Patents

Literature

53results about How to "Fully flushed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

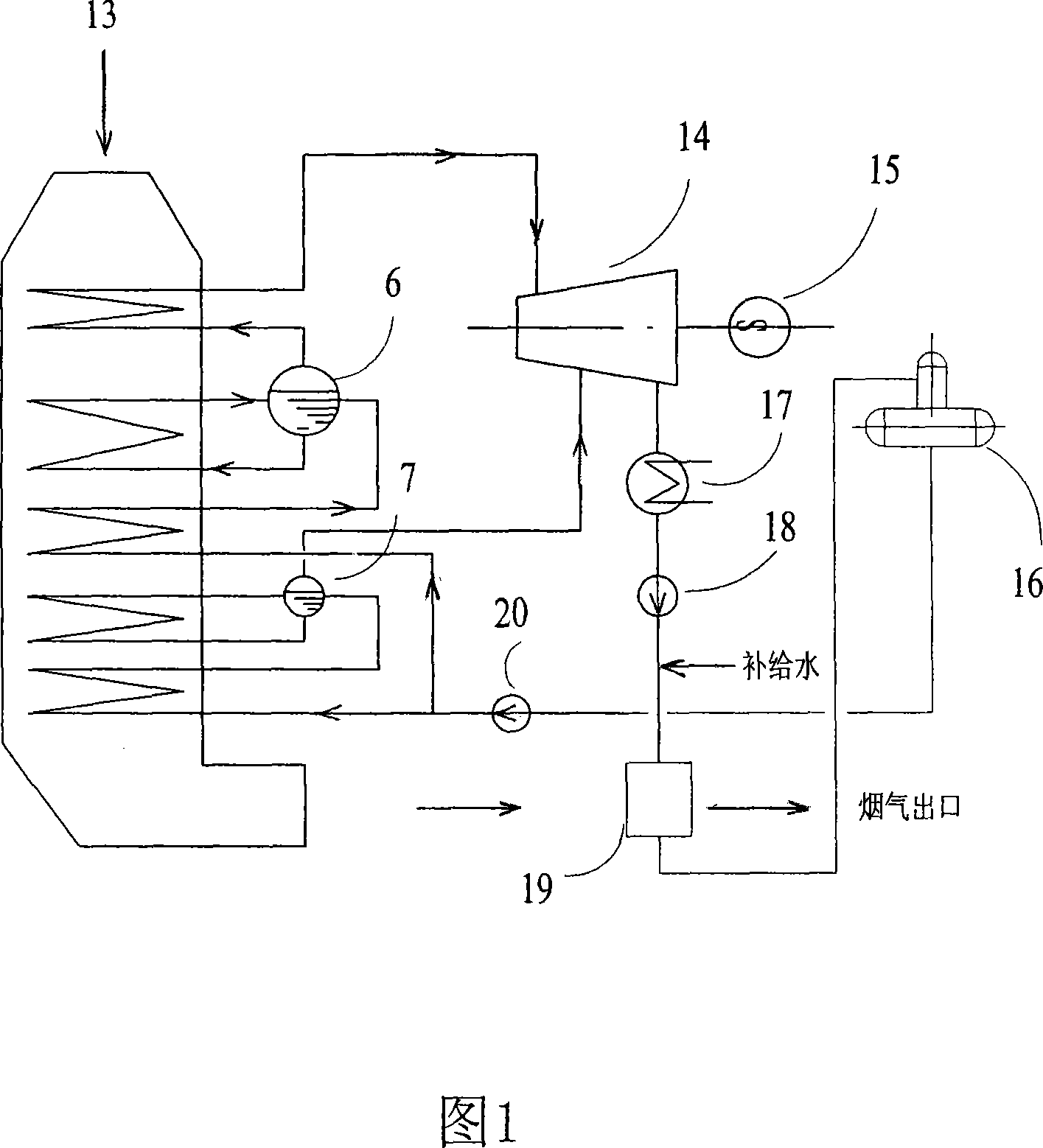

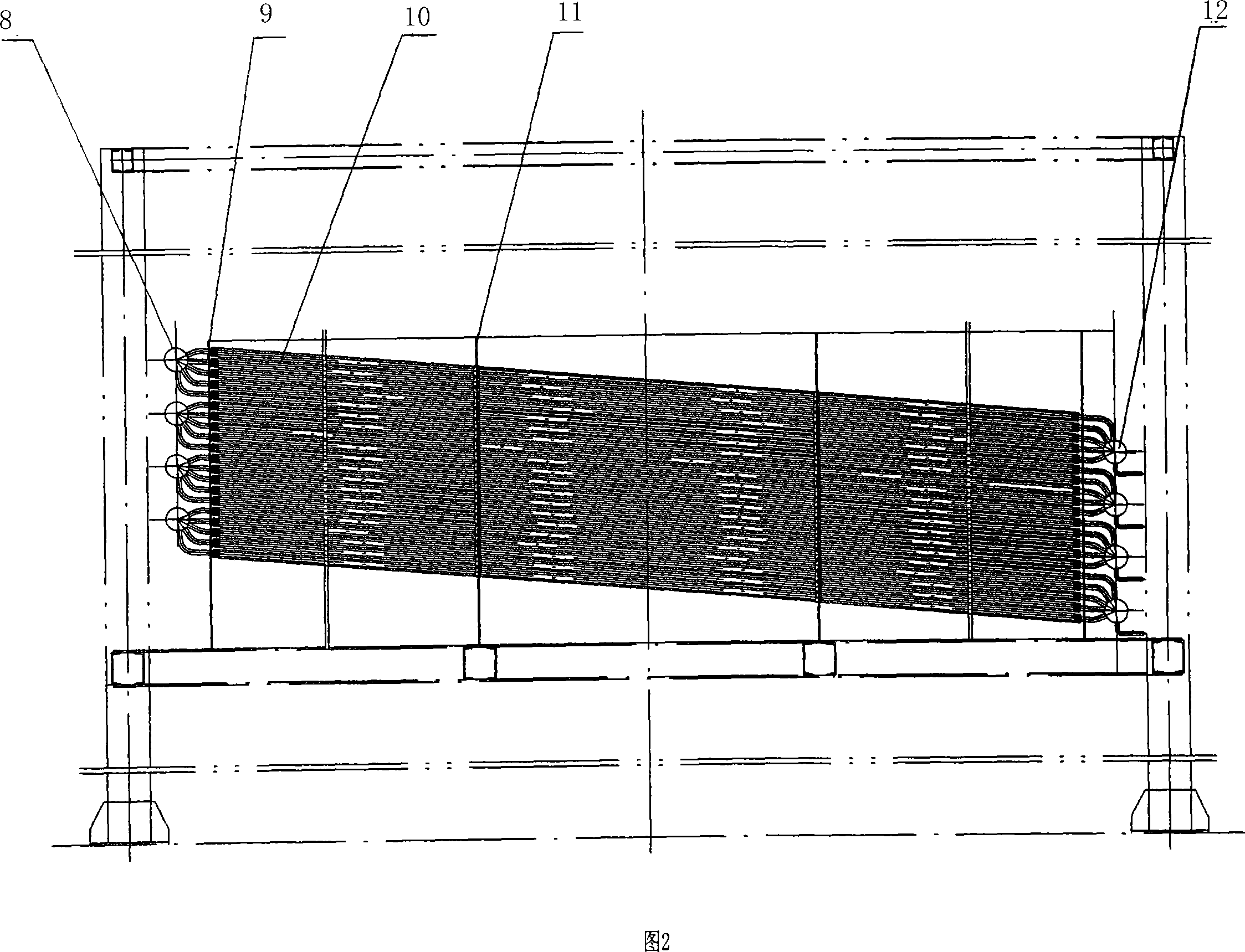

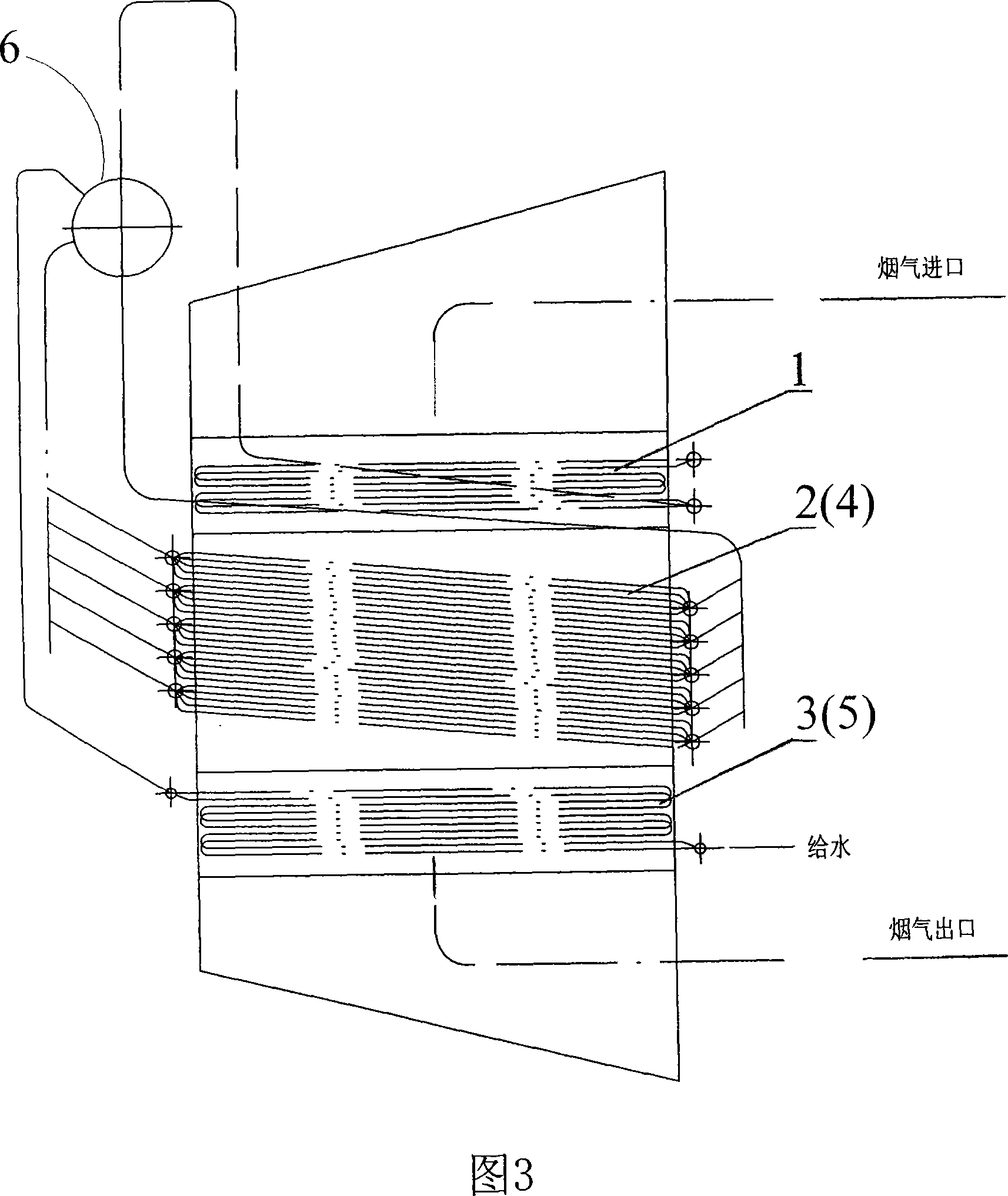

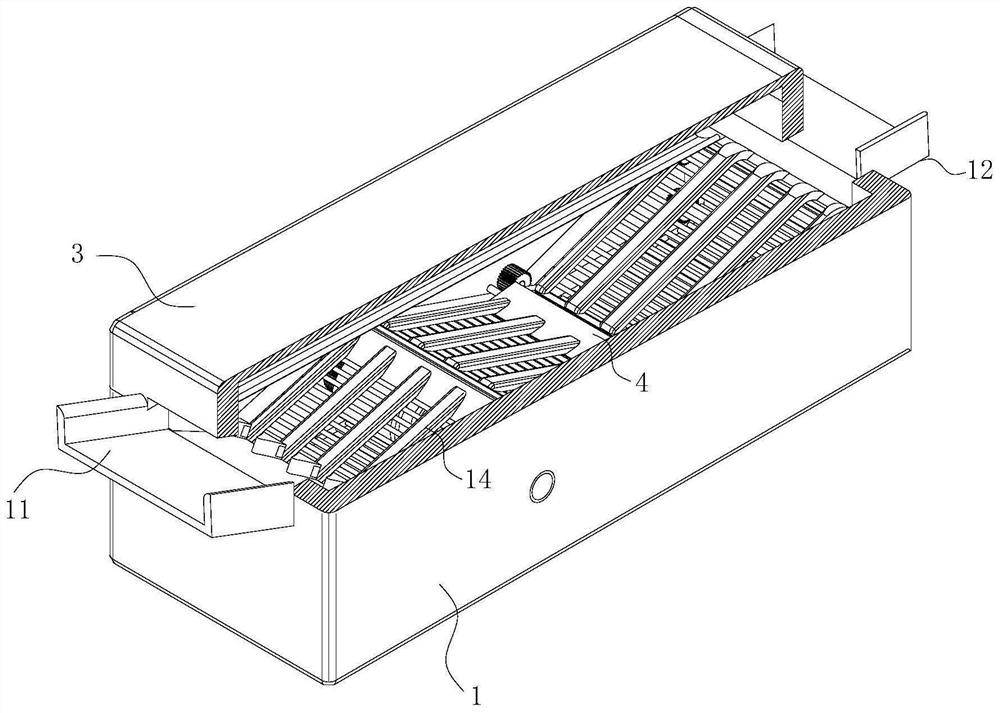

Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

InactiveCN101021305AEasy to discharge ashSmall footprintSteam boilersSteam boilers componentsWhole bodyEvaporation

The present invention provides an exhaust-heat boiler capable of effectively utilizing low-temperature heat transmission to make power generation and its power generation system. Said exhaust-heat boiler whole body adopts vertical type arrangement and tube-box type structure, in the boiler tube-box interior are successively set super heater, evaporation zone, low-pressure evaporation zone, coal economizer and low-pressure coal economizer from top to bottom, in which the evaporation zone and low-pressure evaporation zone have several groups of evaporators, these evaporators are obliquely placed in smoke flue, their inclination angle is 5 deg-15 deg. Said invention also provides the concrete structure of every evaporator, and provides the working principle of said exhaust-heat boiler and its power generation system and their concrete operation method.

Owner:JIANGSU DONGJIU HEAVY IND

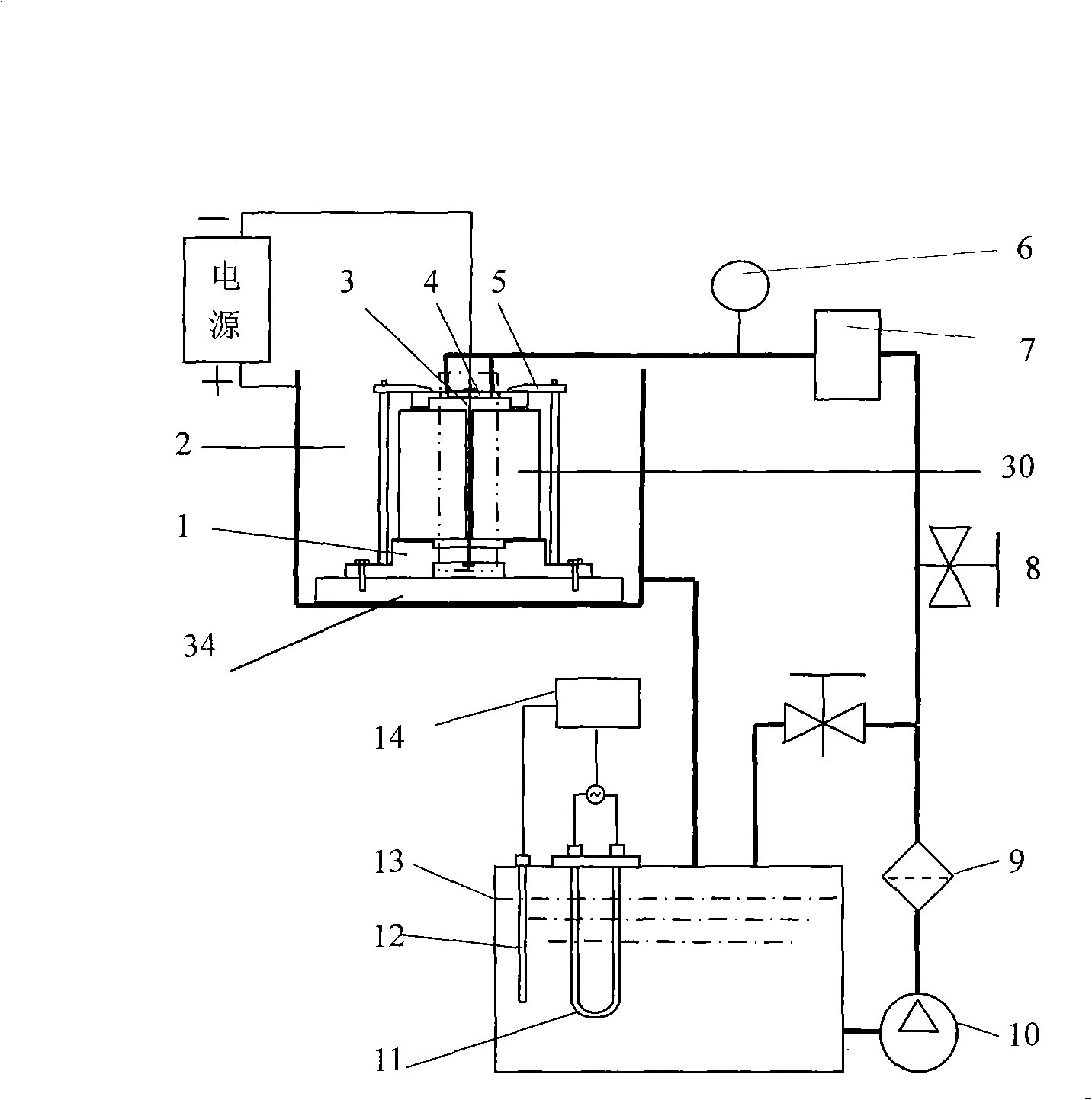

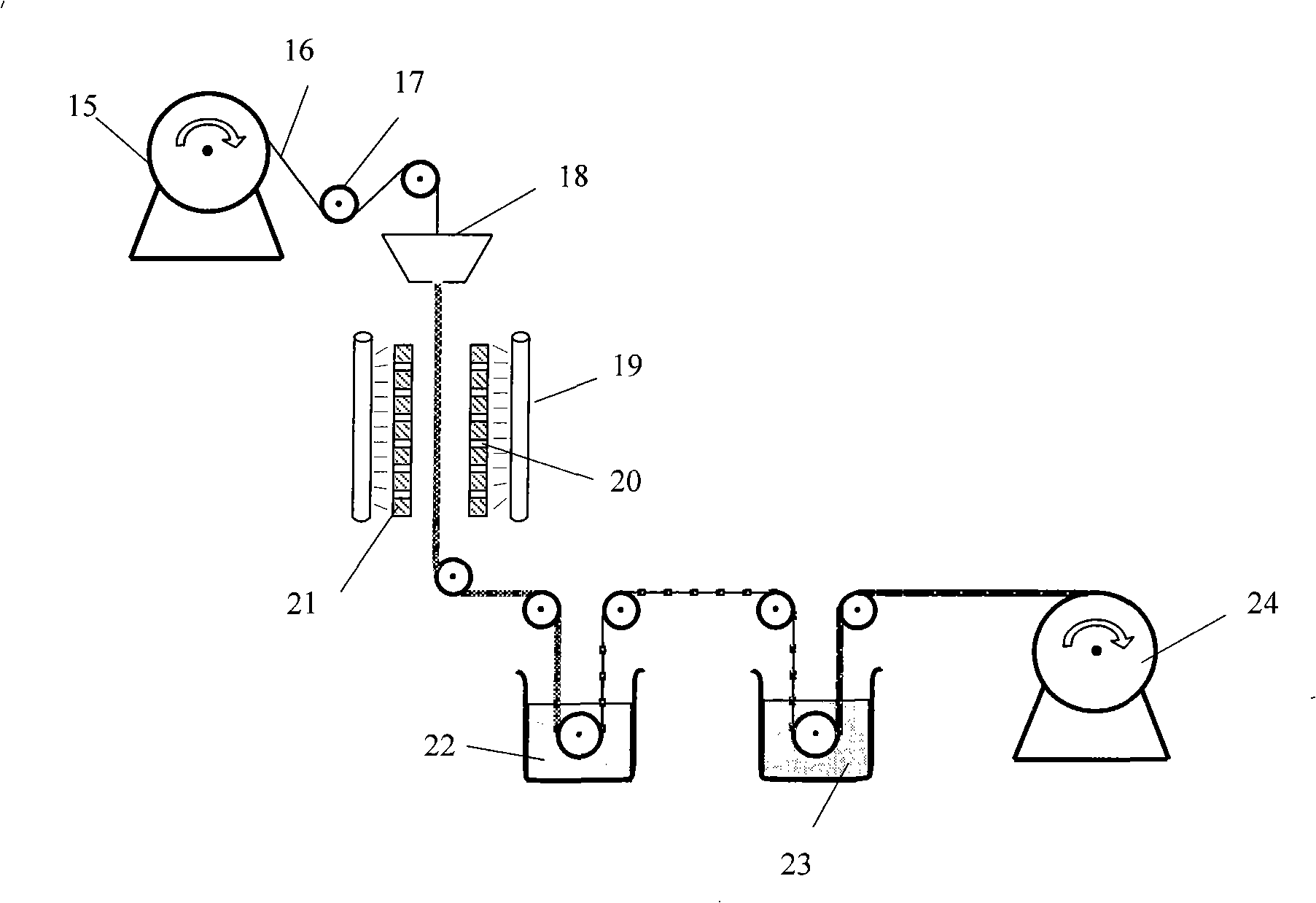

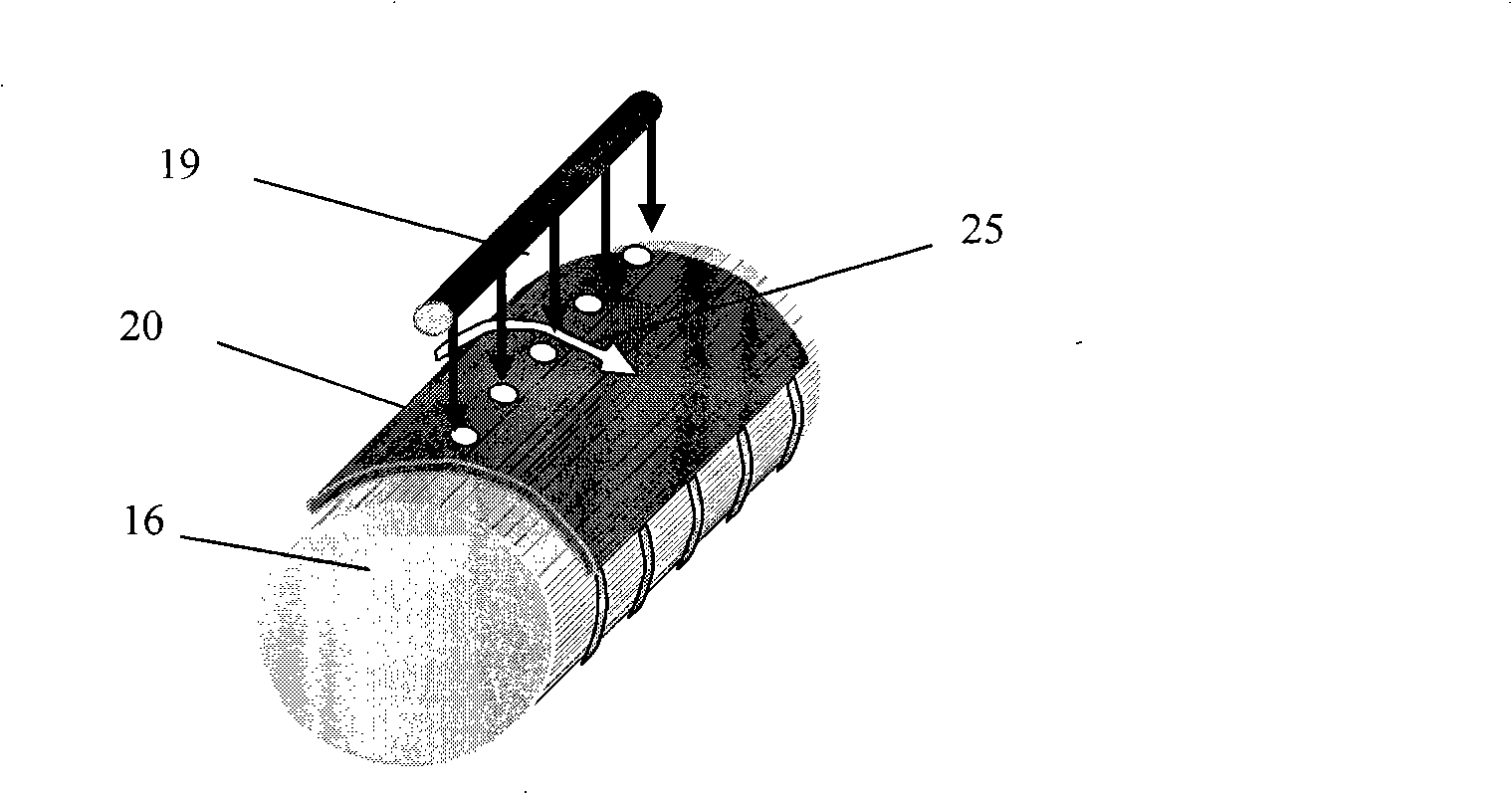

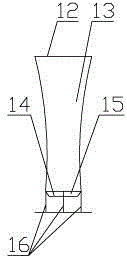

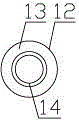

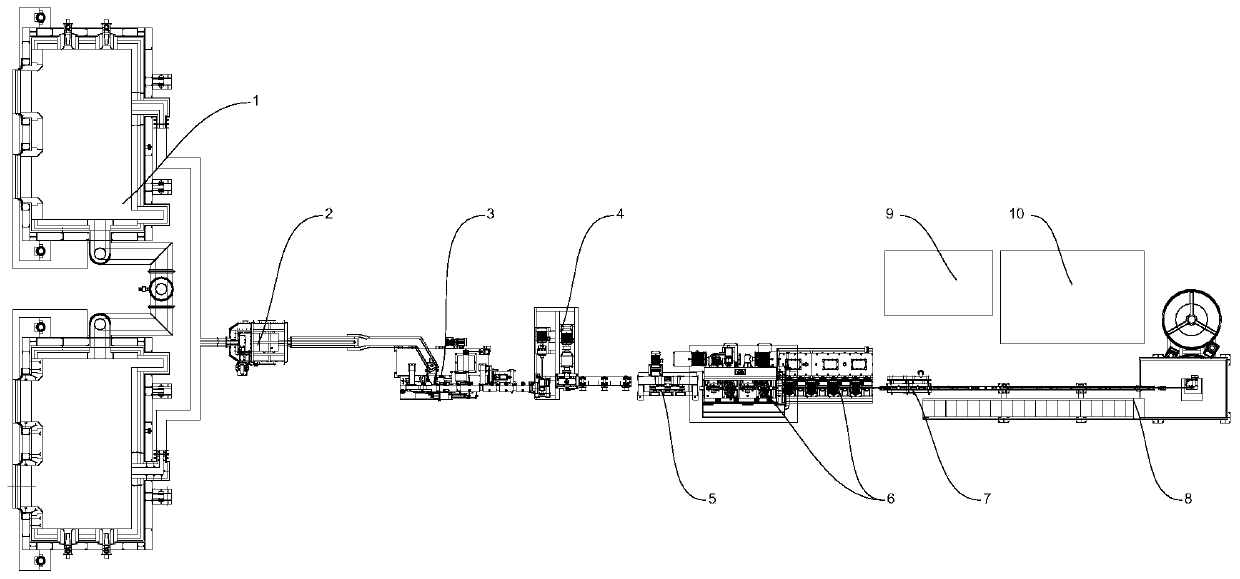

Electrolytic machining technique and device for small bore diameter inner wall surface fine groove

InactiveCN101259549AFast curingImprove curing effectMachining electrodesMachining working mediaElectrolysisEngineering

The invention discloses an electrolytic machining technique of a micro-groove on an inner wall surface of a small aperture and a device. The technique is that: a cathode of a forming tool of a variable cross-section structure which is provided with insulation sections and conductive sections at intervals and is made of conductive metal wires of 200 to 1000 mum is positioned in an unthreaded hole of a workpiece which is processed in advance by utilizing the electrolytic machining device of the invention, the workpiece is taken as an anode, then electrolytic solution is radially flowed along an electrode wire, the electrolytic machining is carried out in the unthreaded hole, the pressure of the electrolytic solution is maintained at 1 to 5 MPa, and the micro-groove structure is obtained at the inner wall surface of the unthreaded hole by flushing the products after the processing. The diameter size of the cathode of the forming tool which is prepared by adopting the ultra-violet light masking solidification technology and the electroforming process can be as small as a few hundred microns, and a rib cooling hole structure with the hole diameter size of about 1mm can be obtained by combining the electrolytic machining technique. The adopted technical process of the invention is easy to master and has small investment, the minimal hole diameter which can be processed is small, and the processing precision is high.

Owner:ZHEJIANG UNIV OF TECH

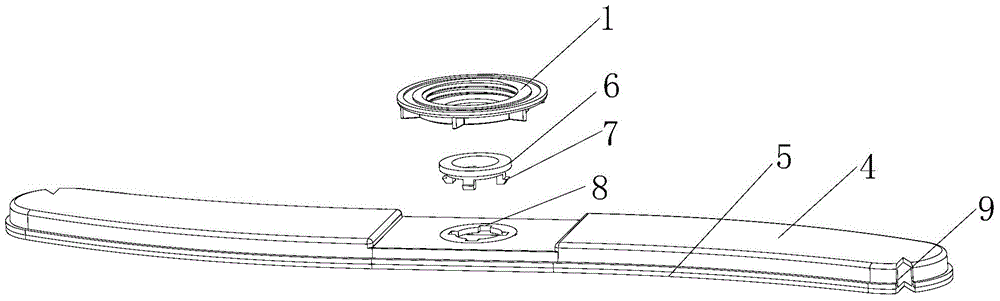

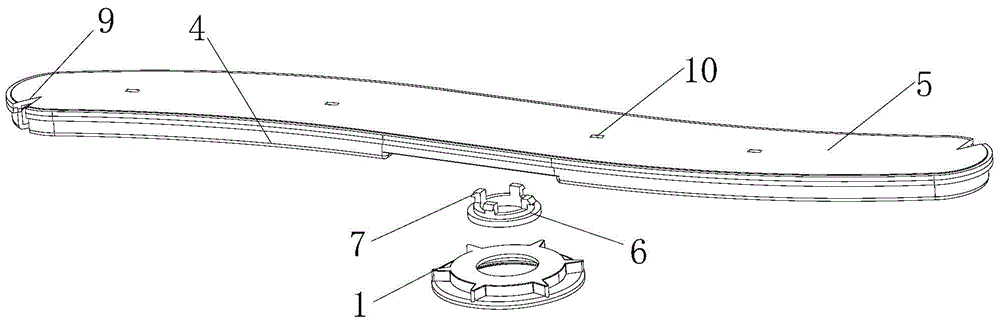

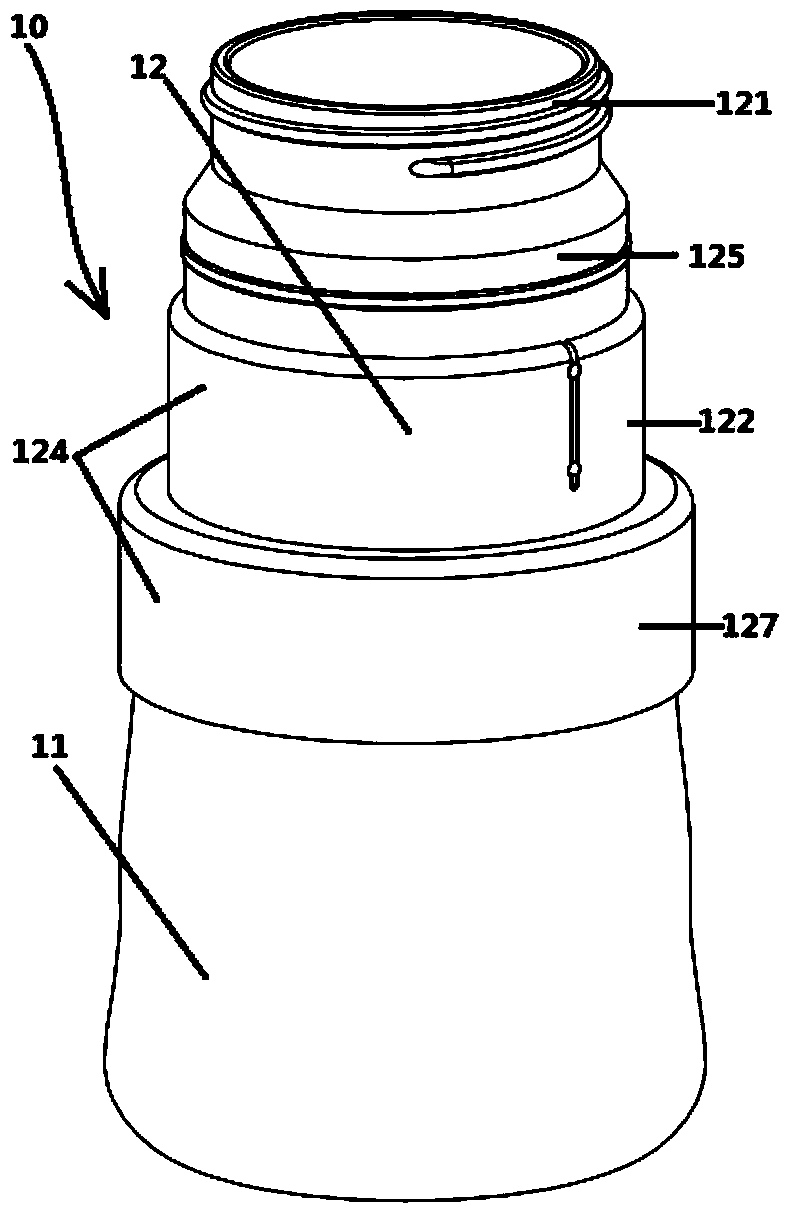

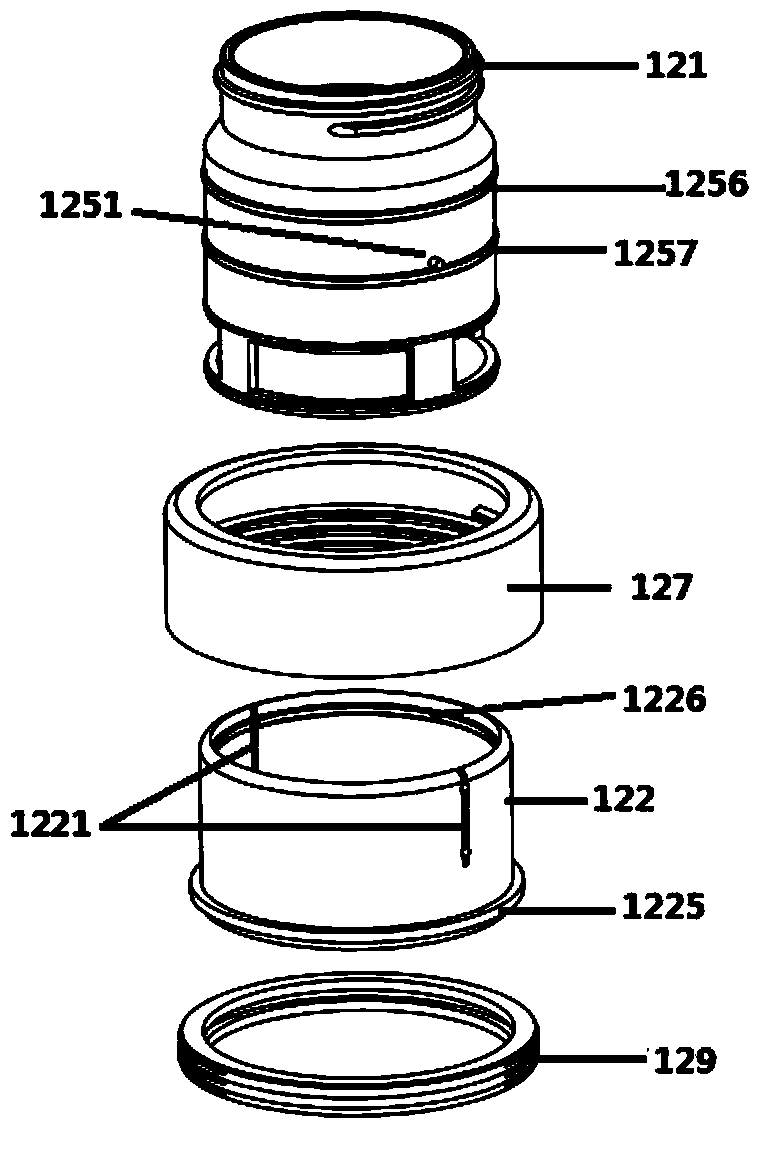

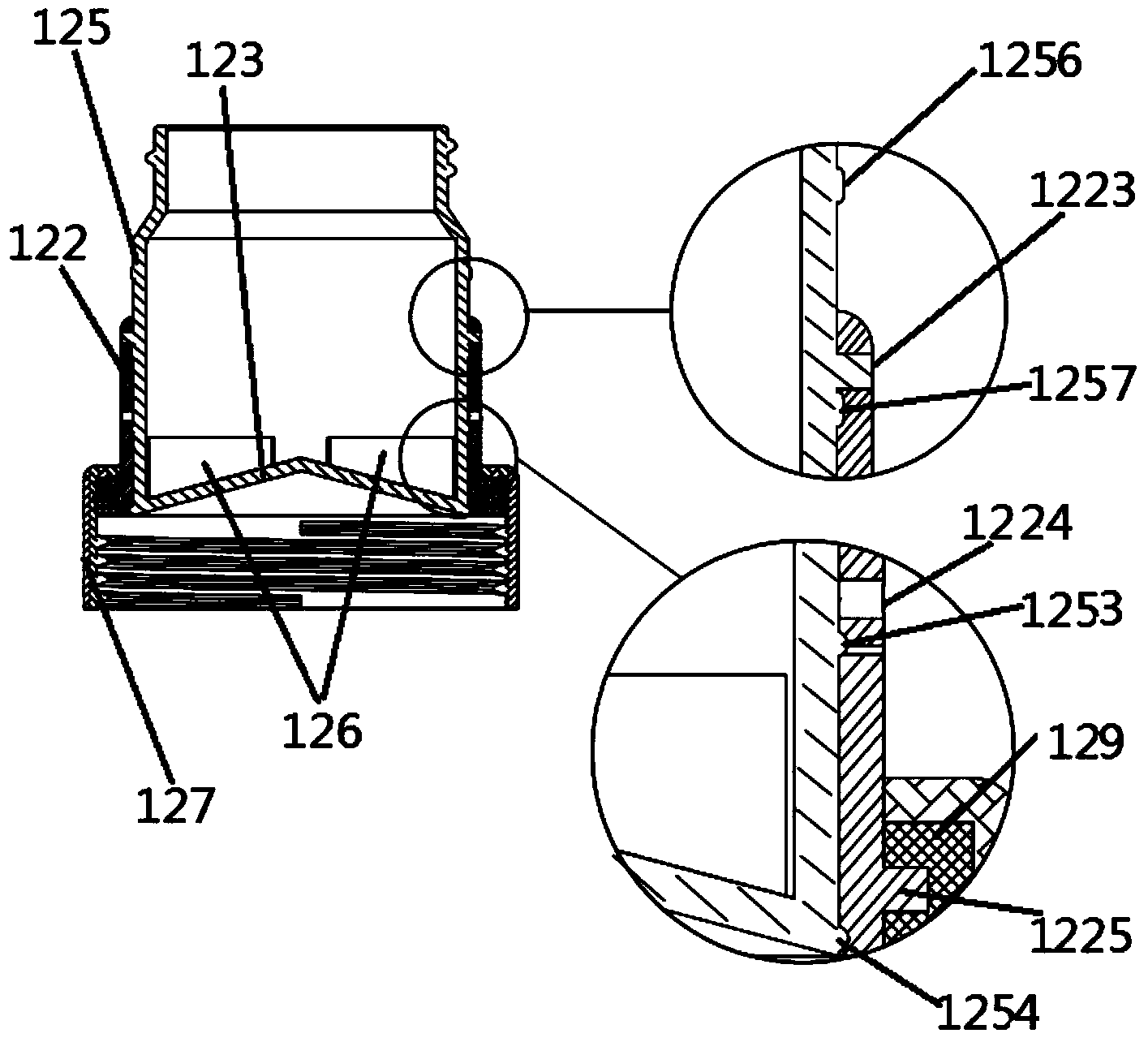

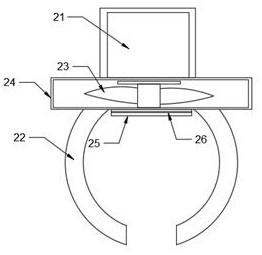

Dishwasher top sprinkler assembly and dishwasher

ActiveCN106137075AEasy to operateEasy to disassemble and cleanTableware washing/rinsing machine detailsMechanical engineering

The invention discloses a dishwasher top sprinkler assembly and a dishwasher, and relates to the technical field of dishwashers. The top sprinkler assembly is rotatably mounted above an inner container of the dishwasher through a top sprinkler fixing component, and is communicated with a sprinkling pipeline; a water outlet is formed in the top sprinkler assembly; the top sprinkler fixing component is connected with the top sprinkler assembly in a clamping manner through a clamping buckle-type fixing component. The invention further discloses the dishwasher comprising the dishwasher top sprinkler assembly. The top sprinkler assembly is rotatably mounted above the inner container of the dishwasher in a clamping manner through the top sprinkler fixing component and the clamping buckle-type fixing component, so that the dishwasher is convenient to operate, time-saving and labor-saving, and convenient to detach for cleaning.

Owner:QINGDAO HAIER DISHWASHER +1

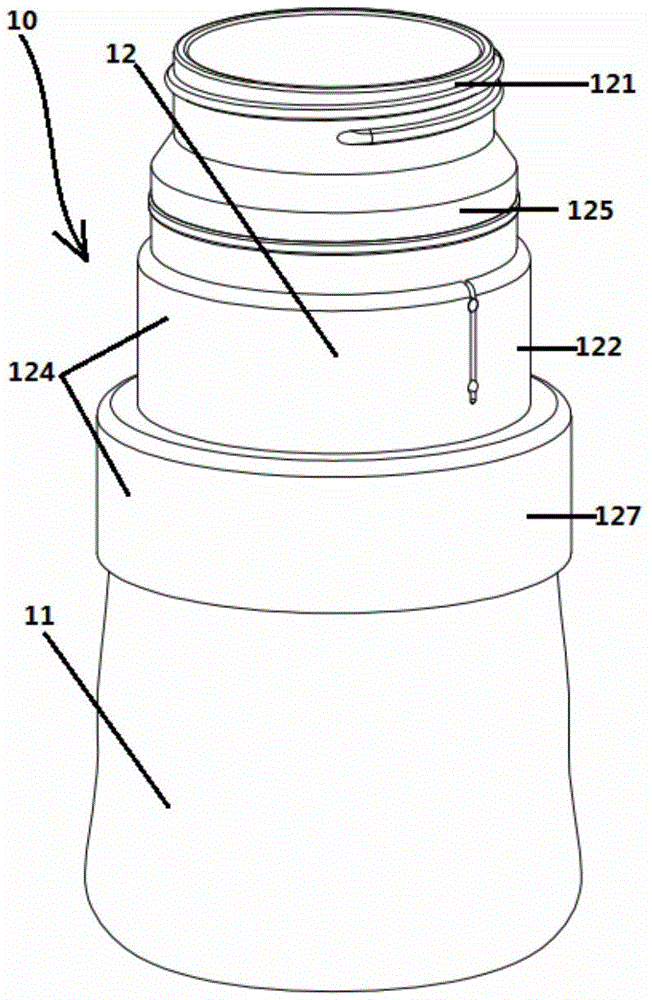

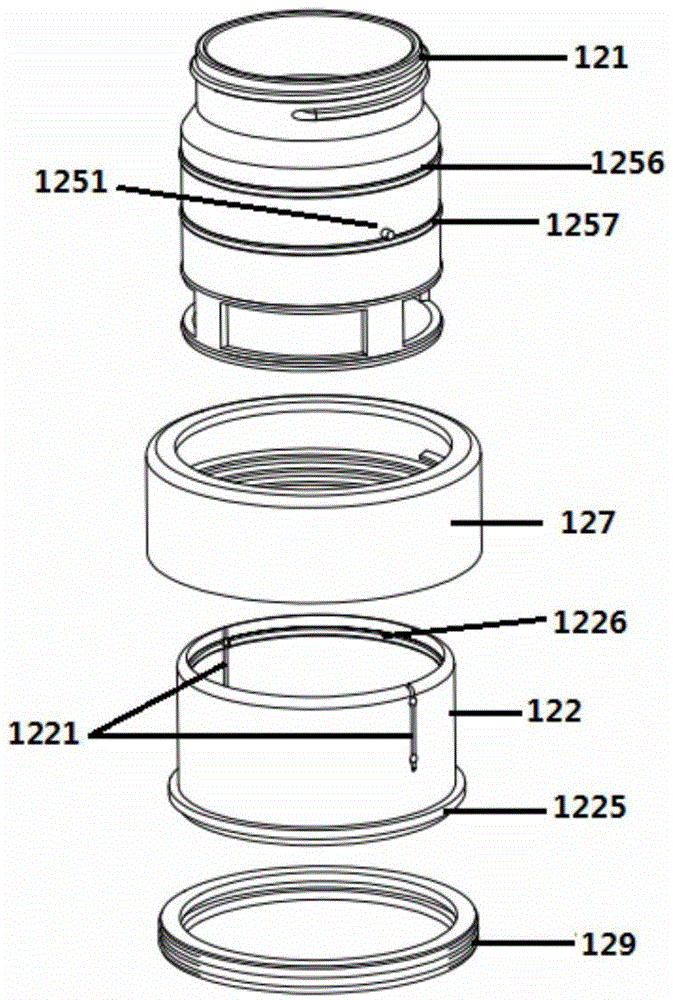

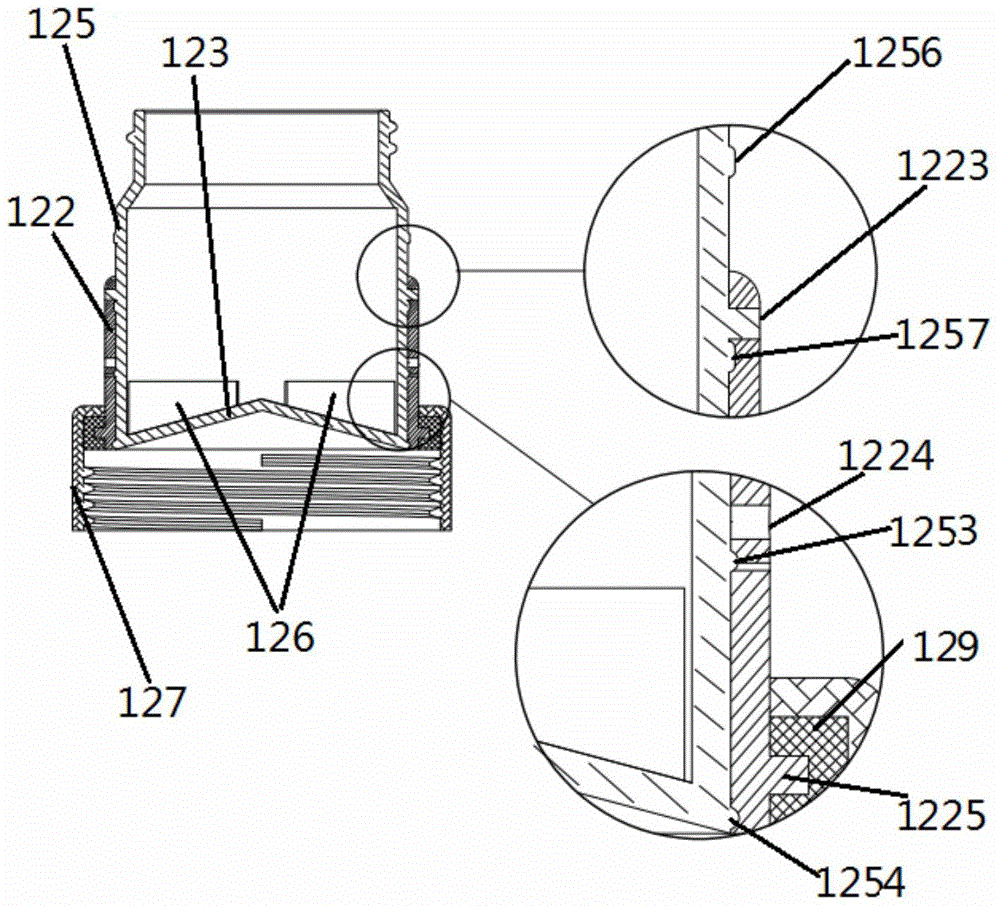

Powdered milk box and powdered milk blending device

ActiveCN104168869ANo residueSimple stepsPharmaceutical containersMedical packagingEngineeringLiquid milk

The invention discloses a powdered milk box and a powdered milk blending device. The powdered milk box comprises a box body, a box bottom and a second connecting mechanism. The upper portion of the powdered milk box can be connected with a pacifier and can be connected with a milk bottle through the second connecting mechanism. The powdered milk box has a powdered milk outlet. The box body can move longitudinally relative to the milk bottle connected with the powdered milk box to make the powdered milk box have a first working station and a second working station. In the first working station, the powdered milk outlet is closed, and the box body and the box bottom together form a powdered milk containing cavity isolated from water in the milk bottle. In the second working station, the powdered milk outlet is open, the milk bottle is communicated with the pacifier via the powdered milk box, and a liquid milk channel isolated from the outside in a sealed manner is formed. The powdered milk blending device includes a milk bottle and the above powdered milk box. When using the device, a user prepares water and powdered milk in advance, and then only one step is needed for blending, that is to say, the box body is made to move relative to the milk bottle. Troubles of the prior that the user has to dismount the powdered milk box after powdered milk is poured to reconnect the pacifier with the milk bottle are avoided. The powdered milk box and the powdered milk blending device are quite convenient to use, and powdered milk will not be left.

Owner:林强

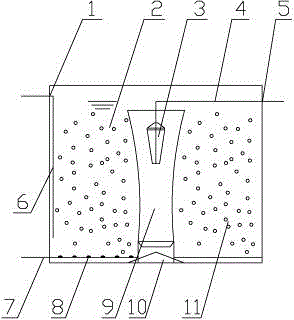

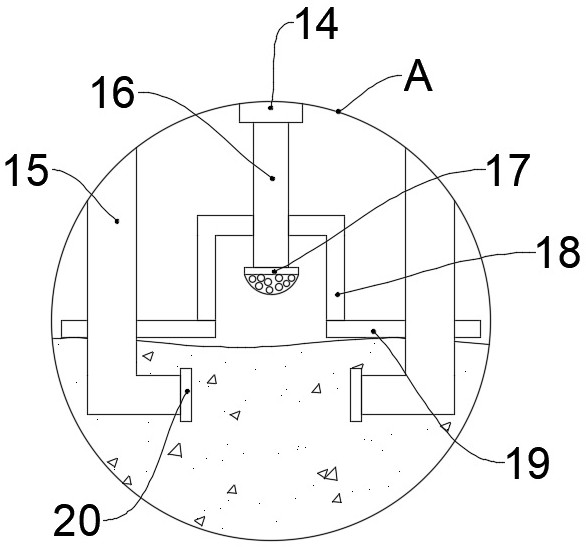

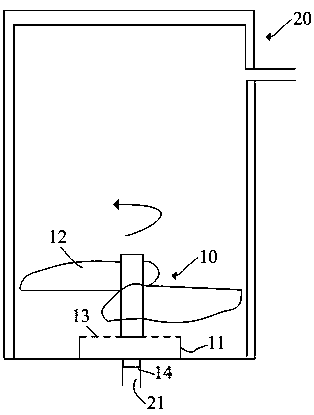

Moving bed bio-membrane reactor

ActiveCN104925939AImproved hydraulic flow propertiesImprove hydraulic conditionsSustainable biological treatmentBiological water/sewage treatmentMoving bed biofilm reactorBiochemical engineering

The invention relates to a moving bed bio-membrane reactor provided with a biochemical reaction pool. A water inlet hole and a water outlet hole are formed in the upper portions of any two side walls of the biochemical reaction pool respectively and connected with a water inlet pipe and a water outlet pipe respectively. Suspended filler is thrown in the biochemical reaction pool, a conical sliding table is arranged in the center at the bottom in the biochemical reaction pool, a flow guiding barrel is arranged over the conical sliding table, a water outlet screen is arranged at the upper portion in the flow guiding barrel, the upper end of the water outlet screen is communicated with the water outlet hole through the water outlet pipe, the bottom of the flow guiding barrel is connected with a water outlet grate support, and an aerator pipe is arranged on the part, located on the periphery of the flow guiding barrel, at the bottom of the biochemical reaction pool. The moving bed bio-membrane reactor is simple and novel in structural design, has very high application and popularization value and is mainly applied to the sewage treatment technology.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

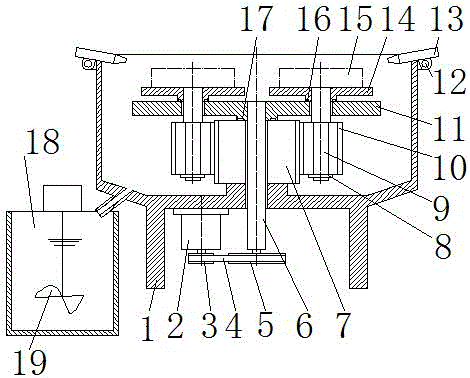

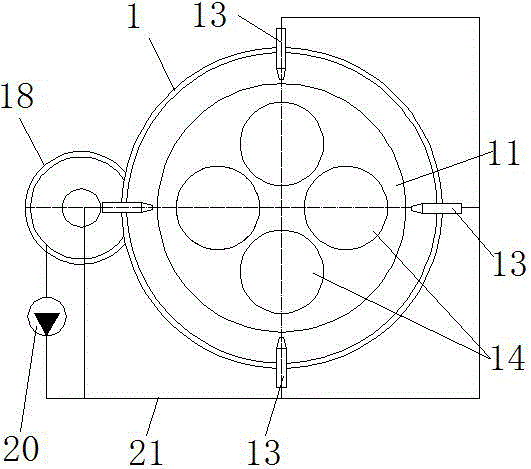

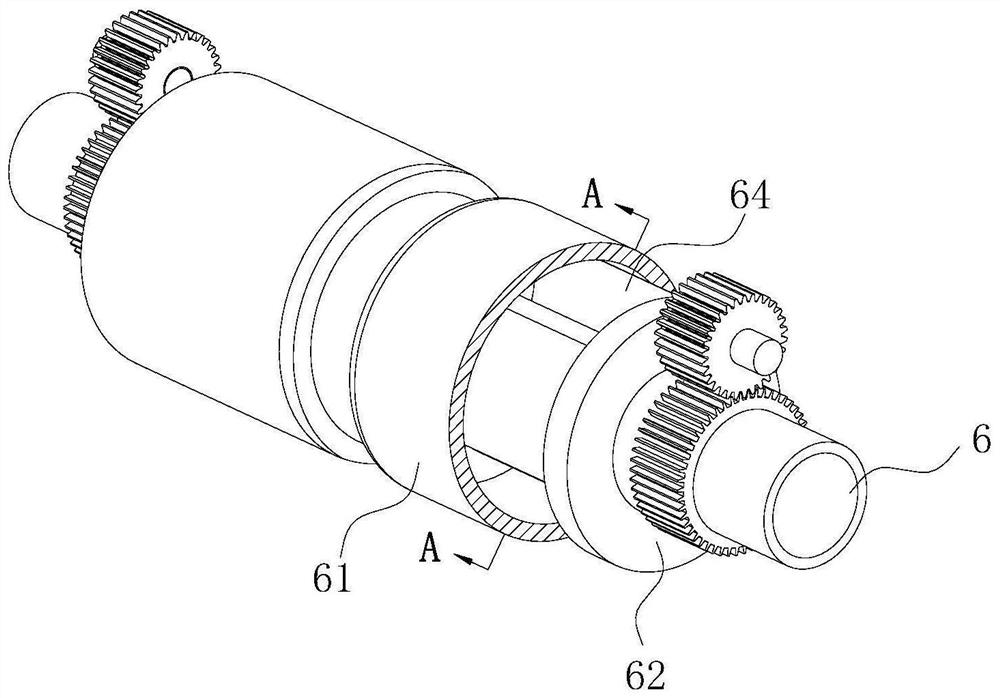

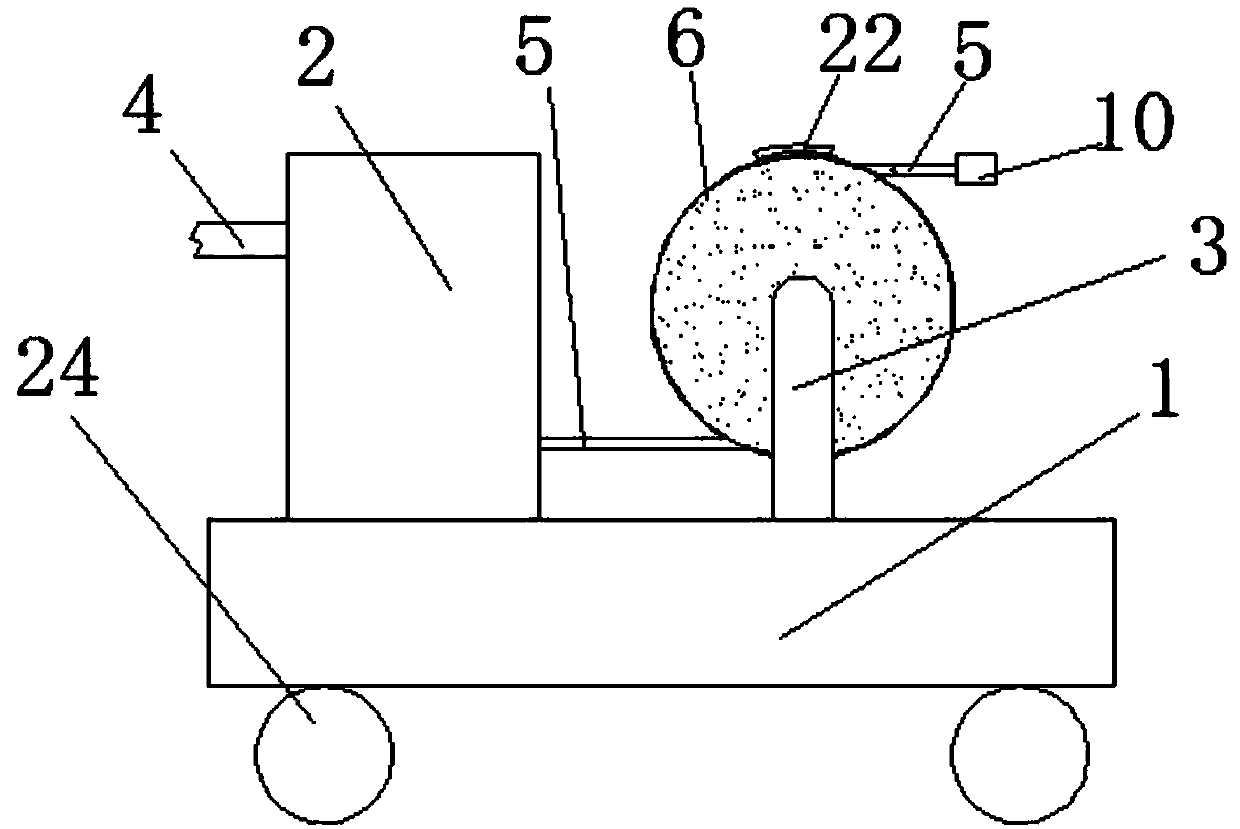

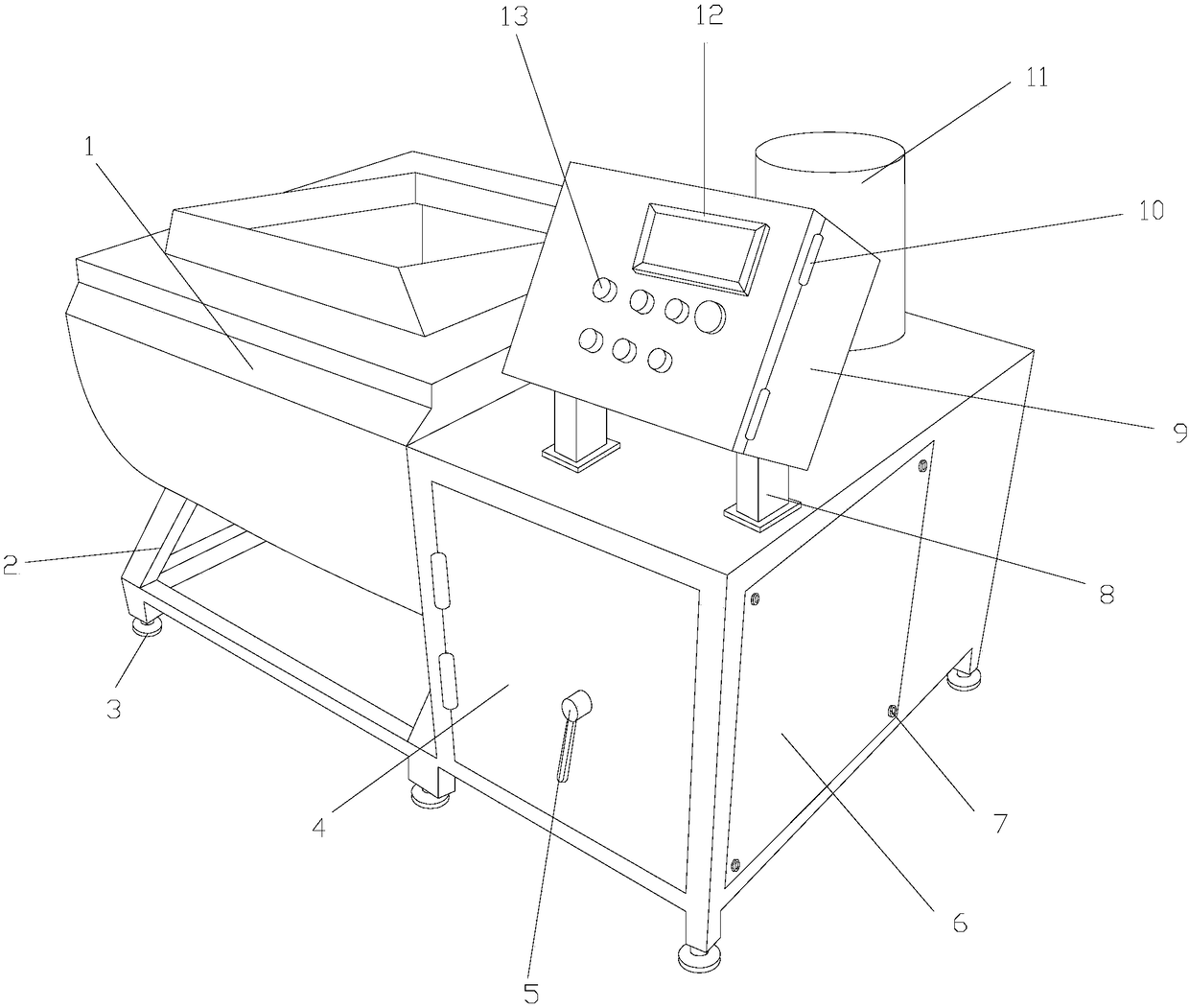

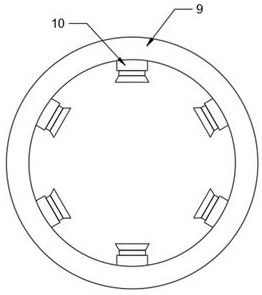

Hub jet polishing machine

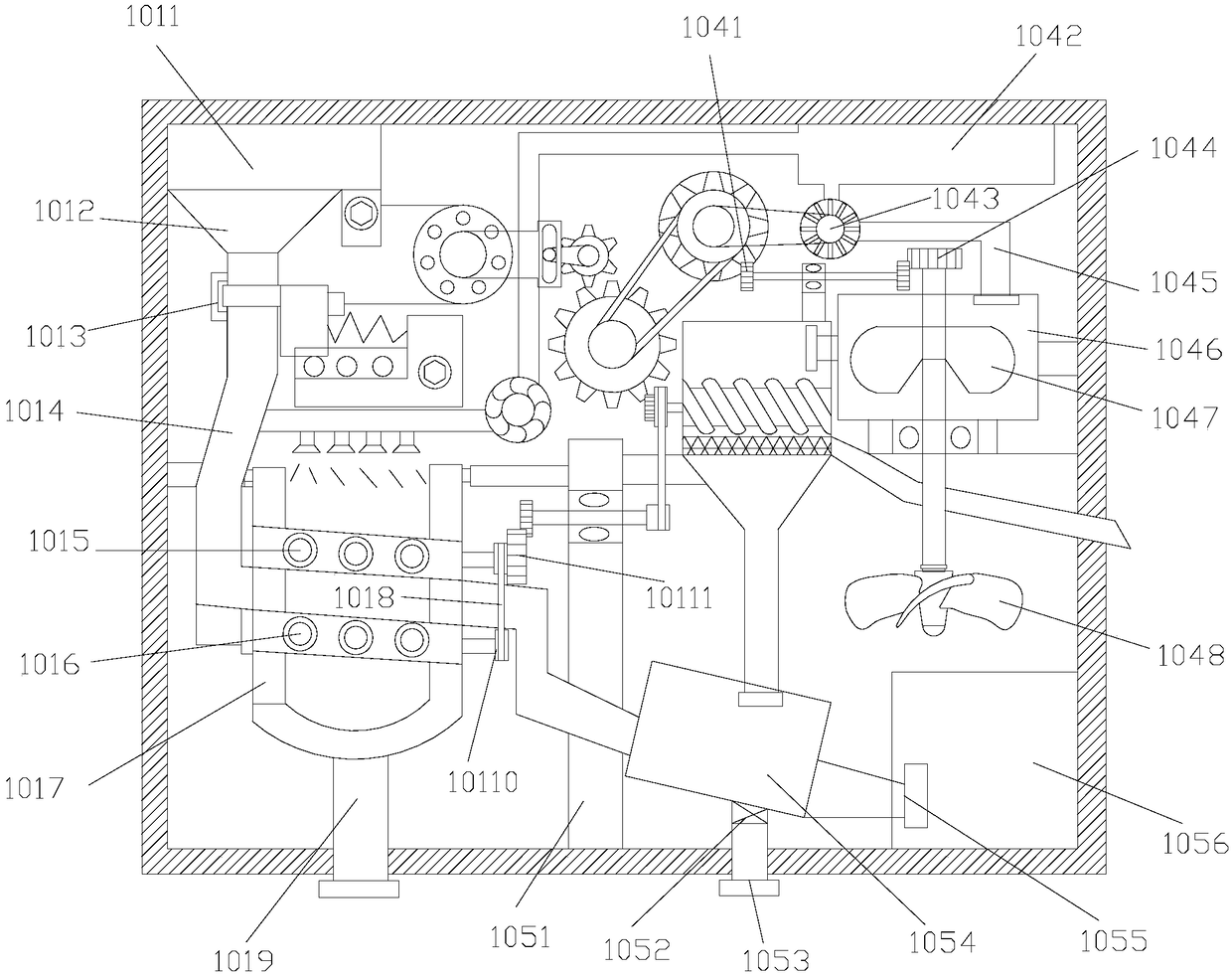

InactiveCN105773435AReduce labor intensityAvoid explosionAbrasive feedersAbrasive machine appurtenancesGear wheelTransmission belt

The invention provides a hub jet polishing machine which comprises two parts including a hub polishing transmission device and a jet polishing solution circulating device, wherein the transmission device is composed of a stand, a drive motor, a belt wheel I, a transmission belt, a belt wheel II, a center shaft, sun gears, elastic retaining rings, planetary shafts, planetary gears, turntables, clamping discs and the like; the jet polishing solution circulating device is composed of a polishing solution tank, a stirrer, a booster pump, a polishing solution pipeline, nozzles and pin shafts. According to the hub jet polishing machine, during working, the drive motor drives the center shaft and the turntables to rotate, the planetary shafts and the planetary gears carry out revolution around the corresponding sun gears, meanwhile, the planetary gears carry out rotation around the corresponding planetary shafts, the clamping discs which are fixedly connected with the corresponding planetary shafts drive a hub to realize revolution and rotation, and a circulating pump jets a polishing solution to the surface of the hub through the nozzles after pressurizing the polishing solution so as to realize surface polishing; and jet polishing is beneficial to health of workers without production of dusts and generating dust explosion accidents.

Owner:HUZHOU TEACHERS COLLEGE +1

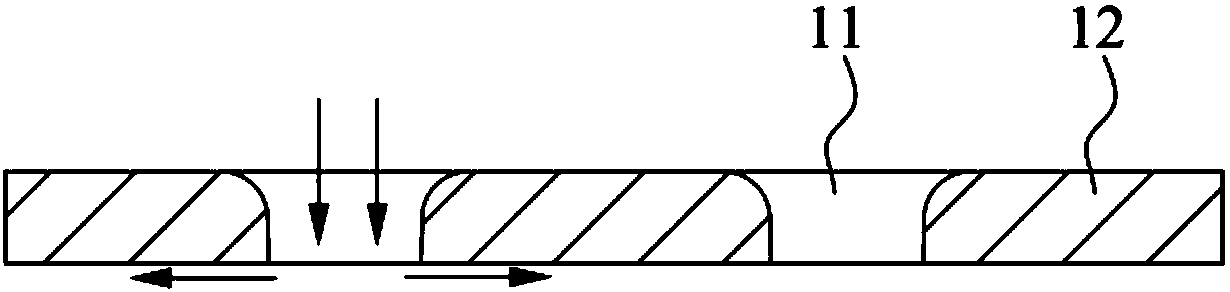

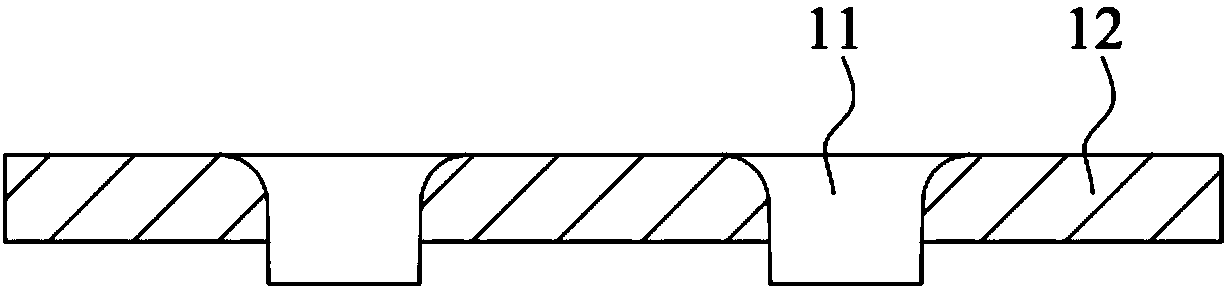

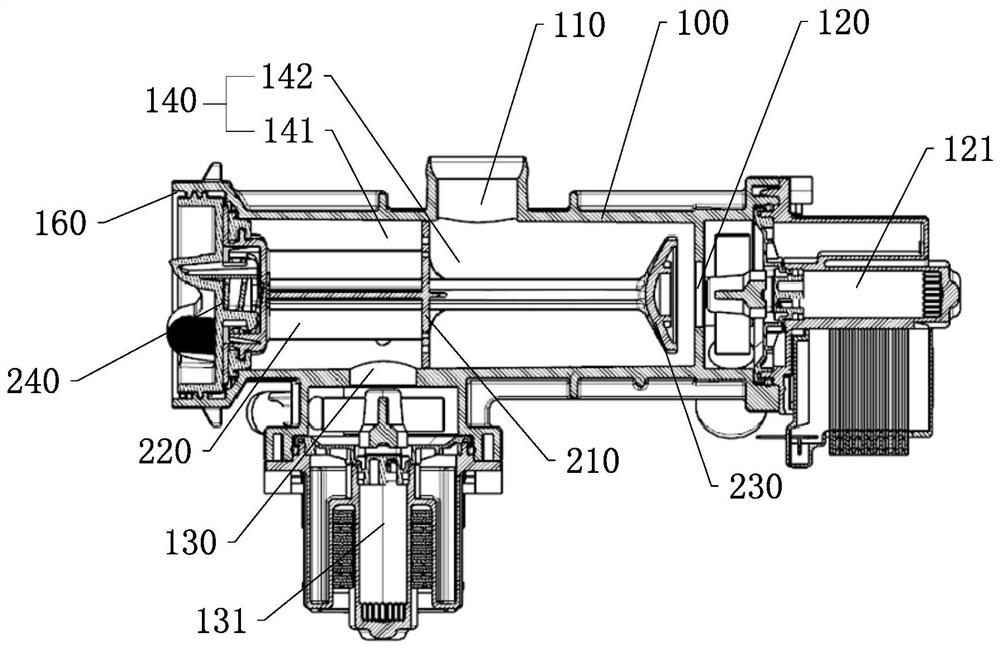

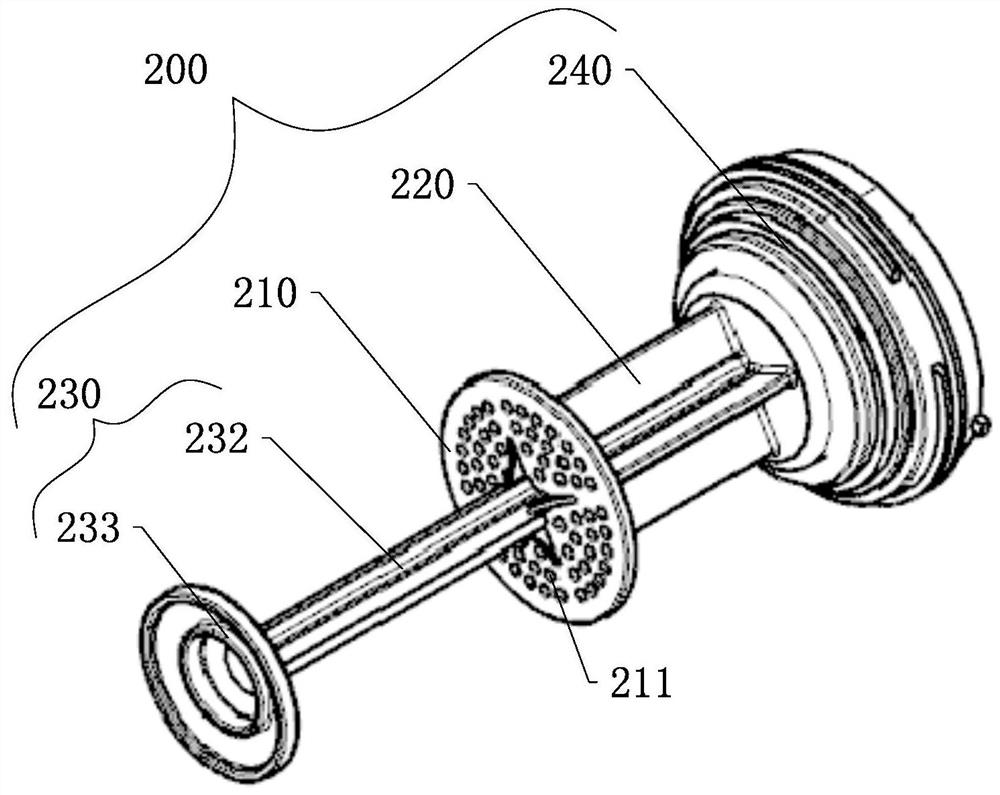

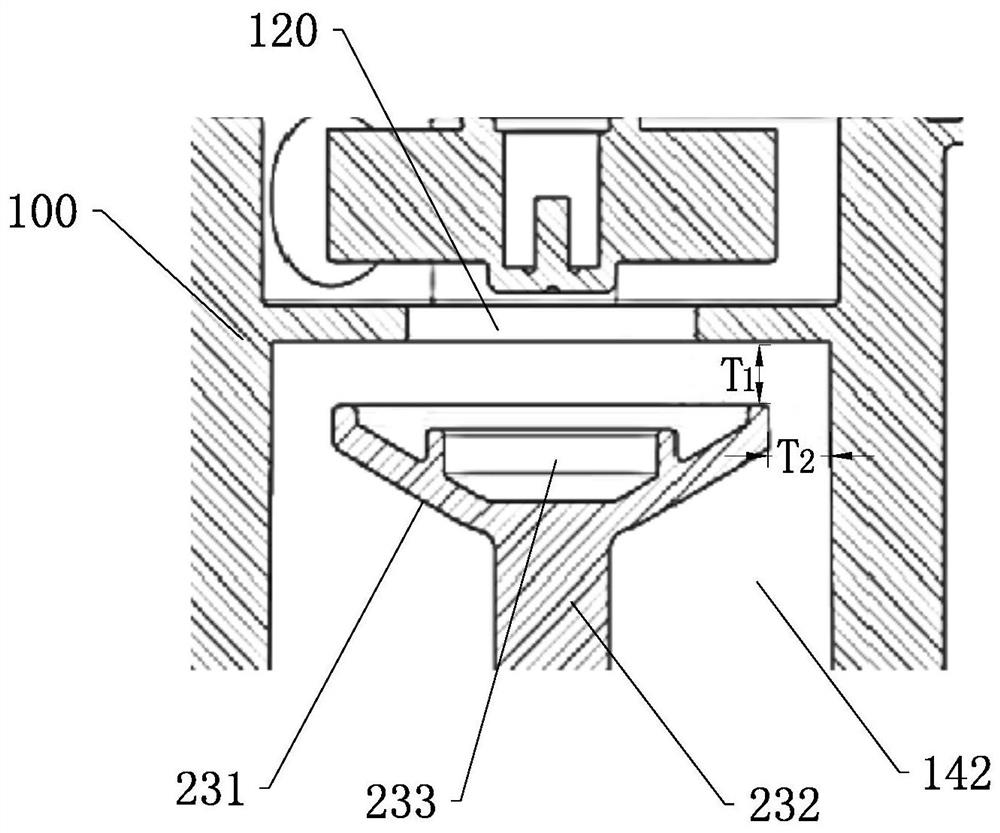

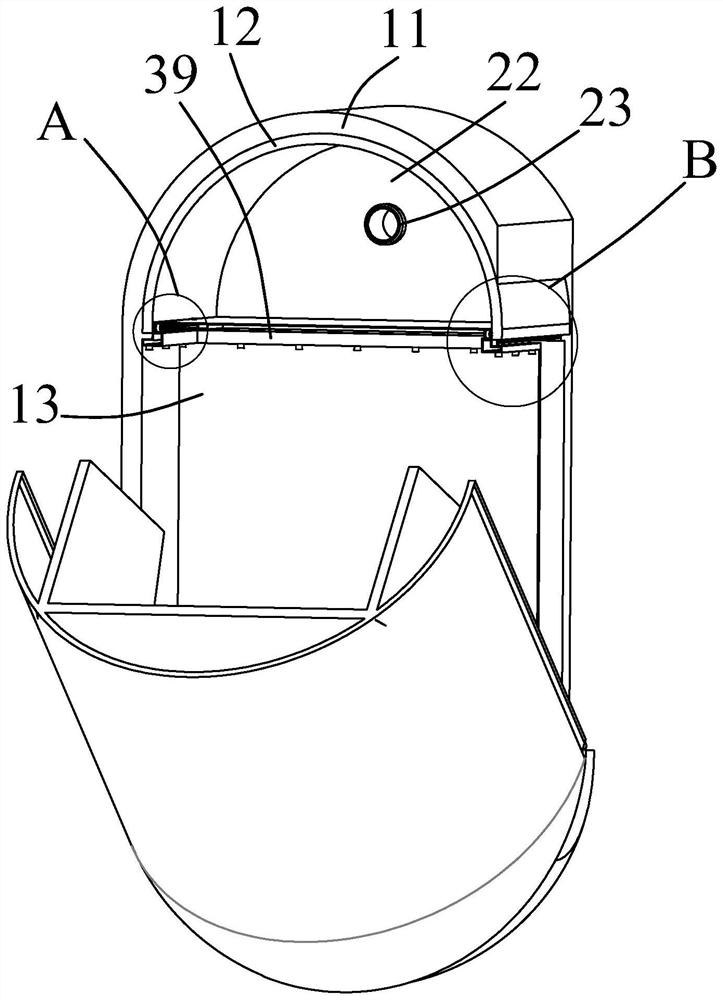

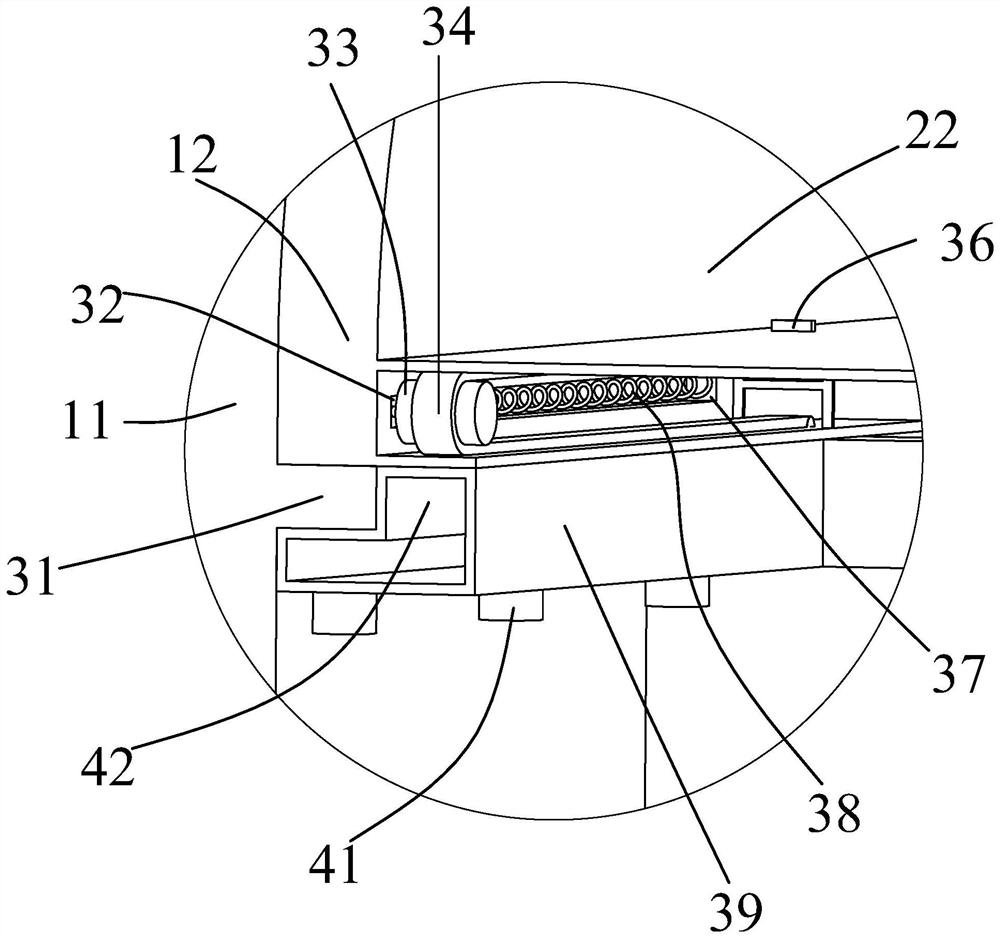

Water nozzle structure, integrated waterway assembly and washing machine

ActiveCN107916540AEnsure normal flowOffset inertiaOther washing machinesTextiles and paperOutfallWater flow

The invention discloses a water nozzle structure, an integrated waterway assembly and a washing machine, pertaining to the technical field of washing equipment. The water nozzle structure comprises awater hole. The outer periphery of a water inlet of the water hole is equipped with water retaining rings. Surfaces of the water retaining rings are smooth slopes. Top ends of the smooth slopes are smoothly connected with the water inlet of the water hole. The outer periphery of the water hole is equipped with grooves. Water flows climb upwards along the smooth slopes when passing through the water retaining rings and go downwards at the water inlet. Water-flow inertia is fully counteracted during a climbing process. Due to the grooves, water flows do not climb to an end surface where the water outlet is located when passing through the water outlet. Therefore, water flows go downwards when passing through the water outlet. The integrated waterway assembly and the washing machine have thefollowing beneficial effects: with the above water nozzle structure, water flows do not climb to the end surface where an upper cover is located when water flows pass through the water outlet; therefore, water flows fall down into a washing cavity through the water outlet; and additives can then be fully flushed so that additive residuals are avoided.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

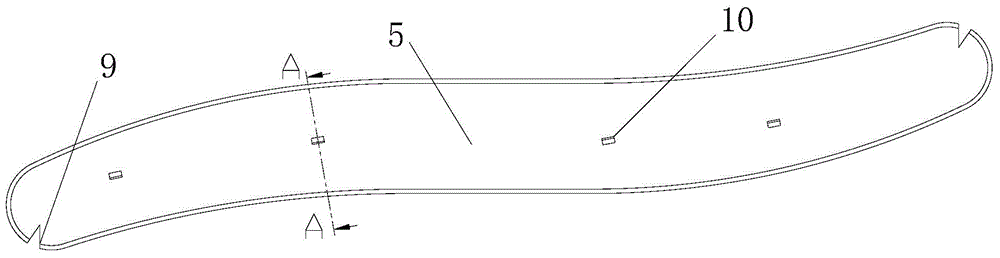

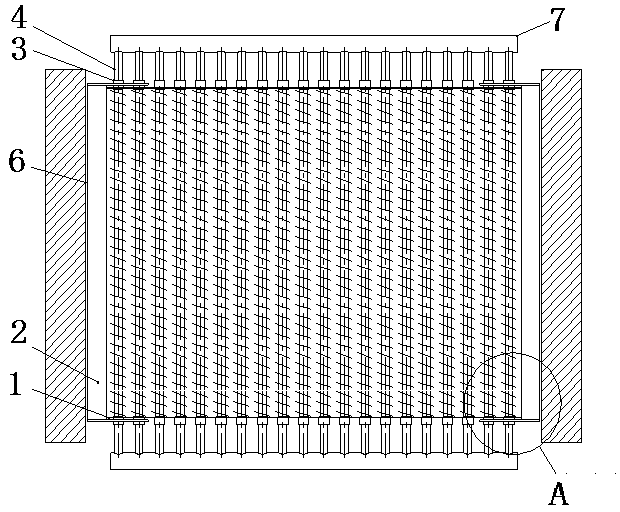

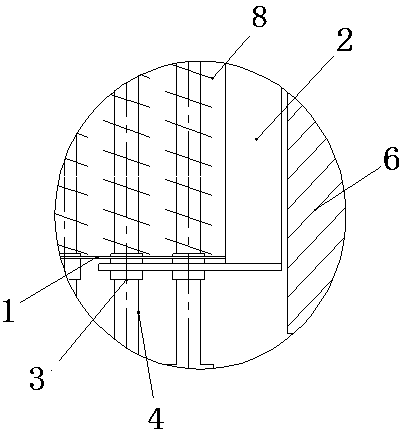

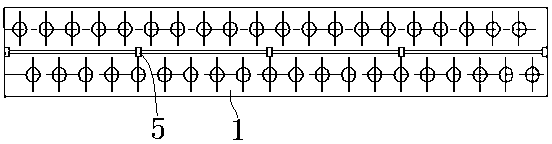

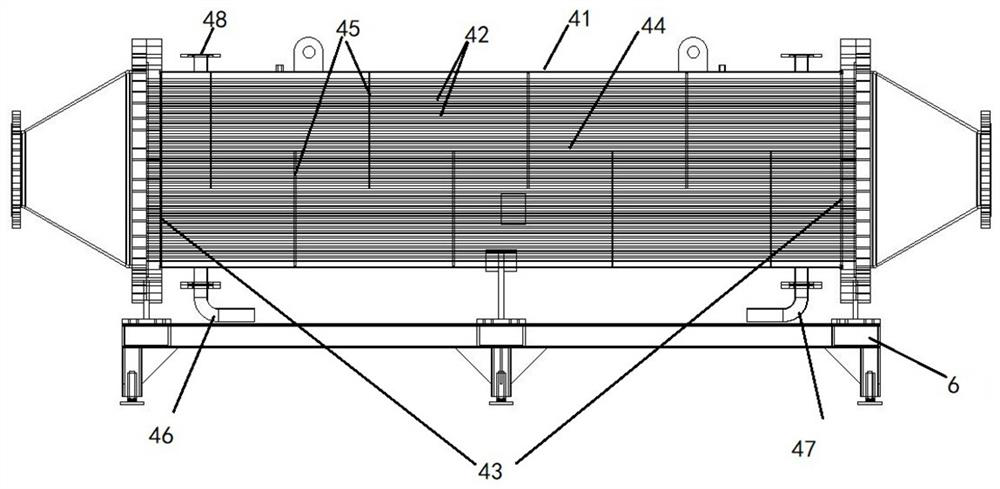

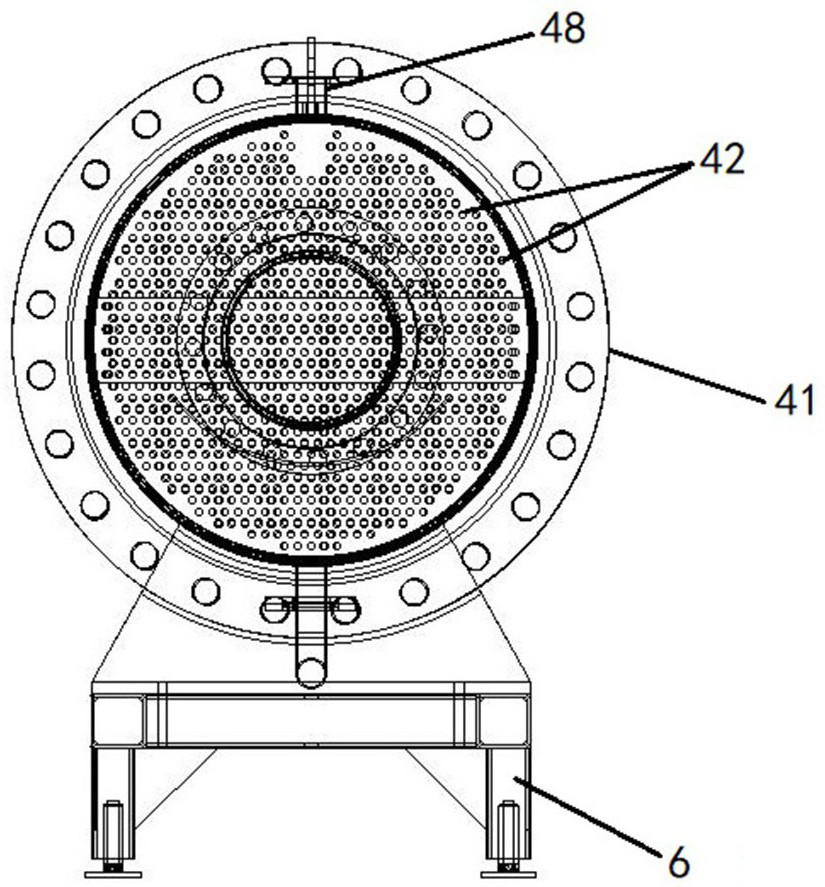

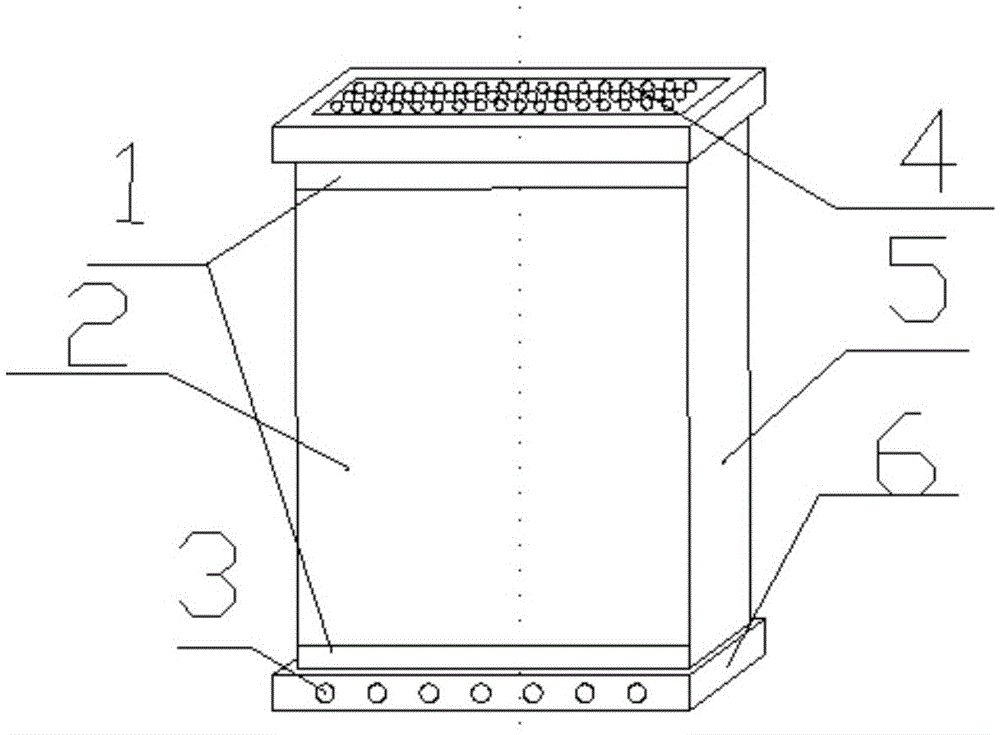

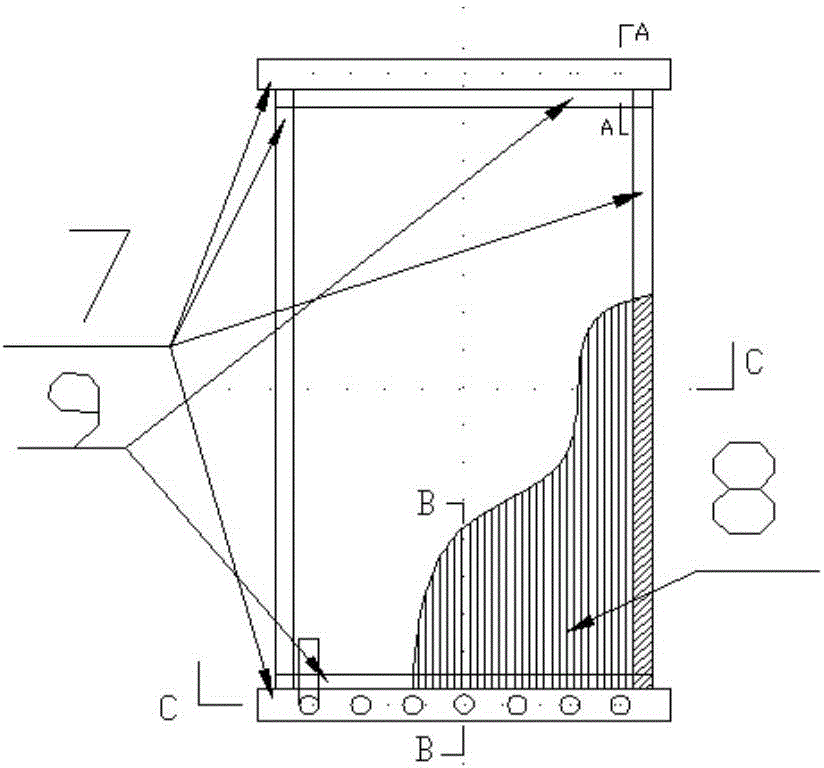

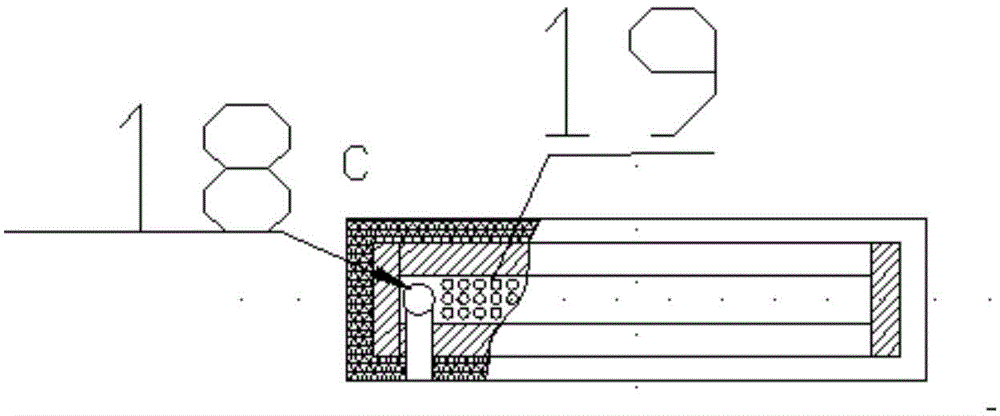

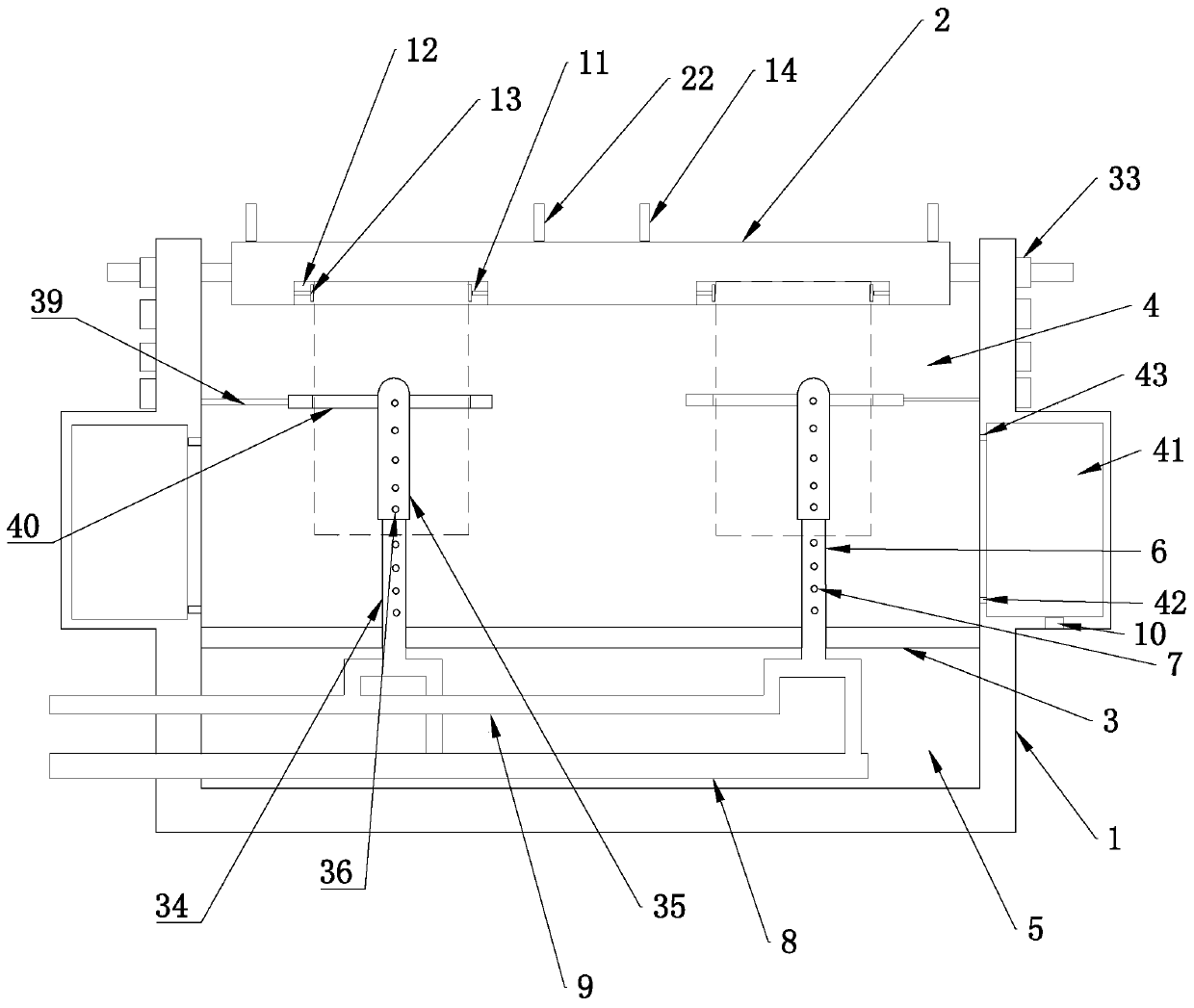

Flue gas baffle device inside horizontal waste heat boiler

InactiveCN103307619AFully constrained flowStable structureCombustion technology mitigationChimneysFlue gasProcess engineering

The invention discloses a flue gas baffle device inside a horizontal waste heat boiler, and aims to solve a 'flue gas corridor' problem caused by short circuit of flue gas of the horizontal waste heat boiler. The flue gas baffle device inside the horizontal waste heat boiler comprises multiple rows of heated surface tube bundles arranged inside a flue, wherein the two ends of each row of the heated surface tube bundle are connected with corresponding headers; a plurality of inter-tube baffles are arranged inside the flue; each inter-tube baffle is parallel to the extending direction of the flue; a plurality of tube holes are formed in each inter-tube baffle; each heated surface tube bundle vertically penetrates through the corresponding tube holes and is fixed with the inter-tube baffles through sleeves; and side wing baffles are arranged between the heated surface tube bundles and the inner wall of the flue. The flue gas baffle device inside the horizontal waste heat boiler achieves uniform distribution of the flue gas in the flue and sufficient scouring of the flue gas to the heated surface tube bundles, so that the heat exchange efficiency of the boiler is improved, and the safe and stable running of the boiler is ensured.

Owner:CHANGSHA BOILER PLANT

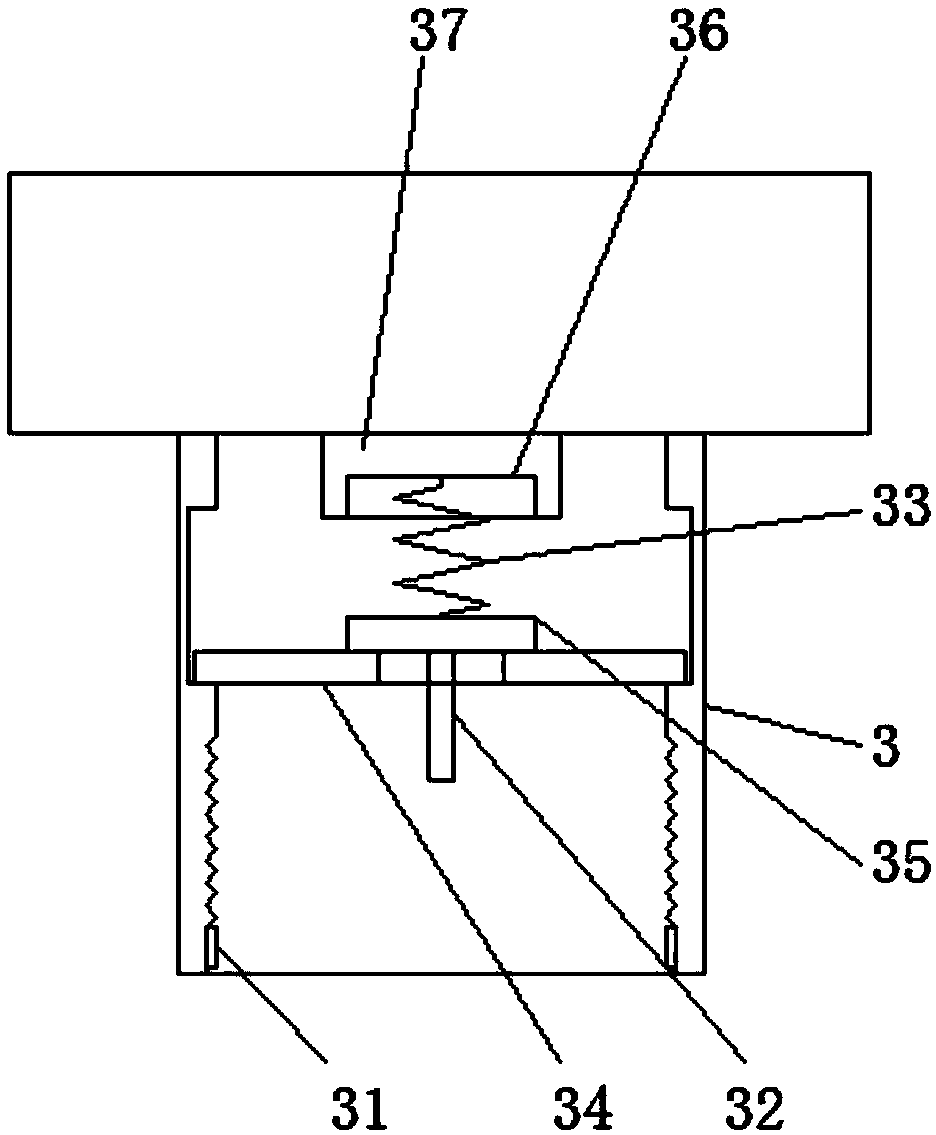

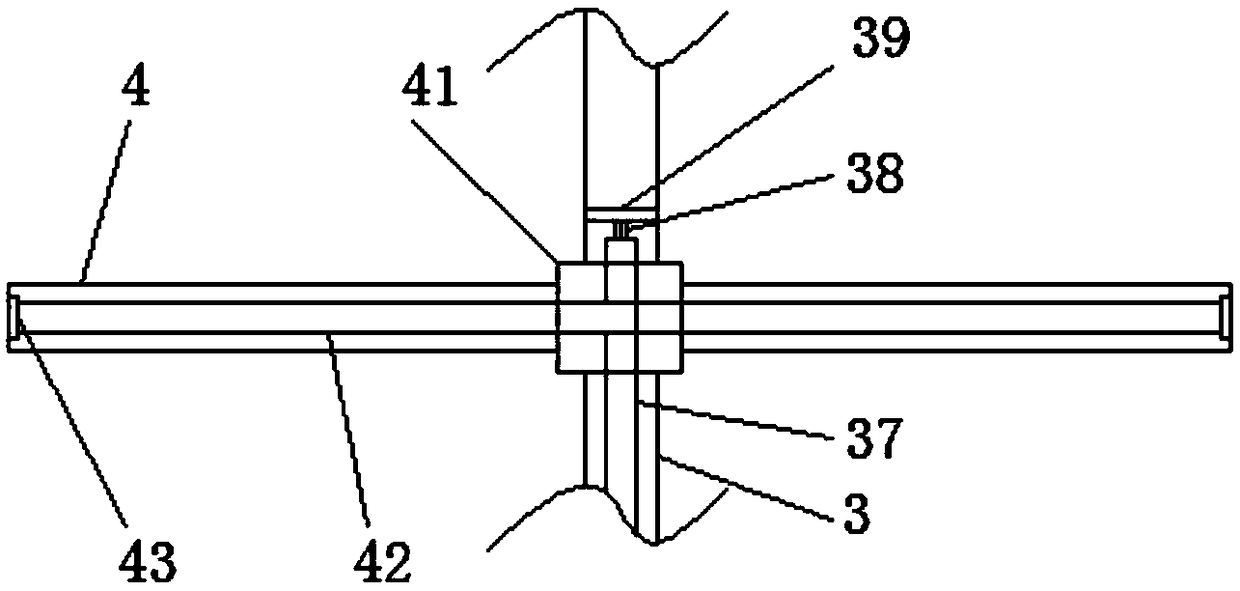

Live pig scouring device for slaughter house

The invention discloses a live pig scouring device for a slaughter house. Clamping plates are fixedly connected to the left end and the right end of the upper part of a scouring device main body; a fixed plate I is arranged in the upper part between the two clamping plates; a fixed plate II is fixedly connected to the lower part between the two clamping plates; an upper pulley is arranged in the fixed plate II; nozzles are fixedly connected at the lower end of the fixed plate II; a water pipe is arranged between the fixed plate I and the fixed plate II; a water pipe valve is arranged at the left end of the water pipe, and the water pipe valve is rotatably connected with the water pipe; a pulley controller is fixedly connected at the right end of one of the clamping plates; side wall pulleys are arranged in the side wall; the right ends of the side wall pulleys are fixedly connected with connecting rods I; connecting rods II are arranged at the right ends of the connecting rods I; device doors are arranged on the outer side of the scouring device main body; and handles of the doors are fixedly connected with the device doors. The live pig scouring device for the slaughter house disclosed by the invention is simple in structure and convenient to use.

Owner:CHONGQING MINGGAO FOOD CO LTD

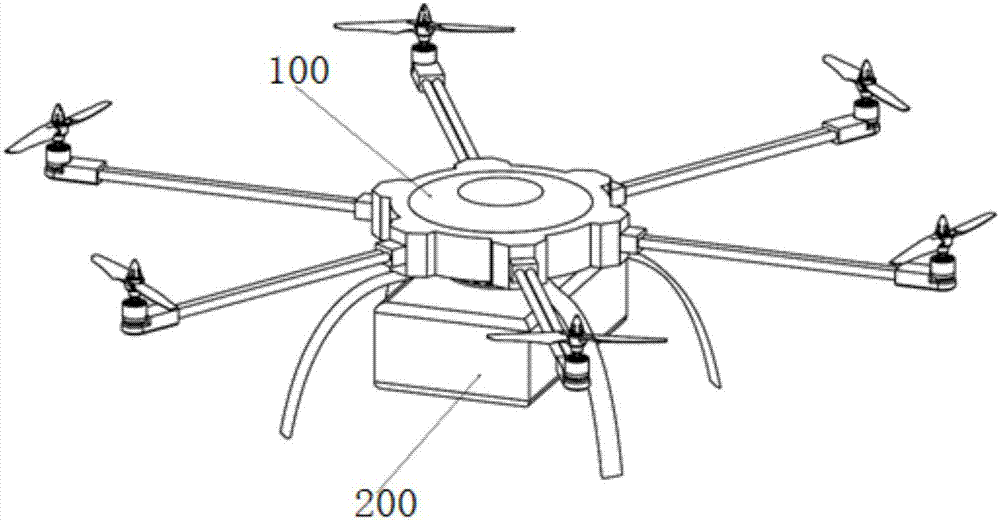

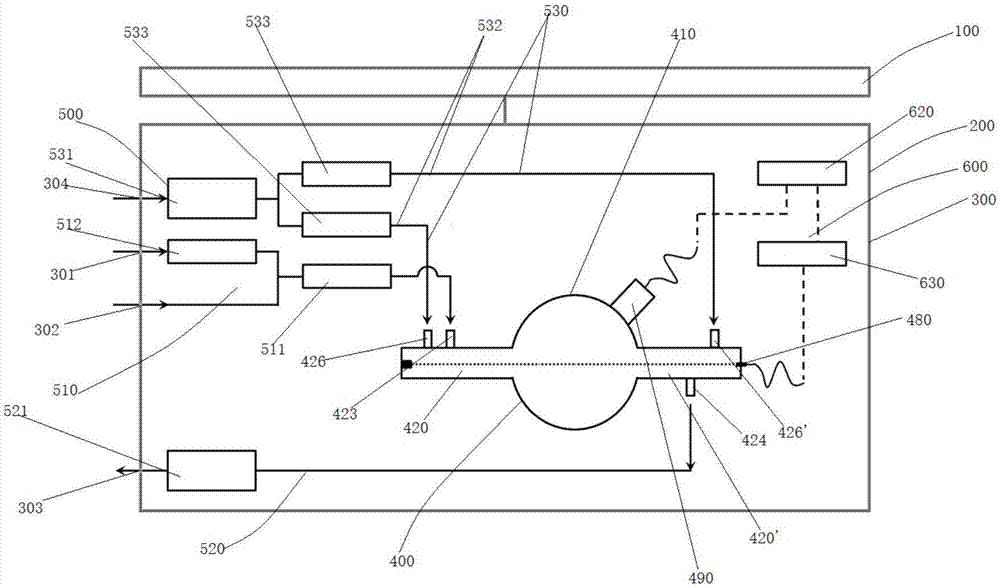

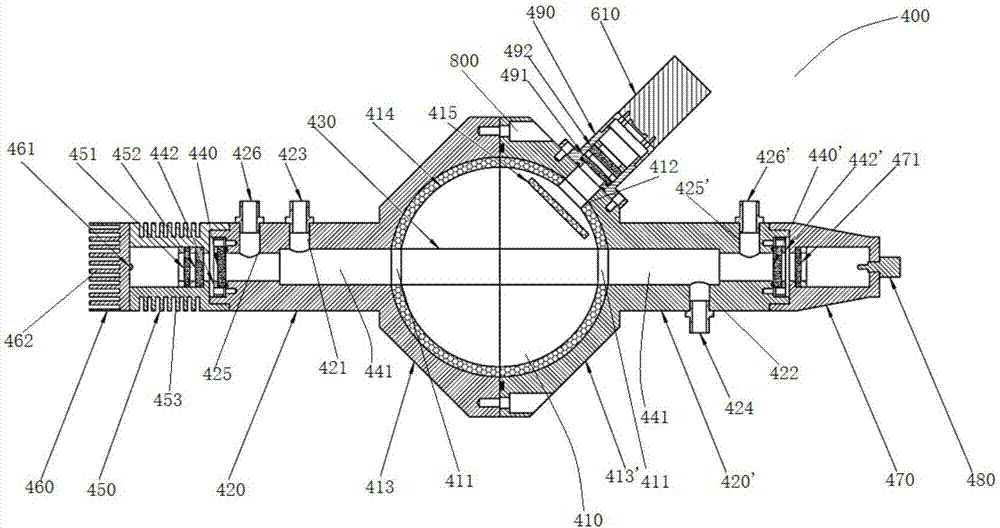

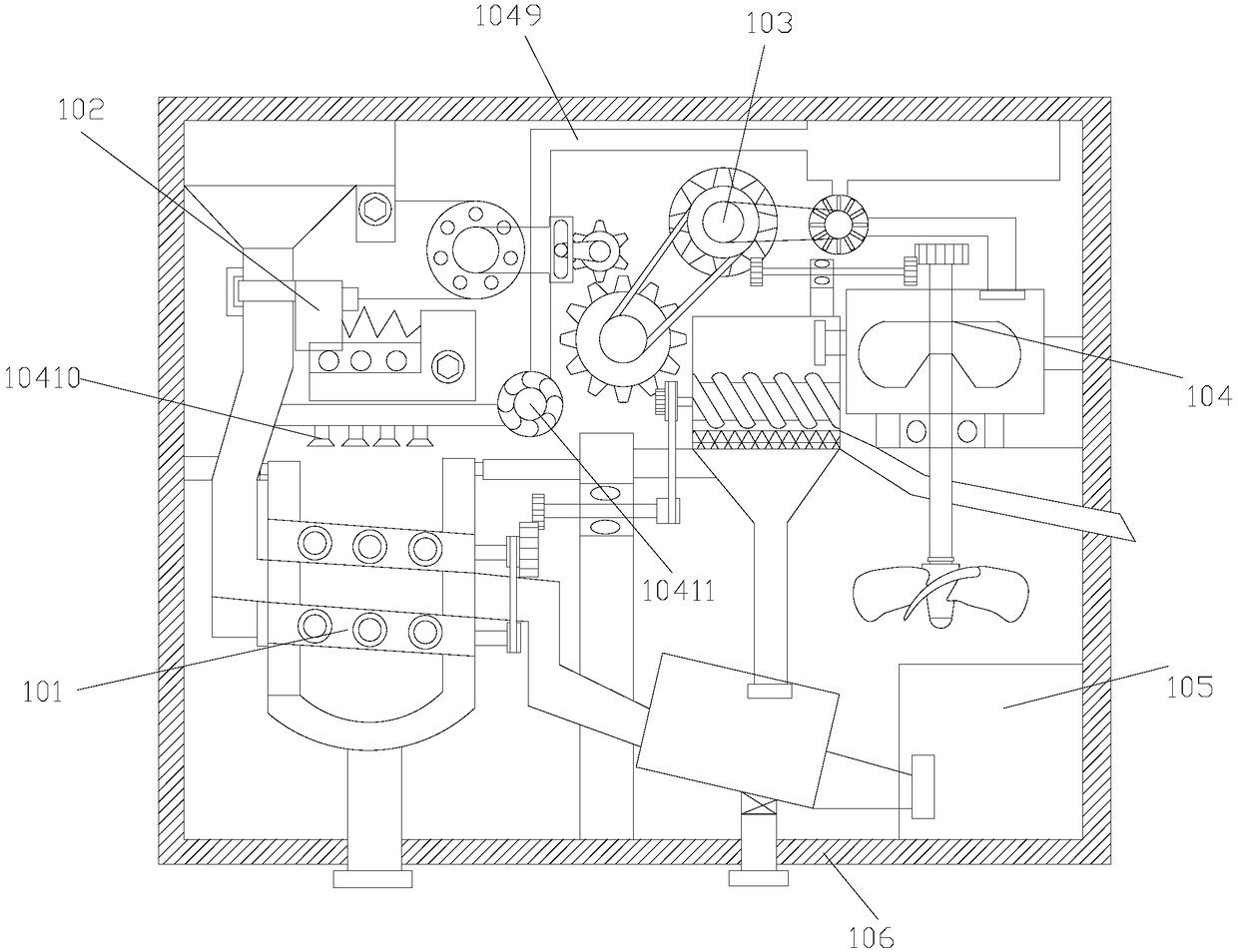

Unmanned-aerial-vehicle-mounted atmospheric aerosol single-scattering albedo profile measurement system

ActiveCN106908858ACompact and lightweightIncrease flexibilityTransmission systemsScattering properties measurementsMeasuring instrumentData acquisition

The invention discloses an unmanned-aerial-vehicle-mounted atmospheric aerosol single-scattering albedo profile measurement system. The system includes an unmanned aerial vehicle, a control unit, an atmospheric aerosol single-scattering albedo measuring instrument and a data transmission assembly; the control unit includes a data acquisition and processing terminal and an unmanned aerial vehicle control module which is in communication with the unmanned aerial vehicle; the atmospheric aerosol single-scattering albedo measuring instrument includes a box body, a measuring optical cavity and a gas channel transmission assembly, wherein the box body is installed on the unmanned aerial vehicle, the measuring optical cavity is formed in the box body, and the air channel transmission assembly is arranged in the box body and includes a sample gas background gas channel and an gas exhaust channel; the data transmission assembly includes a photomultiplier tube, a data acquisition card and a spectrometer. The measurement system is compact in structure, light, portable and high in measurement accuracy, and can be used for accurate measurement of vertical profiles of atmospheric aerosol single-scattering albedos.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

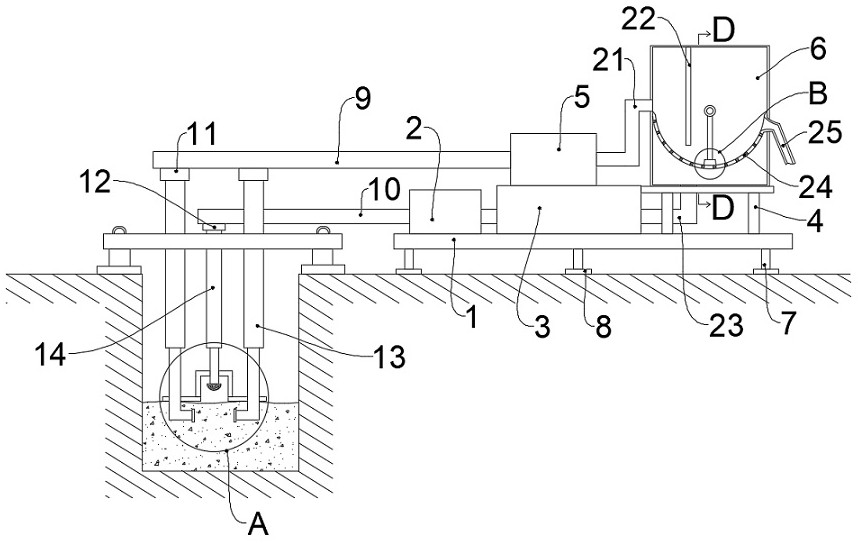

Deep foundation pit rapid dewatering device

The invention discloses a deep foundation pit rapid dewatering device. The device comprises a first supporting frame, wherein a first pump machine, a water storage mechanism and a second supporting frame are sequentially arranged on the upper side of the first supporting frame from left to right, a second pump machine is fixedly connected to the upper side of the water storage mechanism, a filtering bin is arranged on the upper side of the second supporting frame, the first pump machine is connected with the water storage mechanism through a pipeline, a second connecting pipe is arranged between the water storage mechanism and the filtering bin, a first connecting pipe is arranged between the second pump machine and the filtering bin, a main drainage pipe is fixedly connected to the left side of the first pump machine, a drainage pipe connector is arranged on the lower side of the other end of the main drainage pipe, a fixed water guide pipe is arranged on the lower side of the drainage pipe connector, and a movable water guide pipe is movably connected into the fixed water guide pipe. According to the device, by scouring soil in a foundation pit, muddy water containing the soil inthe foundation pit can be conveniently and rapidly discharged, meanwhile, workers can conveniently arrange the muddy water, and the foundation pit dewatering speed can be greatly increased.

Owner:刘宏庆

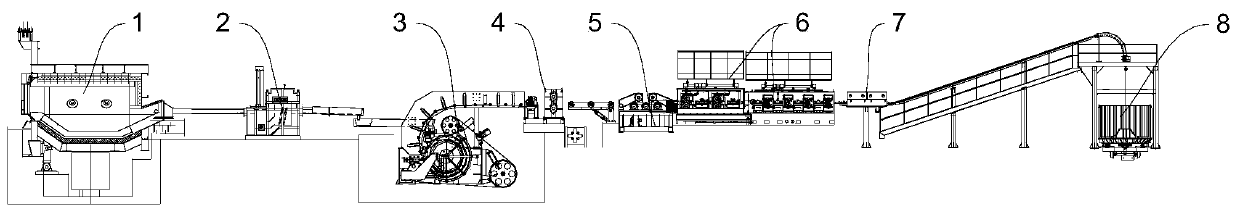

Aluminum rod continuous casting and rolling production line

InactiveCN110102573AFree from scratchesAvoid wear and tearRolling equipment maintainenceGuiding/positioning/aligning arrangementsProduction lineEmulsion

The invention relates to the field of aluminum rod production rolling, in particular to an aluminum rod continuous casting and rolling production line. The aluminum rod continuous casting and rollingproduction line comprises an aluminum furnace used for melting a raw material, a casting machine used for cooling and solidifying molten metal, a roll shearing pulling device used for pulling an aluminum rod formed by the casting machine, a continuous rolling machine used for rolling forming of the aluminum rod, and a taking-up device used for taking up. The taking-up device does not use rod leading oil, and heat dissipating oil fume pollution of the aluminum alloy rod is avoided while it is ensured that the surface of the aluminum alloy rod is not scratched; and additionally, a lubricating oil and emulsion circulating system is arranged in the continuous rolling machine, lubricating oil lubricates and cools a bearing and a gear independently, an emulsion cools a rolled piece independently, thus abrasion caused by a traditional emulsion to the bearing and the gear is effectively avoided, the service lives of the bearing and the gear of the continuous rolling machine are prolonged, andthe accidents of rod blocking and breaking caused by quick aging and abrasion of the bearing and the gear in the production process are avoided.

Owner:四川久勋科技有限公司

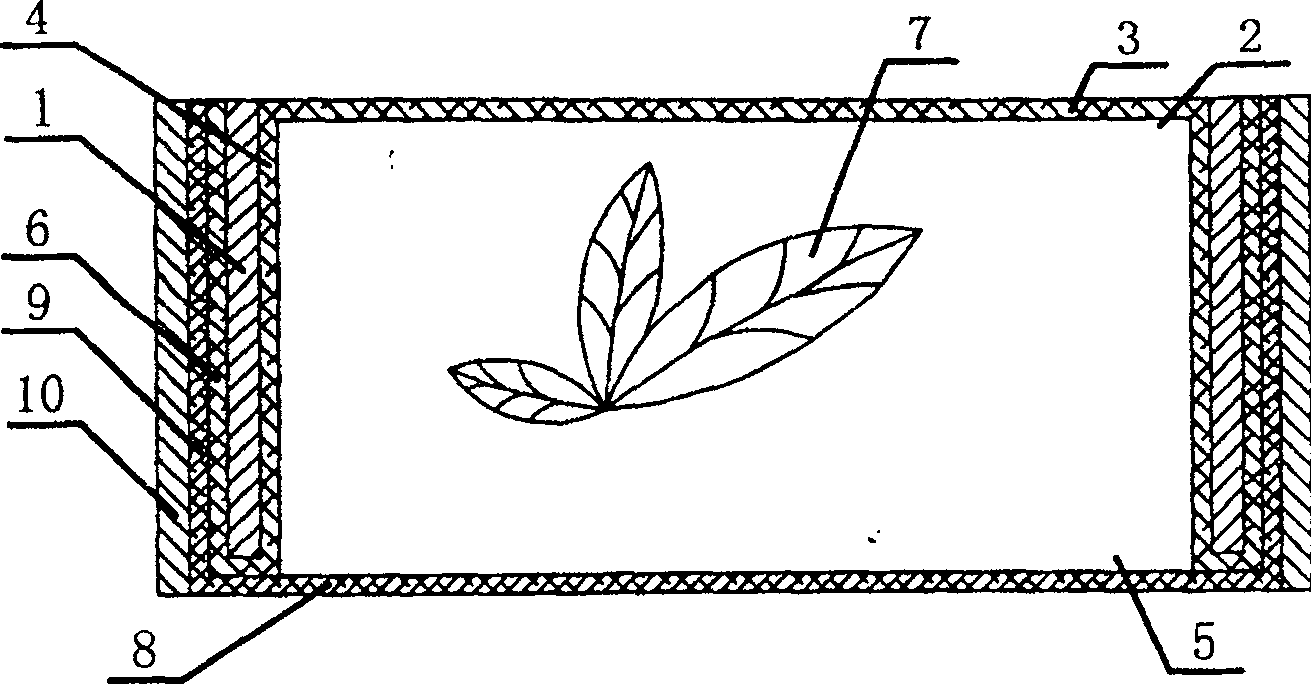

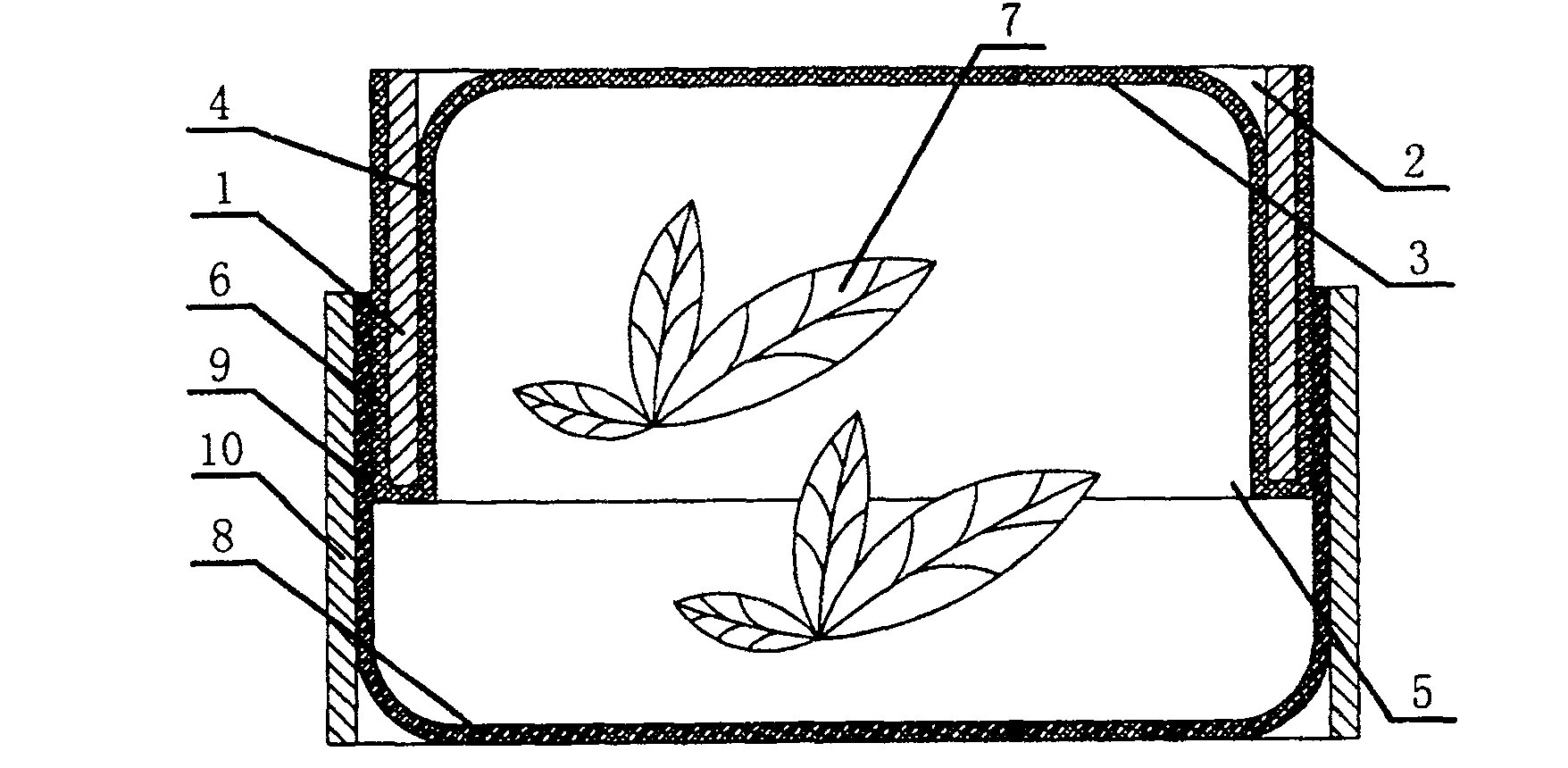

Foodstuff bag box

The invention belongs to the technical field of bases or containers with holes placed in cookers. Solve the problem of placing the ingredients in the container and cooking them together with food or water, and the food dregs produced will disperse into the food or water, which will affect the diet, and wrap the ingredients in filter paper and place them in the high-temperature flowing liquid pipeline, which has multi-directional osmosis Sex, the effect of brewing is not good. The food material package box includes a plastic tube (1), the upper nozzle (2) of the plastic tube (1) is provided with an upper filter paper (3), and the plastic tube (1) The lower nozzle (5) is provided with filter paper (8) below. With a rigid structure, the plastic tube can be designed according to the shape of the inner wall of the container, so that the plastic tube can match the inner wall of the container. When the high-temperature flowing liquid passes through the plastic tube, all the liquid can pass through the filter paper, so that the gap between the filter paper The ingredients are fully washed and the active ingredients are released.

Owner:邵志成

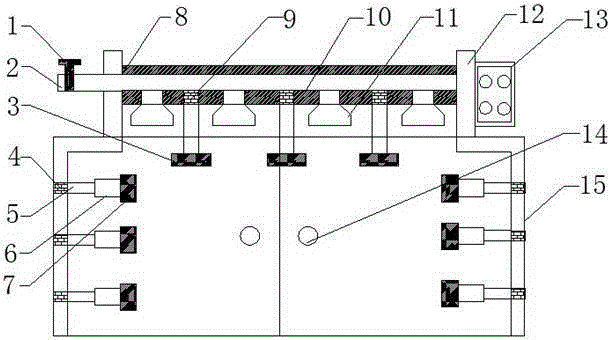

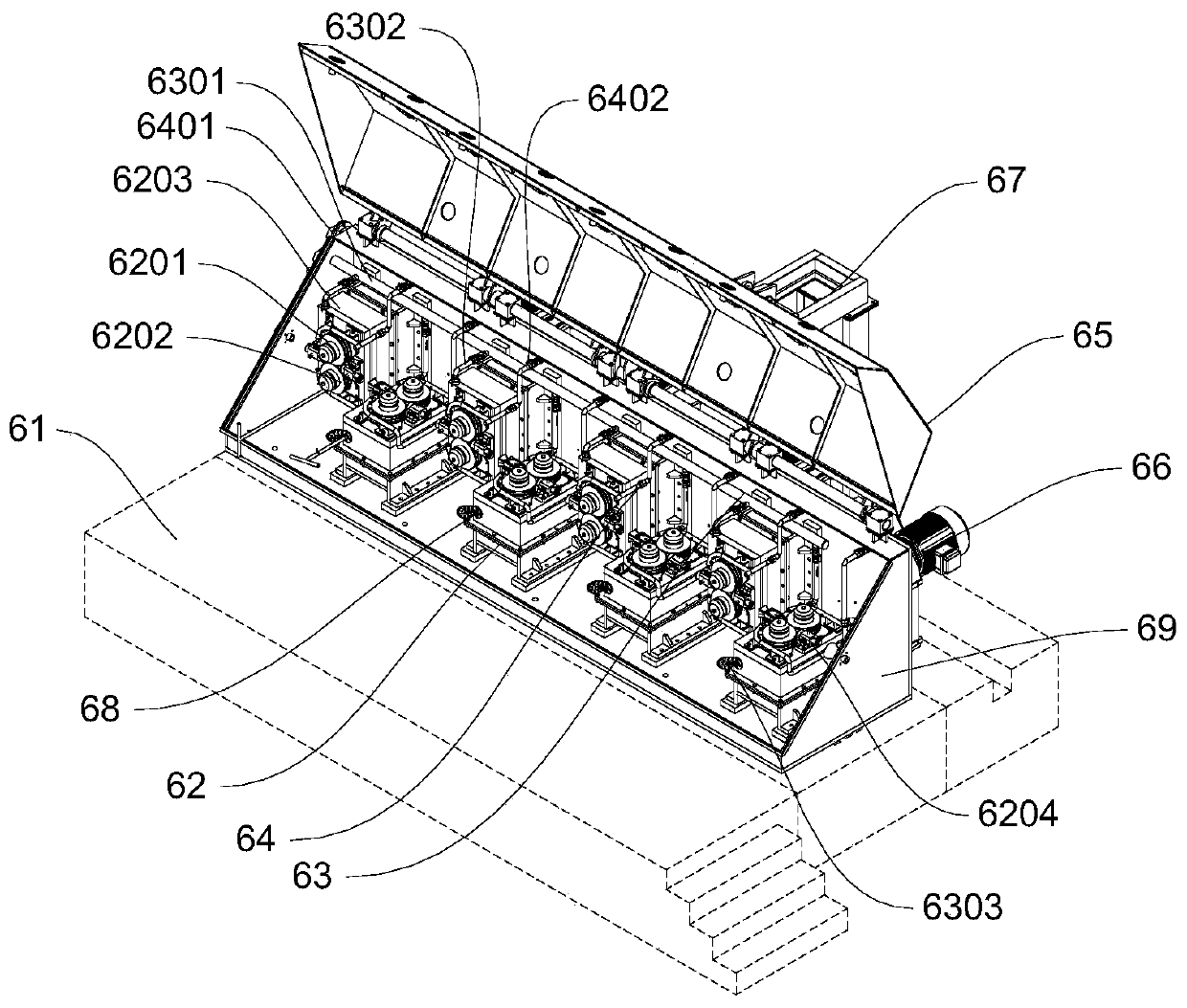

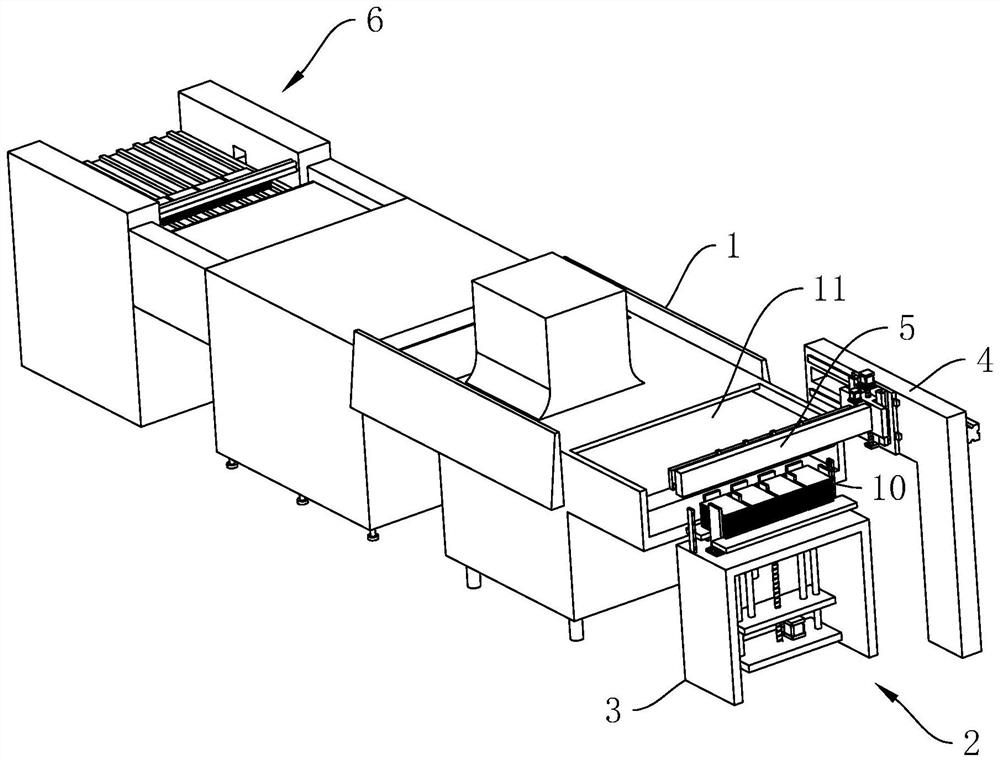

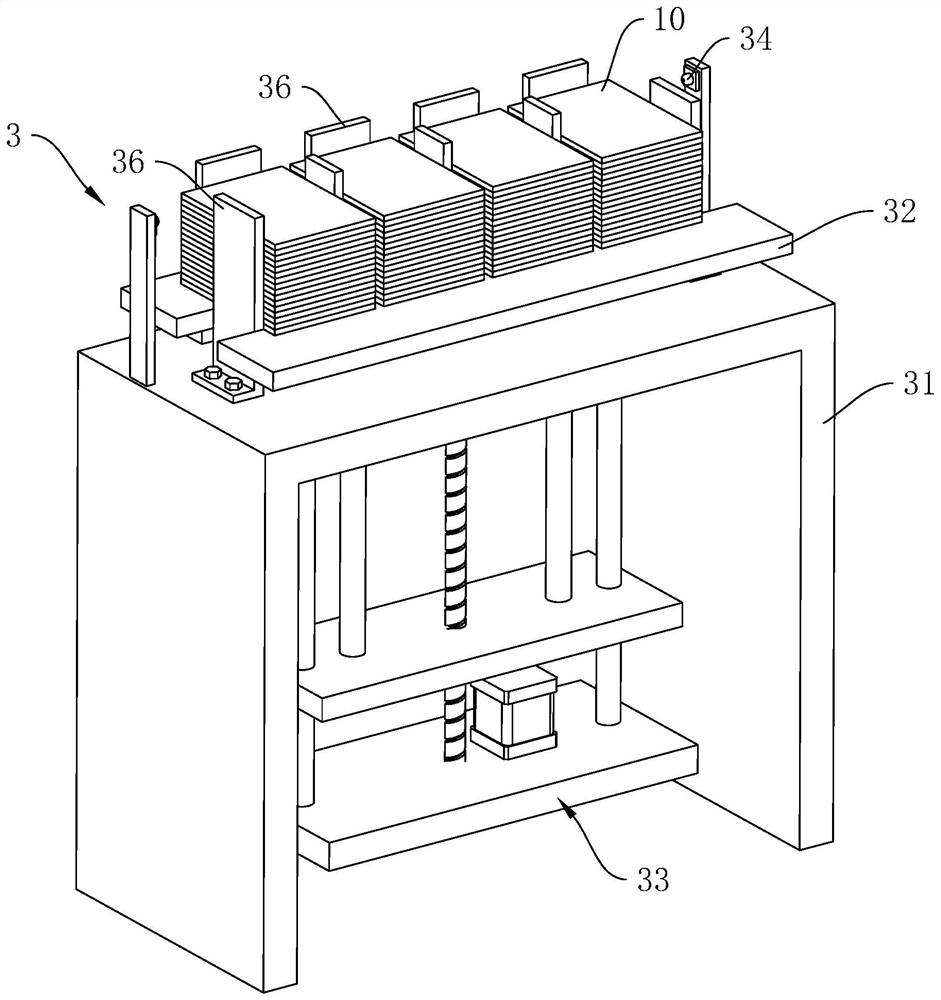

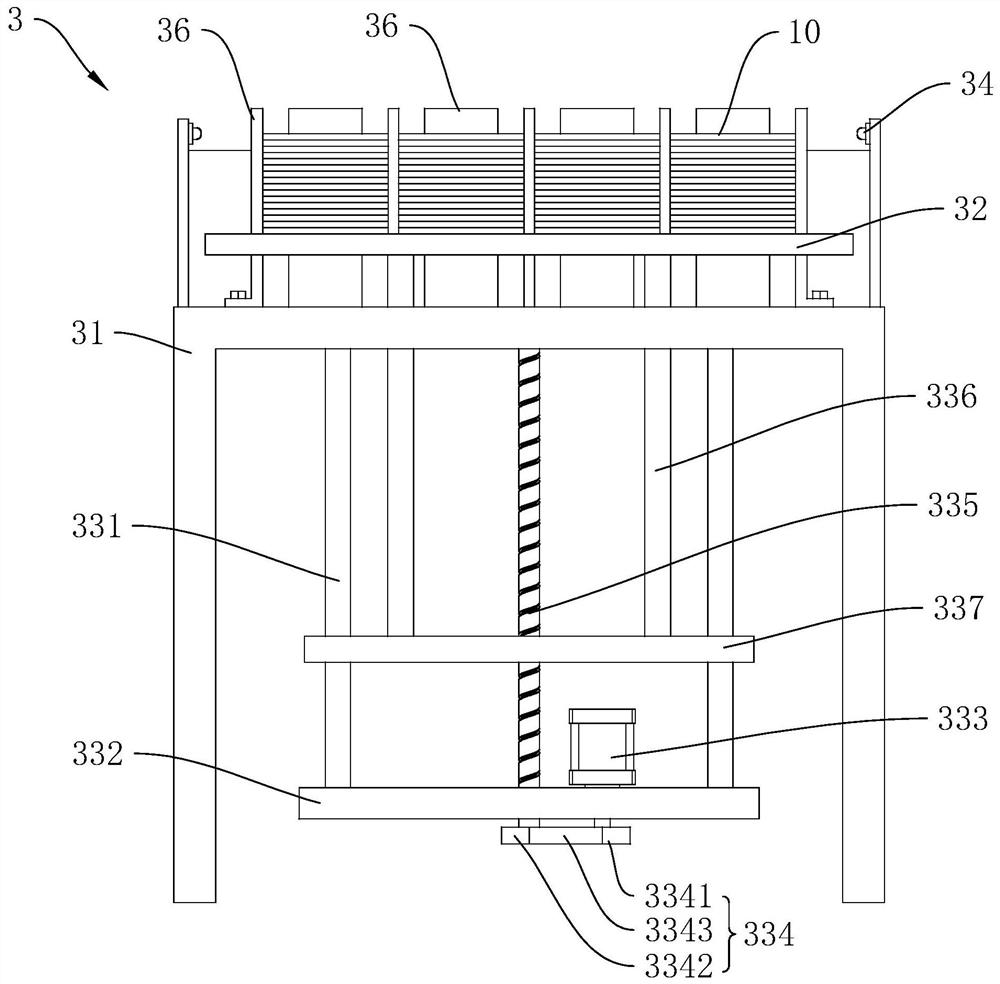

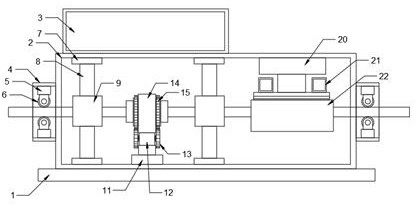

Board washing machine for PCB processing and use method thereof

InactiveCN113003218AImprove feeding efficiencyEnsure intervalCleaning using liquidsDe-stacking articlesMachiningTransfer line

The invention relates to a board washing machine for PCB machining. The board washing machine comprises a board washing machine body, a conveying line is arranged in the board washing machine body, a feeding mechanism is arranged at the feeding end of the conveying line, and a discharging mechanism is arranged at the discharging end of the conveying line. The feeding mechanism comprises a jacking and separating device, a two-shaft driving device and a grabbing device, the jacking and separating device is arranged at the feeding end of the conveying line, the two-shaft driving device is arranged on the side of the conveying line, the grabbing device is arranged at the output end of the two-shaft driving device, the grabbing device comprises a plurality of suction nozzles, and the suction nozzles can be far away from or close to one another. According to the machine, the mode that the PCB is manually separated for feeding is replaced, the PCB can be fed in multiple rows in parallel, the feeding efficiency of the PCB is effectively improved, the interval between the adjacent PCB is guaranteed, the board washing machine body can sufficiently wash the PCB in the follow-up process, and the cleaning quality of the PCB is improved.

Owner:佛山市数力电子科技有限公司

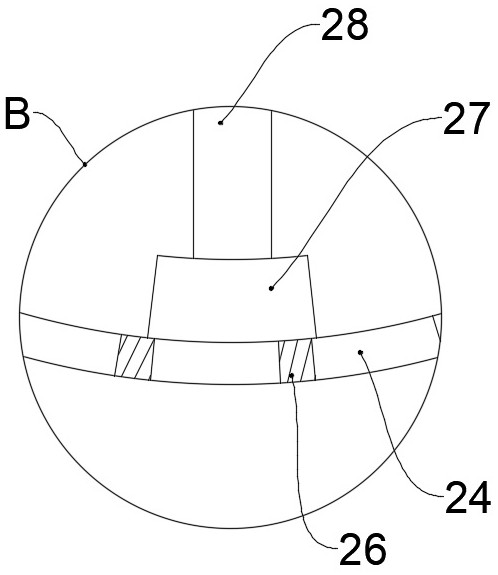

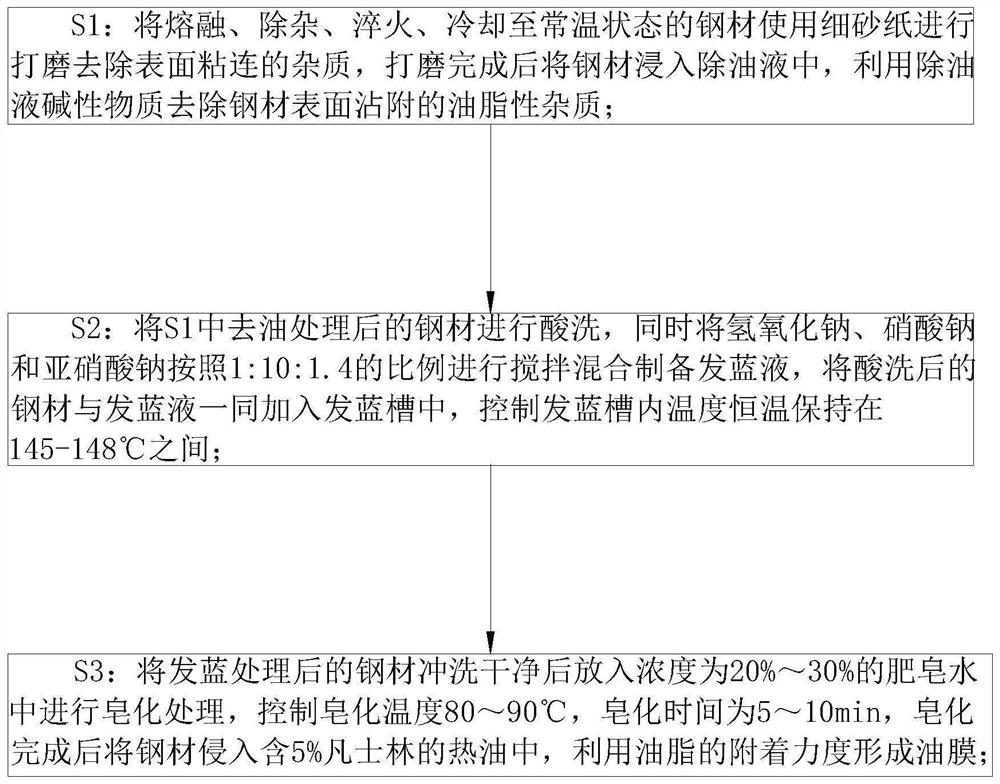

Anti-corrosion method of steel and anti-corrosion steel

InactiveCN111636059AHomogenize surface oxide filmUniform chemical compositionMetallic material coating processesStructural engineeringBluing

The invention belongs to the technical field of metal protective materials, and particularly relates to an anti-corrosion method of steel and the anti-corrosion steel. A bluing tank comprises a tank body, a conveyor belt, a sealing cover and an electromagnetic heating device; the tank body is of a cuboid structure with a cavity formed inside; the sealing cover is mounted at the opening in the upper end of the tank body; a feeding hole is formed in one side of the tank body, and a discharging hole is formed in the other side of the tank body; a feeding tank is fixedly connected to the position,outside the feeding hole, of the tack body, and a discharging tank is fixedly connected to the position, outside the discharging hole, of the tank body; the feeding tank and the discharging tank areboth obliquely formed; the electromagnetic heating device is connected to the bottom of the tank body in an embedded manner; guide rods which are uniformly distributed are rotationally connected intothe cavity of the tank body; each guide rod is sleeved with a rotating wheel; the conveying belt meshes with the rotating wheels; and according to the method and the steel, the conveying belt is usedfor driving a component to be subjected to bluing reaction in the slow moving process, the component is automatically turned over in the moving process, and then contact between the component and bluing liquid is uniform.

Owner:夏鹏宇

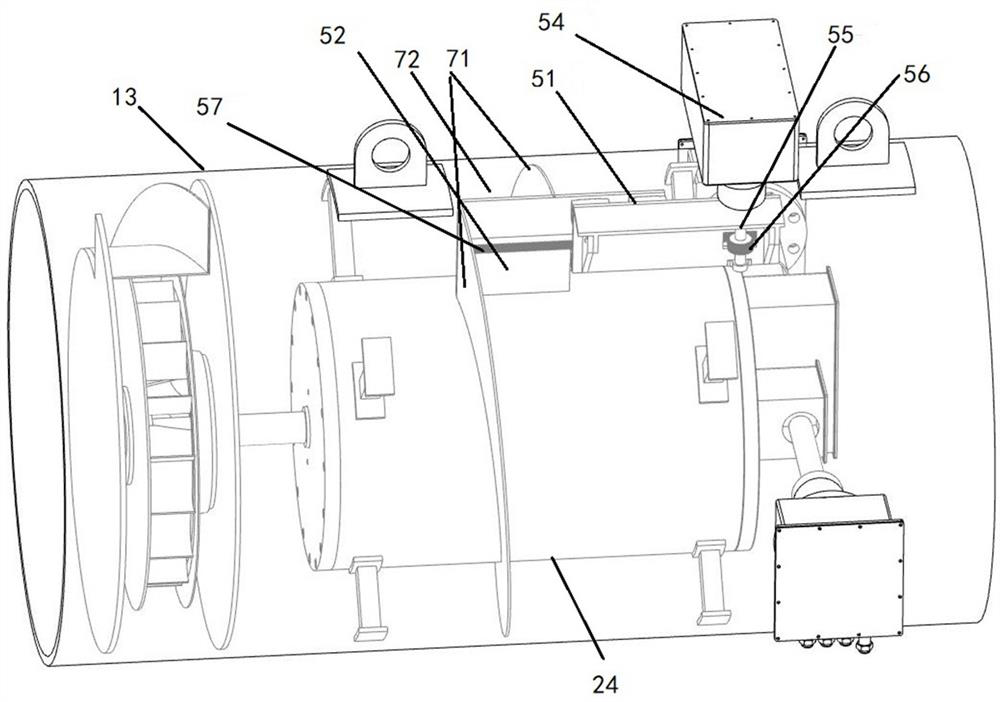

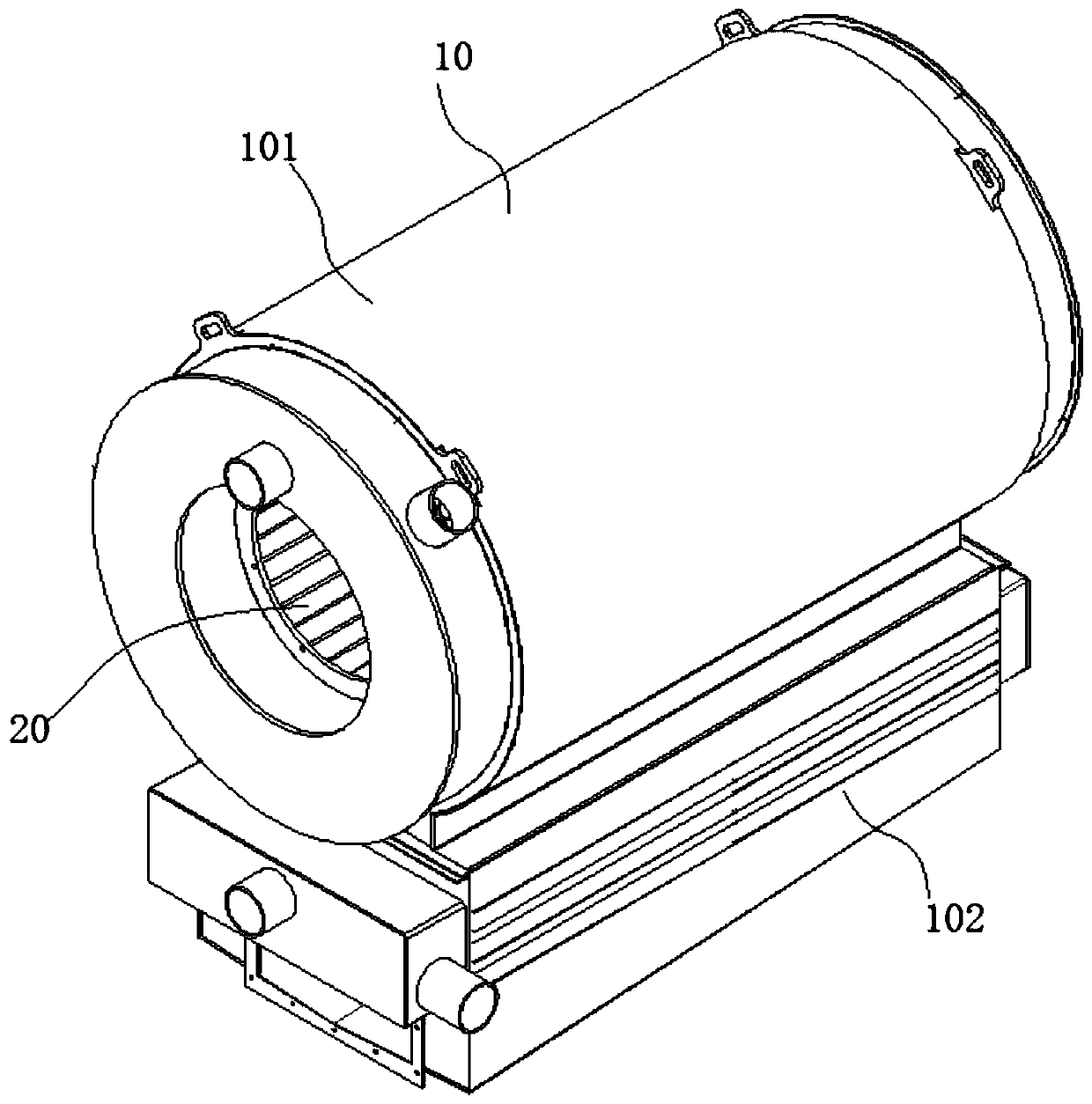

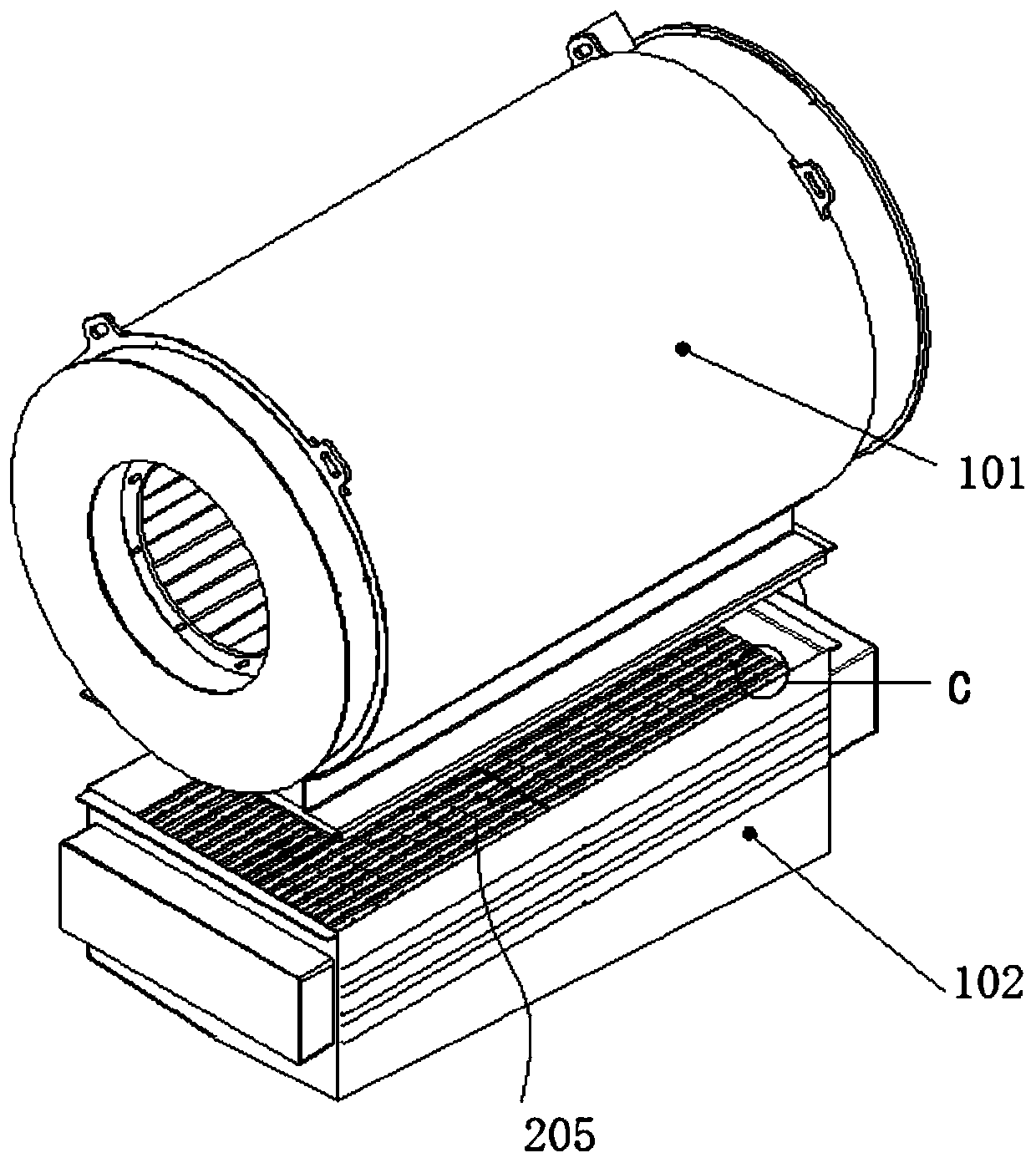

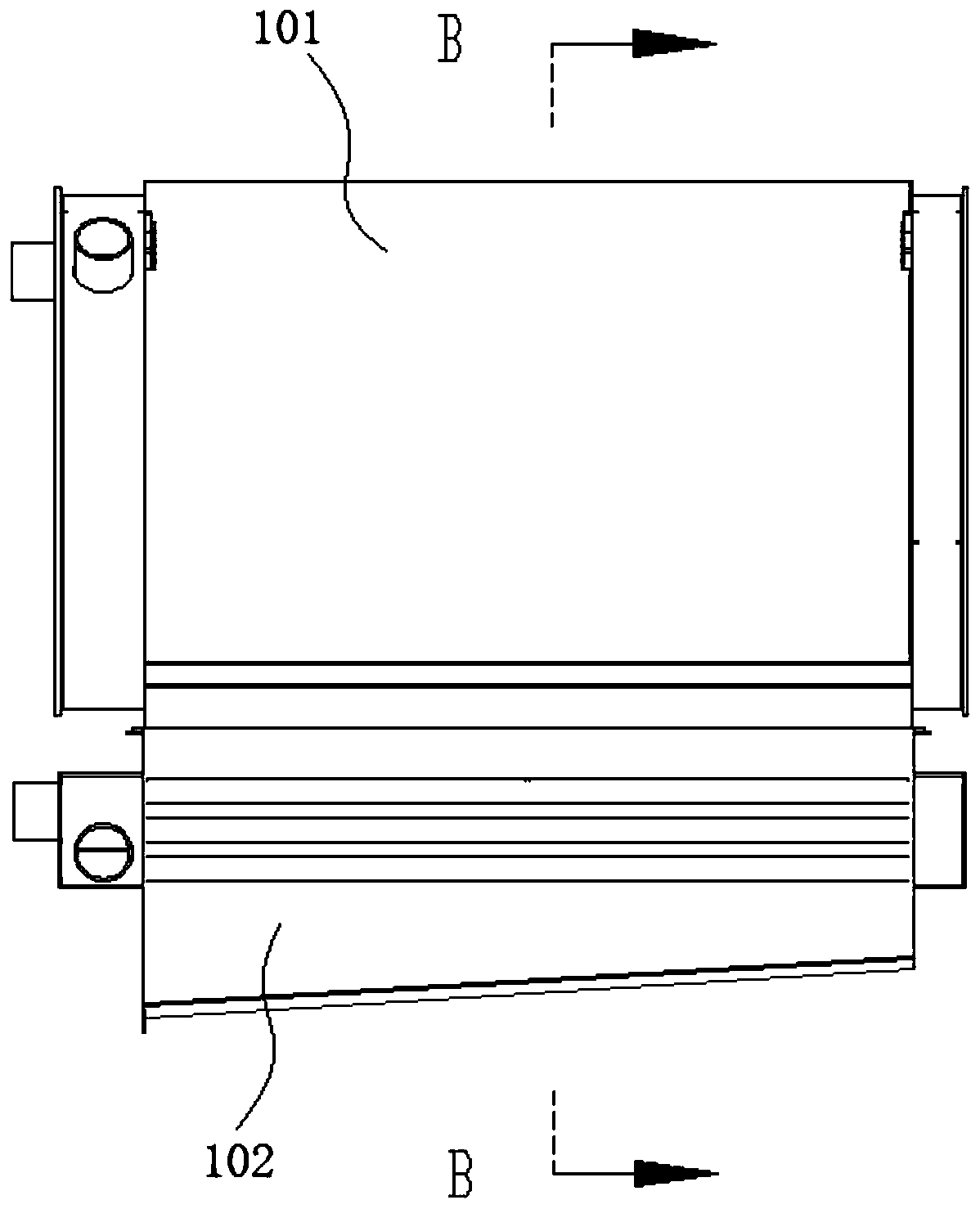

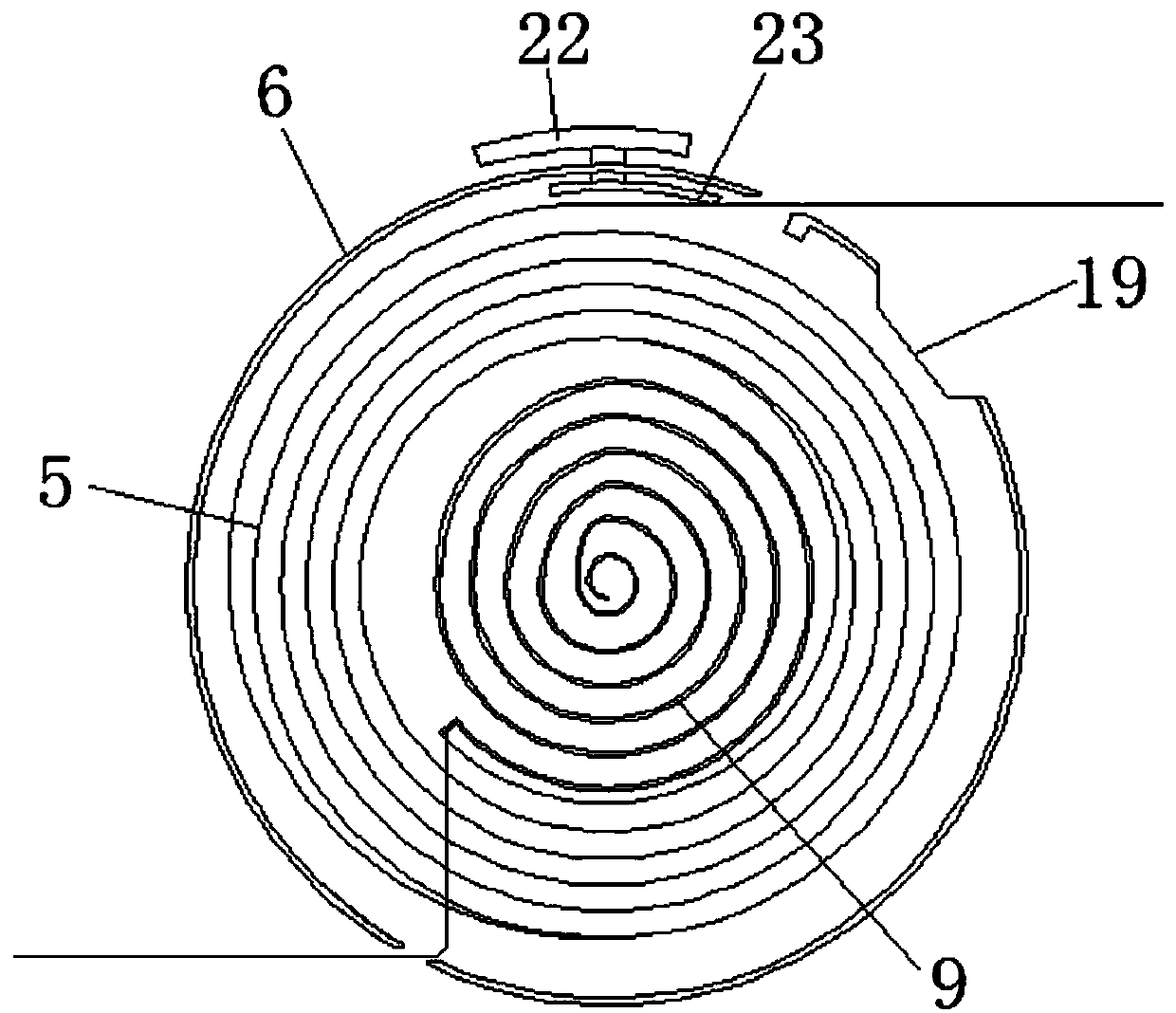

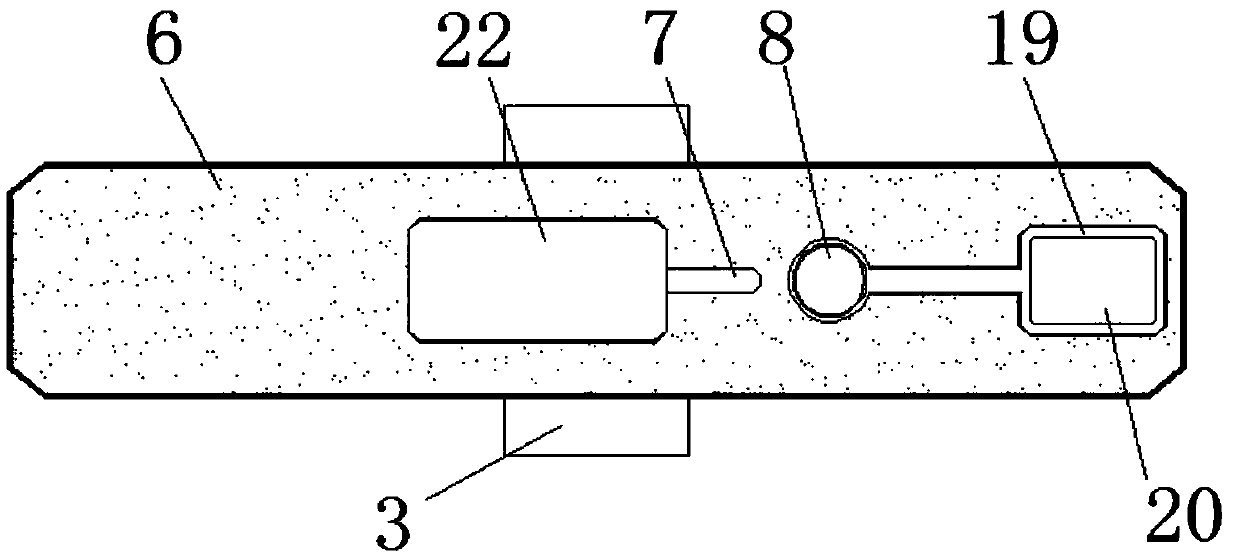

Centrifugal fan with flow and temperature adjusting function

InactiveCN114320976AContinuous and stable operationReduce heating ratePump componentsPump controlElectric machineryCentrifugal fan

The invention provides a centrifugal fan with flow and temperature regulation, which is characterized in that a temperature regulation device for regulating the temperature of fluid in the centrifugal fan in a coolant heat exchange manner is arranged at an air outlet of the fan, and the temperature regulation device is arranged in the fan or at an air inlet of the fan or at the air outlet of the fan; the flow adjusting device capable of adjusting the actual flowing-through flow by adjusting the actual flowing-through area of the fluid is arranged in a mode of sealing the flowing-through area of the fluid, and the flow adjusting device is combined with the variable frequency motor for use, so that the flow adjusting range of the centrifugal fan, especially the low-frequency adjusting range, can be effectively widened; the flow of the fan can be further reduced by reducing the actual flowing area of fluid, and ideal air pressure is obtained; the temperature adjusting device for adjusting the temperature of fluid in the centrifugal fan in a coolant heat exchange mode is arranged at the air outlet of the fan, air discharged from the fan can be directly cooled, the fluid does not need to be cooled independently, and convenience and high efficiency are achieved.

Owner:南京深度系统工程有限公司

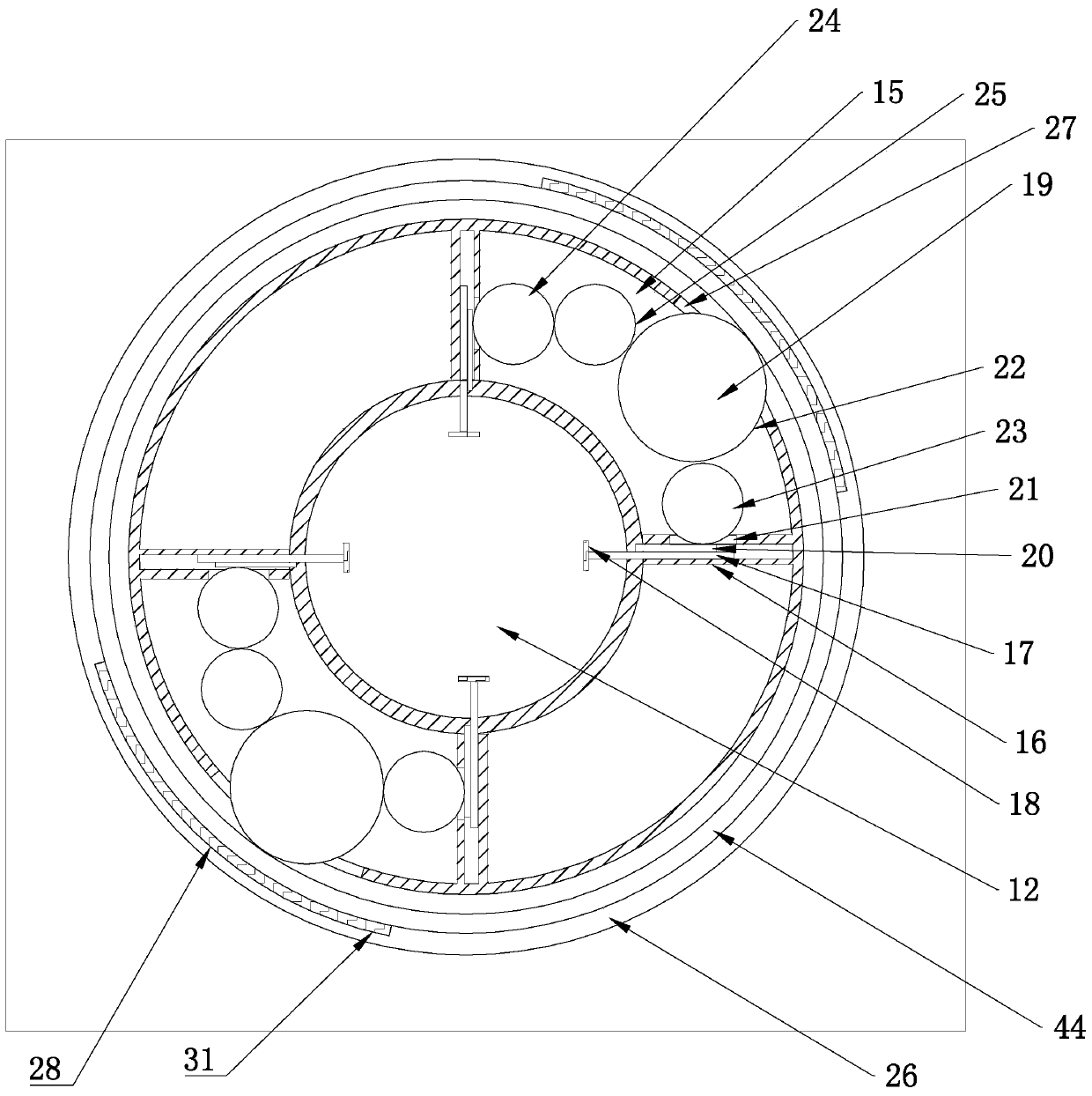

Cleaning and disinfecting device for down feather processing

ActiveCN112301433APrevent Adhesive BuildupReduce noiseWool fibre washing/scouringMechanical engineeringDown feather

The invention relates to a cleaning and disinfecting device for down feather processing. The cleaning and disinfecting device comprises a shell and an inner cleaning barrel arranged in the shell, wherein a shell upper cover is detachably connected to the upper end of the shell, a power output mechanism is arranged between the shell and the inner cleaning barrel, a down feather collecting mechanismis arranged in the inner cleaning barrel, an auxiliary down feather cleaning mechanism is arranged on the down feather collecting mechanism, and an inner cleaning barrel upper cover is detachably connected to the upper end of the inner cleaning barrel. According to the cleaning and disinfecting device for down feather processing, multiple sets of water pumps and beveling type pipelines are adopted for providing circulating annular rotating water flow for the inner cleaning barrel, the water flow can be driven to flush feathers more sufficiently, meanwhile, the down feathers can be prevented from being adhered to the wall and accumulated, and meanwhile, the down feathers can be flapped and cleaned more sufficiently through the auxiliary cleaning mechanism, noise generated in a cleaning process is low, the down feathers can be conveniently collected after cleaning is finished, cleaning and disinfecting processes are shortened, and the working intensity of workers is reduced.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

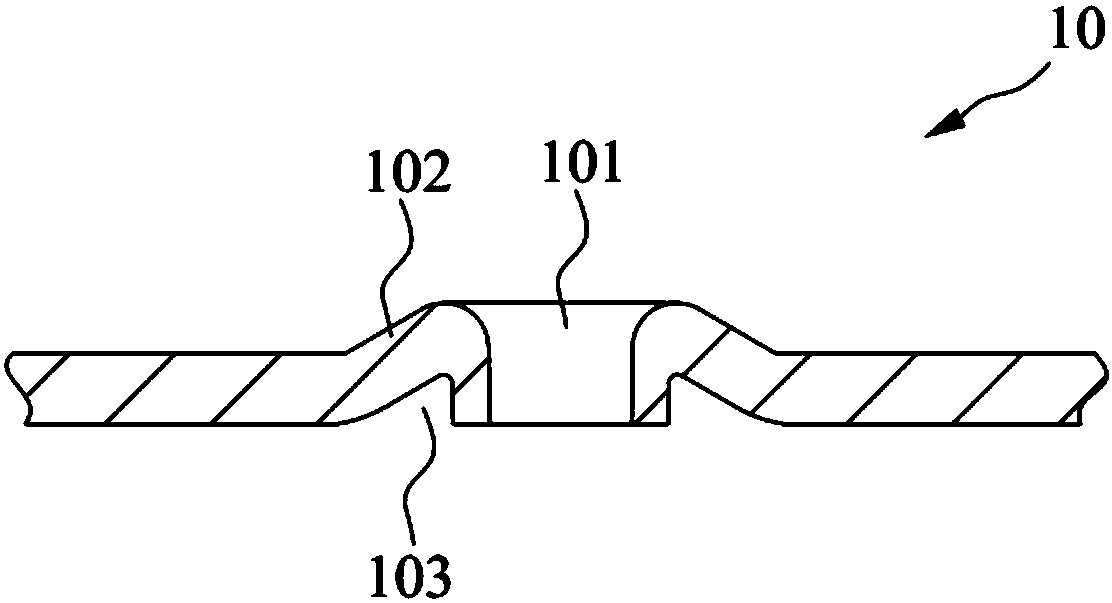

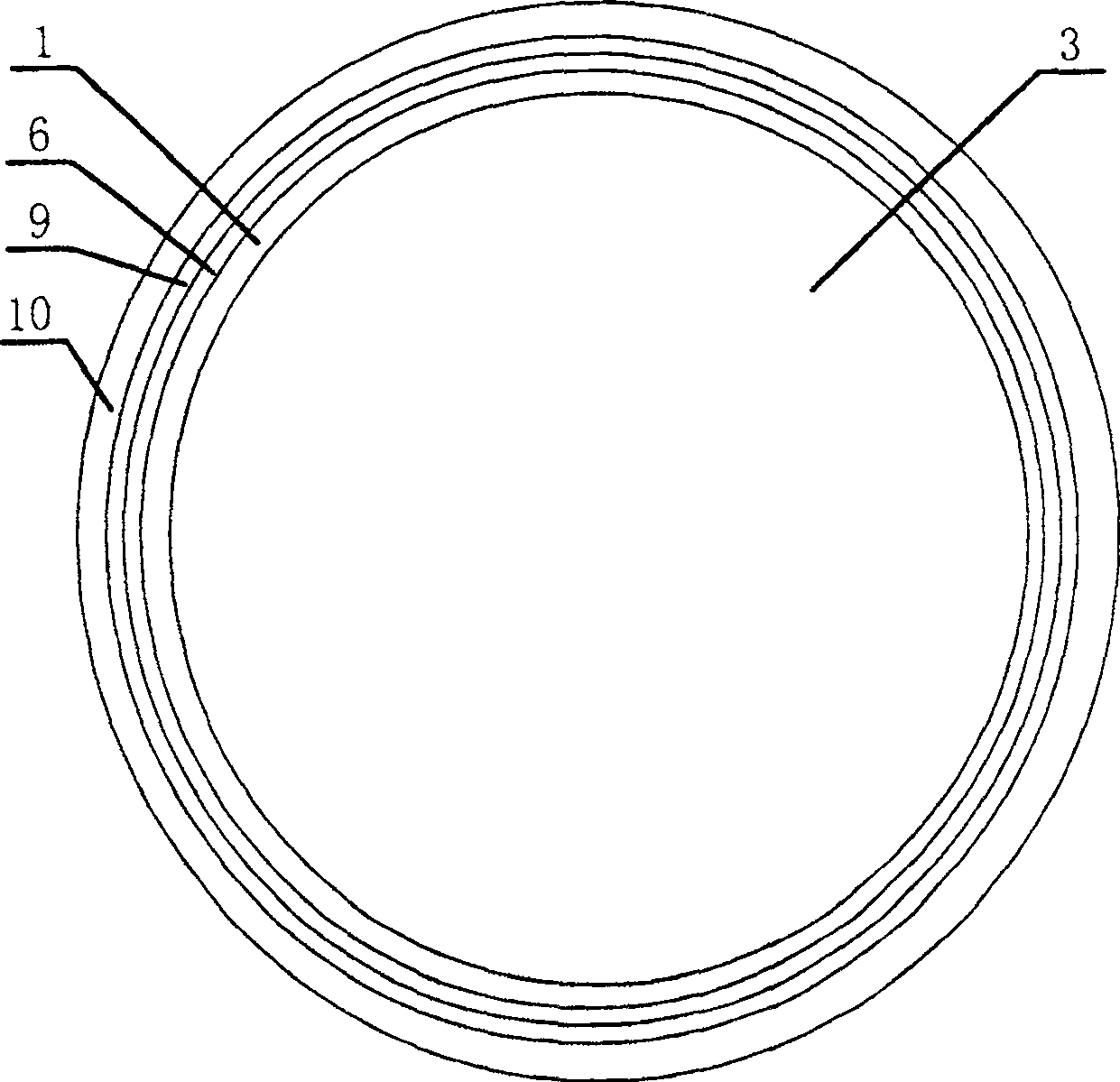

Heat exchanger and condensing boiler

PendingCN110926026AIncrease the heat exchange areaImprove heat transfer effectAir heatersSustainable buildingsEngineeringMechanical engineering

The invention provides a heat exchanger and a condensing boiler. The heat exchanger includes an inner heat exchange tube and an outer heat exchange tube located on an outer ring of the inner heat exchange tube. The inner heat exchange tube has a receiving cavity. The direction of the central axis of the receiving cavity is consistent with the directions of the central axes of the inner and outer heat exchange tubes. The inner and outer heat exchange tubes are both light tubes. The heat exchanger has high heat exchange efficiency and is beneficial to a high-power boiler.

Owner:VALPO ENERGY & ENVIRONMENT TECH CO LTD +1

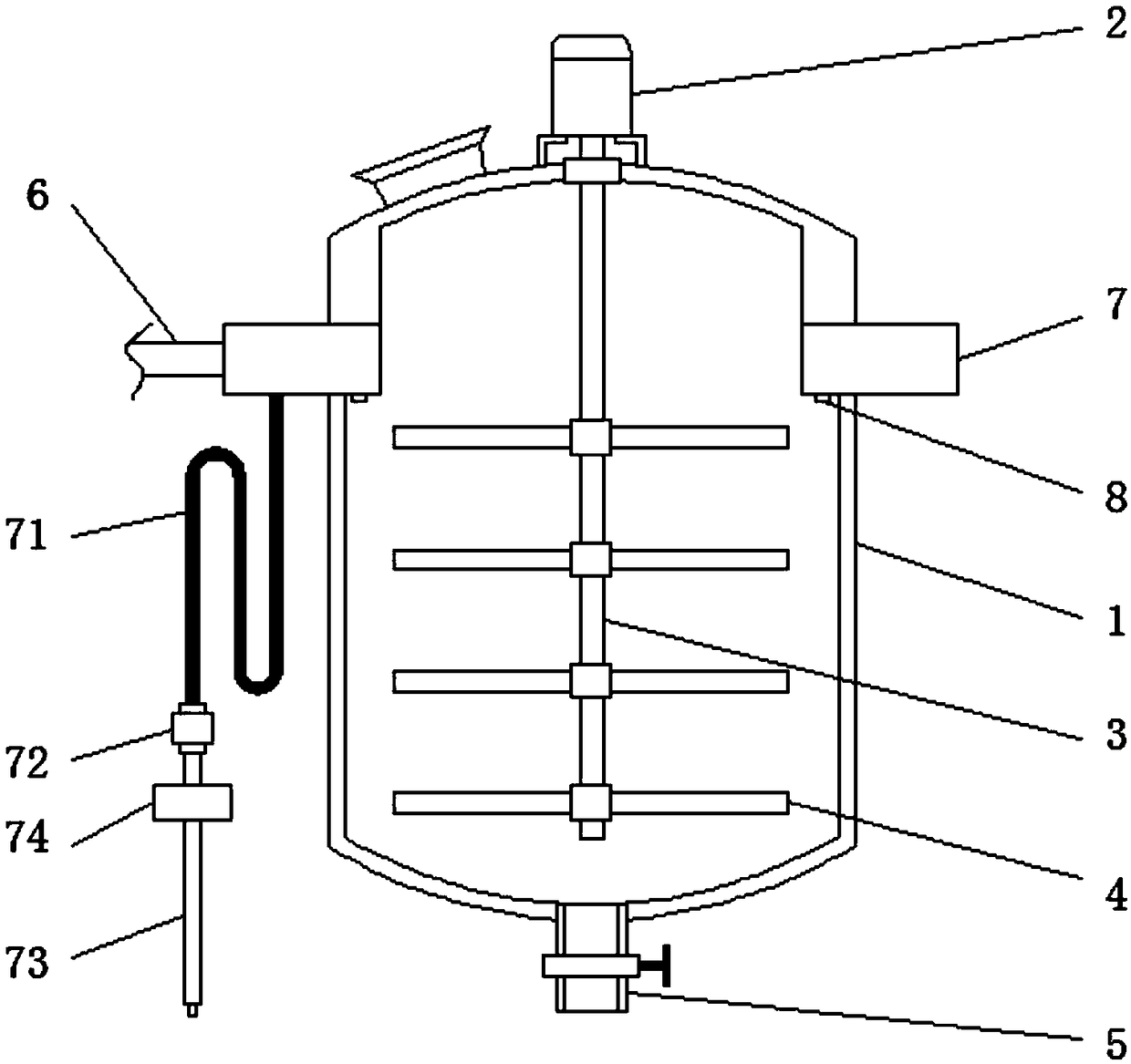

Cleaning device for chemical reaction kettle

InactiveCN108607858AGood cleaning effectImprove cleaning effectHollow article cleaningChemical/physical/physico-chemical stationary reactorsChemical reactionChemical engineering

The invention discloses a cleaning device for a chemical reaction kettle. The cleaning device for the chemical reaction kettle comprises a shell and a water inlet pipe. A motor is fixed to the shell,and the bottom end of the shell communicates with a discharging outlet. The motor is connected with a stirring shaft, and stirring blades are arranged on the stirring shaft. The water inlet pipe communicates with a water collecting disc, the water collecting disc and the shell are welded into a whole, and the water collecting disc extends to the interior of the shell and communicates with a wateroutlet spray hole. The cleaning device for the chemical reaction kettle comprises the water collecting disc, when the residue on the inner wall needs to be cleaned away, a connecting pipe can be inserted into the bottom end of the stirring shaft, and therefore the connecting pipe and the stirring blades can be located in a communicating state, water flow located inside the water collecting disc can be sprayed out of the stirring blades through the connecting pipe and sprayed to the inner wall of the shell, the residue on the inner wall can be scoured away, the situation that a reaction at thenext time cannot be affected is guaranteed, and the practicability is high.

Owner:钱富良

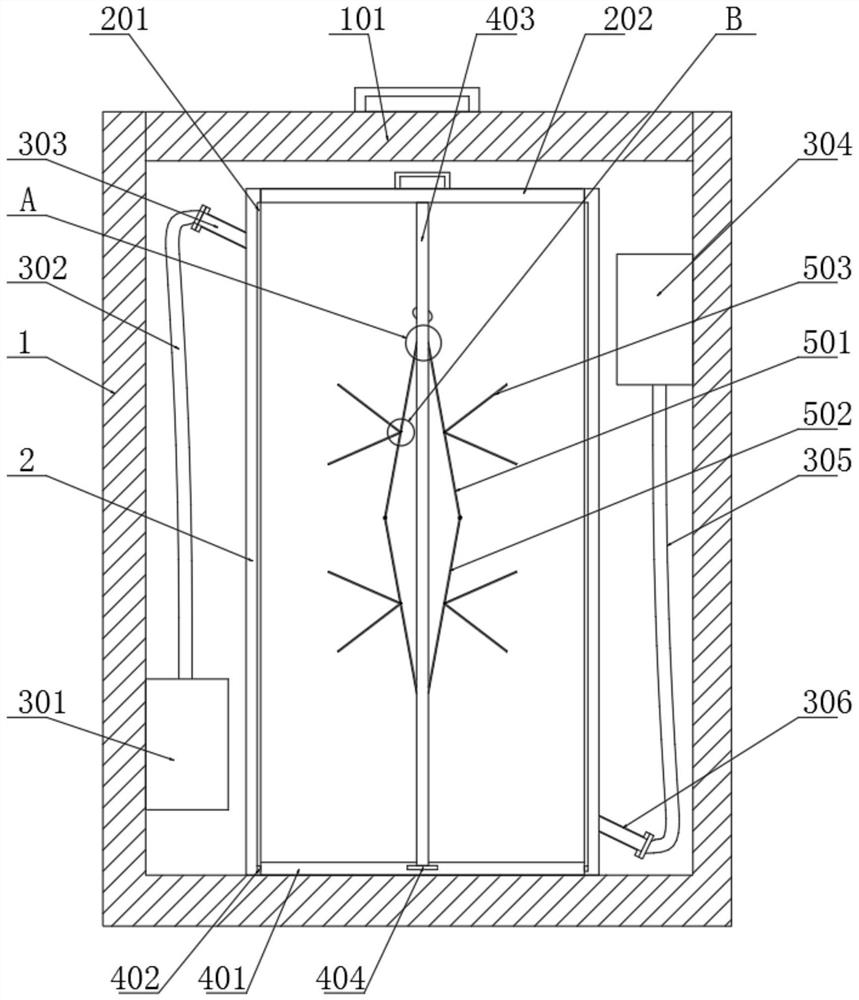

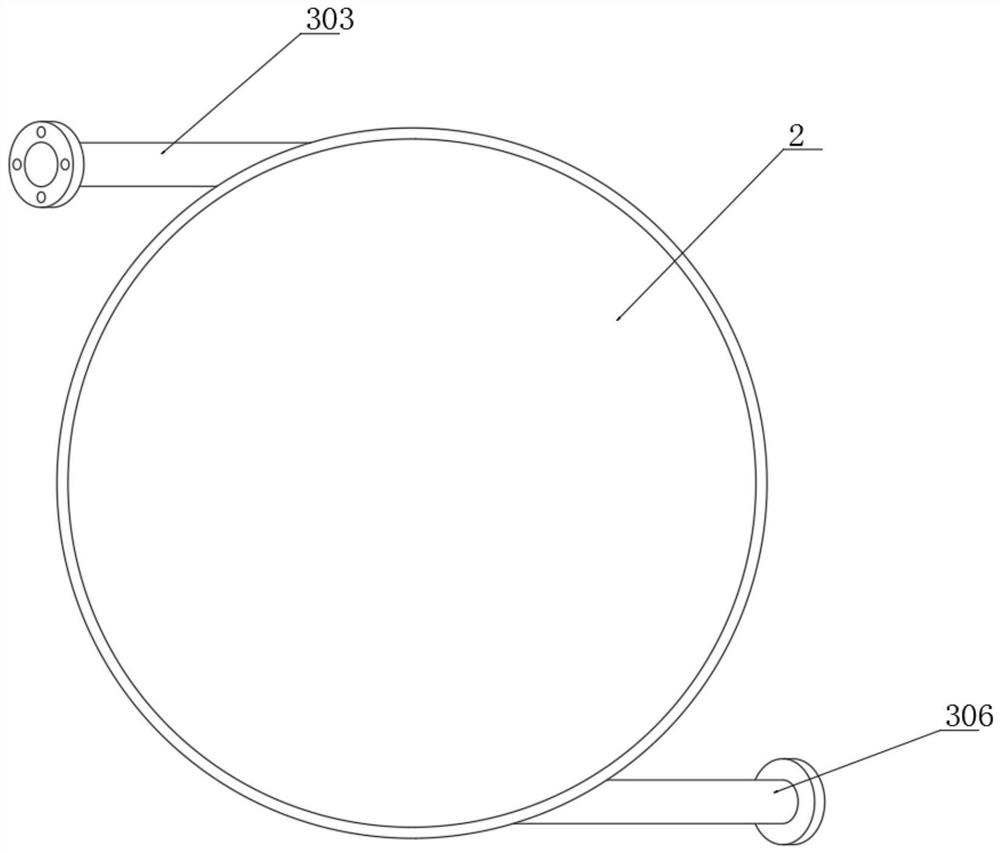

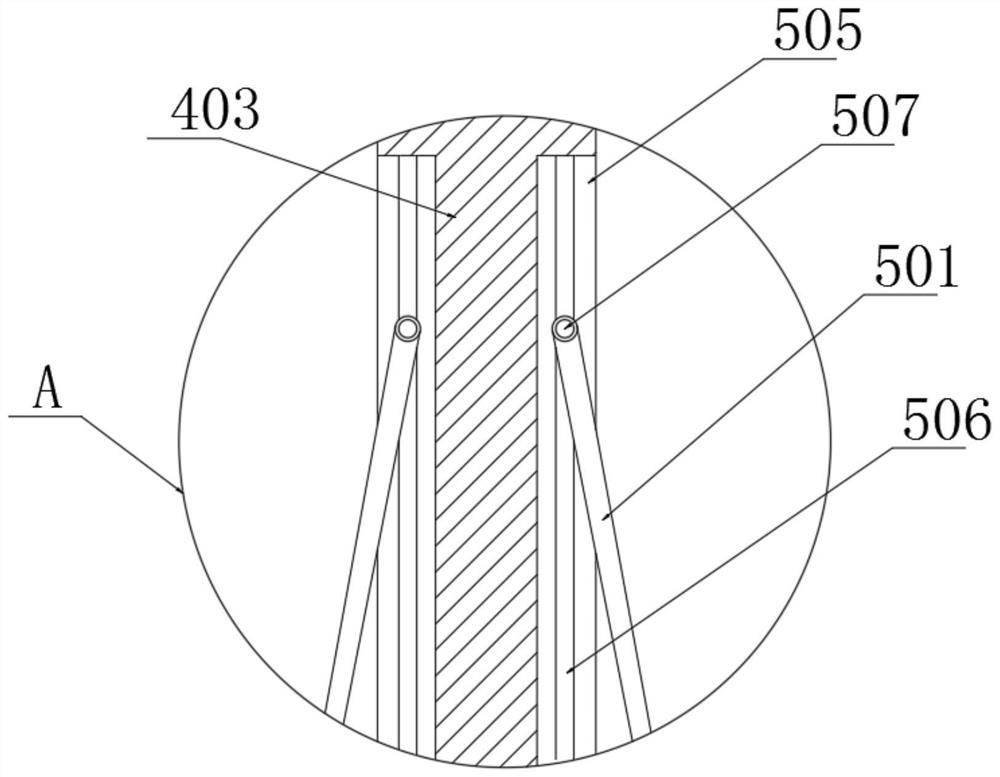

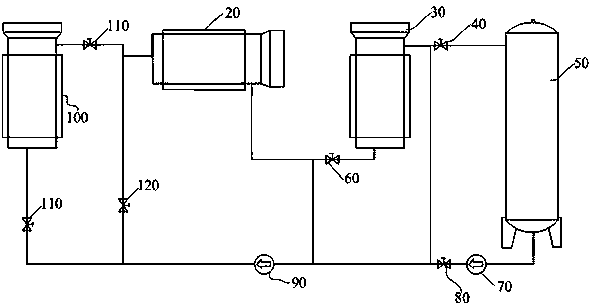

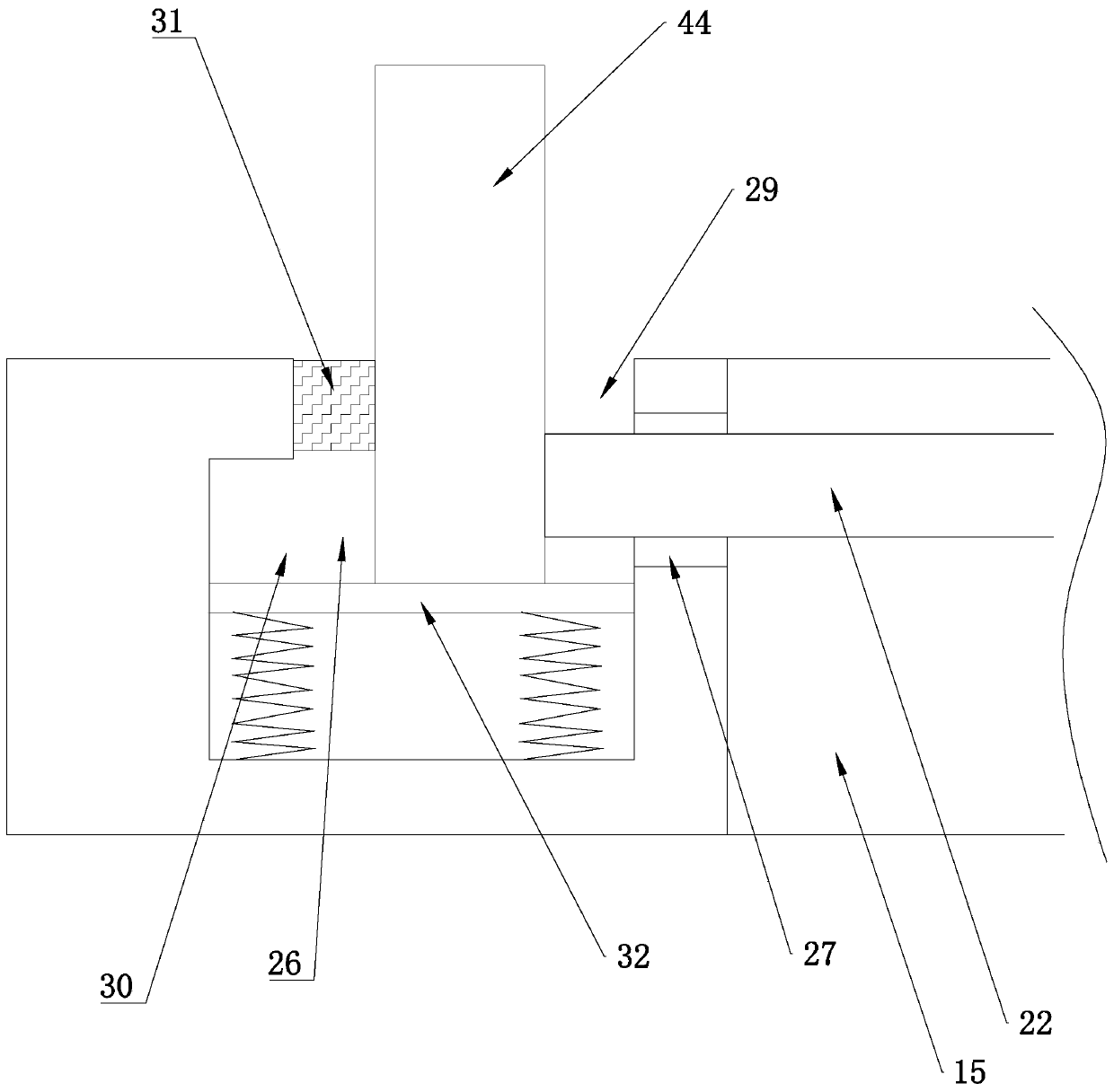

Cleaning method and system for dyeing kettle of supercritical CO2 dyeing system

ActiveCN108796922AWash thoroughlyChange flow velocityTextile treatment machine arrangementsTextile/flexible product manufactureImpellerDynamic balance

The invention provides a cleaning method and system for a dyeing kettle of a supercritical CO2 dyeing system. The cleaning method comprises the following steps: mounting turbulent flow impellers in adyeing kettle; starting a pressure pump, introducing a proper amount of CO2 to form supercritical CO2 so as to drive turbulent flow impellers to rotate; starting a circulating pump, so as to drive a supercritical CO2 fluid to circularly flow; slowly starting a decompression separation valve, simultaneously starting the pressure pump, regulating the decompression separation flow to keep the pressure of the whole dyeing system to be constant, so as to realize the dynamic balance between introduced CO2 and separated CO2; and separating and recycling CO2. The turbulent flow impellers are mounted in the dyeing kettle and are used for stirring CO2 airflow, so that the flow speed and flow direction of the CO2 fluid are changed, each corner in the dyeing kettle can be flushed by the CO2 fluid in an eddy manner, the cleaning efficiency and thoroughness are improved.

Owner:QINGDAO JIFA GROUP

Composite type immersed membrane component

ActiveCN104548943AImprove the utilization rate of aerationReduce energy consumptionSemi-permeable membranesTreatment using aerobic processesUltrafiltrationChemistry

The invention provides a composite type immersed membrane component; compared with the prior art, the composite type immersed membrane component improves the impact resistance of a membrane, saves energy consumption, and greatly improves the efficiency of sewage treatment; when the composite type immersed membrane component treats sewage, the sewage penetrates through a flat-plate membrane and is subjected to further fine filtration by an ultrafiltration membrane, and thus the water quality of finally-produced water of a membrane system reaches or exceeds an water inlet indicator of a reverse osmosis membrane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cleaning equipment of drainage pipeline

The invention discloses a cleaning device for drainage pipes, which comprises a car body. The upper surface of the car body is provided with a water pump and two symmetrical support columns in sequence. One side of the water pump is connected with a water inlet pipe through a water inlet, and the water pump is far away from the water inlet pipe. One side of the water outlet is connected with an outlet pipe, and a storage box is connected between the two supporting columns. A chute is provided on the top of the storage box, a hole is provided on one side of the chute, and a clockwork spring is provided inside the storage box. The outlet pipe passes through the storage box and connects with the clockwork spring. The end of the outlet pipe far away from the water pump is connected to a flushing device through a hole in the storage box. A waterproof motor is installed in the flushing device, and the output shaft of the waterproof motor is connected to a drive through a coupling. Rod, drive rod is keyed with drive gear at one end away from waterproof motor. The invention is convenient to use, efficiently cleans the drainpipe and greatly reduces the labor load during the arrangement of the waterpipe.

Owner:孙建军

Novel fruit washing device

The invention discloses a novel fruit washing device. The structure of the novel fruit washing device comprises a washing device, a supporting frame, a skidproof cushion, a box door, a handle, a baffle plate, rivets, supporting rods, a control box, a hinge, a bucket, a display screen and operation buttons, wherein the bottom of the supporting frame is in threaded connection with the top of the skidproof cushion; the skidproof cushion is vertically connected with the bottom of the supporting frame; the tops of the supporting rods are welded to the bottom of the control box; the bottoms of the supporting rods are fixedly connected with the top of the washing device; and the bottom of the display screen is connected with the front end of the control box through the hinge. According to the novel fruit washing device disclosed by the invention, the washing device is arranged on the structure, so that dirt on the surfaces of the fruits can be sufficiently scoured; water quality is further improved through filtering, and then secondary washing treatment is performed on the fruits, so that the fruits are cleaner, and the washing effect is improved; besides, hydropower energy supply is realized by the novel fruit washing device, so that resources are saved; and in the later stage, fruits are slowly blown to dry by a fan, so that washing is completed in one step, and the novel fruit washing device is more practical and convenient.

Owner:苏州艺居馆家居有限公司

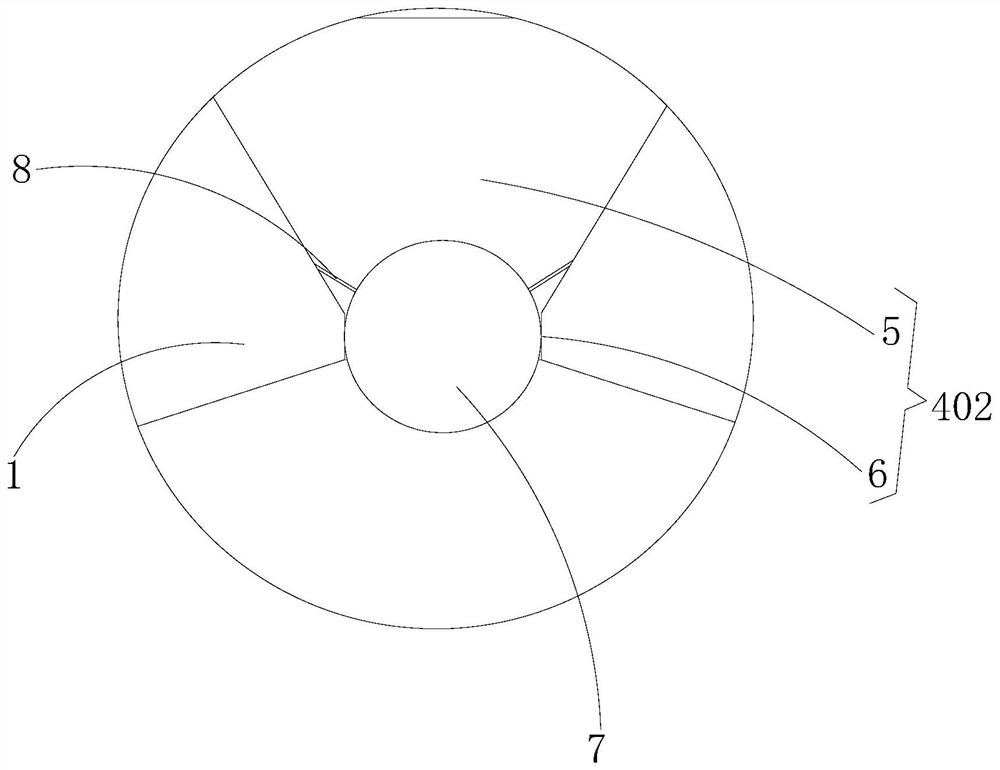

Circulating drainage assembly of clothes treatment equipment and clothes treatment equipment

PendingCN112442865ASimple structureImprove filtering effectOther washing machinesTextiles and paperForeign matterEnvironmental engineering

The invention discloses a circulating drainage assembly of clothes treatment equipment and the clothes treatment equipment. The circulating drainage assembly comprises a shell, provided with an innercavity, a water inlet, a drainage outlet and a circulating water outlet; and a filter, assembled in the inner cavity and provided with a first filtering part which divides the inner cavity into a circulating cavity and a drainage cavity along the axial direction of the inner cavity; wherein the water inlet and the drainage outlet are in communication with the drainage cavity, and the circulating water outlet is in communication with the circulating cavity; in a drainage working mode of the circulating drainage assembly, washing water entering the drainage cavity from the water inlet is drainedfrom the drainage outlet; and in a circulating working mode of the circulating drainage assembly, the washing water entering the drainage cavity from the water inlet is filtered by the first filtering part, then enters the circulating cavity and is drained from the circulating water outlet. The inner cavity is divided into the circulating cavity and the drainage cavity in the axial direction through the first filtering part, foreign matters and clothes thread residues in the washing water are filtered, and the situation that the washing water entering the circulating cavity contains the foreign matters and the clothes thread residues which can block clothes spraying is prevented.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

Anti-splashing urinal equipment

The anti-splashing urinal equipment comprises a box body, a containing inner cavity is formed in the box body, a turnover plate capable of being turned over is arranged in the containing inner cavity, a side plate sliding towards an opening of the box body is arranged on the upper side of the turnover plate, a guide pipe is arranged on the lower side of the containing inner cavity in a communicating mode, and the guide pipe is arranged in the containing inner cavity in a communicating mode. A rotating shell is hinged to the outer side of the box body, a side baffle is arranged on one side of the rotating shell, an open inner cavity with an opening is formed in the side baffle, an inner box body is arranged at the top of the containing inner cavity, and a movable matching support is arranged on the lower side of the inner box body; according to the equipment, by means of relative rotation between the rotating shell and the box body, peculiar smell can be prevented from escaping when the rotating shell seals the side plates, and convenience can be brought to people after the rotating shell is unfolded; and in the process, the urine can be efficiently flushed by utilizing the telescopic movable matching bracket and the bottom side spray head.

Owner:徐淑炜

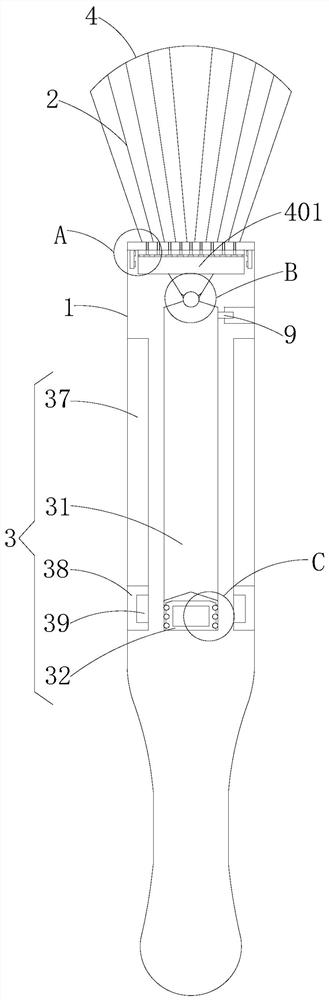

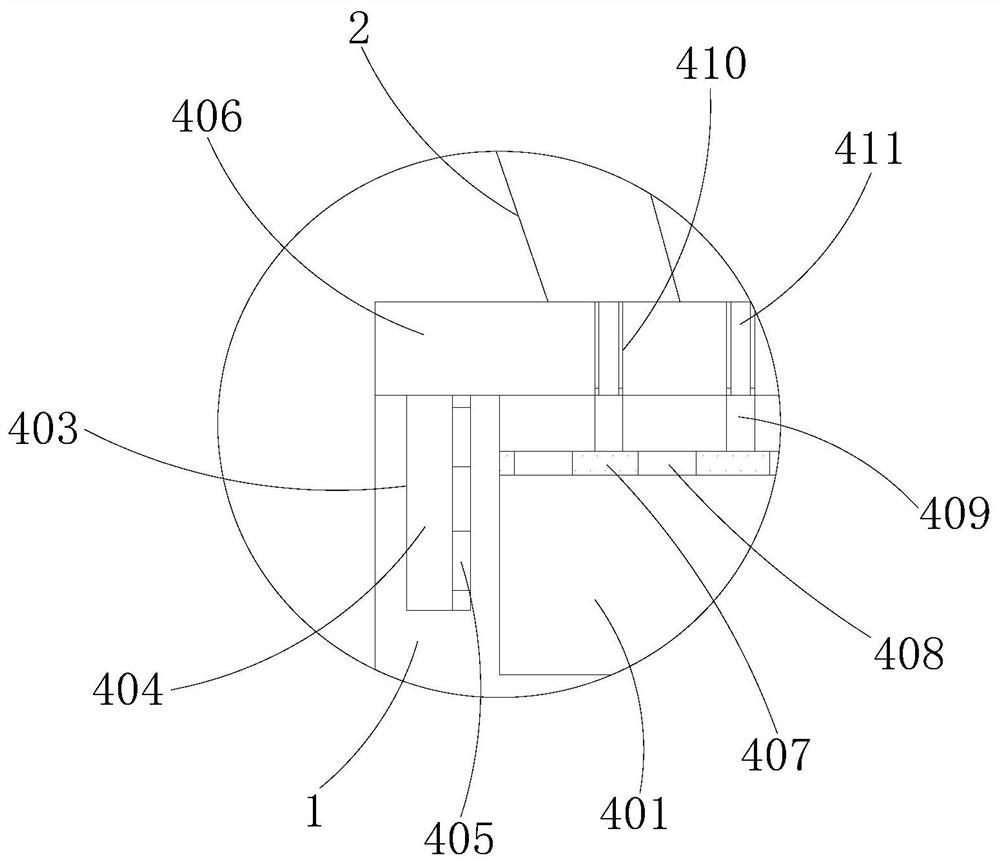

Cosmetic brush for washing and cleaning by high-speed airflow

ActiveCN109393724BClean enoughBlow out effectivelyBrushesPackaging toiletriesBristleProcess engineering

Owner:东莞市郁金香科技有限公司

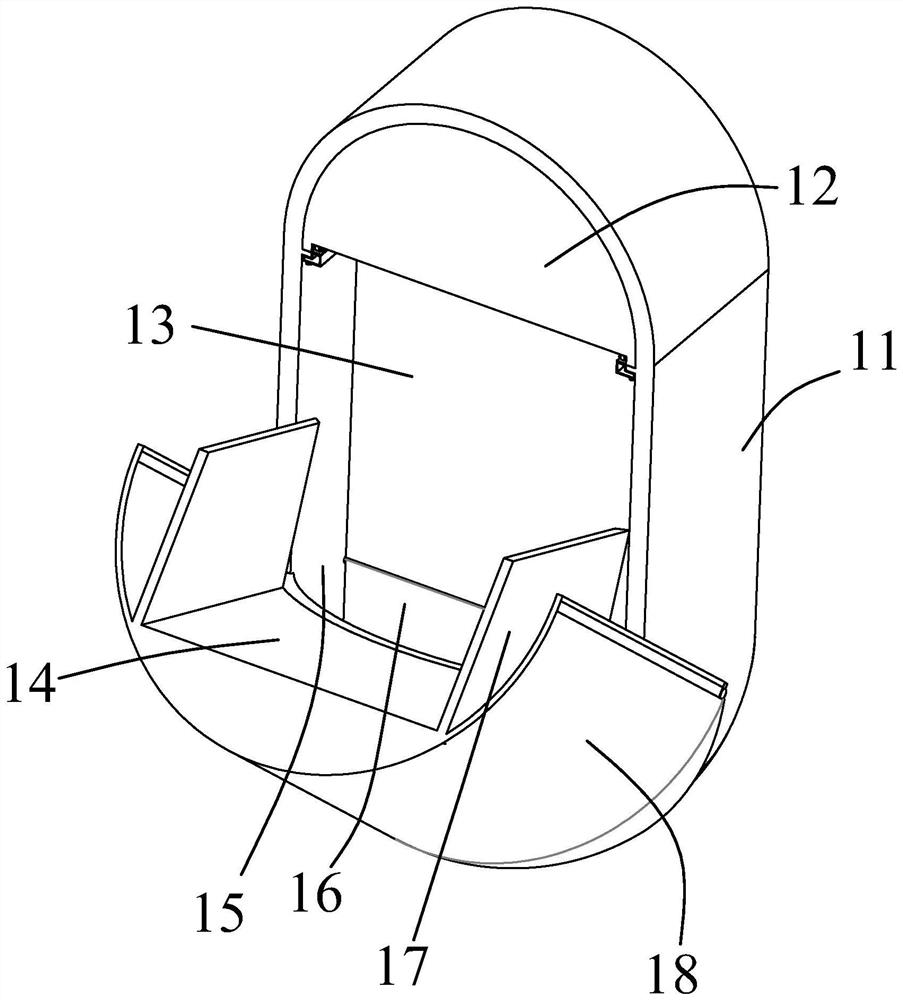

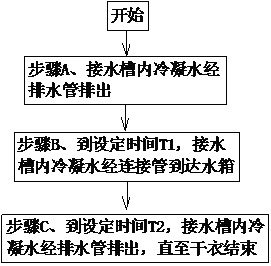

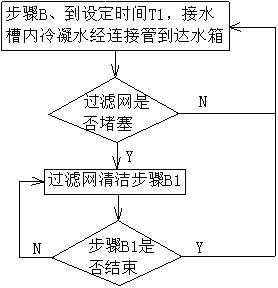

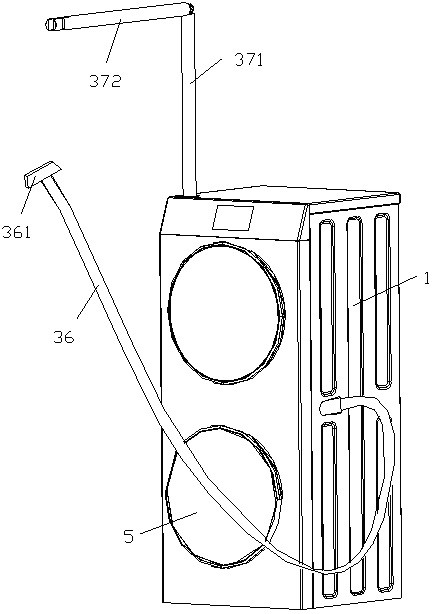

Condensed water collection method of clothing care all-in-one machine and clothing care all-in-one machine

ActiveCN108315944BImprove cleanlinessFully flushedOther washing machinesIroning apparatusProcess engineeringMechanical engineering

The present invention provides a method for collecting condensed water of an all-in-one clothes care machine and the all-in-one clothes care machine. The water is collected into the water tank through the connecting pipe; wherein, the set time T1 is a time node counted from the startup of the clothes drying system. By installing a water tank in the shell and controlling the direct discharge of the condensed water generated in the front and rear stages of the drying process, only the condensed water generated in the middle stage of the drying process is collected; the lint in the air duct in the middle stage of the drying process is reduced and condensation The filter has also been fully washed in the early stage, and the condensed water collected at this time basically does not contain impurities, which is conducive to improving the cleanliness of the collected condensed water and reducing the impurities contained in the collected condensed water.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

A dish washing device

The invention discloses a container immersion cleaning device. The container immersion cleaning device comprises a cleaning box and a fixed cover plate; multiple spray washing columns are arranged inthe cleaning box; multiple first water outlet holes are formed in the outer peripheral surfaces of the spray washing columns; the spray washing columns are connected with air inlet pipes and water inlet pipes; the fixed cover plate is provided with gripper modules for fixing containers opposite to the spray washing columns; the containers are fixedly mounted on the fixed cover plate through the gripper modules; opening directions of the containers are downwards; when the fixed cover plate is mounted on the cleaning box, the spray washing columns extend into the containers; the air inlet pipesare connected with air pumps to generate a lot of bubbles in use, water currents around the spray washing columns carry air to flush the containers to achieve full flushing of the containers; the containers are not easy to shake along with the water currents in the flushing process, so that difficult damage of the containers in the cleaning process is guaranteed; and cleaning agents, buffer liquid, clear water and the like can be put in the water inlet pipes in sequence to flush the containers by multiple times to achieve thorough and convenient flushing.

Owner:ZHEJIANG MARICULTURE RES INST

Preparation device of copper alloy bar for wear-resistant gear

InactiveCN112845288AEasy to cleanEasy to holdDrying gas arrangementsCleaning using toolsGear wheelElectric machinery

The invention discloses a preparation device of a copper alloy bar for a wear-resistant gear. The device comprises a bottom plate, a cleaning box and brushes, the cleaning box is installed at the upper end of the bottom plate, a fixing frame is installed in the middle of the left end of the cleaning box, a fixing barrel is installed at the inner side of the fixing frame, a limiting frame is installed at the inner side of the fixing barrel, and a limiting wheel is installed in the middle of the limiting frame; a water pump is installed at the upper side of the left end in the cleaning box, a water conveying pipe and a cleaning frame are installed at the bottom end of the water pump, and a nozzle is mounted at the inner side of the cleaning frame; and a fixing seat is mounted in the middle of the bottom end of the inner side of the cleaning box, a dual-shaft motor is arranged at the upper end of the fixing seat, a gear is mounted at the front end of a rotating shaft of the double-shaft motor, a fixing frame is mounted at the upper end of the double-shaft motor, rotating rings are mounted at the left side and the right side of the fixing frame, gear rings are mounted at the outer sides of the rotating rings, fixing pipes are arranged at the front ends of the rotating rings, telescopic motors are arranged at the inner sides of the fixing pipes, and the brushes are mounted at the front ends of the telescopic motors. The preparation device is reasonable in structure and easy to operate, the alloy bar can be cleaned conveniently, and the cleaning effect and cleaning efficiency of the alloy bar are improved.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com