Patents

Literature

47results about How to "Avoid Adhesive Buildup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

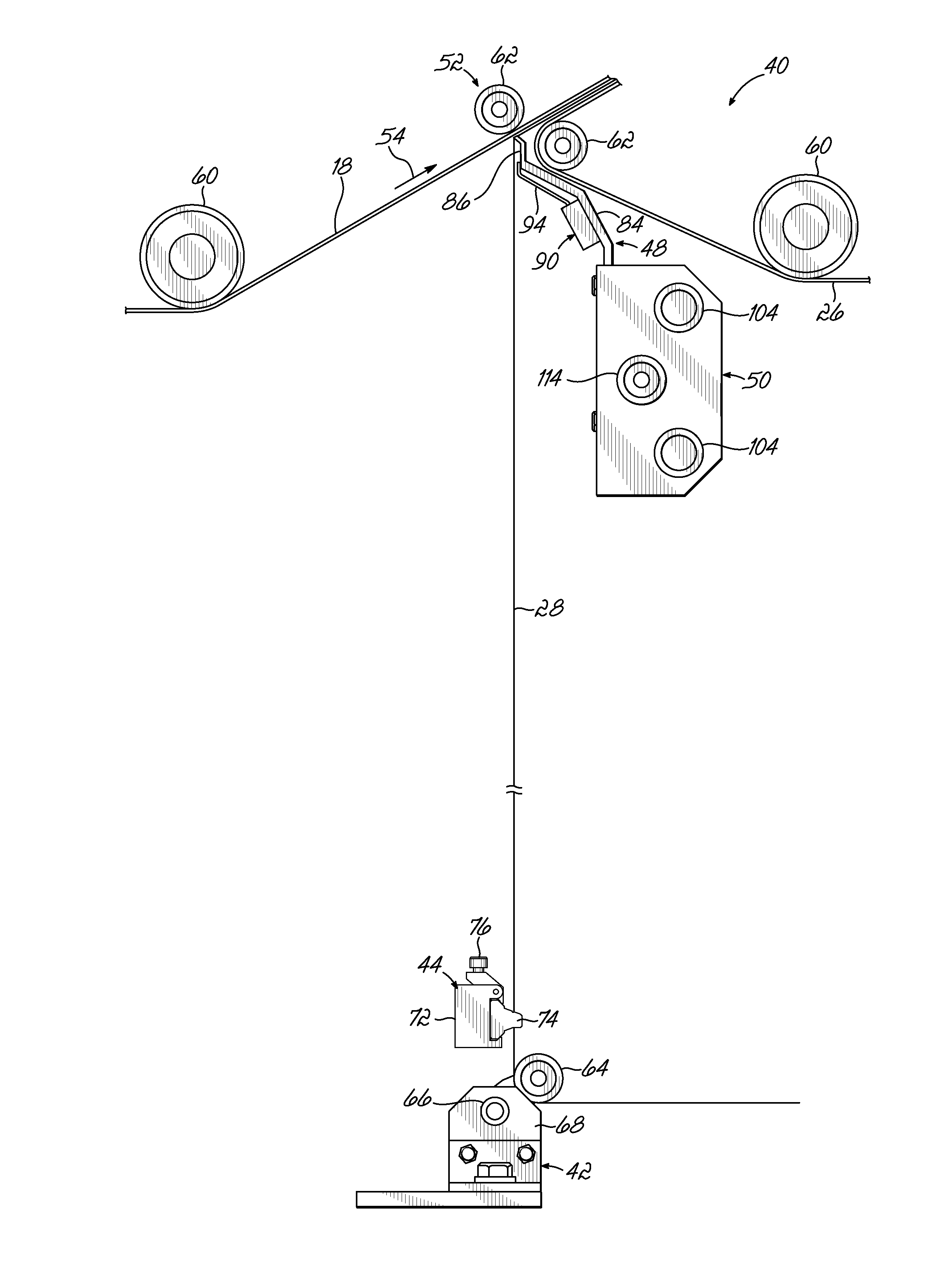

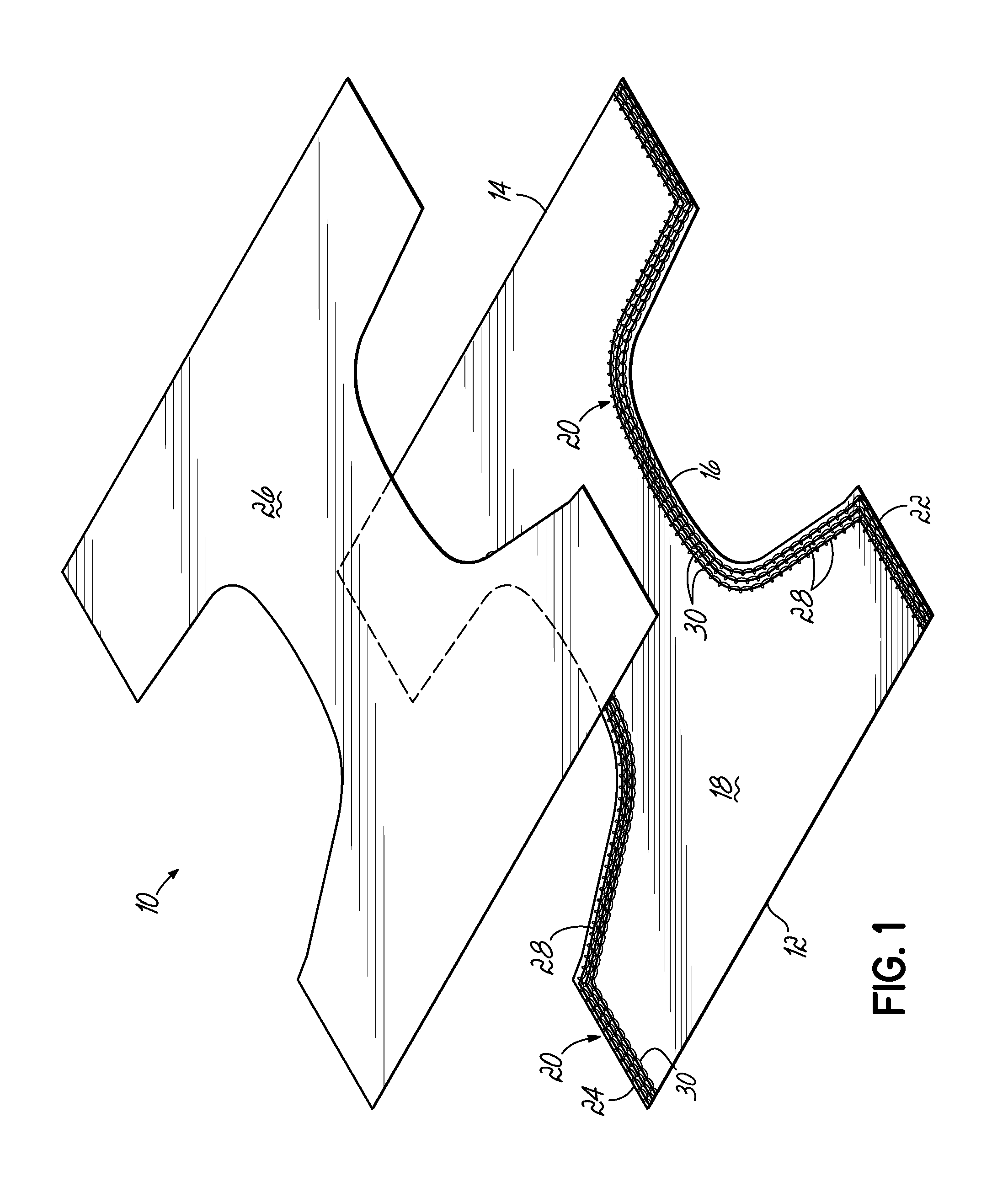

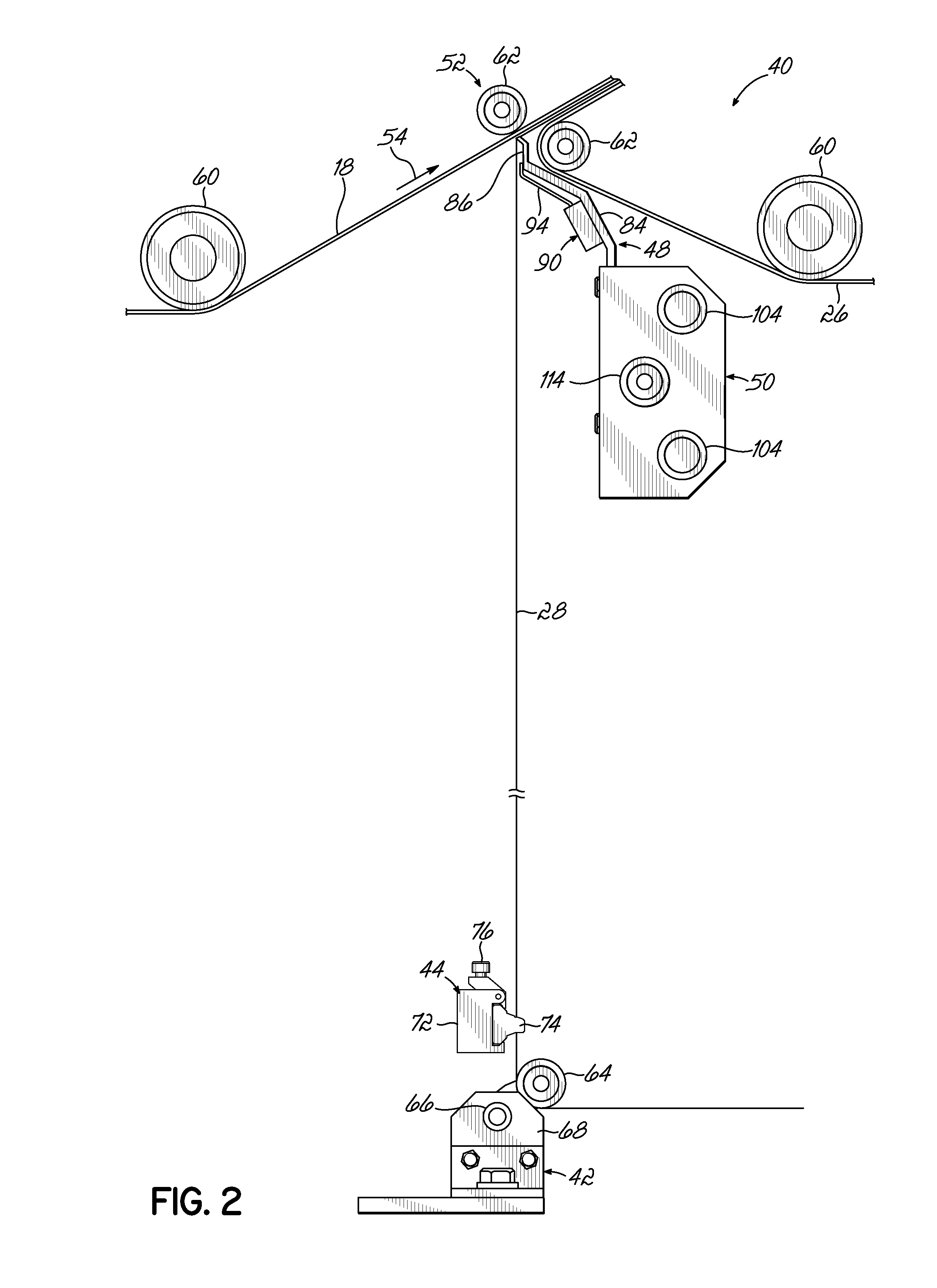

System and method for applying individually coated non-linear elastic strands to a substrate

InactiveUS20130233472A1Avoid Adhesive BuildupMinimizing sliding contactLiquid surface applicatorsLamination ancillary operationsEngineeringAdhesive

A system and method applies a plurality of stretched elastic strands onto a substrate such as along a predetermined non-linear path, to form a leg gather of a disposable absorbent personal hygiene product. The system includes an adhesive dispensing module for individually applying adhesive to the elastic strands. A heated strand guide located downstream of the dispensing module includes guide openings for the respective elastic strands. A drive mechanism coupled to the strand guide actuates movement of the strand guide in a direction transverse to the movement direction of the substrate, thereby causing the elastic strands to be applied to the substrate along the predetermined non-linear path.

Owner:NORDSON CORP

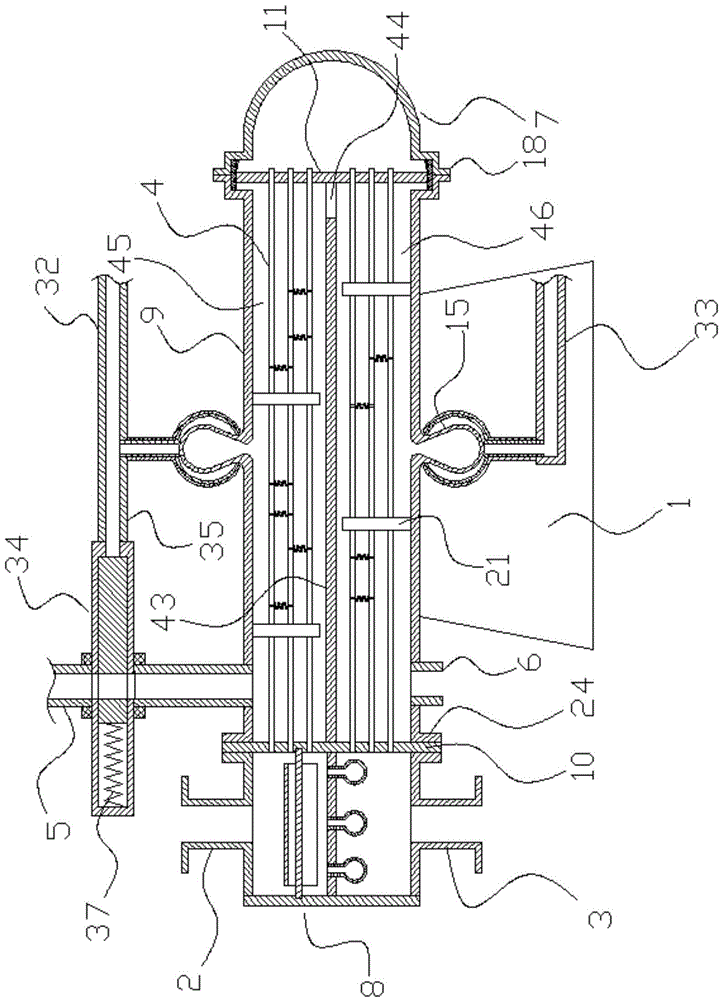

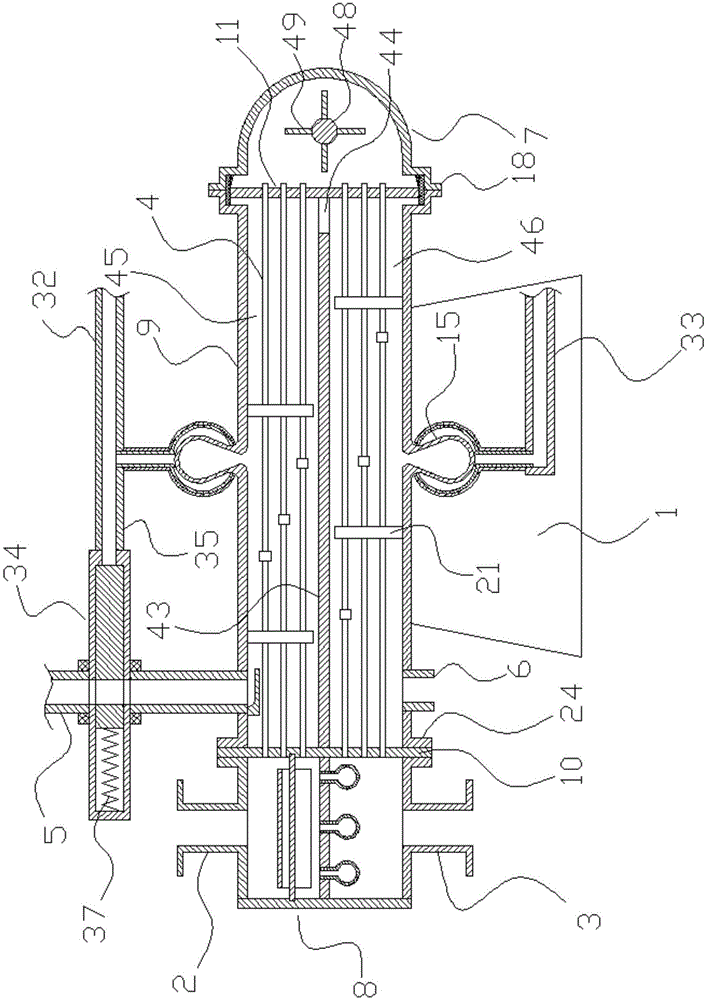

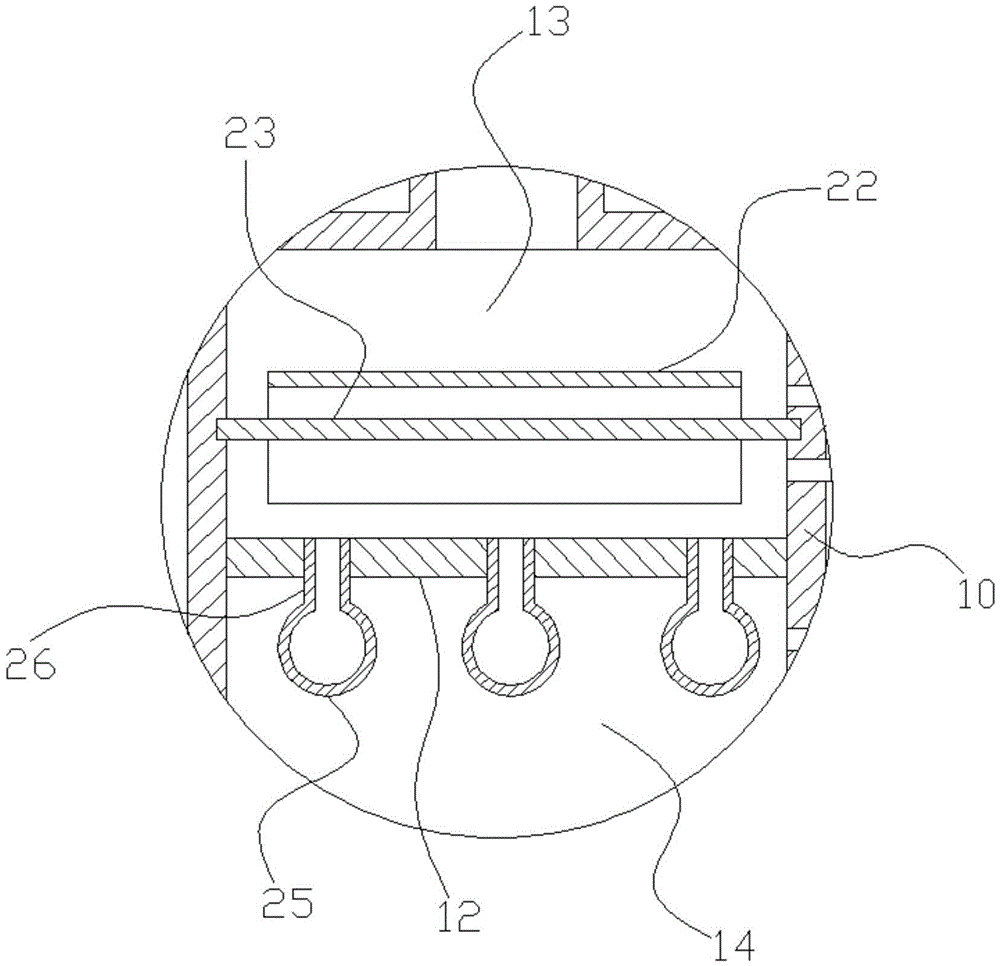

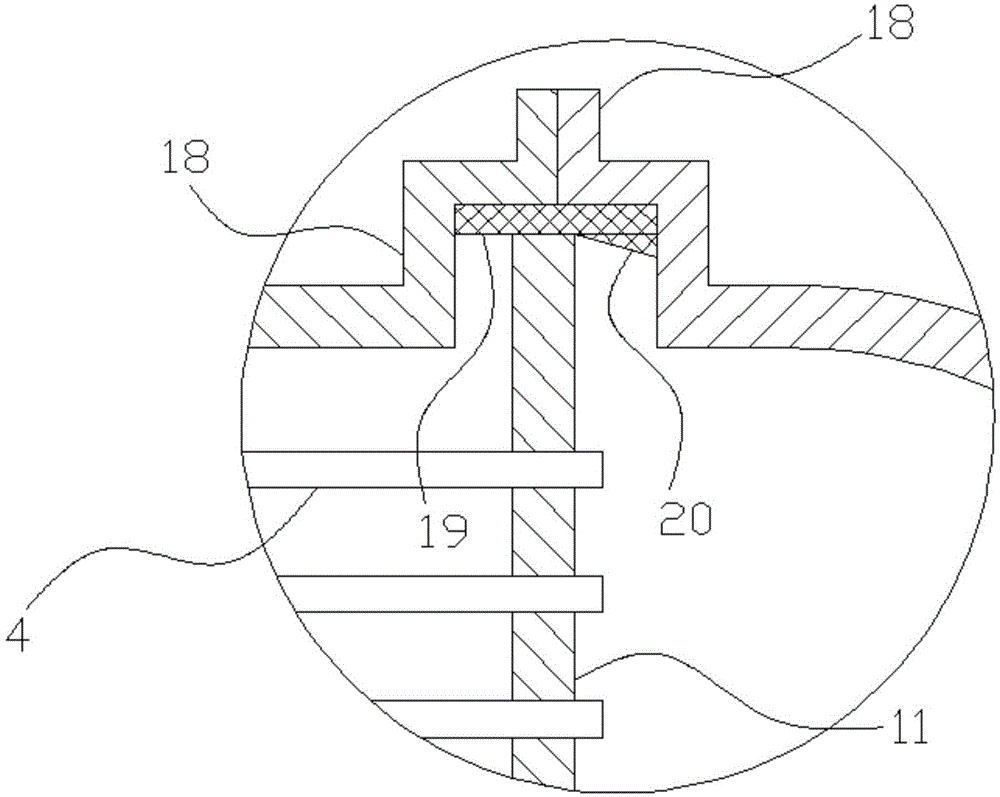

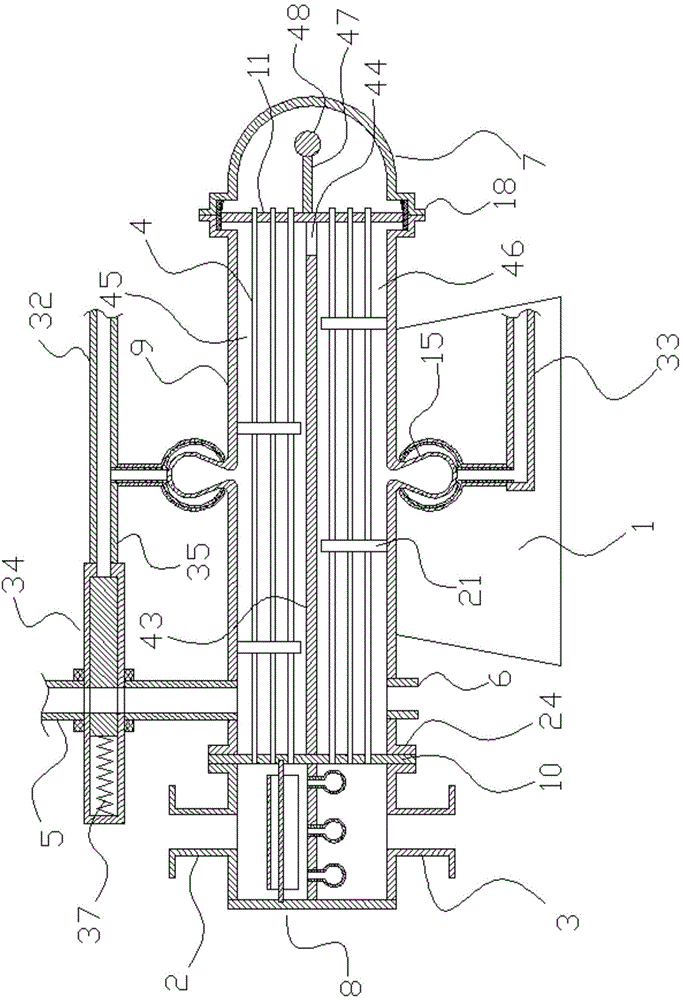

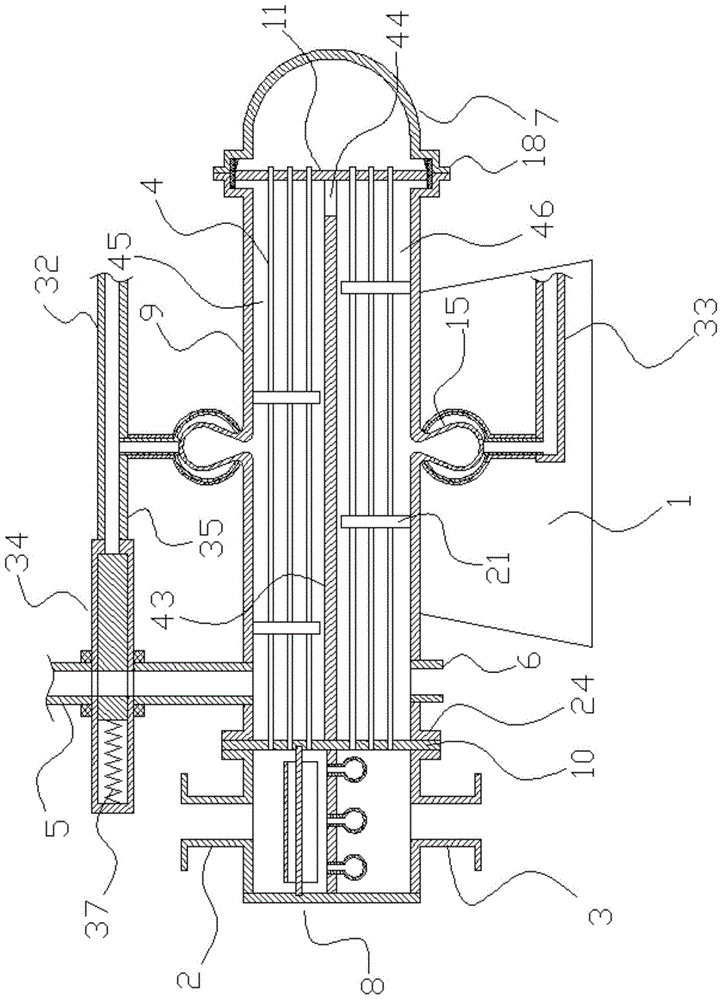

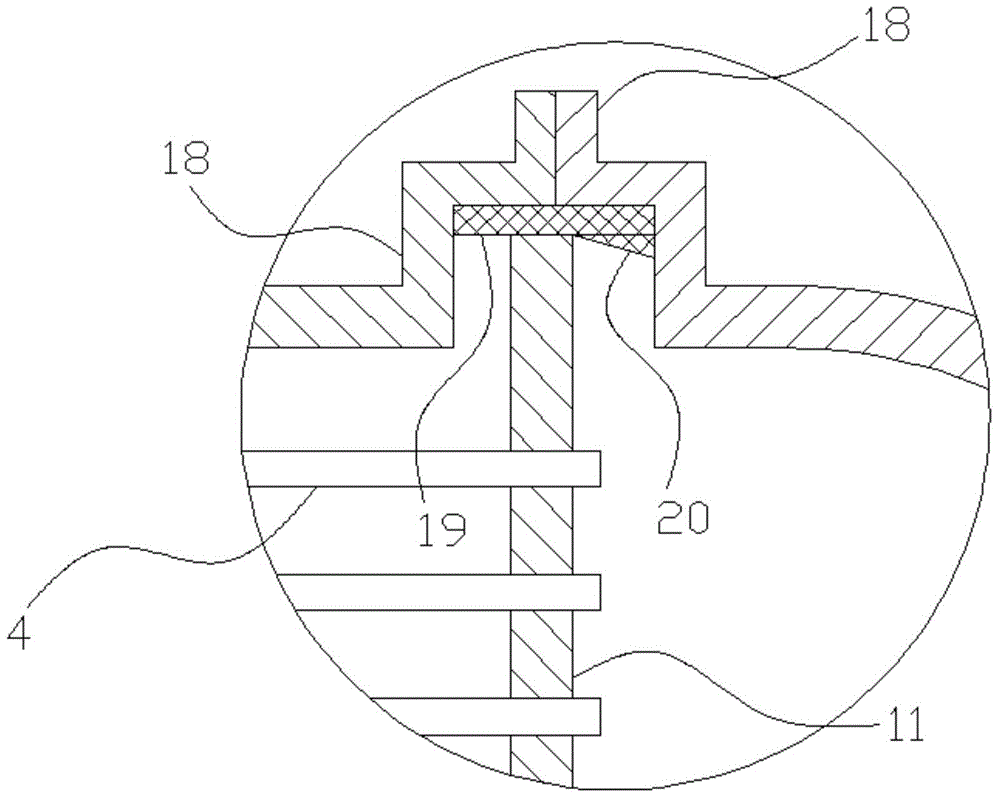

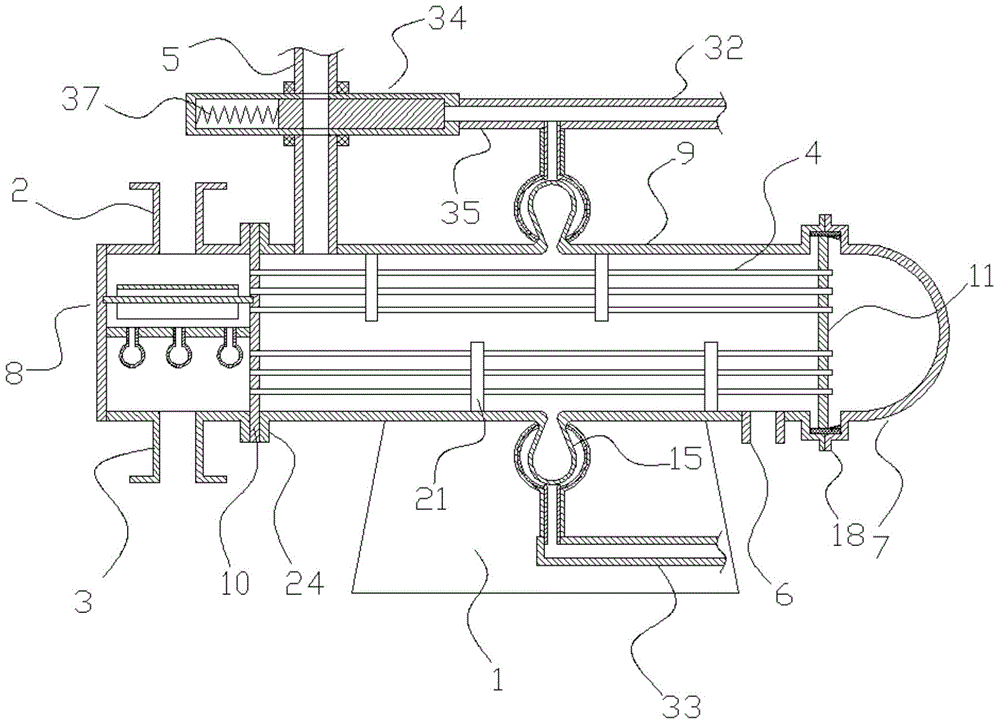

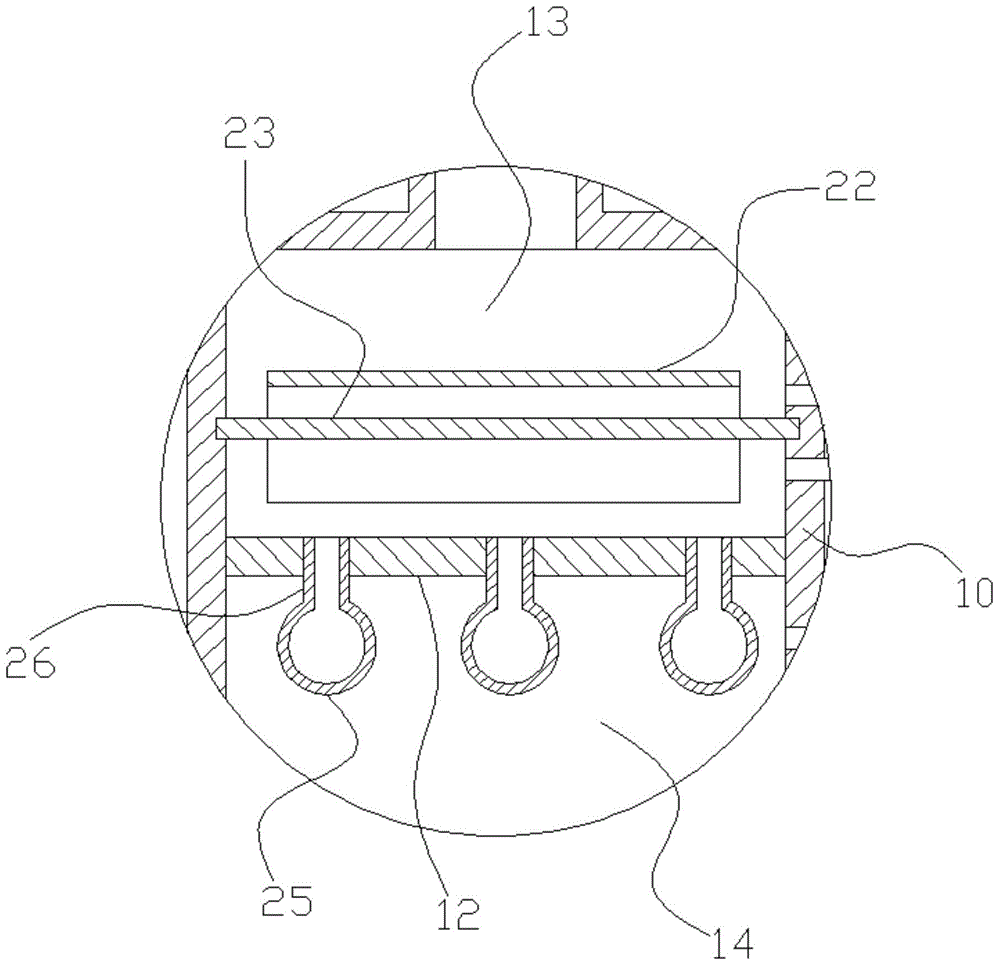

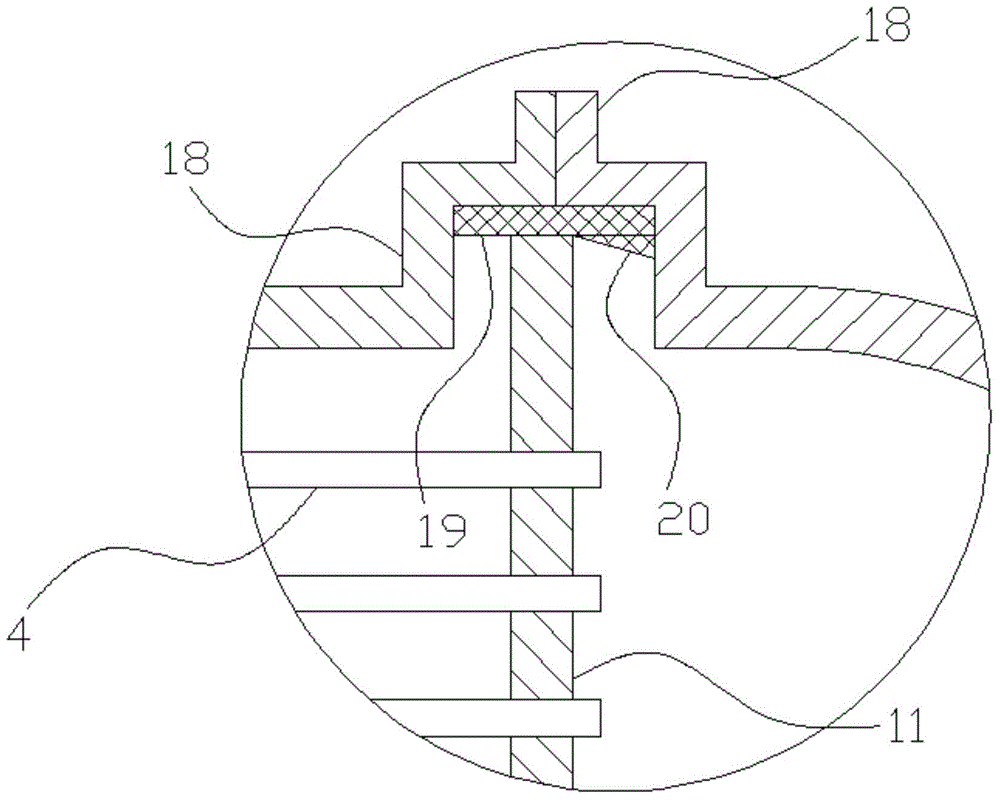

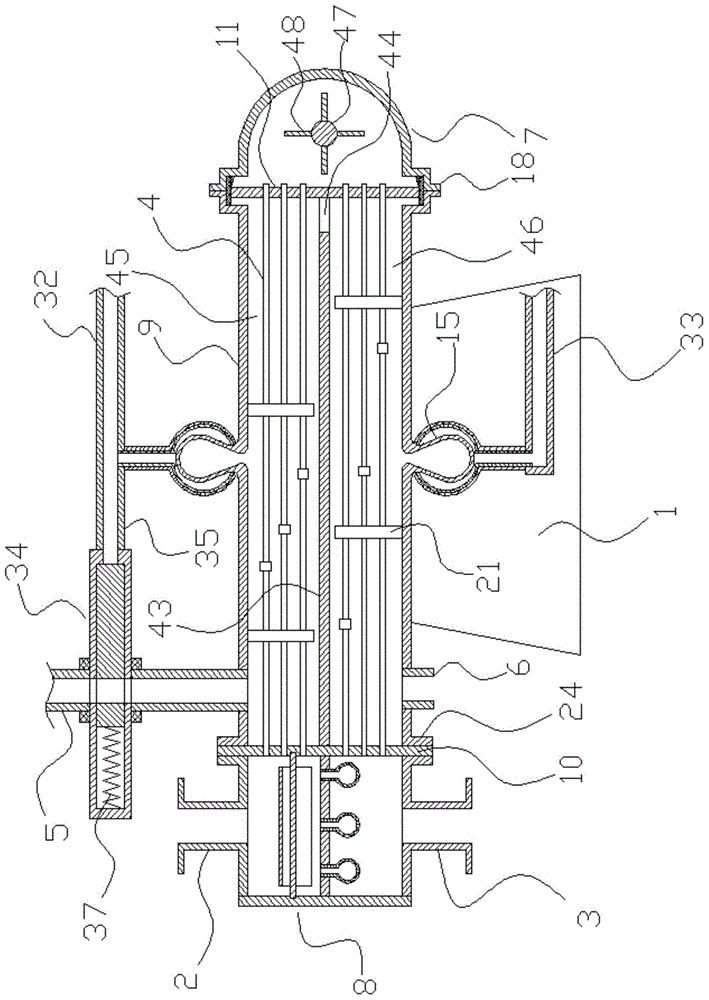

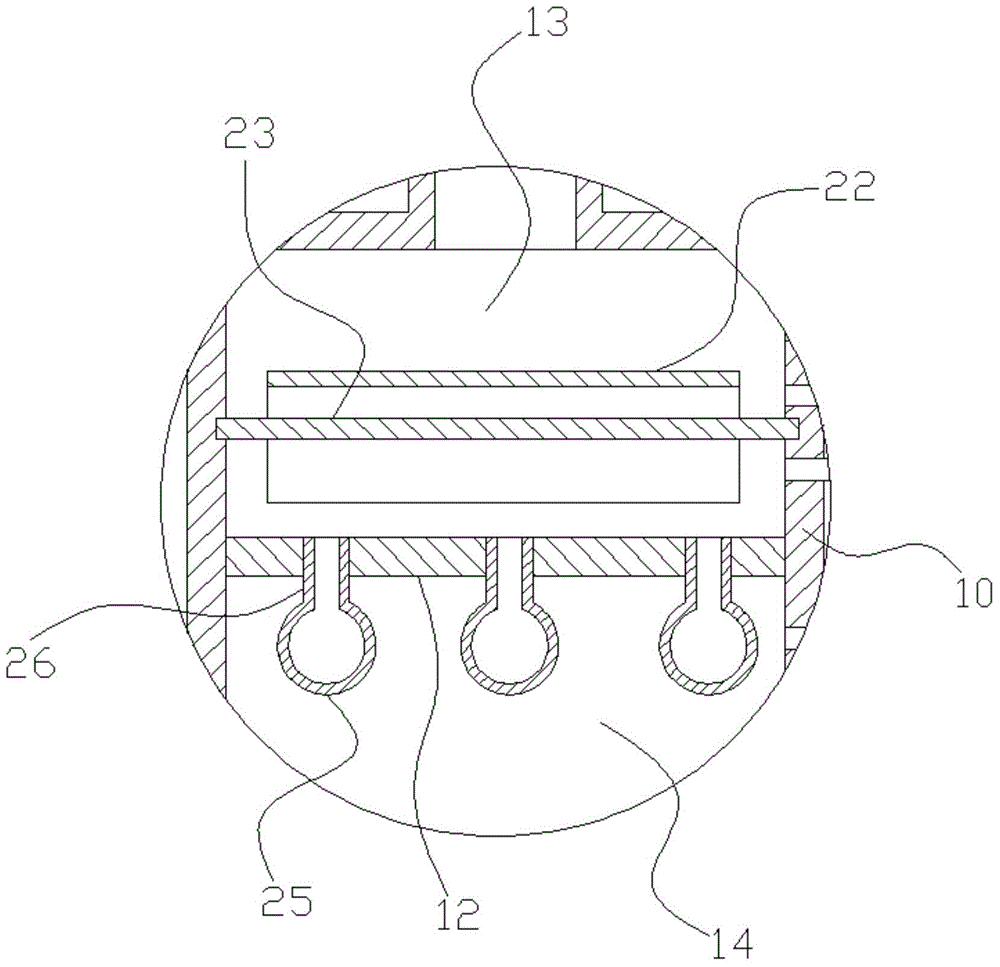

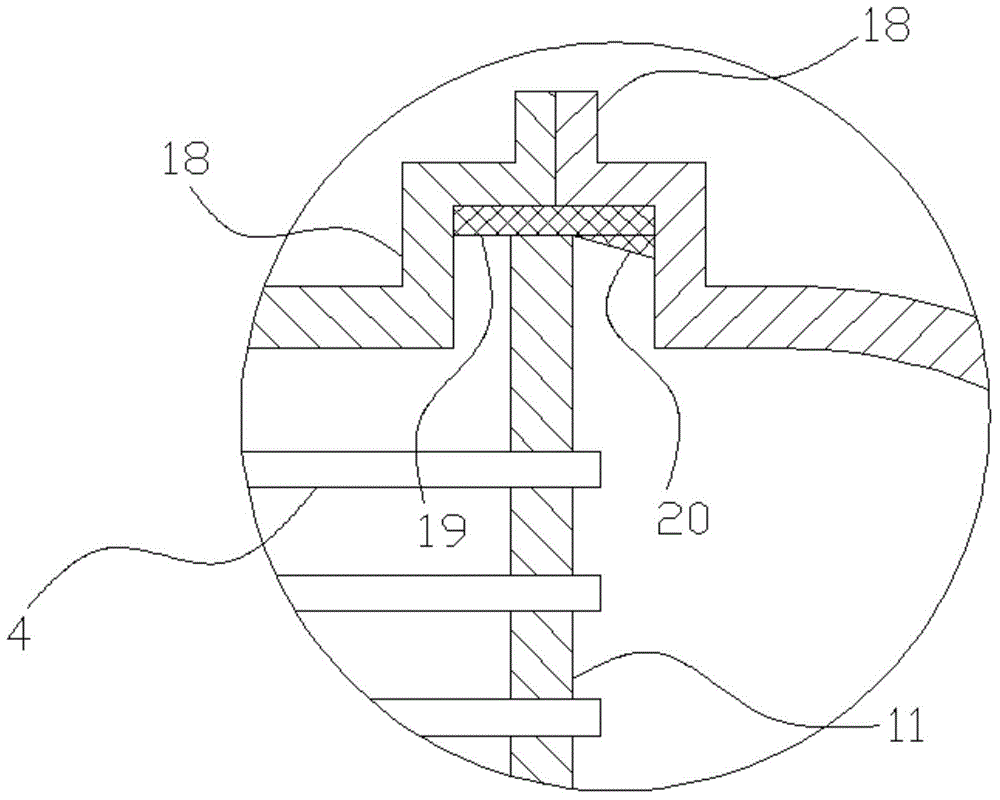

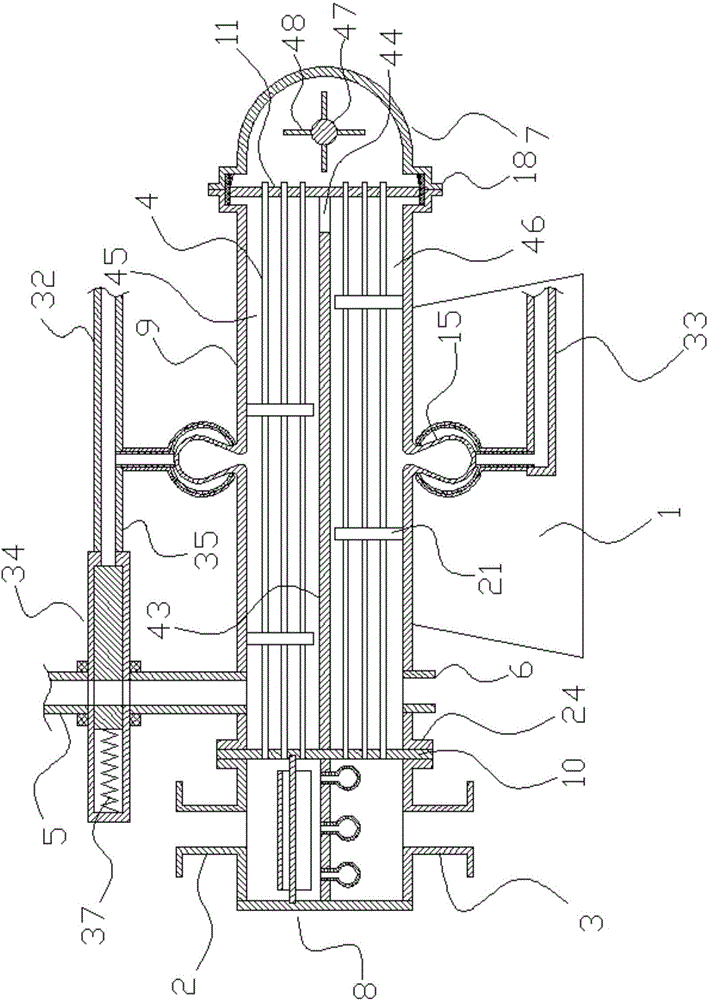

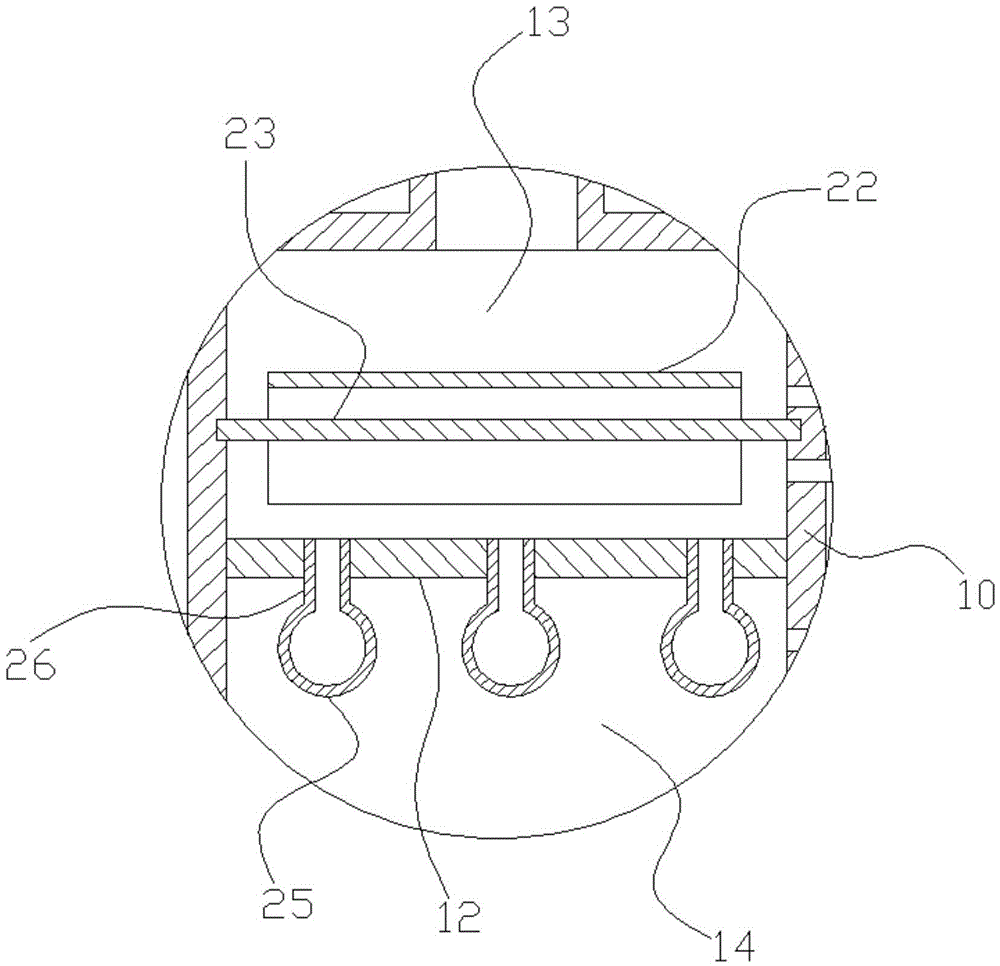

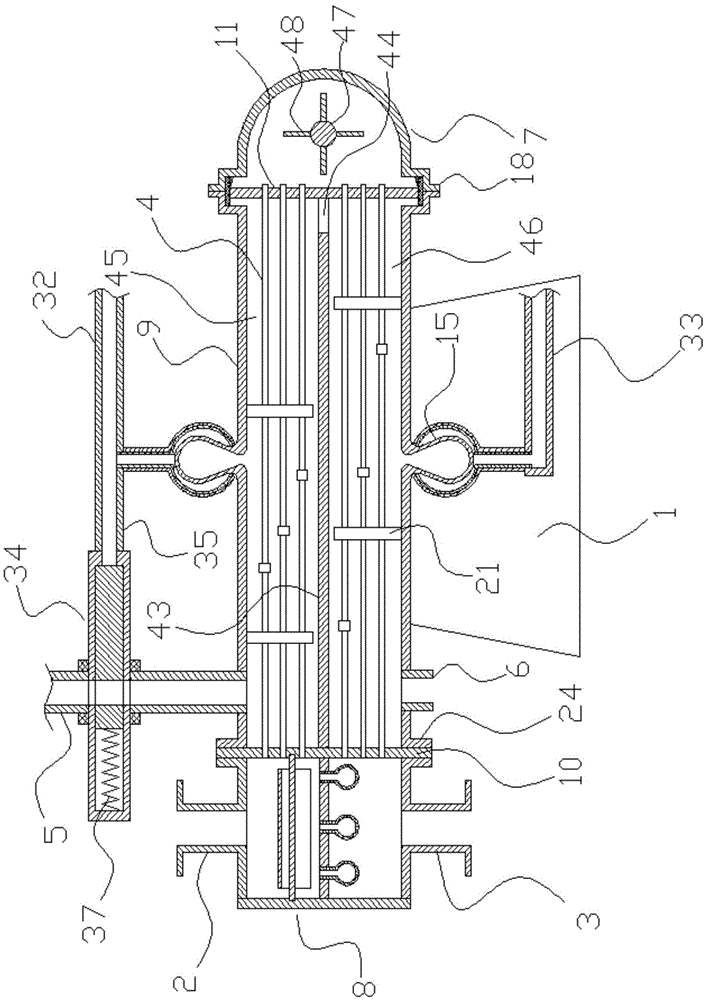

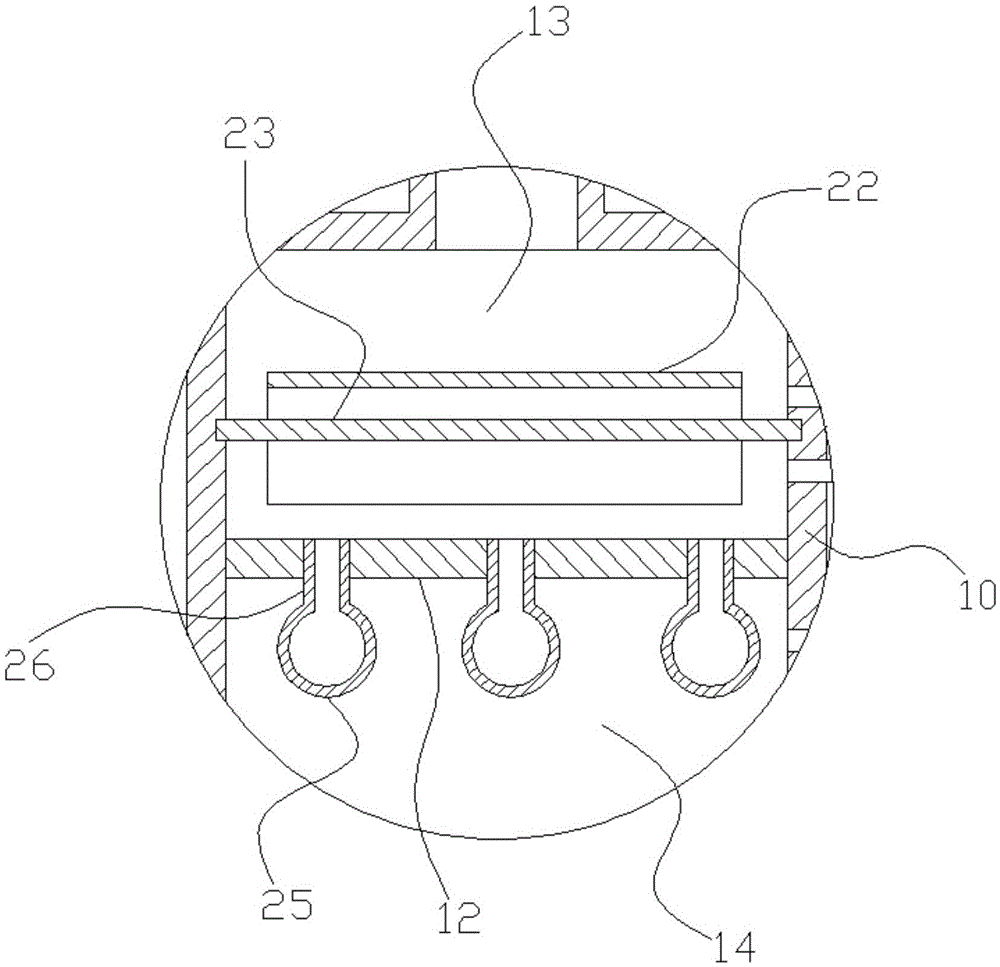

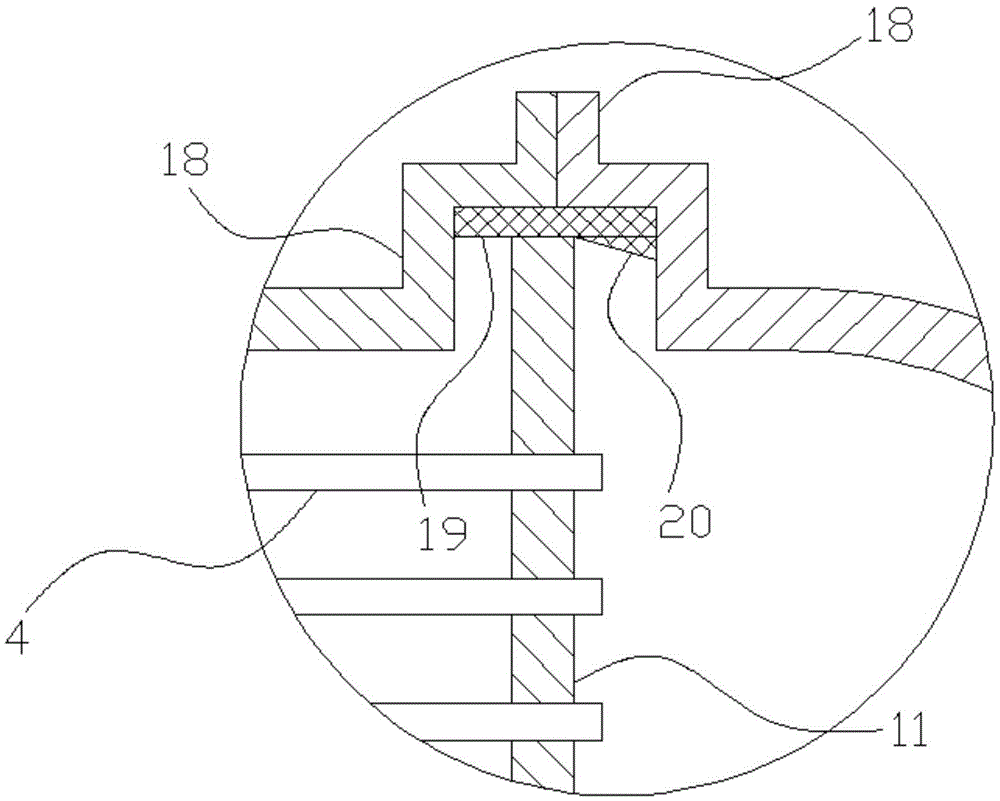

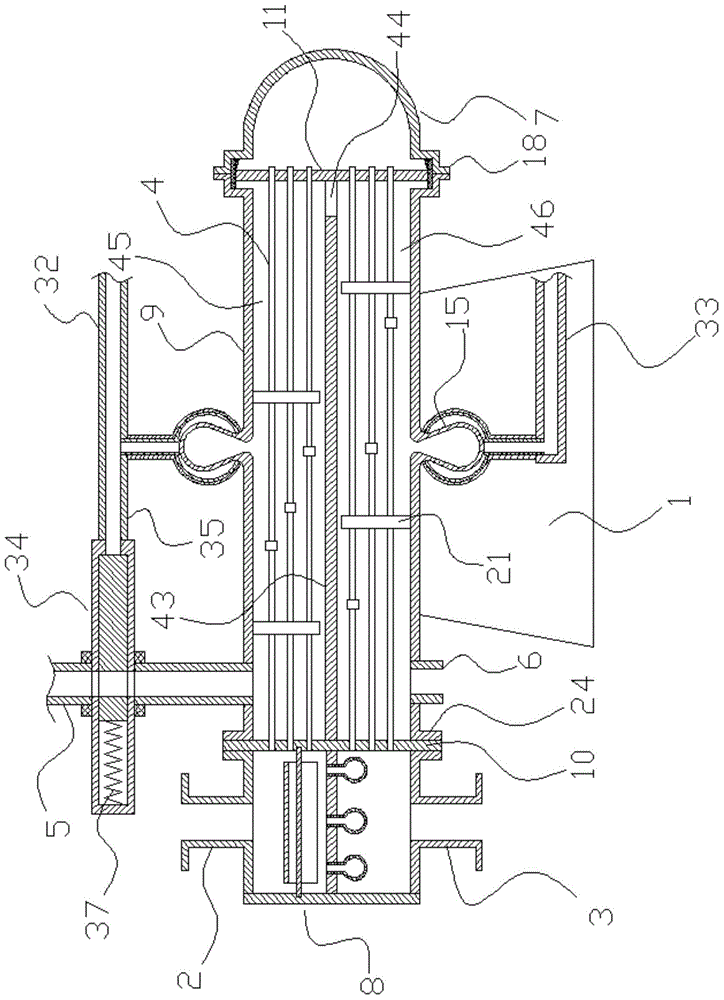

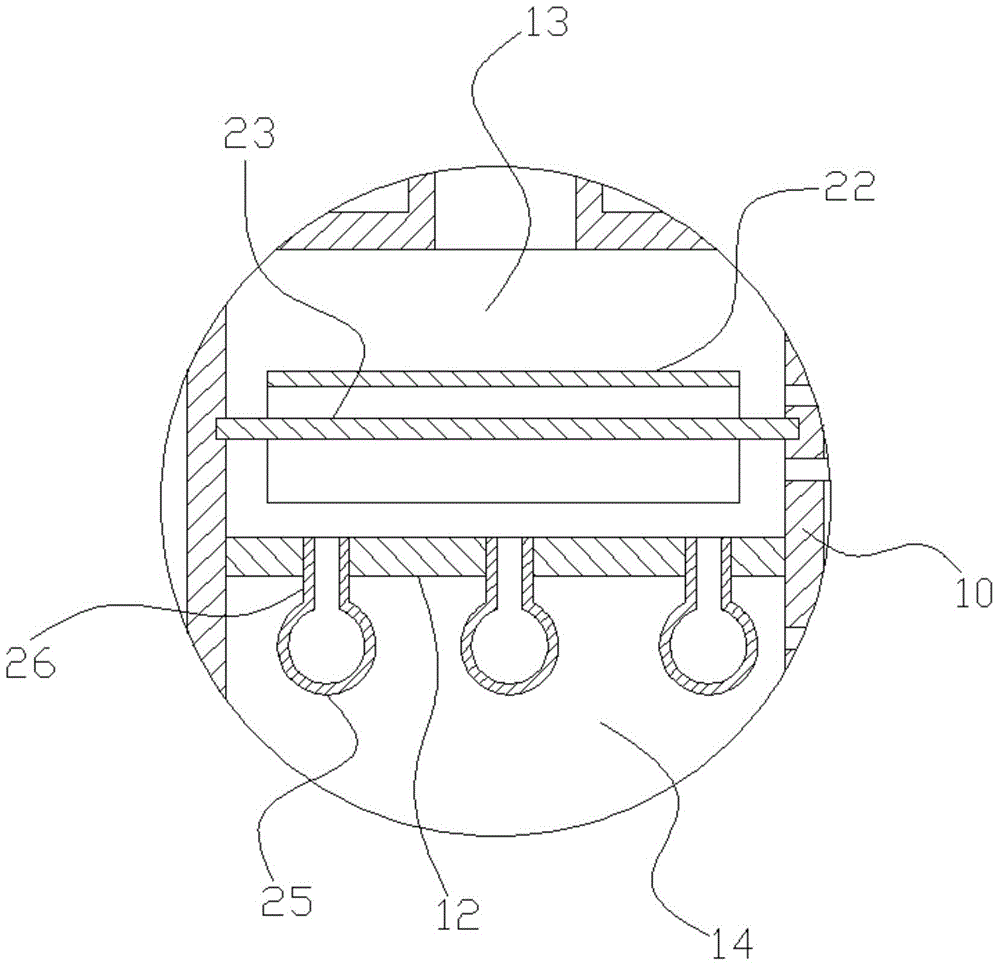

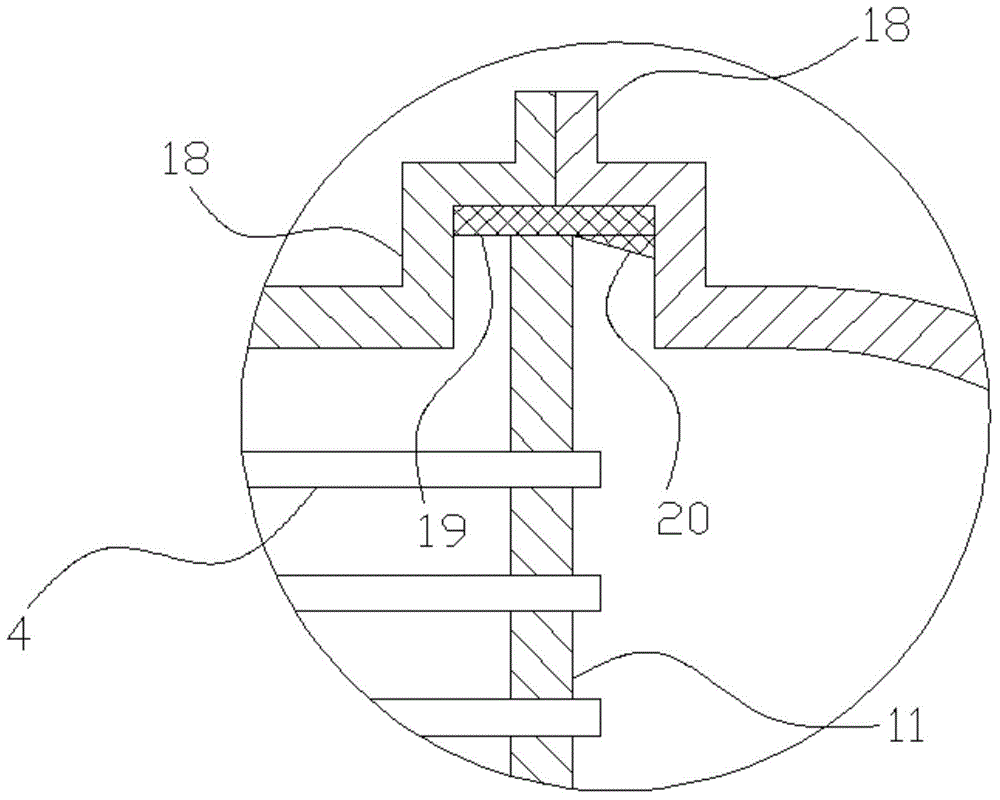

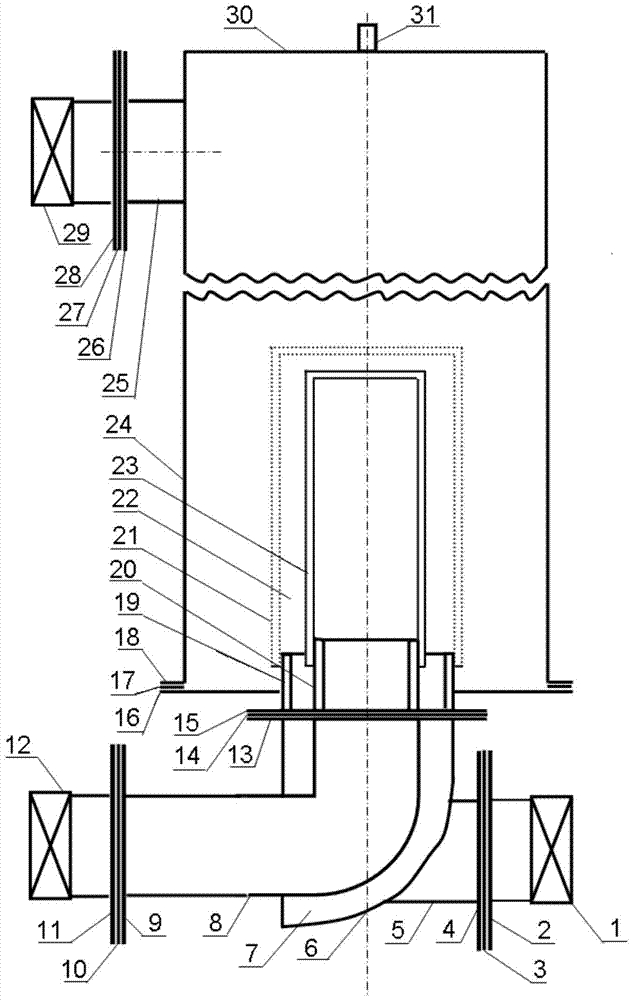

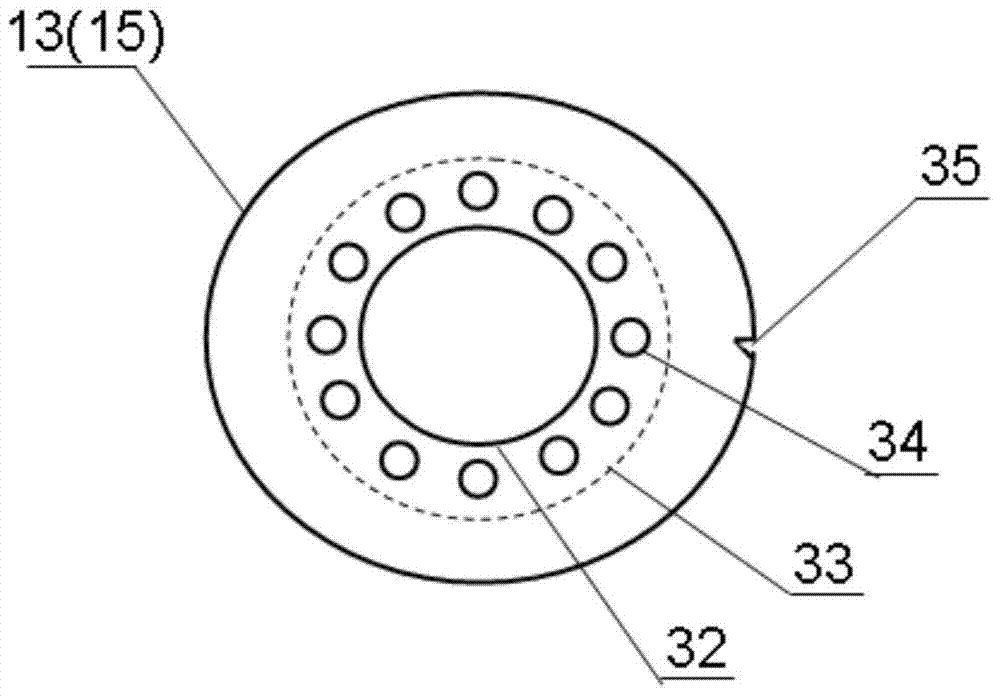

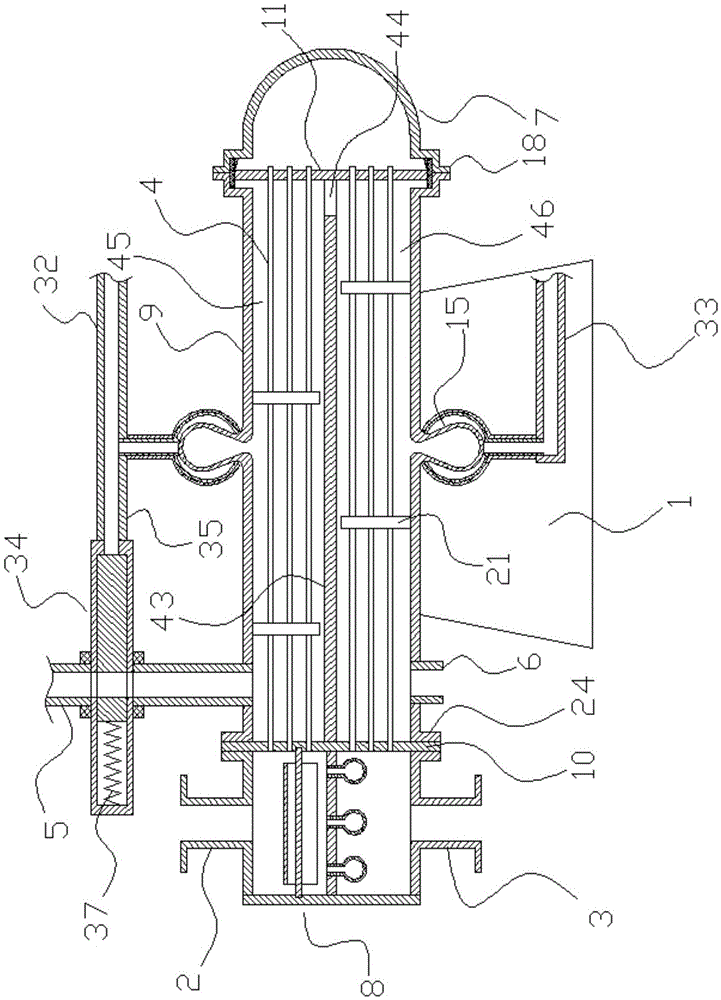

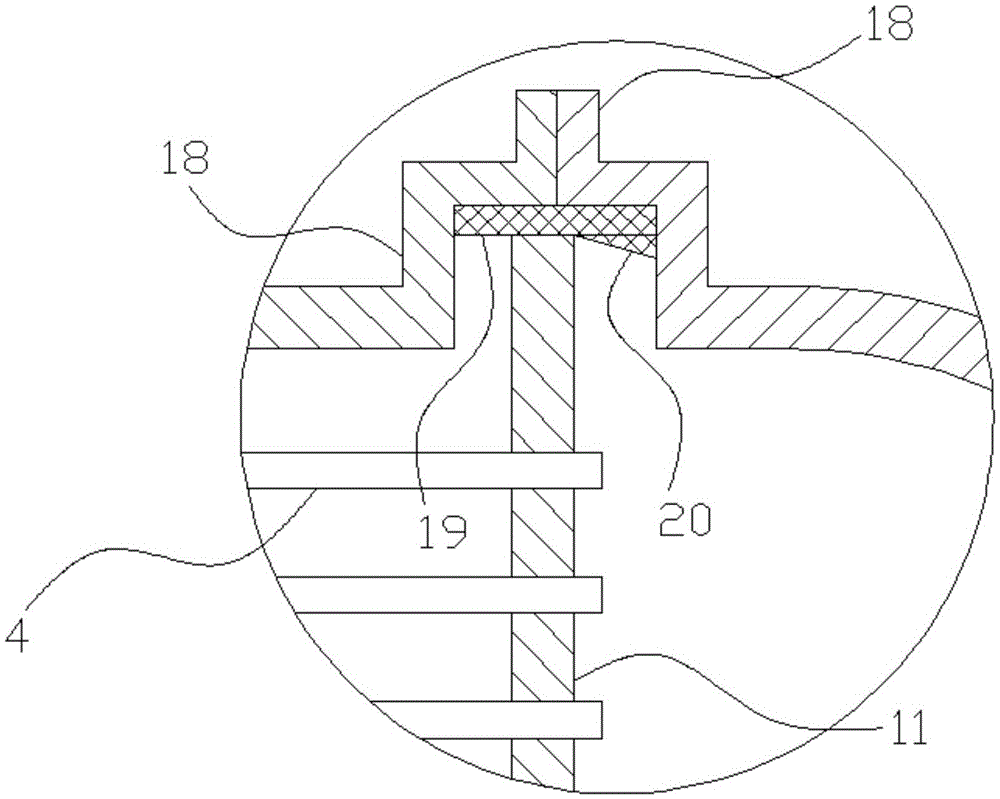

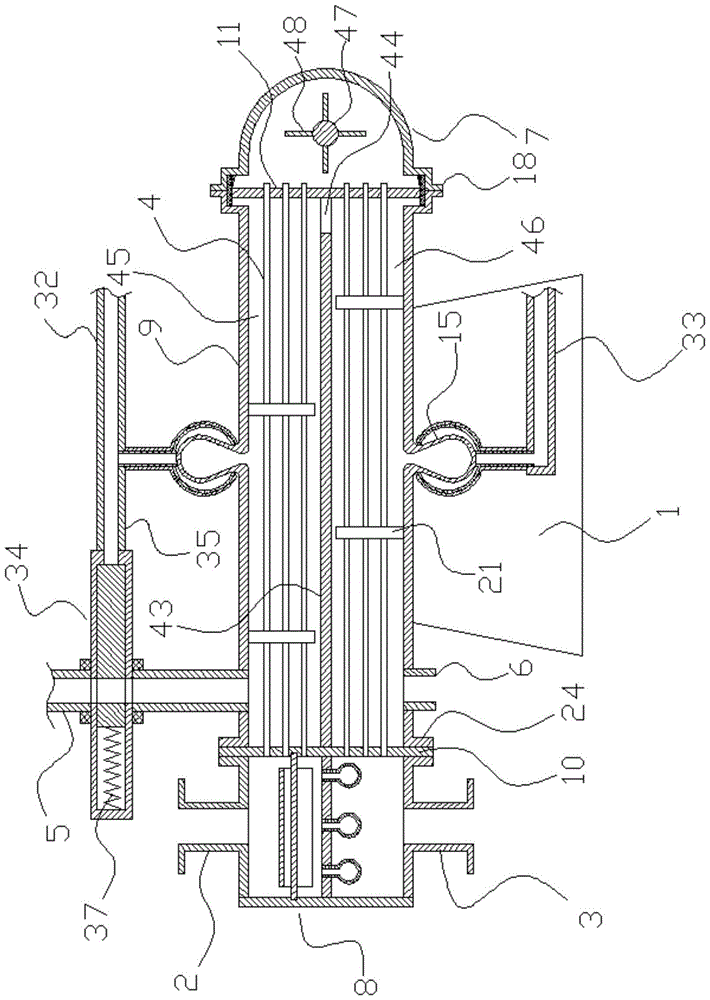

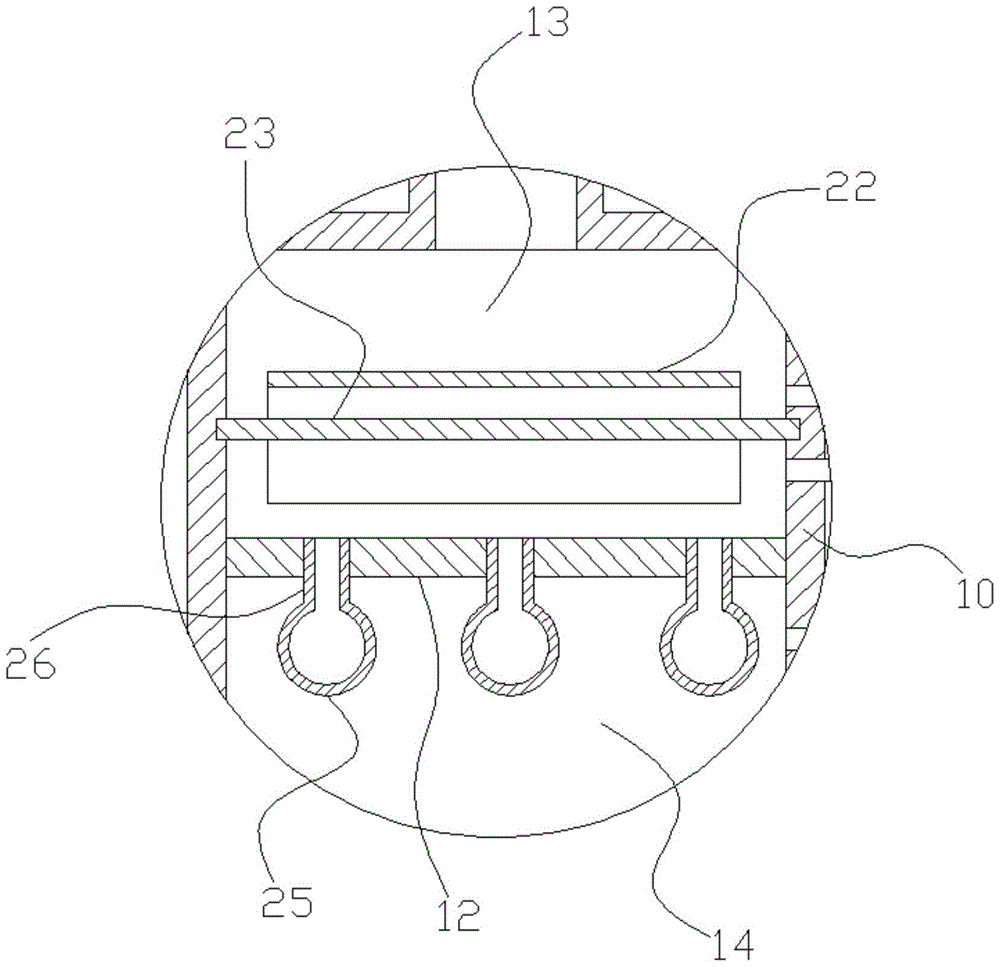

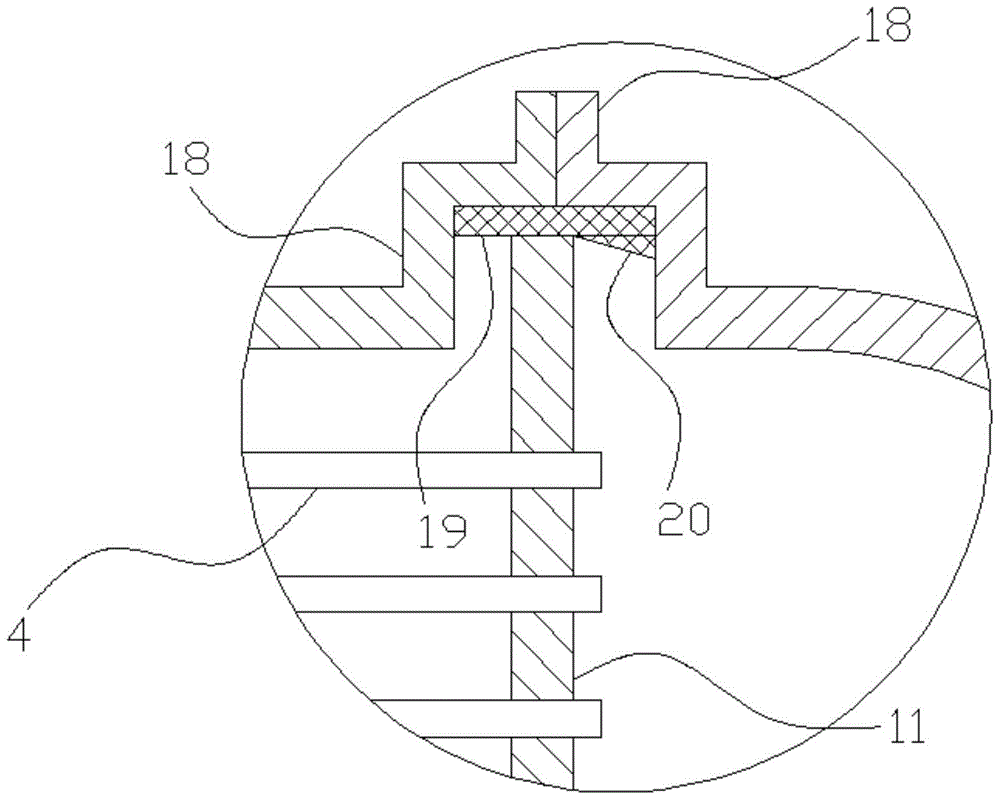

Shell-and-tube heat exchanger

InactiveCN104634141AAvoid damageSmooth circulationCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

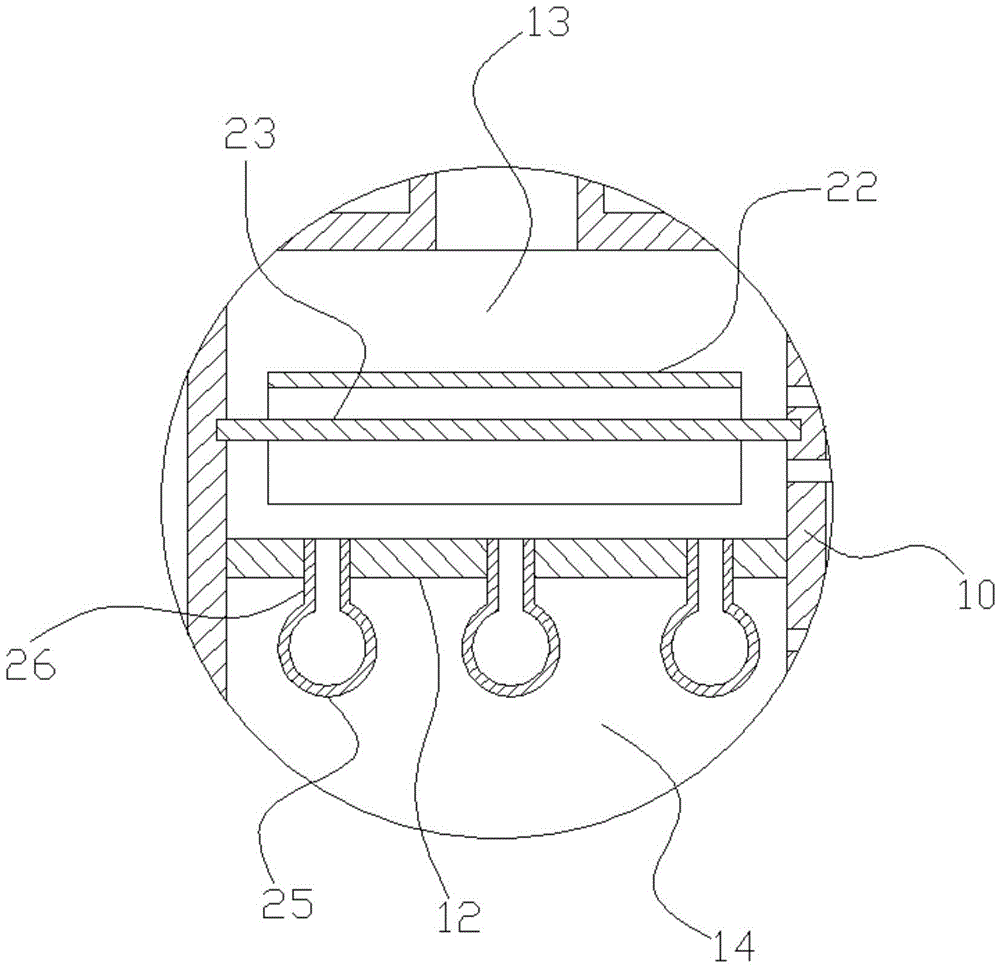

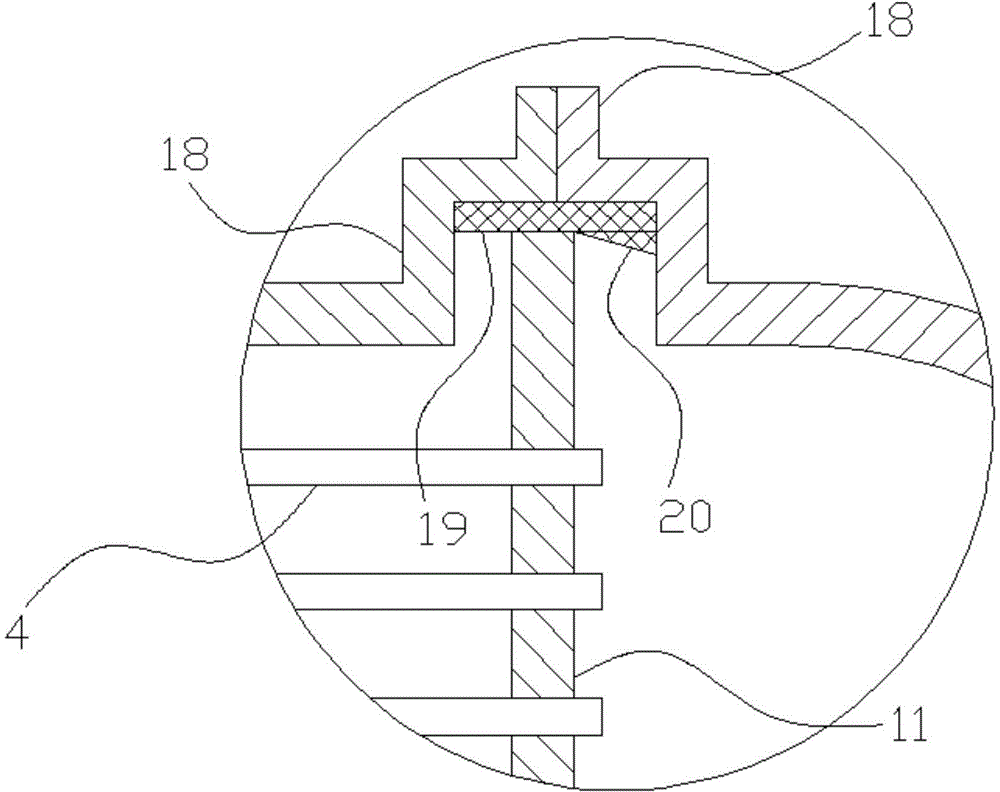

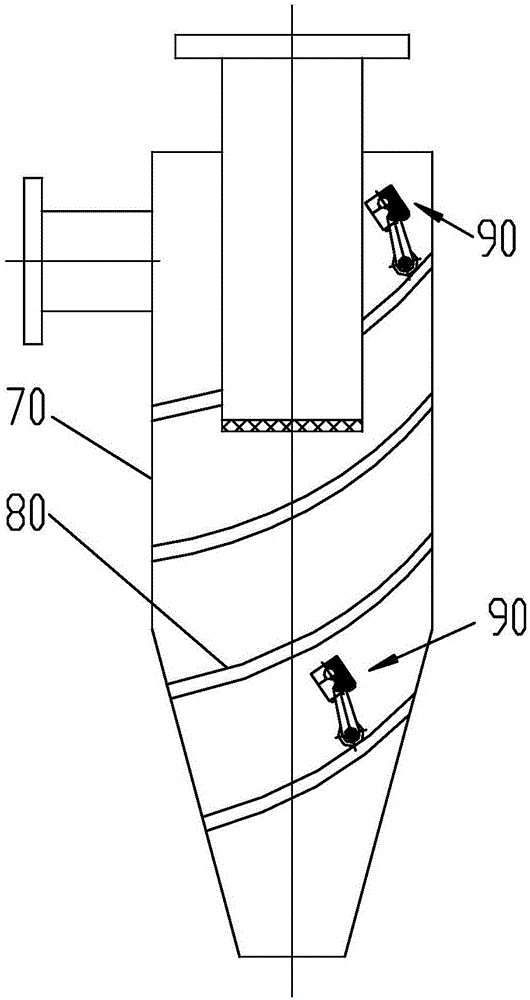

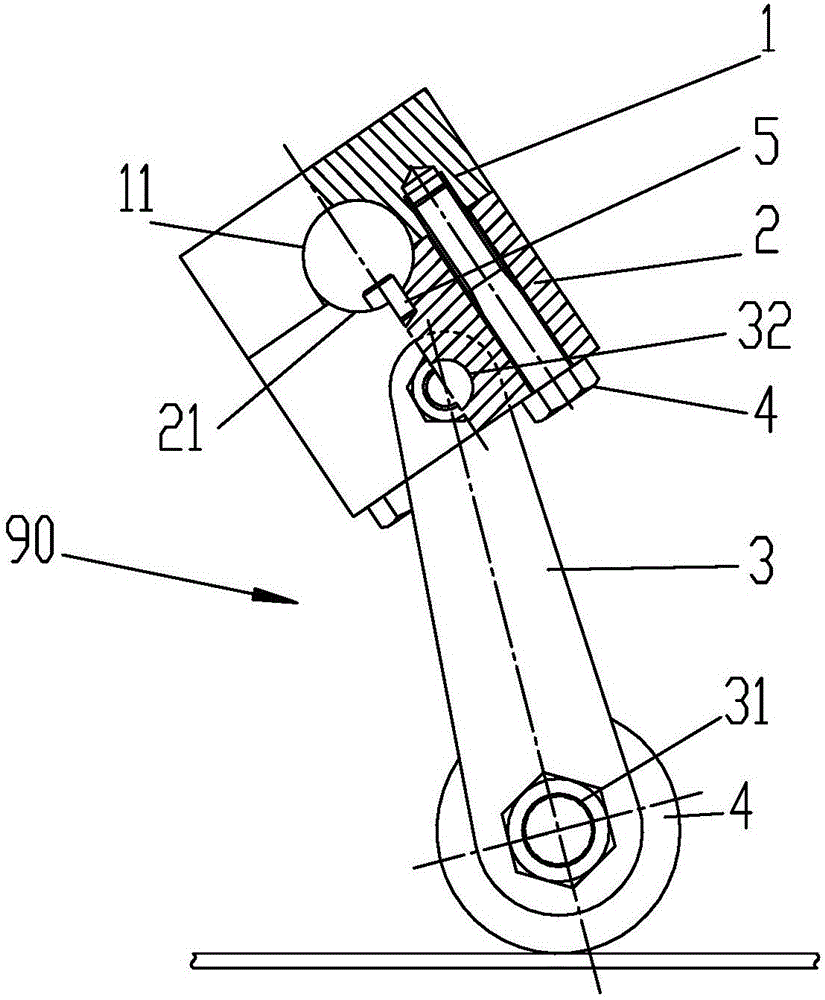

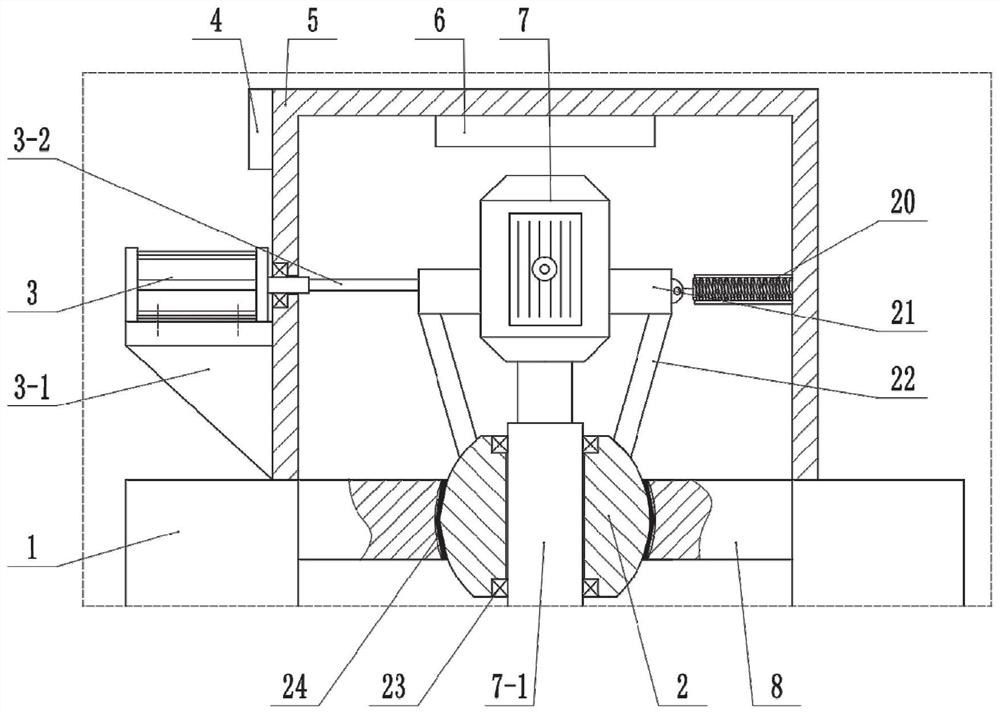

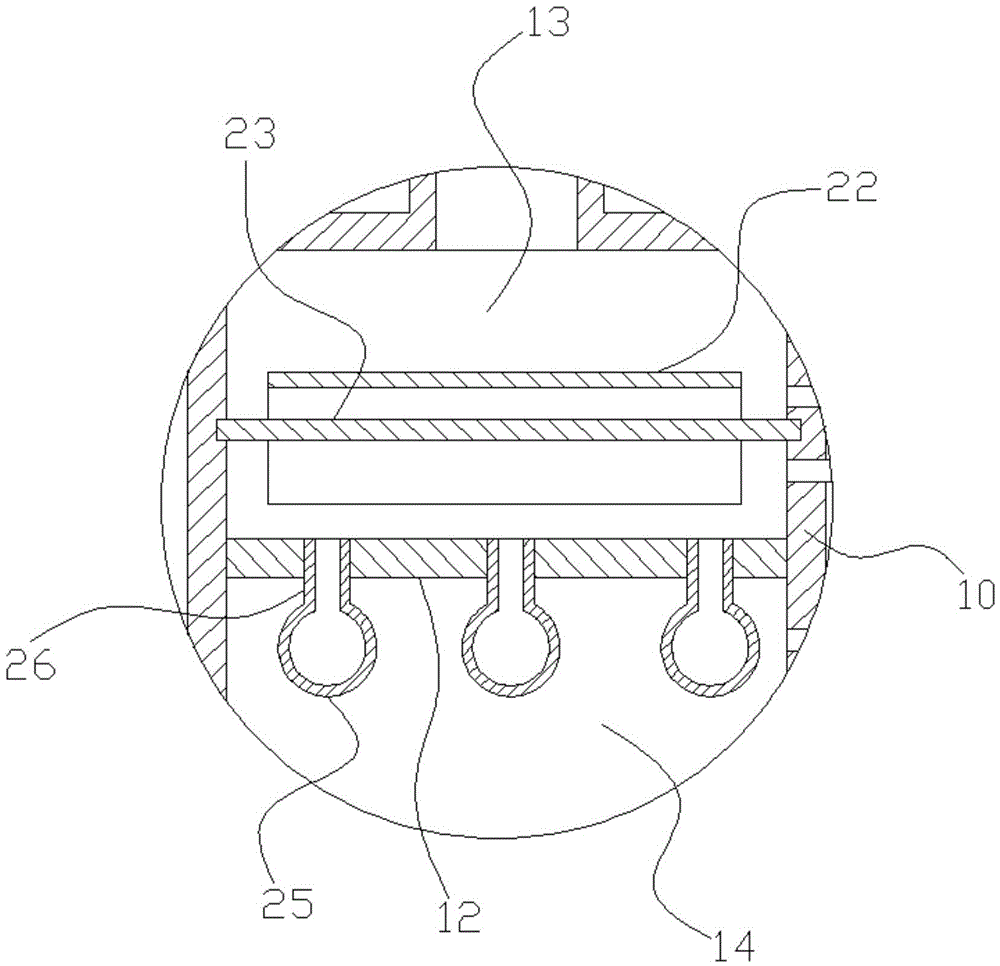

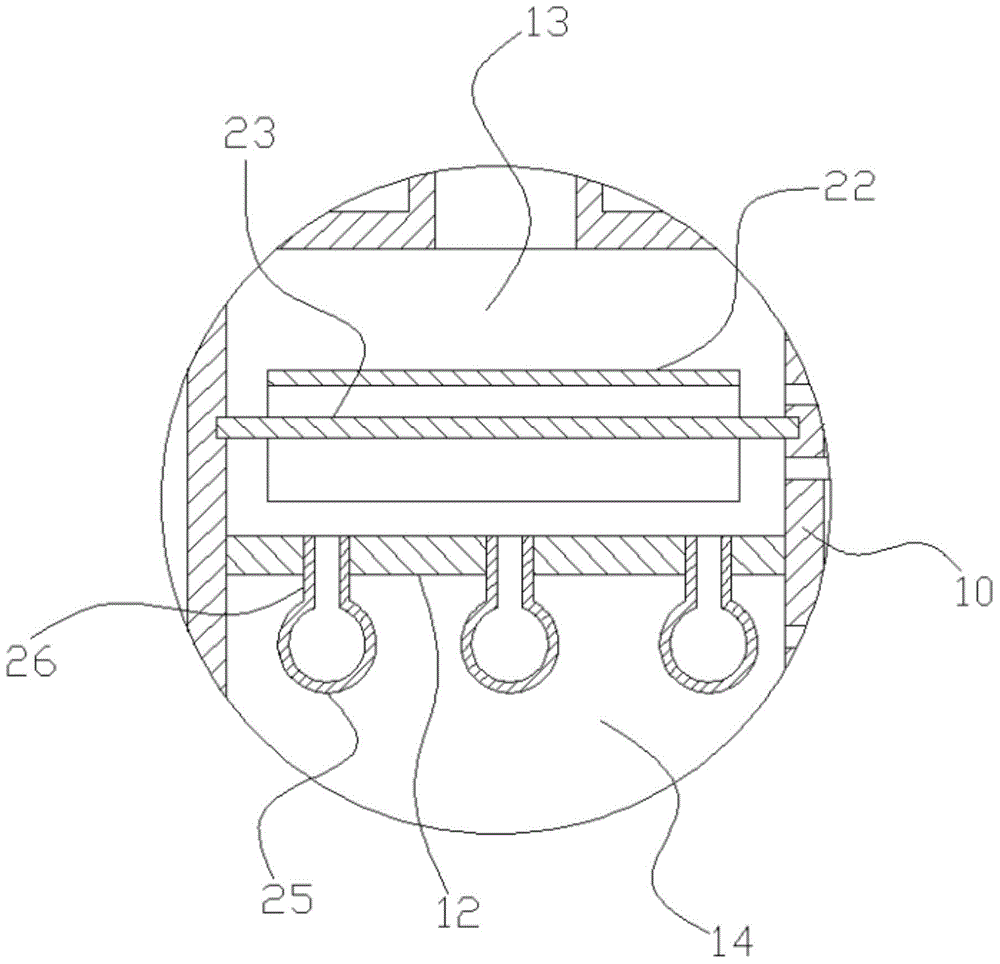

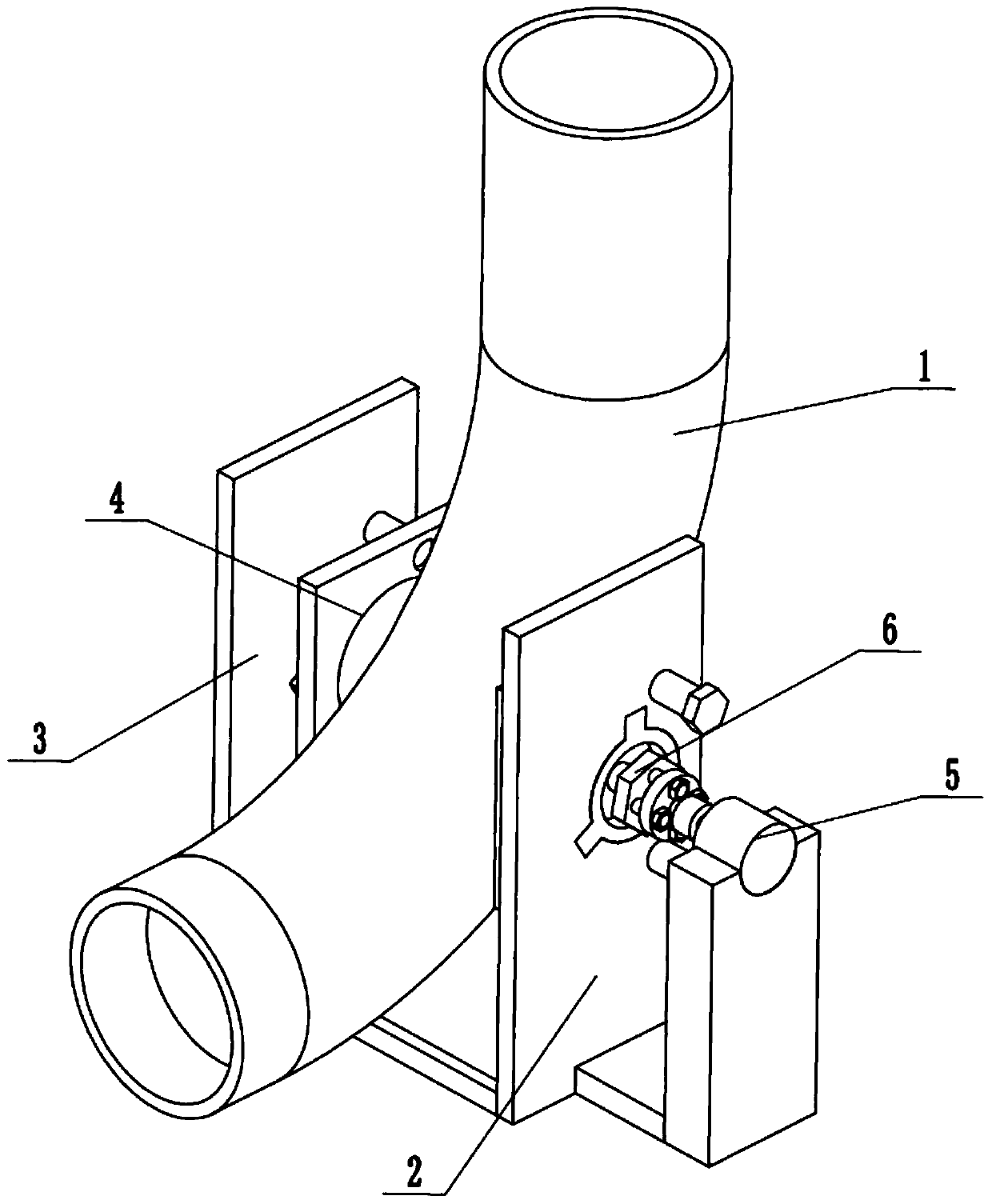

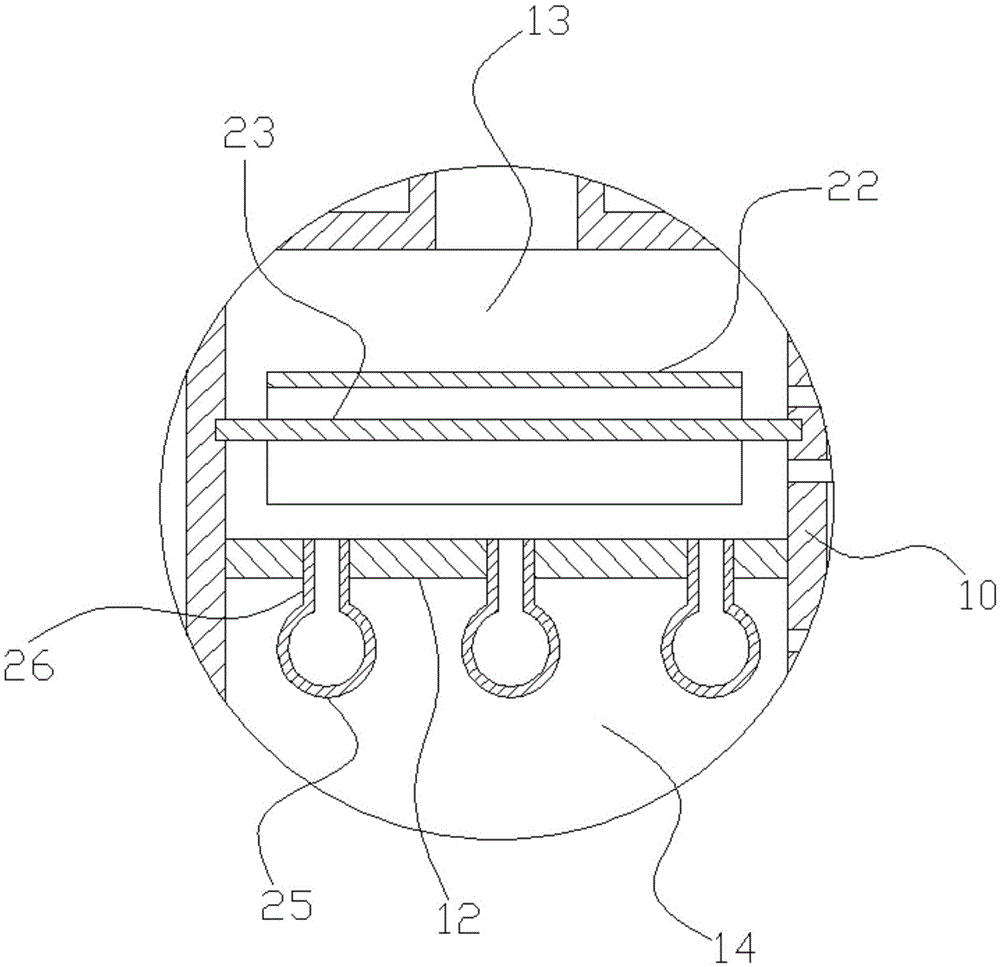

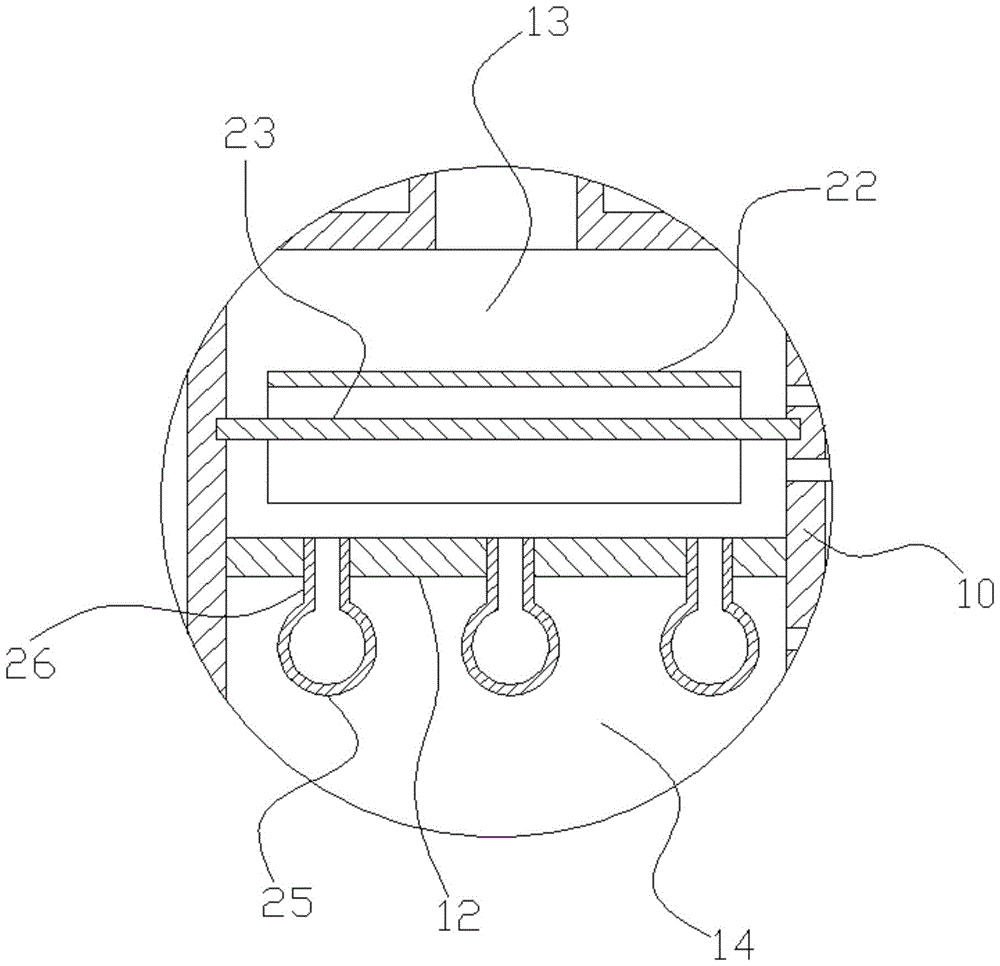

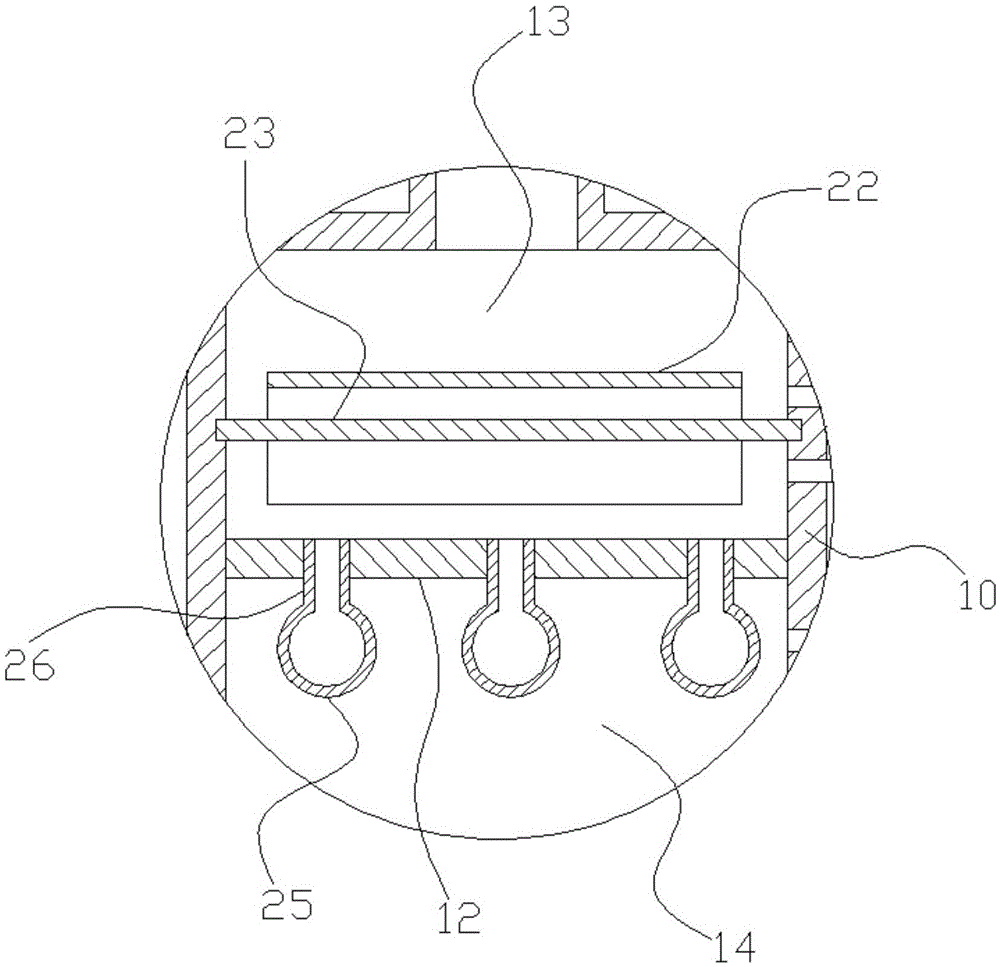

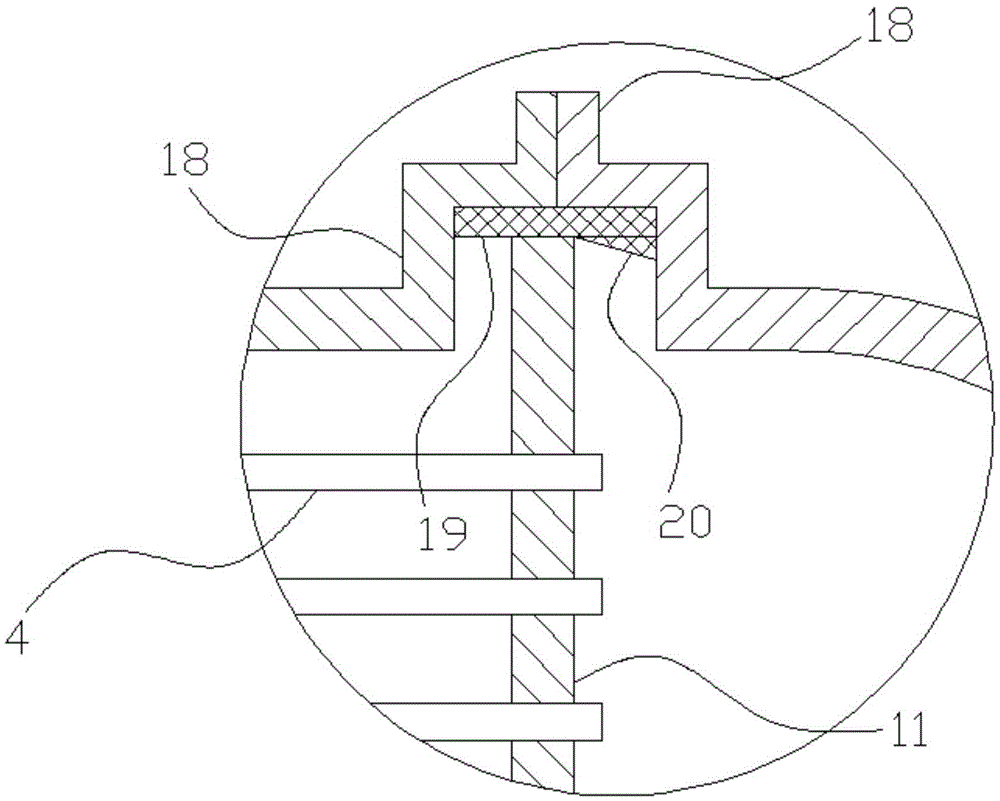

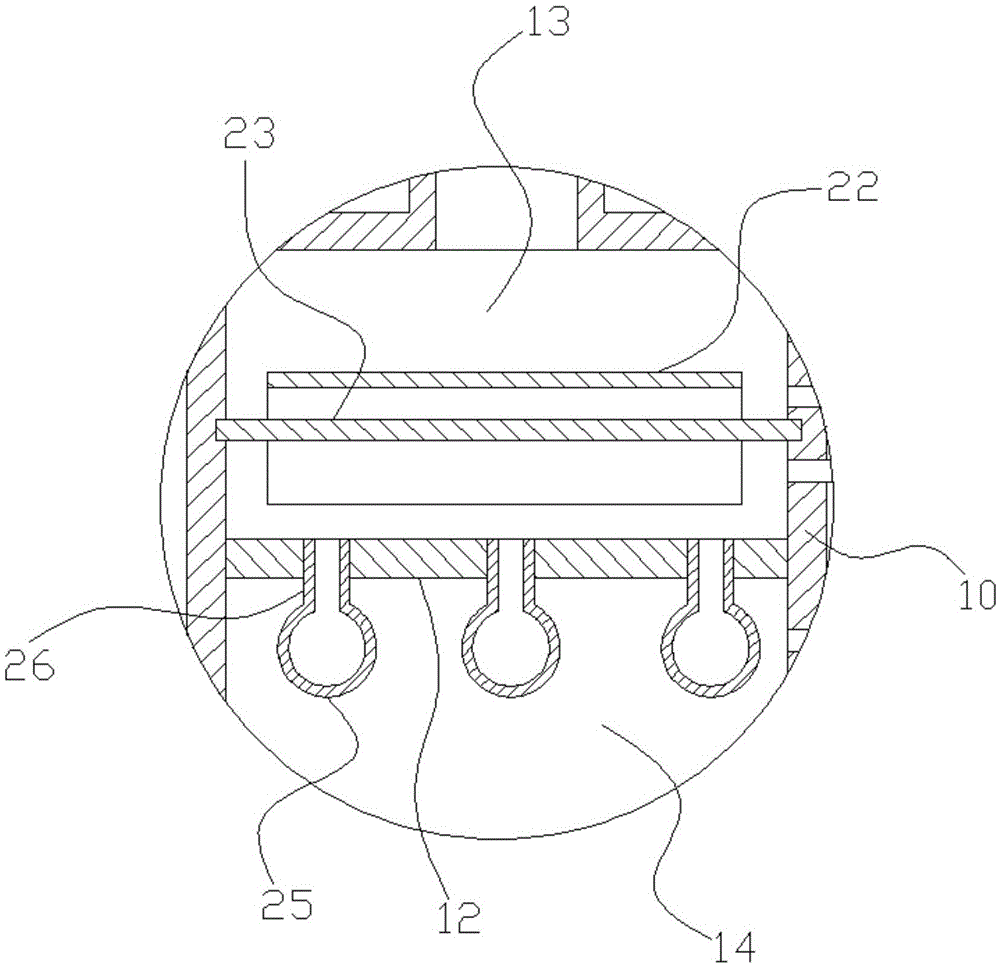

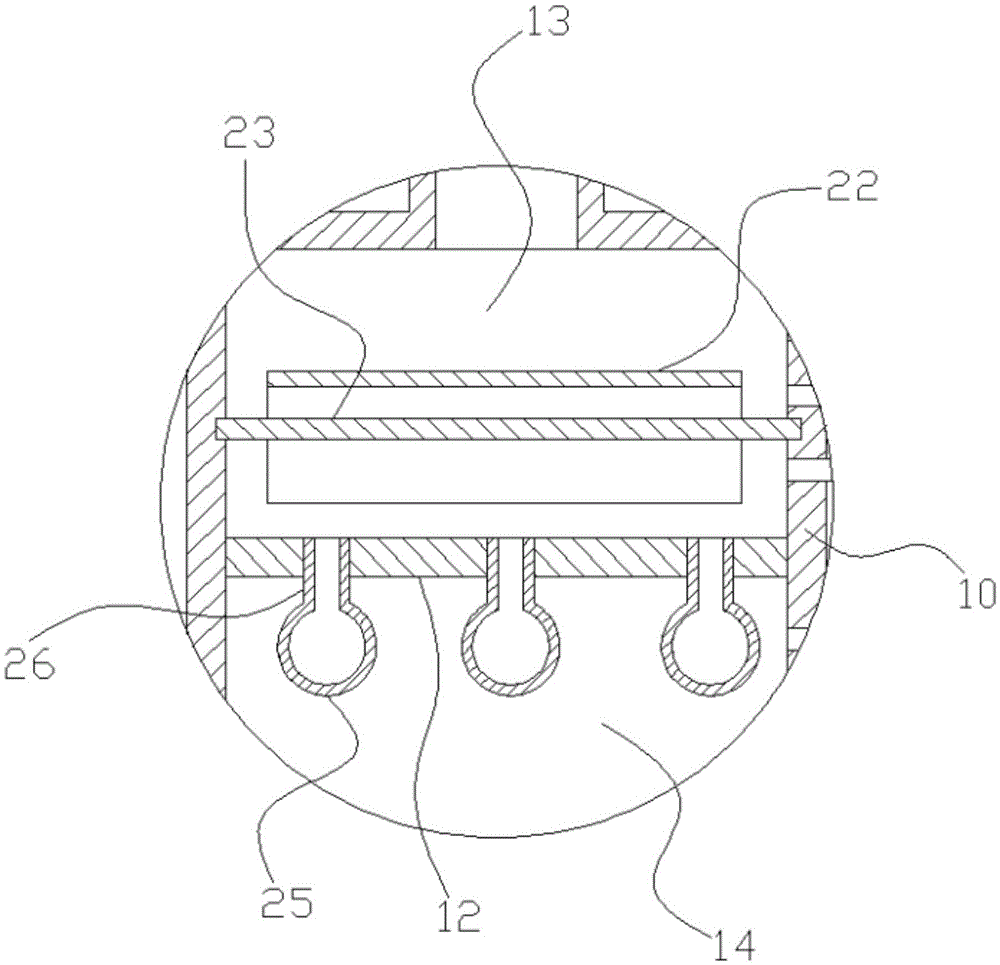

Cyclone separator with spiral blade with rapping function

InactiveCN106040450AAvoid Adhesive BuildupClear accumulation effect is obviousReversed direction vortexCycloneSpiral blade

The invention provides a cyclone separator with a spiral blade with a rapping function. The cyclone separator comprises an inverted-conical tubular body and the spiral blade arranged on the internal wall of the inverted-conical tubular body, wherein rapping hammers which can be used for rapping the spiral blade are arranged above the spiral blade, each rapping hammer comprises an input shaft, a splice plate, a hammerhead jib, a clamping plate and a hammerhead which can be used for rapping the spiral blade, and a driving motor which is used for providing input power is connected onto each input shaft; one end of each clamping plate is provided with a first hinge position, the other end of each clamping plate is provided with a second hinge position, the first hinge positions are hinged to the hammerhead jibs, and the second hinge positions are hinged to the hammerheads. In a manner of arranging the rapping hammers on the spiral blade, during cyclone separation, through rapping the spiral blade, a material attached to the spiral blade is shaken off due to vibration and is prevented from attached accumulation; the structure is simple and reliable, a rapping process can be adjusted according to conditions of the material, the rapping effect is controllable, and thus the entire device is relatively low in cost and is applicable to industrial application.

Owner:扬州日发干燥工程有限公司

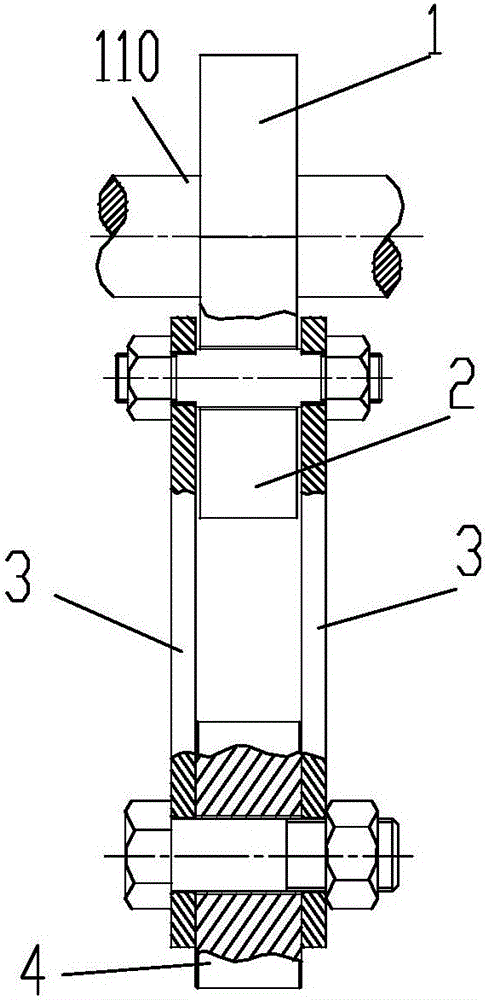

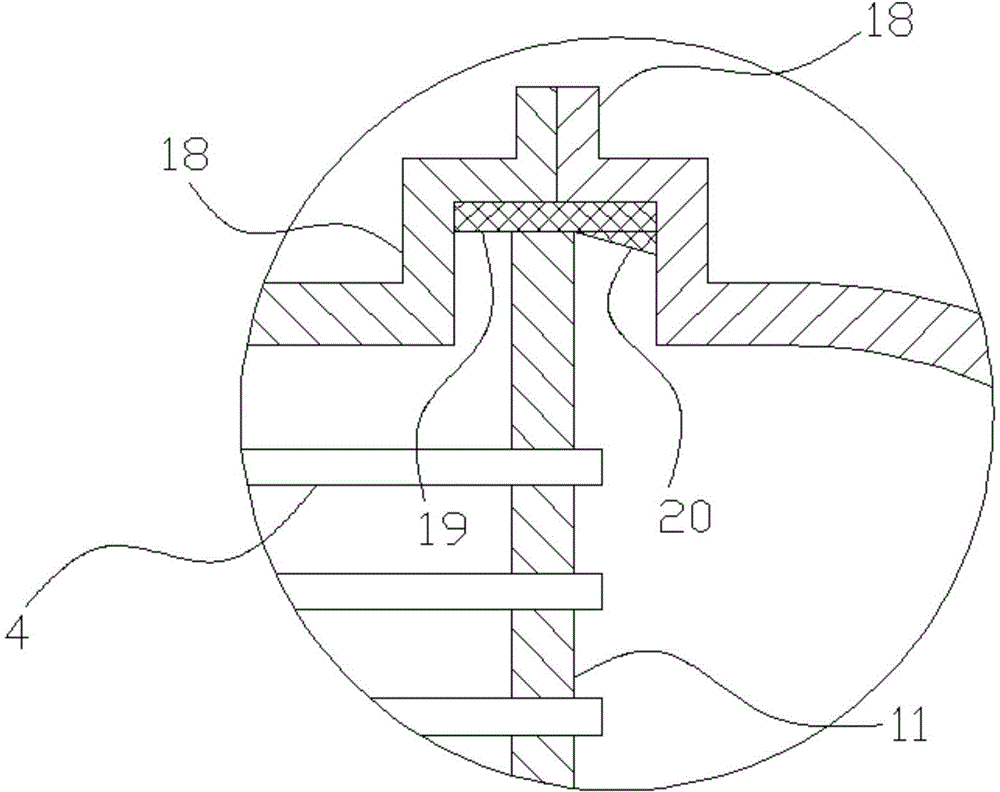

Preparation method for upper nozzle used for continuous casting

The invention discloses a preparation method for an upper nozzle used for continuous casting. The upper nozzle is composed of an inner layer and an outer layer, wherein the inner layer comprises aluminum titanate, silicon nitride and aluminum nitride, and the outer layer comprises a porous mullite ceramic particle, fine mullite powder, fine zirconia mullite powder, fine Cr2O3 powder, fine clay powder and 200-mesh active alpha alumina micro powder. The preparation method comprises the following steps: 1) mixing: a step of respectively and uniformly mixing inner layer raw materials and outer layer raw materials in a mixer with stirring and carrying out granulation; 2) molding: a step of respectively subjecting the inner layer and the outer layer of the upper nozzle to compression molding through isostatic pressing; and 3) sintering: a step of drying a molded green body and sintering the green body in a reducing atmosphere at a temperature of 1460 to 1500 DEG C or in an anoxic environment. The upper nozzle has service life of more than 20 h and good thermal shock resistance and can effectively prevent alumina in molten steel from adhesion and accumulation in the inner cavity of the upper nozzle and prevent obstruction of steel flow.

Owner:WUXI SHENJIA HYDRAULIC TECH

Water filling opening for continuous casting

InactiveCN103769574ASmall coefficient of thermal expansionGood thermal shock resistanceMelt-holding vesselsChromium sesquioxideSilicon nitride

The invention discloses a water filling opening for continuous casting. The water filling opening for the continuous casting is formed by an inner layer and an outer layer; the raw materials of the inner layer comprise, by weight, 76 to 80 parts of minus 200-mesh aluminum titanate, 12 to 14 parts of minus 200-mesh silicon nitride, 6 to 8 parts of minus 200-mesh aluminum nitride and 4 to 6 parts of phenolic resin; raw materials of the outer layer comprise, by weight, 30 to 34 parts of 20-to-200-mesh poriferous mullite ceramic particles, 42 to 46 parts of minus 200-mesh mullite fine powder, 6 to 8 parts of minus 200-mesh zirconium mullite fine powder, 3 to 5 parts of minus 200-mesh chromium sesquioxide fine powder, 4 to 6 parts of minus 200-mesh clay fine powder, 1 to 3 parts of minus 200-mesh active alpha aluminum oxide micro powder and 3 to 5 parts of silica solution; the water filling opening is baked through the above inner and outer layer raw materials under an oxygen-free condition with the temperature to be at 1460 to 1500 DEG C after the raw materials are performed mixing granulation and mechanical pressing.

Owner:WUXI SHENJIA HYDRAULIC TECH

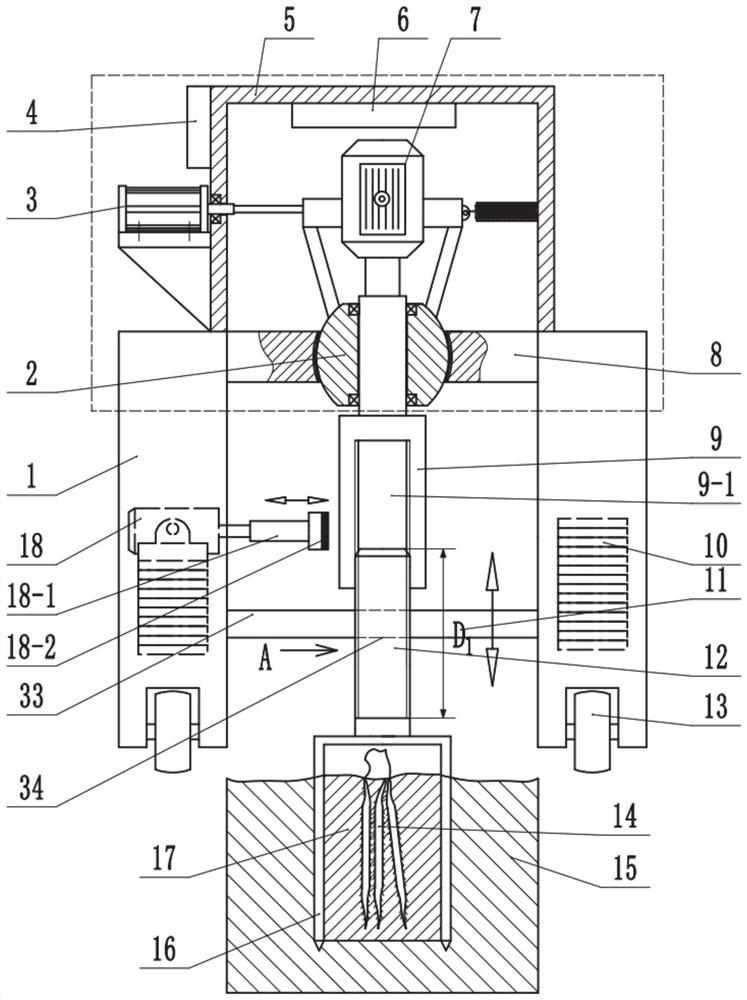

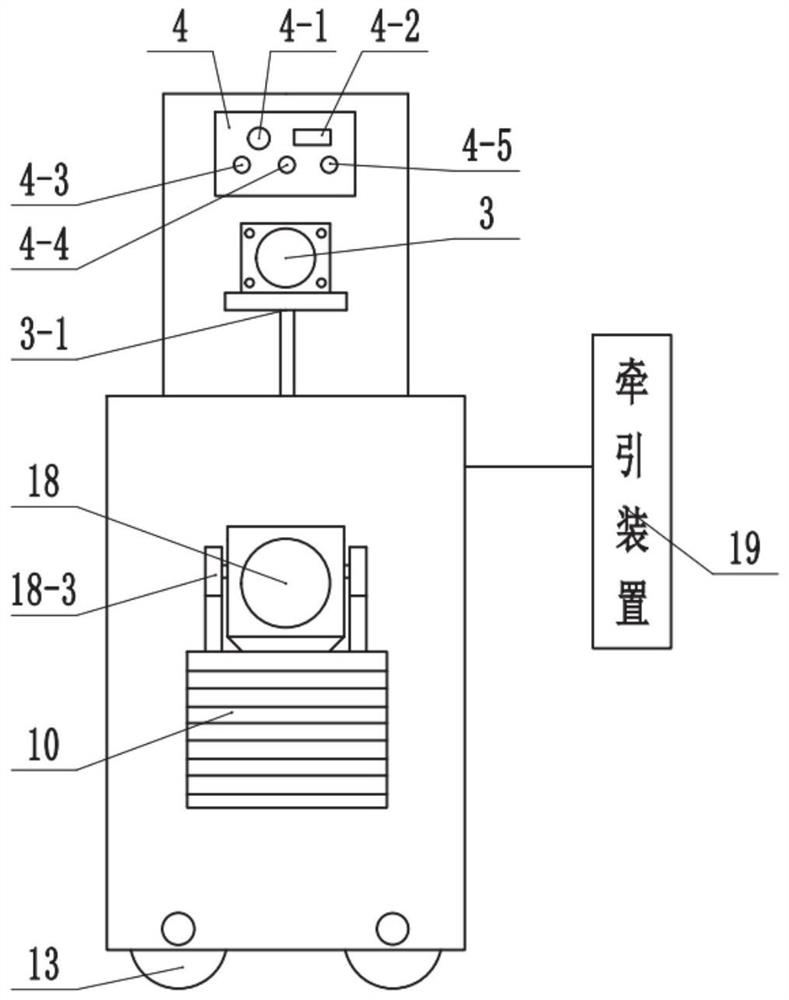

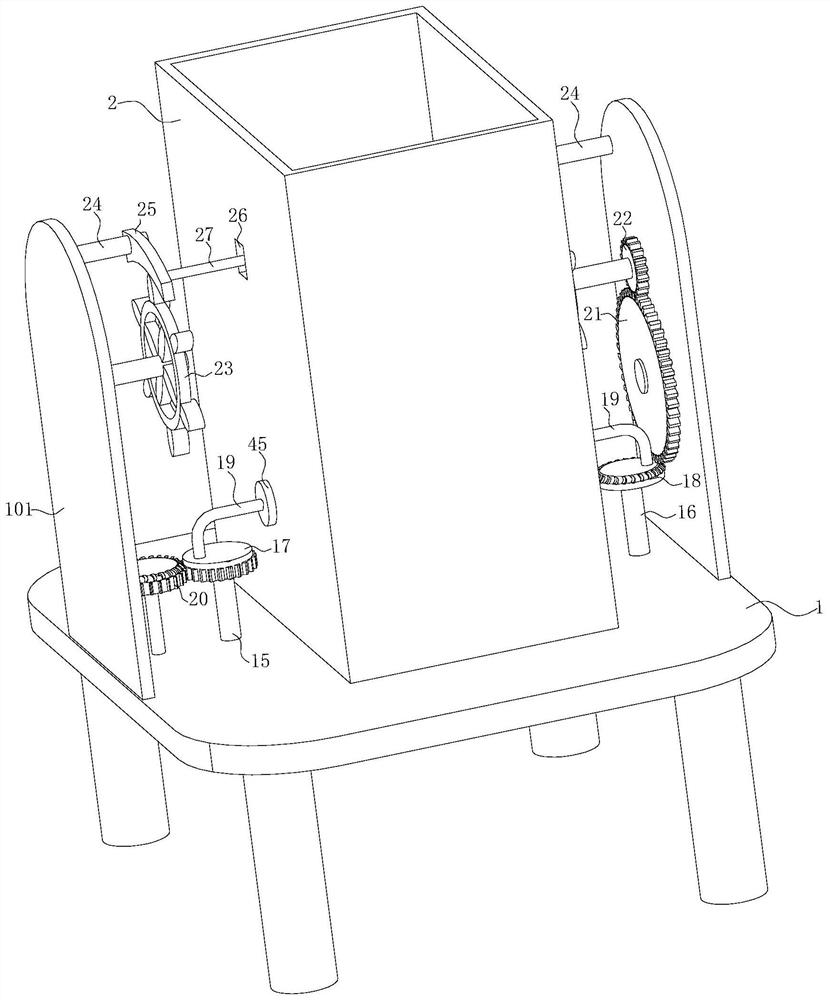

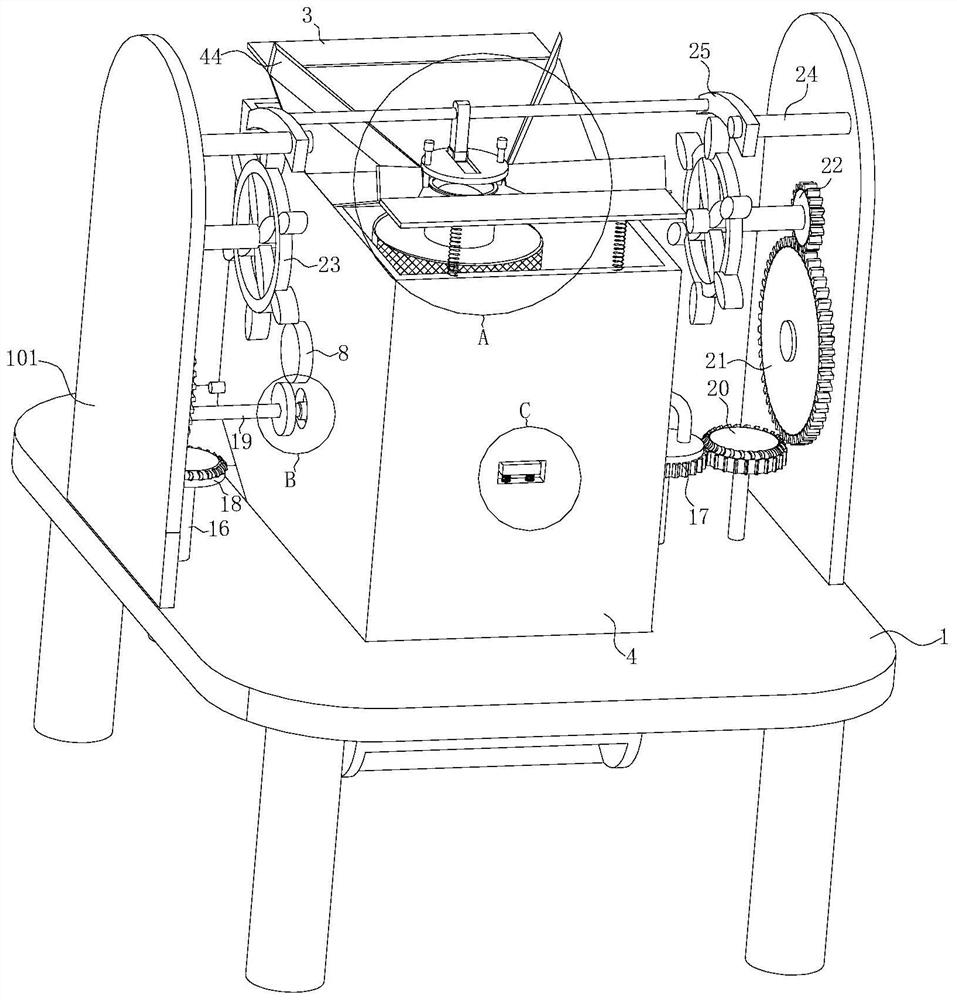

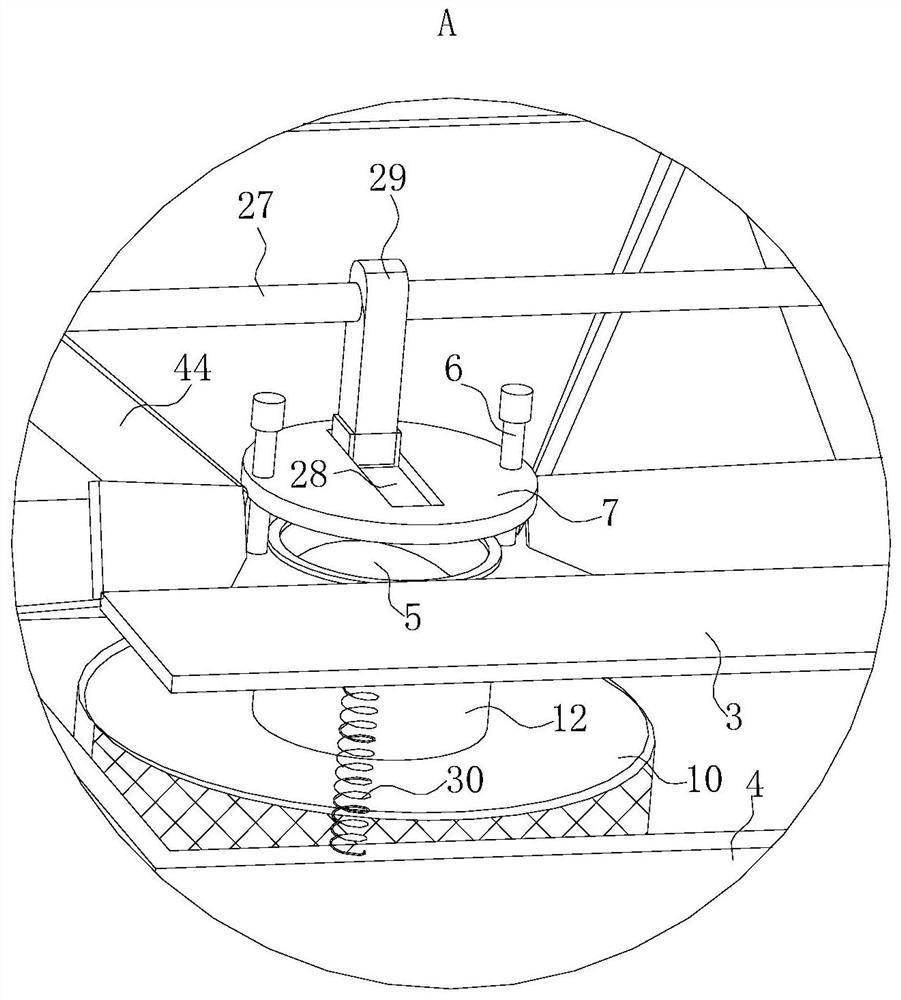

Chinese yam harvesting device, equipment and method

Owner:SHANDONG AGRI & ENG UNIV

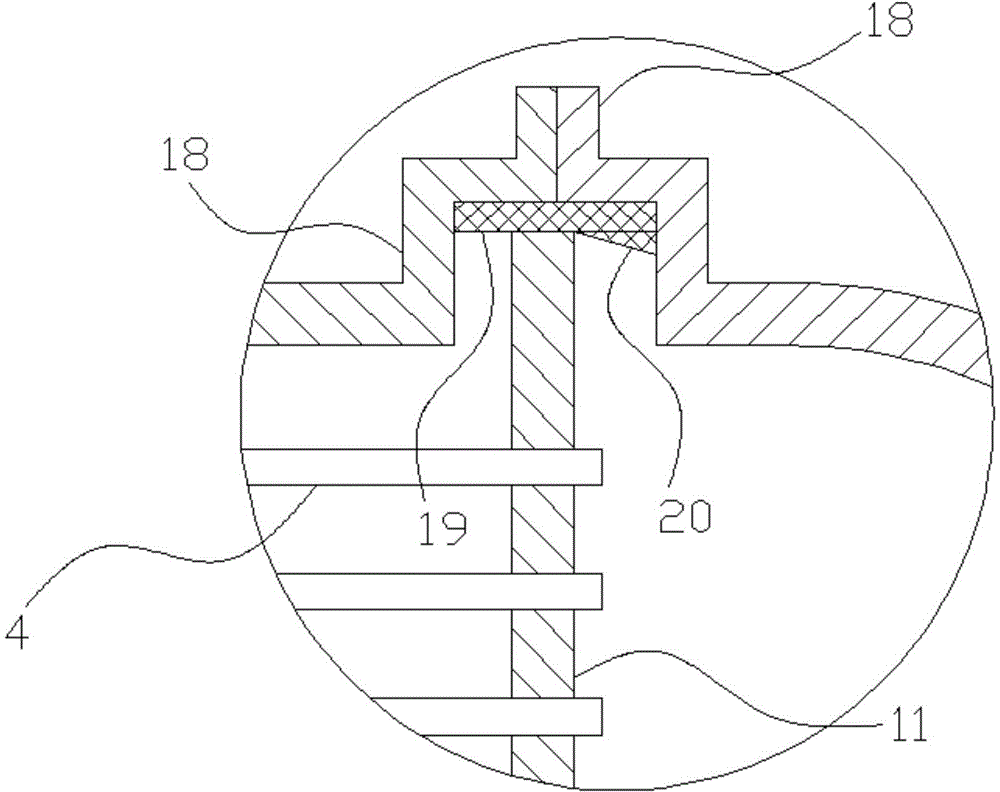

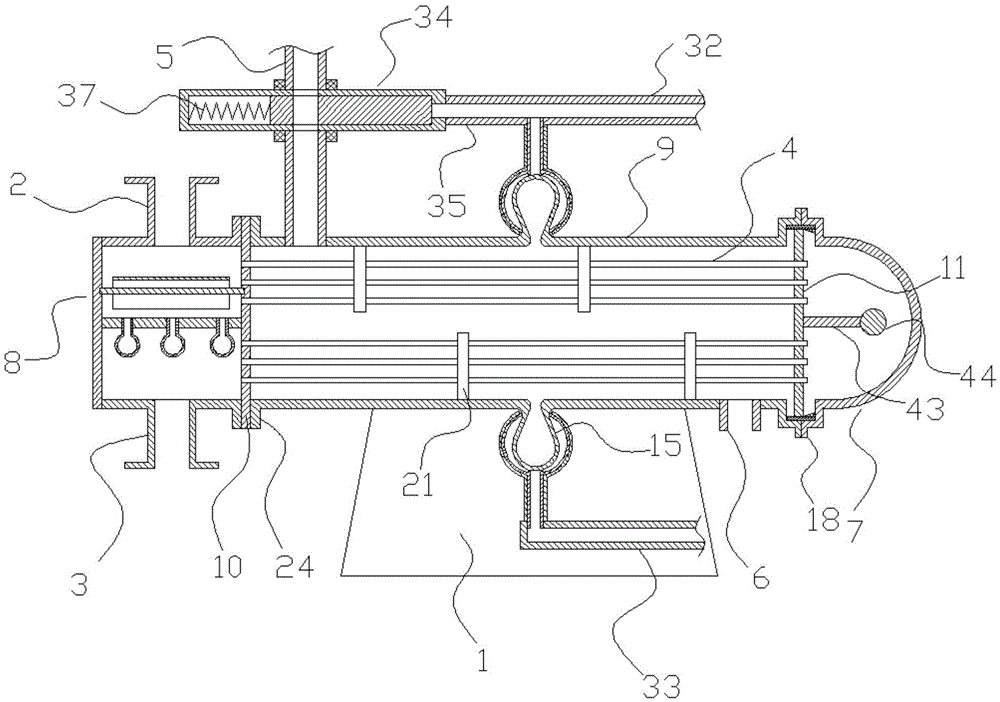

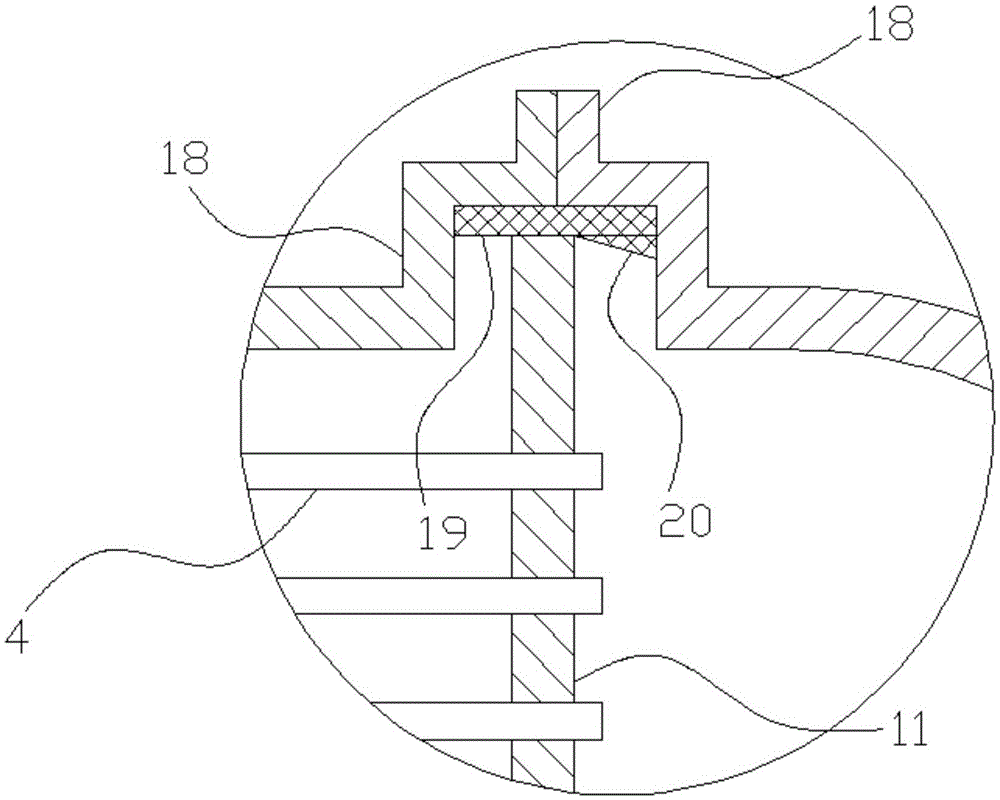

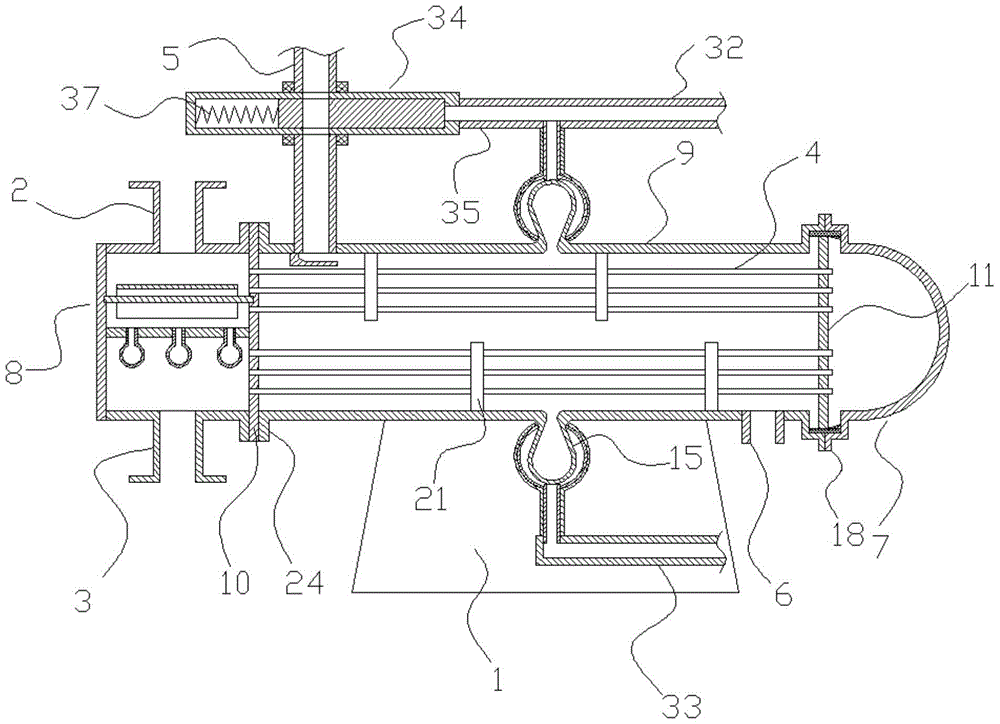

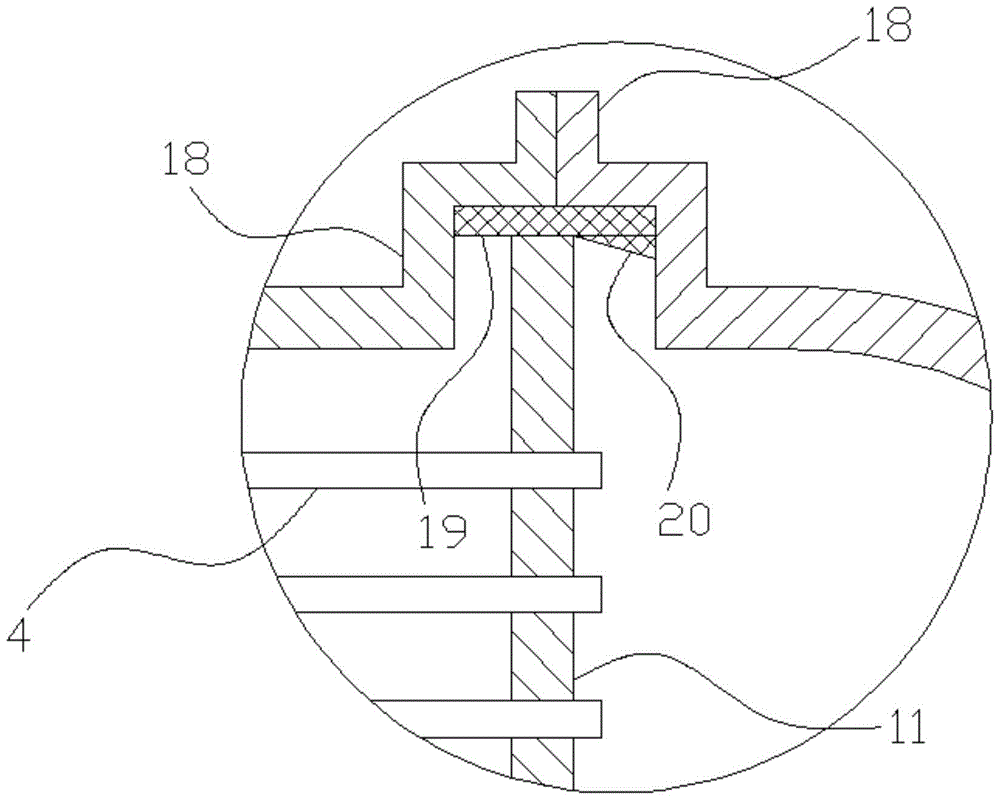

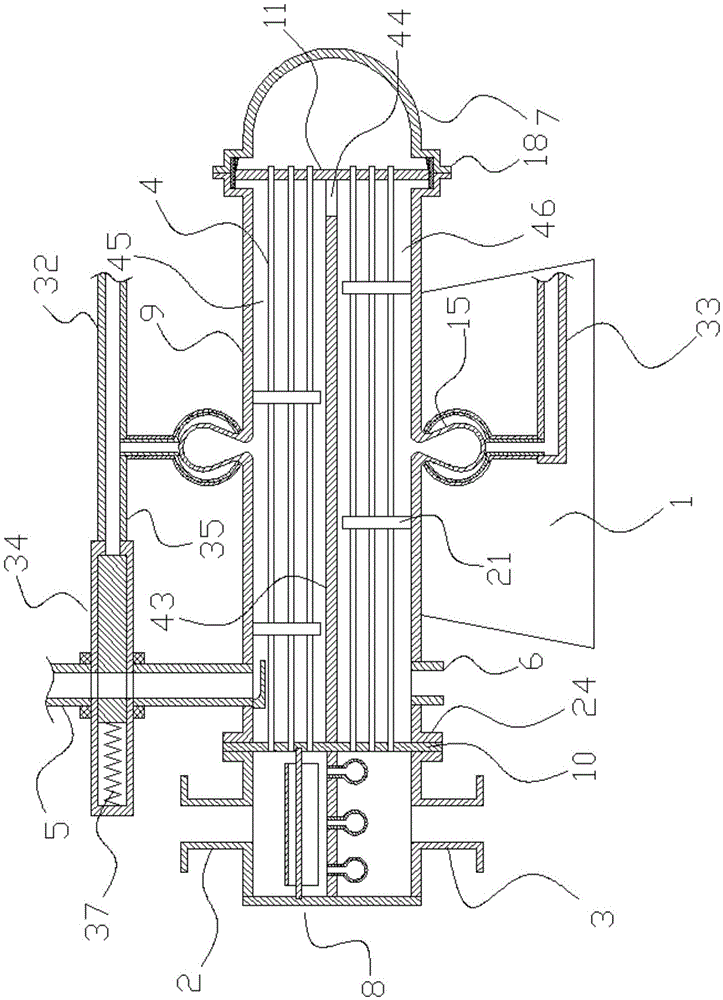

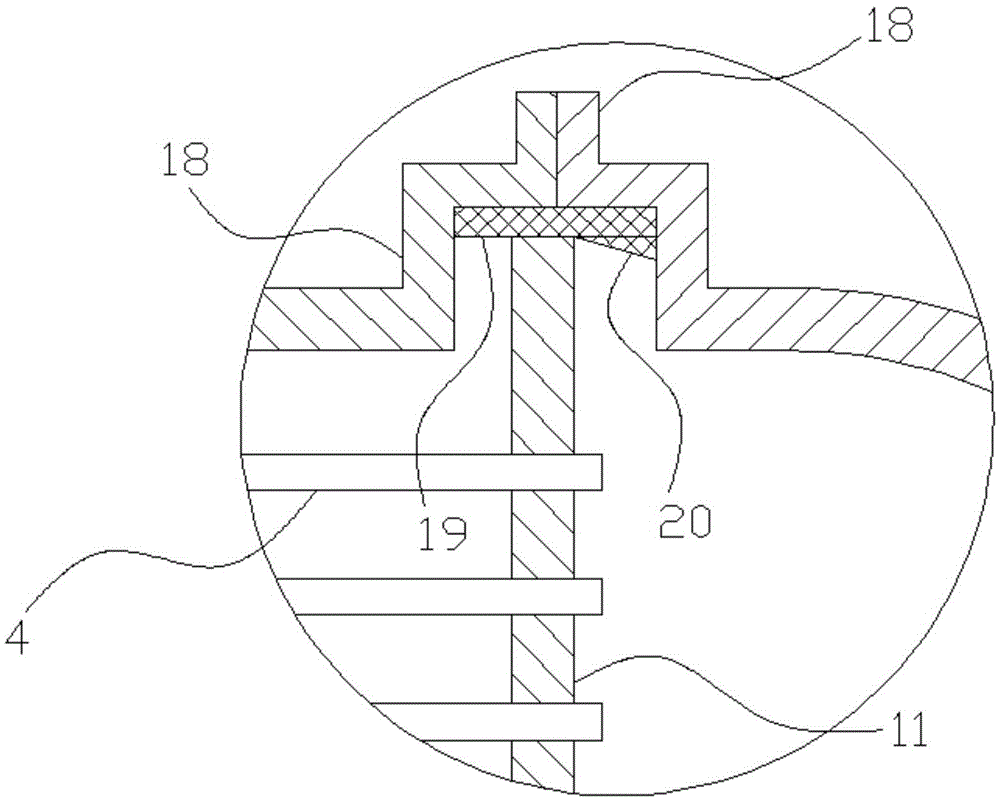

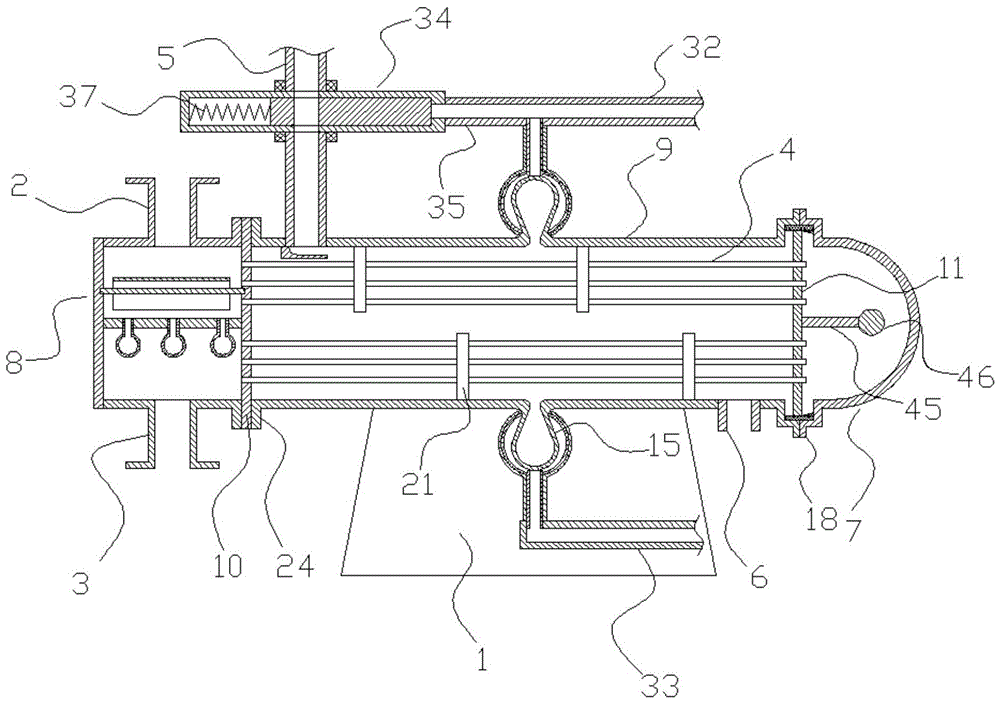

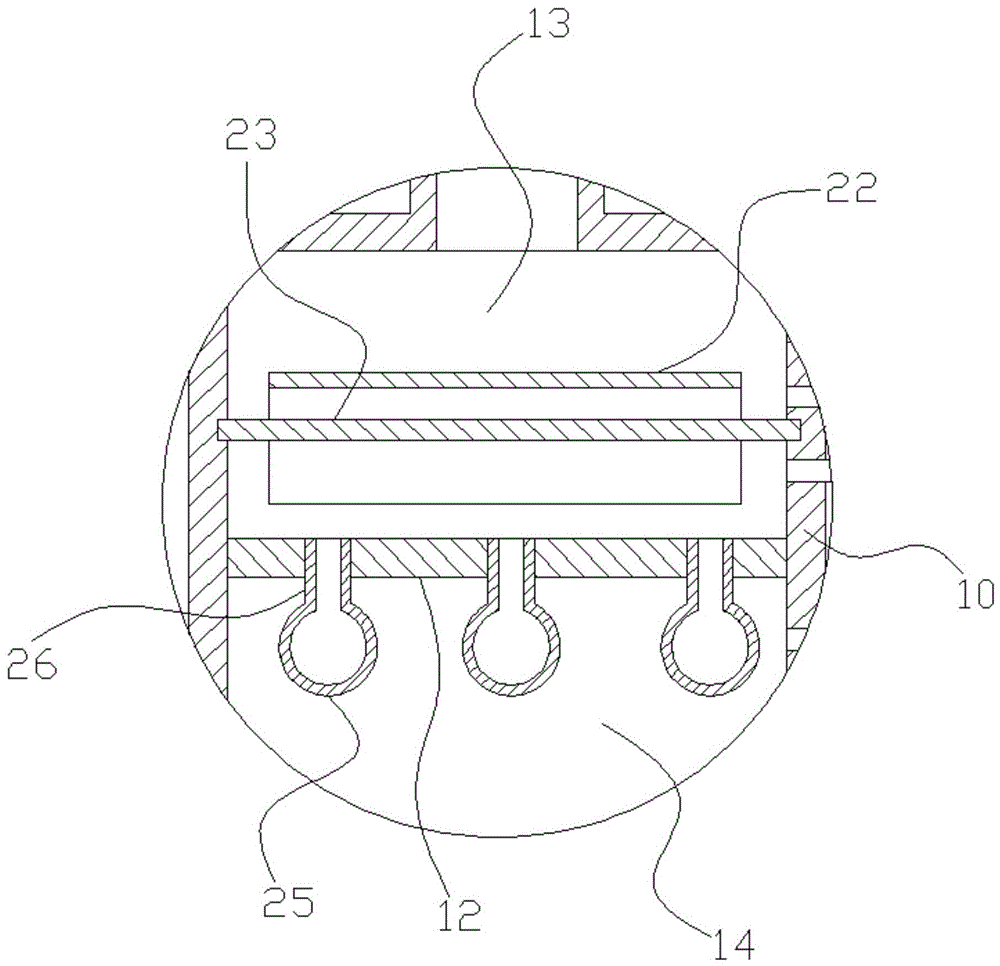

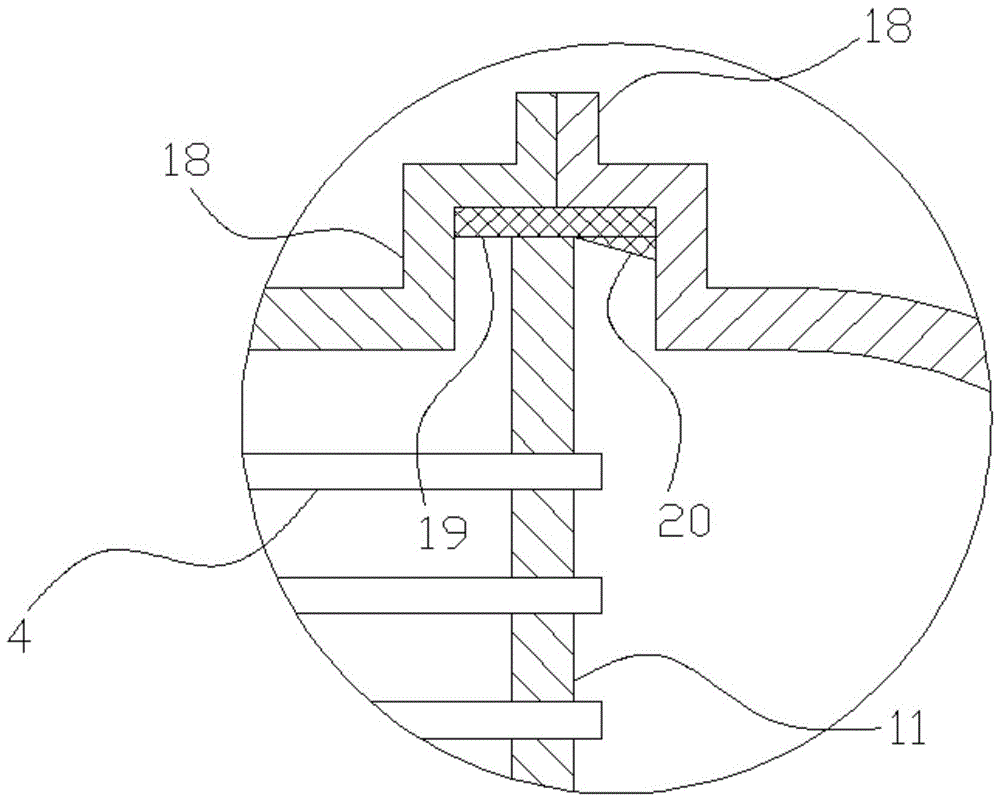

Tube array type heat exchange device

InactiveCN104654836AAvoid structural damageAvoid Adhesive BuildupHeat exchanger casingsStationary tubular conduit assembliesEngineeringExpansion joint

The invention discloses a tube array type heat exchange device, and aims at providing a heat exchange device with the advantages that the heat exchange between two kinds of liquid can be effectively realized, the temperature difference compensation capability is realized, and the damage due to too great temperature difference stress between a casing and a heat exchange tube can be prevented. The tube array type heat exchange device comprises a tube pass part, a casing pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the casing pass part comprises a heat exchanger outer casing, a casing pass inlet tube and a casing pass outlet tube, the heat exchanger outer casing consists of a sealing head, a casing head and a tube box, a fixing tube plate is arranged between the casing head and the tube box, a sealing head tube plate is arranged between the sealing head and the tube box, the inside of the casing head is separated into a tube pass flow inlet cavity and a tube pass flow outlet cavity through one tube pass flow separation plate, and an expansion joint is arranged on the tube box. The tube array type heat exchange device has the beneficial effects that the characteristic that the expansion joint part is relatively easy to deform can be used for being matched with the slidable sealing head tube plate to achieve the structural temperature difference compensation effect, and the structure damage due to too great temperature difference stress can be avoided.

Owner:CHINA JILIANG UNIV

Tube-shell type heat exchange device

InactiveCN104654832AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Chemical engineering heat exchanger

InactiveCN104596323AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectCompound (substance)

The invention discloses a chemical engineering heat exchanger and aims to provide a heat exchanger which can effectively realize heat exchange between two liquors, has capability of temperature difference compensation and can be prevented from being damaged due to excessively large temperature difference stress between a shell and heat exchange tubes. The chemical engineering heat exchanger comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and the plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell body comprises a seal head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a seal head tube plate is arranged between the seal head and the tube box; a tube pass flow baffle is used for dividing the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The chemical engineering heat exchanger has the benefits that a structural temperature difference compensation effect can be achieved in combination with the slidable seal head tube plate based on a characteristic of easiness for deformation at the expansion joint, and structural damage caused by excessively large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Tube array type heat exchanger

InactiveCN104654835AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube array type heat exchanger, and aims at providing a heat exchanger with the advantages that the heat exchange between two kinds of liquid can be effectively realized, the temperature difference compensation capability is realized, and the damage due to too great temperature difference stress between a casing and a heat exchange tube can be prevented. The tube array type heat exchanger comprises a tube pass part, a casing pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the casing pass part comprises a heat exchanger outer casing, a casing pass inlet tube and a casing pass outlet tube, the heat exchanger outer casing consists of a sealing head, a casing head and a tube box, a fixing tube plate is arranged between the casing head and the tube box, a sealing head tube plate is arranged between the sealing head and the tube box, one tube pass separation plate separates the inside of the casing head into a tube pass flow inlet cavity and a tube pass flow outlet cavity, and an expansion joint is arranged on the tube box. The tube array type heat exchanger has the beneficial effects that the characteristic that the expansion joint part is relatively easy to deform can be utilized to be matched with the slidable sealing head tube plate to achieve the structural temperature difference compensation effect, and the structure damage due to too great temperature difference stress is avoided.

Owner:卢晓丽

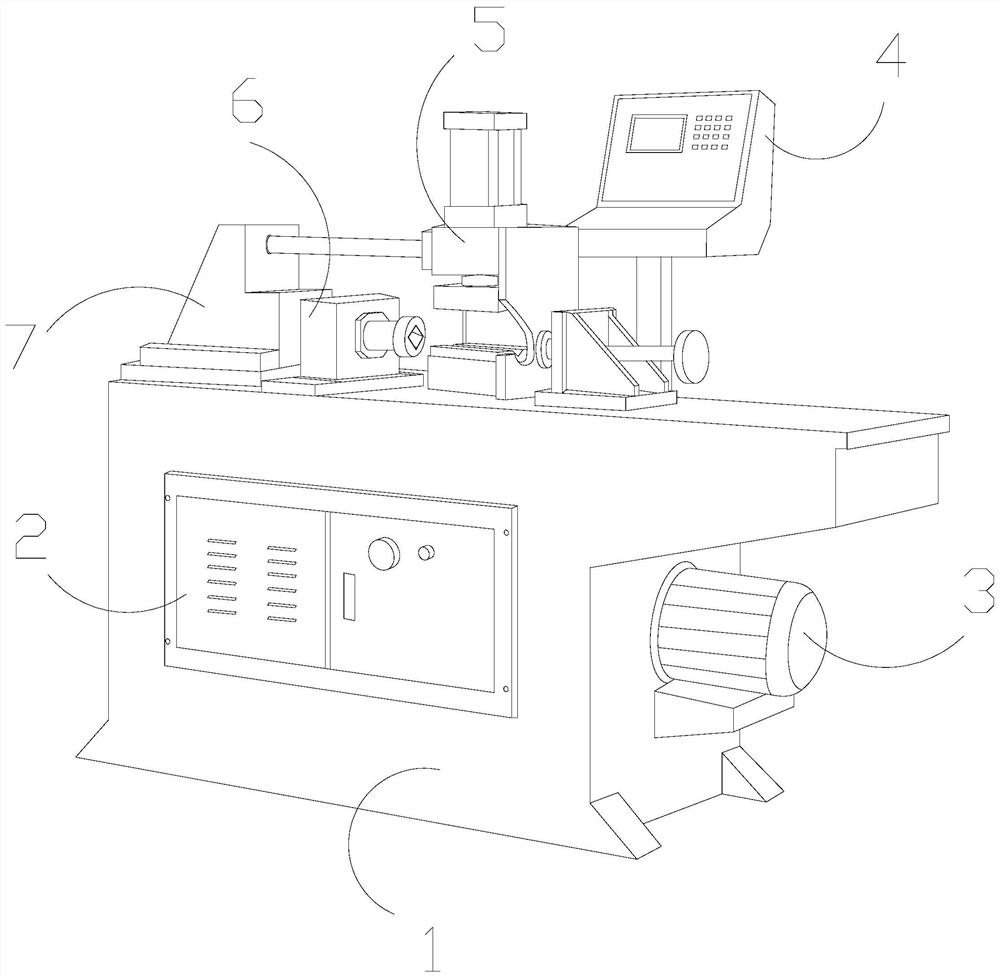

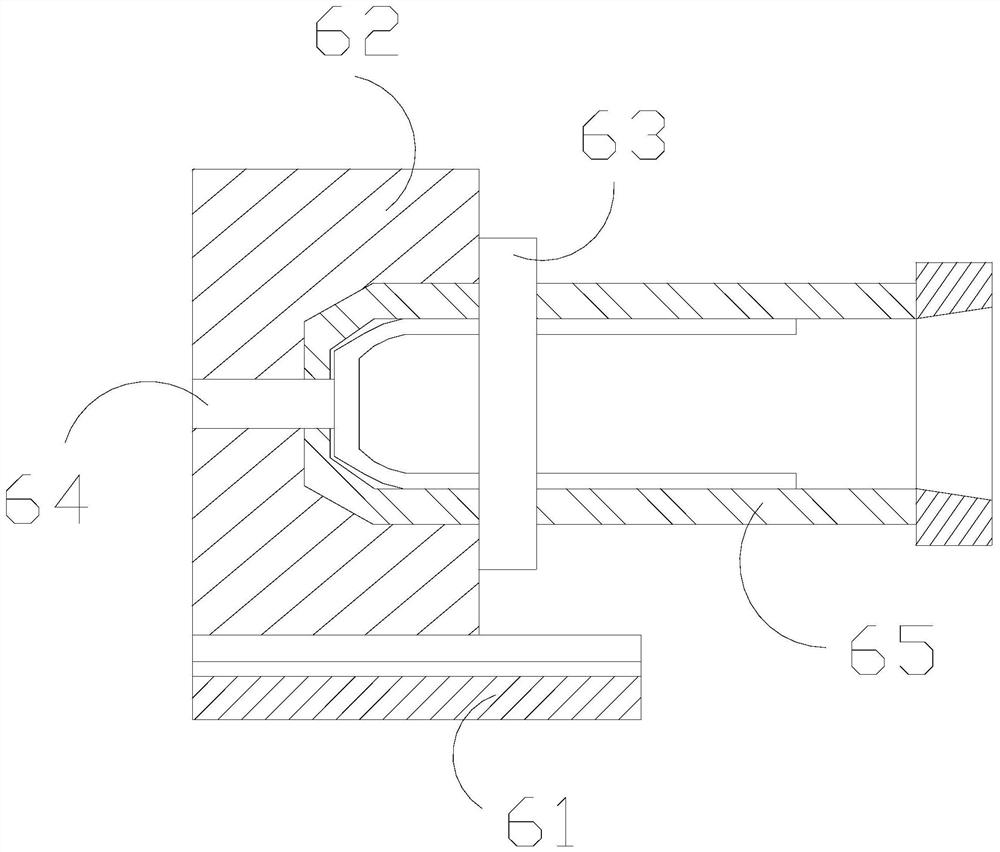

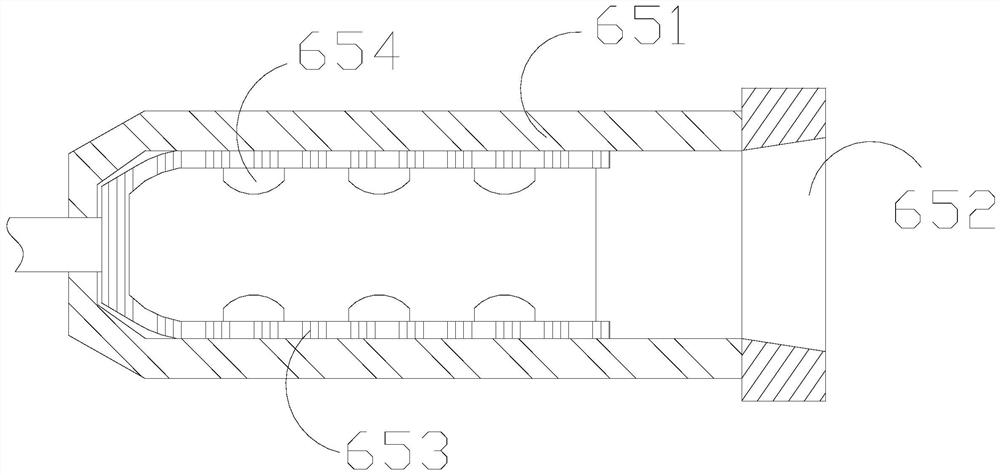

Square pipe joint necking machine

The invention discloses a square pipe joint necking machine. The square pipe joint necking machine is structurally provided with a machine body, a control door, a motor, an adjusting table, a pressingframe, a necking device and a rear driving table, wherein in a clamping process for a pipe joint, an extrusion force is exerted on an elastic ejection device, an ejection body retracts towards the interior of a side ring cavity, and the pipe joint to be necked can make contact with a square necking die conveniently; the elastic ejection device is not subjected to the extrusion force of the pipe joint, and is ejected to the front side end of the square necking die while carrying out concave bending deformation under the springing of spring steel, so that residual chippings are sprung and ejected off, the chippings are prevented from being adhered and accumulated on the wall surface of the square necking die, and after the chippings are ejected off, the necking body is rotated, and the chippings are thrown to a contact port; and a one-way door is extruded to be opened towards the interior of an inner groove chamber, the chippings fall into the inner groove chamber and are collected, then the chippings fall into the bottom of the inner groove chamber through holes in a middle clamping plate and are firmly stuck by a bottom sticking strip, and therefore the situation that in the rotating process, the one-way door is continuously opened and closed, and the chippings fall out is avoided.

Owner:北京亮祥教育咨询有限公司

Double-pass double-liquid heat exchange device

InactiveCN104697368AAvoid damageSmooth circulationCorrosion preventionHeat exhanger sealing arrangementEngineeringTemperature difference

The invention discloses a double-pass double-liquid heat exchange device and aims to provide a heat exchange device which can effectively realize heat exchange between two liquid, has the temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged caused by overlarge temperature difference stress between the shell and the heat exchange tubes. The double-pass double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; the inner part of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity through a tube pass flow isolation plate; an expansion joint is arranged on the tube box. The double-pass double-liquid heat exchange device has the benefits that through the characteristic that the deformation of the expansion joint is relatively easy and in cooperation with the slideable sealing head tube plate, a structural temperature difference compensation function can be realized, and the structure damage caused by overlarge temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Tube-shell type double-liquid heat exchange device

InactiveCN104654834AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type double-liquid heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type double-liquid heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Traditional Chinese medicine decoction piece crushing process and device thereof

The invention discloses a traditional Chinese medicine decoction piece crushing process and device thereof in the technical field of traditional Chinese medicine decoction piece crushing. The traditional Chinese medicine decoction piece crushing process comprises the following steps that 1, decoction pieces are placed on a partition plate, a sealing block is manually pushed aside to enable the decoction pieces to enter a telescopic bent pipe along a drainage notch and flow into a filter barrel, and then the sealing block is sealed. According to the traditional Chinese medicine decoction piece crushing process and the device thereof, when the decoction pieces are crushed by a filter box, a swing mechanism can swing and shake the filter barrel while a blade is rotated at a high speed for crushing, so that the crushed medicine powder can flow out of the filter barrel, the appropriate space is guaranteed when the decoction pieces in the filter barrel are crushed and shaken, the slices which are not cut and crushed can be quickly moved to the position where the slices can be crushed under the action of shaking, then the problem that the decoction pieces distributed on the upper side and the lower side of the blade cannot be moved to the position of the crushing blade in time, and consequently the decoction pieces cannot be cut is solved, the uniformity of crushing of the decoction pieces is guaranteed, and the crushing effect is improved.

Owner:谭姜媛

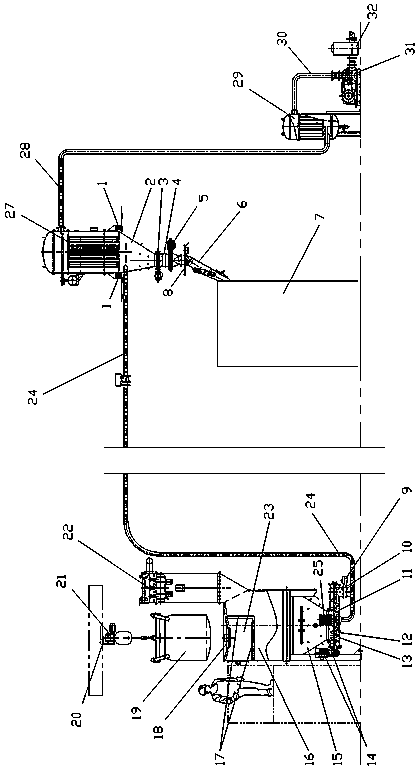

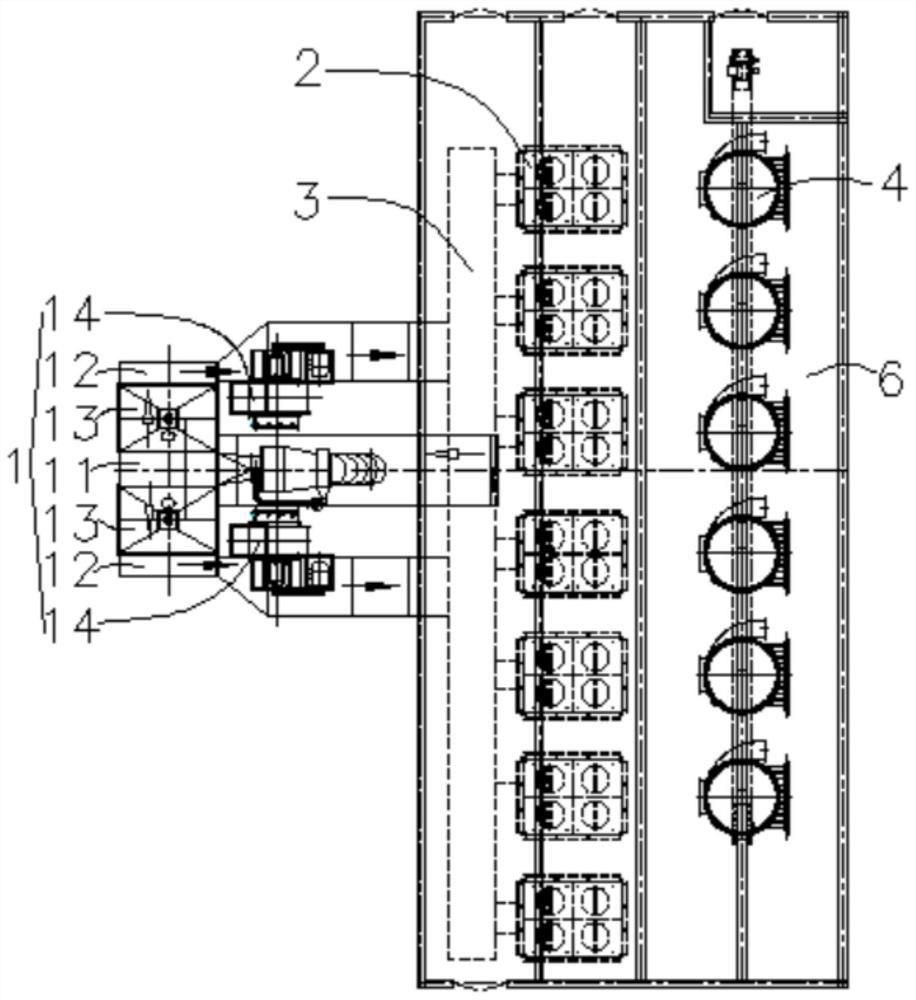

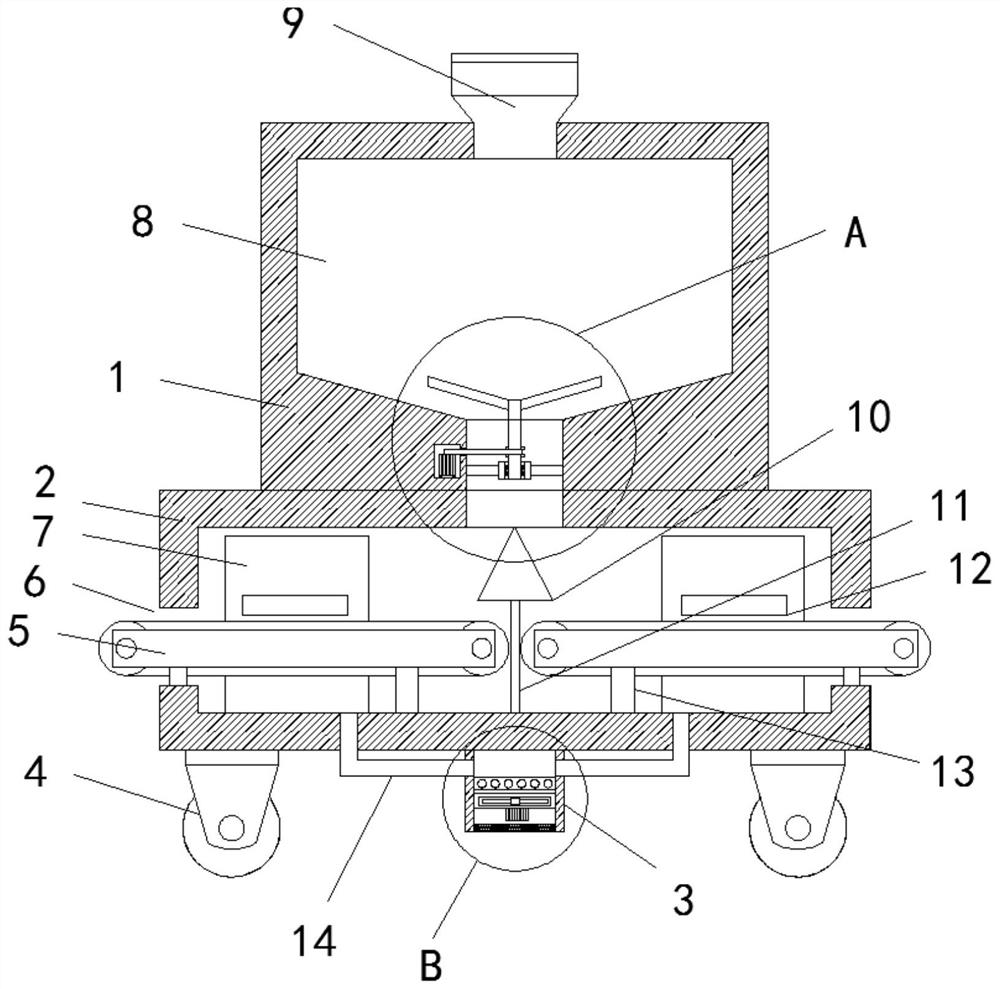

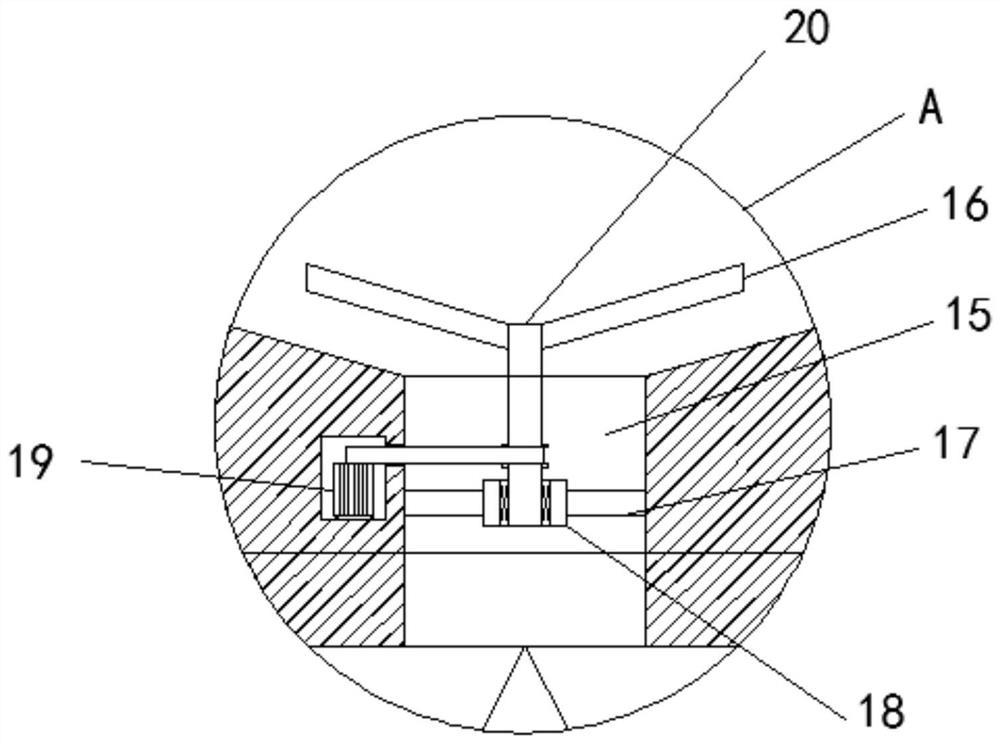

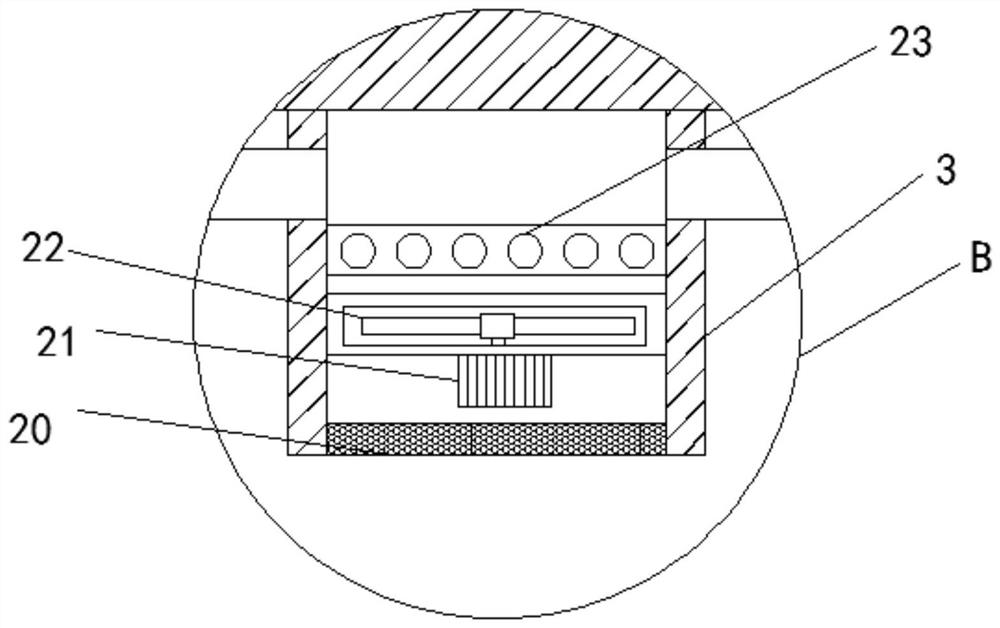

Automatic weighing and batching system for carbon black powder

PendingCN107812456AGuaranteed pollutionNo pollution in the processTransportation and packagingMixer accessoriesReduction driveFiltration

The invention relates to an automatic weighing and batching system for carbon black powder. A pneumatic sieve is arranged at the inner side of a material loading hopper and at the entrance of the upper edge, and the upper part of the material loading hopper is connected with a dust recycling device; a material unloading hopper is connected with the lower edge of the material loading hopper, the lower end of the material unloading hopper is connected with a horizontally arranged feeding cylinder, a spindle provided with a material pushing blade is arranged at the inner side of the feeding cylinder, one end of the spindle extends from one end of the feeding cylinder and then is connected with an output shaft of a feeding motor reducer, and the other end of the feeding cylinder is connected with a first pipeline by virtue of a discharging valve; one end of the first pipeline is connected with a filtration piece, the other end of the first pipeline is communicated with the inner cavity ofa metering hopper, and the metering hopper is supported on a platform by virtue of a pressure sensor; an upper opening of the metering hopper is connected with a roots fan by virtue of a filter; an outlet at the lower end of the metering hopper is connected with the upper end of a hose by virtue of a first valve, the lower end of the hose is connected with one end of a feeding pipe by virtue of asecond valve and a vibrating valve, and the other end of the feeding pipe is connected with an internal mixer; and a crane is arranged above the entrance of the upper edge of the material loading hopper. The automatic weighing and batching system for the carbon black powder has the advantages that both time and labor are saved, efficiency is high, labor intensity is low, and no pollution is produced.

Owner:大连第二橡塑机械有限公司

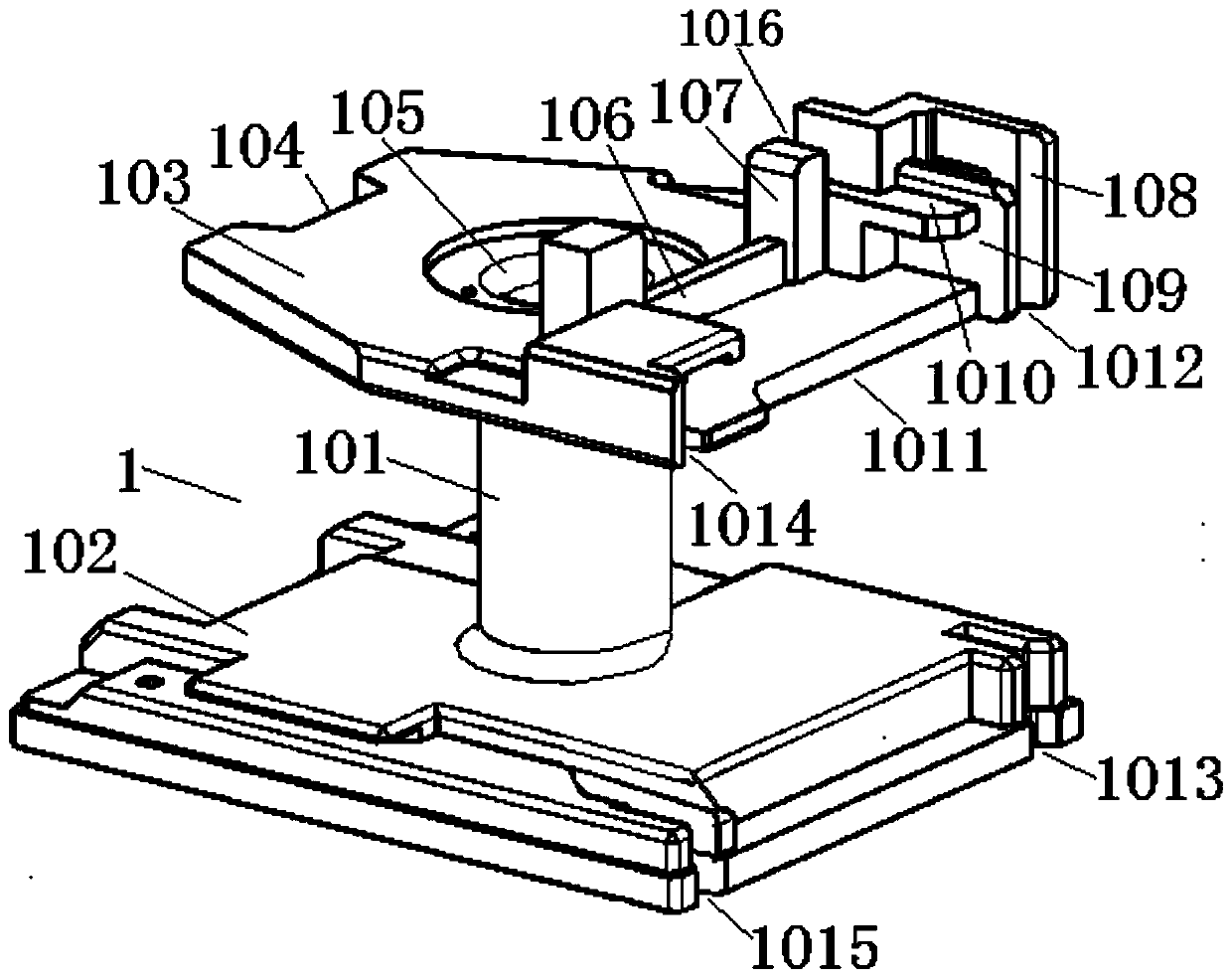

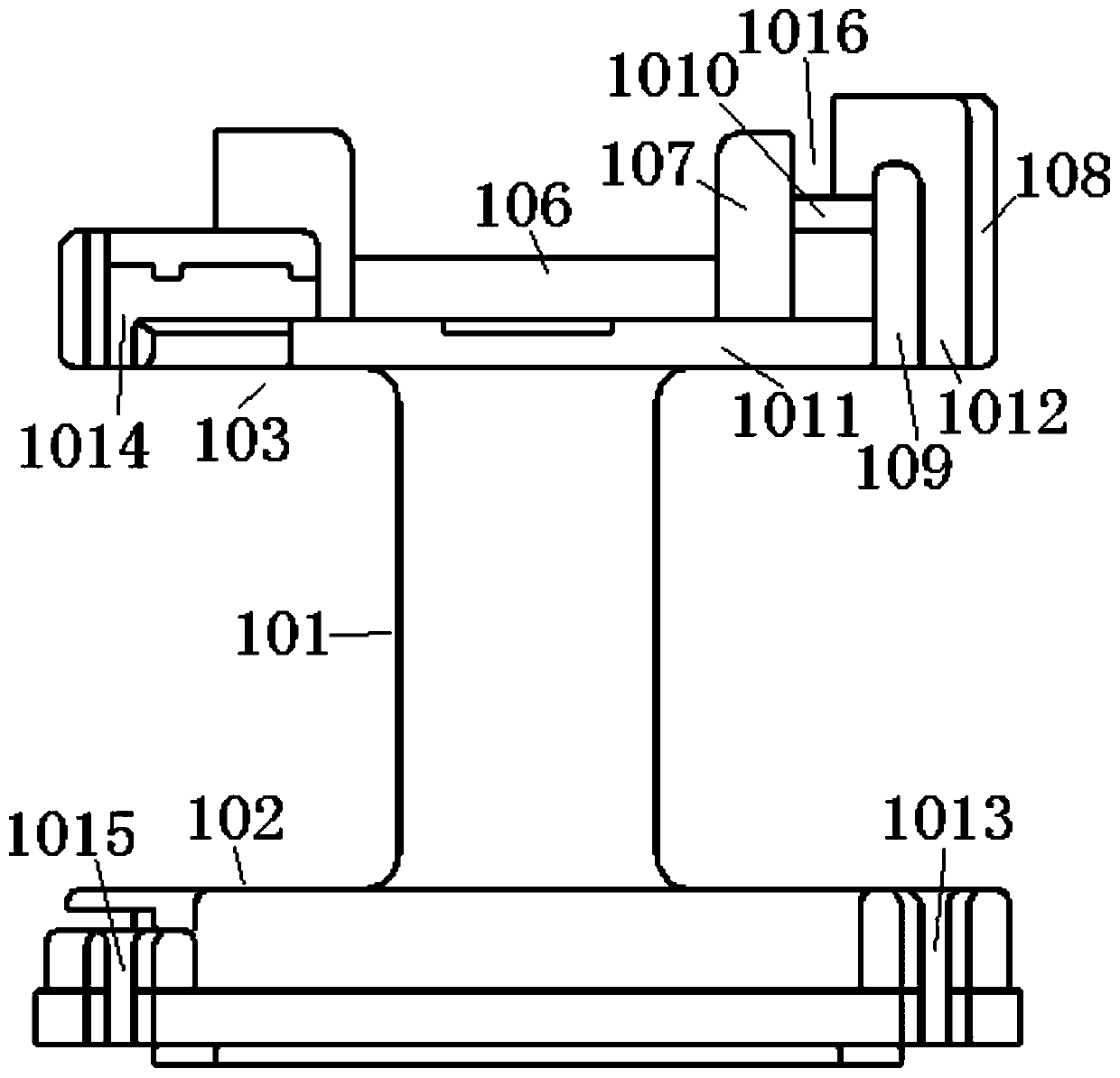

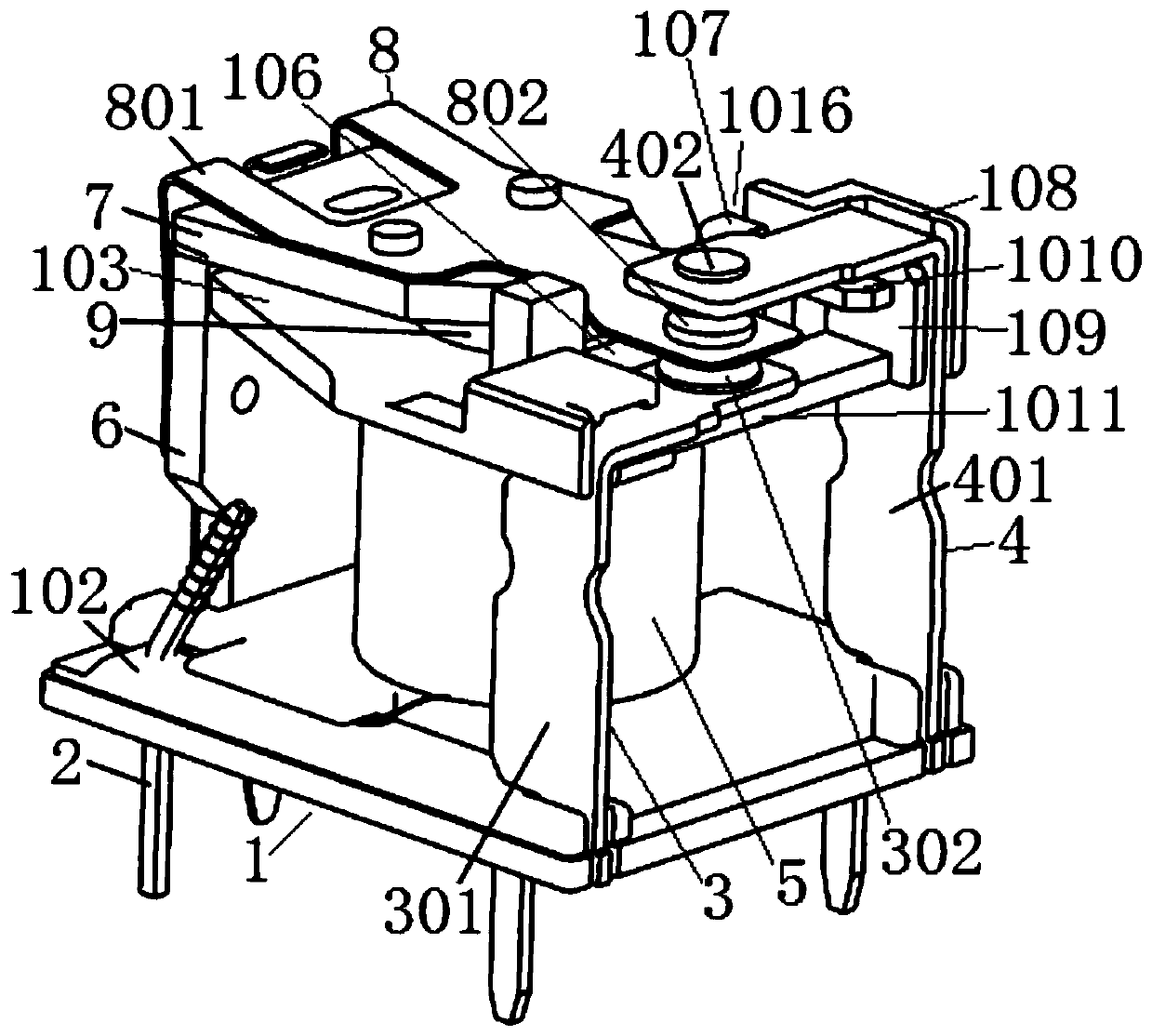

Coil frame for clapper-type relay and clapper-type relay

PendingCN110444445ADoes not affect peripheral contour dimensionsStable Embedded FixationElectromagnetic relay detailsBobbinEngineering

The invention discloses a coil frame for a clapper-type relay and a clapper-type relay. The coil frame comprises a bobbin, and a first coil baffle and a second coil baffle located at two ends of the bobbin, wherein the top of the second coil baffle is provided with a contact fitting area between a static spring part and a moving spring part; the outer edge of the second coil baffle at the contactfitting area is provided with a concave flow guiding notch; and during the assembly structure with a relay shell, the second coil baffle and the corresponding part on the inner wall of the shell forma flow guiding channel through the flow guiding notch. When the coil frame is applied to the clapper-type relay, accumulation of contact splashes between the moving contact and the static contact in the contact fitting area to form a via conductor can be effectively prevented, and the relay can be ensured to work stably and safely for a long time.

Owner:SICHUAN HONGFA ELECTROACOUSTIC

Dead-angle-free production allocation machine

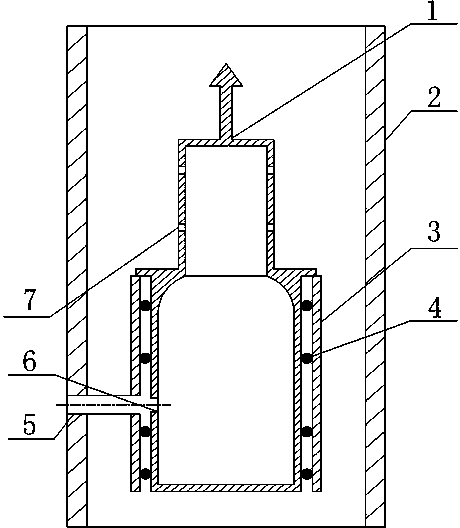

InactiveCN103470230AEliminate cloggingPrevent Adhesive BuildupFluid removalViscosityPetroleum engineering

The invention discloses a dead-angle-free production allocation machine which comprises a barrel (2), at least one oil outlet pipe (5), a center pipe (3) and a blanking plug (1). The center pipe (3) is arranged in the barrel (2) and is connected with the inner wall of the barrel (2), the lower end of the blanking plug (1) is arranged in the center pipe (3), at least one oil inlet (6) is formed in the lower portion of the blanking plug (1), a plurality of oil outlets (7) are formed in the upper portion of the blanking plug (1), and an arc surface is arranged on the upper portion of the inner wall of an oil inlet cavity of the blanking plug (1). The dead-angle-free production allocation machine with the structure has the advantages that dead angles of current-layer oil gas on the upper portion of the oil inlet cavity can be eliminated when the current-layer oil gas flows in the blanking plug (1), high-viscosity components in the oil gas can be prevented from being adhered and accumulated in the dead angles, can drop under the vibration effects of production pipes and then are fed into an oil outlet cavity along with the current-layer oil gas, and accordingly the oil outlets (7) can be prevented from being blocked by fluid which turns viscous suddenly.

Owner:CHENGDU KESHENG PETROLEUM TECH

Double-pass double-liquid heat exchange device

InactiveCN104697368BAvoid damageSmooth circulationCorrosion preventionHeat exhanger sealing arrangementTemperature differenceEngineering

The invention discloses a double-pass double-liquid heat exchange device and aims to provide a heat exchange device which can effectively realize heat exchange between two liquid, has the temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged caused by overlarge temperature difference stress between the shell and the heat exchange tubes. The double-pass double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; the inner part of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity through a tube pass flow isolation plate; an expansion joint is arranged on the tube box. The double-pass double-liquid heat exchange device has the benefits that through the characteristic that the deformation of the expansion joint is relatively easy and in cooperation with the slideable sealing head tube plate, a structural temperature difference compensation function can be realized, and the structure damage caused by overlarge temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

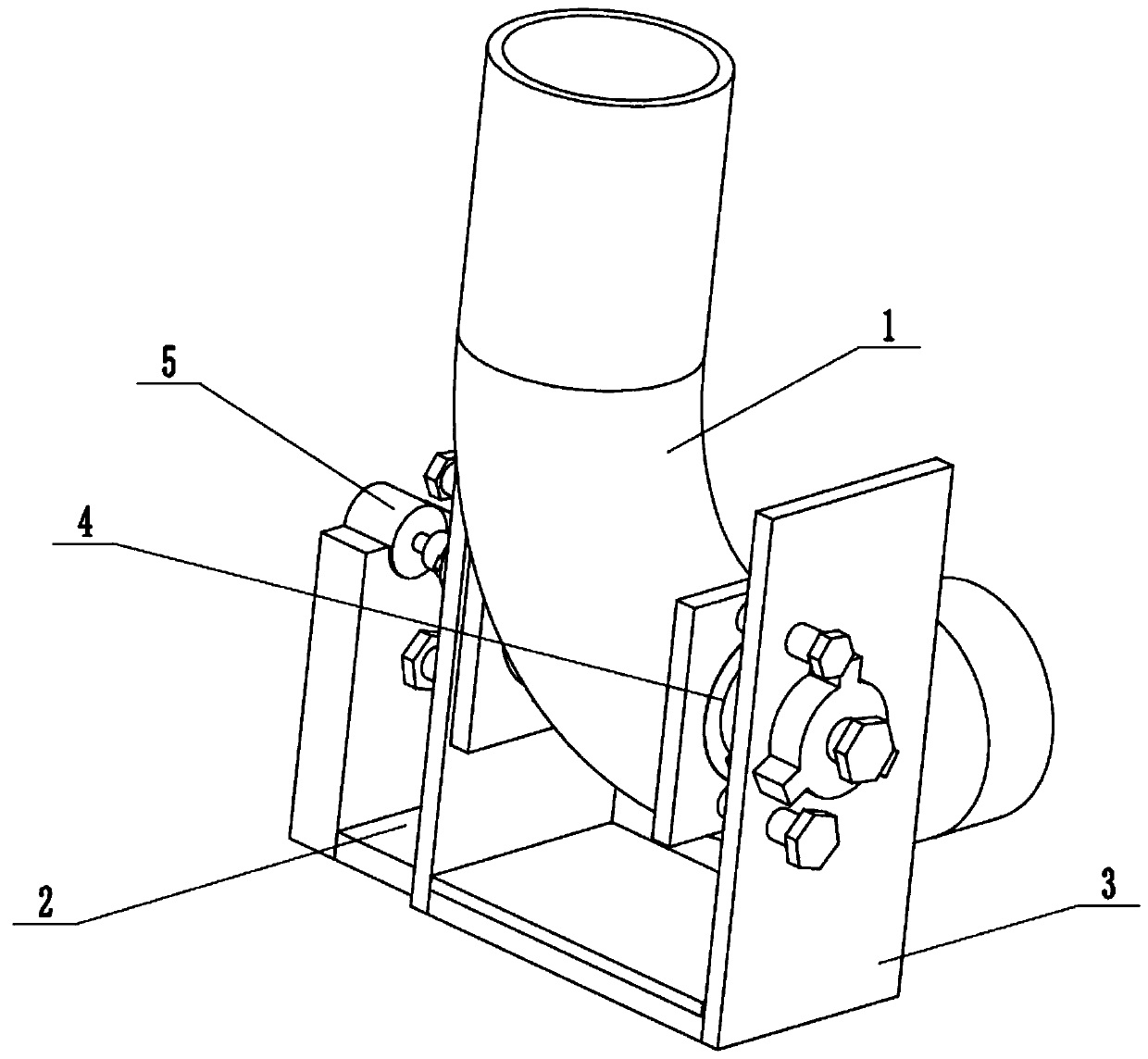

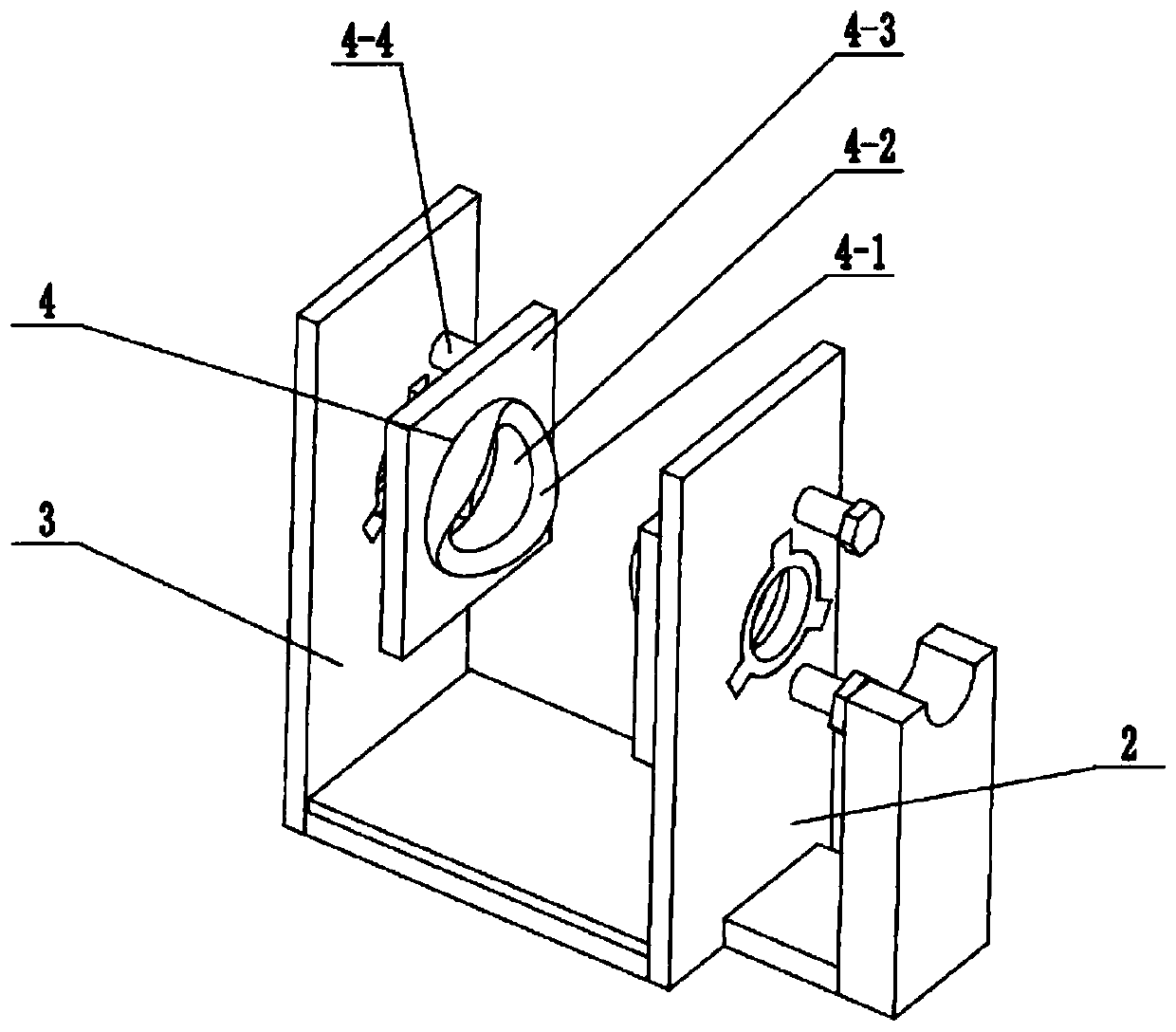

Snake-shaped wellhead viscosity reduction device based on coupling effect

PendingCN110822289APrevent Adhesive BuildupEasy to install and removeEngine sealsPipeline systemsMotive powerViscosity

The invention relates to the field of crude oil viscosity reduction, in particular to a snake-shaped wellhead viscosity reduction device based on coupling effect. The device comprises a coiled pipe bending pipe, a right propulsion fixing base, a left propulsion fixing base, two sealing seats, a propulsion driver and a driving regulator; and the left propulsion fixing base is connected to the rightpropulsion fixing base in a sliding mode, the two sealing seats are connected to the left propulsion fixing base and the right propulsion fixing base in a threaded fit mode correspondingly, the innerends of the two sealing seats are attached to the coiled pipe bending pipe, and the right end of the propulsion driver is fixedly connected to the right propulsion fixing base. The snake-shaped wellhead viscosity reduction device based on the coupling effect has the beneficial effects that crude oil can be scattered and propelled at the bending position of a snake-shaped pipeline where the crudeoil is prone to accumulate, so that the situation that the crude oil transportation is influenced due to the fact that the crude oil adheres and accumulates at the bending position of the snake-shapedpipeline is prevented; and installation and disassembly are extremely convenient, and the device can be used for carrying out relay type propulsion on the crude oil in the snake-shaped pipeline, so that crude oil blockage caused by insufficient transportation power is prevented.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

A shell and tube heat exchanger

InactiveCN104634138BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:中山市斯坦尼化工机械有限公司

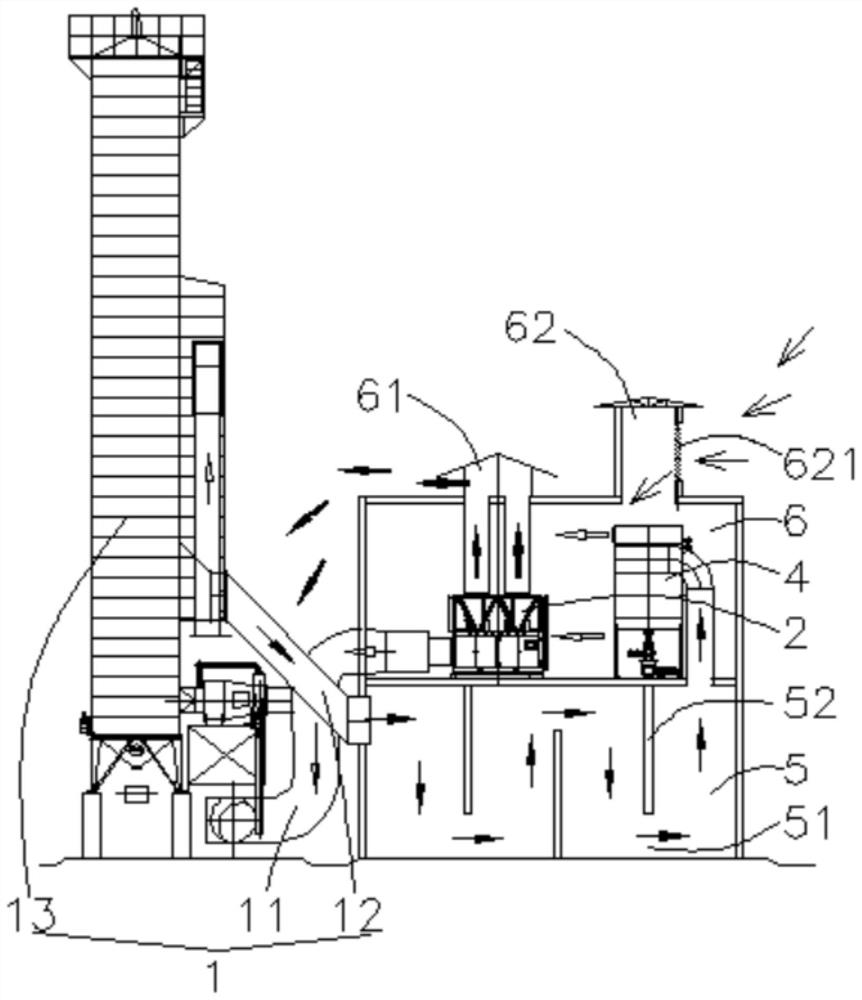

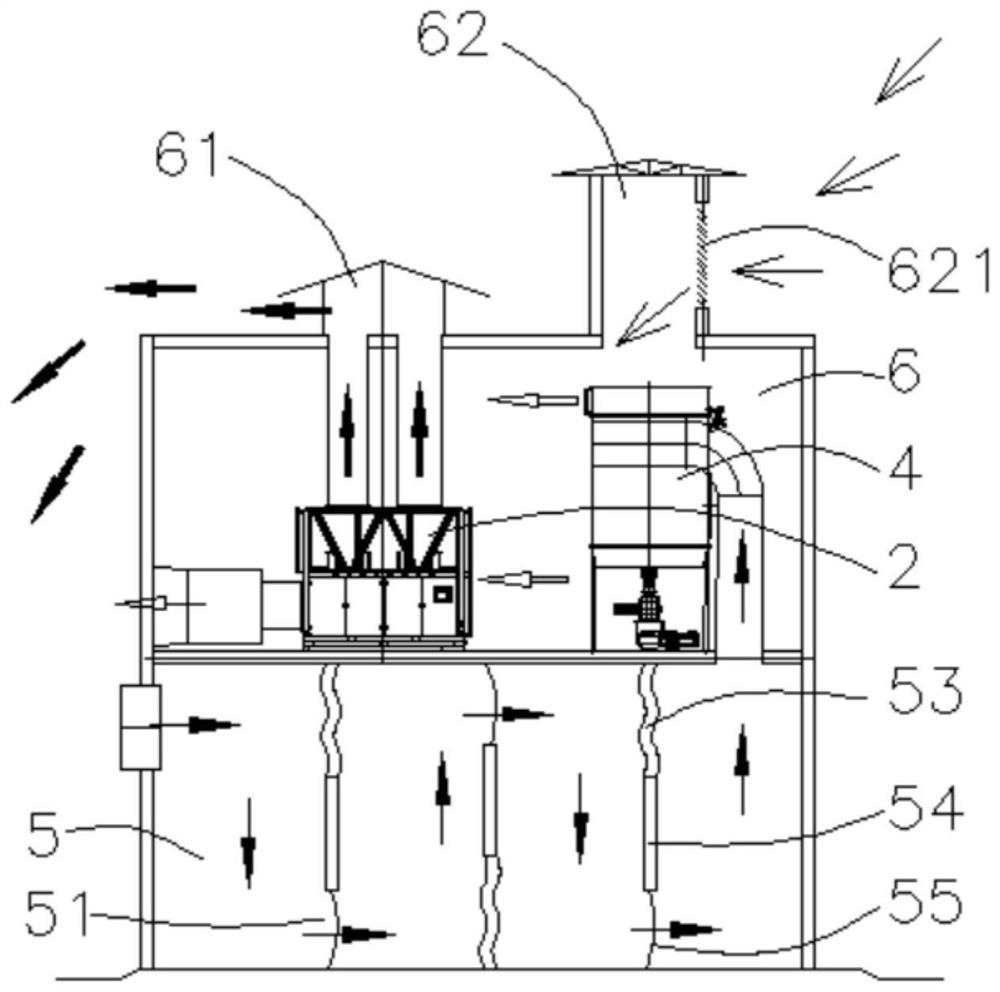

Continuous grain heat pump drying system

PendingCN113639547AAvoid enteringImprove heat utilizationFood processingClimate change adaptationCold airThermodynamics

The invention belongs to the technical field of grain drying equipment, and particularly relates to a continuous grain heat pump drying system. The system comprises a dryer, a plurality of air energy heat pumps, a main hot air pipe, a pulse dust collector, a settling chamber and a hot air room. The hot air room is arranged above the settling chamber, an air inlet of the pulse dust collector communicates with the upper portion of the settling chamber, an air outlet of the pulse dust collector communicates with the hot air room, the air energy heat pumps are arranged in the hot air room, and hot air outlets of the plurality of air energy heat pumps all communicate with the main hot air pipe. A hot air outlet of the main hot air pipe communicates with a hot air channel of the dryer, and a waste gas channel of the dryer communicates with the settling chamber. The hot air room is provided with an exhaust air cap and an air supply air cap which communicate with the outside, the exhaust air cap communicates with cold air outlets of the air energy heat pumps, the air supply air cap communicates with the hot air room, and an air inlet of the air supply air cap is higher than a cold air outlet of the exhaust air cap.

Owner:TSZJANSU CHZHEHNCHAN SIRIEHL OIL EHND FID MASHINERI KO

Double-liquid heat exchange device

InactiveCN104654831AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectTemperature difference

The invention discloses a double-liquid heat exchange device and aims at providing a heat exchange device which can effectively realize heat exchange between two kinds of liquid, has a temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged due to excessive large temperature difference stress. The double-liquid heat exchange device comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the shell pass portion comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube, the heat exchanger shell body consists of a seal head, a shell head and a tube box, a fixing tube plate is arranged between the shell head and the tube box, a seal head tube plate is arranged between the seal head and the tube box, a tube pass flow isolating plate divides the internal portion of the shell head into a tube pass flow inlet chamber and a tube pass flow outlet chamber, and an expansion joint is arranged on the tube box. The double-liquid heat exchange device has the beneficial effects that a structural temperature difference compensation effect can be achieved through the characteristic of relatively easy deformation of the position of the expansion joint in combination with the slidable seal head tube plate, and structural damage is prevented from being caused due to excessively large temperature difference stress.

Owner:CHINA JILIANG UNIV

Drying device for composite plastic particles

InactiveCN111844515AAvoid incomplete dryingImprove drying efficiencyDrying solid materialsParticle packingDry box

The invention relates to a drying device for composite plastic particles. The drying device comprises a device main body, a drying box, a heating device and traveling wheels, wherein the device main body is arranged above the drying box; the traveling wheels are arranged at four corners of the bottom surface of the drying box; and an aggregate cavity is formed in the device main body. According tothe drying device for the composite plastic particles, a distributing block is arranged below a leakage hole and can disperse materials in the leakage hole, so that incomplete drying caused by plastic particle accumulation is avoided, and therefore, the drying efficiency is greatly improved; and the rear side of a conveying device is provided with a uniform heat box, a heat outlet of the uniformheat box is flush with the upper surface of the conveying device, and due to the design, the drying speed of the plastic particles is greatly improved, waste of heat is avoided, and energy consumptionis reduced.

Owner:江苏腾越新材料科技有限公司

Shell and tube heat exchanger

InactiveCN104613794BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a shell-and-tube heat exchanger and aims to a heat exchanger, which allows effective heat exchange between two liquids, which allows thermal difference compensation and which prevents damage caused by high thermal difference between a housing and heat exchange tubes. The shell-and-tube heat exchanger comprises a tube side portion, a shell side portion and a plurality of supports; the tube side portion comprises a tube side inlet tube, a tube side outlet tube and a plurality of heat exchange tubes; the shell side portion comprises a shell, a shell side inlet tube and a shell side outlet tube; the shell is composed of a sealing head, a shell head and a tube box; a fixing tube plate is disposed between the shell head and the tube box; a sealing head tube plate is disposed between the sealing head and the tube box; a tube side partition plate divides the inside of the shell head into a tube side inflow cavity and a tube side outflow cavity; the tube box is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the expansion joint which easily deforms and the sealing head tube plate are used together to function in structural thermal difference compensating, and structural damage caused by high thermal difference stress is avoided.

Owner:佛山市顺德区华名新能源科技有限公司

a heat exchanger

InactiveCN104764347BAvoid damageSmooth circulationPipeline expansion-compensationCorrosion preventionPlate heat exchangerTemperature difference

The invention discloses a heat exchanger. The heat exchanger can effectively realize the heat exchange between two fluids, and has the temperature difference compensating ability, and can prevent the damage caused by too big temperature difference stress between a shell body and a heat exchange pipe. The heat exchanger comprises a tube pass part, a shell pass part, and several brackets; the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube, and a plurality of heat exchange tubes; the shell pass part includes an outer shell body of the heat exchanger, a shell pass inlet tube, and a shell pass outlet tube; the outer shell body of the heat exchanger is composed of an enclosure head, a shell head and a tube box; a fixing tube plate is arranged between the shell head and the tube box, and an enclosure head tube plate is arranged between the enclosure head and the tube box; a tube pass flow isolating plate partitions the inner part of the shell body into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The heat exchanger has the following beneficial effects: through the characteristics of relatively easy deformation of the expansion joint, and cooperation of the slideable enclosure tube plate, the heat exchanger can play a role of structural temperature compensation, and avoid the structural damage caused by too big temperature difference stress.

Owner:CHINA JILIANG UNIV

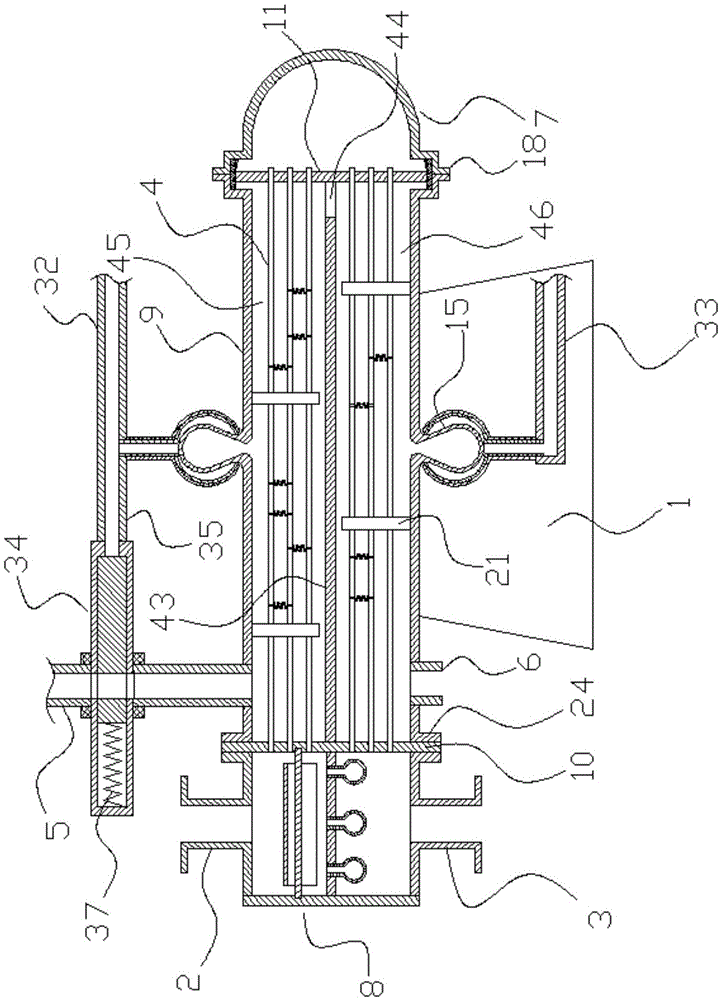

A device for treating low-concentration refractory organic industrial wastewater

ActiveCN105016534BImprove oxidation capacityIncrease concentrationMultistage water/sewage treatmentFiltrationCatalytic oxidation

The invention discloses a device for treating low-concentration refractory organic industrial wastewater. Ozone enters the second cavity through the membrane wall of the inner filter element; at the same time, the macromolecules contained in the sewage and the small molecular organic substances existing in a multi-molecular aggregation state enter with the sewage. After the second cavity, it is intercepted and concentrated by the outer filter element; the concentrated organic matter reacts with ozone to form small molecular inorganic matter; while a single small molecular organic matter in the sewage meets and reacts with ozone when passing through the membrane wall of the outer filter element to form small molecular inorganic matter The ozone in the sewage and the unoxidized organic matter enter the filter cartridge and continue to react to form small molecular inorganic substances; the treated sewage overflows from the high level of the filter cartridge to the middle water pool, and the remaining ozone enters the ozone destroyer through the exhaust pipe Then discharged into the atmosphere. On the basis of inheriting the advantages of the filtration method and the ozone catalytic oxidation method, the present invention overcomes the disadvantages of the filtration method and the ozone catalytic oxidation method, and makes the advanced treatment of low-concentration refractory organic industrial wastewater possible.

Owner:TAISHAN MEDICAL UNIV

A shell and tube heat exchanger

InactiveCN104634141BAvoid damageSmooth circulationCorrosion preventionHeat exchanger casingsShell and tube heat exchangerPlate heat exchanger

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

A chemical heat exchanger

InactiveCN104596323BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectCompound (substance)

The invention discloses a chemical engineering heat exchanger and aims to provide a heat exchanger which can effectively realize heat exchange between two liquors, has capability of temperature difference compensation and can be prevented from being damaged due to excessively large temperature difference stress between a shell and heat exchange tubes. The chemical engineering heat exchanger comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and the plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell body comprises a seal head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a seal head tube plate is arranged between the seal head and the tube box; a tube pass flow baffle is used for dividing the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The chemical engineering heat exchanger has the benefits that a structural temperature difference compensation effect can be achieved in combination with the slidable seal head tube plate based on a characteristic of easiness for deformation at the expansion joint, and structural damage caused by excessively large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Shell-and-tube double-liquid heat exchange device

InactiveCN104654834BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type double-liquid heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type double-liquid heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

A shell-and-tube heat exchanger

ActiveCN104613793BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesTemperature stressPlate heat exchanger

The invention discloses a tube-and-shell heat exchanger and aims to provide a heat exchanger, allowing effective heat exchange between two liquids, having thermal difference compensating capacity and preventing damage caused by thermal difference stress between a shell and heat exchange tubes. The tube-and-shell heat exchanger comprises a tube side portion, a shell side portion and a plurality of supports; the tube side portion comprises a tube side incoming tube, a tube side outgoing tube and a plurality of heat exchange tubes; the shell side portion comprises a housing, a shell side incoming tube and a shell side outgoing tube; the housing is composed of a seal head, a shell head and a tube box; a fixing tube plate is disposed between the shell head and the tube box; a seal head tube plate is disposed between the seal head and the tube box; a tube side partition plate divides the inside of the shell head into a tube side inflow cavity and a tube side outflow cavity; the tube box is provided with an expansion joint. The tube-and-shell heat exchanger has the advantages that the expansion joint featuring ease of deformation and the seal head tube plate slidable fit to function in structural thermal difference compensation, and structural damage caused by excessively high thermal temperature stress is avoided.

Owner:枣庄科顺数码有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com