Dead-angle-free production allocation machine

A technology with dispenser and no dead angle. It is used in the production of fluids, wellbore/well components, and earth-moving drilling. It can solve problems such as shedding and blockage of oil outlets, and achieve the effect of preventing adhesion and accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

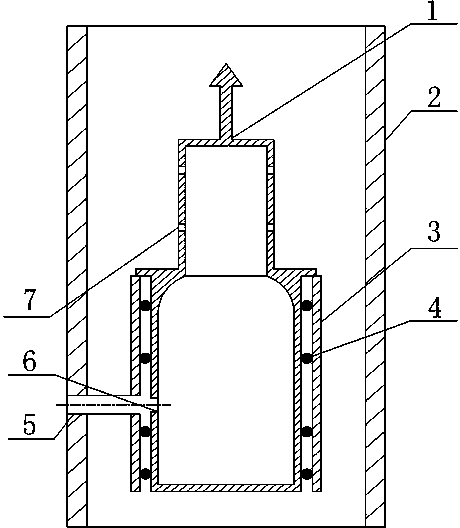

[0016] As shown in Figure 1, this embodiment includes a cylinder body 2, at least one oil inlet pipe 5, a central pipe 3 and a plug 1, the central pipe 3 is arranged in the cylinder body 2 and connected to the inner wall of the cylinder body 2, and the plug 1. The lower end is arranged in the central pipe 3. The lower part of the plug 1 is provided with at least one oil inlet 6, and the upper part is provided with a plurality of oil outlets 7. The upper part of the inner wall of the oil inlet chamber of the plug 1 is arranged as an arc surface.

[0017] The oil inlet pipe 5 passes through the cylinder body 2 and the center pipe 3 in turn, and is arranged in the center of the oil inlet port 6; the axes of the cylinder body 2, the center pipe 3, and the plug 1 coincide; Arrange upwards uniformly; O-rings 4 are arranged between the fitting gap between the plug 1 and the central tube 3; the number of O-rings 4 arranged between the fitting gap between the plug 1 and the central tube...

Embodiment 2

[0020] As shown in Figure 1, on the basis of Embodiment 1, this embodiment further provides a non-dead-angle distributing device according to the present invention, including: oil inlets 6 are arranged in multiples, and oil inlet pipes 5 are arranged along the cylinder. The oil inlet 6 is evenly distributed along the circumference of the plug 1, and the oil inlet pipe 5 and the oil inlet 6 are arranged in the center one by one. With this structure, the oil and gas in this layer enter the plug 1 with little resistance, and spray from all sides. The oil and gas in this layer entering the oil inlet chamber at the lower part of the plug collide with each other, which can be fully mixed to improve the flow effect of the oil and gas in this layer in the plug.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com