Patents

Literature

110results about How to "Avoid uneven spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

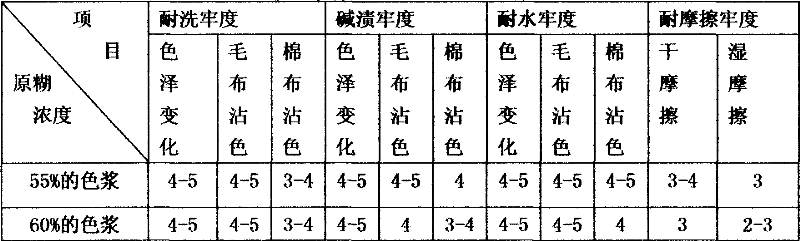

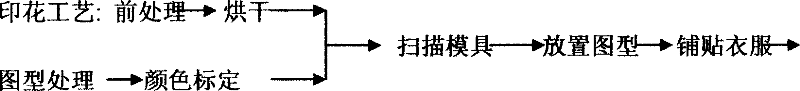

Digit printing processing method of cashmere produce

The present invention relates to a digital printing processing method for cashmere products, which comprises the following steps: scanning a garment blank to manufacture a mould, pattern processing, color calibration, placing the pattern simulation to be printed at a requested position by the mould with a computer software, extending and filling the garment blank according to the mould, anti-scanning the garment blank extended and filled according to the mould, checking the printing position of the pattern to be printed at the garment blank with a computer software, digital printing, drying a pre-steaming garment blank, steaming, washing using water, drying, slopwork and finishing. Said method is characterized in that: a pretreatment process is set before scanning a garment blank to manufacture a mould, wherein the prescription of the pretreatment solution is that there contains, based on the weight, an adhesion additive of 2-5%, a printing oil of 2-3%, a brightening agent of 2-3%, a paste of 55-60%, tartaric acid of 3%, urea of 5%, and the balance water. The main merits of said present invention are as follows: a phenomenon of painting unequality due to a nozzle blocking caused by upright fuzz during a digital printing process for cashmere products is resolved, positioning and fixed-point printing is achieved correctly, and the intention of preventing dyes polluting fabrics is reached.

Owner:INNER MONGOLIA ORDOS RESOURCE

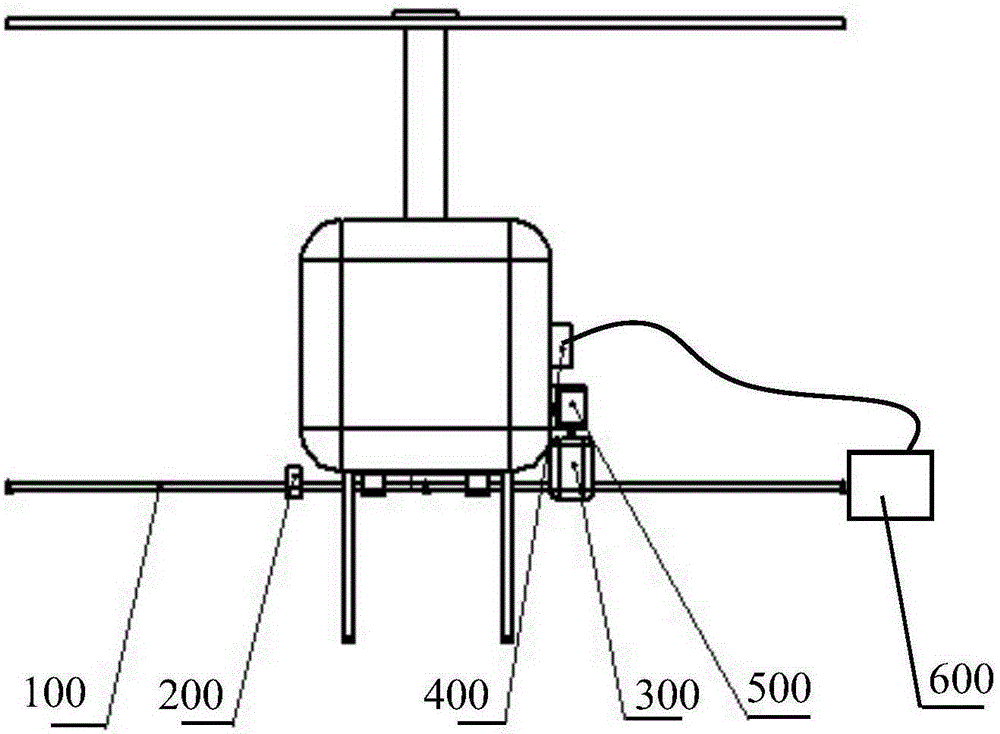

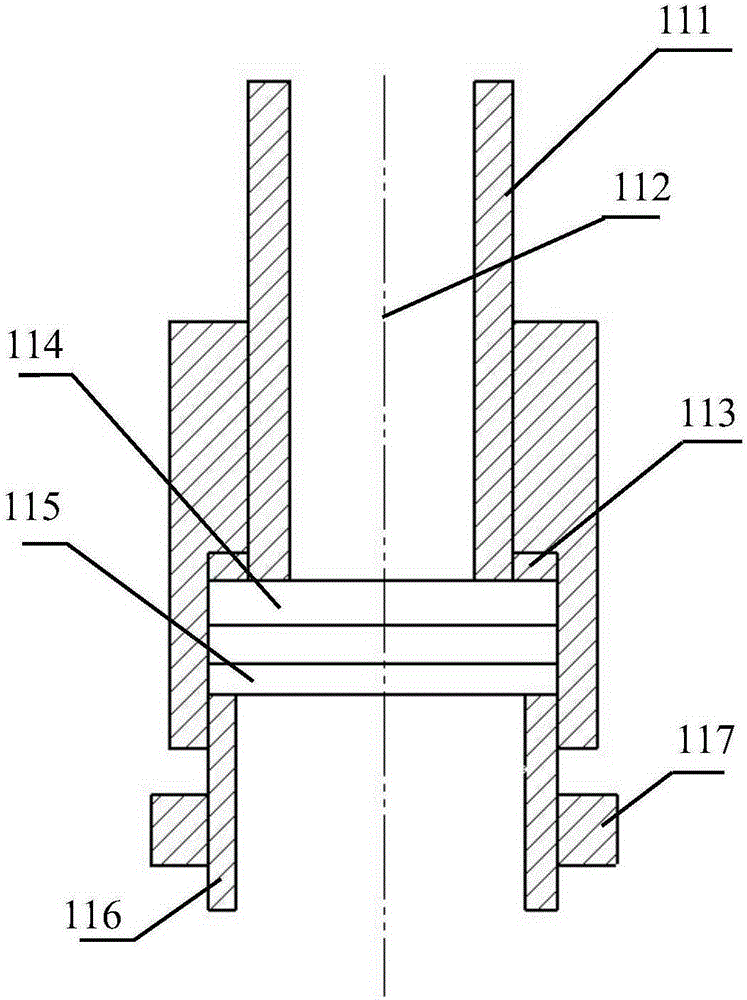

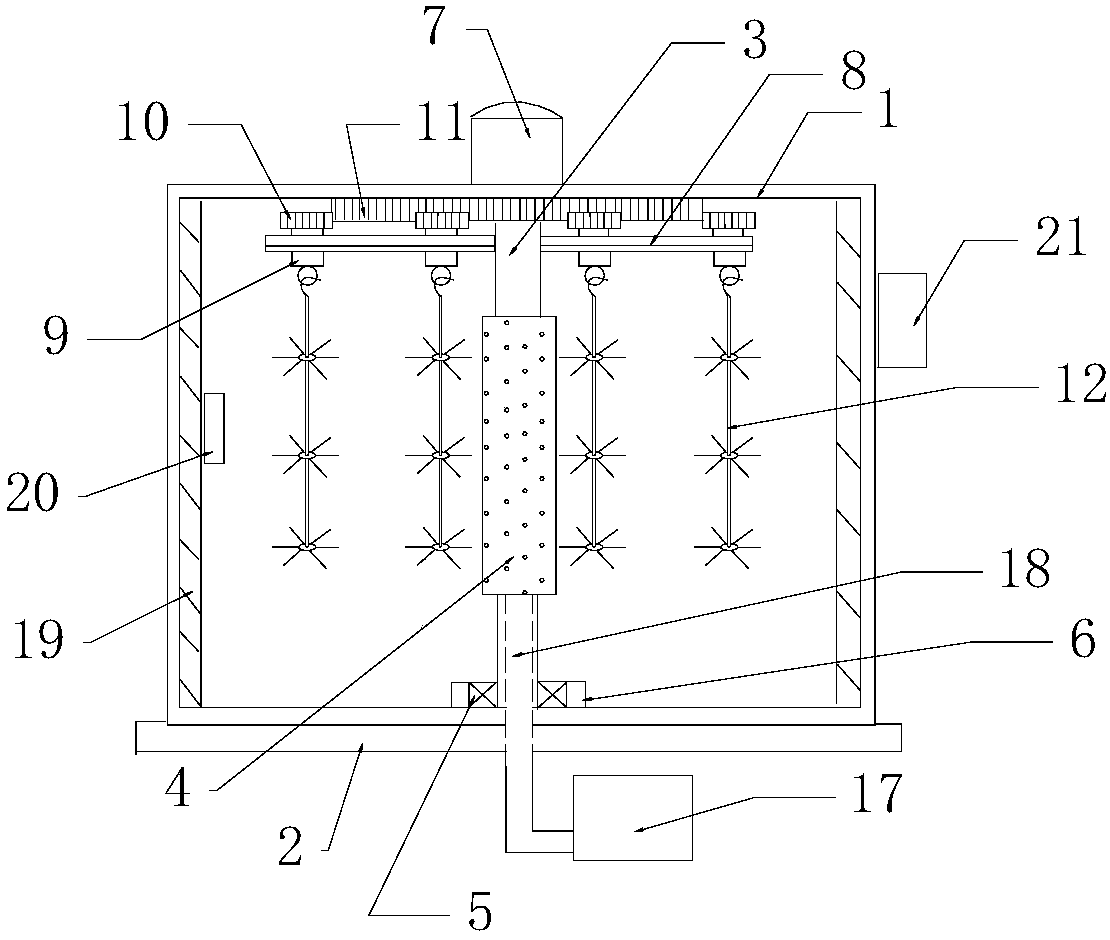

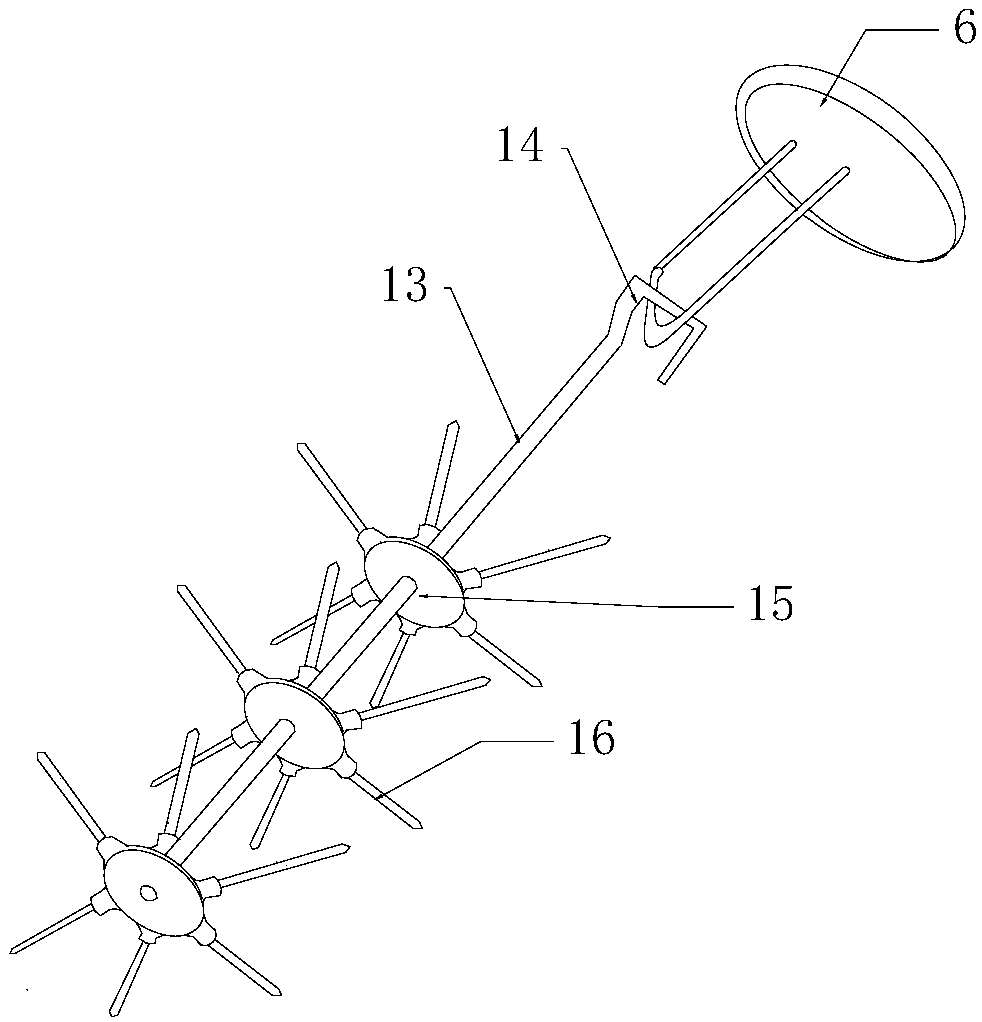

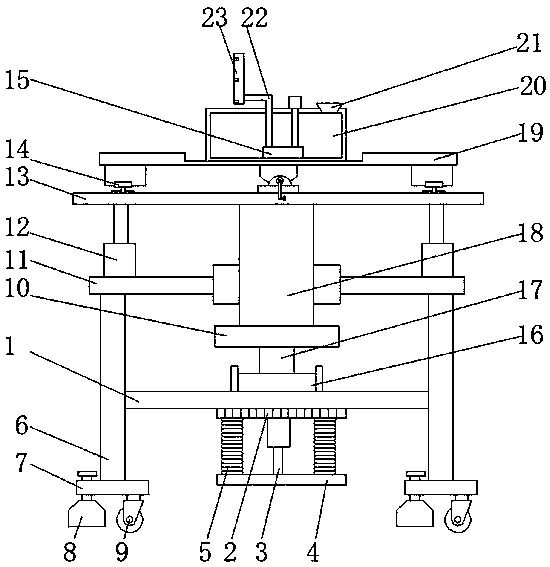

Directional spraying device and directional spraying control method for plant protection plane

InactiveCN105217038AIncrease profitAvoid uneven sprayingAircraft componentsLaunching weaponsGyroscopeMeasuring instrument

The invention discloses a directional spraying device for a plant protection plane. The directional spraying device comprises a spraying frame, a telescopic connecting rod, a rotating angle motor, an angle inclination measuring instrument and a system control module. The spraying frame is arranged at the bottom of the plant protection plane and comprises nozzles arranged in parallel and upper and lower flow adjusting pieces used for adjusting the flow of the nozzles in front-back inclination of the plant protection plane. The telescopic connecting rod is arranged between the spraying frame and the plant protection plane, and the left-right inclination angle of the spraying frame is adjusted by controlling the telescoping length of the telescopic connecting rod. The rotating angle motor is arranged at one end of the spraying frame, and the spraying frame is made to rotate around the axis by controlling the rotating angle of the rotating angle motor. The angle inclination measuring instrument is arranged in the middle of the spraying frame and used for detecting the inclination direction and inclination angle of the plant protection plane. The system control module is connected with the angle inclination measuring instrument and used for recording electrical signals detected by an inertia gyroscope and controlling the telescoping length of the telescopic connecting rod and the flow of the nozzles. The invention further discloses a directional spraying control method for the plant protection plane. The spraying angle can be accurately adjusted by adjusting the flow of the nozzles.

Owner:JILIN ACAD OF AGRI MACHINERY

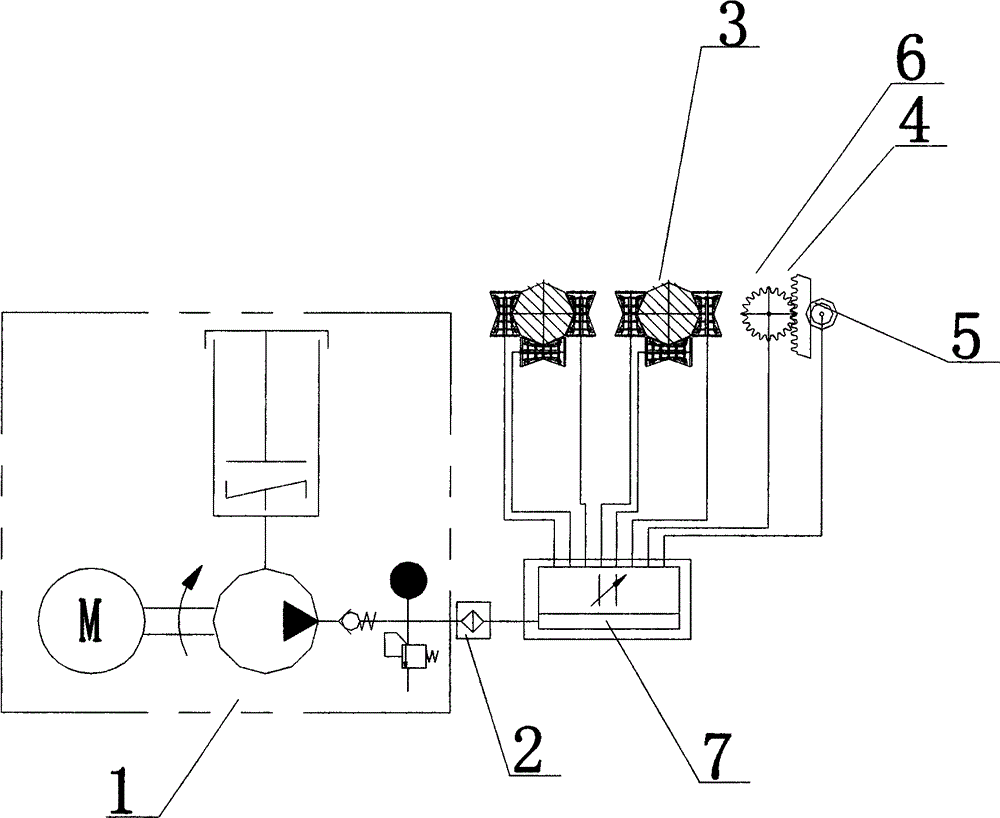

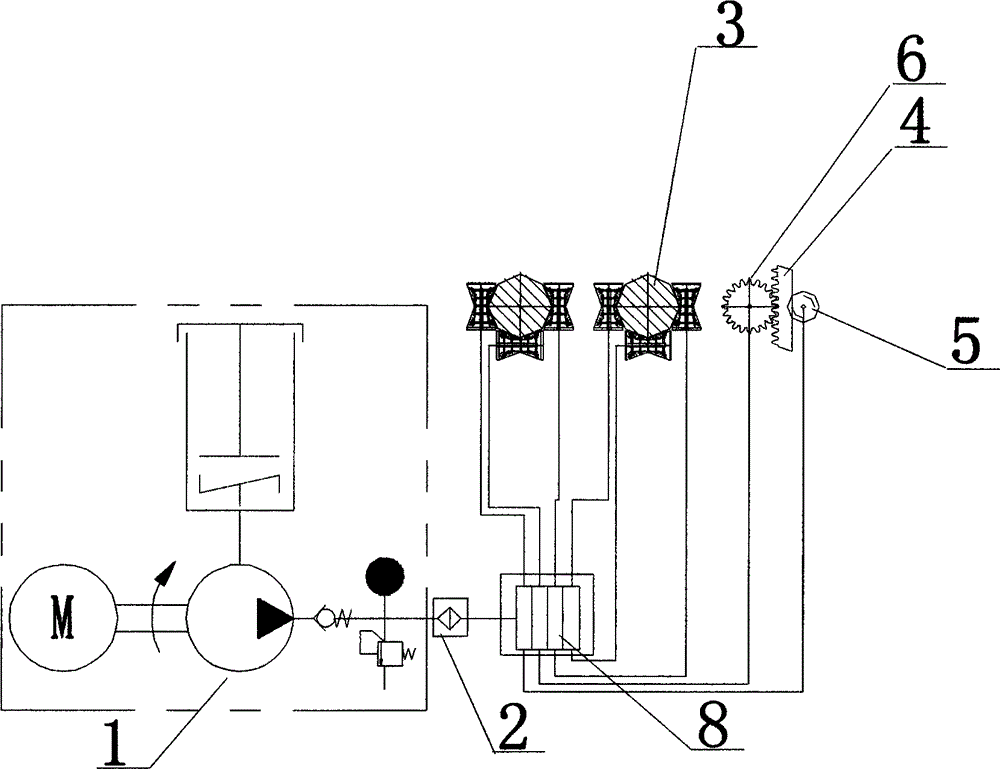

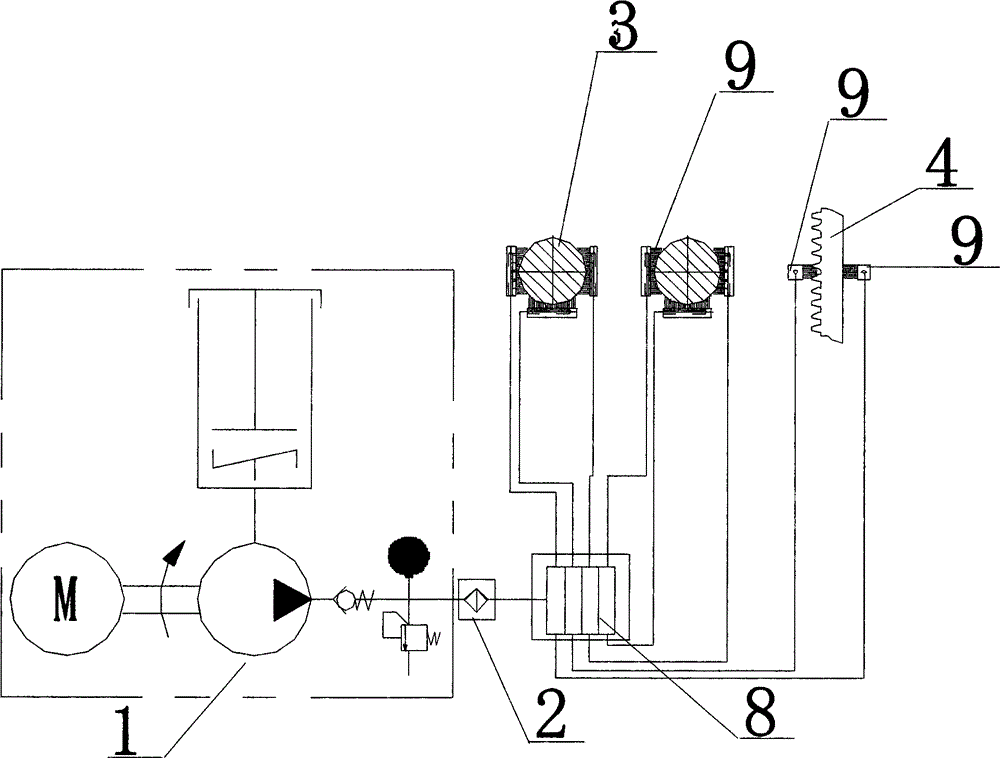

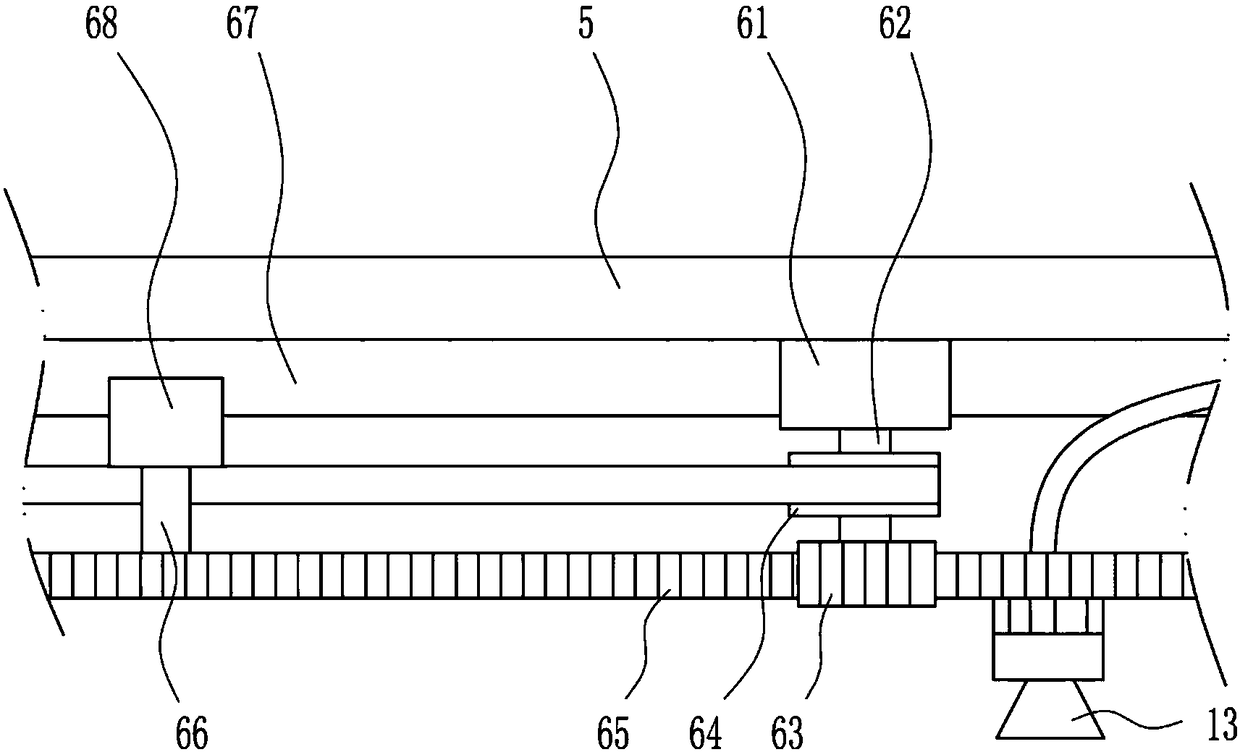

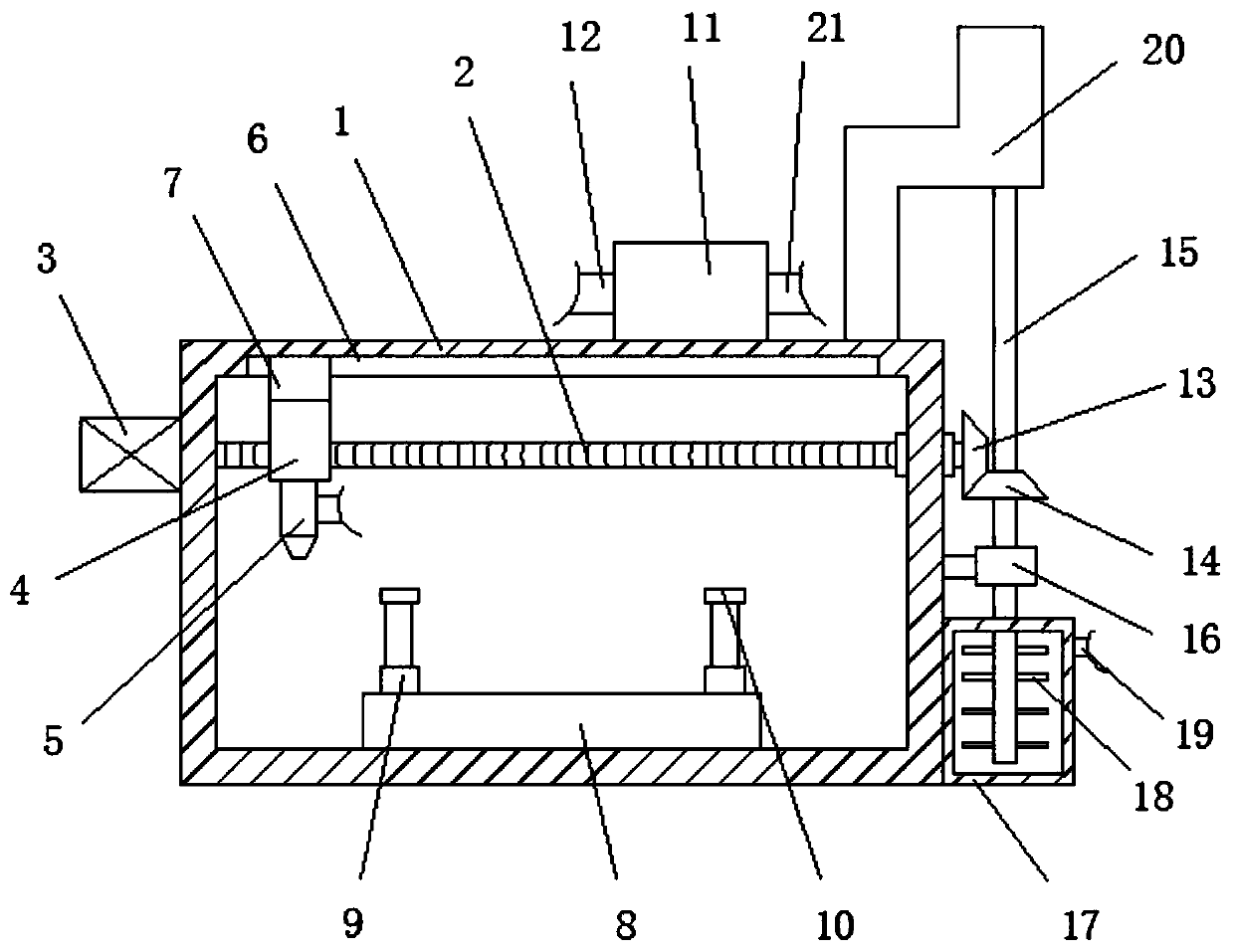

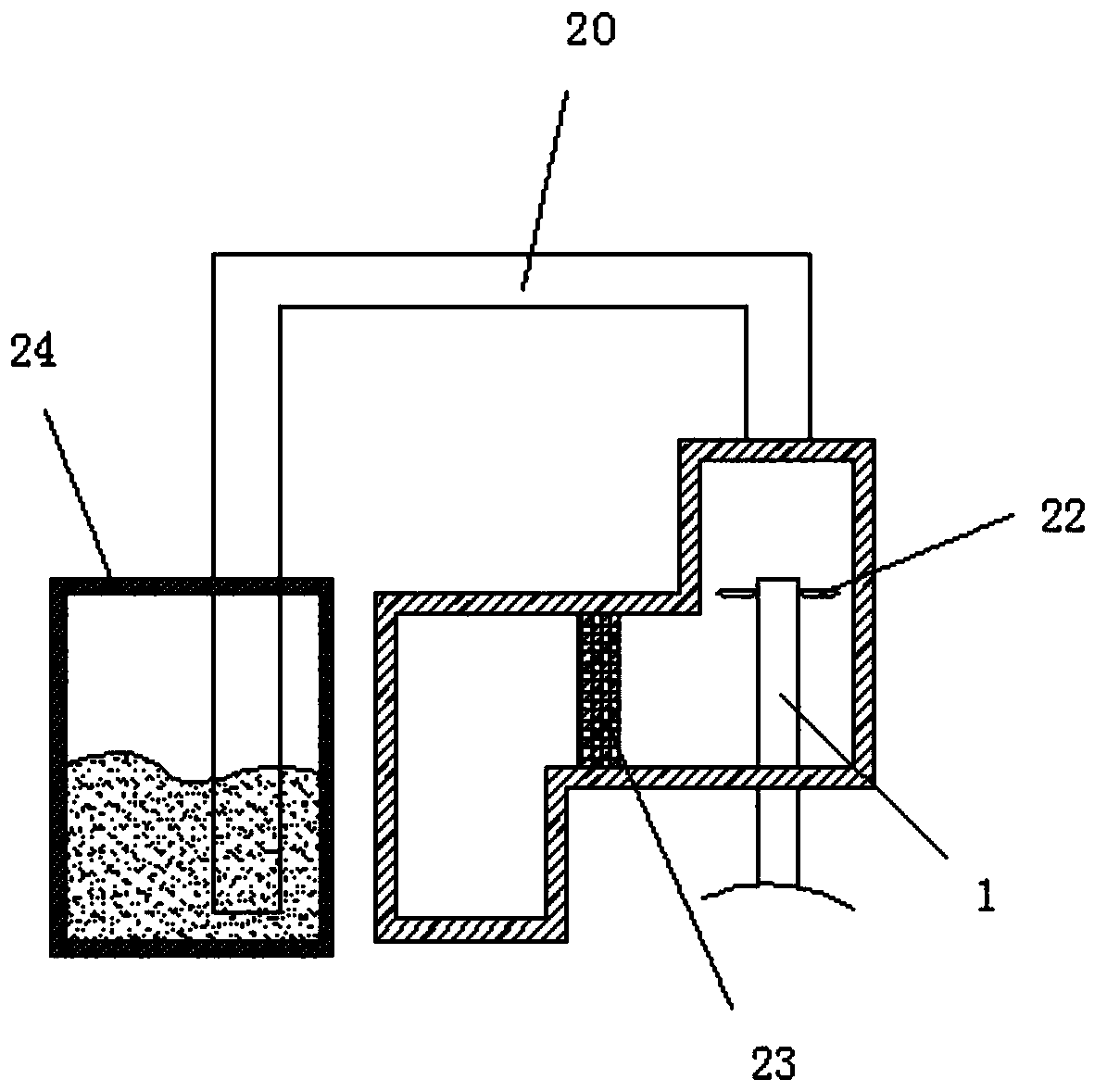

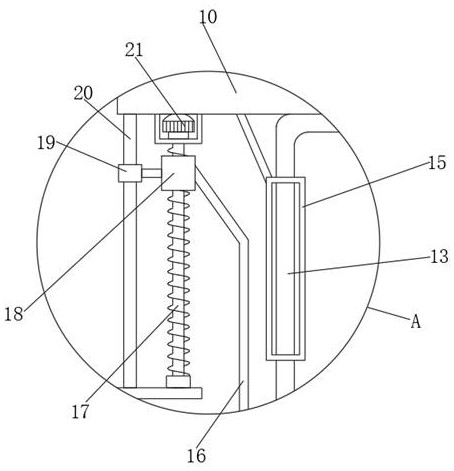

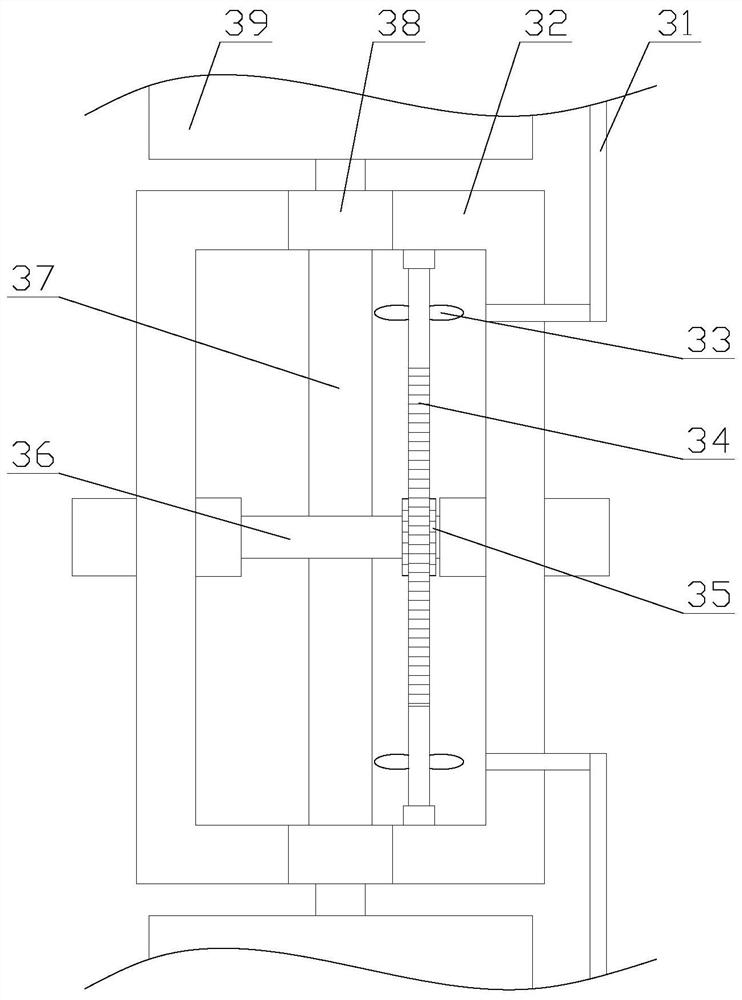

Multi-variety centralized lubrication system for construction elevator

InactiveCN103910268AUniform displacementAvoid uneven sprayingElevatorsDistribution equipmentLubricationOil and grease

The invention discloses a multi-variety centralized lubrication system for a construction elevator. The multi-variety centralized lubrication system comprises an electric lubricating pump communicated with a filter. The filter is communicated with a distributor communicated with a lubricating accessory. The lubricating accessory is a combined component of a lubricating guide brush or lubricating guide roller and a lubricating guide gear. The lubricating guide brush is provided with a cavity inside, and the cavity is communicated with the distributor. The multi-variety centralized lubrication system has the advantages that the pressure and discharging amount of lubricating grease on lubricating points are even and consistent, defects of unevenness and nonregulation of an existing system can be avoided; usage of the lubricating grease can be saved effectively (the lubricating grease evenly coats on contact faces of guide rails or racks through the guide roller), and defects that no accurate target exists and the lubricating grease is wasted heavily according to the existing system are avoided; when the lubricating grease arranged in an electric lubricating pump of the existing system is in a low level, defects that no grease is sprayed out, spraying power is powerless and spray amount is small exit, and the defects can be overcome by the aid of the novel system.

Owner:WENZHOU WEIDONG LUBRICATION EQUIP

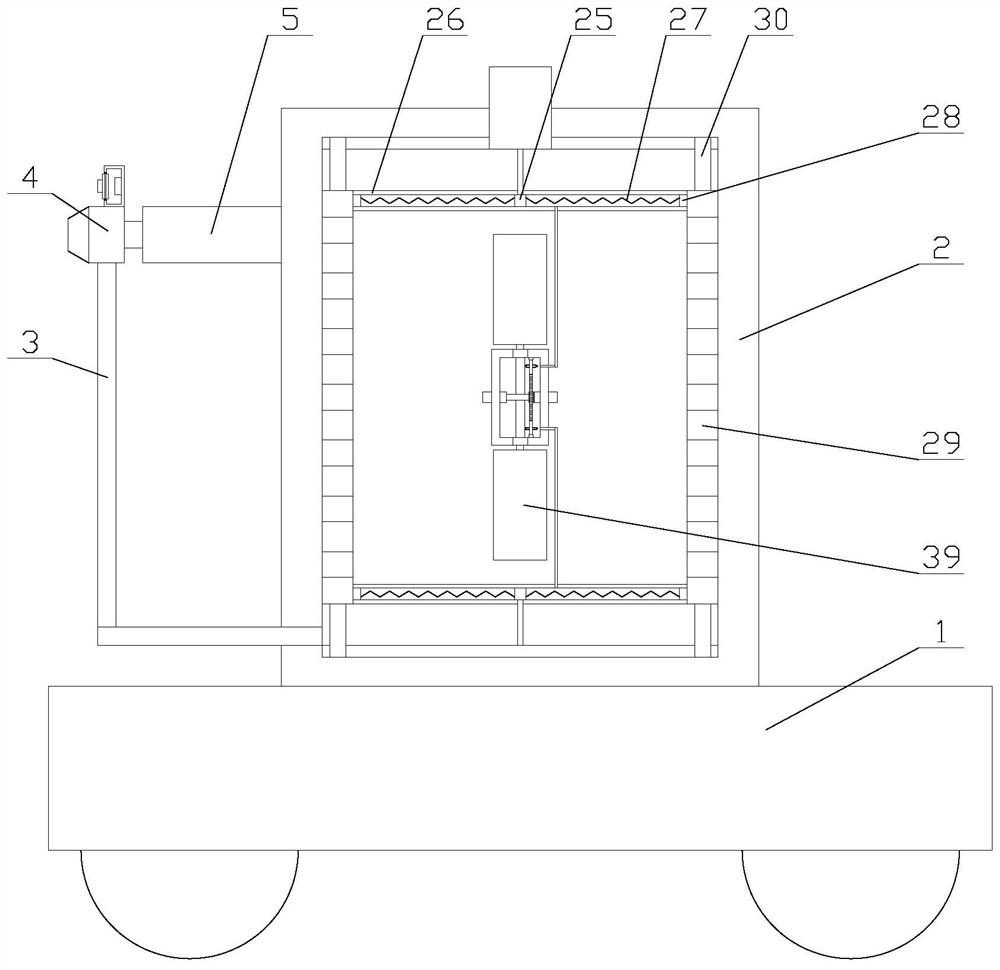

Atomizing oil injection mixing device for feed production

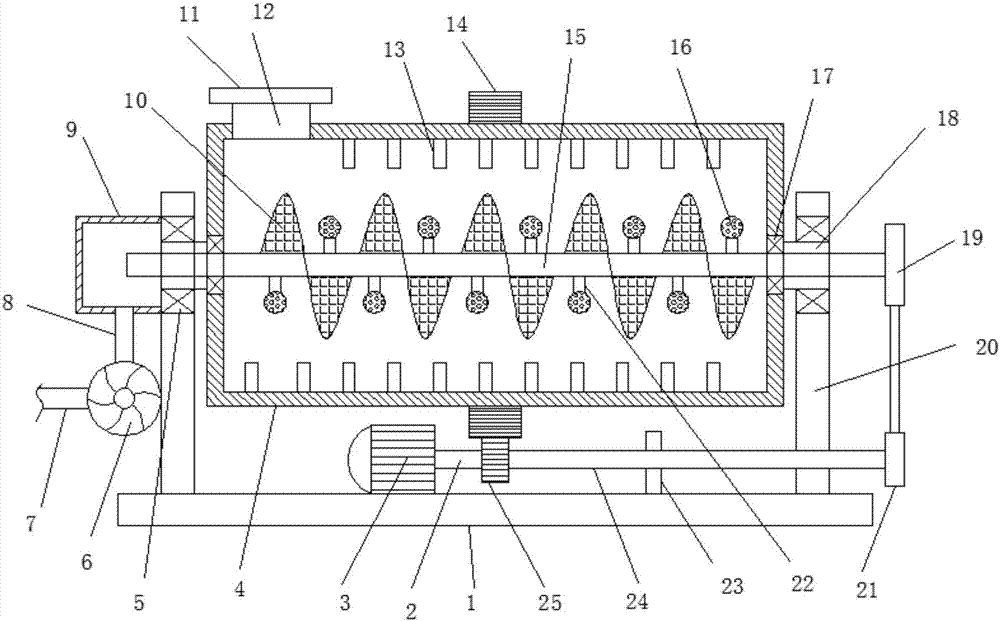

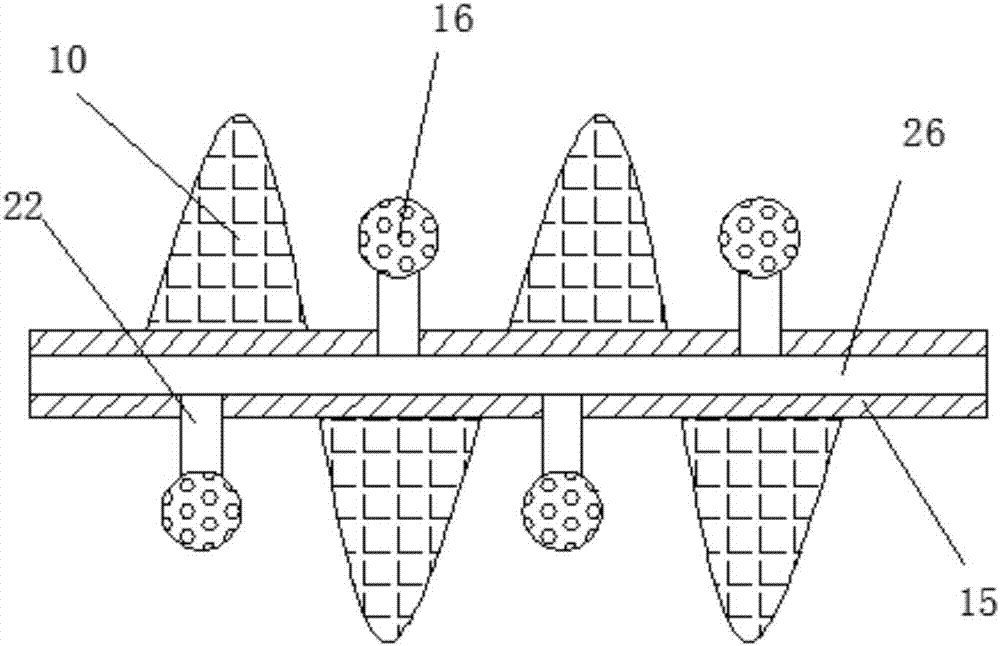

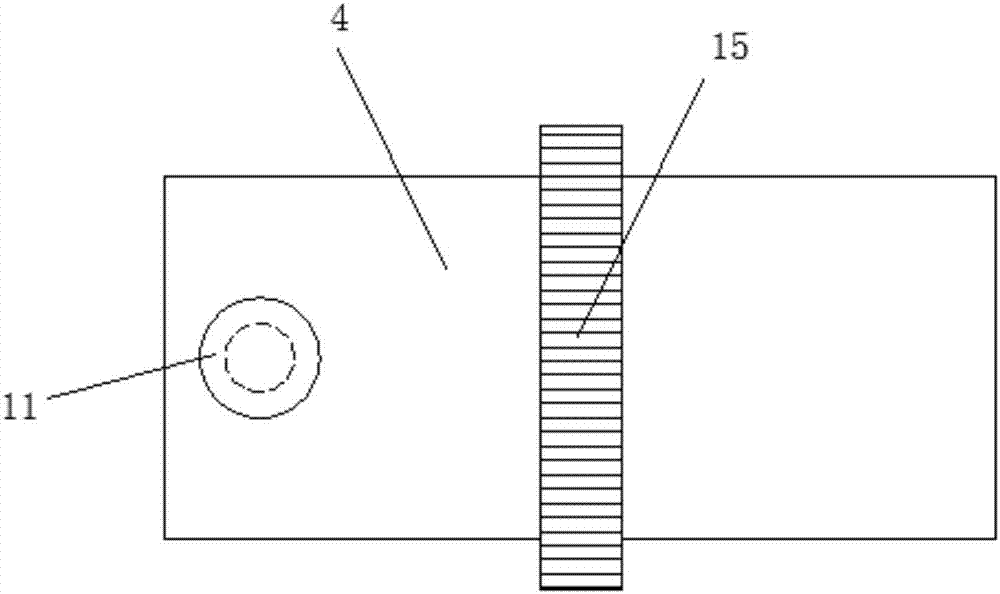

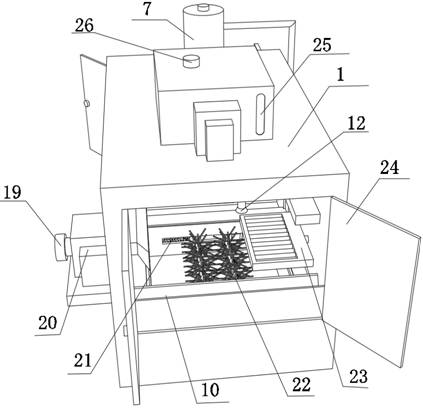

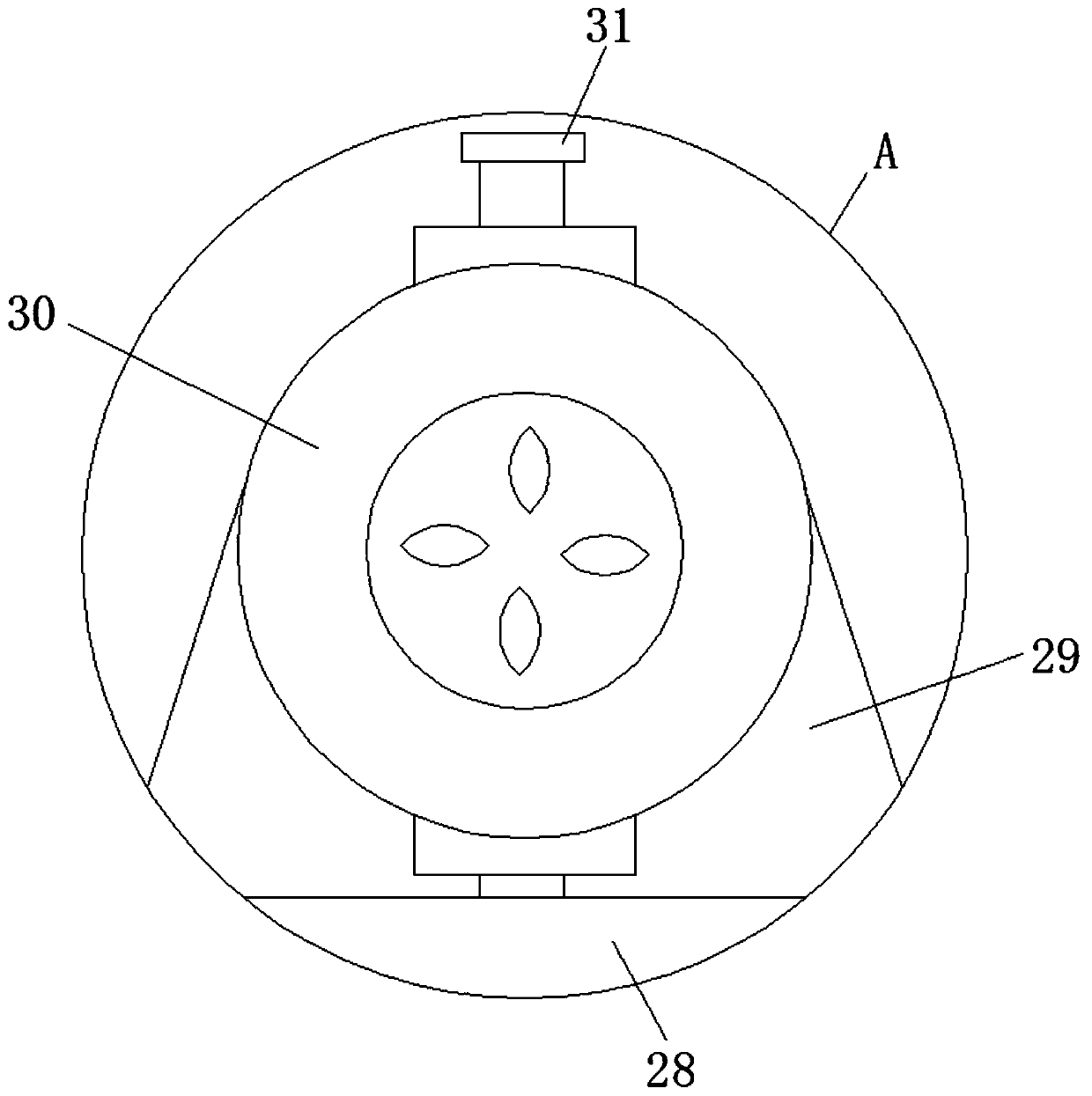

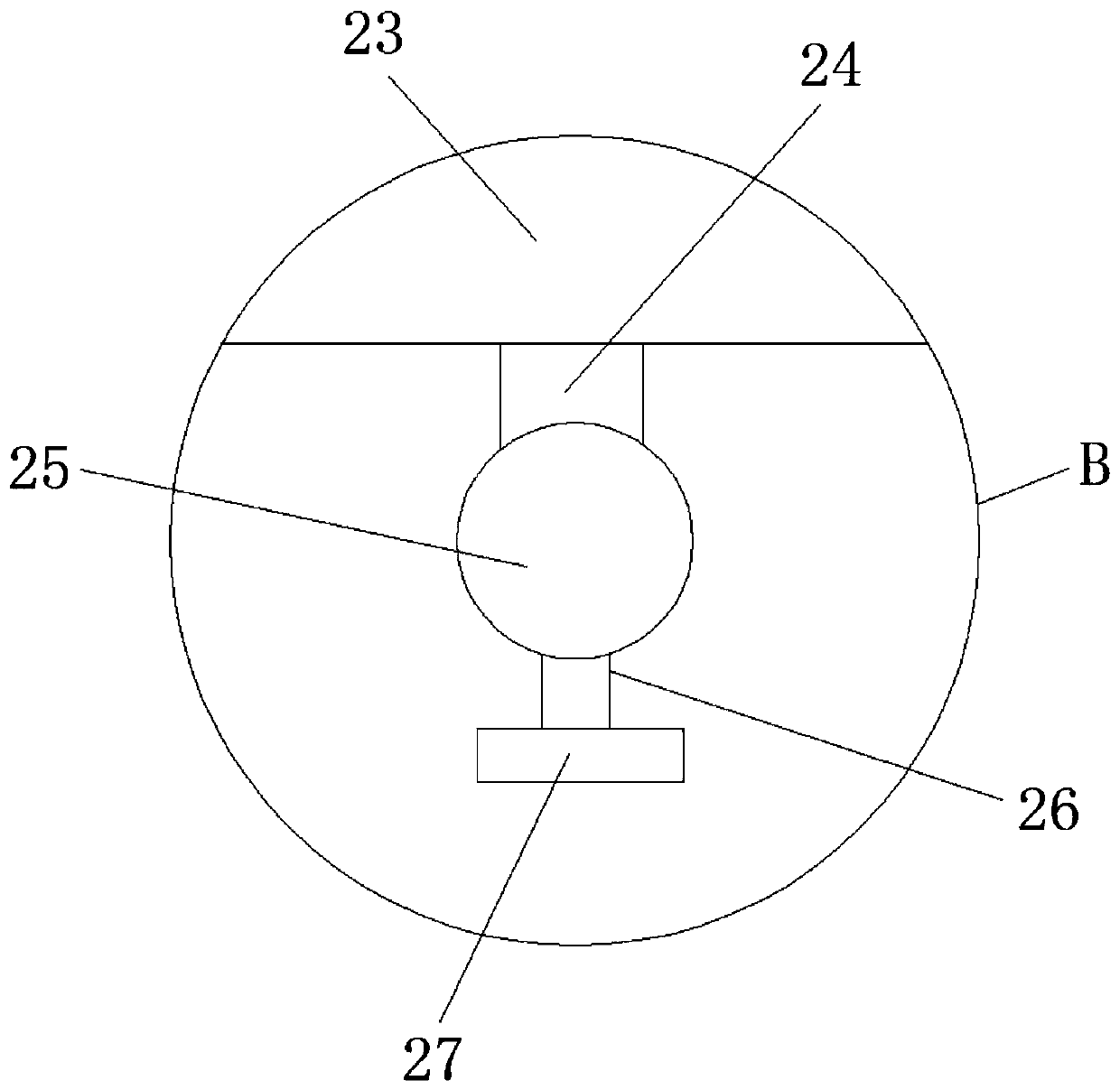

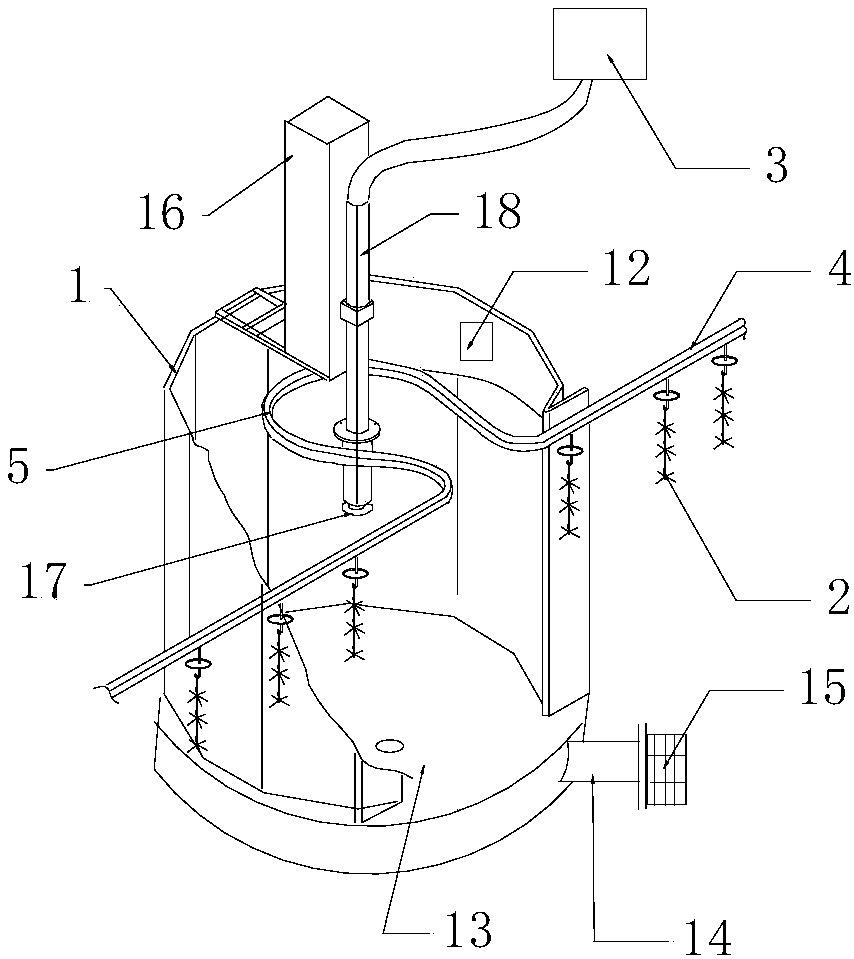

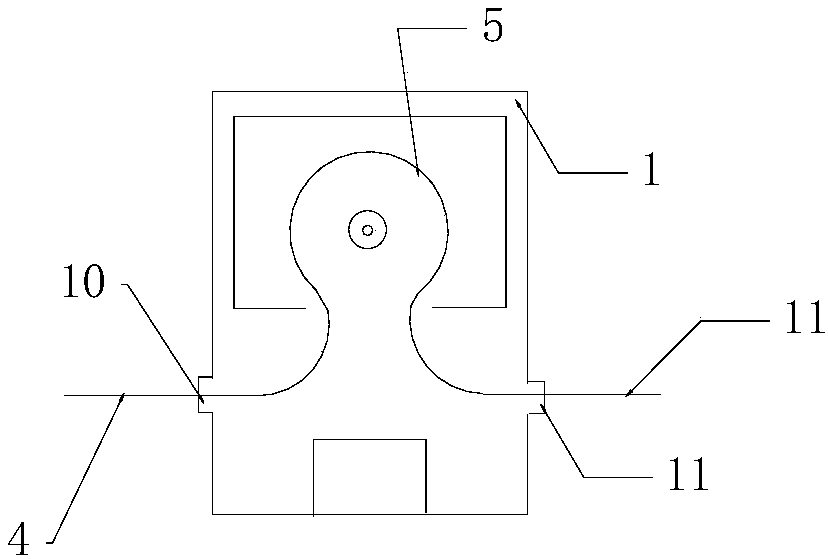

InactiveCN107362732AImprove fuel injection effectImprove processing qualityRotating receptacle mixersFeeding-stuffDrive shaftFuel tank

The invention discloses an atomizing oil injection mixing device for feed production. The atomizing oil injection mixing device comprises a support base, wherein support frames are connected to two sides of the upper end of the support base; the upper end of each support frame is connected with a rotary sleeve; an oil injection tank is connected between the two rotary sleeves; a stirring shaft is arranged in the oil injection tank; mixing screws and oil injection pipes are uniformly connected to the middle of the stirring shaft at intervals; the right end of the stirring shaft penetrates the corresponding rotary sleeve to be connected with a driven pulley; a driving motor is connected to the middle of the upper end of the support base; the right end of the driving motor is connected with a driving shaft; the right end of the driving shaft is connected with a driving gear; the upper end of the driving gear meshes with a driven ring gear; the right end of the driving gear is connected with a rotating shaft; the right end of the rotating shaft is connected with a driving pulley; an oil inlet tank is mounted at the upper end of the left side of the support frame at the left end; the middle of the lower end of the oil inlet tank is connected with an oil inlet pipe; and the left end of an oil guide pump is connected with an oil guide pipe. The atomizing oil injection mixing device can perform atomizing oil injection on a feed while mixing and stirring the feed, so that the processing quality of the whole feed is improved.

Owner:郑州秉茂达电子科技有限公司

Energy-saving environmentally-friendly type wood painting device

InactiveCN108187948AReduce consumptionReduce power consumptionLiquid spraying apparatusEnvironmentally friendlyEnergy consumption

The invention relates to a painting device, in particular to an energy-saving environmentally-friendly type wood painting device. The energy-saving environmentally-friendly type wood painting device aims at achieving the technical effects that paint is saved, and energy consumption is low. The energy-saving environmentally-friendly type wood painting device comprises a first mounting plate, a support seat, a storage plate, a first support plate, a second mounting plate, a moving mechanism, a first linkage mechanism, a stirring mechanism, a second linkage mechanism, a liquid conveying mechanism, a third mounting plate, a second support plate, a spray head and a stirring frame. The support seat is fixedly connected to the top of the first mounting plate in the vertical direction. The storageplate is fixedly connected to the top of the support seat. The energy-saving environmentally-friendly type wood painting device has the beneficial effects that paint is rapidly sprayed to wood; and efficiency is high, energy is saved, and environmental protection is achieved.

Owner:崔建凯

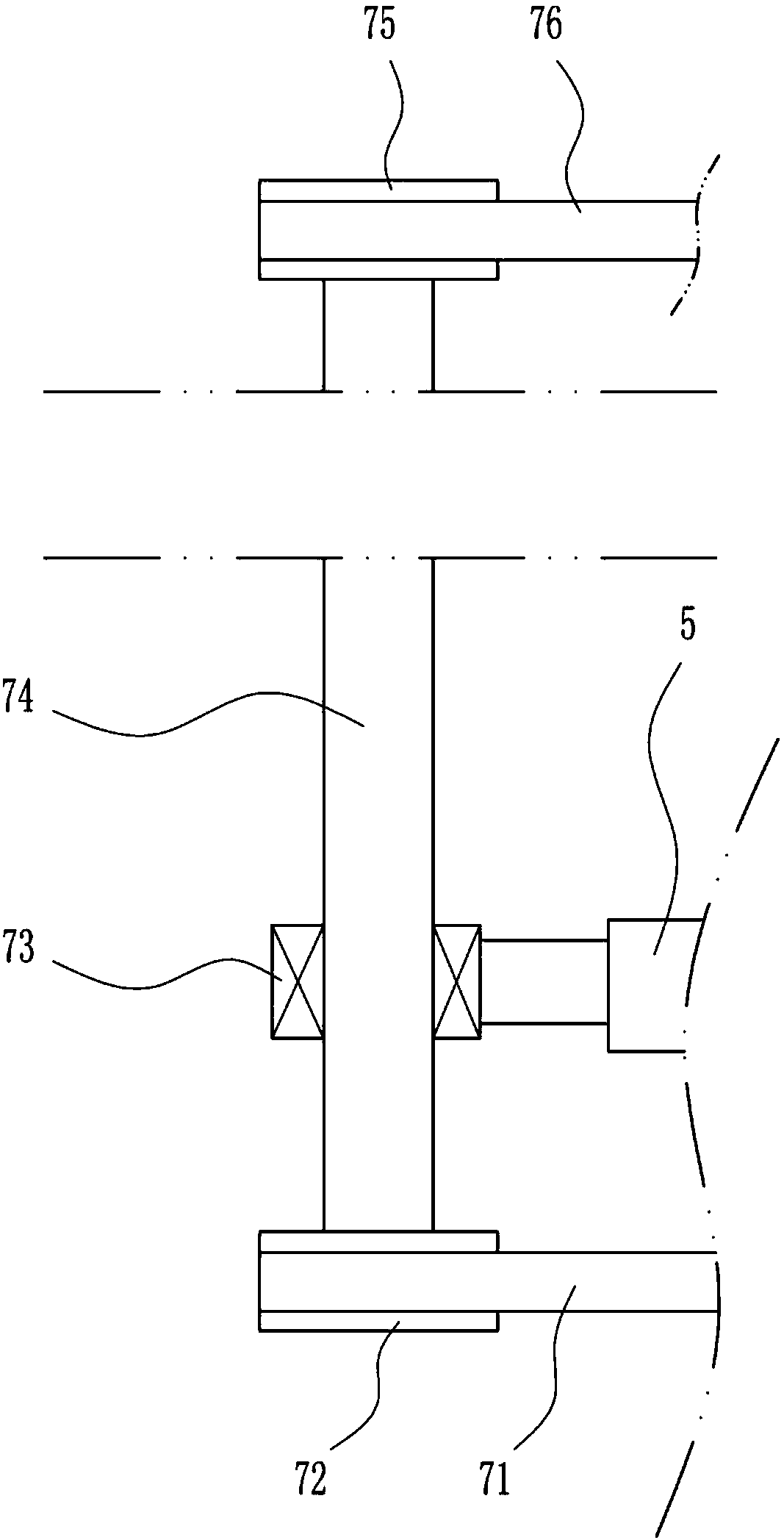

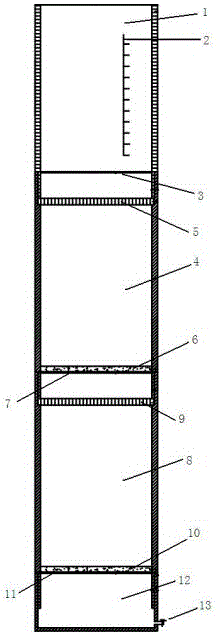

Indoor multistage simulated leaching test method

InactiveCN104459085AAvoid churnAvoid uneven sprayingEarth material testingTest requirementsMaterials science

The invention discloses an indoor multistage simulated leaching test method which comprises the following steps: (1) establishing an indoor multistage simulated leaching test device, wherein a leaching solution storage device is arranged above a soil body container; a graduated scale is arranged on the side surface of the leaching solution storage device; a bottom pinhole of the leaching solution storage device is formed in the bottom of the leaching solution storage device; the lower part of the leaching solution storage device is connected with the soil body container; the soil body container is arranged between the leaching solution storage device and a leaching solution collector; a soil body container bottom gap is formed in the bottom of the soil body container; a permeable stone is arranged on the soil body container; a pinhole gasket is arranged at the joint of the upper part of the soil body container and the leaching solution storage device; one or more soil body containers can be set according to the test requirements; the leaching solution collector is arranged on the lowest part of a device body; and a valve is arranged on the outer side of the bottom of the device body; and (2) injecting a quantitative leaching solution into the leaching solution storage device, enabling the leaching solution to flow into a soil body sample by virtue of the pinhole gasket, and finally enabling the leaching solution to flow into the leaching solution collector. According to the method disclosed by the invention, the multistage undisturbed samples can be loaded, the leaching depth can be measured, and the device is small in sample disturbance, simple in structure and convenient to use.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

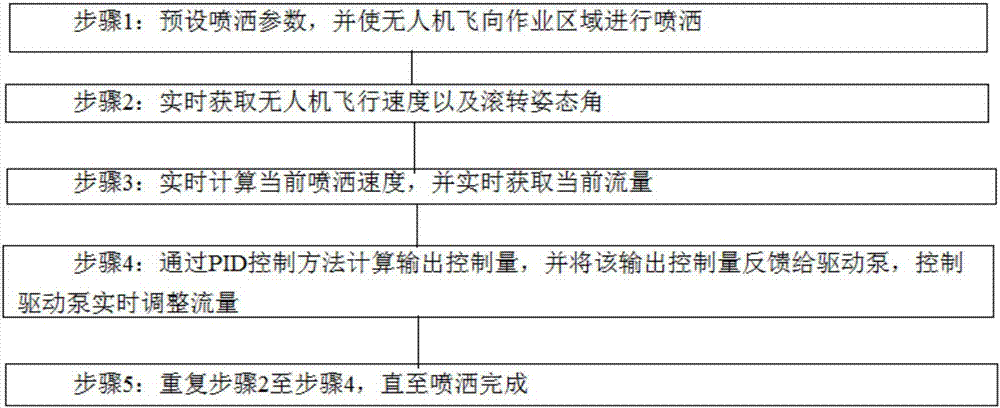

Method and system for automatic spraying controlling of unmanned aerial vehicle, and unmanned aerial vehicle spraying control system

InactiveCN106873648AAvoid uneven sprayingReal-time adjustment of spraying speedFlow control using electric meansControl systemClosed loop

The invention discloses a method and system for automatic spraying controlling of an unmanned aerial vehicle, and an unmanned aerial vehicle spraying control system. The method comprises: step one, presetting a spraying parameter and enabling an unmanned aerial vehicle to fly to an operating area to carry out spraying; step two, obtaining a flight speed and a rolling attitude angle of the unmanned aerial vehicle in real time; step three, calculating a current spraying speed in real time and obtaining a current flow in real time; step four, calculating an output control value by using a PID control method, feeding back the output control value to a driving pump, and controlling the driving pump to adjust the flow in real time; and step five, repeating the steps two, three, and four until the spraying is completed. According to the method for automatic spraying controlling of an unmanned aerial vehicle, the speed and attitude angle of the unmanned aerial vehicle are obtained in real time; and the real flow and pressure are obtained to carry out closed-loop controlling of the flow. Therefore, real-time and precise controlling of the spraying flow of the unmanned aerial vehicle can be realized; and non-uniform spraying at different speeds and tilt angles can be prevented.

Owner:AHEADX

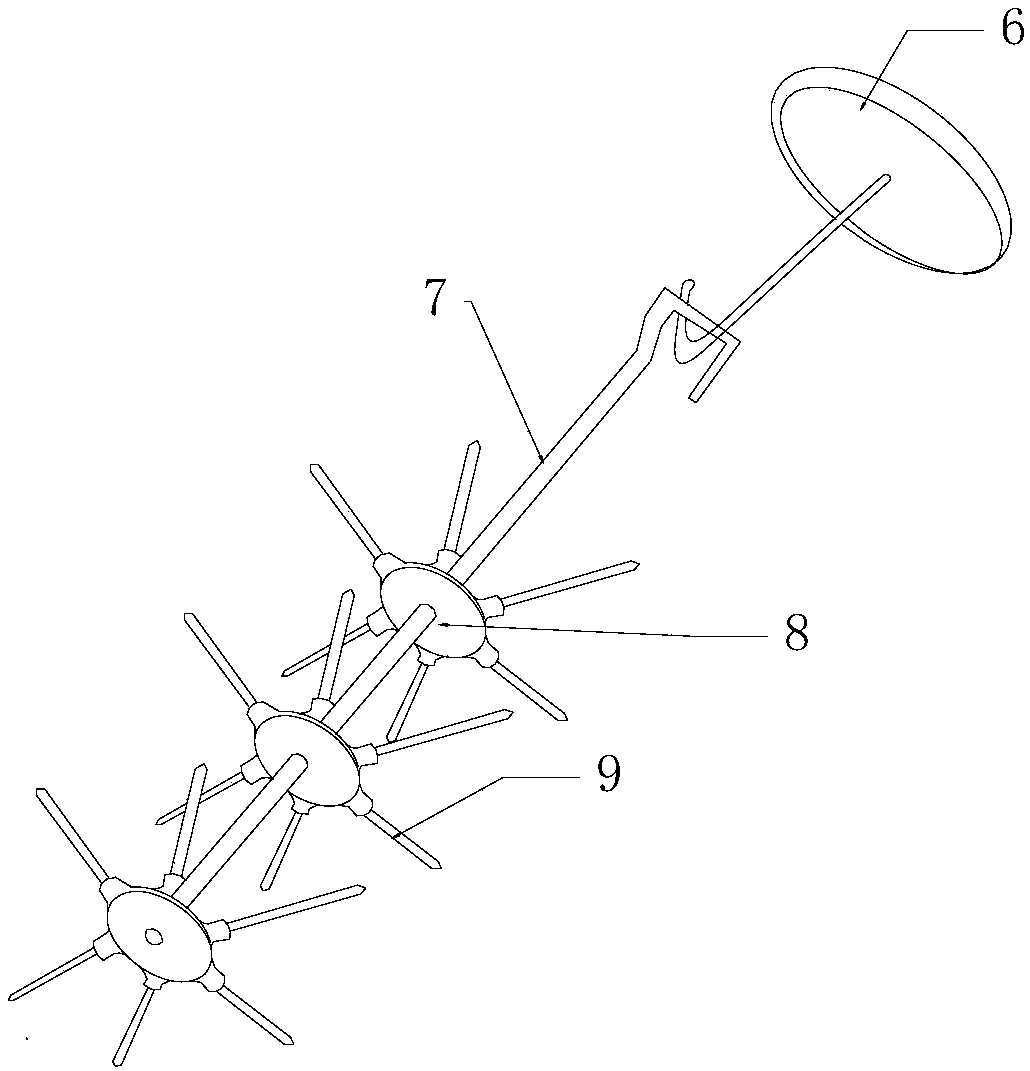

Automatic paint spraying device of coat hanger

InactiveCN108405252ASpray evenlySolve the disadvantages of not being able to spray paint evenlyPretreated surfacesCoatingsFixed bearingGear wheel

The invention belongs to the technical field of processing of coat hanger production equipment, and discloses an automatic paint spraying device of a coat hanger. The automatic paint spraying device comprises a paint spraying chamber, and a base is arranged in the paint spraying chamber; a rotating shaft is vertically arranged in the middle position in the paint spraying chamber; a paint sprayingmachine is arranged on the outer side of the rotating shaft; a rotating bearing is arranged between the lower end of the rotating shaft and the base; a fixed bearing matched with a supporting rotatingshaft is arranged on the rotating bearing; the upper end of the paint spraying machine penetrates through the top of the paint spraying chamber, and is connected and fixed to the output end of a servo motor; a rotary disc is arranged in the position, close to the inner top of the paint spraying chamber, of the upper end of the paint spraying machine in an interpenetrating manner; a plurality of autorotation shafts which are uniformly arranged on the rotary disc at intervals in a circular ring shape are arranged on the outer side of the upper end of the rotary disc in an interpenetrating manner; auxiliary gears are fixed to the upper ends of the autorotation shafts; a fixed gear ring is fixed to the outer edge part of the rotary disc; the fixed gear ring meshes with an auxiliary gear ring;and coat hanger hanging tools are connected to the lower ends of the autorotation shafts. According to the automatic paint spraying device, the coat hanger hanging tools can perform autorotation, sothat the coat hangers are uniformly sprayed, and processing quality of equipment and spraying efficiency of the coat hangers are improved.

Owner:广西荔浦安吉利木业有限公司

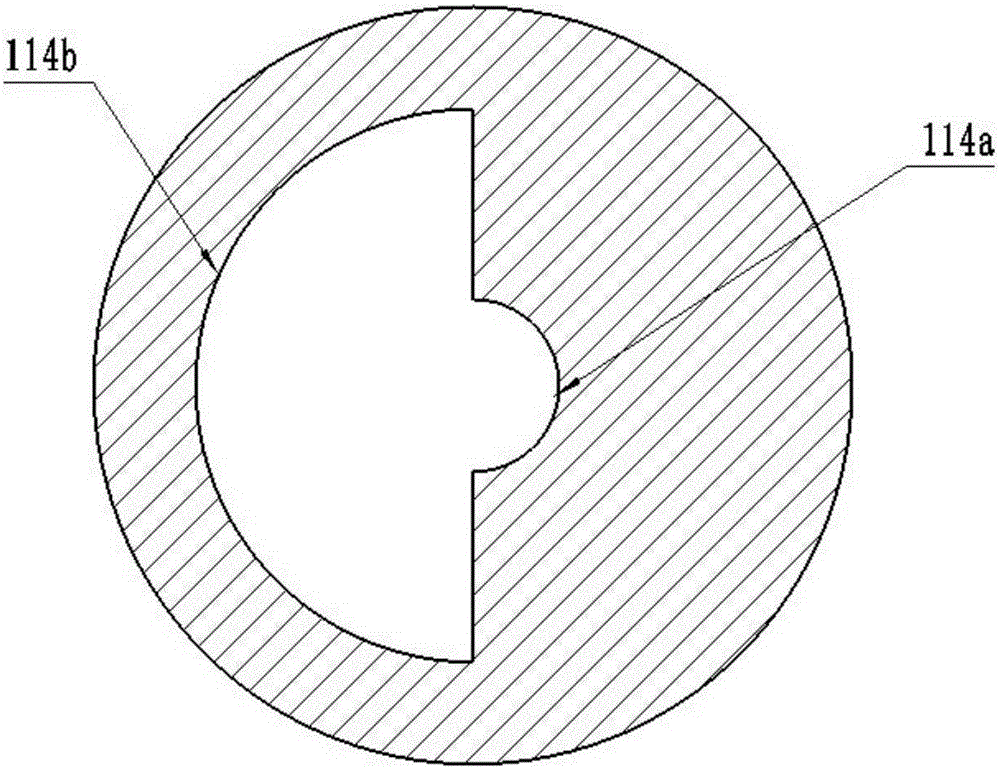

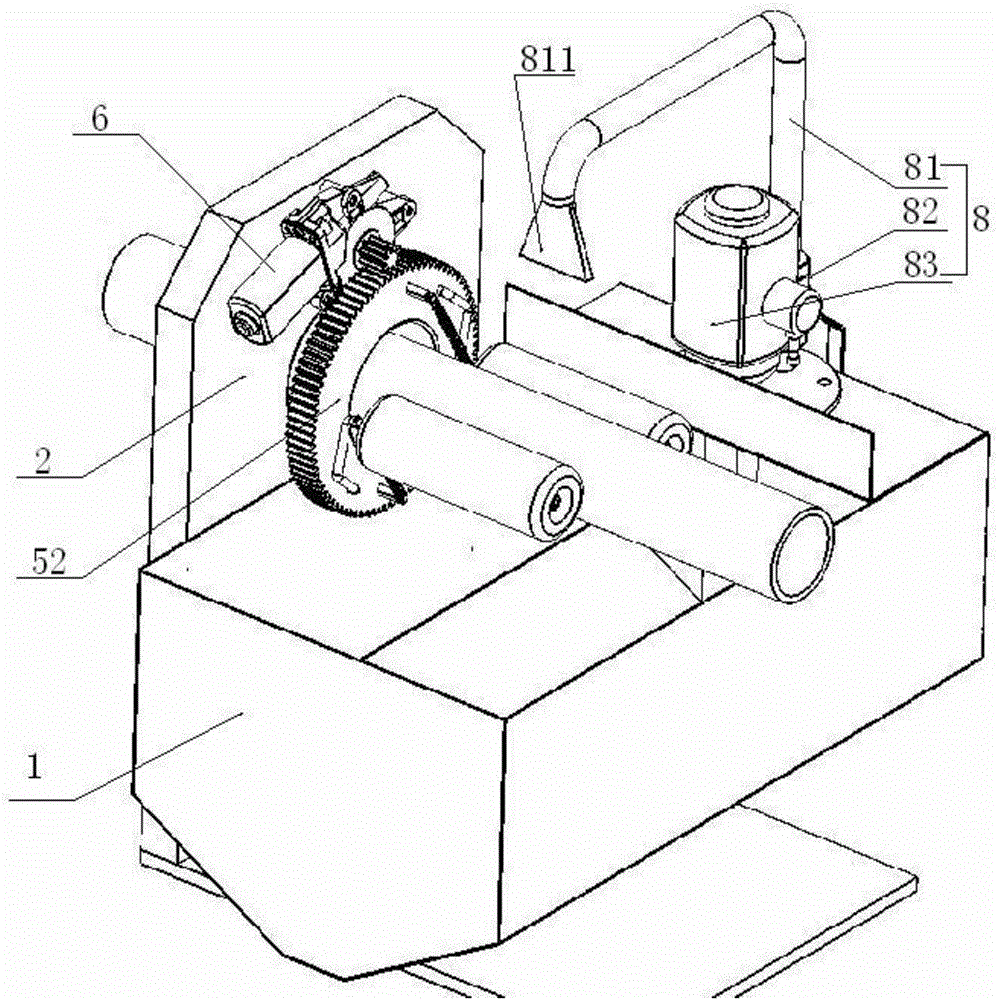

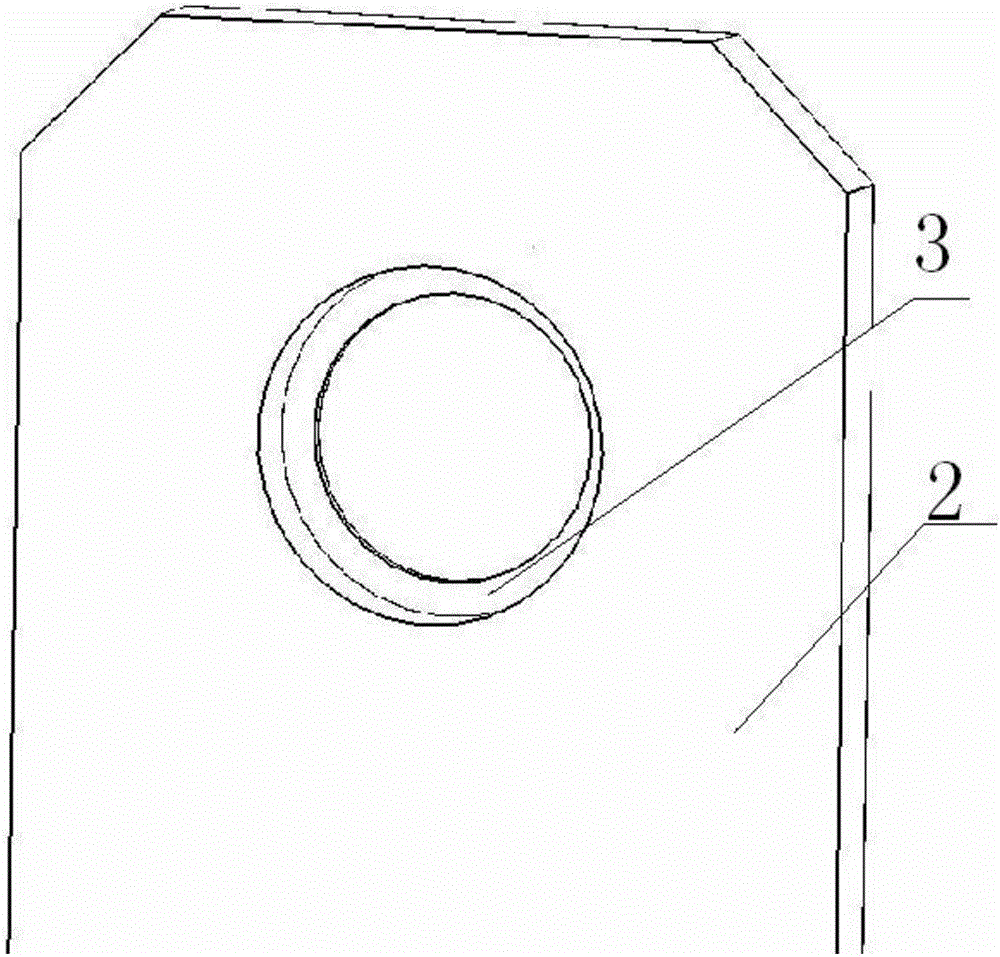

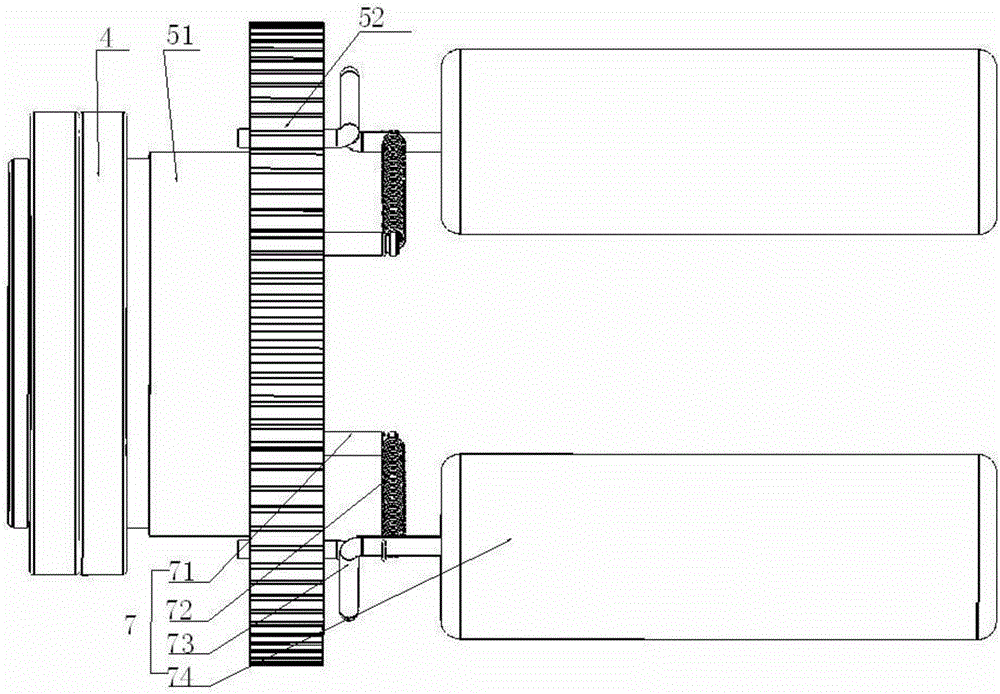

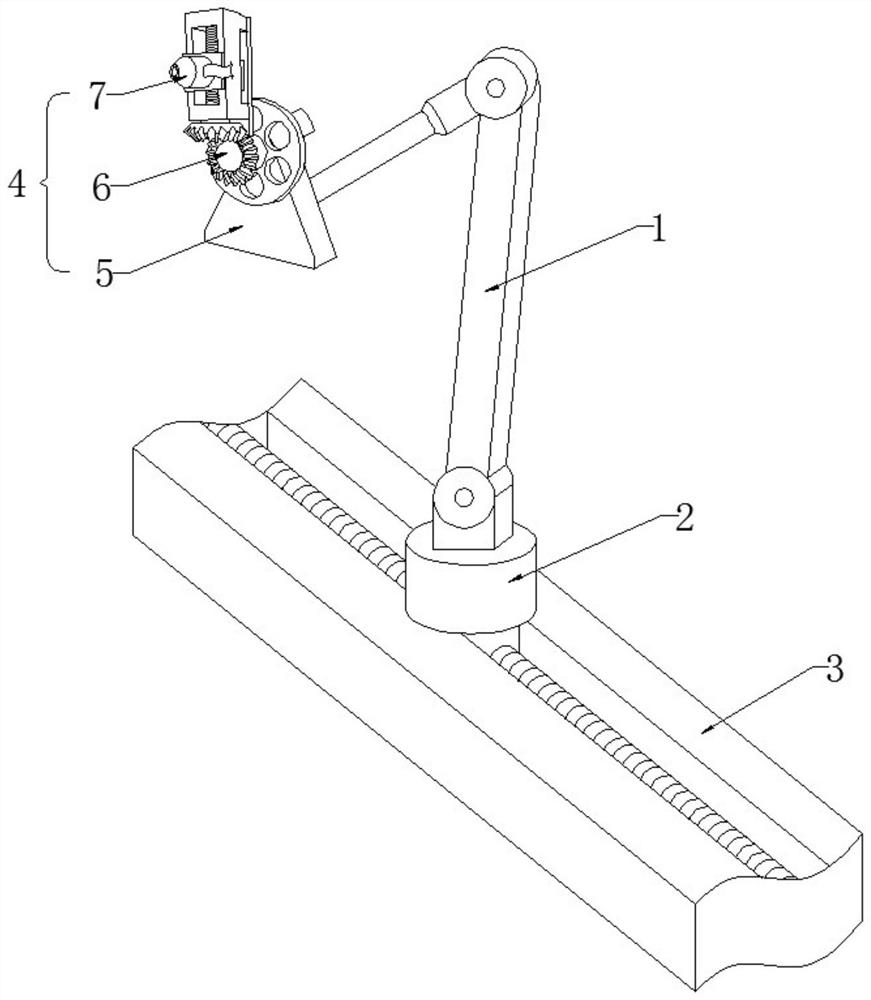

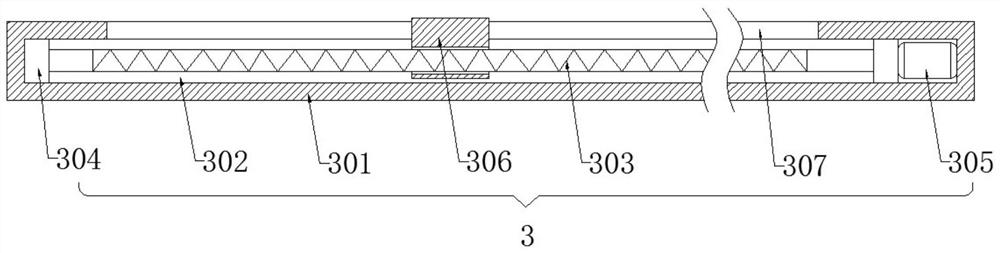

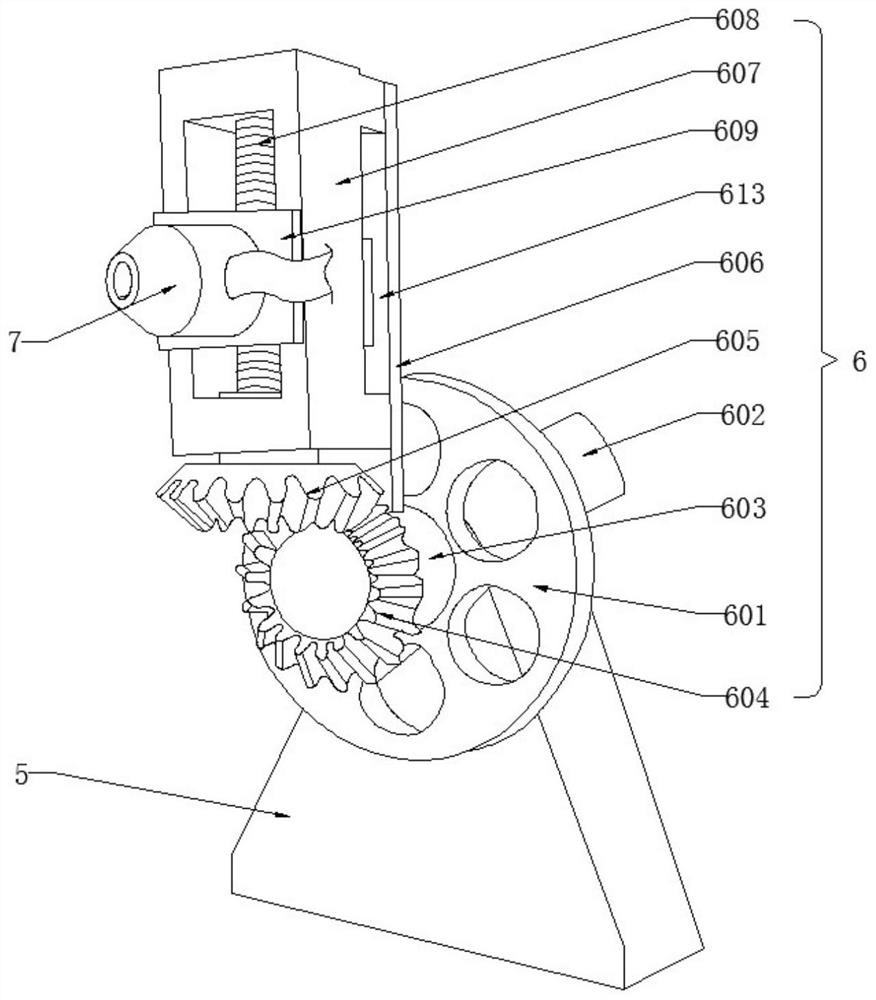

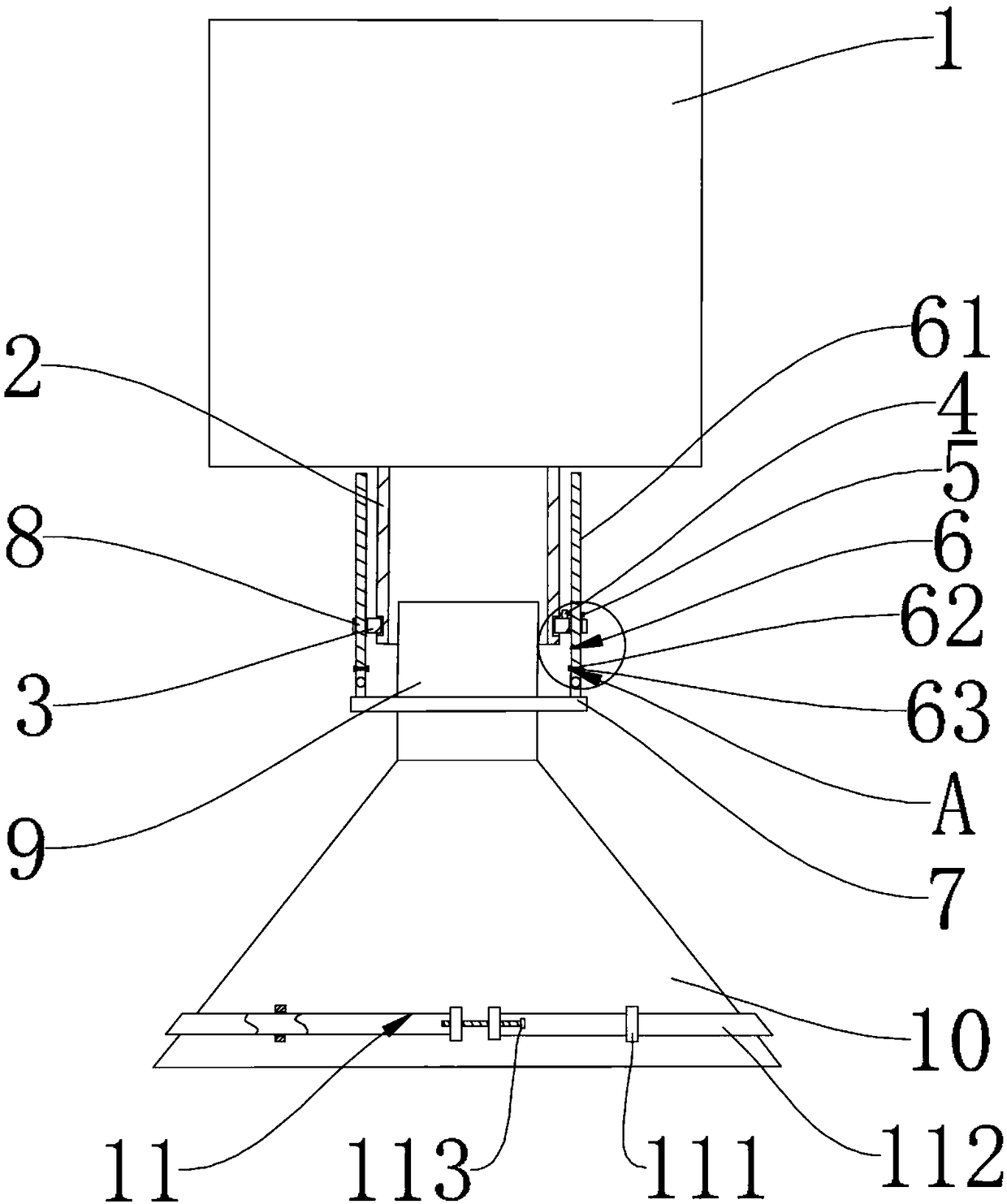

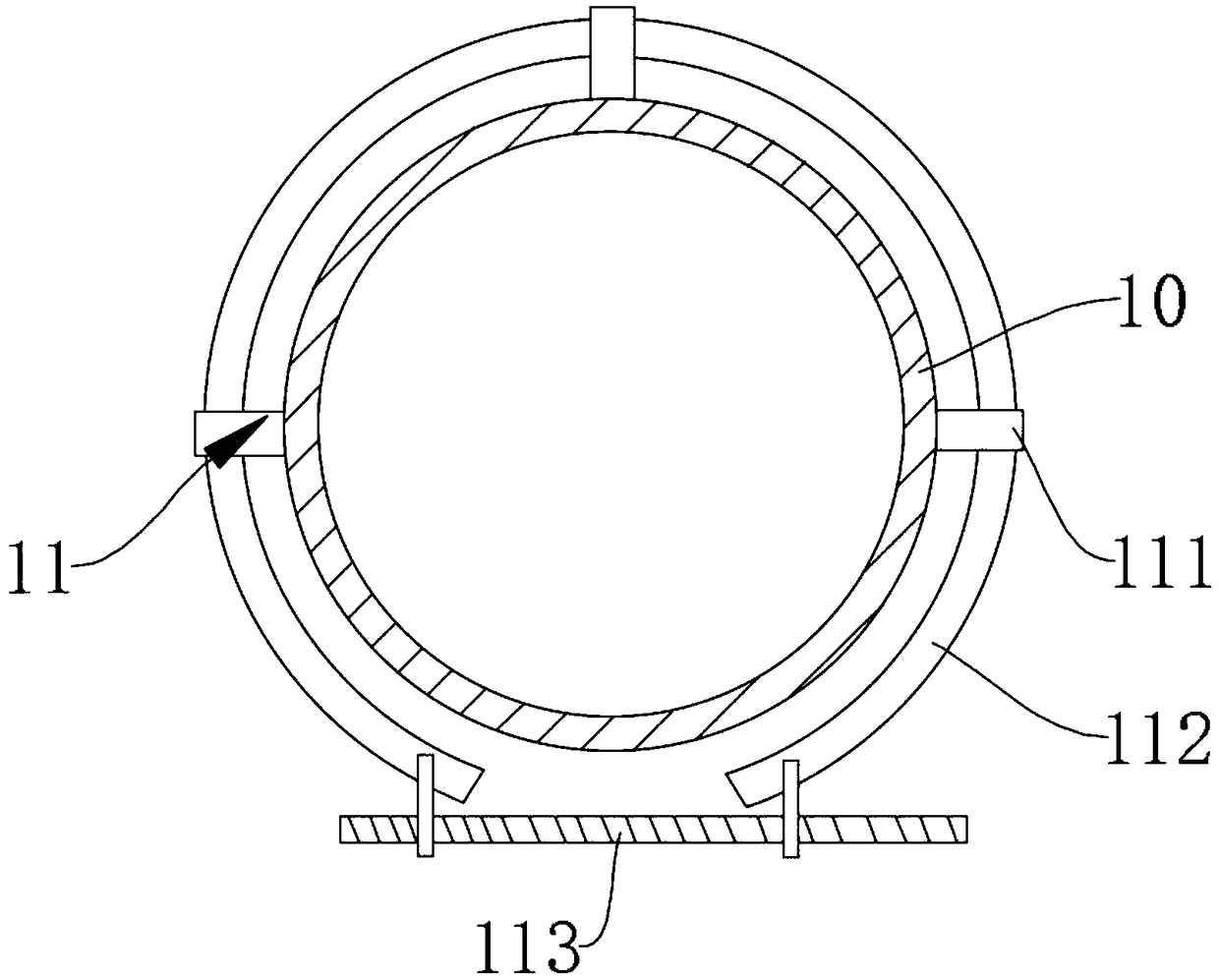

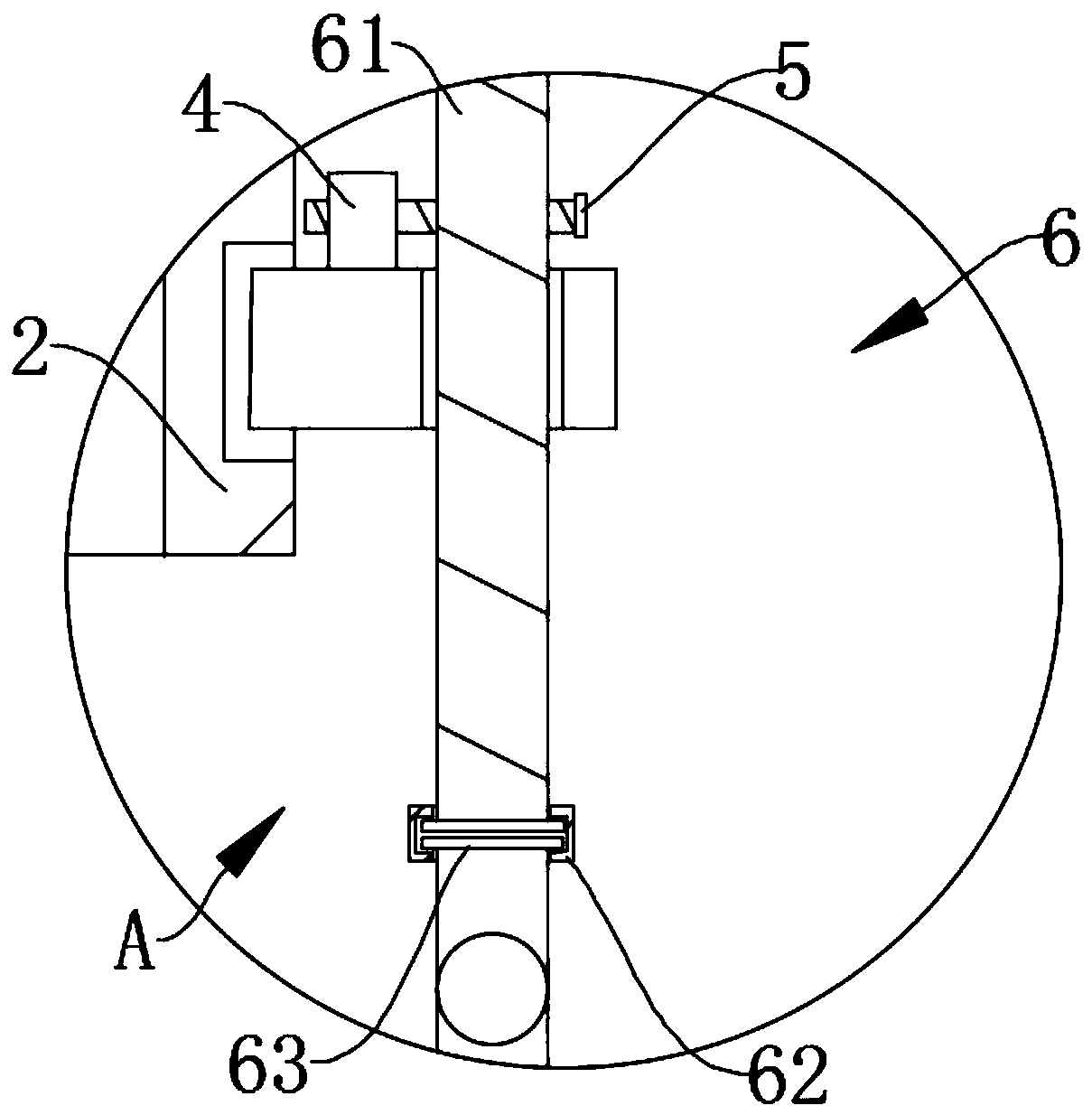

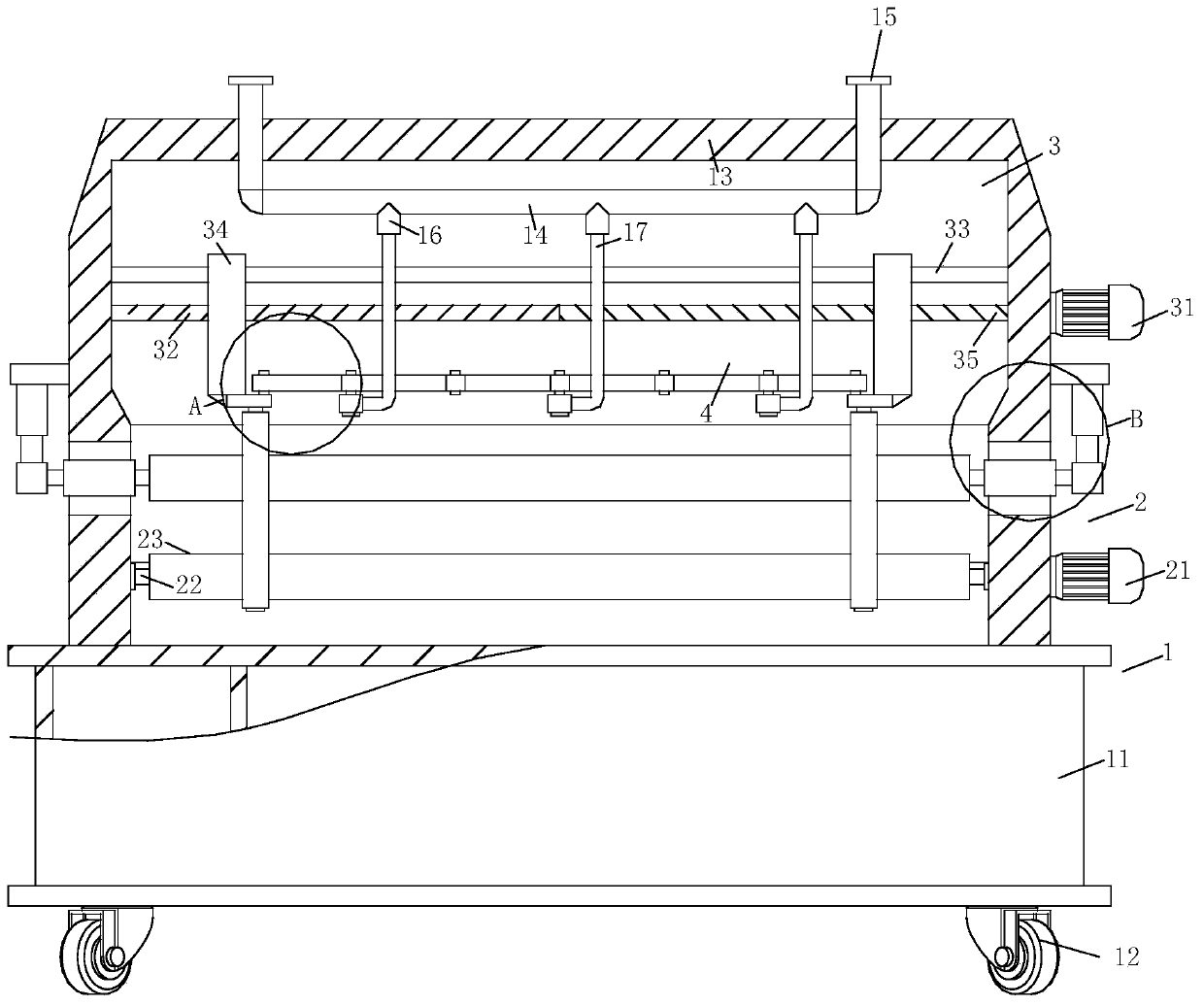

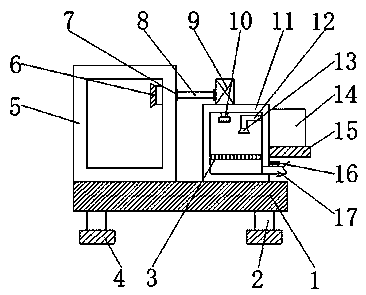

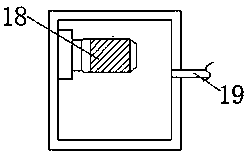

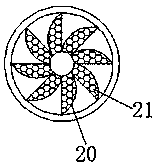

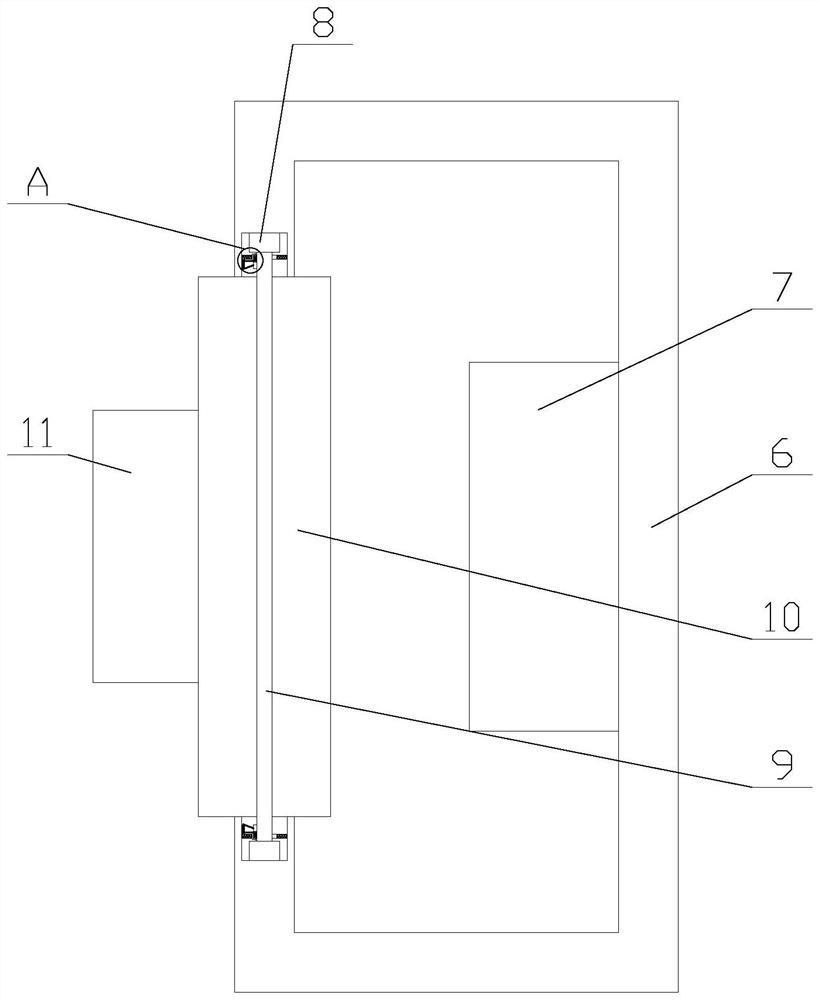

Automatic roller coating machine for mining PVC pipe conductive carbon black

InactiveCN106583109AProtect your healthAvoid uneven sprayingLiquid surface applicatorsSpraying apparatusEngineeringDrive motor

The invention discloses an automatic roller coating machine for mining PVC pipe conductive carbon black. The machine comprises a base, a working plate, a working hole, a bearing, a rotating mechanism, a shaft sleeve, a gear disc, a driving motor, a coating device, a dowel pin, a spring, a crank mechanism, a roller, a spraying device, a spraying pipe, a valve, a liquid pump, a rotating handle, a connecting rod, a rolling shaft and a nozzle. The automatic roller coating machine for the mining PVC pipe conductive carbon black has the following beneficial effects that a plastic extruding machine continuously extrudes out PVC pipes; then, the roller coating work of the PVC pipes is completed through the continuously rotating roller and continuously sprayed paint in the extruding engineering; and as the machinery replaces the manual spraying mode, the nonuniform spraying condition is effectively prevented, and the health of workers is effectively protected.

Owner:王防震

Paint spraying method for shell

ActiveCN112427182AEvenly paintedAvoid uneven sprayingLiquid surface applicatorsSpraying apparatusElectric machinerySpray method

Owner:六安中达信息科技有限公司

High-efficiency spraying device for electric vehicle accessories

The invention discloses a high-efficiency spraying device for electric vehicle accessories. The high-efficiency spraying device comprises a box body and a fixed plate, the fixed plate is fixedly installed at the bottom of an inner cavity of the box body, electric push rods are correspondingly installed on the two sides of the top of the fixed plate, fixed blocks are installed at the tops of the electric push rods, and a spraying mechanism is installed at the top of the inner cavity of the box body; and the spraying mechanism comprises a screw rod, a motor, a screw rod nut, a sprayer, a limit sliding groove and a limit sliding block, the motor is installed on the left side wall of the box body, a transmission shaft of the motor penetrates through the left side wall of the box body, and is fixedly connected with one end of the screw rod, the other end of the screw rod is movably connected with the inner wall of the box body through a bearing, and the screw rod nut is installed on the outer wall of the screw rod in a sleeving mode. According to the high-efficiency spraying device, the screw rod is driven by the motor to rotate, thus the sprayer is driven for reciprocating spraying, thus spraying is even, meanwhile a stirring rod is driven to stir coating, thus the coating is even, thus the spraying effect is better, and the situation that spraying is uneven due to deposition is avoided.

Owner:XUZHOU JIULONG ELECTRONICS IND CO LTD

Automatic spraying industrial robot and method

InactiveCN112170066AGuaranteed spraying effectRealize wrap around spraying jobSpraying apparatusSprayerEngineering

The invention discloses an automatic spraying industrial robot and method. The automatic spraying industrial robot comprises an industrial robot body, a base is arranged at the bottom of the industrial robot body, a moving platform is arranged at the bottom of the base, and a spraying mechanism is arranged at one end of the top of the industrial robot body, wherein the spraying mechanism comprisesa mounting base, the back face of the mounting base is fixedly connected with one end of the top of the industrial robot body; and a rotating assembly is arranged on the surface of the mounting base,and a sprayer assembly is arranged on the surface of the rotating assembly. The automatic spraying industrial robot has the beneficial effects that surrounding spraying operation on the end face of apipeline can be achieved, compared with a traditional spraying mode, waste of paint is effectively reduced, the phenomenon that subsequent pipeline surface spraying is uneven is effectively avoided,and therefore the overall spraying effect of the pipeline is effectively guaranteed.

Owner:NANJING YUSHENG ROBOT CO LTD

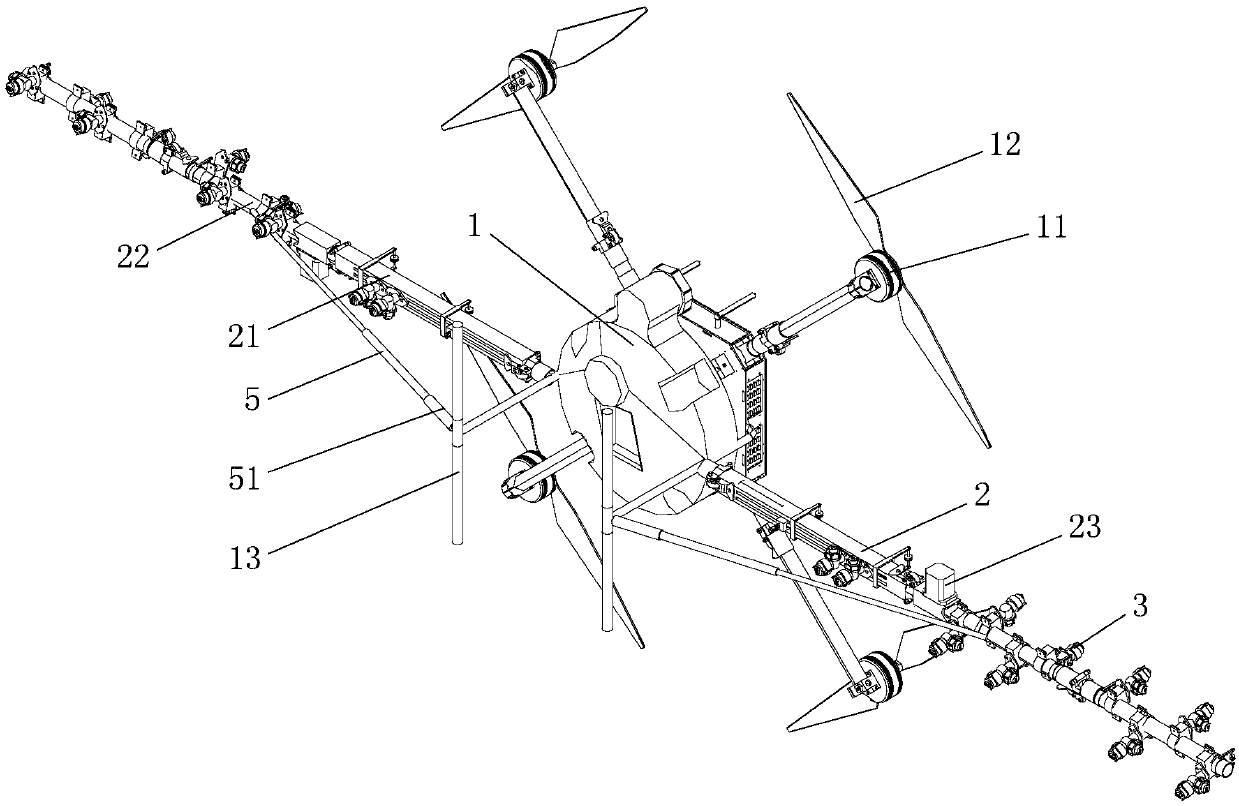

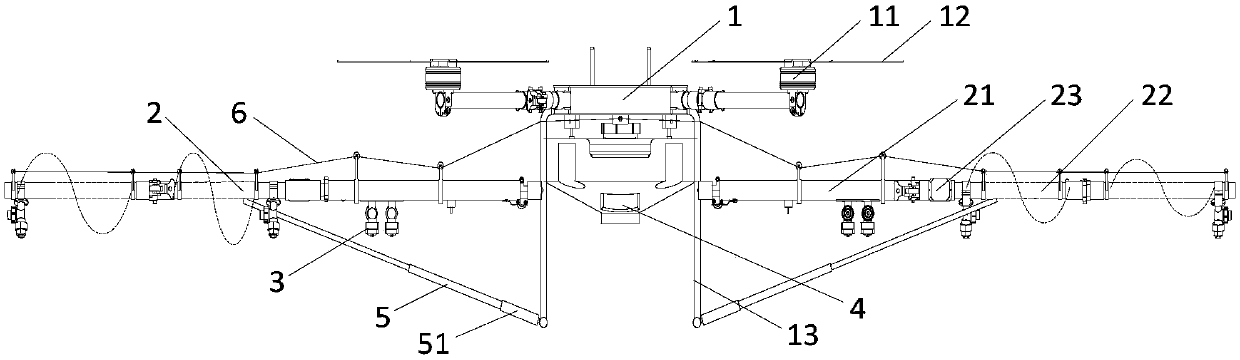

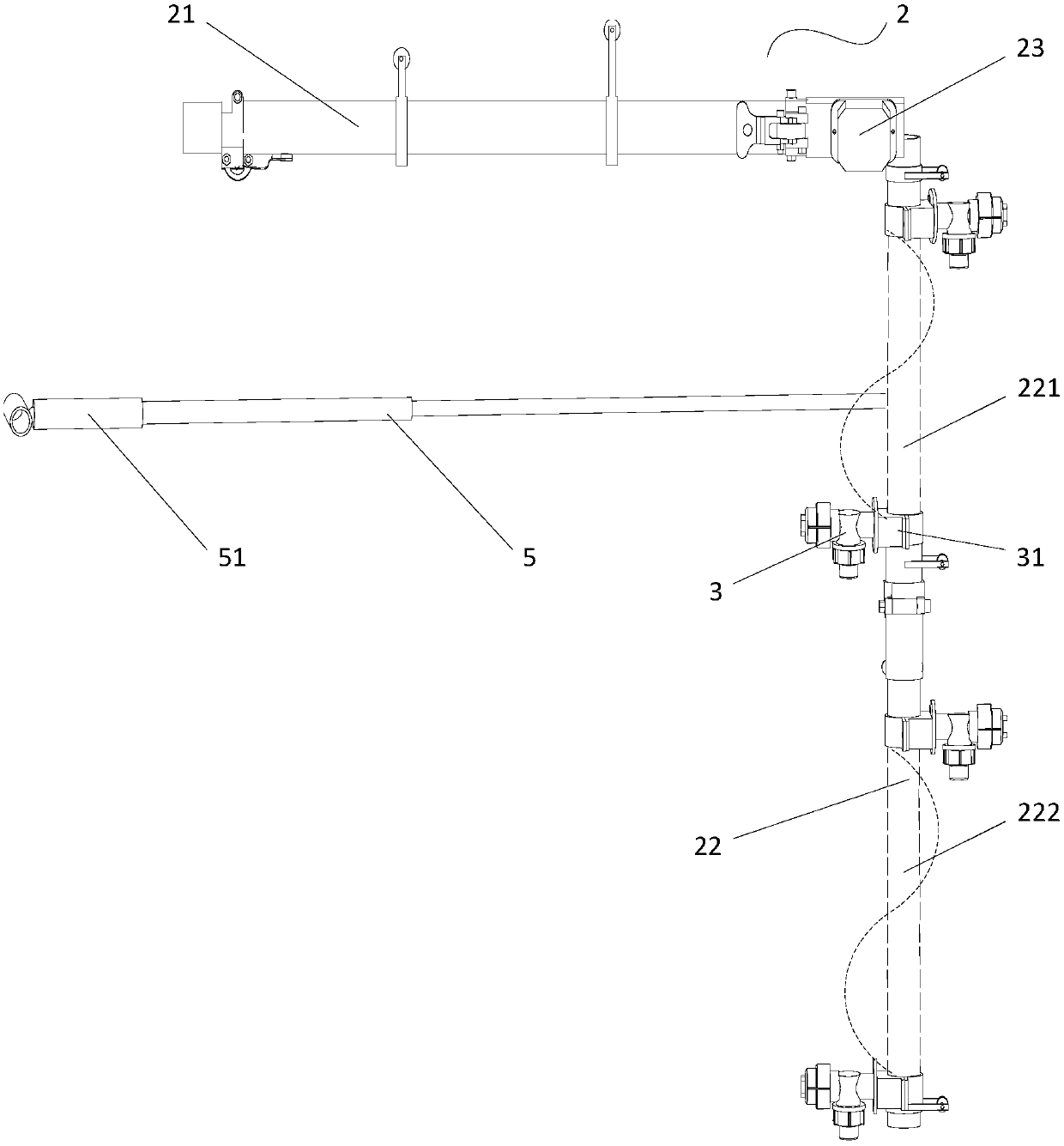

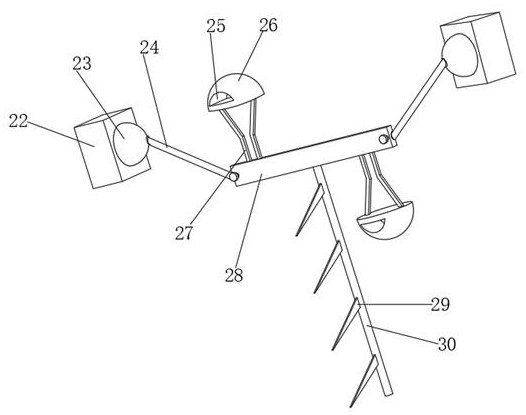

Plant protection drone

PendingCN109677614ARealize horizontal sprayingAchieve vertical sprayingAircraft componentsLaunching weaponsVertical planeAgricultural engineering

The invention discloses a plant protection drone. The plant protection drone comprises a drone body, a spray bar and a plurality of spray heads, wherein the spray bar comprises an inner spray bar andan outer spray bar; one end of the inner spray bar is connected with the drone body; the other end of the inner spray bar is connected with the outer spray bar; during working, the outer spray bar canbe rotated in a vertical plane relative to the inner spray bar to move to a vertically downward position or a horizontal position; and the spray heads are arranged on the inner spray bar and the outer spray bar along the length direction of the spray bar at intervals. The plant protection drone disclosed by the invention has the beneficial effects that when the plant protection drone works, the outer spray bar can be rotated in a vertical plane relative to the inner spray bar to move to a vertically downward position or a horizontal position, so that the horizontal spraying and the longitudinal spraying of a medicine can be realized and the plant protection drone can adapt to various sprayed objects, is suitable for spraying needs of different crops and different environments, meets practical application needs and has strong practicability and a broad application prospect.

Owner:LINYI UNIVERSITY

Spraying device for building decoration

InactiveCN108487605AEasy to useFully contactedBuilding constructionsWorking environmentArchitectural engineering

The invention provides a spraying device for building decoration, and relates to the field of building decoration processing equipment. The spraying device comprises a bottom plate; supporting columnsare fixedly mounted at the bottom of the bottom plate; the ends, away from the bottom plate, of the supporting columns are fixedly mounted with transverse plates; a guiding pipe is arranged in the middle of the bottom plate, and a lifting rod is sleeved with the guiding pipe; and the lower end of the lifting rod is sleeved with a sleeve. According to the spraying device for building decoration, the spraying device is flexibly moved through universal wheels, and the spraying device is suitable for different working environments; when an appropriate spraying area is found, supporting feet are adjusted by controlling adjusting bolts, thus the supporting feet make full contact with the ground, and the spraying device is advantageously fixed; meanwhile, a second electric push rod stretches todrive a supporting plate to vertically downwards move, thus the supporting plate is completely close to the ground, the functions of overall strong supporting and fixing are achieved, and uneven spraying caused by the small deviation during working is prevented; and friction force between the spraying device and the ground can be increased through supporting teeth on the lower surface of the supporting plate.

Owner:博艳萍

Paint plating device and paint plating method for valve machining

ActiveCN112371428AAccelerate solidificationQuality assurancePretreated surfacesCoatingsHydraulic cylinderGear wheel

The invention discloses a paint plating device and a paint plating method for valve machining, relates to the technical field of valve machining, and aims at solving the problem that paint is easily accumulated at a contact point. The device comprises a machine body; a first electric sliding groove is formed in the inner wall of the top of the machine body; a hydraulic cylinder is arranged on theinner wall of the first electric sliding groove; the extending end of the hydraulic cylinder is rotatably connected with a connecting base through a connecting column; a third motor is arranged on theinner wall of the bottom of the connecting base; and three gears are arranged on the inner wall of one side of the connecting base. The paint plating method for the device comprises the following steps that the paint is added to a first material box; a valve is placed in a net box; and a cleaning spraying member and a second motor are started to drive the net box to complete cleaning and spin-drying in the rotating process. In the air blowing process, the valve rotates continuously at the same time to accelerate solidification of the valve after feeding; and no acting point exists in the solidification period of the feeding position of the valve, and therefore the situation of paint accumulation is avoided, and the quality and efficiency of paint plating are guaranteed.

Owner:林仙夫

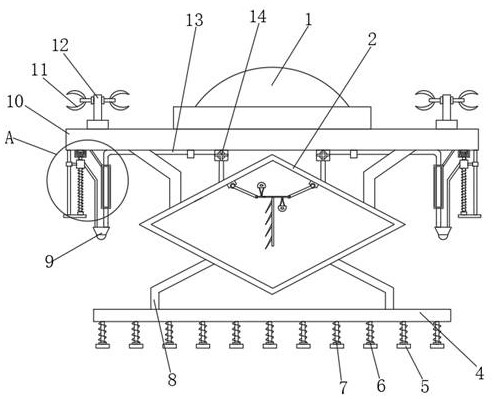

Plant protection unmanned aerial vehicle for agricultural planting

InactiveCN112046753AMeet the needs of useStir wellLiquid spraying apparatusInsect catchers and killersAgricultural engineeringElectric machinery

The invention discloses a plant protection unmanned aerial vehicle for agricultural planting. The plant protection unmanned aerial vehicle for agricultural planting comprises an unmanned aerial vehicle body, a top plate is arranged on the outer wall of the bottom of the unmanned aerial vehicle body, rotating rods are rotatably connected to the outer wall of the top of the top plate, fan blades arearranged on the outer walls of the two sides of each rotating rod, reinforcing rods are arranged on the outer wall of the bottom of the top plate, a water tank is arranged on the outer walls of one ends of the reinforcing rods, the cross section of the water tank is rhombic, supporting rods are arranged on the outer wall of the bottom of the water tank, a bottom plate is arranged on the outer walls of one ends of the supporting rods, telescopic rods are arranged on the outer wall of the bottom of the bottom plate, and the circumferential outer walls of the telescopic rods are sleeved with springs. When the unmanned aerial vehicle conducts pesticide spraying work on crops, a pump body and a motor can be started, the pump body can pump out pesticide liquid in the water tank and spray the pesticide liquid out of spray heads to conduct pesticide spraying work on the crops, meanwhile, people can start the motor, the motor drives threaded lead screws to rotate to adjust the height of the spray heads, and use requirements of people are met.

Owner:浙江恩润工业设计有限公司

Multi-angle adjusting device for hardware product spraying gun muzzle

InactiveCN108745673AAvoid excessive spraying dead angleAvoid wastingSpray nozzlesEngineeringMechanical engineering

The invention discloses a multi-angle adjusting device for a hardware product spraying gun muzzle. The multi-angle adjusting device comprises a spraying gun, a coating outlet is formed in the lower portion of the spraying gun, a sliding base is rotatably arranged at the coating outlet, a fixed base is arranged on the sliding base, and the fixed base and bolts do meshing motion; a first adjusting device is arranged on one side of each bolt, each first adjusting device comprises a lead screw, a limiting base and a fixing rod, the lower end of each lead screw is rotatably arranged in the corresponding limiting base in a sleeved mode, each fixing rod is rotatably connected to the interior of the corresponding limiting base in a sleeved mode, the lower ends of the fixing rods are hinged to thefixed base, therefore, the gun muzzle angle can be adjusted in multiple angles, and then the multi-angle adjusting device can be used in multiple environments; meanwhile, the condition that more spraying dead corners exist due to the length of the spraying gun muzzle is avoided, the spraying range of the spraying gun muzzle can be changed, and coating waste in the spraying process is avoided; andin addition, the condition that spraying is not uniform due to the fact that the spraying range is narrow is avoided. The multi-angle adjusting device is easy to operate, high in practicability and convenient to use and popularize.

Owner:安徽晶鹏智能装备科技有限公司

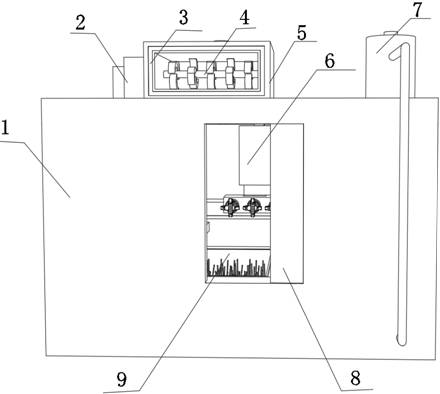

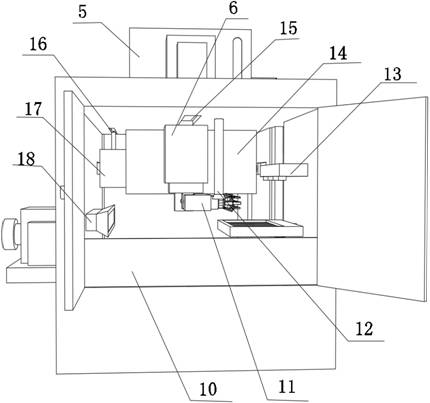

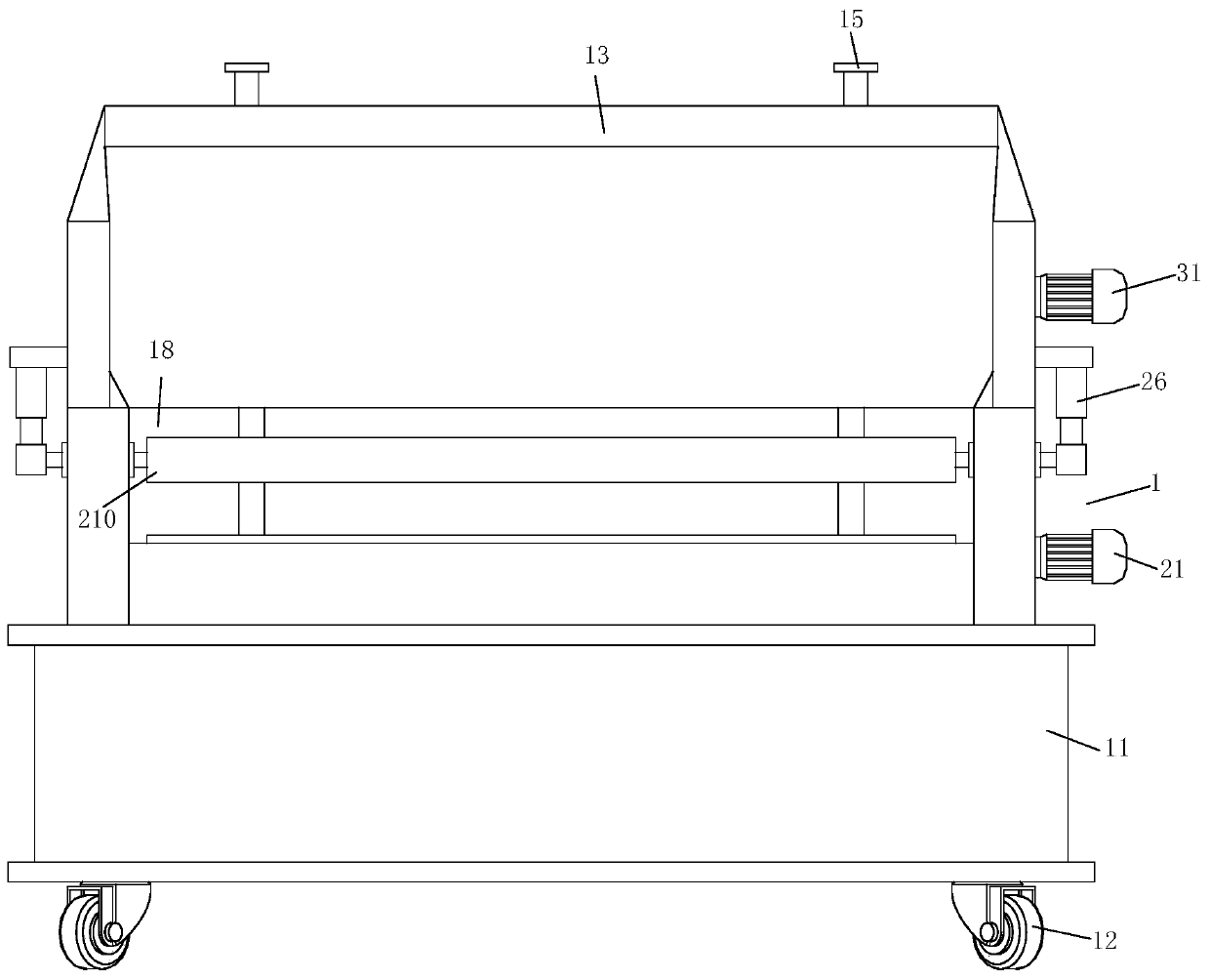

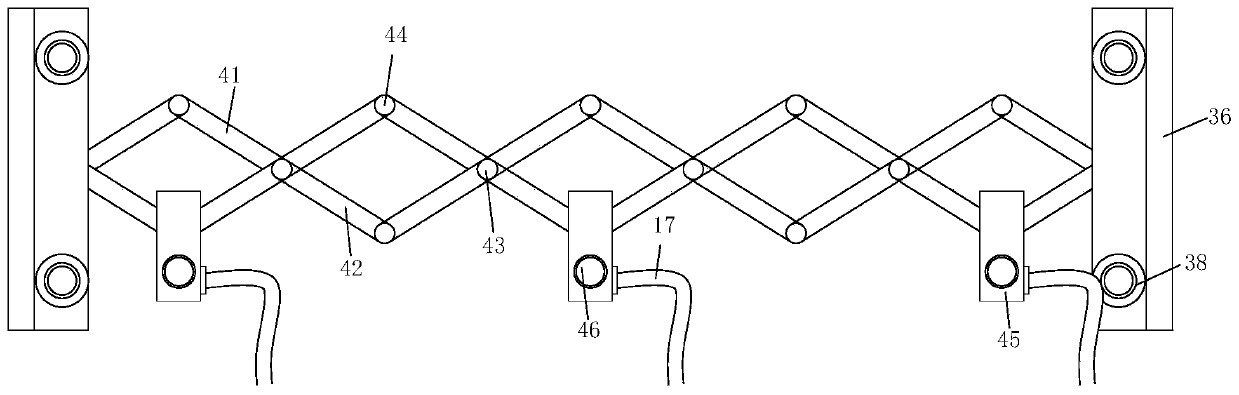

Automatic sprayer

ActiveCN111250300APrevent left and right shiftSmooth transmissionSpraying apparatusVehicle frameSprayer

The invention relates to the technical field of sprayers, in particular to an automatic sprayer. The automatic sprayer comprises an equipment frame, a transmission mechanism, a guide mechanism and a spraying mechanism, wherein the transmission mechanism, the guide mechanism and the spraying mechanism are mounted on the equipment frame; the transmission mechanism and the guide mechanism are arranged in a staggered mode; the spraying mechanism is mounted on the guide mechanism; the equipment frame comprises a frame, foot wheels, a machine enclosure, a material tube, a flange, branch tubes, a rubber hose and a charge hole, wherein the four corners of the lower side of the frame are equipped with the foot wheels; and the upper side of the frame is fixedly connected to the machine enclosure. The automatic sprayer disclosed by the invention is convenient for spraying operation of the spraying mechanism, and can guarantee stable board transmission; and spacing between clamping rollers and spacing between barrel sleeves can be effectively regulated, so that conveying requirements of different boards can be met.

Owner:广德金恒金属处理有限公司

Live pig scouring device for slaughter house

The invention discloses a live pig scouring device for a slaughter house. Clamping plates are fixedly connected to the left end and the right end of the upper part of a scouring device main body; a fixed plate I is arranged in the upper part between the two clamping plates; a fixed plate II is fixedly connected to the lower part between the two clamping plates; an upper pulley is arranged in the fixed plate II; nozzles are fixedly connected at the lower end of the fixed plate II; a water pipe is arranged between the fixed plate I and the fixed plate II; a water pipe valve is arranged at the left end of the water pipe, and the water pipe valve is rotatably connected with the water pipe; a pulley controller is fixedly connected at the right end of one of the clamping plates; side wall pulleys are arranged in the side wall; the right ends of the side wall pulleys are fixedly connected with connecting rods I; connecting rods II are arranged at the right ends of the connecting rods I; device doors are arranged on the outer side of the scouring device main body; and handles of the doors are fixedly connected with the device doors. The live pig scouring device for the slaughter house disclosed by the invention is simple in structure and convenient to use.

Owner:CHONGQING MINGGAO FOOD CO LTD

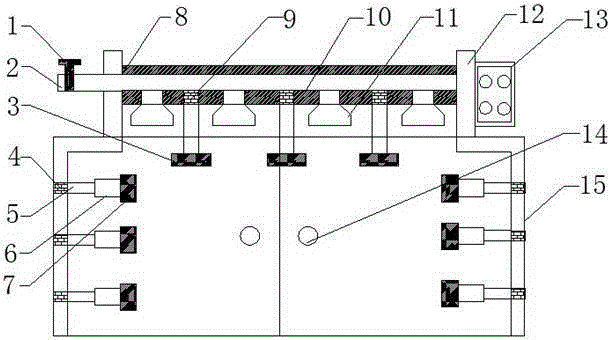

Coating-saving equipment capable of achieving even spraying on aluminum top plate

ActiveCN111468352ADry in timeAvoid scratchesPretreated surfacesLiquid spraying apparatusStructural engineeringManufacturing engineering

The invention discloses coating-saving equipment capable of achieving even spraying on an aluminum top plate. The equipment comprises a machining box. Two symmetric supporting columns are fixedly mounted on the left side and the right side of the bottom of the machining box, and a supporting plate is fixedly mounted at the ends, close to each other, of the two supporting columns. A collection boxis fixedly mounted at the top of the supporting plate. A discharging pipe communicates with the middle of the bottom of the machining box, and the bottom of the discharging pipe penetrates through andextends into the collection box. Openings are formed in the left side and the right side of the machining box, a guide rail is fixedly mounted between the two openings, the top of the guide rail is movably connected with a carrier loader, guide wheels are fixedly mounted at the left end and the right side of the guide rail through connectors, mounting plates are welded to the left side and the right side of the bottom of the guide rail, rotating motors are fixedly mounted at the bottoms of the mounting plates, gear motors are fixedly mounted on the front faces of the rotating motors, take-upwheels are fixedly mounted at the output ends of the gear motors, and metal ropes are fixedly mounted on the outer surfaces of the take-up wheels. By means of the equipment, even spraying is achieved,manual turnover is achieved after drying to achieve spraying and drying again, and time and coating are saved.

Owner:安徽规矩铝模科技有限公司

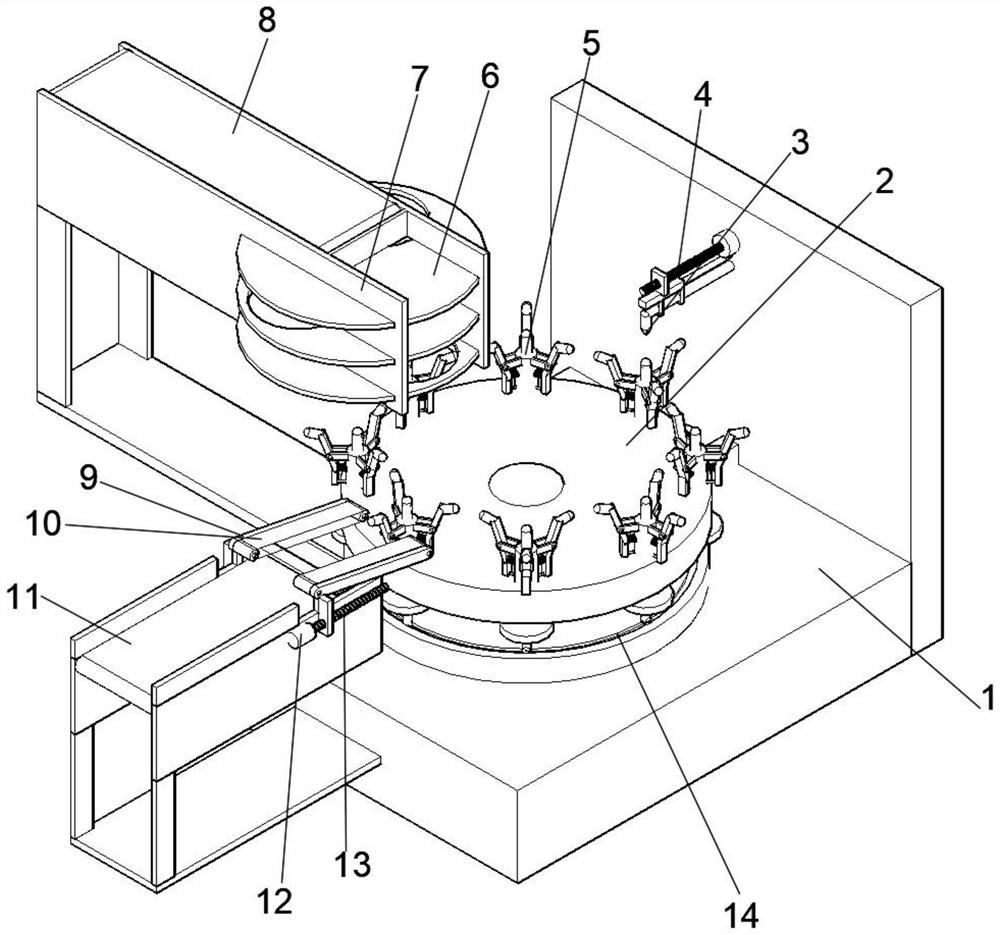

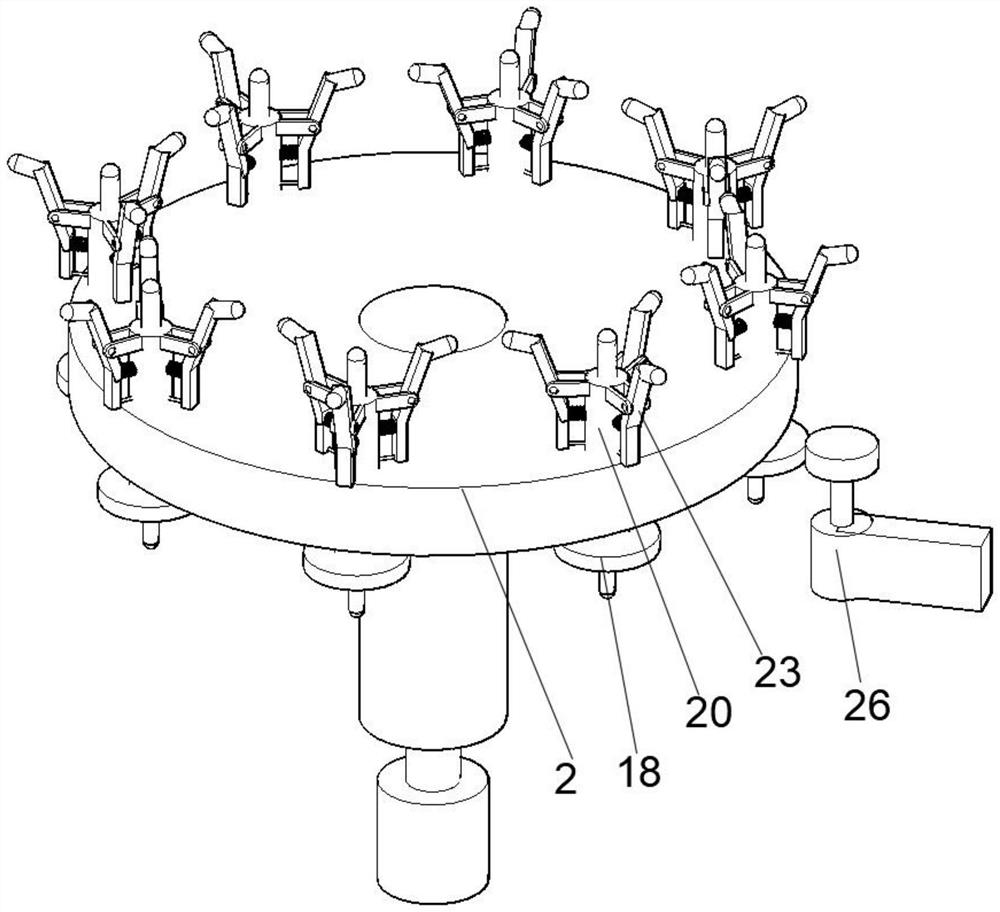

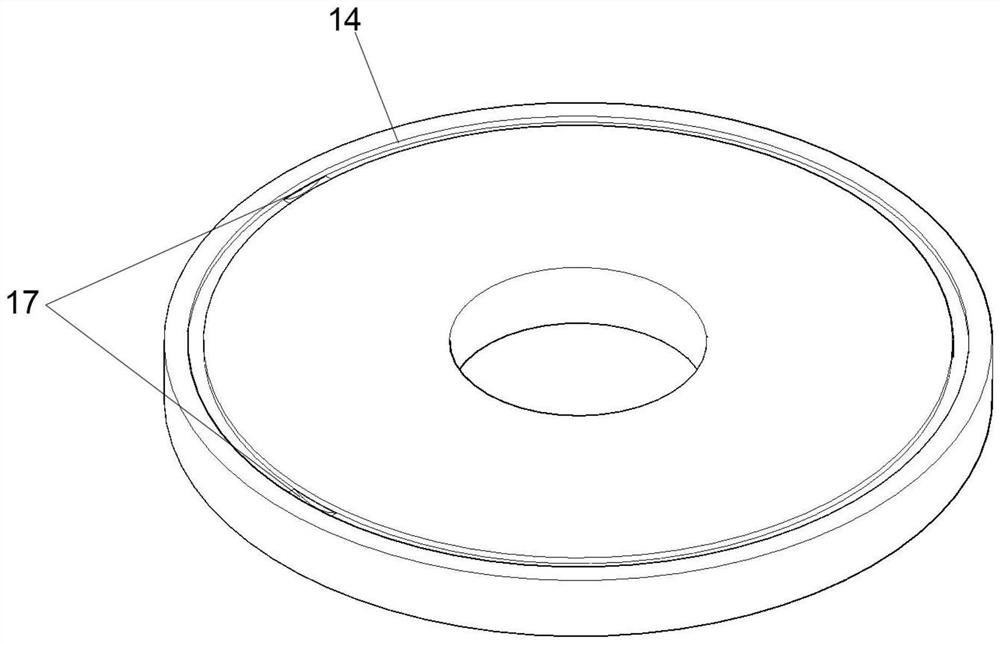

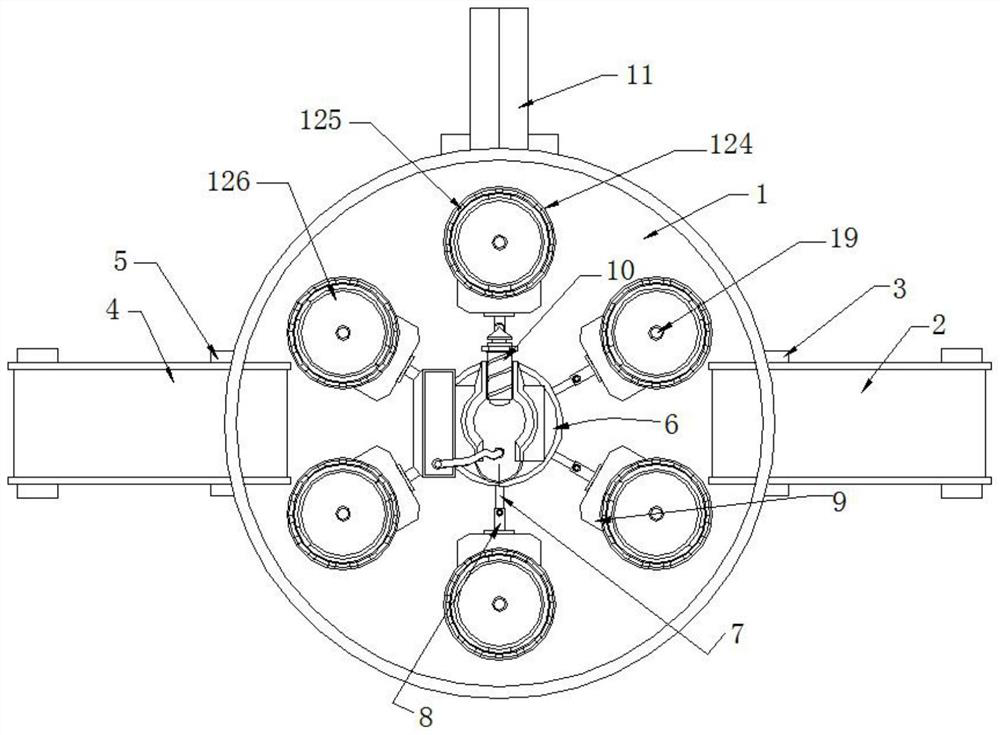

Coat hanger paint spraying machine

InactiveCN108187947ARealize automatic painting operationImprove efficiencySpraying apparatusEngineeringMachining

The invention belongs to the technical field of coat hanger machining equipment. A coat hanger paint spraying machine comprises a conveying rail, a paint spraying bin, a coat hanger rack, a paint spraying device and a paint supplying device, the coat hanger rack is connected to the conveying rail, and a sliding groove is formed in the bottom of the conveying rail. The coat hanger rack is movably assembled in the sliding groove, the conveying rail comprises a conveying section for horizontally conveying a coat hanger and a paint spraying section for conveying the coat hanger in a vertical suspension mode, and the paint spraying section penetrates through the paint spraying bin and is fixedly mounted in the paint spraying bin through a support. The coat hanger rack can conduct self-rotationin the paint spraying section with a suspension point as the center, the paint spraying device is arranged in the center of the paint spraying bin, and the paint supplying device is connected with thepaint spraying device through a pipeline. According to the coat hanger paint spraying machine, paint spraying treatment can be conducted on the irregular hook face of the upper portion of the wood coat hanger, the production efficiency is high, the machining quality is high, and paint consumption is less .

Owner:广西荔浦安吉利木业有限公司

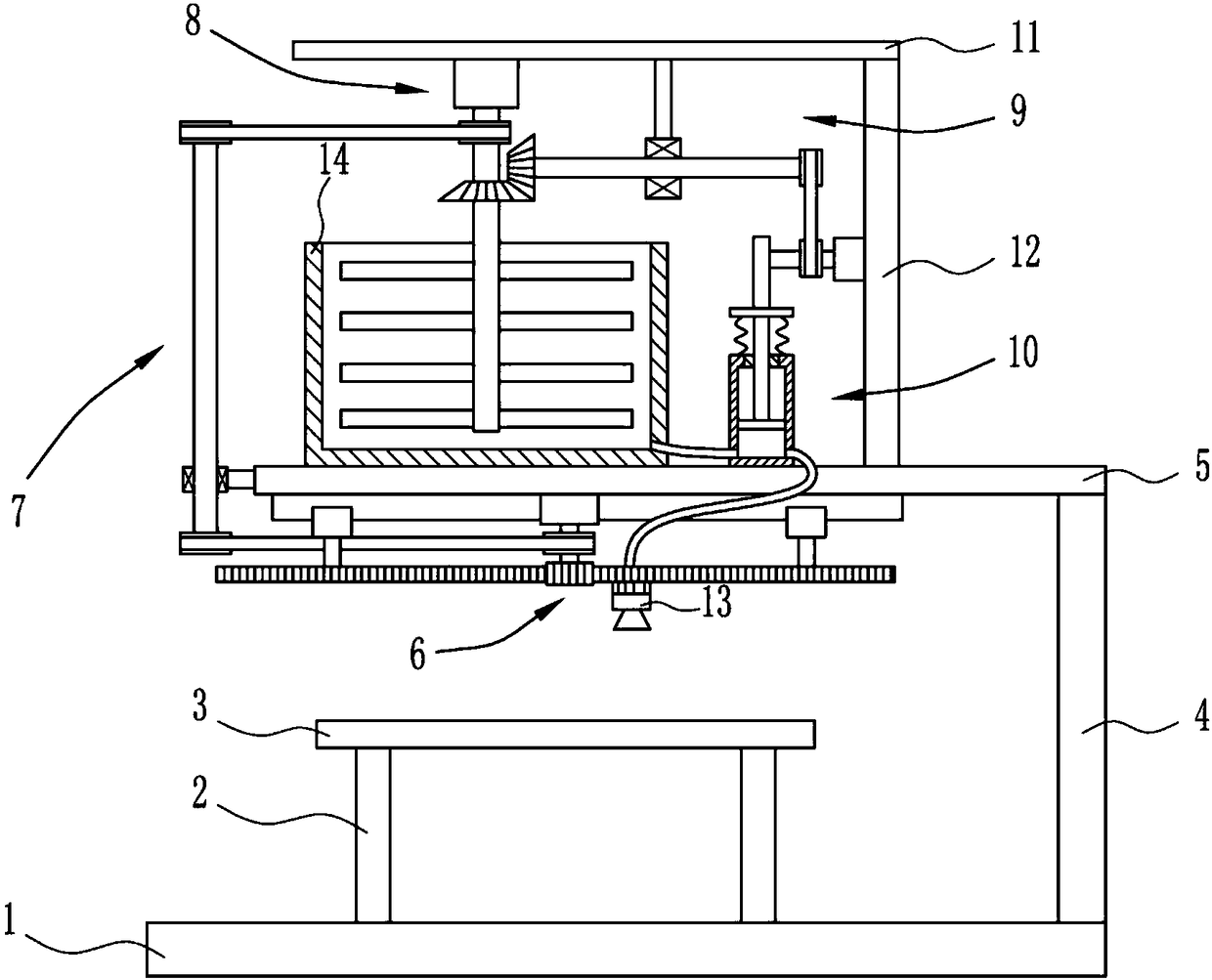

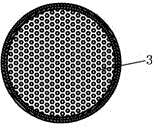

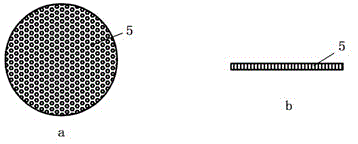

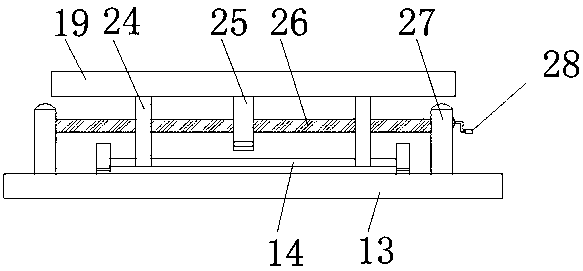

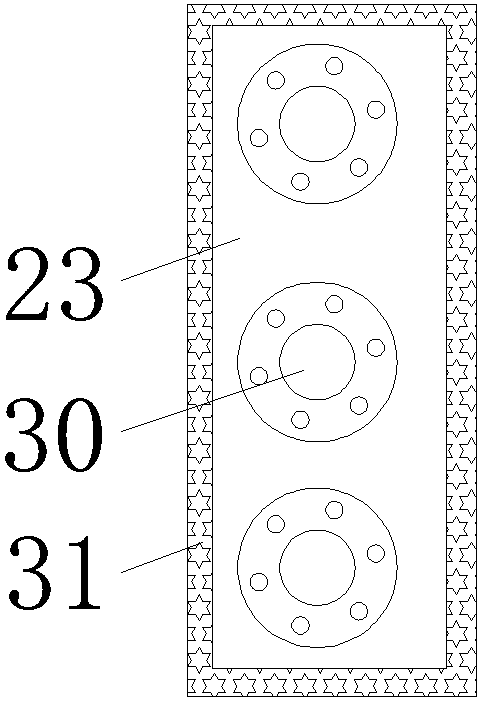

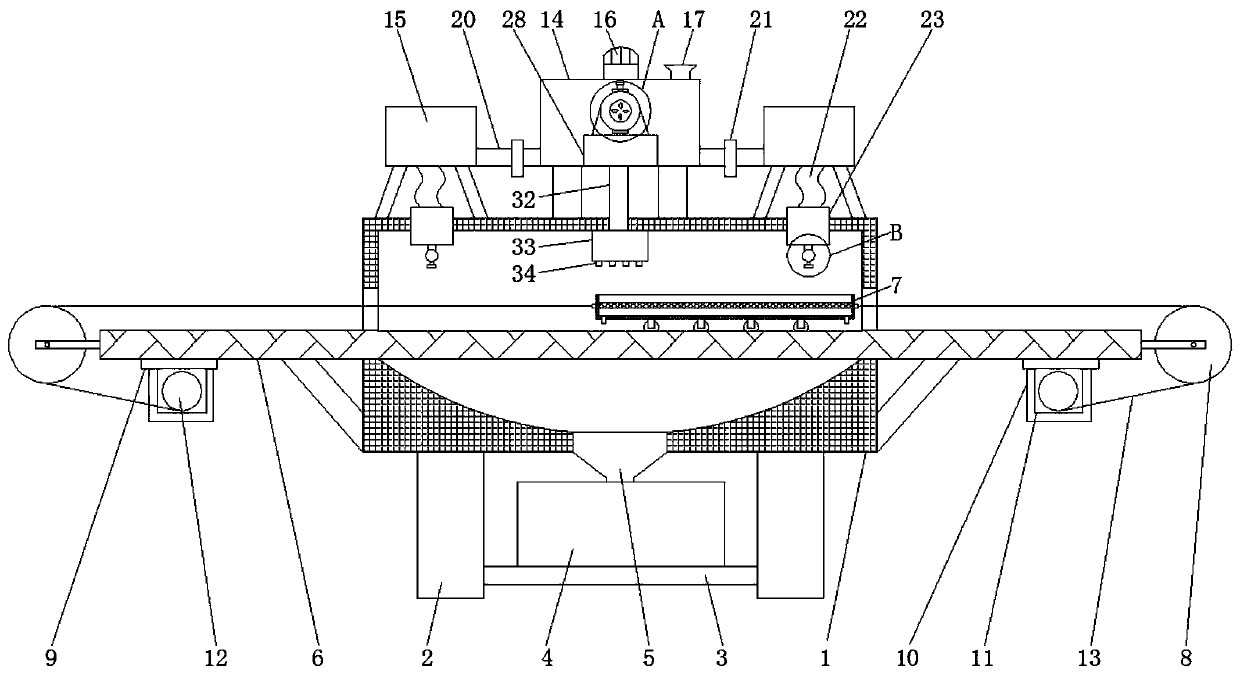

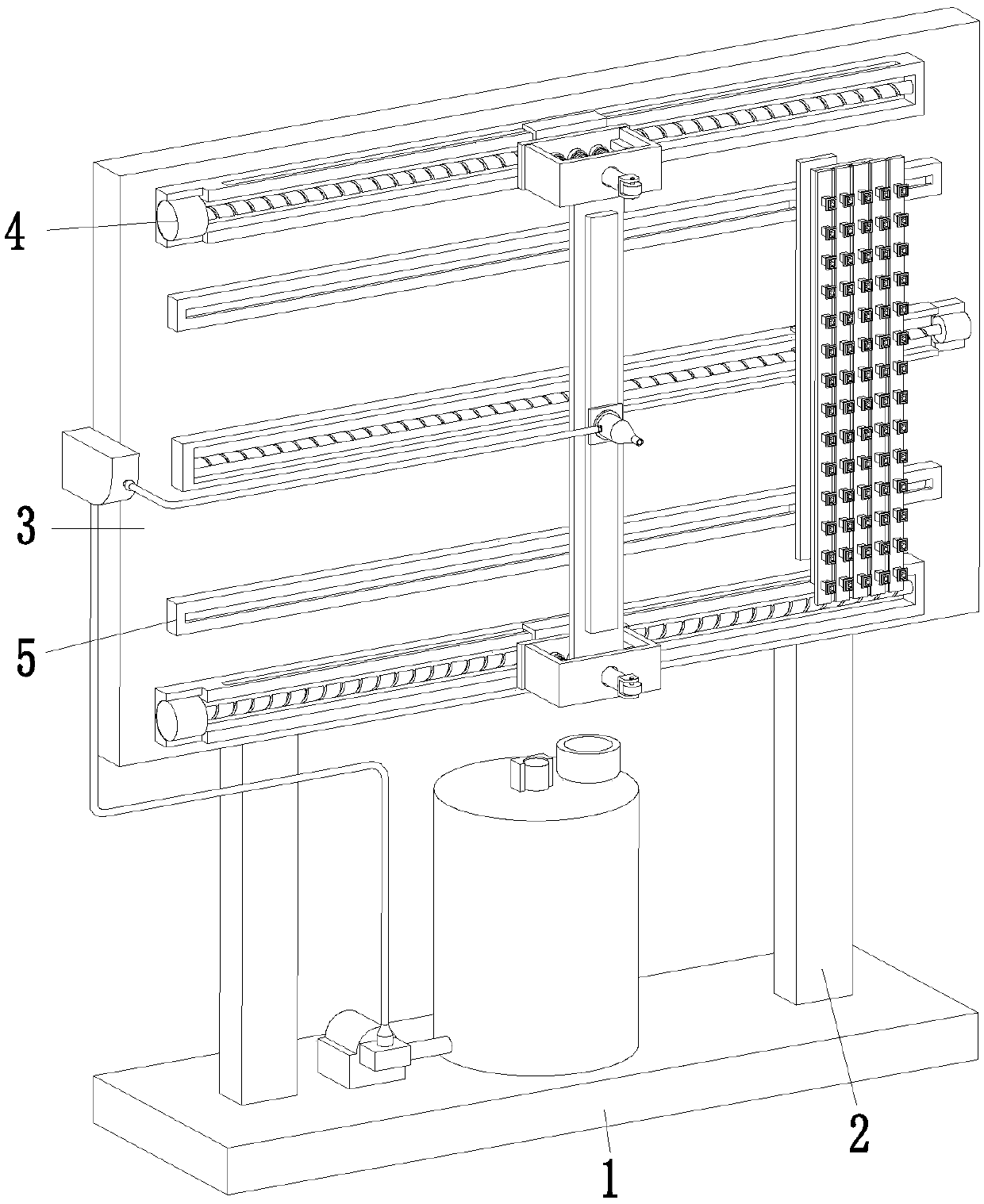

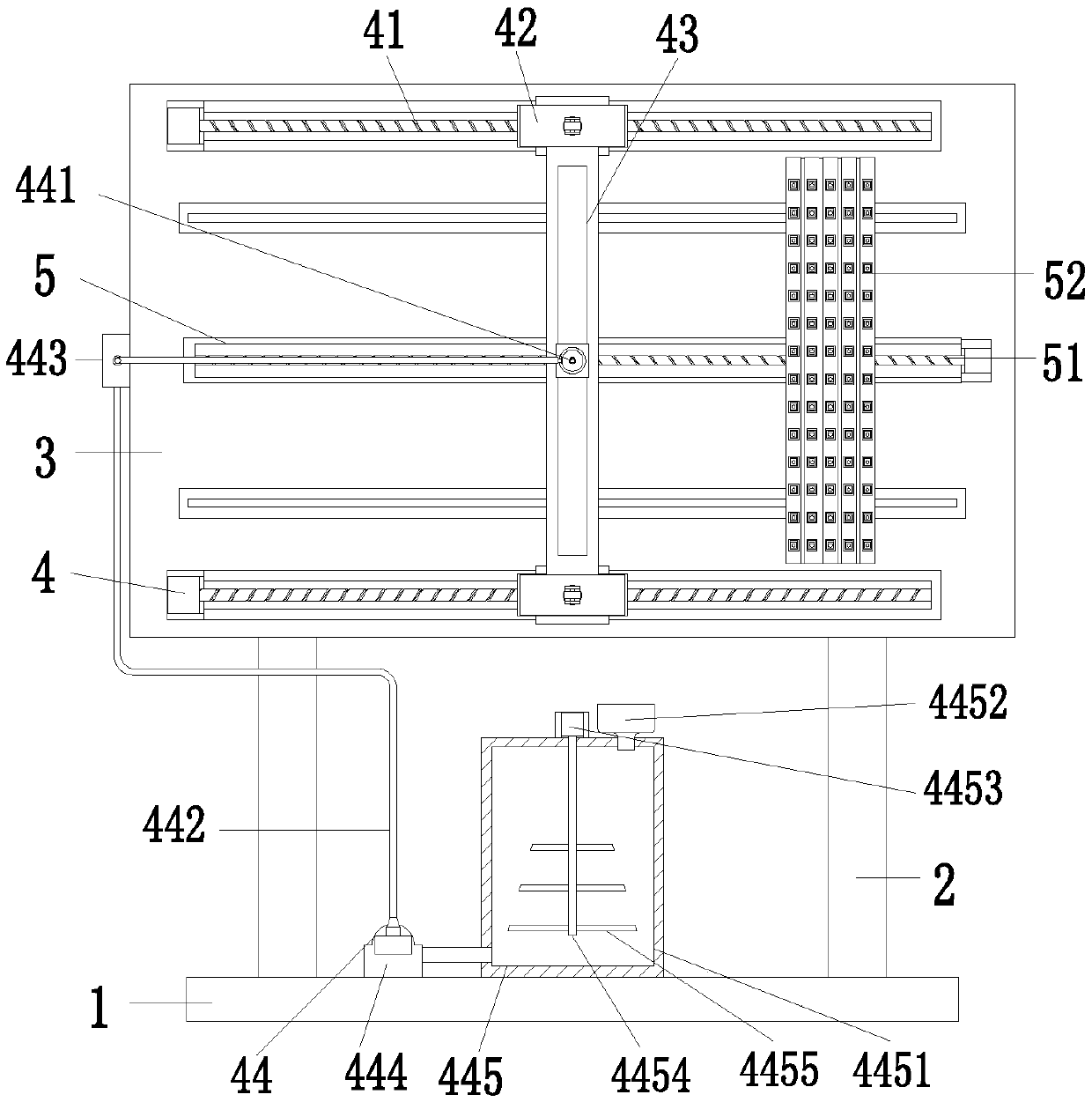

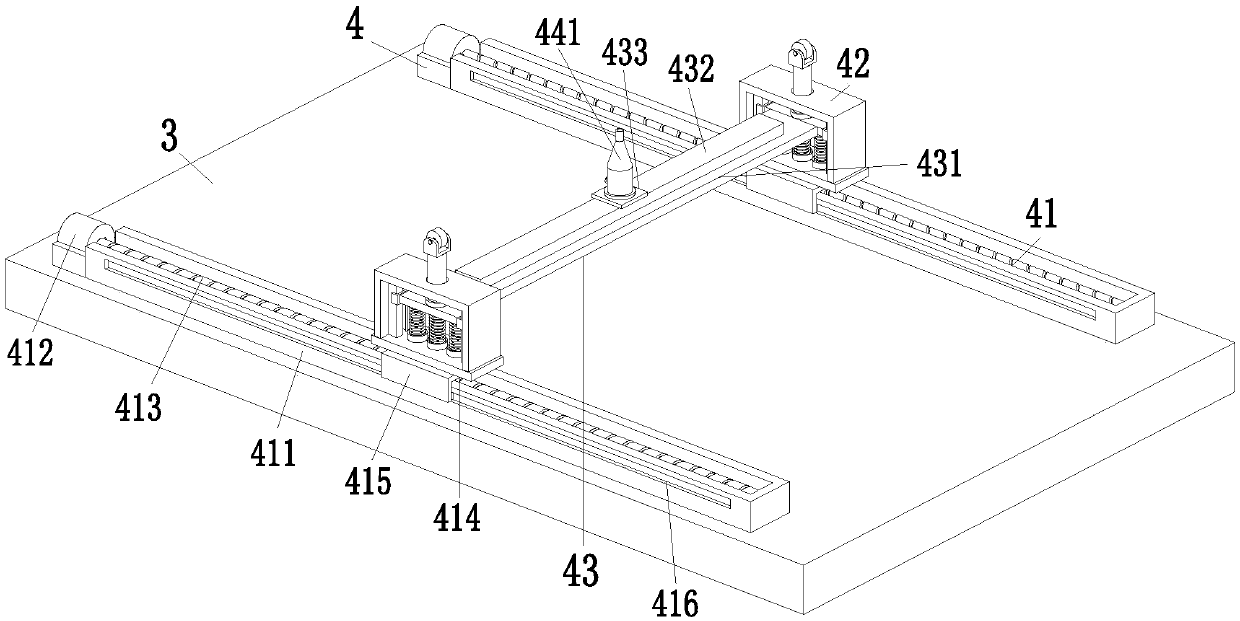

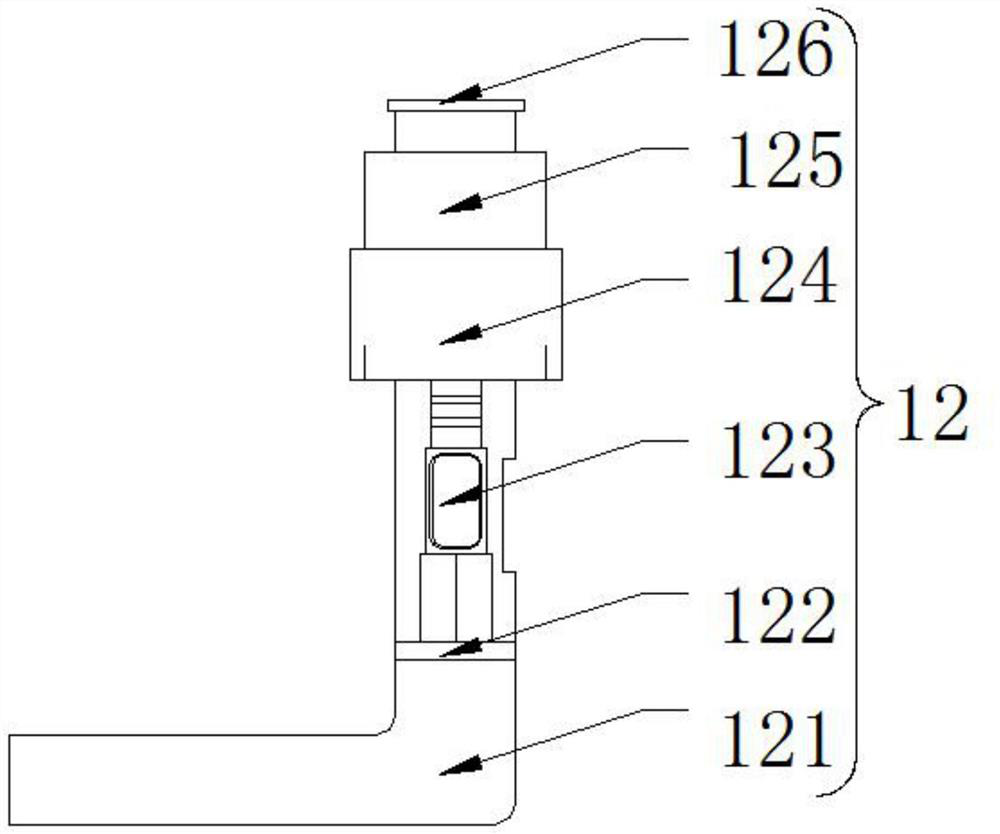

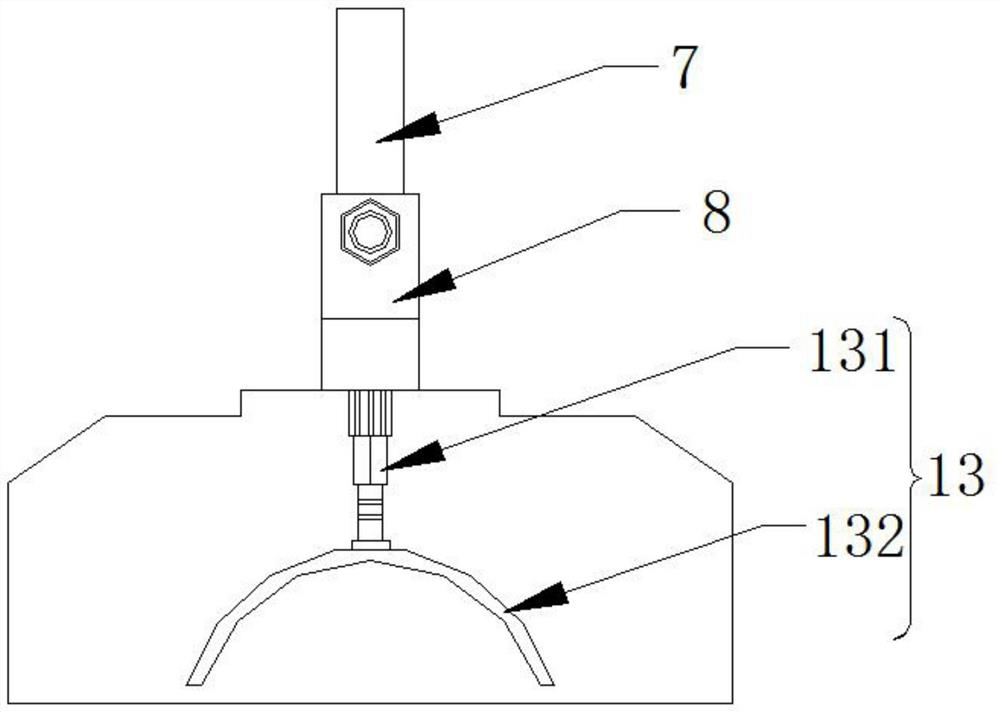

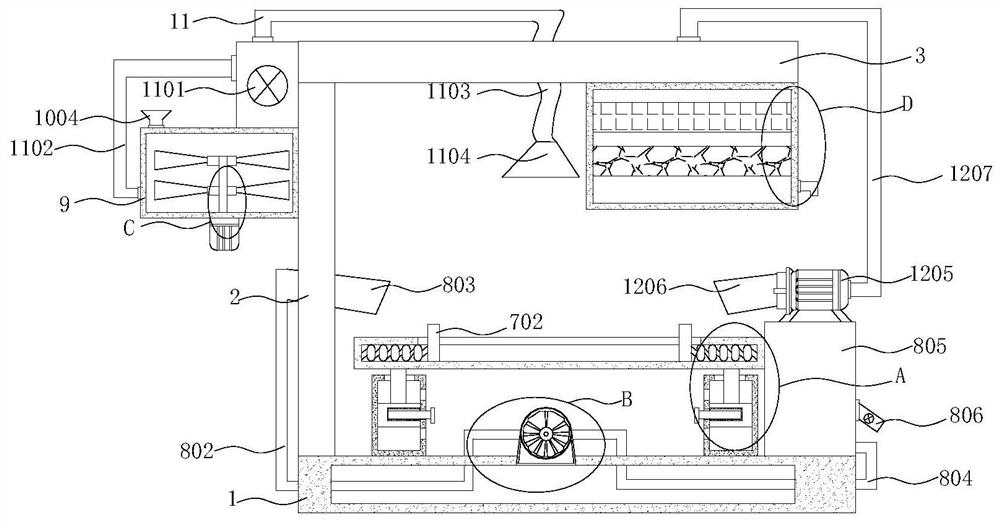

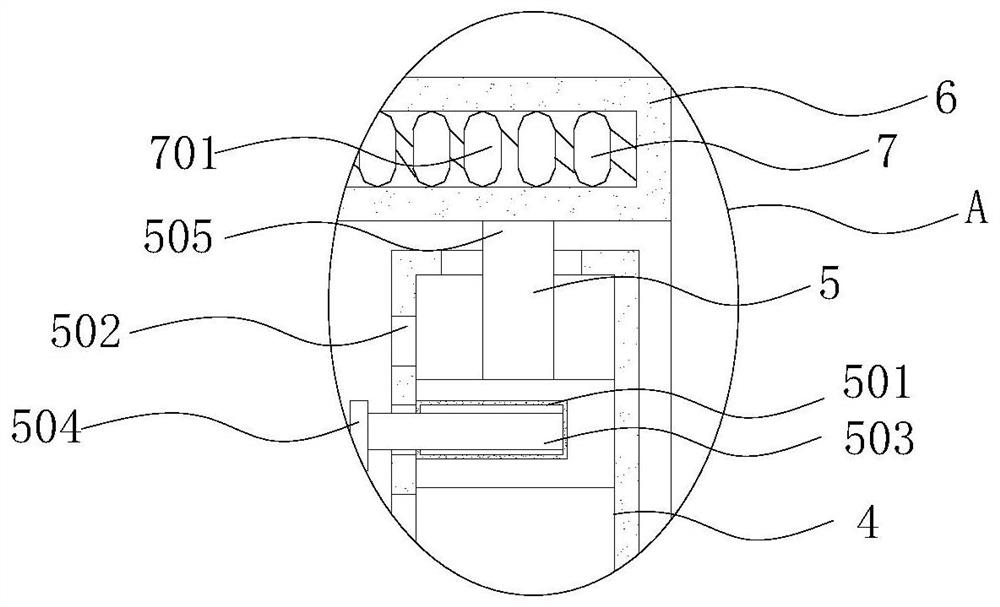

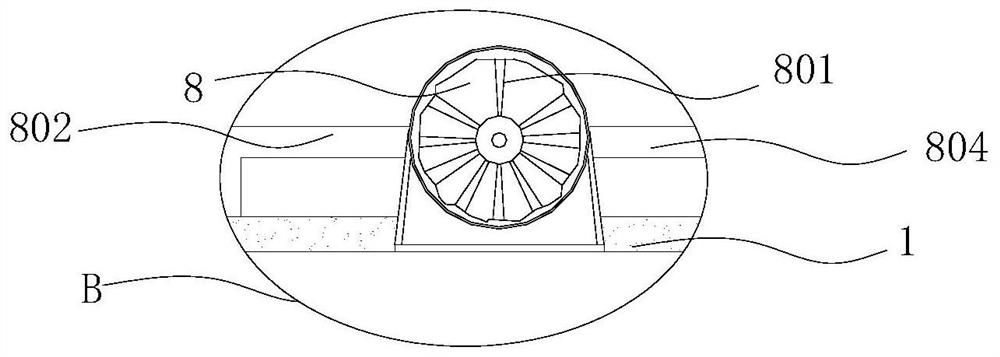

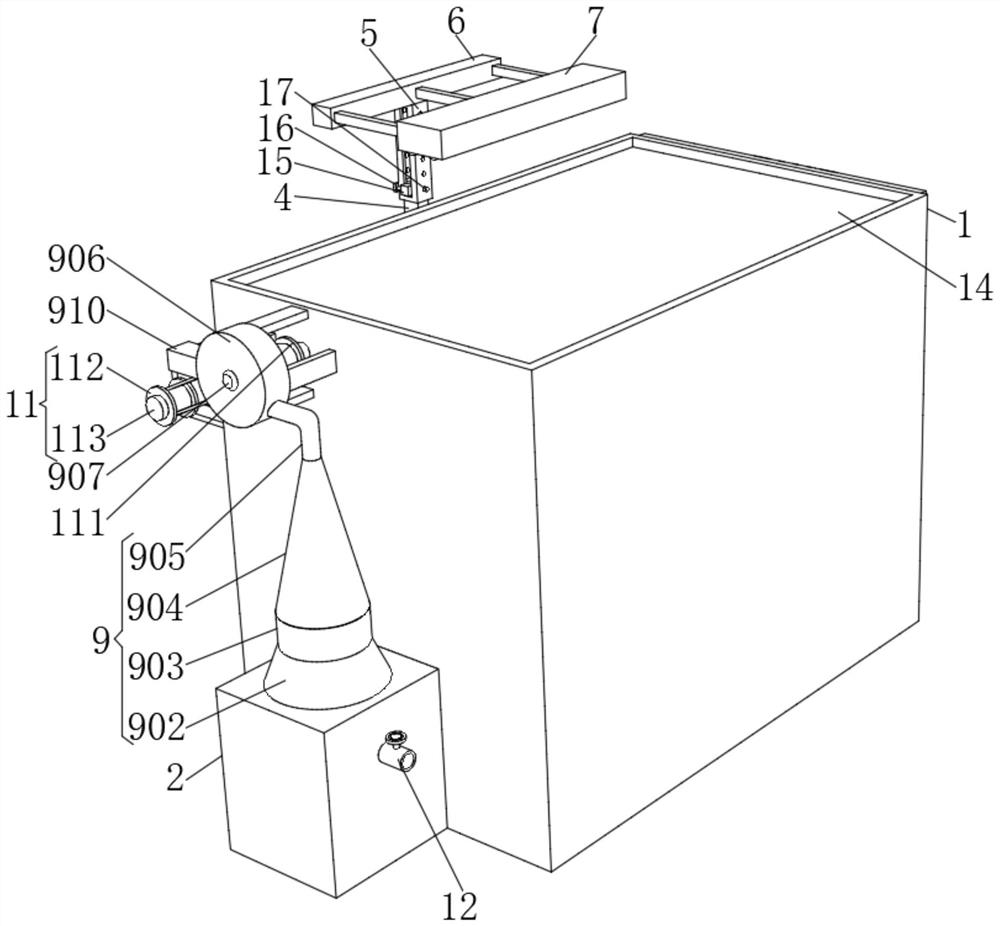

Spraying equipment for arc-shaped metal hard screen surface honeycomb coating

The invention relates to spraying equipment for an arc-shaped metal hard screen surface honeycomb coating. The spraying equipment for the arc-shaped metal hard screen surface honeycomb coating comprises a bottom plate, support frames, a fixed plate, a spraying device and a die device, wherein the support frames are symmetrically arranged at the upper end of the bottom plate; the fixed plate is arranged at the upper ends of the support frames; the spraying device is arranged in the middle of the front end of the fixed plate; and the die device is arranged on the fixed plate and is located on the right side of the spraying device. The spraying equipment for the arc-shaped metal hard screen surface honeycomb coating provided by the invention can solve the problems that when an existing arc-shaped metal hard screen is sprayed, the distance between a spray gun and the metal hard screen cannot be stably controlled, so that a spraying effect is poor, uneven spraying is caused, and the honeycomb coating cannot be formed after spraying; can realize a function on automatically honeycomb-spraying the surface of the arc-shaped metal hard screen surface; and has the advantages that the sprayingeffect is good, even spraying is realized, the distance between the spray gun and the metal hard screen can be controlled, and the honeycomb coating can be formed after spraying.

Owner:西安呱牛信息技术有限公司

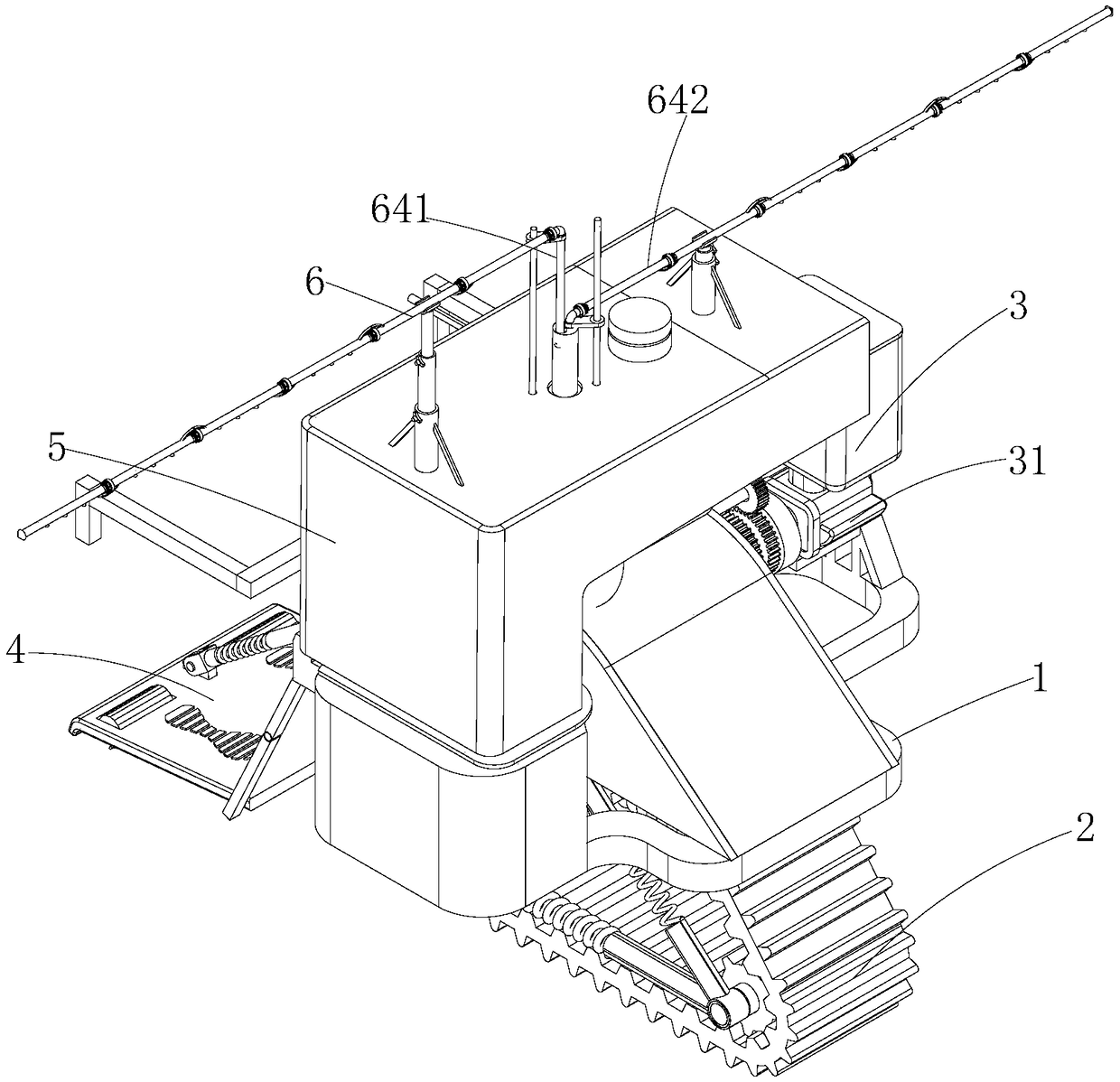

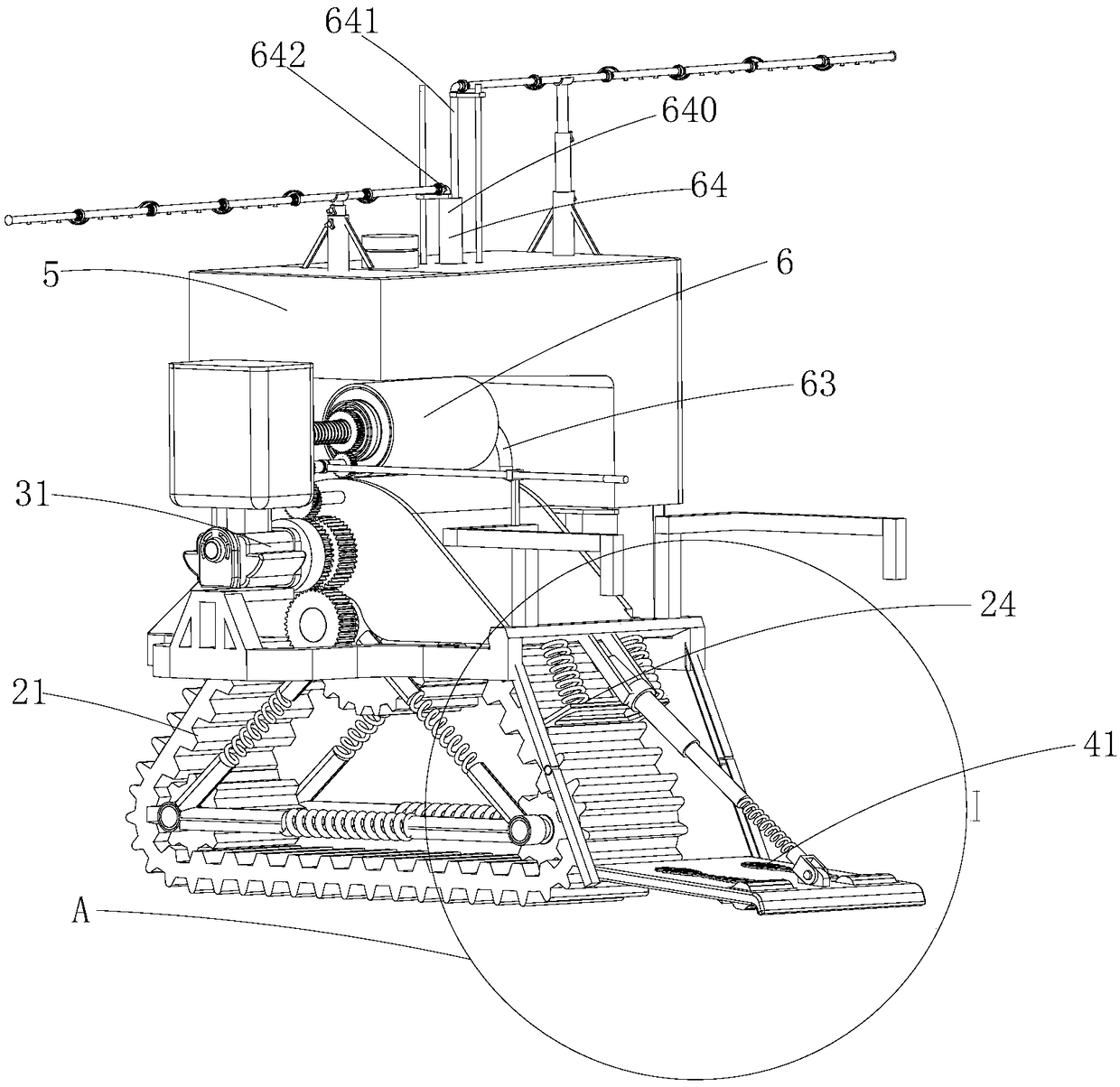

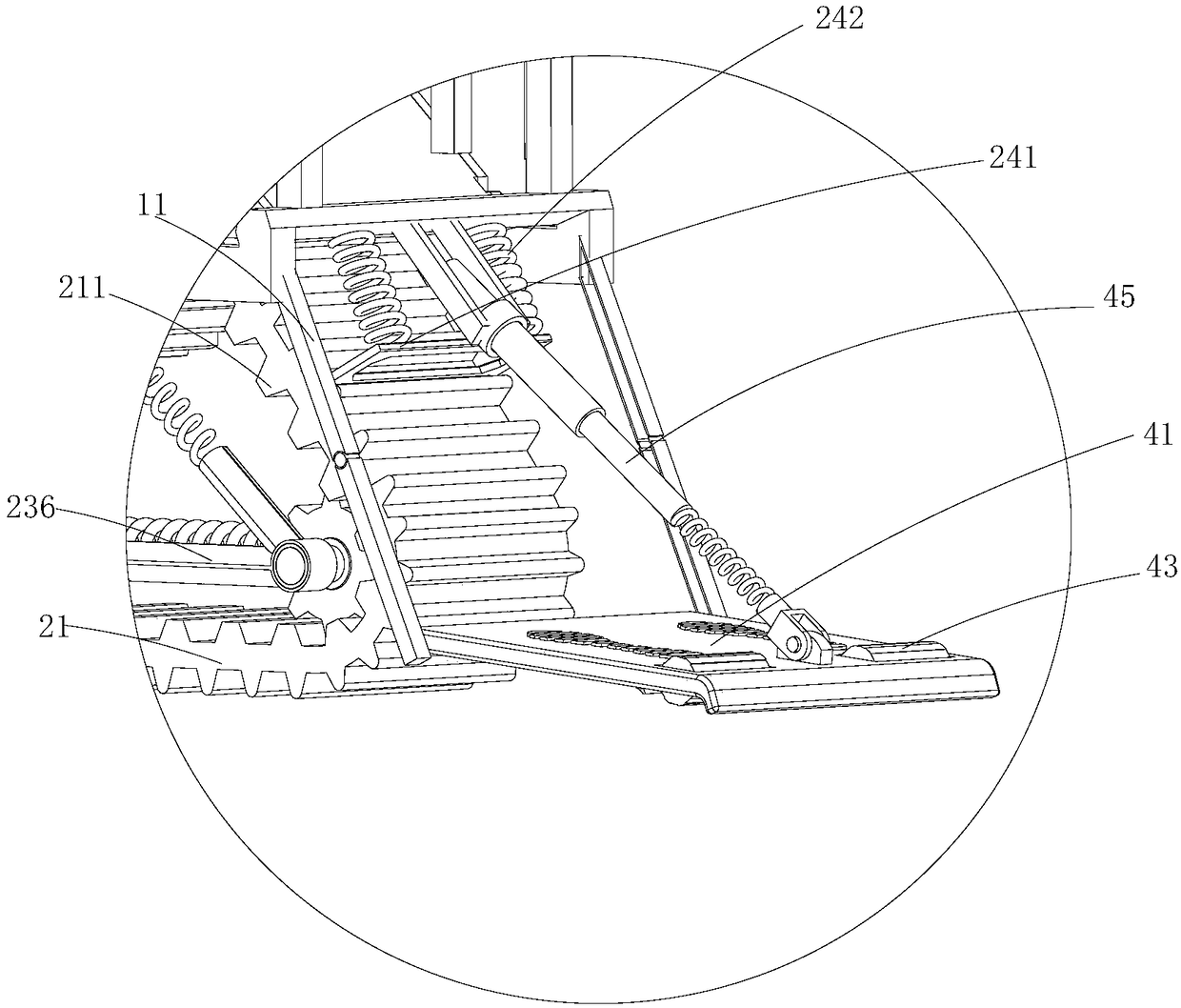

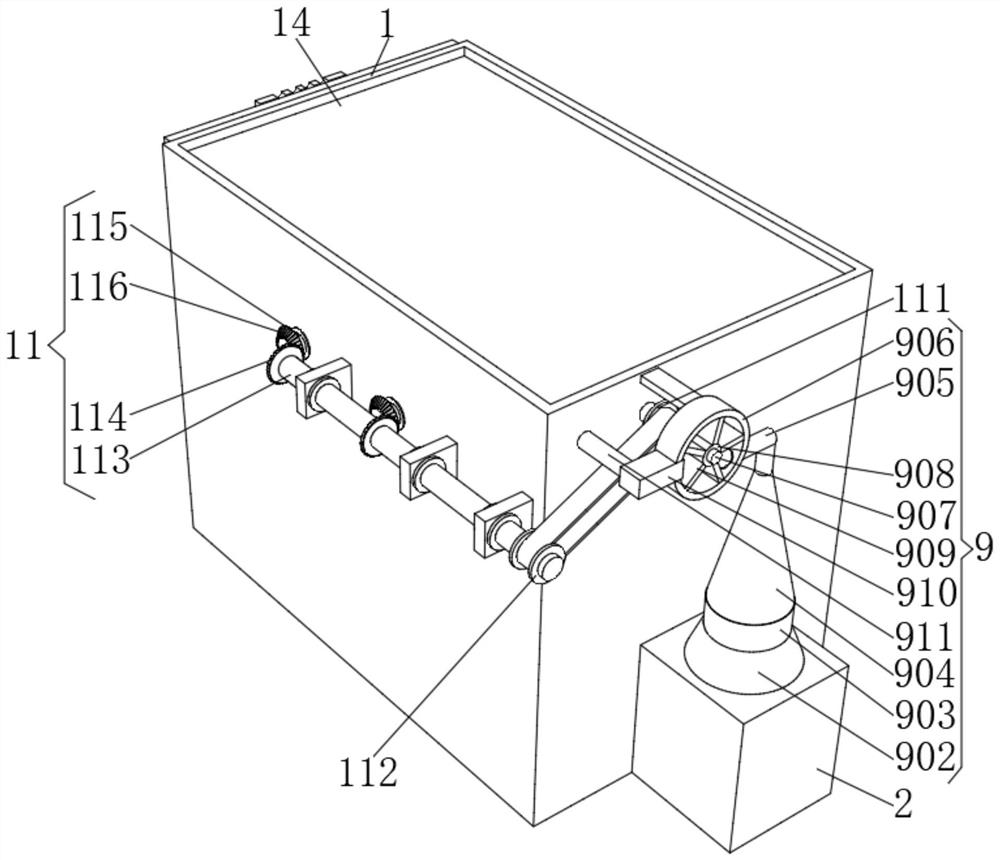

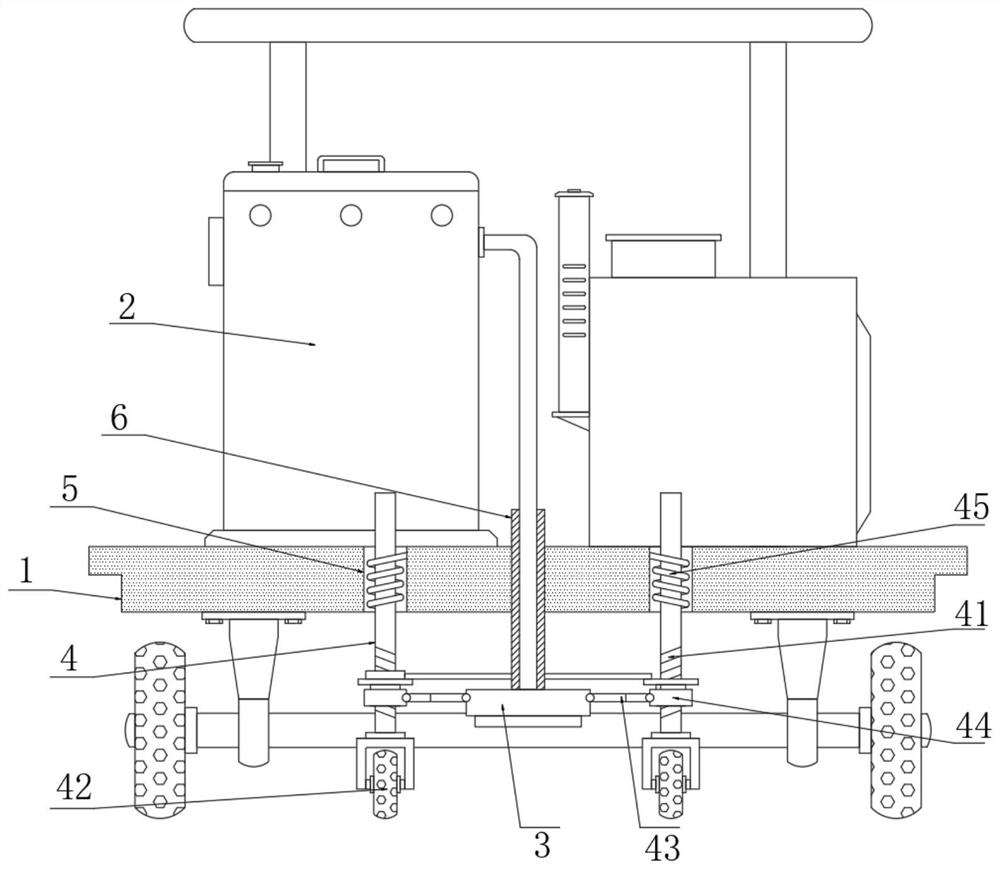

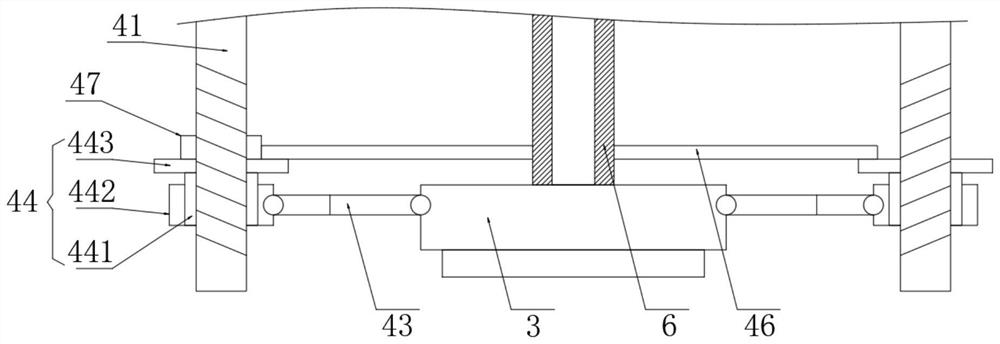

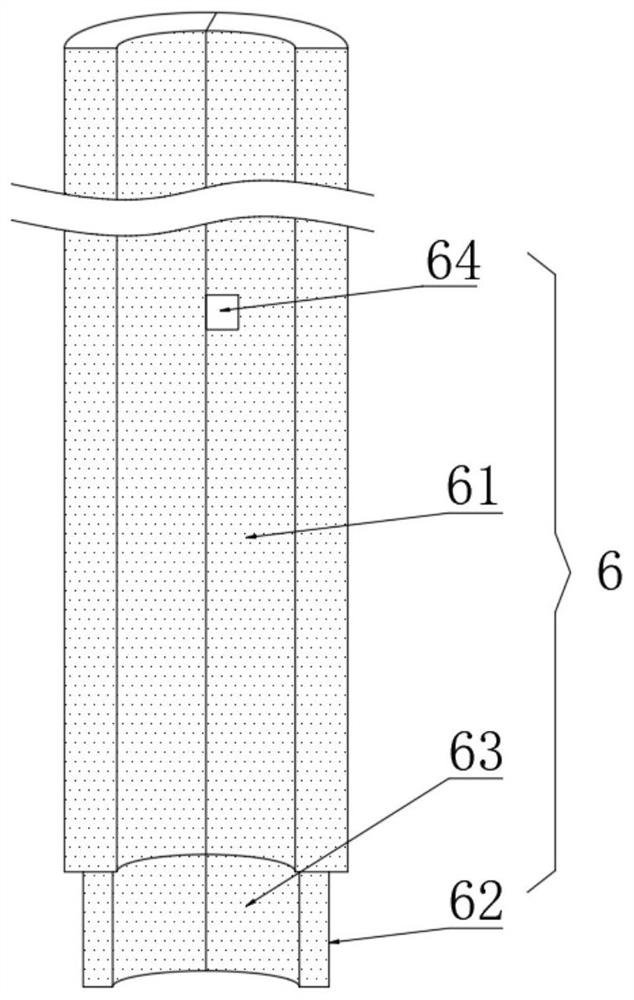

Small equipment for spraying pesticide into tea garden

The invention discloses small equipment for spraying pesticide into a tea garden. The small equipment includes a rack; a crawler device located in the middle of the rack for driving the whole equipment to move forward and backward; a driving device for driving the crawler device; a grading device for flattening the soil brought up by the crawler device; a pesticide storage box for storing pesticide liquid; and a spray device for spraying the pesticide liquid to tea trees. According to the invention, the shock caused by the driving device can be quickly absorbed by the arrangement of a shock absorbing device, so that the shock transferred onto other equipment is reduced, the whole equipment is ensured to have high stability when spraying the pesticide to the tea trees and uneven spraying ofpesticide by the spraying device due to the shock during the spraying of the pesticide is avoided.

Owner:陈玲聪

Multi-station spraying device of limiting structure for mobile phone shell machining tool

ActiveCN113441327AAvoid spillingImprove drying efficiencyPretreated surfacesCoatingsSprayerEngineering

The invention discloses a multi-station spraying device of a limiting structure for a mobile phone shell machining tool, and relates to the technical field of mobile phone shell machining, in particular to a working frame and an external frame, an adjusting assembly is arranged in the middle of the interior of the working frame, a connecting base is mounted outside the top of the adjusting assembly, a sprayer is arranged outside the connecting base; an auxiliary assembly is arranged at one end of the outer portion of the sprayer and comprises a connecting rod, a base, a first hydraulic air rod and an outer frame. According to the multi-station spraying device of the limiting structure for the mobile phone shell machining tool, when a sprayer is not needed, a built-in frame can be driven to move front and back under the action of a second hydraulic air rod and a sliding block, so that when the built-in frame moves to a nozzle opening of the sprayer, an adsorption end opening wraps the nozzle opening. By means of the design of the second suction pump and the adsorption end opening, residual spraying liquid at the nozzle opening can be cleaned, and the situation that spraying is not uniform enough when the sprayer is used again is avoided.

Owner:深圳市亿铭粤科技有限公司

Accessory spraying device for conveying machine machining

InactiveCN111889278ASolve the problem of adjusting the height of the placement seatImprove applicabilityCleaning using gasesSpray boothsEngineeringMachining

The invention discloses an accessory spraying device for conveying machine machining, and relates to the technical field of conveying machines. The accessory spraying device for conveying machine machining comprises a base. A side support is mounted at the top of the base in a welded manner. A top plate is arranged above the base. The free end of the side support is fixedly connected with the topplate. A connecting seat is mounted at the top of the base in a welded manner. An adjusting mechanism is arranged on the connecting seat. A containing seat is fixedly mounted on the base through the adjusting mechanism, a fixed mechanism is arranged on the containing seat, and a dust removal mechanism is arranged above the containing seat. The accessory spraying device is convenient to use, the position of the containing seat can be adjusted, and the problem that the height of the containing seat cannot be adjusted conveniently according to machining materials of different thicknesses is effectively solved; and meanwhile, diffusion of harmful gas generated by spraying can be reduced easily, the body health of workers is prevented from being influenced, outside air is prevented from being popularized, and the device is beneficial to application and popularization.

Owner:湖州吴兴双德输送机械有限公司

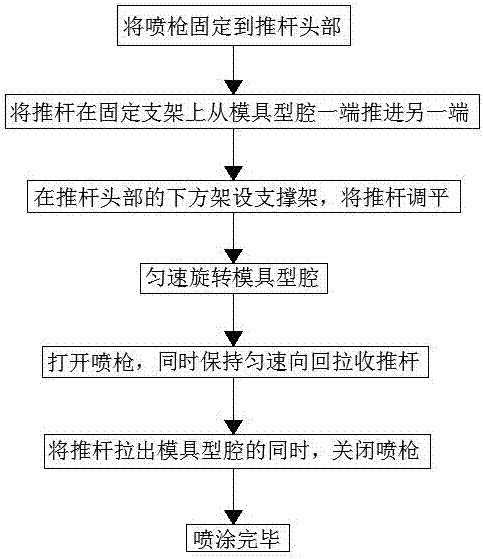

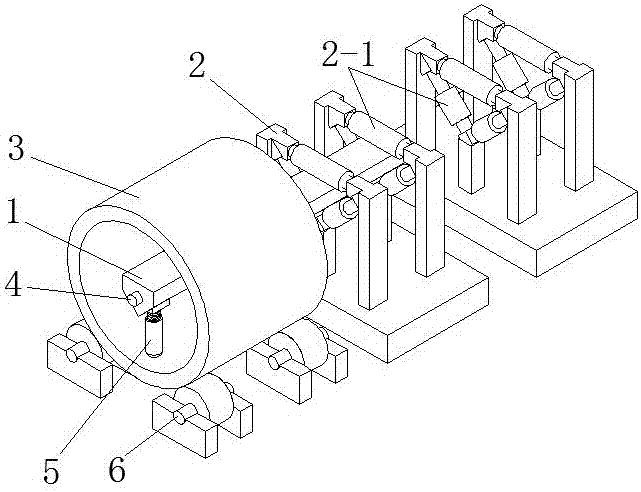

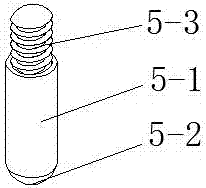

Method and device for spraying inner wall of mold die cavity of horizontal centrifuge

ActiveCN106890957AEnsure consistencySolve uneven thicknessMoulding toolsEngineeringMechanical engineering

The invention discloses a method and device for spraying an inner wall of a mold die cavity of a horizontal centrifuge, and belongs to the technical field of spraying of coatings. The method comprises the following steps of fixing a spray gun to the head of a push rod; erecting the push rod to a fixing bracket, and pushing the push rod from one end of the mold die cavity to the other end of the inner part of the mold die cavity on the fixing bracket; erecting a supporting frame under the head of the push rod, and leveling the push rod by the supporting frame, so that the rod body of the push rod is parallel to the axis of the mold die cavity; rotating the mold die cavity at a uniform speed, turning on the spray gun, and pulling the push rod back at the uniform speed; and pulling the push rod out of the mold die cavity at the uniform speed, and turning off the spray gun so that the spraying is completed. Through the adoption of the method disclosed by the invention, in the process of spraying, the consistency of the height of the spray gun is guaranteed, the problem of uneven thickness of the coating caused by the changes of the height of the front end of the push rod is solved, and the spraying quality is improved; and besides, through the adoption of the mechanized operation realized by the method disclosed by the invention, the quality problem which is liable to cause by manual operation is avoided, and the spraying efficiency is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

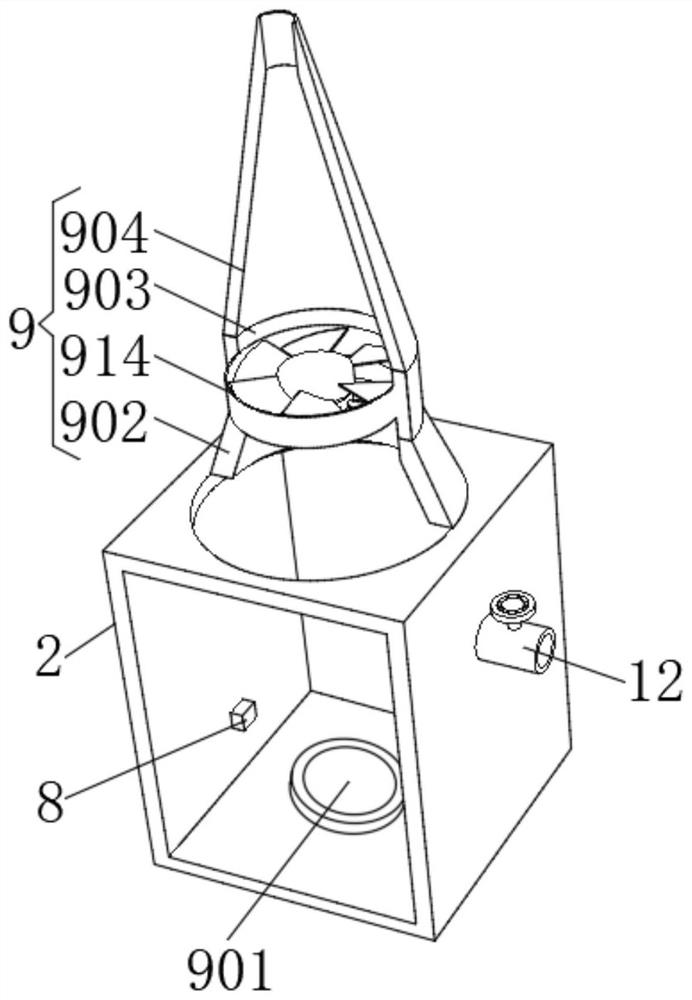

High-efficiency spinning dedusting device

InactiveCN108404552AImprove practicalityEasy to useCombination devicesDispersed particle filtrationEngineeringControl valves

The invention discloses a high-efficiency spinning dedusting device. A spinning box and a dedusting box are sequentially and fixedly connected to the top of the base from left to right, a dust suctionwindow is arranged on an inner cavity of the spinning box, the right side of the dust suction window is communicated with a dust suction pipe, the right side of the dust suction pipe penetrates through the right side of a fan, the right side of the dust suction pipe is communicated with the fan, the output end of the fan penetrates through the dedustign box and extends into the inner cavity of the dedusting box to be communicated with a dedusting opening, and a filtering plate is fixedly connected to the bottom of the dedusting box. By means off mutual match among the filtering plate, the spinning box, the dust suction window, the dust suction pipe, the fan, the dedusting opening, the dedusting box, a water spraying pipe, a water spraying head, a water tank, a control valve, a water pump,a water outlet pipe, a water spraying rotating vane and a spraying hole, the problems that an existing dedusting device has a bad dedusting effect in use and make a user work under the environment for a long time to generate certain effects on the body of the user are solved; convenience is brought to the user, and practicability of the dedusting device is improved.

Owner:SUZHOU FABAI TEXTILE CO LTD

Spraying equipment with adjusting function

InactiveCN113134441AAvoid offsetAvoid occlusionSpraying apparatusStructural engineeringDistance sensors

The invention relates to spraying equipment with an adjusting function, which comprises a vehicle body, a charging barrel and a spraying device and further comprises a stirring mechanism and an adjusting mechanism; the adjusting mechanism comprises a distance sensor, an air cylinder and a cleaning assembly; the stirring mechanism comprises a driving assembly, two power assemblies, two moving plates, two limiting assemblies and a plurality of stirring assemblies; and the stirring assemblies comprise connecting blocks and stirring plates. According to the spraying equipment with the adjusting function provided by the invention, the distance between a spraying gun and a container can be adjusted through the adjusting mechanism, the situation that the spraying pressure is too small due to the fact that the distance between the spraying gun and the container is too large is prevented, and therefore the situation that the spraying thickness cannot reach the specification is avoided, the spraying pressure is too large caused by the fact that the distance between the spraying gun and the container is too small is also prevented, the phenomenon of uneven spraying is avoided, the paint stirring function is achieved through the stirring mechanism, the paint is in a flowing state, the probability of the caking phenomenon is reduced, the phenomenon that the spraying gun is blocked by the caking paint is prevented, and therefore the influence on spraying work is prevented.

Owner:董赵卜

Improved contrast cultivation assembly for moss experimental research

InactiveCN114175983AUniform coverageBig impactClimate change adaptationGreenhouse cultivationEngineeringMoss

The invention discloses an improved contrast cultivation assembly for moss experimental research, which comprises a cultivation box, the top of the back of the cultivation box is fixedly connected with a protective frame, the top of the protective frame is fixedly connected with a square column, the square column is sleeved with a telescopic cylinder, the telescopic cylinder is fixedly connected with a transverse plate, and the transverse plate is fixedly connected with the protective frame. The front surface of the transverse plate is fixedly connected with an aquatic plant lamp through a connecting column, the bottom of one side of the cultivation box is fixedly connected with a water tank, a spraying mechanism is arranged in the cultivation box, and an auxiliary mechanism used in cooperation with the spraying mechanism is arranged on the cultivation box. The situation that moss growth conditions at different positions are different due to the fact that moss is sprayed unevenly in a direct spraying mode is avoided, meanwhile, the situation that an experiment fails due to the fact that the moss is separated from a medium easily due to impact force generated by the spraying mode is avoided, and meanwhile water mist entering the cultivation box can be further scattered through an auxiliary mechanism.

Owner:LISHUI UNIV

Coating spraying device and method for road maintenance

ActiveCN112391926AAvoid uneven sprayingChange spacingSpraying apparatusRoads maintainenceStructural engineeringRoad surface

The invention discloses a coating spraying device for road maintenance, and belongs to the technical field of road maintenance equipment. The device comprises a vehicle body and a material barrel, thematerial barrel is fixedly mounted on the outer wall of the top of the vehicle body, two groups of openings are formed in the outer wall of the bottom of the vehicle body, and two groups of guide devices are arranged on the outer wall of the bottom of the vehicle body; the guide device comprises guide rods slidably inserted into the inner cavities of the openings, guide wheels are fixedly mountedat the bottom ends of the guide rods, a spraying head is arranged between the two guide rods, and the end, away from the spraying head, of the hose extends to the outer wall of the top of the vehiclebody and communicates with the outer wall of the right side of the material barrel. The guide whees and the spraying head in the device are located on the same horizontal line, the guide wheels drivethe guide rods to move up and down in the inner cavity of the openings, the spraying head can change along with the height change of the road surface, and therefore the distance between the sprayinghead and the marking area is kept unchanged, and uneven marking spraying caused by factors of the road surface is avoided.

Owner:NANJING MAOLE ENG MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com