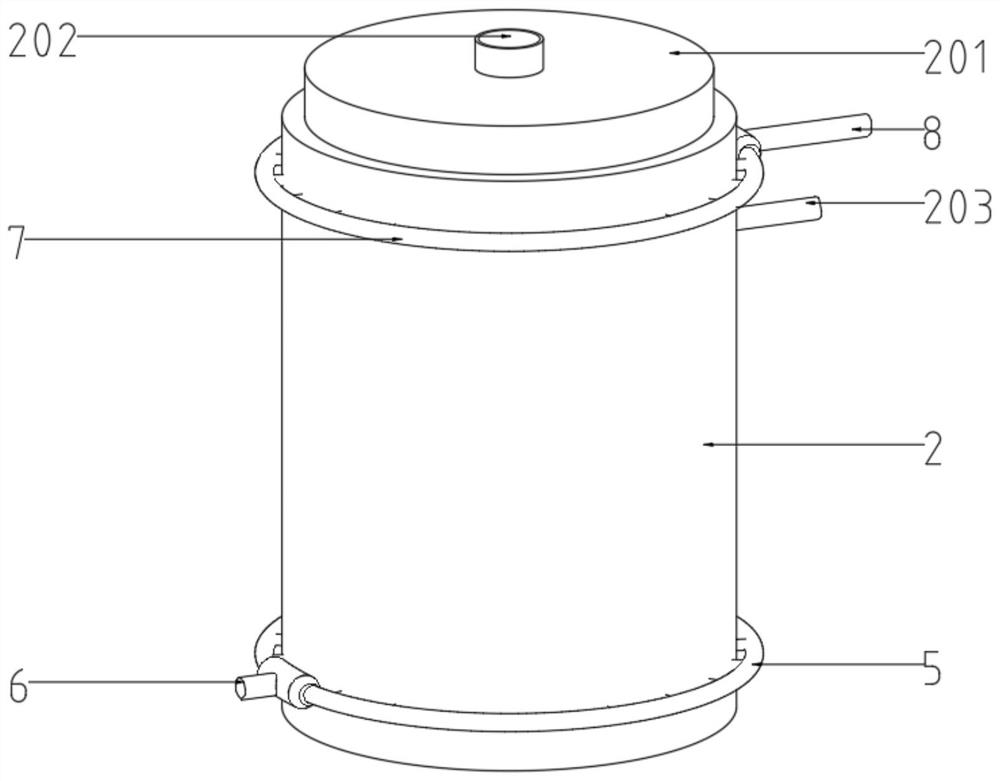

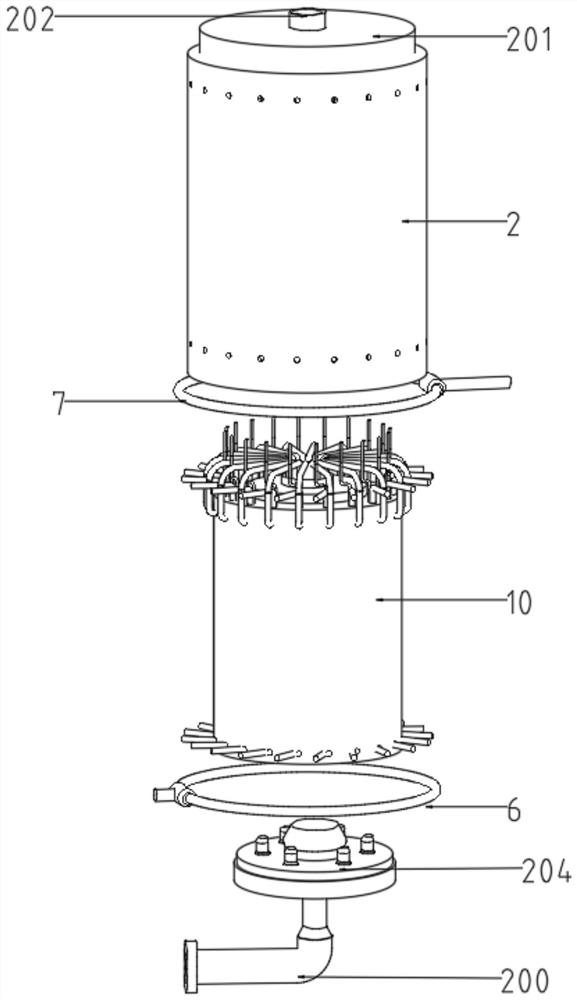

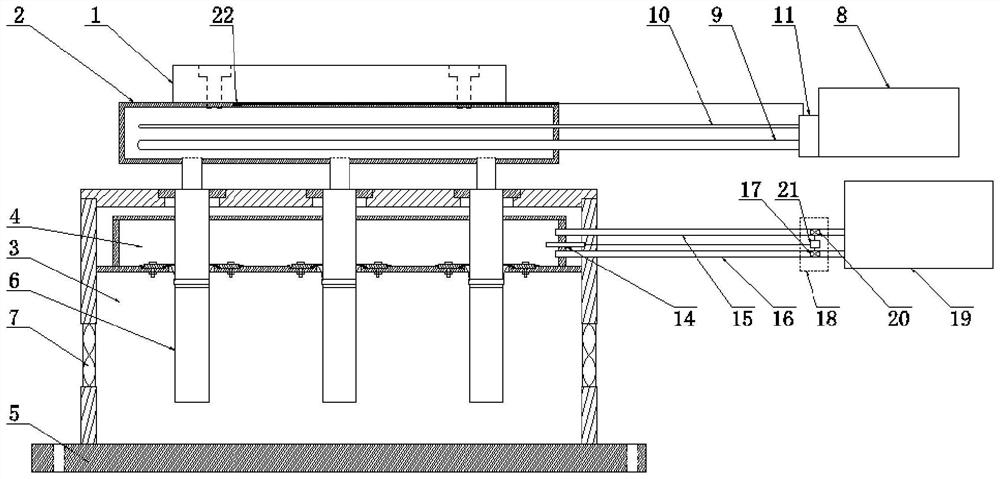

Full-automatic vacuum tight coupling gas atomization device and method thereof

ActiveCN111889690ARealize automatic feedingAchieve tight integrationIncreasing energy efficiencyFrequency changerEngineering

The invention discloses a full-automatic vacuum tight coupling gas atomization device and a method thereof. The full-automatic vacuum tight coupling gas atomization device comprises a smelting chamber, an atomizing chamber, a crucible, a tundish system, a worm gear mechanism, a servo motor, a frequency converter and a central processing system; the smelting chamber and the atomizing chamber are arranged closely and horizontally in up-down parallel, the tundish system is further horizontally arranged on the bottom surface of the inner part of the smelting chamber, an inlet of the upper end of the tundish system communicates with the inner part of the smelting chamber, and an outlet of the lower end of the tundish system communicates with the inner part of the atomizing chamber; the crucibleis further obliquely arranged on one side of the inner part of the smelting chamber, a rotating shaft of the crucible obliquely and downward extends out of the smelting chamber, and is connected withan output end of the servo motor through the worm gear mechanism in a linked mode; and the frequency converter and the central processing system are further arranged on the outer part of the smeltingchamber, and the frequency converter is correspondingly and electrically connected with the servo motor and the central processing system. According to the full-automatic vacuum tight coupling gas atomization device, the full-automatic production of industrial grade gas atomization equipment is achieved.

Owner:ZHONGTIAN SHANGCAI ADDITIVE MFG CO LTD

Heating and insulation livestock drinking bowl and anti-freezing water supply mode

The invention discloses heating and insulation livestock drinking bowl and an anti-freezing water supply mode, relating to the livestock water drinking device heating technology field. The heating and insulation livestock drinking bowl comprises a bowl body, a water valve arranged on one side of the bowl body, a silicon heating sheet arranged on the bottom of the bowl, a pressing tongue cooperating with the water valve, a water supply pipe connected to a water inlet and a heating lead wound on the water supply pipe; a water valve water inlet and a water valve water outlet are arranged on the lower end of the water valve; the heating lead is connected to the silicon heating sheet; the water valve also comprises a lifting and pressing shaft; the pressing tongue and the lifting and pressing shaft commonly control opening and closing of the water valve water outlet; and when the water valve water outlet is opened, the water in the water supply pipe flows into a water driving device. The anti-freezing method comprises steps of turning on a water inlet valve to let the drinking water to flow into the drinking device, turning on a heating function of a heating mechanism to heat up the drinking water inside the water drinking device and pre-heating water in the water supply pipe through heating the heating lead. The heating and insulation livestock drinking bowl and the anti-freezing water supply mode have advantages of avoiding artificial water refilling, a simple structure, easy operation and high feasibility.

Owner:WIN BALANCE ENTERPRISE CO LTD

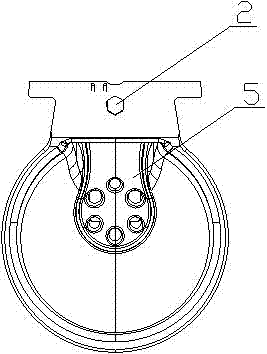

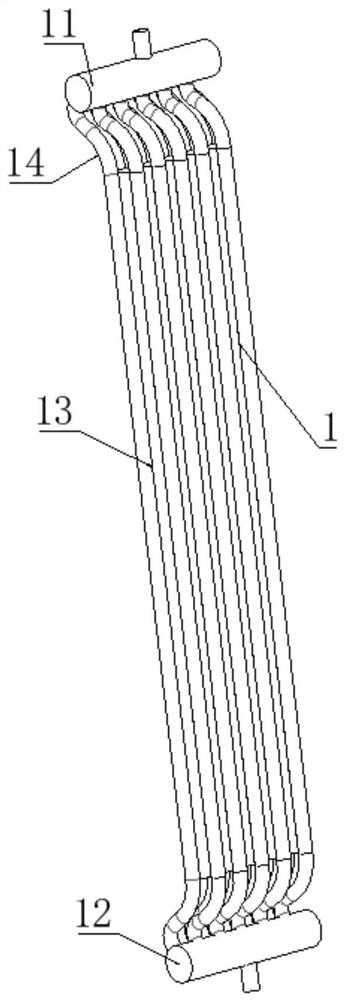

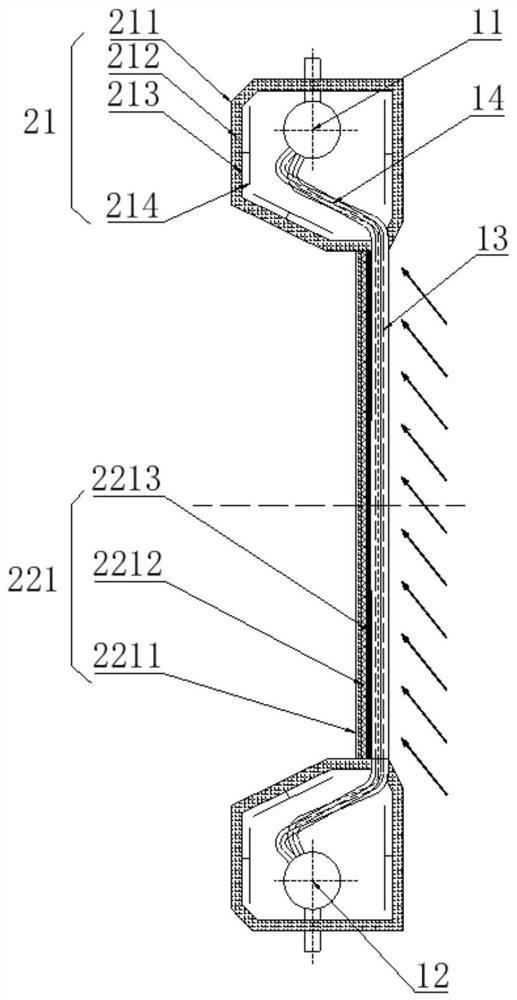

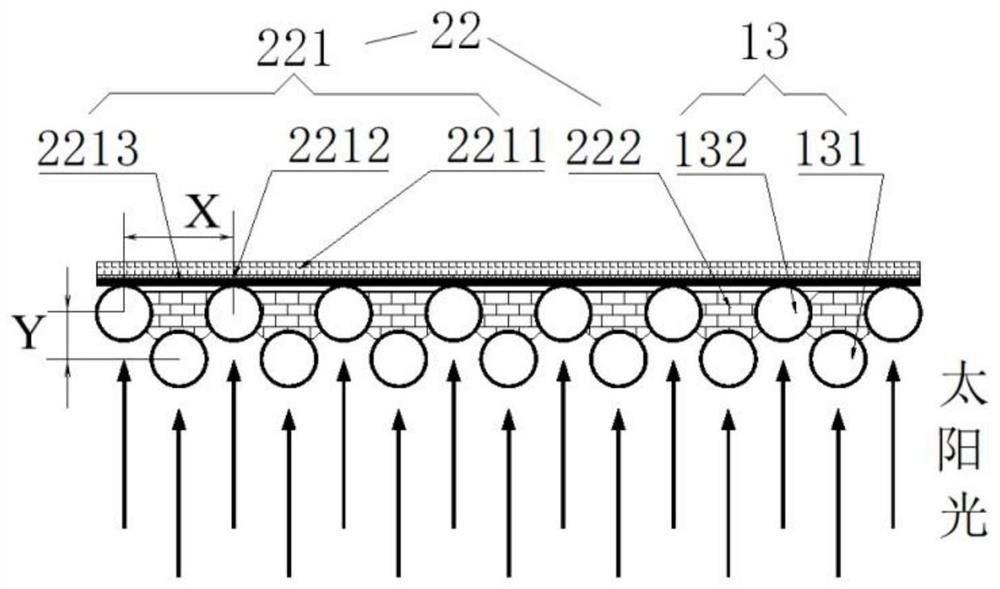

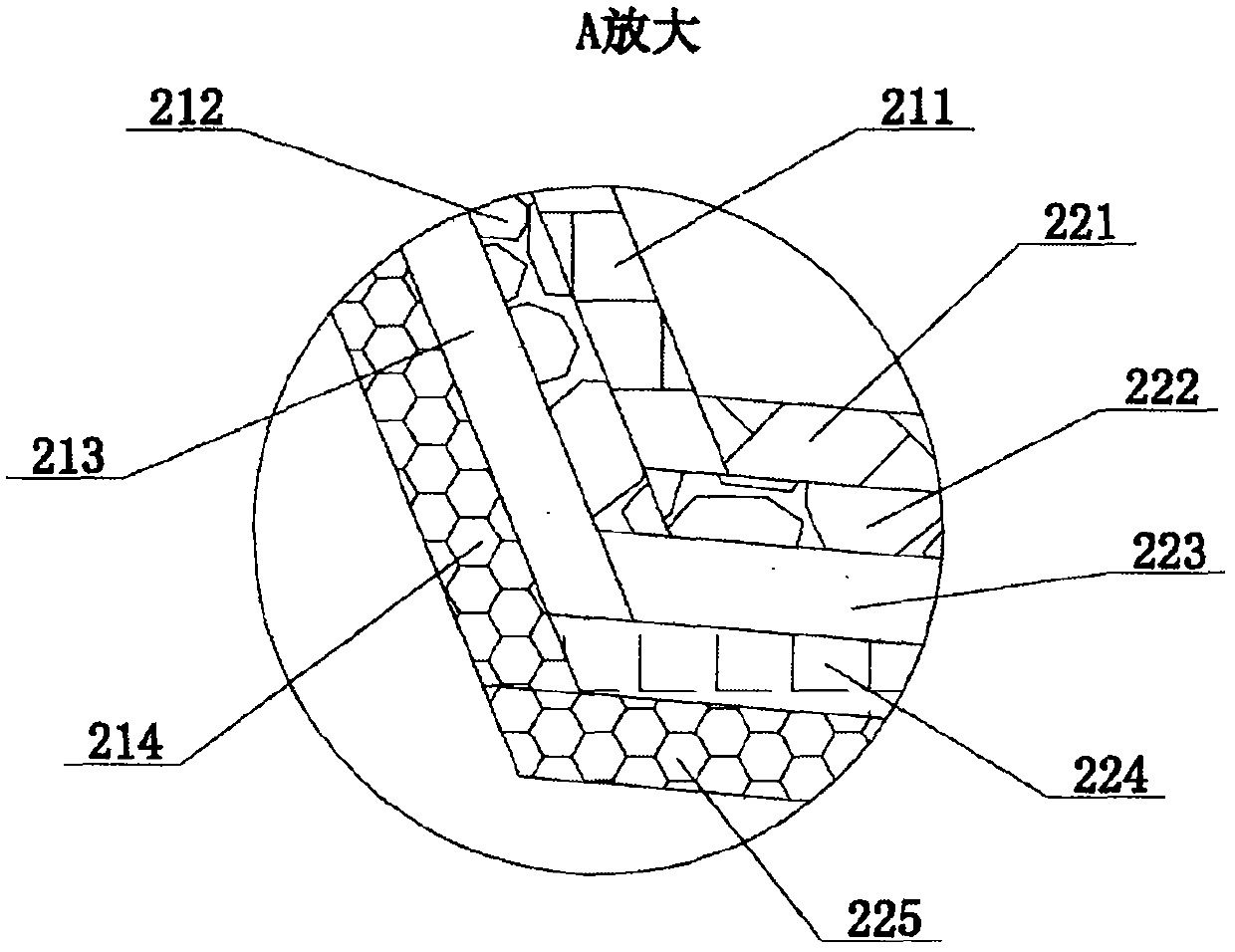

Tower type solar heat absorber with heat storage capacity

PendingCN111981710AHas heat storage capacityReached temperatureSolar heating energySolar heat storageThermodynamicsEngineering

The invention provides a tower type solar heat absorber with heat storage capacity. The tower type solar heat absorber comprises a heat absorption screen, wherein the heat absorption screen is erectedand circumferentially arranged around the center of the heat absorber, and the heat absorption screen comprises an upper header, a lower header and heat absorption pipes which are fixedly connected with the upper header and the lower header through connecting pipes and are arranged in rows; the heat absorption screen is further provided with a heat storage and insulation device, the heat storageand insulation device comprises a header insulation device and a heat absorption pipe heat storage and insulation device, and the header insulation device surrounds the upper header, the lower headerand the connecting pipes; and the heat absorption pipe heat storage and insulation device is arranged on the backlight sides of the heat absorption pipes. The tower type solar heat absorber is provided with the heat storage and insulation device, the heat storage and insulation device can insulate the upper header, the lower header and the heat absorption pipes respectively, the heat storage and insulation mode that thermochemistry of the heat storage and insulation device is matched with electric heat tracing enables the adaptability of the heat absorber to weather changes to be higher, blockage caused by condensation of fused salt in a pipeline is prevented, the overall reliability of the heat absorber is improved, the service life of the heat absorber is prolonged, and the maintenance and use cost is reduced.

Owner:ZHEJIANG UNIV

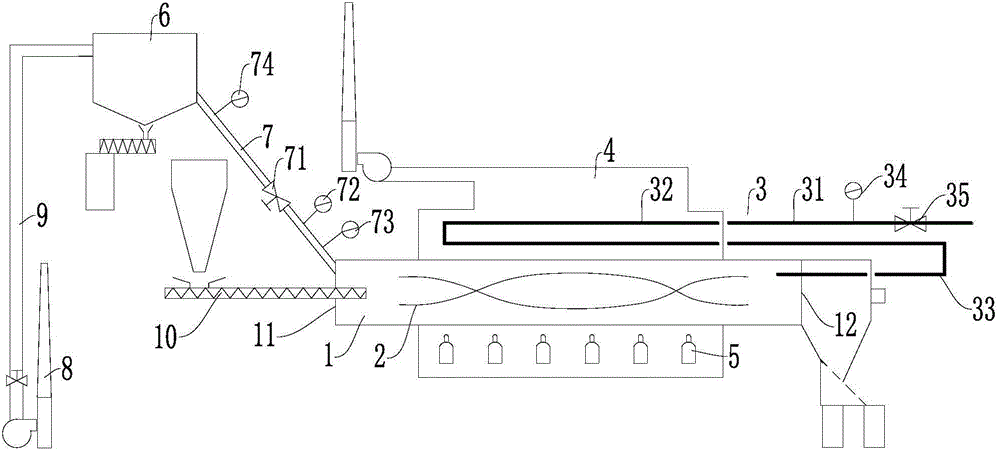

Equipment and method for producing powdery vanadium oxide

The invention discloses equipment for producing powdery vanadium oxide, belongs to the field of metallurgy, and aims to provide special equipment for producing the powdery vanadium oxide from APV. By the aid of the equipment, the APV can be fully oxidized and the grade of the vanadium oxide can be increased. The equipment comprises a rotary kiln device, a dust removal system and an air pipeline, wherein the rotary kiln device comprises a rotary kiln drum, a combustion device and a transmission device, the transmission device is connected with the rotary kiln drum and provides the rotating speed for the rotary kiln drum, the rotary kiln drum is arranged in the combustion device, one end is a feeding end, the other end is a discharging end, and the feeding end is higher than the discharging end; the dust removal system is arranged at the feeding end of the rotary kiln drum and communicated with an inner cavity of the rotary kiln drum; the air pipeline is communicated with the inner cavity of the rotary kiln drum and delivers hot air to the inner cavity of the rotary kiln drum, and one end of the air pipeline enters the inner cavity of the rotary kiln drum from the discharging end. According to the equipment, the APV reacts in a constant-temperature and negative-pressure oxidation atmosphere, the reaction is more thorough, and the grade of the vanadium oxide product is increased.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

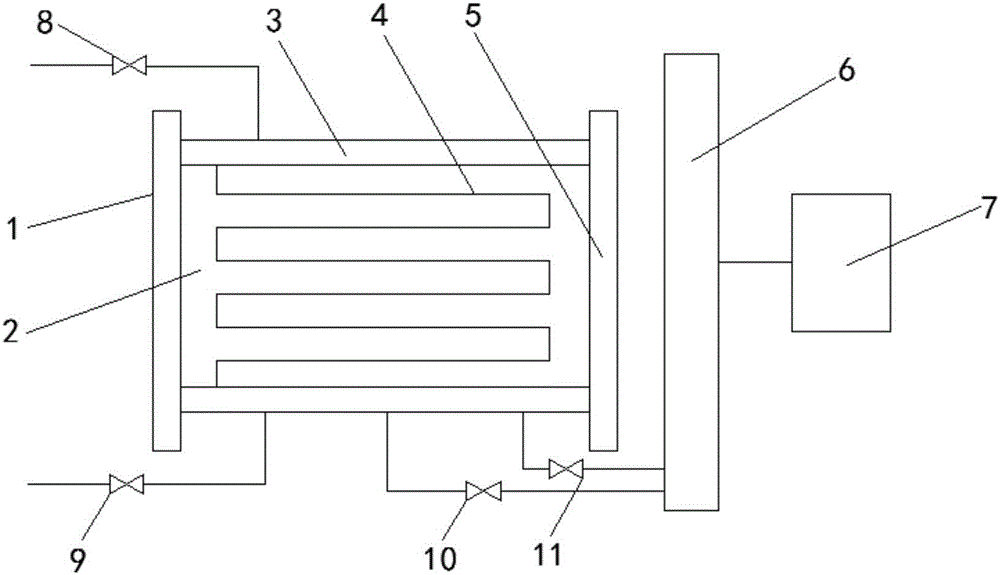

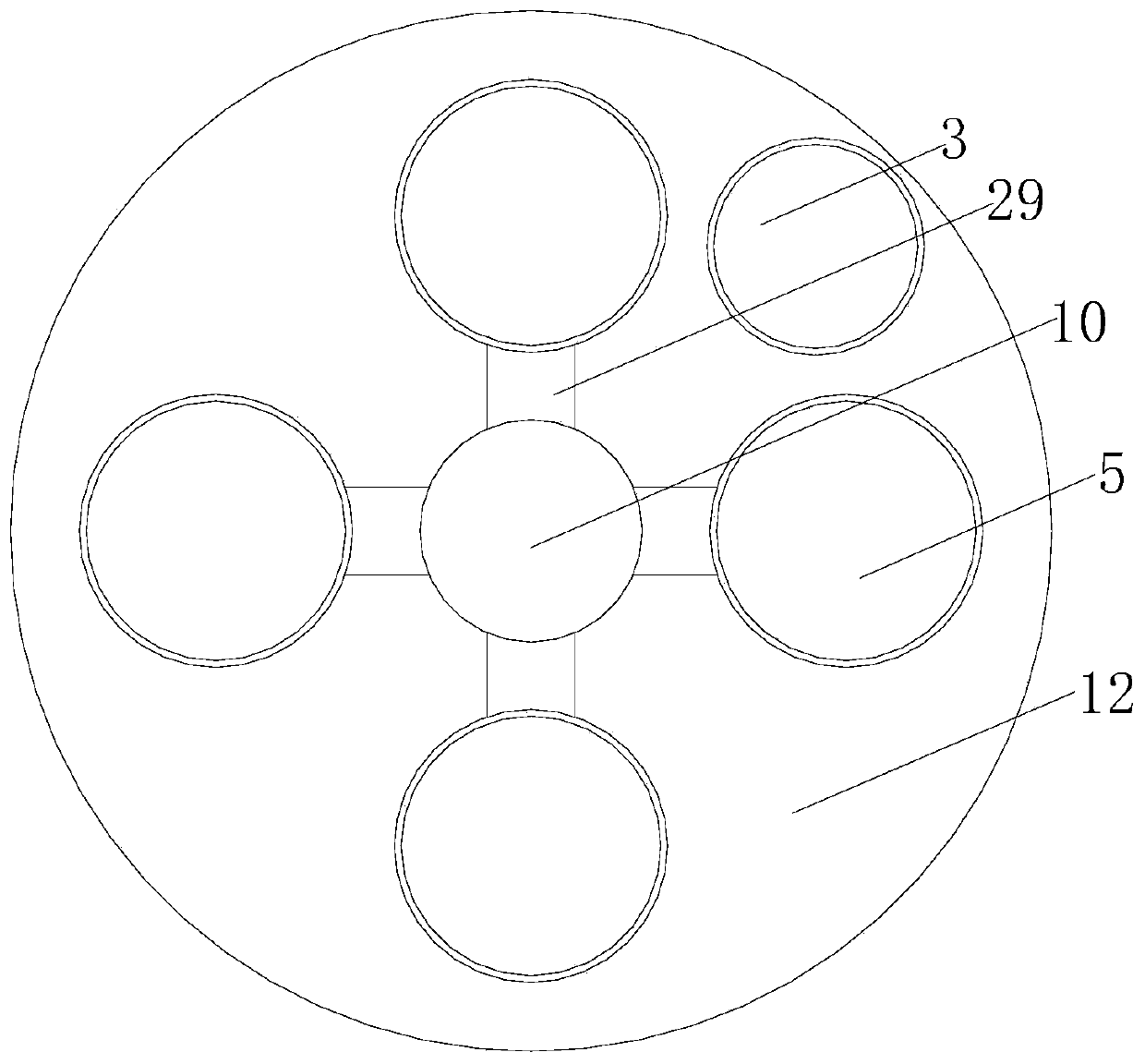

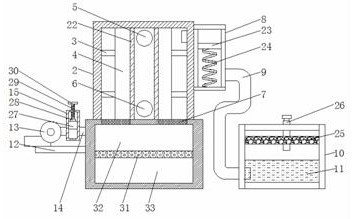

Steam heating device for green food production

ActiveCN111012160APrevent disengagementReduce access difficultySteam cooking vesselsWarming devicesThermodynamicsProcess engineering

The invention discloses a steam heating device for green food production. The device includes a tank body, wherein first communicating openings are formed in the top of the tank body in a penetratingmanner; steam cabinets are arranged at the top of the tank body and located above the first communicating openings; a heat preservation shell is arranged on one side of the interior of the tank body;a heating water tank is fixedly installed in the heat preservation shell through a cushion block; a heating wire is arranged in the heating water tank; and a steam outlet pipe is installed in the middle of the top of the heating water tank in a penetrating and inserting mode. According to the steam heating device, through cooperation of the first communicating openings, steam distributing bins, asteam collecting box, a steam-water separator, the steam outlet pipe and second communicating openings, the four steam cabinets can be heated through steam at the same time, meanwhile, the number of heated materials in the same time is greatly increased, and therefore the material heating efficiency can be improved, the steam utilization rate is increased, steam waste can be prevented, and the cost can be reduced.

Owner:CHAOHU MEADVILLE FOOD CO LTD

Heat accumulating type food heat-preservation device with metal porous structure

InactiveCN101773357BSpeed up meltingEfficient deliveryTable equipmentsWarming devicesHeating timeHeat losses

The invention relates to a heat accumulating type food heat-preservation device with a metal porous structure, comprising a top cover, a shell, a vacuum layer, an outer wall, an inner wall, through-hole metal foam, a phase-change material and an electric heating device. In the invention, a through-hole metal foam material is sintered between the inner wall and the outer wall according to an intensifying heat-exchange principle of a phase-change material inside the through-hole metal foam, and the phase-change material is packaged in a through-hole metal foam gap between the inner wall and theouter wall; when the heat accumulating type food heat-preservation device is electrified to be heated, the phase-change material is melted when heated and stores electric energy in a latent heat of fusion way, and the through-hole metal foam has high heat conductivity so as to intensify the melt of the phase-change material and shorten the heating time; the phase-change material is concreted and releases the stored latent heat, and the through-hole metal foam can more efficiently transfer heat to foods by utilizing the high heat conductivity and heat the foods to make up the heat loss of the foods. The heat accumulating type food heat-preservation device preserves the heat by adopting a latent heat heating principle, overcomes the defect of a passive heat insulation technology of the traditional heat-preservation devices and has long heat-preservation time and high efficiency.

Owner:XI AN JIAOTONG UNIV

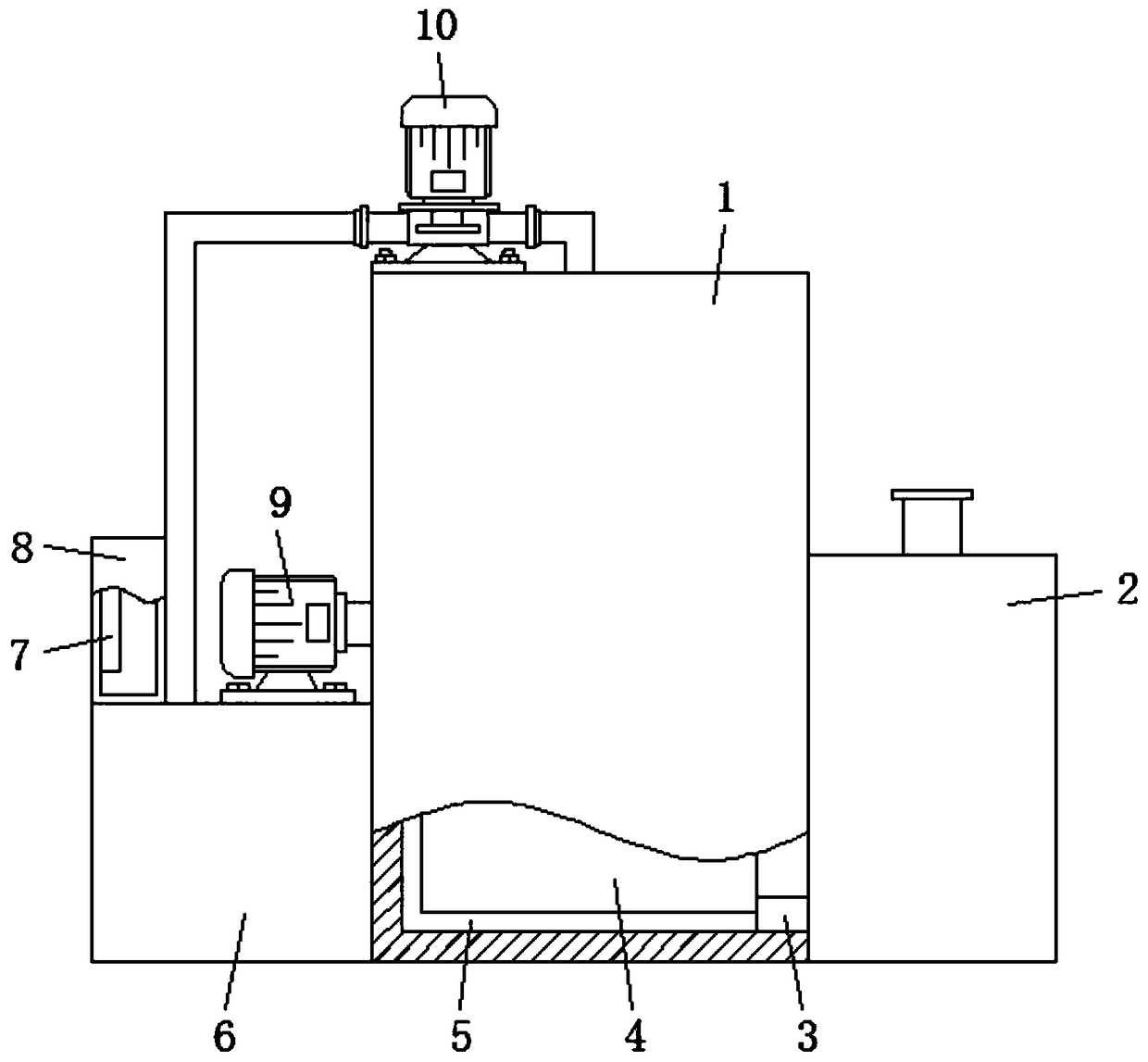

Tea table with heating function

InactiveCN107334273AEasy to usePlay the role of heating and heat preservationServing tablesAgricultural engineeringWater tanks

The invention discloses a tea table with a heating function. The tea table with the heating functions comprises a tea table body, wherein a pipeline is disposed in the tea table body; a water tank is hung on the right side wall of the tea table body; a motor and a switch are disposed on the left side wall of the tea table body; a heater is disposed in the right side wall of the water tank; a water inlet pipe is disposed on the bottom of the pipeline; the water inlet pipe extends to the bottom of the water tank; a water pump is disposed on the water inlet pipe; a water outlet pipe is disposed on the top end of the pipeline; the water outlet pipe extends into the water tank; the motor is connected to the water pump; and the switch is connected to the motor. The tea table disclosed by the invention has the heating function; used water is heated; use is safe; and heating and heat preservation of foods on the tea table can be achieved.

Owner:广西智创企业管理培训有限公司

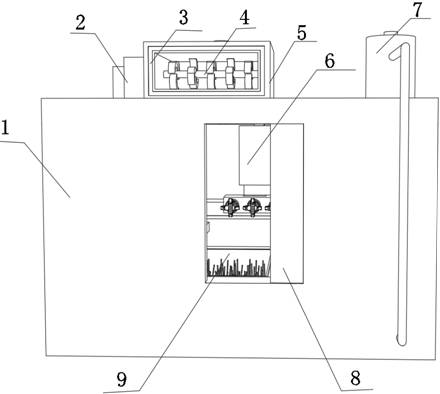

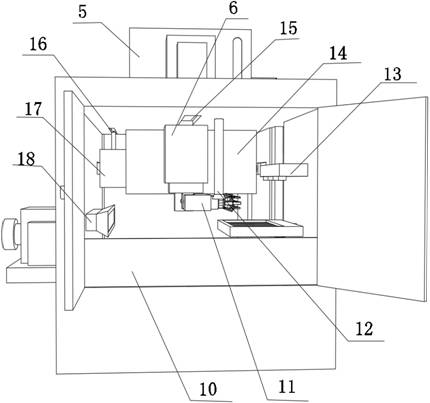

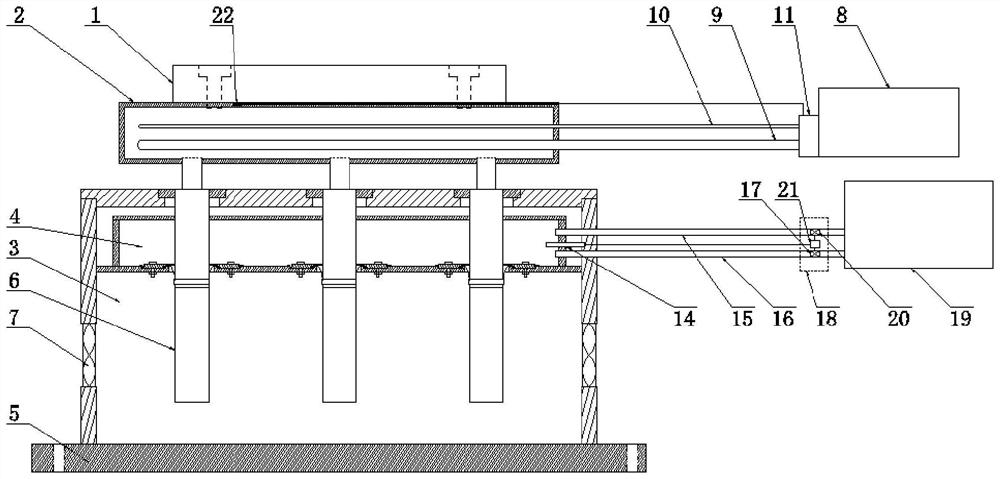

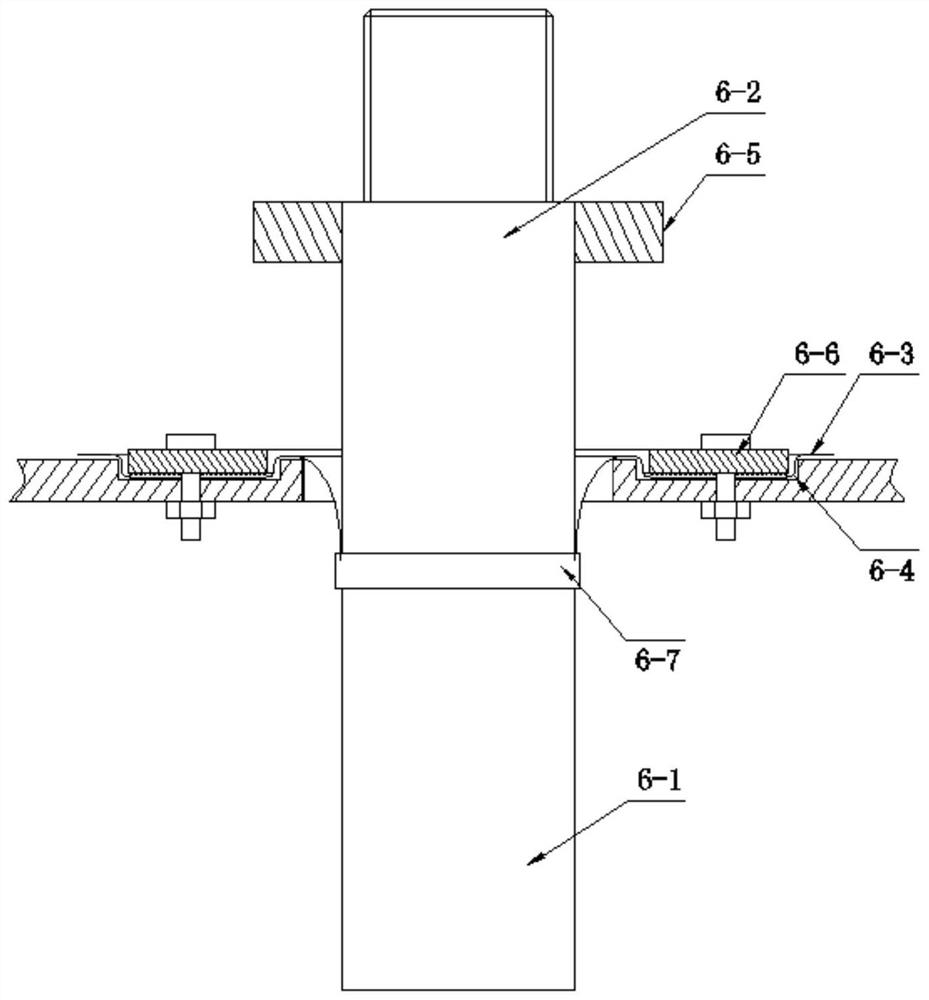

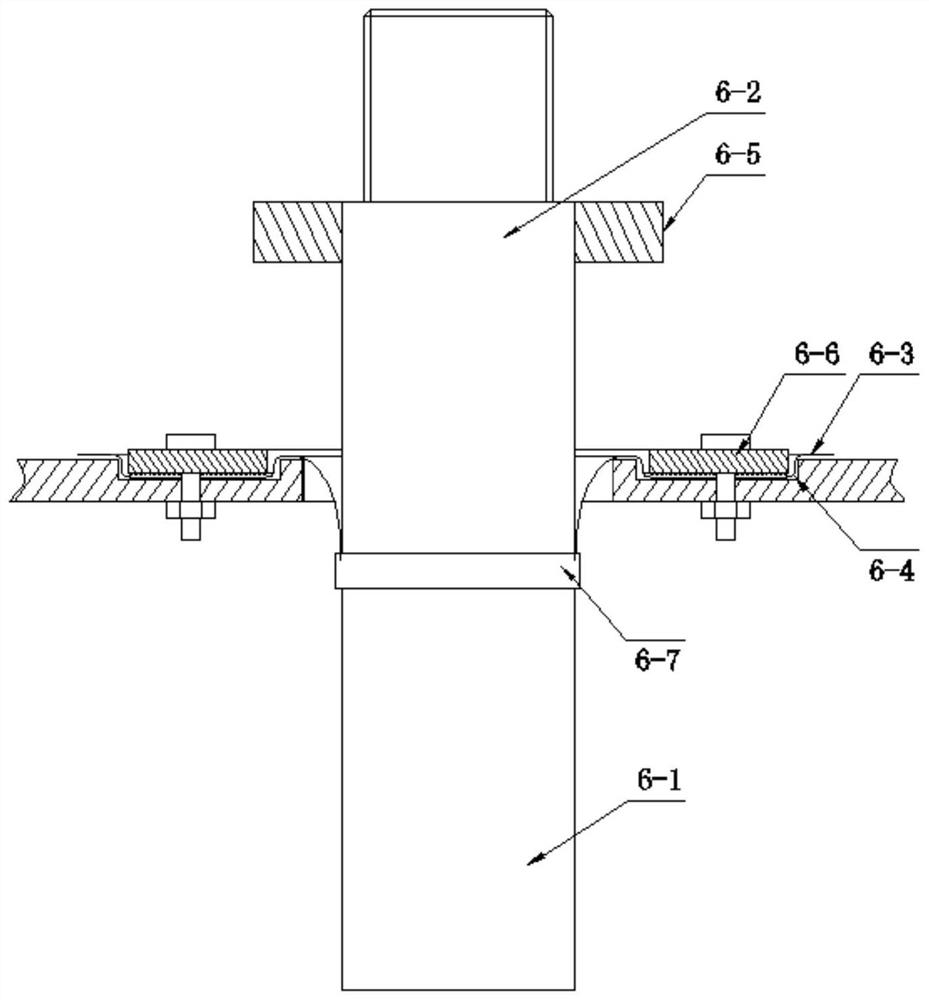

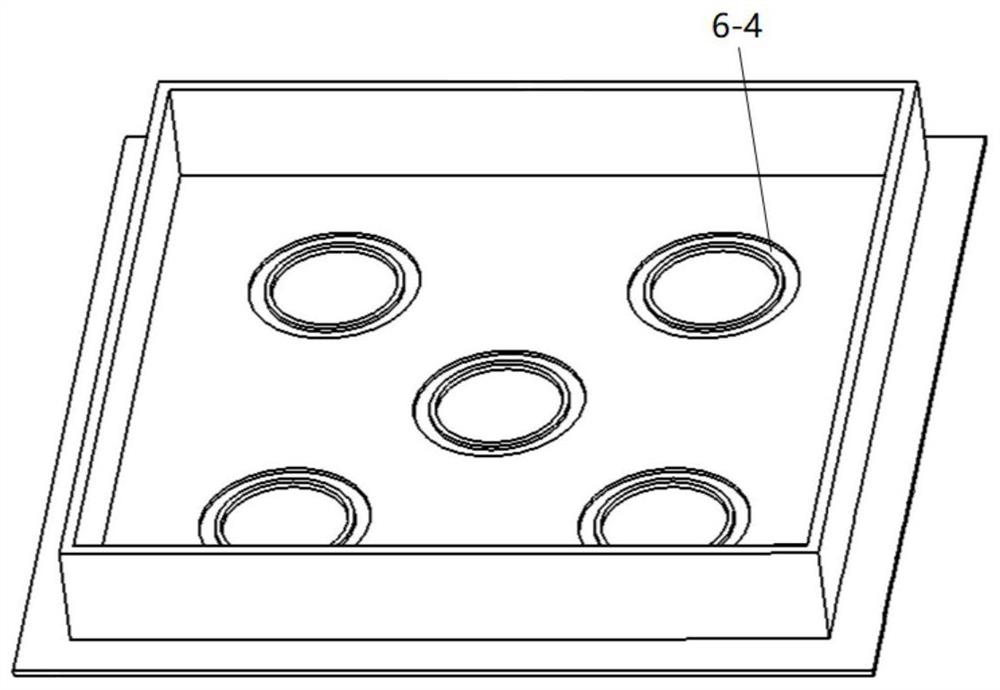

Ultrasonic in-situ loading device for laser melting deposition forming

ActiveCN113084167AAvoid damageIncrease the ultrasonic amplitudeAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlMaterials science

The invention relates to an ultrasonic in-situ loading device for laser melting deposition forming, in particular to the ultrasonic in-situ loading device for laser melting deposition forming. The invention aims to solve the problem that directional solidification structures can be easily generated in the forming process of existing laser melting deposition equipment. The device is composed of a base plate, a temperature control plate, an air cooling bin, a water cooling bin, a fixed base and an ultrasonic vibrator. According to the device, a high-frequency ultrasonic field can be generated in the laser melting deposition forming process, homogenization and grain refinement of the structure of a formed product are achieved, and the strength of the laser melting deposition product is improved. Meanwhile, the temperature control plate capable of adjusting the temperature is arranged below the base plate so that the temperature of the base plate can be adjusted. The device is suitable for laser melting deposition forming.

Owner:HARBIN INST OF TECH

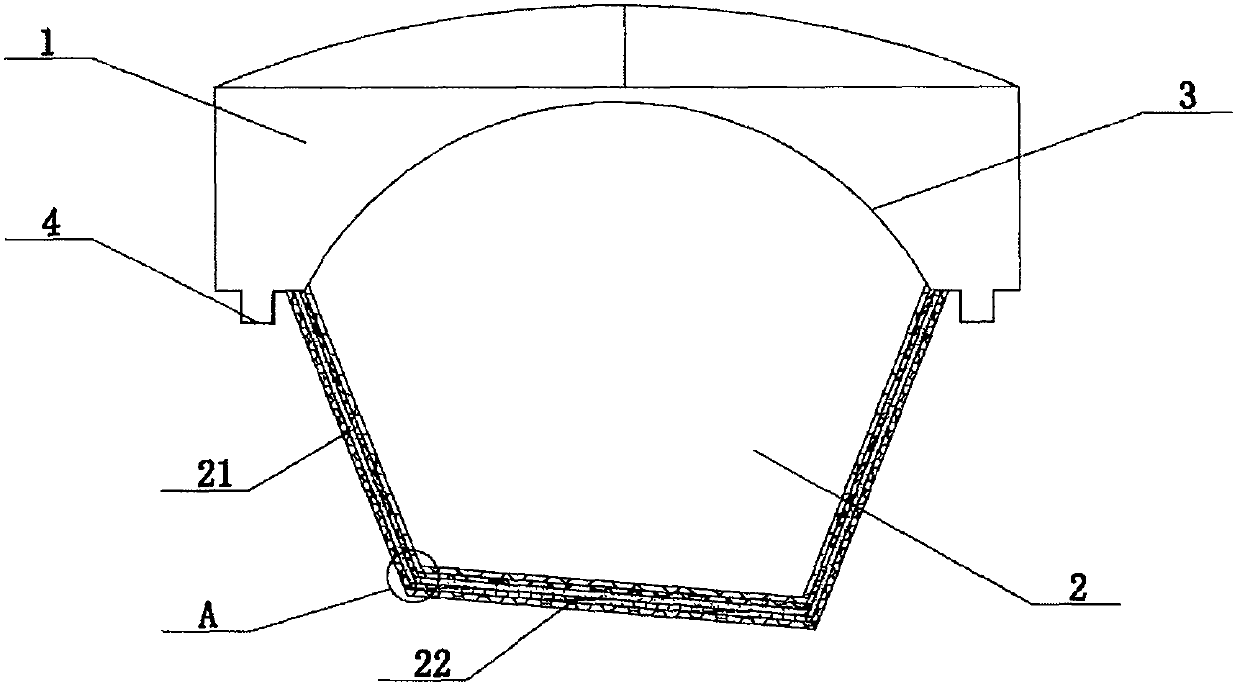

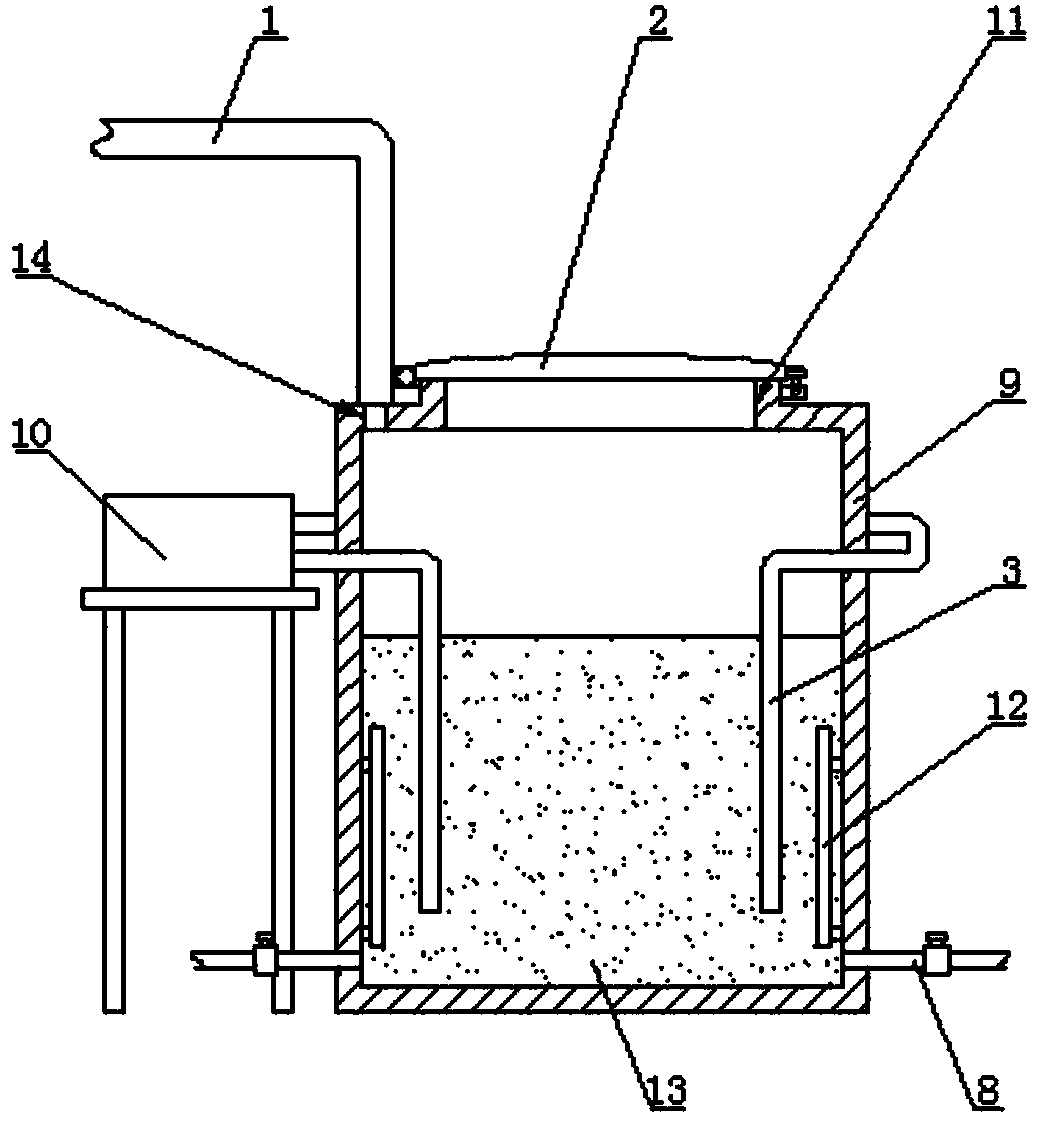

Insulation structure of fermentation tank for warm room biogas preparation

InactiveCN110468031AApplicable insulationGuaranteed outputBioreactor/fermenter combinationsBiological substance pretreatmentsDaily livingInsulation layer

The invention provides an insulation structure of a fermentation tank for warm room biogas preparation. The insulation structure comprises a warm room, a fermentation tank and an HDPE film wherein thewarm room is used for coating the fermentation tank; the fermentation tank comprises a tank wall and a tank bottom, and the cross section formed by the tank wall and the tank bottom has a trapezoidalstructure; the HDPE film is arranged on the tank wall, the tank bottom and the upper opening of the fermentation tank to form a closed structure; the tank wall comprises a first insulation layer, a concrete layer, a second insulation layer and a first cushion layer which are sequentially arranged from inside to outside; and the tank bottom comprises a third insulation layer, a concrete layer, a fourth insulation layer, a waterproof layer and a second cushion layer which are sequentially arranged from inside to outside. The insulation structure is applicable to insulation of various biogas digesters, and can be used for effectively ensuring that the inside of a biogas digester is still in a constant-temperature state in winter or cold weather to achieve an effect of heating and insulatingin winters, so that the yield of biogas can be guaranteed, and daily living needs of people can be met.

Owner:LUANNAN LINHAI TECH DEV

Bee breeding box with temperature adjusting structure

The invention discloses a bee breeding box with a temperature adjusting structure. The bee breeding box comprises a fixing plate and a guide pipe air outlet, wherein a honeycomb plate is mounted at the upper end of the fixing plate, a fixing guide block is arranged at one end of the honeycomb plate, a limiting partition plate is mounted at one end of the fixing guide block, a through hole is formed in the honeycomb plate, an aluminum pipe is mounted in the through hole, a rear honeycomb plate is mounted at the rear end of the honeycomb plate, air spraying holes are formed in the outer surface of the rear honeycomb plate, a guide pipe is arranged in the rear honeycomb plate, a guide pipe air inlet is formed in one end of the guide pipe, a control valve is mounted on the outer surface of the guide pipe air inlet, and a guide pipe air outlet is formed in the other end of the guide pipe. The heat supply box body is arranged, air in the heat supply box body is heated, and then the hot air in the heat supply box body is conveyed into the bee breeding box through power provided by a sucking pump, so that heat is provided for the bee breeding box, the heating and heat preservation effects are achieved, and bee death caused by too cold weather is avoided.

Owner:湖南森牧源食品生物有限公司

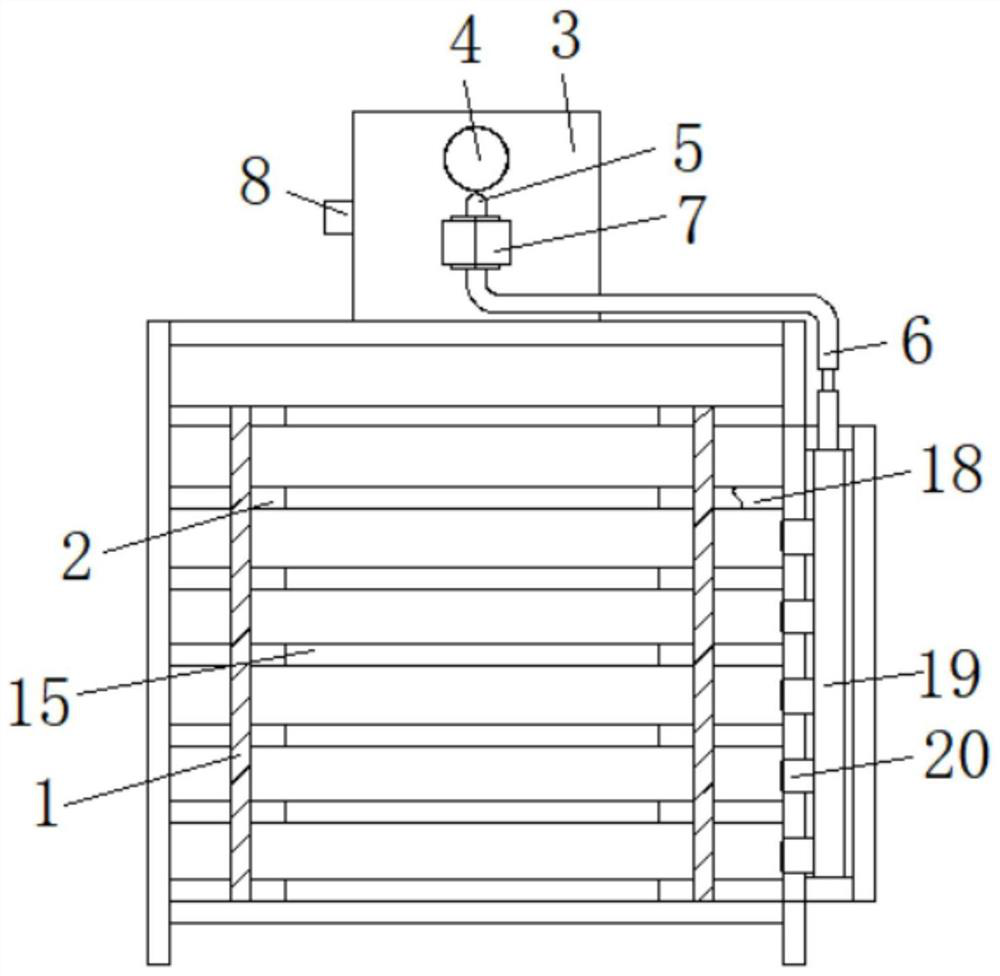

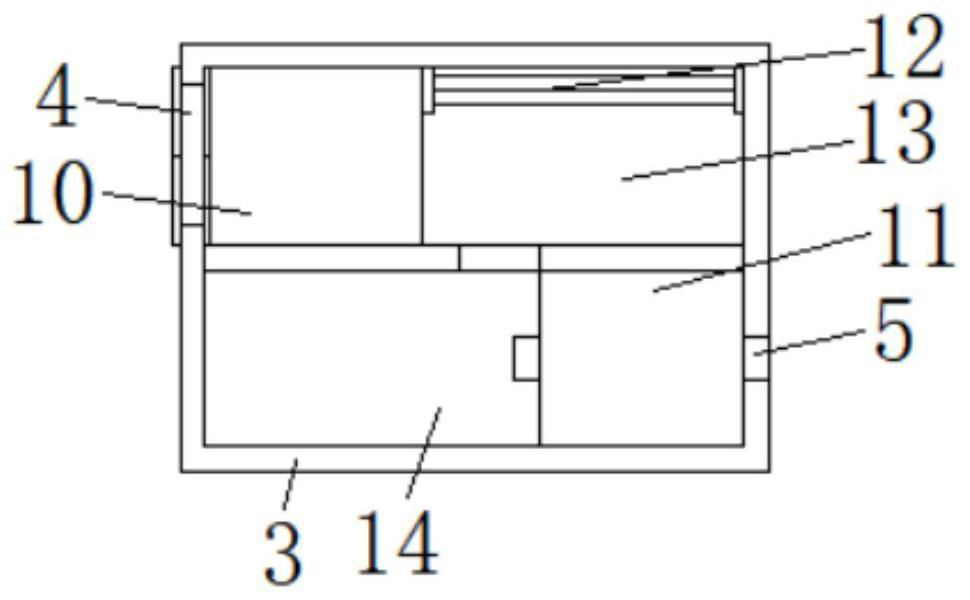

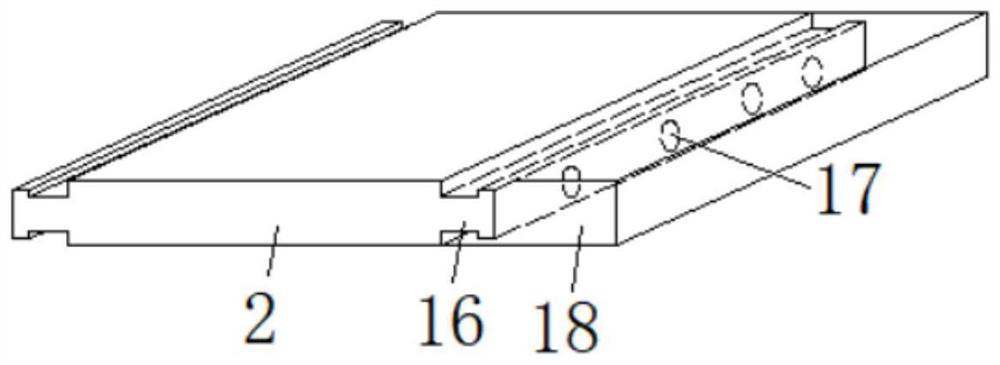

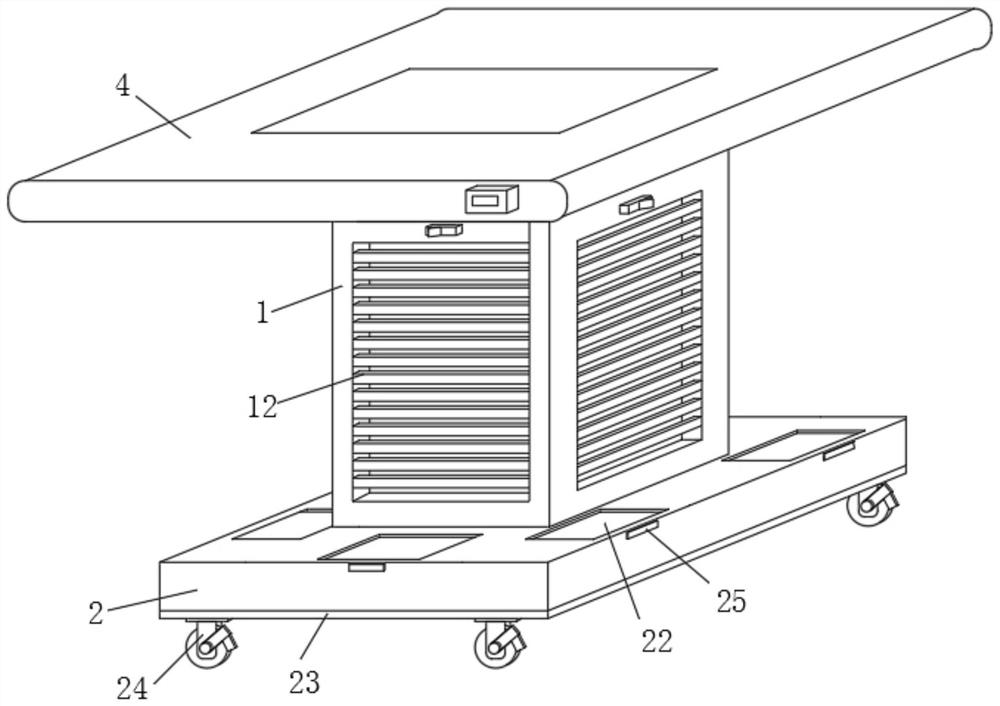

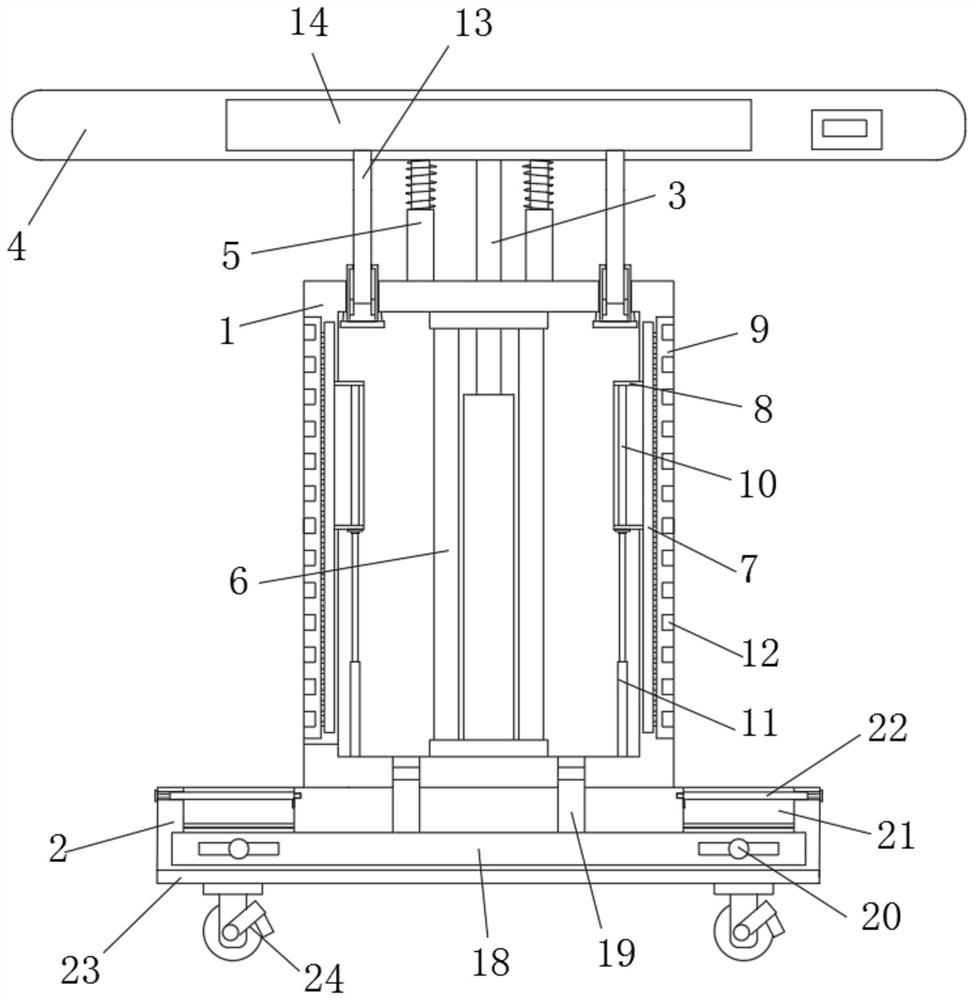

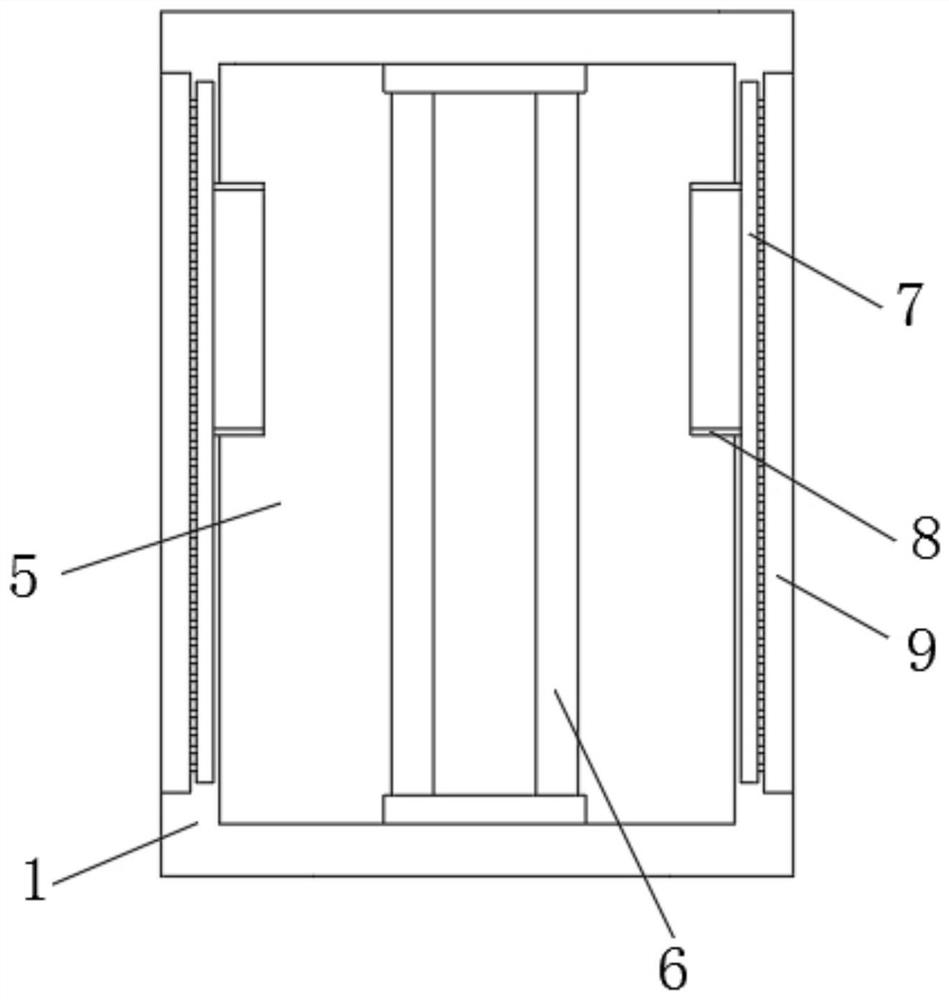

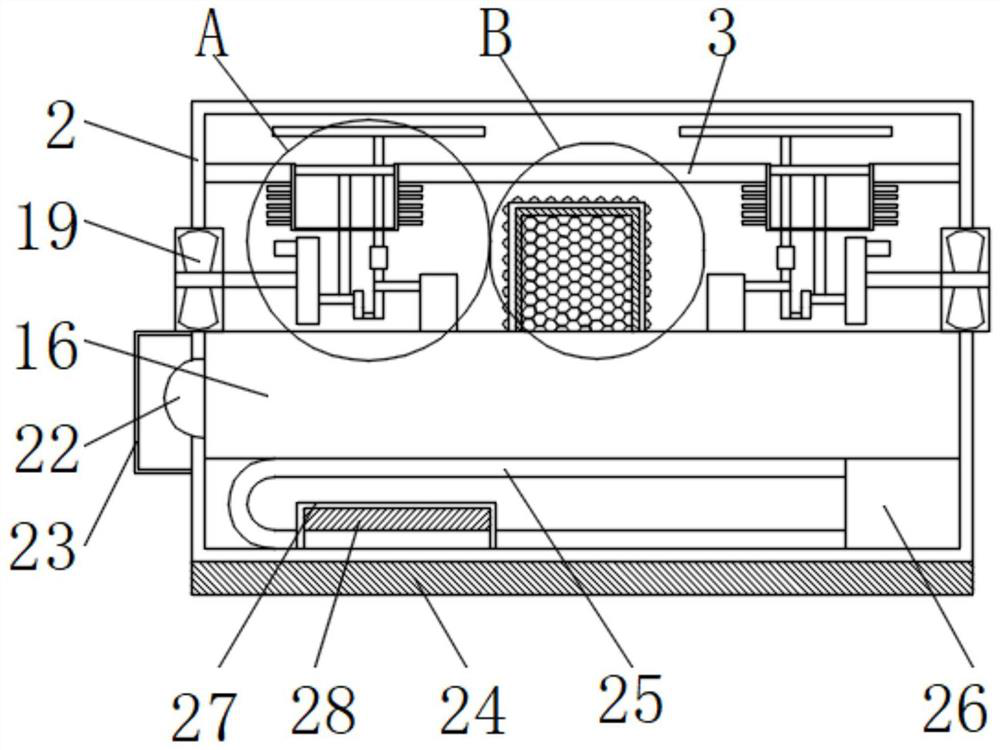

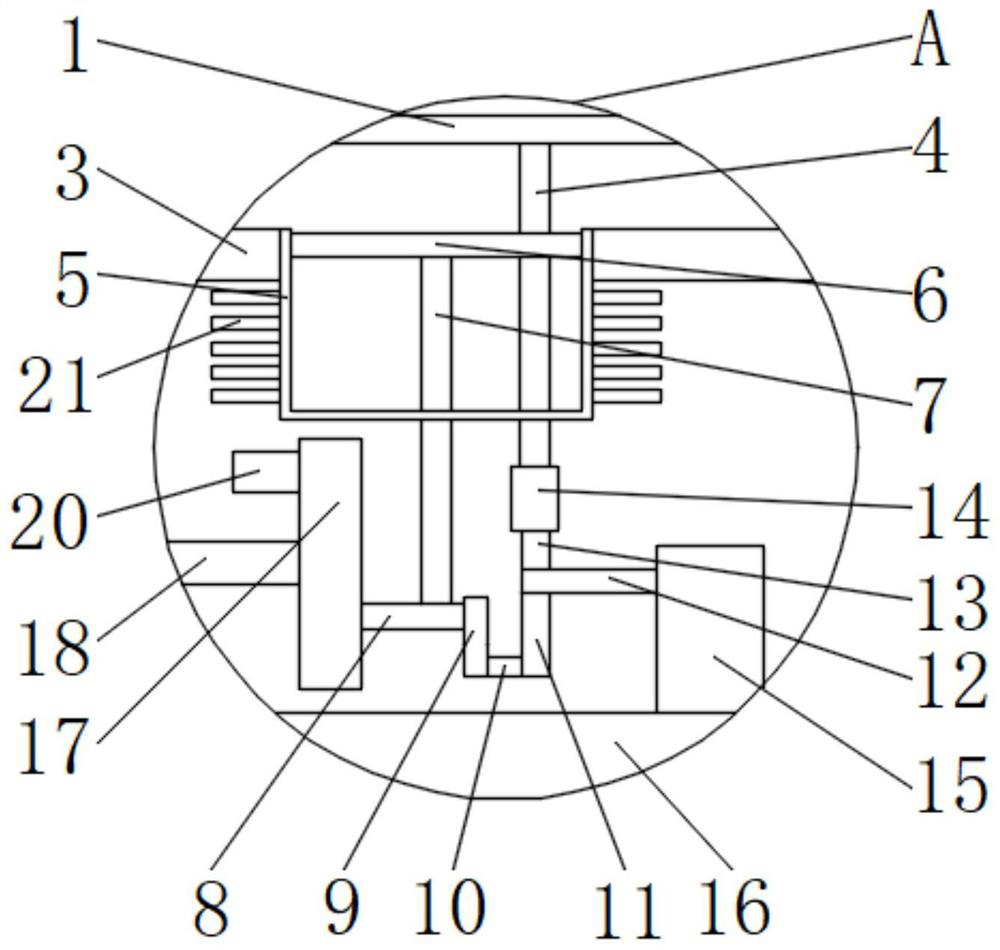

An integrated multi-adjustment electric heater and its use method

ActiveCN110220239BReduce export lossPlay the role of heating and heat preservationLighting and heating apparatusElectric heating systemProcess engineeringThermal treatment

The invention discloses an integrated multi-adjustable electric heater and a use method thereof, belonging to the field of electric heaters. An integrated multi-adjustable electric heater and a use method thereof comprise a hollow furnace box, the bottom of the hollow furnace box is fixedly installed with a base, and the hollow furnace box is hollow. An electric telescopic cylinder is fixedly installed on the inner bottom of the furnace box, and the telescopic end of the electric telescopic cylinder runs through the hollow furnace box and is fixedly connected to the table. The inner wall connected to the cavity is provided with a hot gas opening and closing mechanism, which can use any heat conduction surface arbitrarily according to the actual use situation, reducing unnecessary loss of heat loss, and by connecting the hollow furnace box with the table and the base, the table and the base can be realized. The heat treatment can effectively heat and keep the food on the countertop warm, and can also warm the feet, improving the comfort of the electric heater.

Owner:鞍山百胜节能环保科技有限公司

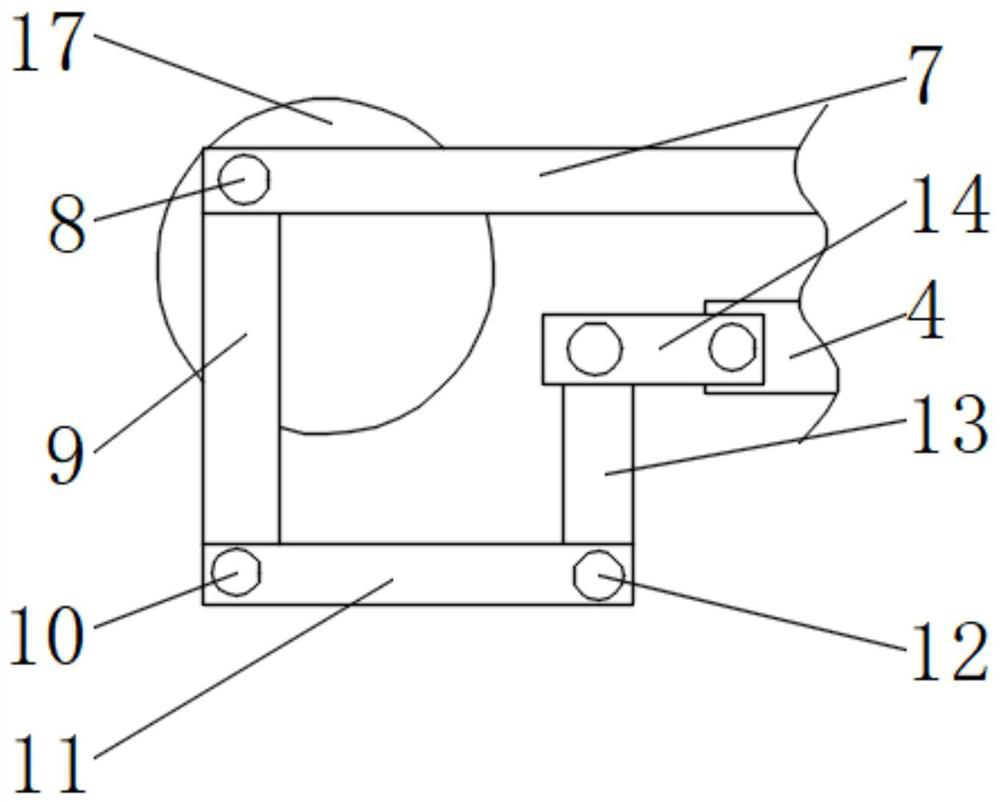

Face recognition assembly used in high temperature and low temperature environment

ActiveCN112423552BHeat dissipation fastDissipate heat in timeCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringWater circulation

The invention discloses a face recognition assembly used in high-temperature and low-temperature environments, which relates to the field of face recognition technology, and includes a power piston and a sliding piston, and the power piston is assembled on the inner wall of the upper end of the protective shell and the upper end of the fixed connection plate. In the cavity, the lower end of the power piston is fixedly connected to the upper end of the No. 1 sliding rod, and the left end of the fixed connection plate is provided with a fixed shell, and the sliding piston is assembled in the fixed shell and slidably connected with the inner wall of the fixed shell. The face recognition assembly used in the high temperature and low temperature environment is equipped with a power piston and a sliding piston to drive the cooling fan to rotate through the thermal expansion and contraction of the gas, so as to perform timely and efficient heat dissipation in the high temperature environment. The belt and the water circulation pipe have the effect of heat preservation and heating in the low temperature environment, and the noise reduction shell is set to play an environmental protection effect, which improves the applicability and work efficiency of the face recognition device, and is convenient to use.

Owner:深圳市创族智能实业有限公司

A kind of equipment and method for producing powdery vanadium pentoxide

The invention relates to equipment for producing powdery vanadium pentoxide, which belongs to the field of metallurgy. The purpose is to provide a kind of equipment specially used in producing vanadium pentoxide by APV. It can fully oxidize APV and improve the grade of vanadium pentoxide. It includes a rotary kiln device and a dust removal system. The rotary kiln device includes a rotary kiln shell, a combustion device, and a transmission device connected to the rotary kiln shell to provide a rotating speed for the rotary kiln shell. The rotary kiln shell is set in the combustion device. One end is The feed end, the other end is the discharge end, the feed end is higher than the discharge end, the dust removal system is set at the feed end of the rotary kiln shell and communicates with the inner cavity of the rotary kiln shell; The air pipe that transports hot air to the inner cavity of the rotary kiln cylinder, and one end of the air pipeline enters the inner cavity of the rotary kiln cylinder from the discharge end. The invention enables the APV to react in constant temperature, negative pressure and oxidizing atmosphere, the reaction is more thorough, and the taste of the vanadium pentoxide product is improved.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

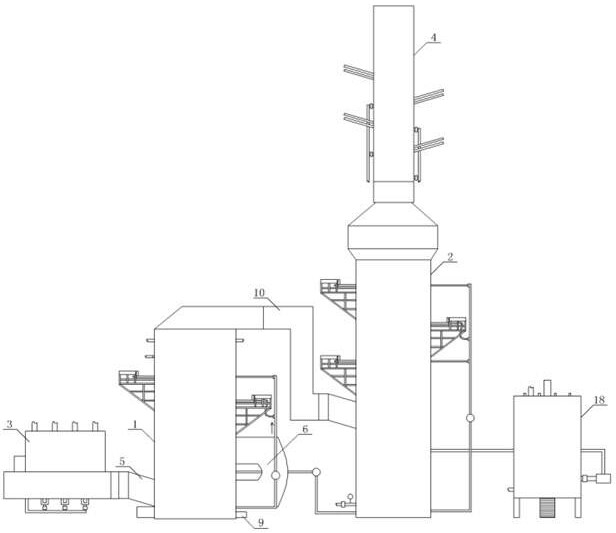

A sintering flue gas desulfurization and denitrification purification system and process

ActiveCN109675421BEasy to produceConvenience for follow-up productionDispersed particle separationAmmonium sulfatesFlue gasProcess engineering

The invention discloses a sintering flue gas desulfurization and denitrification purification system, which includes a pre-washing tower, a desulfurization tower, a denitrification device, and a clean flue gas whitening device; the system of the invention has the advantages of high efficiency in desulfurization and denitrification; After treatment, it can be directly discharged into the atmosphere to meet the needs of environmentally friendly production. The invention also discloses a process of sintering flue gas desulfurization and denitrification purification system, including ozone reaction process, absorption reaction process, oxidation reaction process, smoke demisting, whitening, and by-product processing; denitrification, and then use ammonia water and compressed air to carry out absorption and oxidation reactions respectively. While desulfurizing the flue gas, the by-product ammonium sulfate solution can be obtained; and the flue gas can be directly discharged into the atmosphere after further demisting and whitening, meeting the requirements of Standard discharge; and by-product ammonium sulfate solution can be further processed to obtain product ammonium sulfate, increasing economic benefits.

Owner:云南天朗环境科技有限公司

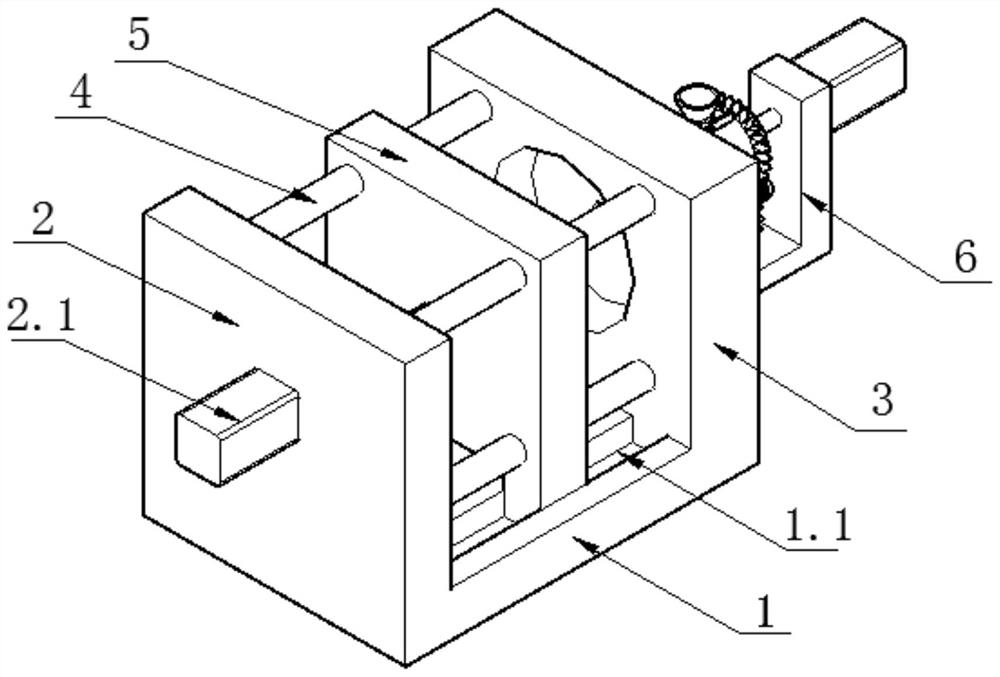

Portable injection mold for manufacturing intravascular stent

A mold base is fixedly installed at the top end of a workbench, a liquid injection pipe is fixedly installed in the middle of the top end of the mold base, a connecting pipeline is fixedly connected to the top end of the liquid injection pipe, and a convenient injection molding mechanism is fixedly installed in the middle of the top end of the workbench. The hydraulic telescopic rod can drive the lifting mold plate and the injection molding head to move up and down, the injection molding head is directly inserted into an injection molding pipe, injection molding raw materials are downwards injected into the attaching position of the outer sealing sleeve and the injection molding sleeve, and the outer sealing sleeve is tightly attached to the outer surface of the injection molding sleeve, so that the injection molding raw materials only flow along an injection molding rail groove; the intravascular stent is subjected to injection molding in the injection molding track groove, the molding mode is simple and convenient, injection molding raw materials cannot permeate, it is guaranteed that burrs cannot occur, the two injection molding heads and the injection molding pipe are subjected to injection molding at the same time, the raw materials can uniformly flow downwards, it is guaranteed that the intravascular stent subjected to injection molding is more uniform in structure, and the situation that due to insufficient raw materials, a part of the intravascular stent is sunken is avoided.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

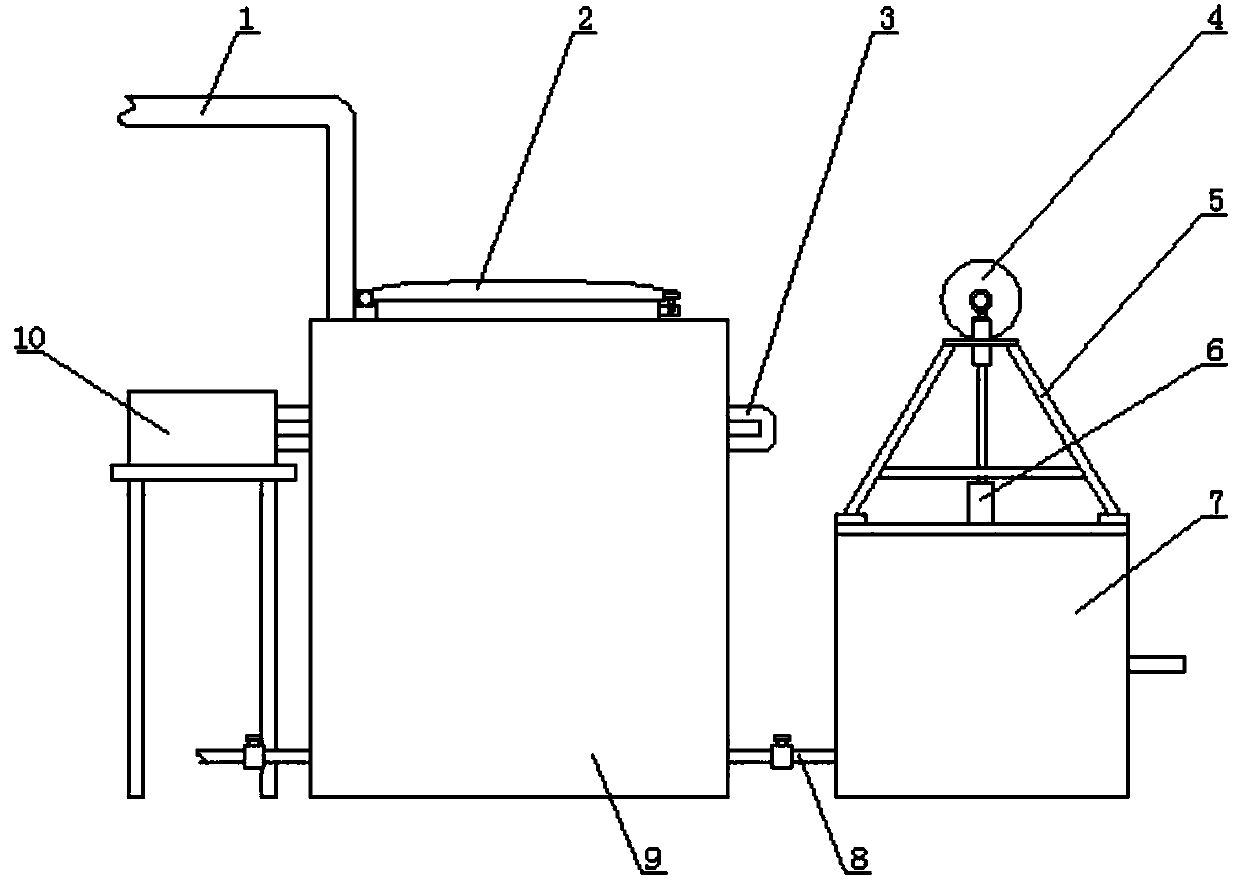

Mould surface TD (Thermal Diffusion) treatment pre-mixing production device

ActiveCN107779811AImprove quality and yieldSimple structureSolid state diffusion coatingMaterials scienceWide mouth

The invention relates to the field of mould manufacturing, in particular to a mould surface TD (Thermal Diffusion) treatment pre-mixing production device. The mould surface TD treatment pre-mixing production device comprises a premixing device and a surface TD treatment device; the premixing device comprises a wide mouth premixing tank; a premixing sealing cover is movably embedded into the inneredge of a wide mouth which is formed in the wide mouth premixing tank; a machine frame is mounted on the upper end surface of the premixing sealing cover; the upper end of a rotating shaft is rotatably mounted in a flat end surface which is formed on the machine frame; the lower end of the rotating shaft penetrates through the premixing sealing cover and extends into the wide mouth premixing tank;the upper end part of the rotating shaft is connected with an output end of a power output device; the mould surface TD treatment pre-mixing production device comprises a hollow tank body which is provided with an opening; at least two air inlets are uniformly formed in the side wall of the hollow tank body at an interval; an air inlet is mounted in each of the air inlets; an exhaust end of eachair inlet pipe is positioned at the bottom of the inner side of the hollow tank body; an air inlet end of each air inlet pipe communicates with an exhaust end of an air compressing pump.

Owner:天津开山金属模具科技有限公司

An energy-saving and environment-friendly combustion furnace

ActiveCN108548317BControl flowBurn fullyDamper arrangementSolid fuel combustionThermodynamicsCombustion chamber

The invention relates to the field of boiler equipment, and discloses an energy-saving and environment-friendly combustion furnace, comprising a bottom furnace, a top furnace is fixedly installed on the top of the bottom furnace, a fixed rod is fixedly installed on the inner wall of the top furnace, and the fixed rod The number is six, and one or two of the six fixed rods are symmetrically distributed on the inner walls of the two sides and the back of the top furnace, and the ends of the six fixed rods away from the top furnace are fixedly connected to the same boiler. The energy-saving and environment-friendly combustion furnace uses a fan to allow air to enter the combustion chamber to ensure full combustion of coal. At the same time, by turning the threaded rod, the sealing plug can be adjusted to move up and down, thereby controlling the flow of air, thereby controlling the air content inside the combustion chamber, so that The oxygen content inside the combustion chamber is appropriate, so that the coal can be burned more fully, avoiding the common boilers that cannot control the internal air volume, so that the coal cannot be fully burned, resulting in waste of coal.

Owner:南通高新工业炉有限公司

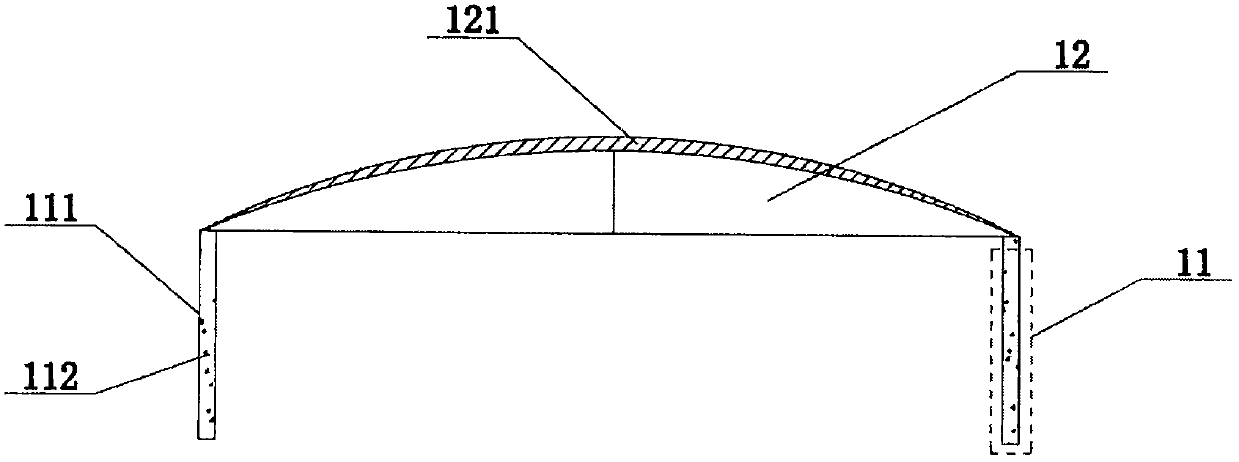

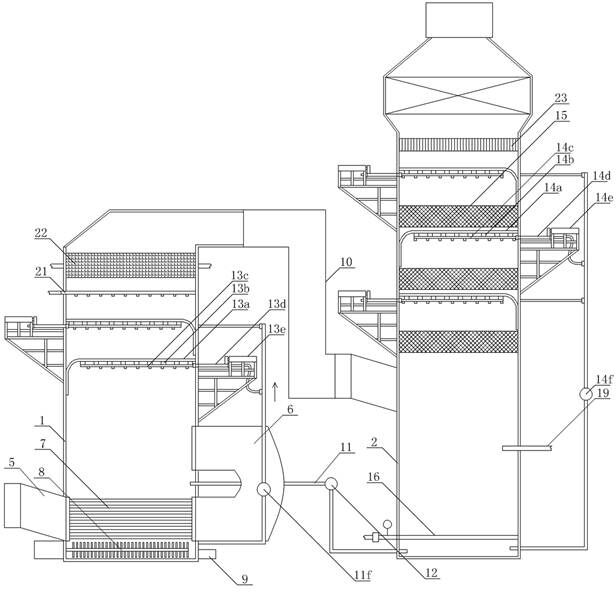

A steam heating device for green food production

ActiveCN111012160BPrevent disengagementReduce access difficultySteam cooking vesselsWarming devicesThermodynamicsProcess engineering

The invention discloses a steam heating device for green food production, comprising a box body, the top of the box body is penetrated with a first communication port, and the top of the box body and above the first communication port are all provided with a steam heating device. cabinet, one side of the inside of the box is provided with a thermal insulation shell, and the inside of the thermal insulation shell is fixed with a heating water tank through pads, and a heating wire is arranged inside the heating water tank, and the middle part of the top of the heating water tank is interspersed and installed There is a steam pipe. This kind of steam heating device for green food production can realize the simultaneous operation of four steam cabinets through the cooperation of the first communication port, steam distribution bin, steam collection box, steam-water separator, steam outlet pipe and the second communication port. At the same time, steam heating is carried out, and at the same time, the amount of material heating at the same time is greatly increased, which is conducive to improving the efficiency of material heating, and improving the utilization rate of steam, which helps to prevent steam waste and also helps reduce waste. cost.

Owner:CHAOHU MEADVILLE FOOD CO LTD

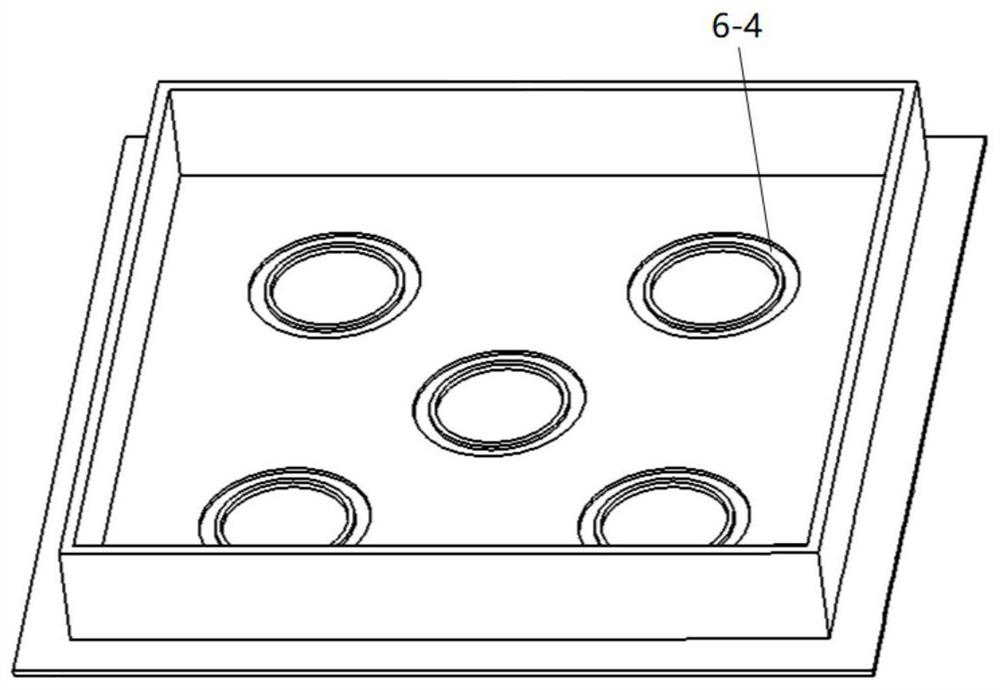

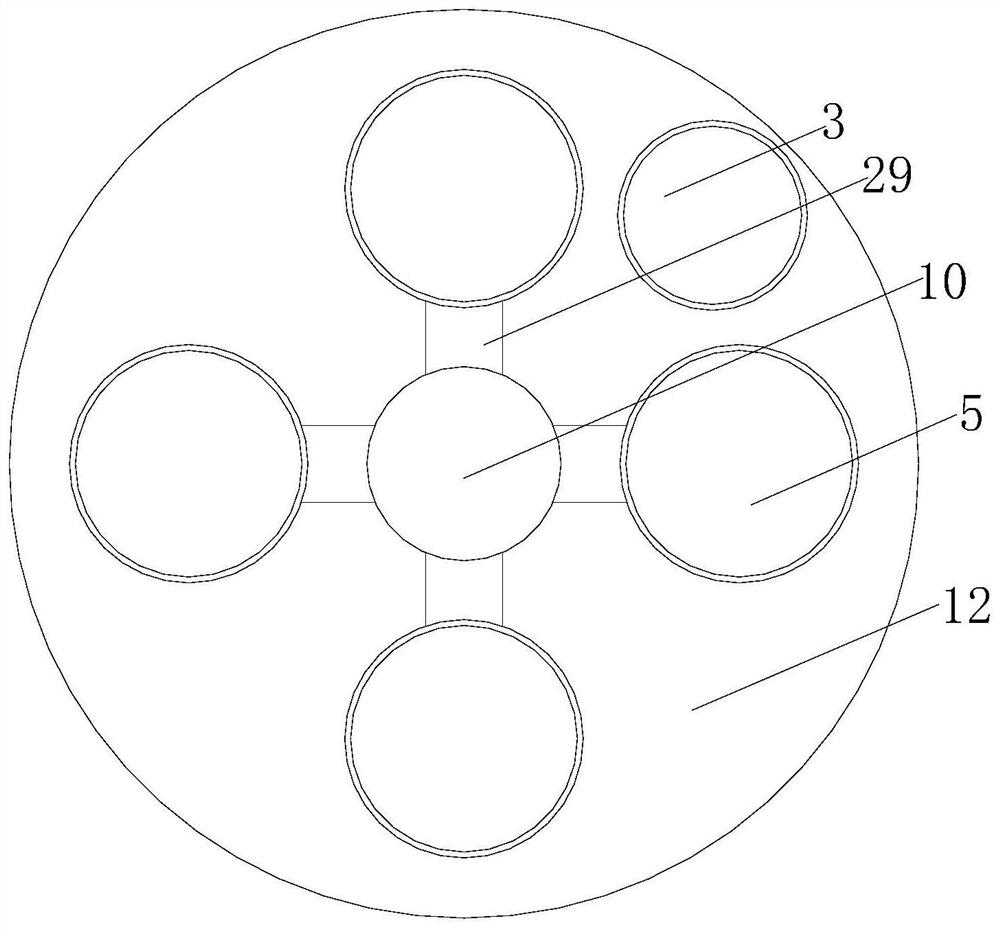

Full-automatic assembly device for battery negative electrode and use method of full-automatic assembly device

InactiveCN114221011APlay the role of heating and heat preservationReduce the effect of heating and insulationPrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

The invention discloses a full-automatic battery negative electrode assembling device and a using method thereof, and belongs to the technical field of assembling devices.The full-automatic battery negative electrode assembling device comprises a workbench, a spot welding piece welding disc, a gluing mechanism, an assembling piece assembling disc and evenly-distributed mechanical arms, and the spot welding piece welding disc, the gluing mechanism, the assembling piece assembling disc and the mechanical arms are all installed at the top of the workbench; and a copper needle inlet chute and a negative electrode bottom inlet chute are mounted at the top of the workbench. According to the glue coating device, the glue coating amount of the glue coating mechanism can be controlled through the arrangement of the amount control mechanism, glue used for glue coating is kept consistent all the time, too much or too little glue coating is avoided, and therefore the machining quality is improved, resource waste is reduced, the sealing ring can be heated and subjected to heat preservation through the arrangement of the air supply mechanism, and the service life of the sealing ring is prolonged. And the sealing ring cannot be heated before being assembled, so that the operation steps are reduced, the processing efficiency is improved, and the problem of poor practicability of the conventional full-automatic battery negative electrode assembling device is solved.

Owner:山东华太新能源电池有限公司

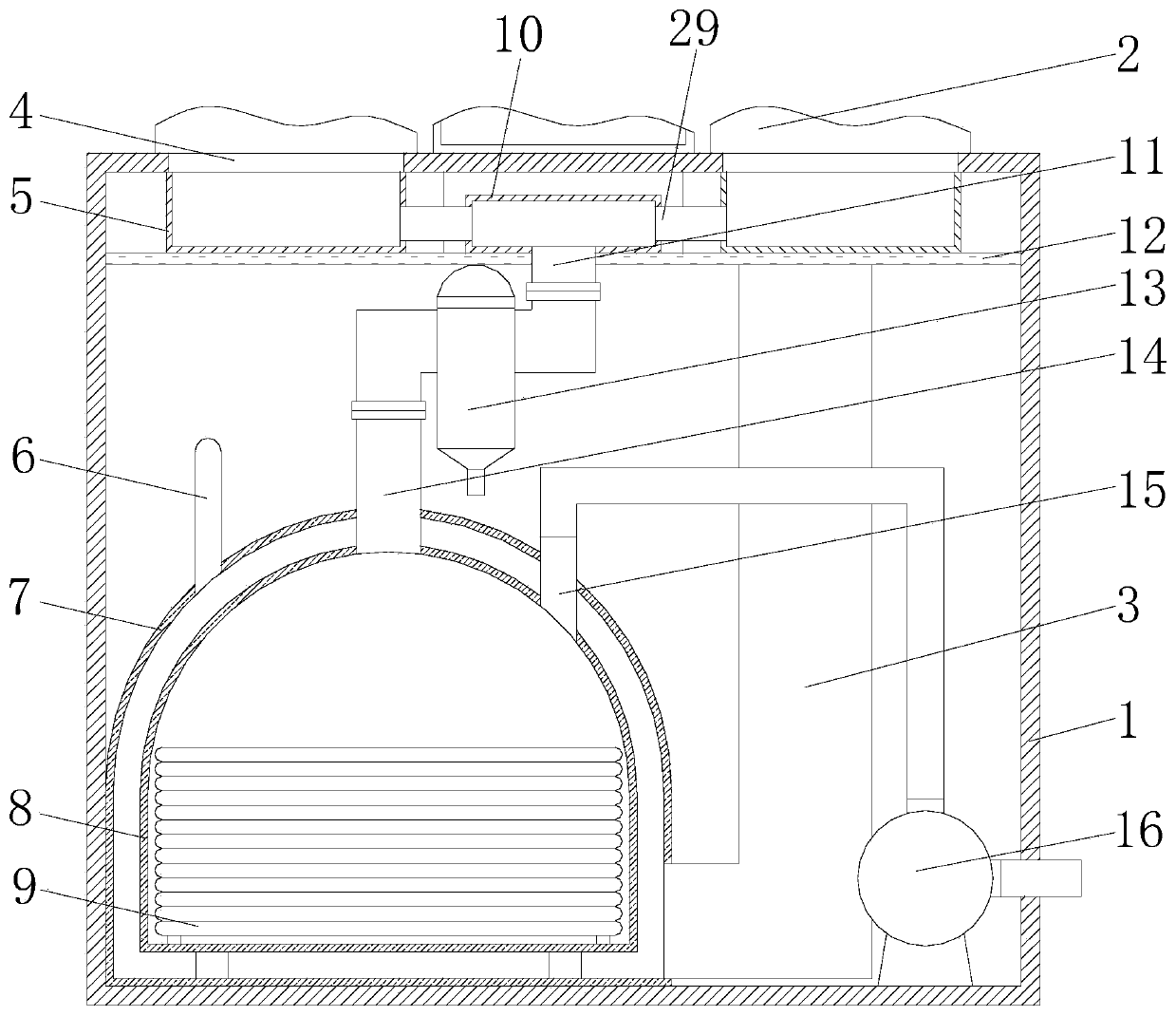

Heat accumulating type energy-saving boiler

InactiveCN113551216AAvoid wastingIncrease heating speedSteam generation using pressureBoiler cleaning apparatusThermodynamicsCombustion

The invention discloses a heat accumulating type energy-saving boiler, and belongs to the technical field of boiler equipment. The heat accumulating type energy-saving boiler comprises a base, a boiler body, a water-steam separator and a control box, a first smoke collecting chamber is arranged at the upper end of the boiler body, a smoke outlet is formed in the upper end of the first smoke collecting chamber, the boiler body is sleeved with a water inlet pipe, and the boiler body is further sleeved with a water outlet pipe. Hot air generated by heating a combustion cover by a combustion disc enters a second smoke collecting chamber, the hot air entering the second smoke collecting chamber enters a smoke guide pipe through a first connecting pipe, and the hot air entering a smoke guide pipe flows in the smoke guide pipe, then is discharged to the first smoke collecting chamber through a smoke outlet pipe, and finally is discharged through the smoke outlet; and when the hot air generated when the combustion cover is heated by the combustion disc flows in the smoke guide pipe, a heating pipe can be further heated and subjected to heat preservation, in this way, the heating speed of water in the heating pipe can be increased, and meanwhile, the hot air can be prevented from being directly discharged, so that waste of heat energy is avoided.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Aluminum alloy die-casting device capable of preventing internal residual liquid blockage

The invention discloses an aluminum alloy die-casting device for preventing internal residual liquid blockage, which comprises a base, one end of the base is fixedly connected with a fixed plate, the center of the fixed plate is fixedly provided with an air cylinder, a piston rod of the air cylinder is fixedly connected with a movable die-casting template, and the other end of the air cylinder is fixedly connected with a fixed die-casting template; the fixed plate and the fixed die-casting template are connected through a sliding rod, the sliding rod is sleeved with a movable die-casting template in a sliding mode, and the bottom of the movable die-casting template is connected with the base in a sliding mode. Hot water can heat and preserve heat of the stamping inner pipe, the situation that the stamping inner pipe catches cold and consequently molten aluminum in the stamping inner pipe is cooled and condensed is avoided, the gear disc drives the stamping pipeline to rotate in the fixed die-casting template, molten metal can collide with the pipe wall of the stamping inner pipe, and the molten metal is prevented from remaining on the surface of the pipe wall. The aluminum alloy die-casting device can effectively prevent residual aluminum liquid from blocking the stamping inner pipe, and the service life of the aluminum alloy die-casting device is prolonged.

Owner:艾斯迪(芜湖)材料技术有限公司

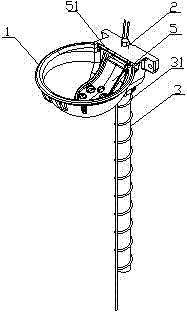

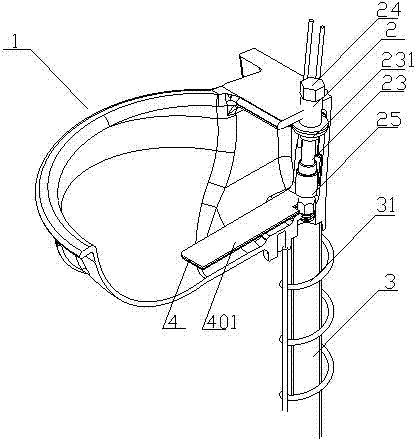

Dripping auxiliary heating device for drip bottle

InactiveCN103861182ARelieve painPlay the role of heating and heat preservationIntravenous devicesEngineeringBottle

The invention belongs to the technical field of medical appliances, and particularly relates to a dripping auxiliary heating device for a drip bottle. The dripping auxiliary heating device for the drip bottle comprises a drip bottle, wherein the drip bottle consists of a bottle body and a bottleneck. The dripping auxiliary heating device is characterized in that the bottle body is sleeved with a water groove; the bottleneck is exposed out of the water groove; a resistance wire is connected to the inner wall of the water groove; a plug is connected to the outer wall of the water groove through a lead; the lead is connected with the resistance wire; a temperature meter is connected to the inner wall of the water groove. The dripping auxiliary heating device has the beneficial effects that liquid infused into a patient can be heated, and the drip bottle can be heated to a temperature close to the body temperature of human body, so that the problem that the drip temperature is too low is solved, and pain of the patient is relieved.

Owner:任玉言

An Ultrasonic In-Situ Loading Device for Laser Melting Deposition Forming

ActiveCN113084167BAvoid damageIncrease the ultrasonic amplitudeAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlPhysical chemistry

An ultrasonic in-situ loading device for laser melting deposition shaping, relating to an ultrasonic in-situ loading device for laser melting deposition shaping. The purpose is to solve the problem that the directional solidification structure is easily produced in the forming process of the existing laser melting deposition equipment. The device is composed of a base plate, a temperature control board, an air-cooled chamber, a water-cooled chamber, a fixed base and an ultrasonic vibrator. The device of the invention generates a high-frequency ultrasonic field during the laser melting deposition forming process, realizes the homogenization of the structure of the shaped product and the refinement of the crystal grains, and improves the strength of the laser melting deposition product. At the same time, the present invention realizes the adjustable temperature of the substrate by providing a temperature-adjustable temperature control plate under the substrate. The invention is suitable for laser melting deposition shaping.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com