Paint plating device and paint plating method for valve machining

A valve and body technology, which is applied in the field of varnishing devices for valve processing, can solve the problems of easy accumulation of paint on contact points and uneven varnishing, etc., and achieve the effect of avoiding uneven spraying and ensuring quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

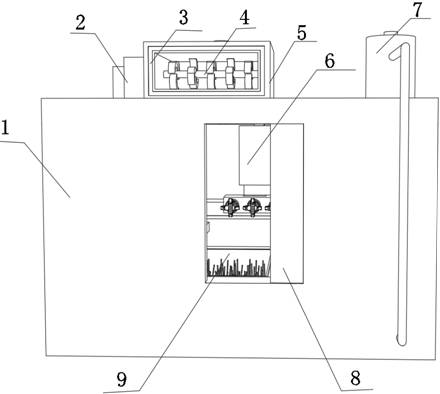

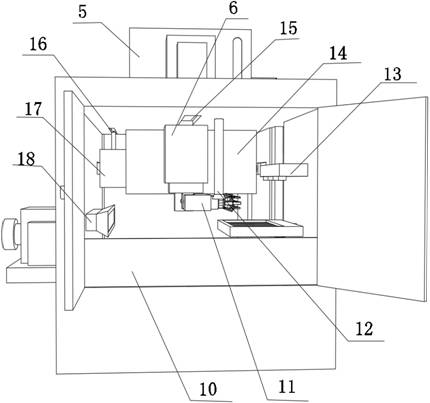

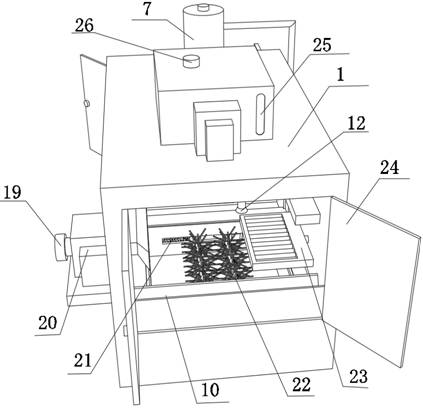

[0040] A paint crossing device for valve processing, such as Figure 1-5 As shown, including the body 1, the top inner wall of the body 1 is provided with a first electric chute 15, the inner wall of the first electric chute 15 is slidably connected with a hydraulic cylinder 6 through a slider, and the extension end of the hydraulic cylinder 6 is connected through a connecting column. The connecting seat 11 is rotatably connected, and the bottom inner wall of the connecting seat 11 is fixed with a third motor 40 by bolts. The inner wall of one side of the connecting seat 11 is connected with three gears 32 through the rotating shaft, and the outer walls of the three gears 32 mesh with each other. One of the gears The input end of 32 is connected with the output end of the 3rd motor 40 through connecting shaft, and one side outer wall of connection base 11 is connected with three clamping hands 41 through rotating shaft rotation, and the input end of three clamping hands 41 is c...

Embodiment 2

[0046] A kind of embodiment 1 is used for the method for crossing the paint of valve processing with the paint crossing device, such as Figure 1-5 shown, including the following steps:

[0047] S1: adding paint to the first material box 5;

[0048] S2: Place the valve in the net cage 17, start the cleaning spray 28 and the second motor 31, drive the net cage 17 to clean and dry the water during the rotation process;

[0049] S3: Take out the cleaned valve, and fix one end of the valve with the clamping hand 41;

[0050] S4: Start the hydraulic cylinder 6 to drive the valve to reciprocate up and down to paint, and the brush wheel 22 passively paints the valve;

[0051] S5: start the blower fan 20 and the third motor 40, and dry the outside air after the valve after the paint has been filtered out of impurities during the rotation process;

[0052] S6: Put the painted valve on the holding frame 23, spray and dry one end of the unpainted valve;

[0053] S7: Open the second box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com