Digit printing processing method of cashmere produce

A technology of digital printing and processing methods, applied in dyeing, textiles and papermaking, etc., which can solve the problems of imitation jacquard and imitation embroidery, dye pollution, nozzle clogging and other problems, so as to avoid uneven color spraying and short supply cycle , Increase the effect of shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Material: 100% cashmere

[0059] Printed product: worsted round neck cardigan for women

[0060] Fabric Weave: Flat Weave

[0061] Yarn count: 68S / 3 (metric system)

[0062] Base color: light pink

[0063] Printing position: access control printing 1 cm below the collar

[0064] Pattern: 12 color regular geometric figures (imitation embroidery printing)

[0065] Pre-treatment formulation: Adhesion aid 4%

[0066] Printing oil 2%

[0067] Brightening agent 2%

[0068] Paste 57%

[0069] Tartaric acid 3%

[0070] Urea 5%

[0071] water x%

[0072] 100%

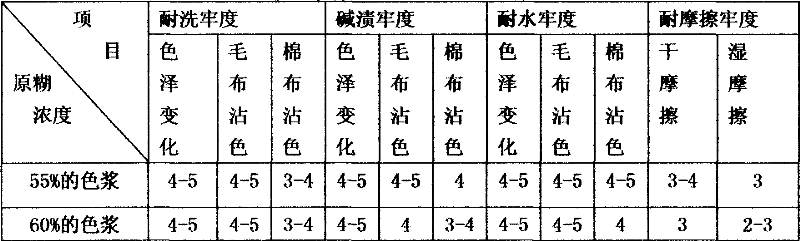

[0073]

[0074]

Embodiment 2

[0076] Material: 100% cashmere

[0077] Printed product: woolen men's pullover

[0078] Weave: The front piece is stitched 10*10 cm from the bottom 21 cm above the rib, and the other is a flat weave

[0079] Yarn count: 24S / 2 (metric system)

[0080] Pattern: moiré over pattern (fixed point, positioning printing)

[0081] Base color: light yellow

[0082] Pre-treatment formula: Adhesion aid 2%

[0083] Printing oil 2%

[0084] Brightening agent 2%

[0085] Paste 55%

[0086] Tartaric acid 3%

[0087] Urea 5%

[0088] water x%

[0089] 100%

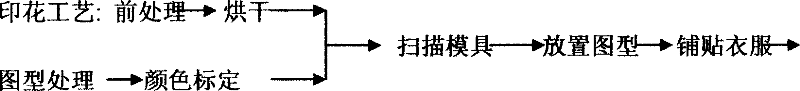

[0090] Printing process: with [embodiment one]

Embodiment 3

[0092] Material: 100% cashmere

[0093] Printed product: round neck vest

[0094] Fabric Weave: Flat Weave

[0095] Yarn count: 24S / 2 (metric system)

[0096] Base color: white

[0097] Flower type: diamond grid (imitation needle circle printing)

[0098] Pre-treatment formulation: Adhesion aid 5%

[0099] Printing oil 2%

[0100] Brightening agent 2%

[0101] Paste 60%

[0102] Tartaric acid 3%

[0103] Urea 5%

[0104] water x%

[0105] 100%

[0106]

[0107]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com