Cleaning and disinfecting device for down feather processing

A technology for cleaning and disinfecting down and down, which is applied in the direction of washing/scouring of animal loose hair fibers, etc. It can solve the problems of high work intensity, cumbersome collection and removal of down and down, and strong stirring force, etc., and achieves simple structure, shortening the cleaning and disinfection process, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

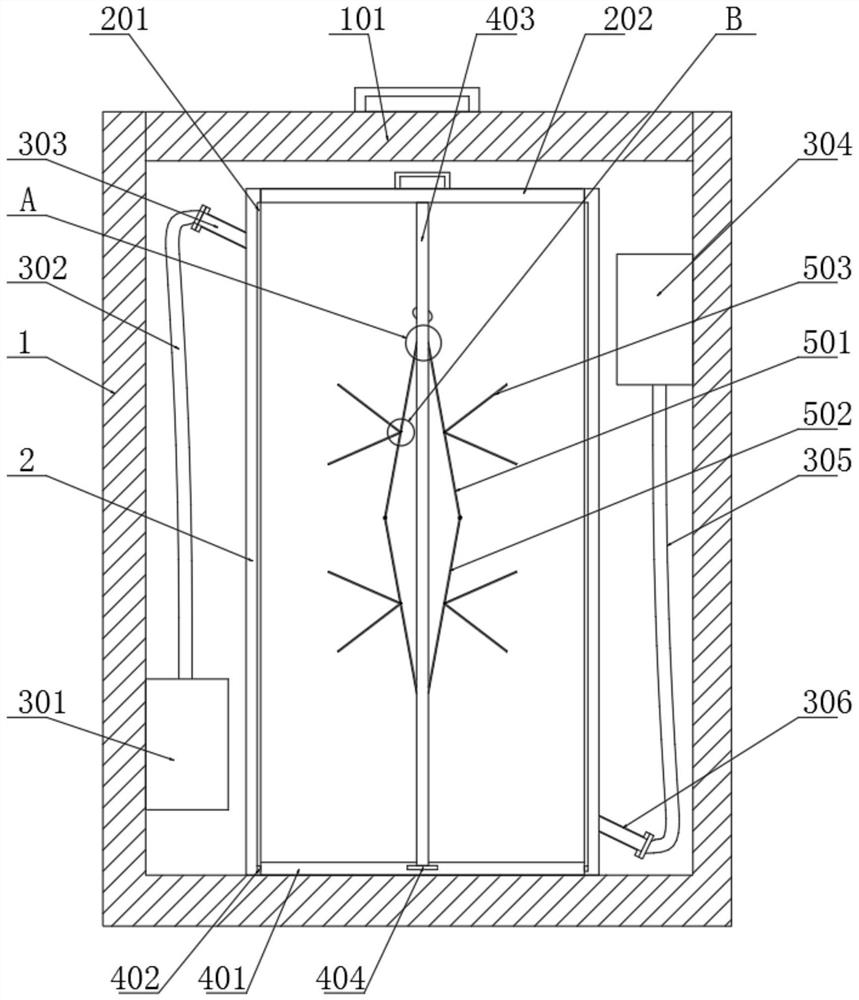

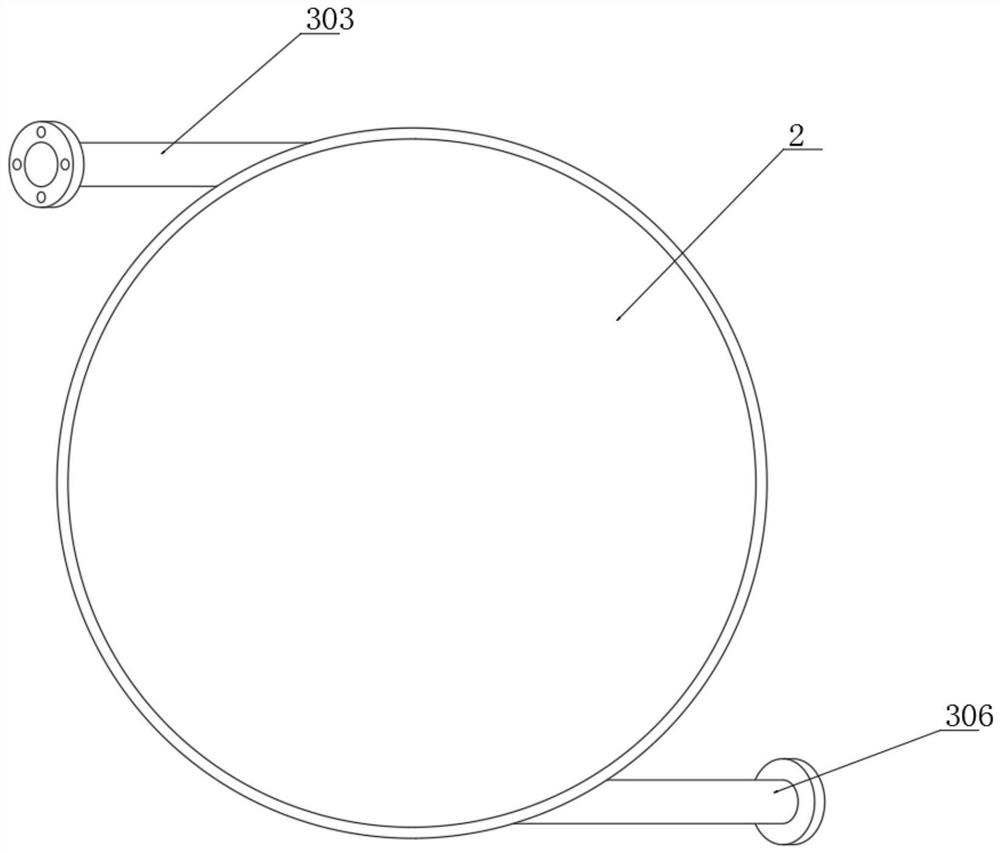

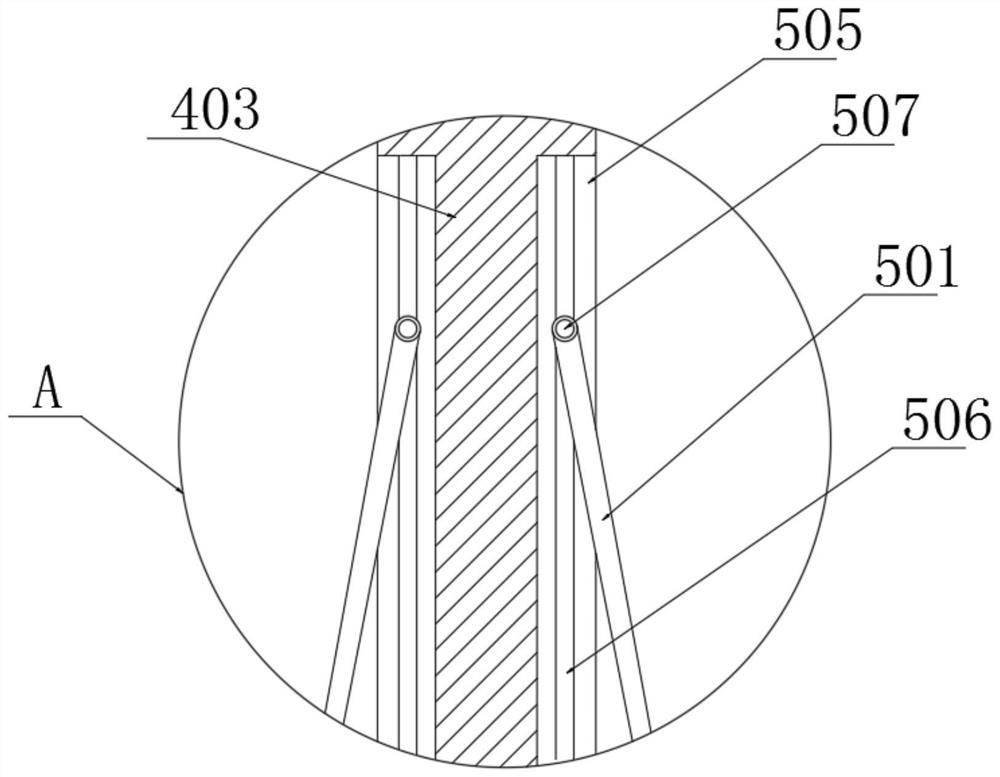

[0027] like Figure 1-4 As shown, a cleaning and disinfection device for down processing includes a housing 1 and an inner cleaning bucket 2 located inside the housing 1. A power output mechanism is arranged between them, and a down collection mechanism is arranged inside the inner cleaning bucket 2, and a feather auxiliary cleaning mechanism is arranged on the down collection mechanism, and an inner cleaning bucket upper cover 202 is detachably connected to the upper end of the inner cleaning bucket 2, and the inner cleaning bucket 202 is detachably connected. The upper cover 202 of the barrel is provided with several water holes; the shell 1 is provided with a water inlet and a water outlet, and valves are provided on the water inlet and the water outlet;

[0028] The space between the shell 1 and the inner cleaning bucket 2 communicates with each other, and the water and cleaning liquid in the shell 1 are distributed in the inner cleaning bucket 2 and in the gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com