Drying device for composite plastic particles

A technology of composite plastics and drying equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., and can solve problems such as low efficiency, low work efficiency, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

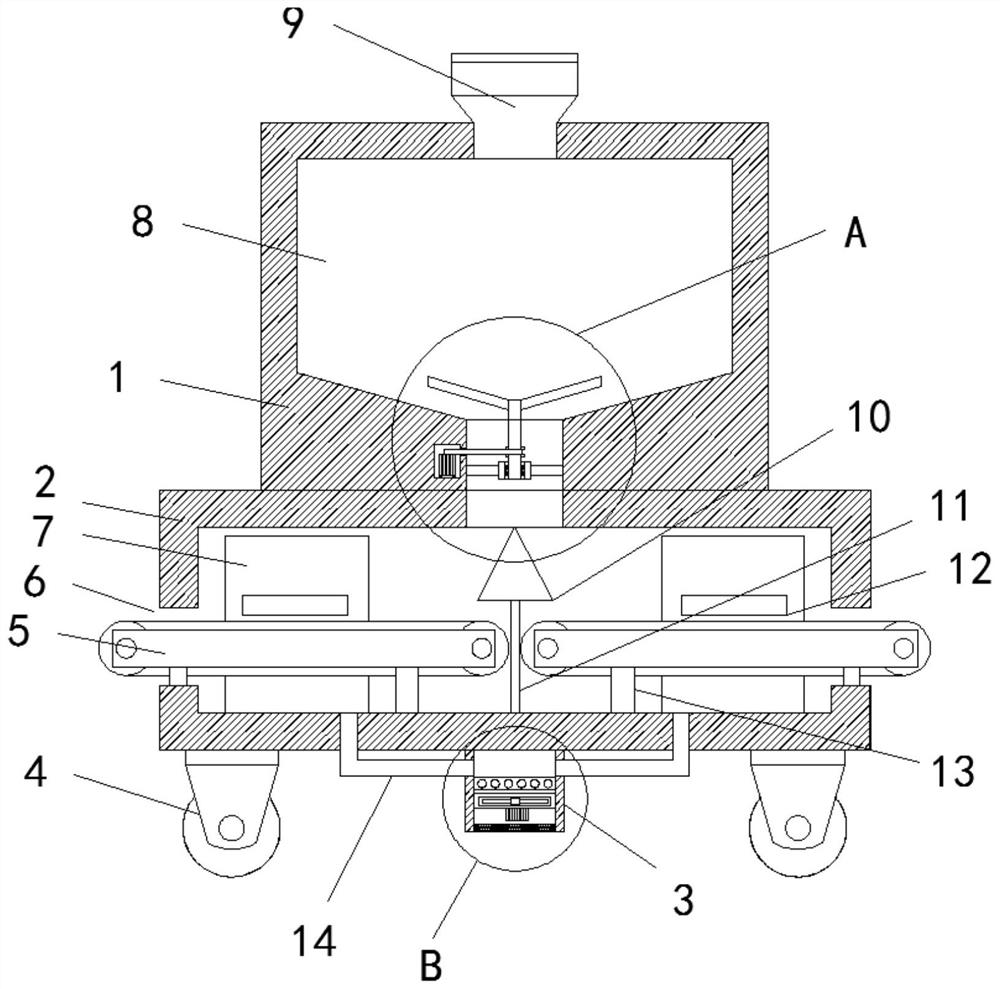

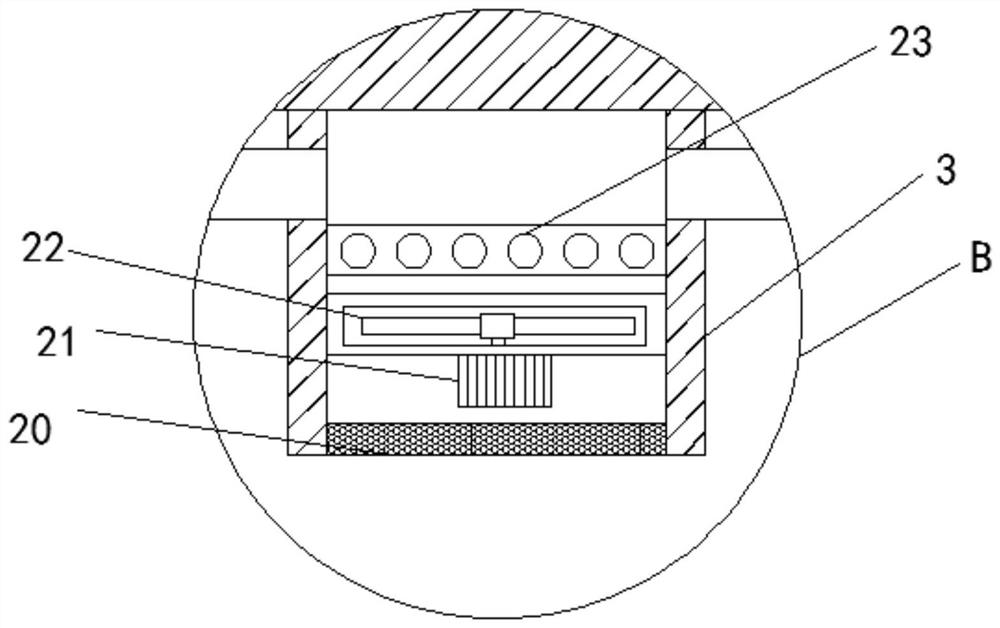

[0022] As a preferred embodiment of the present invention, the inside of the heating device 3 is provided with an exhaust fan 22, the input end of the exhaust fan 22 is connected to the output end of the motor 21, and an electric heating plate is arranged above the exhaust fan 22. 23. A filter screen 20 is provided below the exhaust fan 22, and the mesh diameter of the filter screen 20 is 5-10mm.

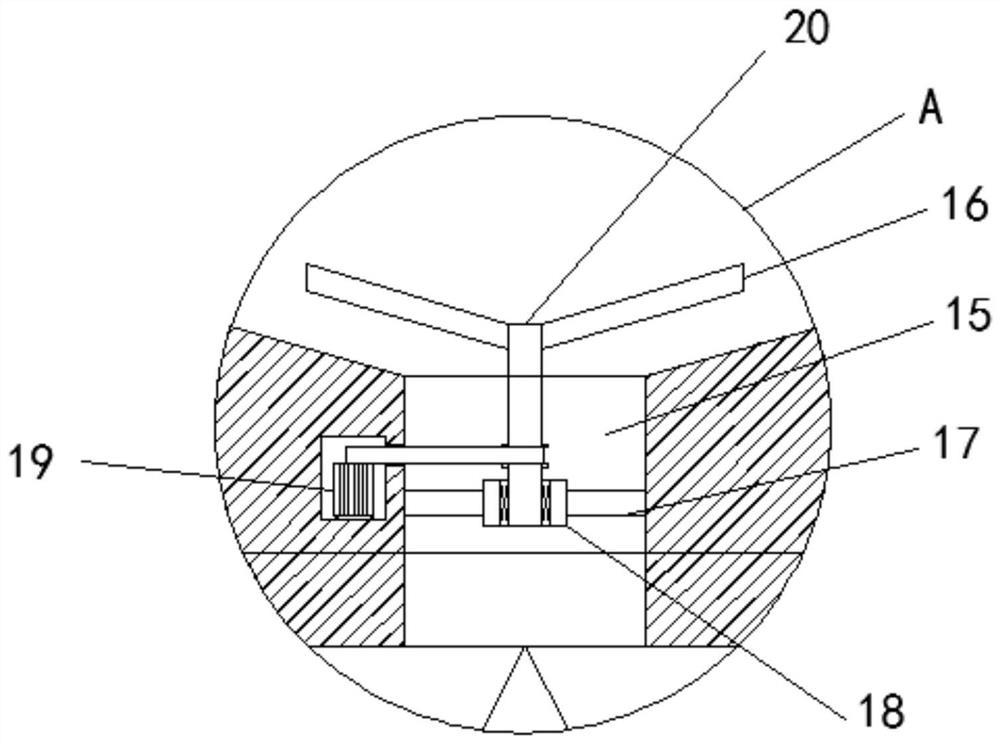

[0023] As a preferred embodiment of the present invention, a bearing seat 18 is provided in the middle of the leakage hole 15, and the two sides of the bearing seat 18 are fixedly connected to the inner wall of the leakage hole 15 through the bracket 17. On the bearing seat 18 A rotating shaft 20 is rotatably connected, and a stirring rod 16 is fixed on both sides of the upper end of the rotating shaft 20. The inner bottom surface of the device main body 1 is provided with a driving motor 19, and the output end of the driving motor 19 is connected to the tooth groove of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com