Automatic welding machine

A technology of automatic welding machine and welding mechanism, which is applied in the direction of welding equipment, resistance welding equipment, resistance electrode holder, etc., which can solve the problems that the product quality cannot be guaranteed uniformly, the degree of automation is not high, and the production cost is increased, so as to shorten the cooling time. The effect of reducing time, shortening processing time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

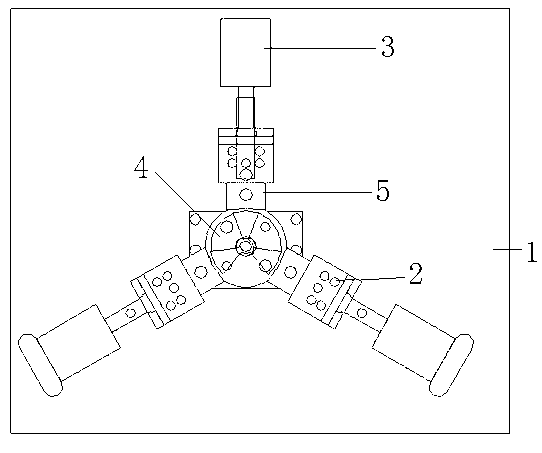

[0034] Such as figure 1 As shown, the automatic welding machine disclosed in this embodiment includes a workbench 1, a welding mechanism arranged on the workbench and a control system for controlling the welding mechanism. The welding mechanism includes a central electrode and three moving parts arranged around the central electrode. Electrode 2, the movable electrode includes a slide rail, a movable electrode block slidably installed on the slide rail, and a movable electrode cylinder 3 for driving the electrode block to slide. system connection.

[0035] During implementation, the workpiece to be processed is socketed on the central electrode, and the control system controls the movable electrode to contact the workpiece to be processed. After the central electrode and the movable electrode are respectively connected to the two poles of the power supply, welding can be realized. One or more workpieces can be fixed on the central electrode, and one or more workpieces can als...

Embodiment 2

[0046] Compared with the automatic welding machine disclosed in Embodiment 1, the automatic welding machine disclosed in this embodiment differs in that in this embodiment, two welding mechanisms are provided on the workbench, and each welding mechanism includes four movable electrode.

[0047] In addition, in this embodiment, a pressing mechanism for positioning and fixing during welding is provided above the center electrode. This is because for workpieces with complex shapes on the central electrode block or movable electrode block, it is necessary to use a pressurizing mechanism to pressurize it from above the central electrode during pressurization to realize positioning and fixing.

[0048] The pressurizing mechanism in this embodiment includes a mounting frame fixed on the workbench, a pressurizing cylinder arranged on the mounting frame, and a pressing plate arranged on the push rod of the pressurizing cylinder, and the pressing plate is opposite to the central electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com