Heat accumulating type energy-saving boiler

A regenerative boiler technology, applied in steam boilers, boiler cleaning devices, cleaning heat transfer devices, etc., can solve the problems of low heating water efficiency, waste of heat energy, etc., and achieve the effect of quick cleaning and avoiding excessive dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

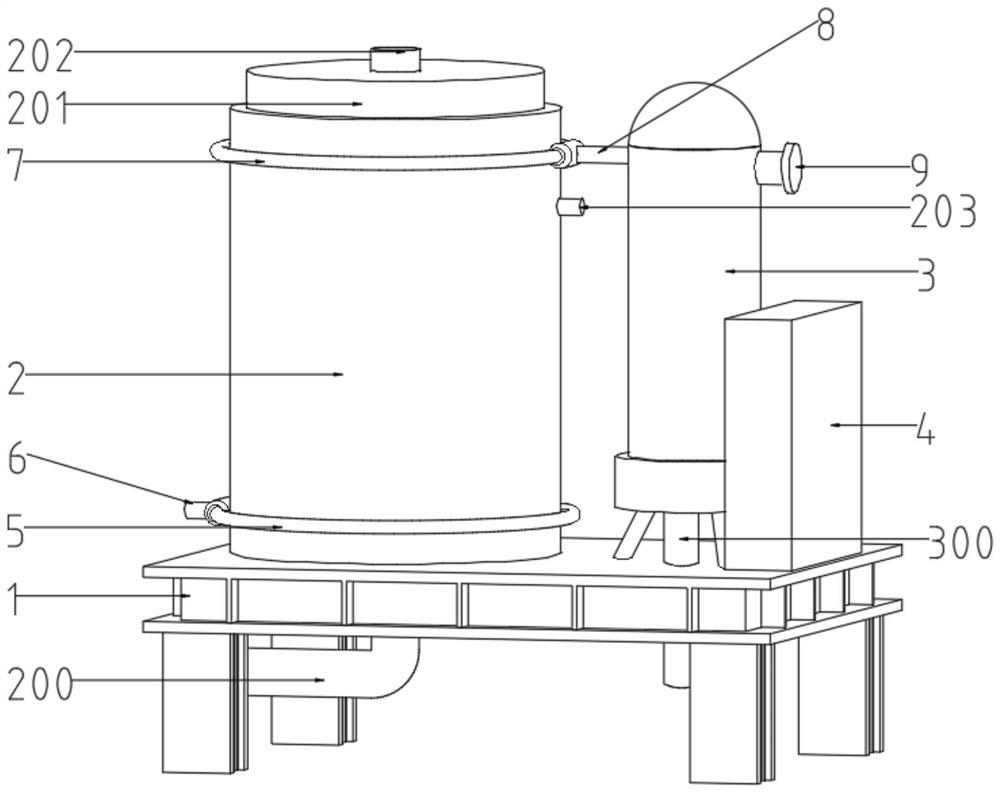

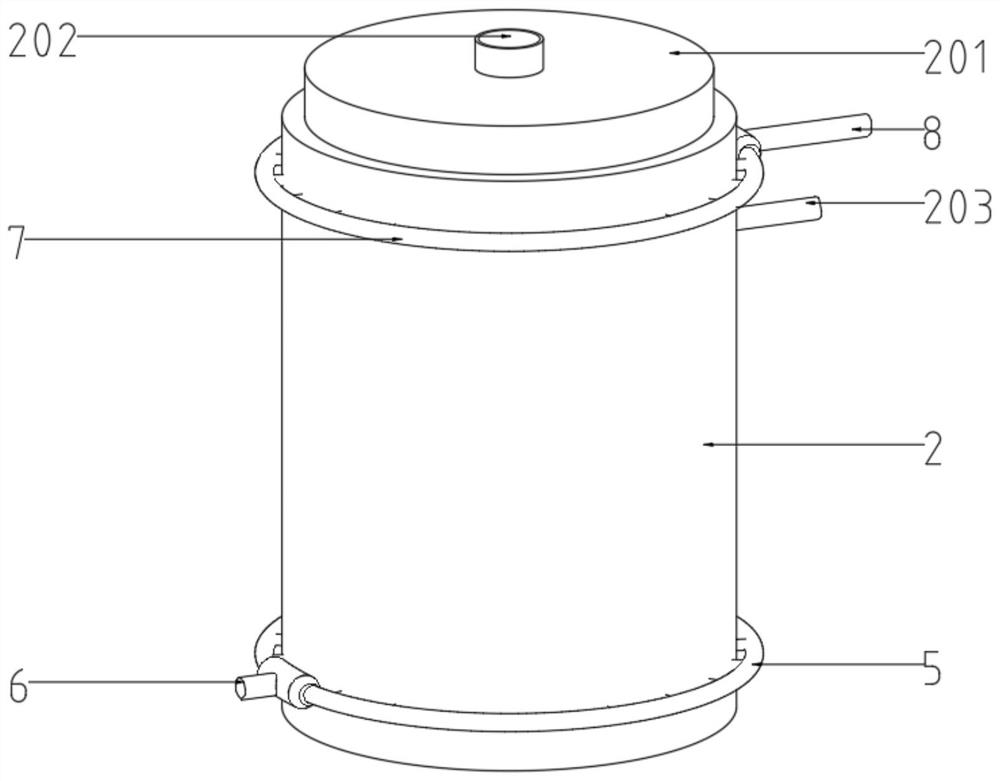

[0029] see Figure 1~3 , in an embodiment of the present invention, a regenerative energy-saving boiler includes a base 1, a furnace body 2, a water vapor separator 3, and a control box 4. The upper end of the furnace body 2 is provided with a first smoke collection chamber 201, and the first smoke collection chamber The upper end of the chamber 201 is provided with a smoke exhaust port 202, and the outside of the furnace body 2 is provided with a water inlet pipe 5, which is sleeved at the lower half of the furnace body 2, and the left end of the water inlet pipe 5 is provided with a water inlet 6. The water inlet 6 can be connected to external water supply equipment. The outside of the furnace body 2 is also provided with a water outlet pipe 7. The water outlet pipe 7 is located above the water inlet pipe 5. The water outlet pipe 7 is connected to the water vapor separator 3 through a transition pipe 8. The water vapor separator The right end of 3 is provided with a gas outl...

Embodiment 2

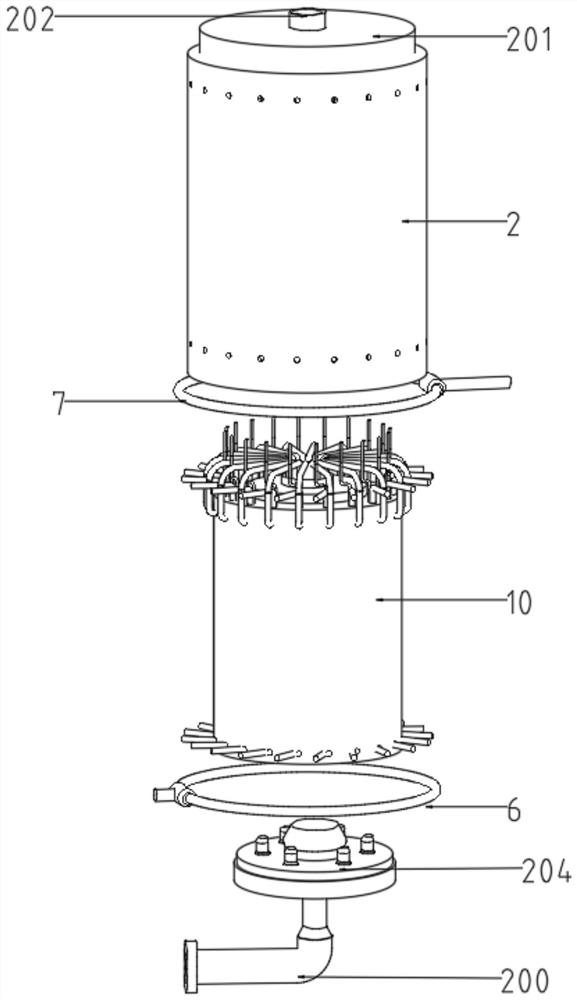

[0031] see Figure 4 , 5 , 6, 7, combined with the basis of embodiment 1, the heating structure includes several smoke guide pipes 101 and some heating pipes 102, the heating structure is composed of several smoke guide pipes 101 and heating pipes 102, and the smoke guide pipes 101 are wrapped in the heating pipe 102 Externally, the smoke guide pipe 101 is composed of two square pipes, which are connected by the second connecting pipe 110, and the ends of the two square pipes close to each other are provided with arc-shaped grooves, and the arc-shaped grooves are connected with the heating pipe 102 correspond to each other, the upper and lower ends of the heating pipe 102 are provided with connecting water pipes 103, the connecting water pipes 103 at the upper and lower ends of the heating pipe 102 are respectively located on the upper and lower sides of the smoke guide pipe 101, and the connecting water pipes 103 at the upper and lower ends of the heating pipe 102 respectivel...

Embodiment 3

[0033] see Figure 8 , 9 , in conjunction with the basis of embodiment 2, the inside of heating tube 102 is provided with heating inner tube 111, is provided with some reinforcing ribs 113 between heating inner tube 111 and heating tube 102, is provided with some round holes on some reinforcing ribs 113, heating The inner tube 111 is provided with a number of connectors 112 through the tube wall, and the plurality of connectors 112 are respectively located between the reinforcing ribs 113. The inside of the heating inner tube 111 is provided with a metal sleeve 114. The metal sleeve 114 is made of thin copper sheet. Several connecting plates 115 are provided between the sleeve 114 and the heating inner tube 111 , and the metal sleeve 114 is connected to the heating inner tube 111 through the connecting plates 115 .

[0034] The working principle of the present invention is:

[0035]When the present invention is in use, the combustion disc 204 is opened to heat the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com