Patents

Literature

60results about How to "Avoid incomplete drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drying control method and device and drying apparatus

ActiveCN110438780AAvoid incomplete dryingTextiles and paperLaundry driersDelay DurationProcess engineering

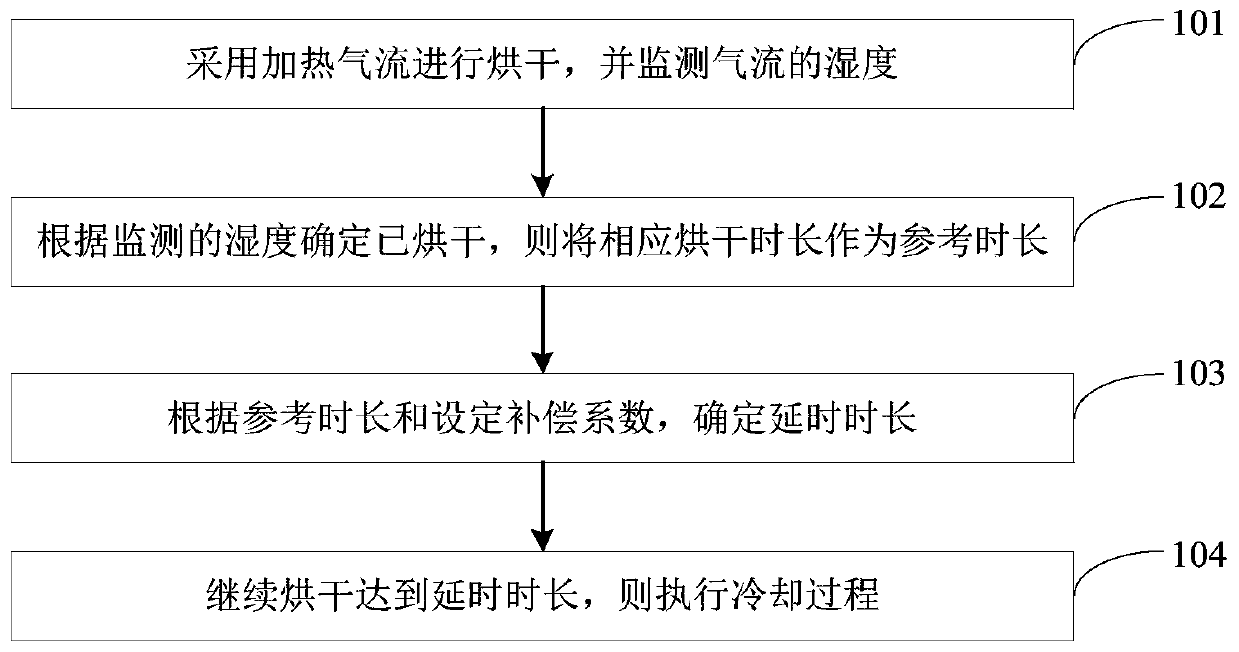

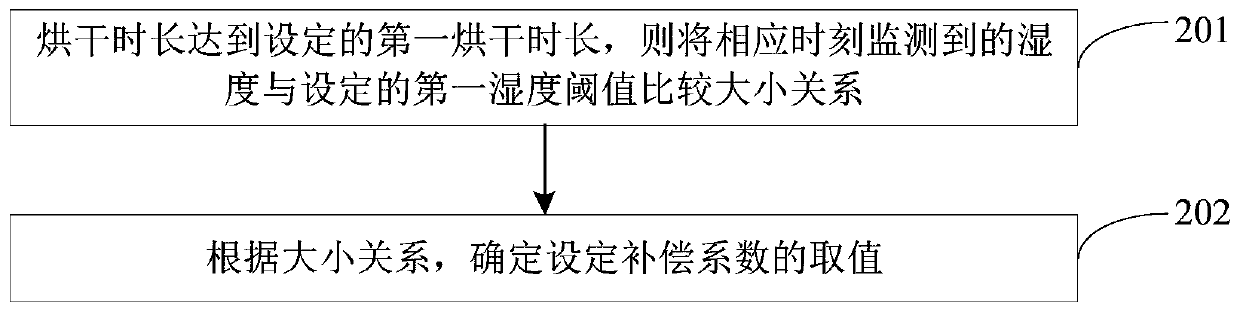

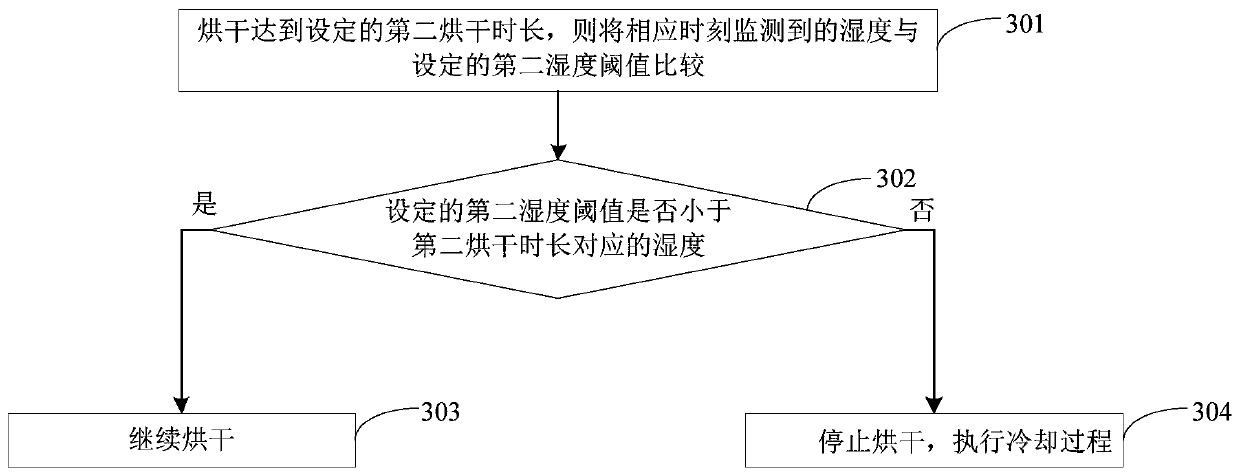

The application provides a drying control method and device and a drying apparatus, wherein the drying control method comprises: drying with heated flows of air, monitoring humidity of the flows of air, using a corresponding drying duration as a reference duration when determining completion of drying according to the monitored humidity, determining a delay duration according to the reference duration and a set compensation coefficient, continuing to perform drying, and executing a cooling process if the delay duration is up. According to the drying control method, the delay duration is determined according to the drying duration upon the completion of drying and the set compensation parameter, the drying apparatus is controlled to continue to perform drying until the delay duration is up,and clothes can be dried thoroughly; compared with the prior art wherein whether to stop drying is judged only by depending on whether humidity detected by a humidity sensor reaches a certain fixed level, the drying control method takes into consideration the fact that clothes with different weights require different durations during drying and the fact that differences of humidity occur in a drying drum; the drying control method allows the delay duration of drying to be controlled dynamically, so that clothes are never dried incompletely after drying.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

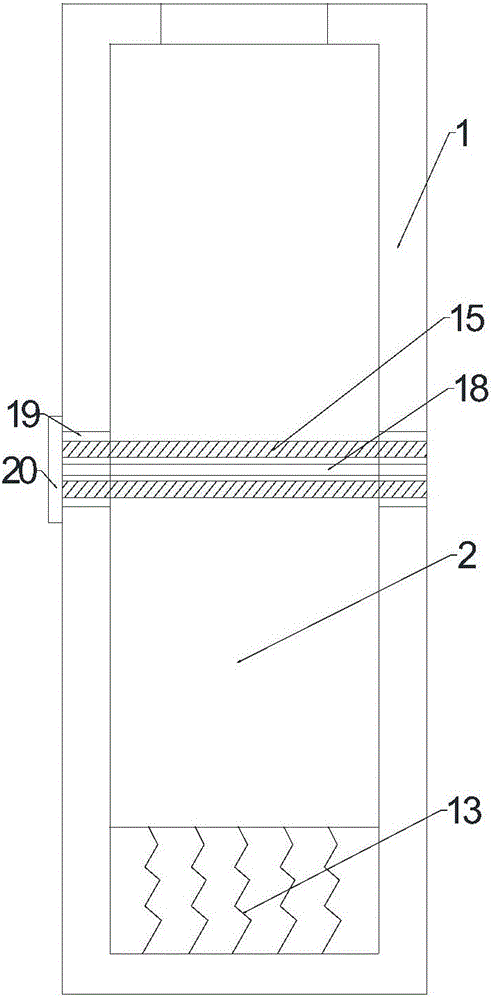

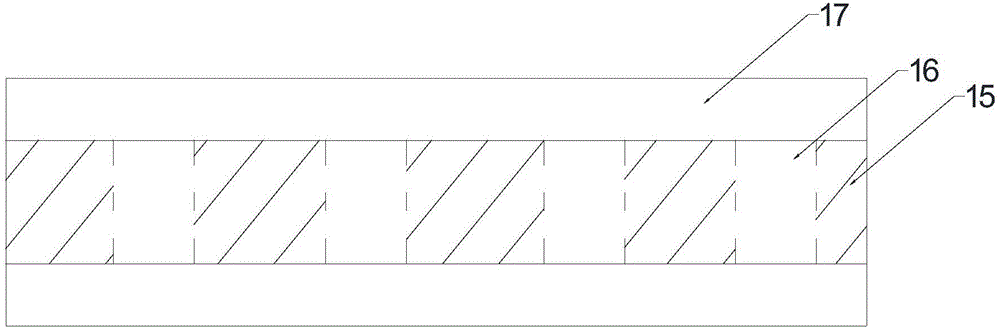

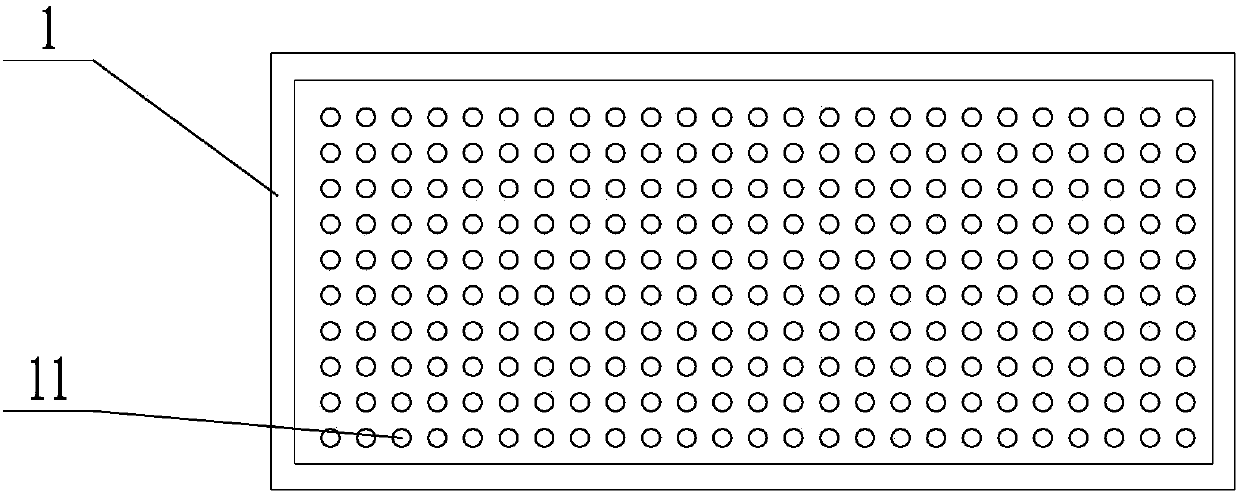

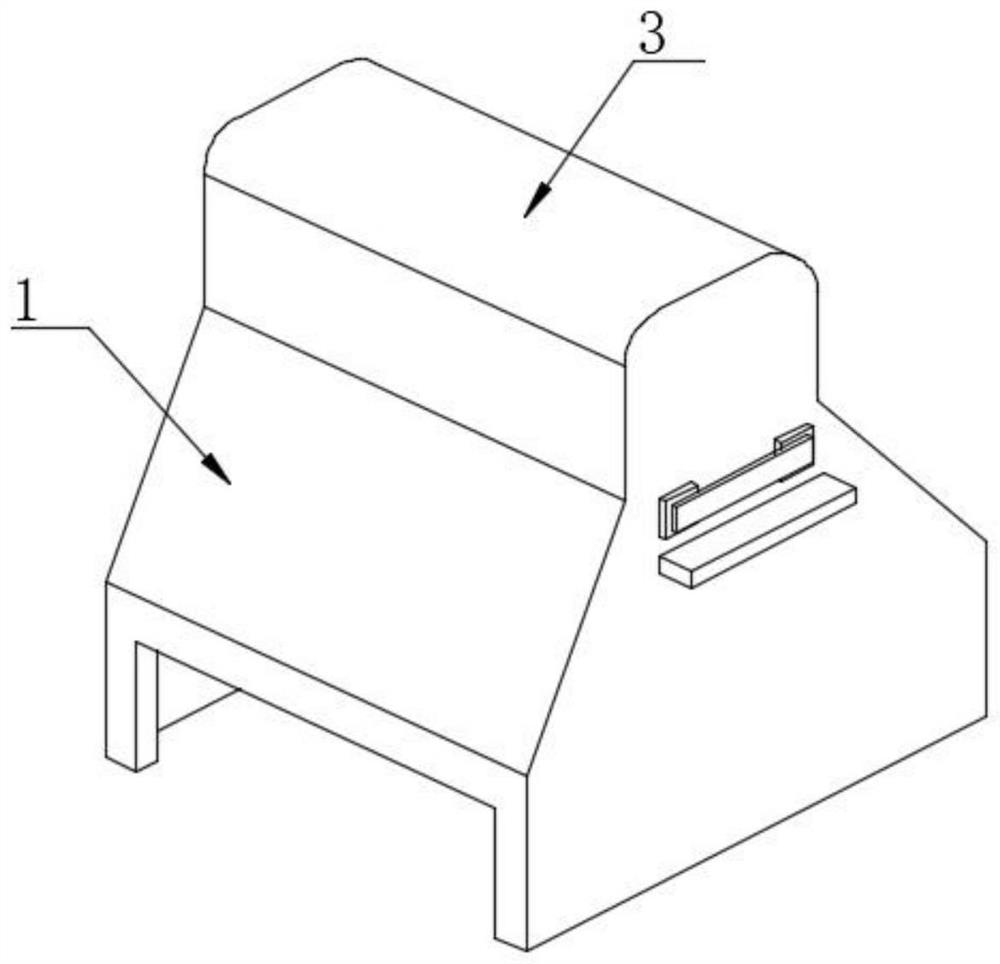

Drying box

InactiveCN106524685ADry evenlyImprove drying efficiencyDrying gas arrangementsDrying machines with local agitationComputer engineeringBreathing

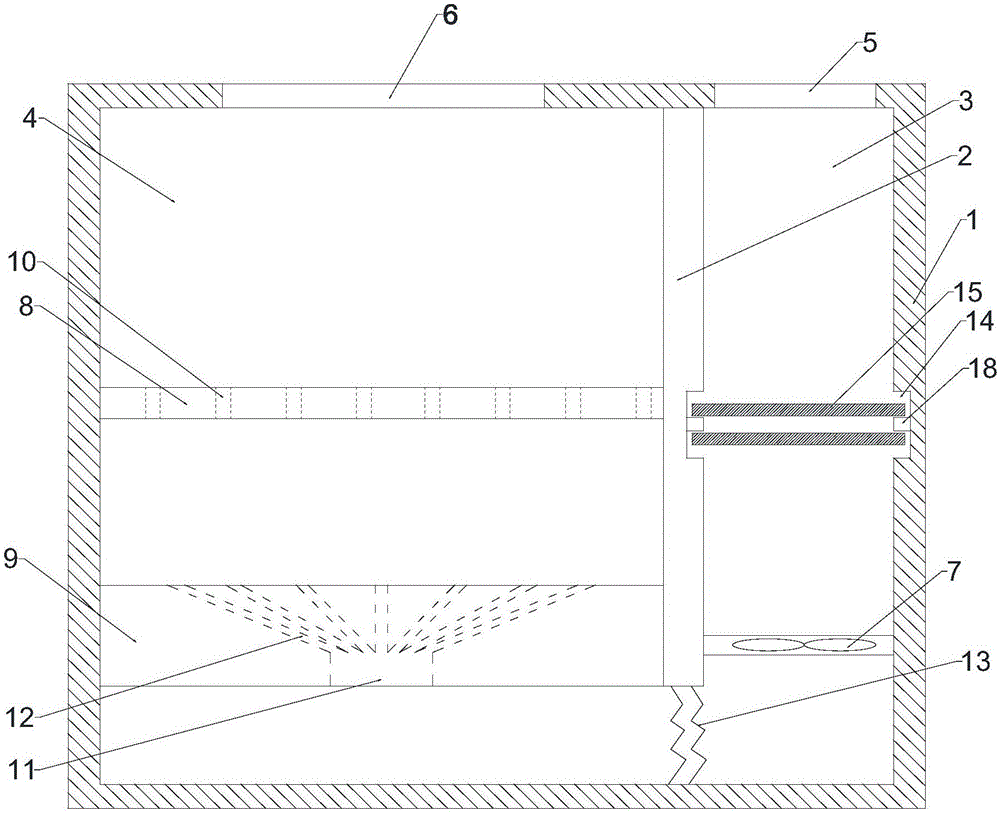

The invention relates to a drying box. The drying box comprises a box body and a partition plate arranged in the box body. The upper end of the partition plate is fixedly connected with the box body. The interior of the box body is divided into an air inlet cavity and a drying cavity by the partition plate. An air passing channel is formed between the lower end of the partition plate and the box body. An air inlet is formed in the air inlet cavity, and an air outlet is formed in the drying cavity. A draught fan is arranged in the air inlet cavity. A bearing plate and an air guiding plate are arranged in the drying cavity from top to bottom. A plurality of ventilation holes are formed in the bearing plate. An air inlet hole and a plurality of air guiding holes communicating with the air inlet hole are formed in the air guiding plate. The air inlet hole is located below the air guiding holes. The drying box is simple and reasonable in structure and convenient to operate, and drying is uniform.

Owner:常州笙绿农业科技有限公司

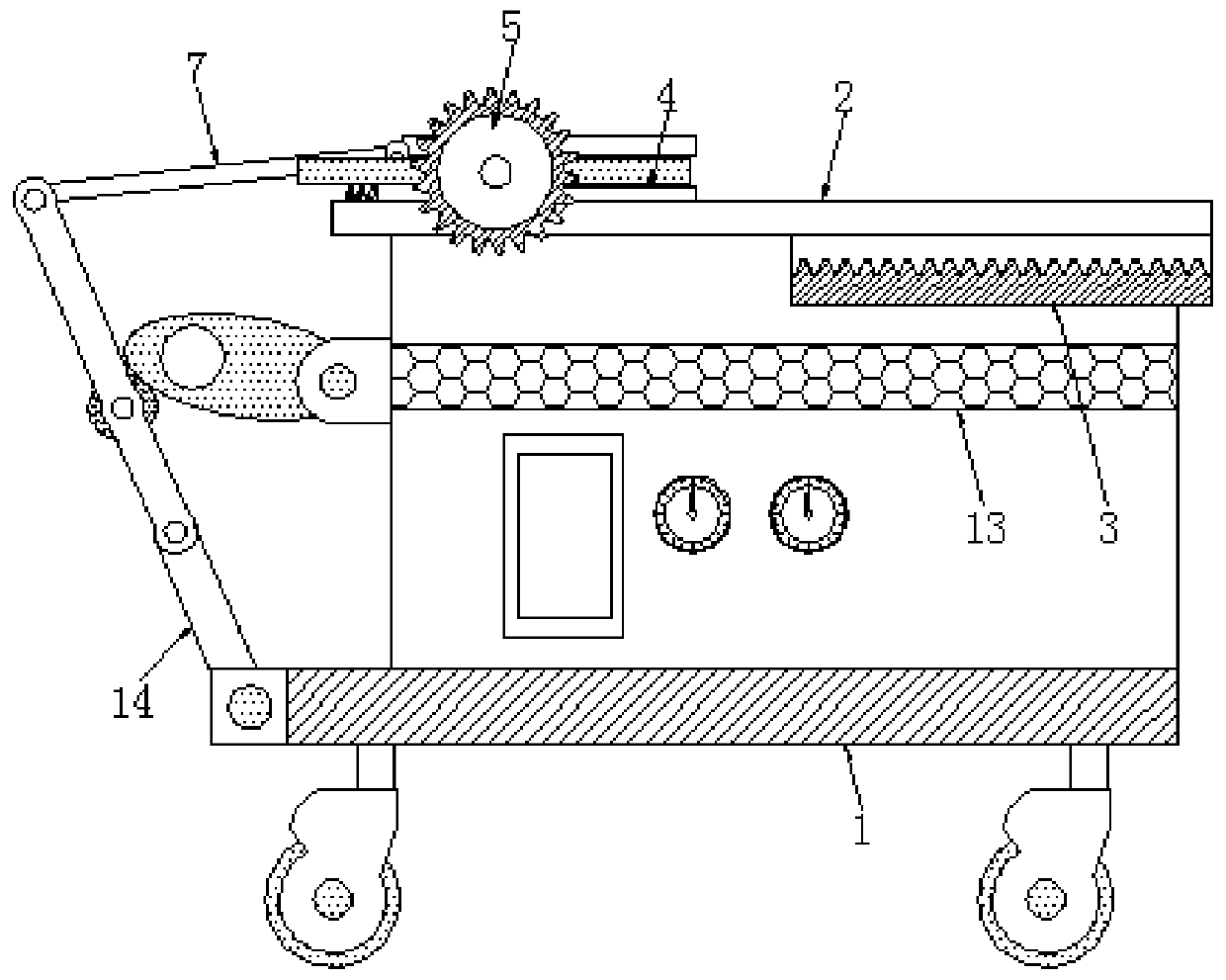

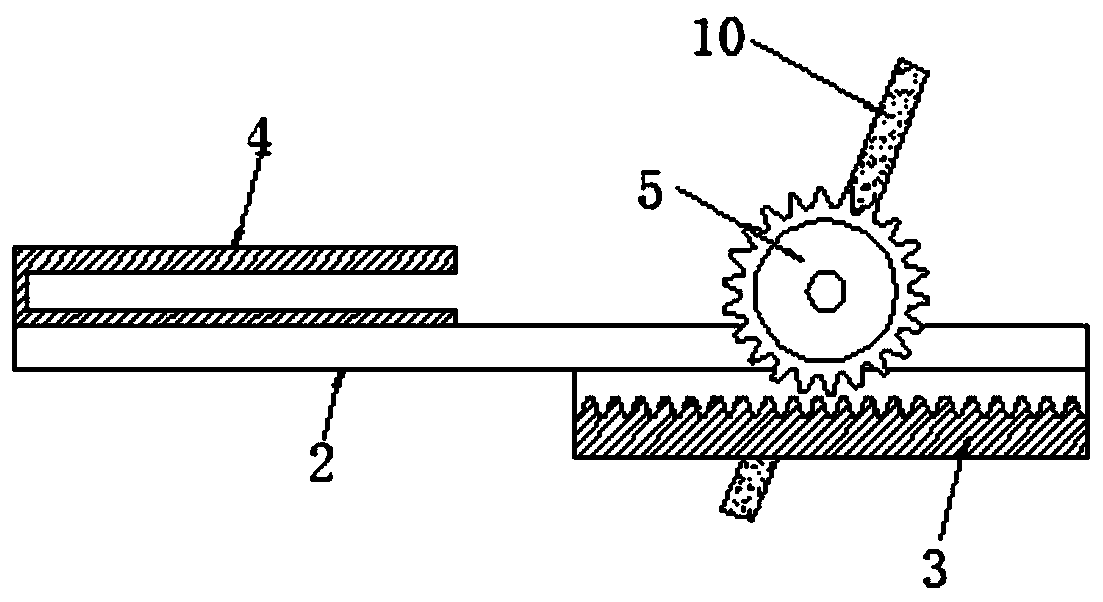

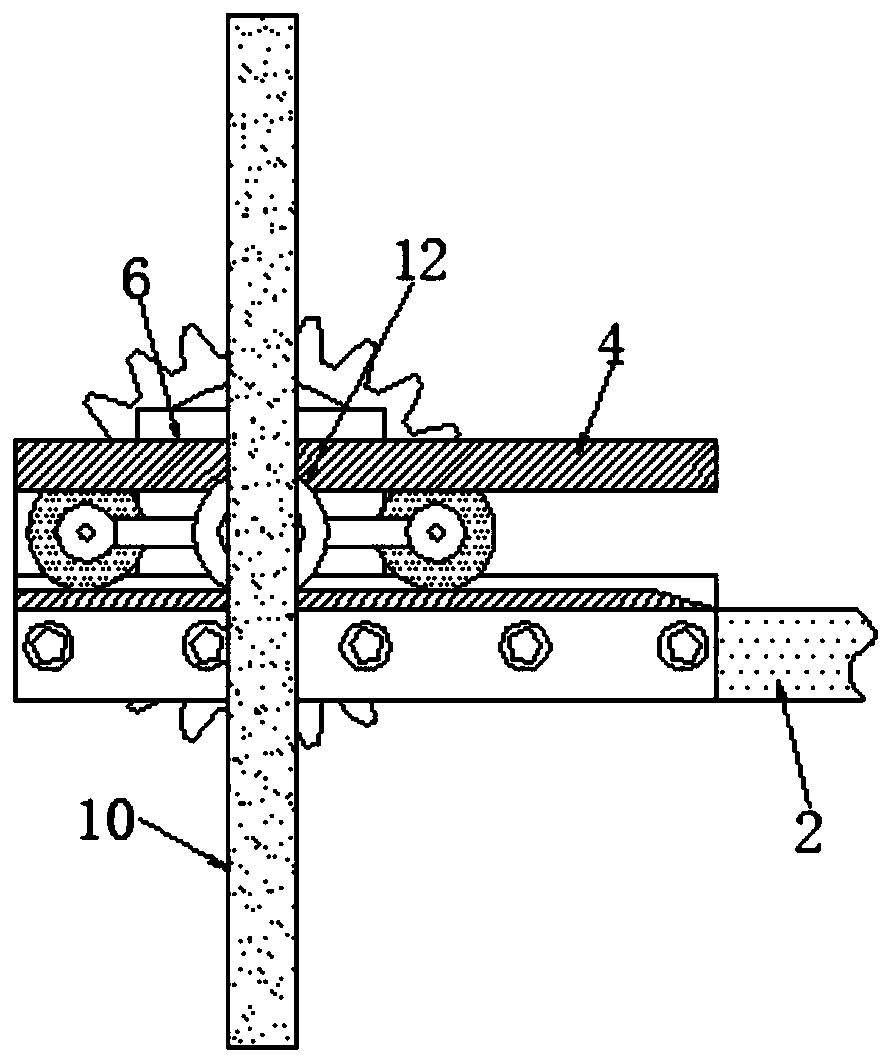

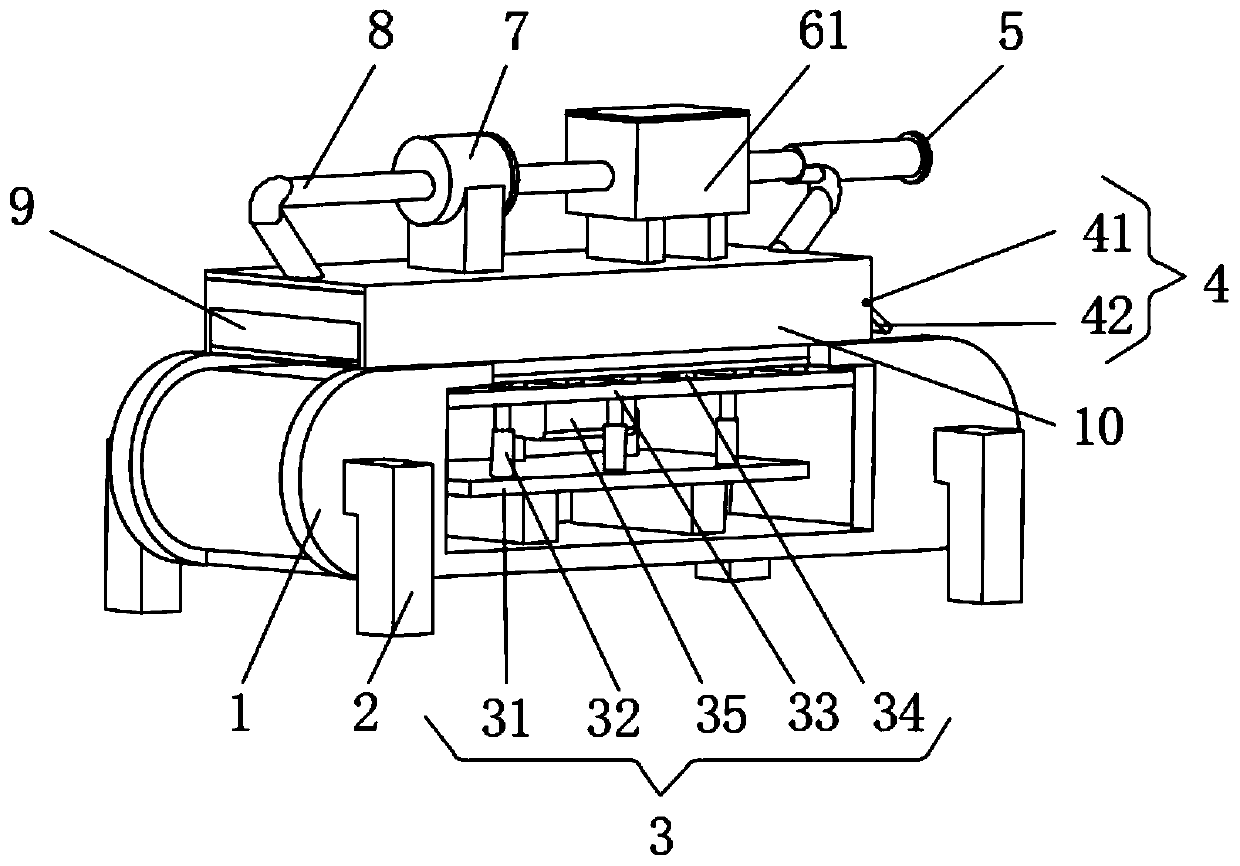

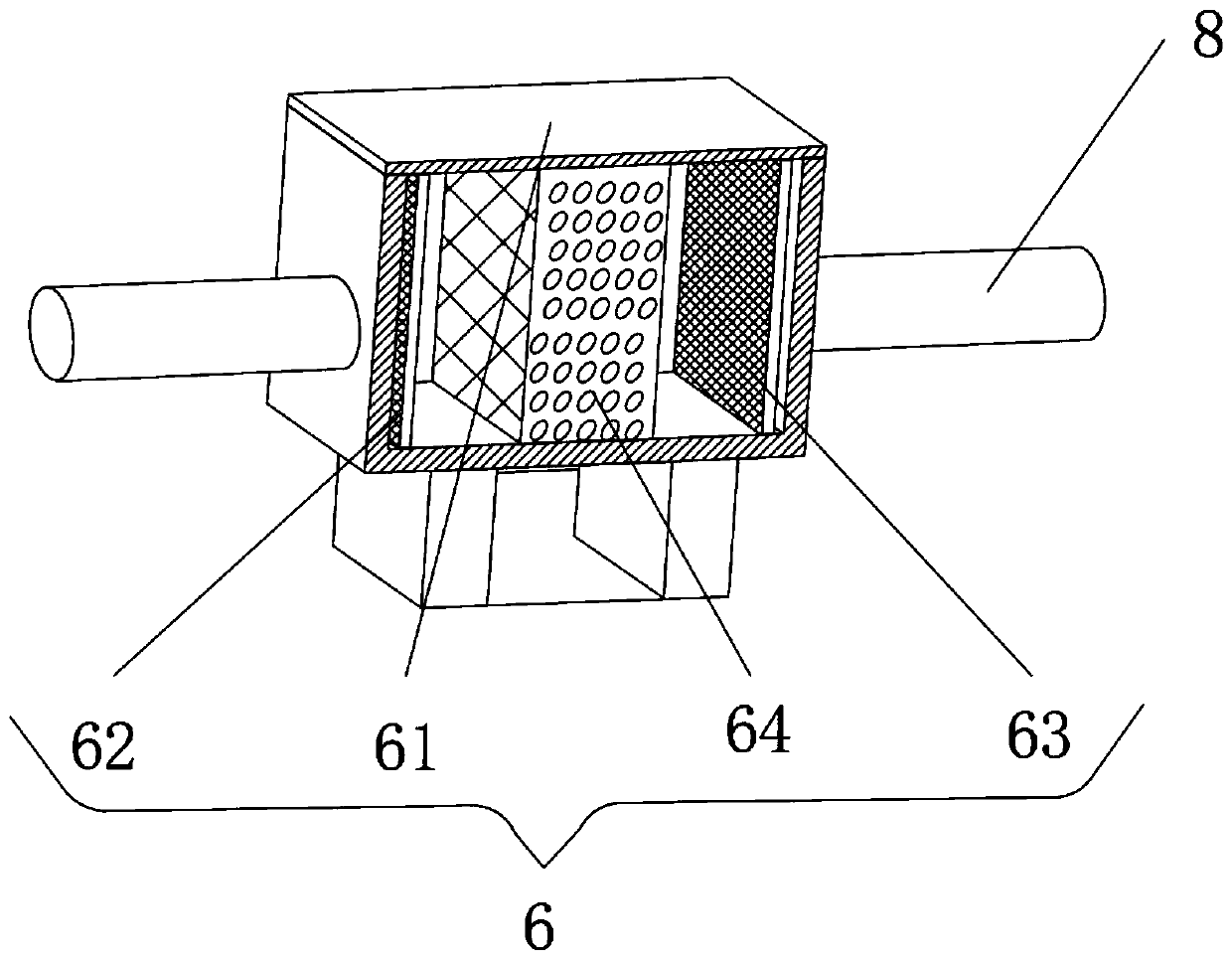

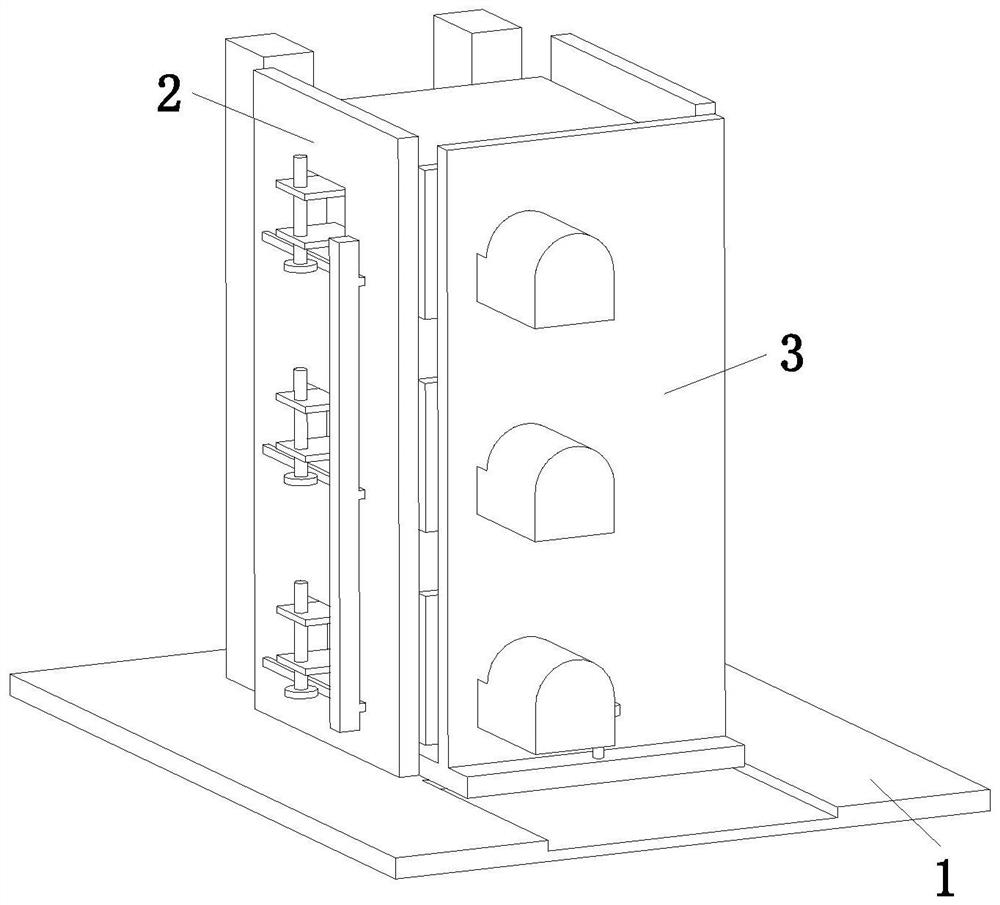

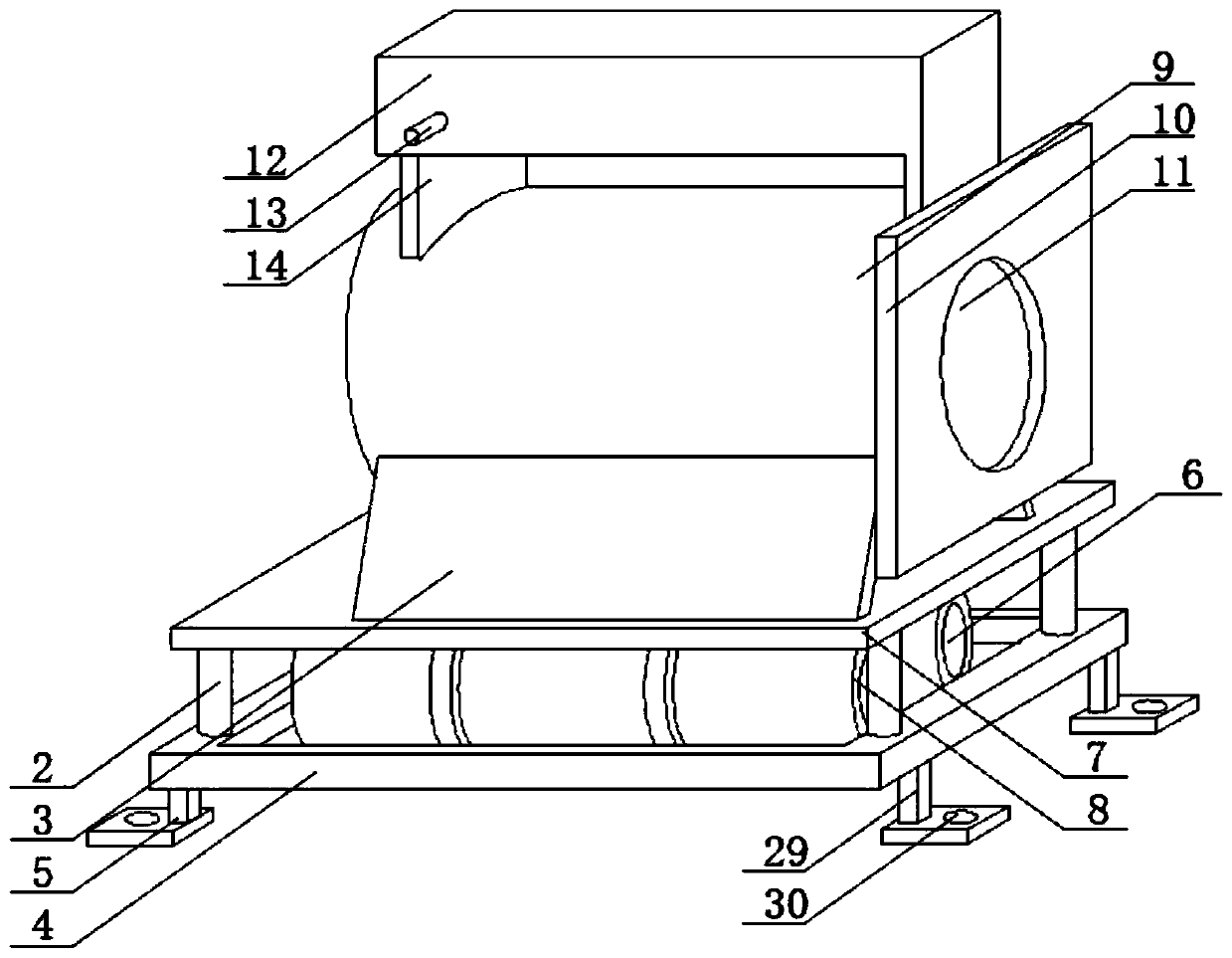

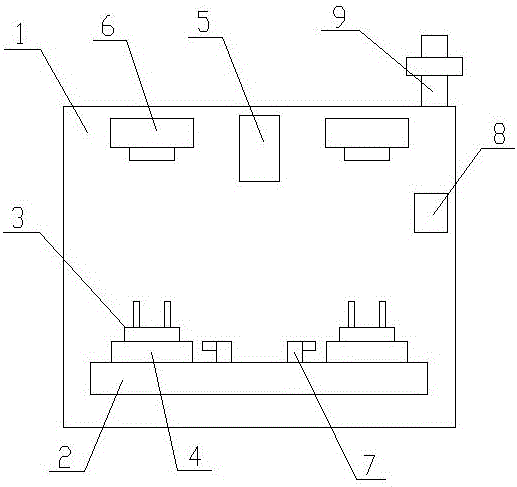

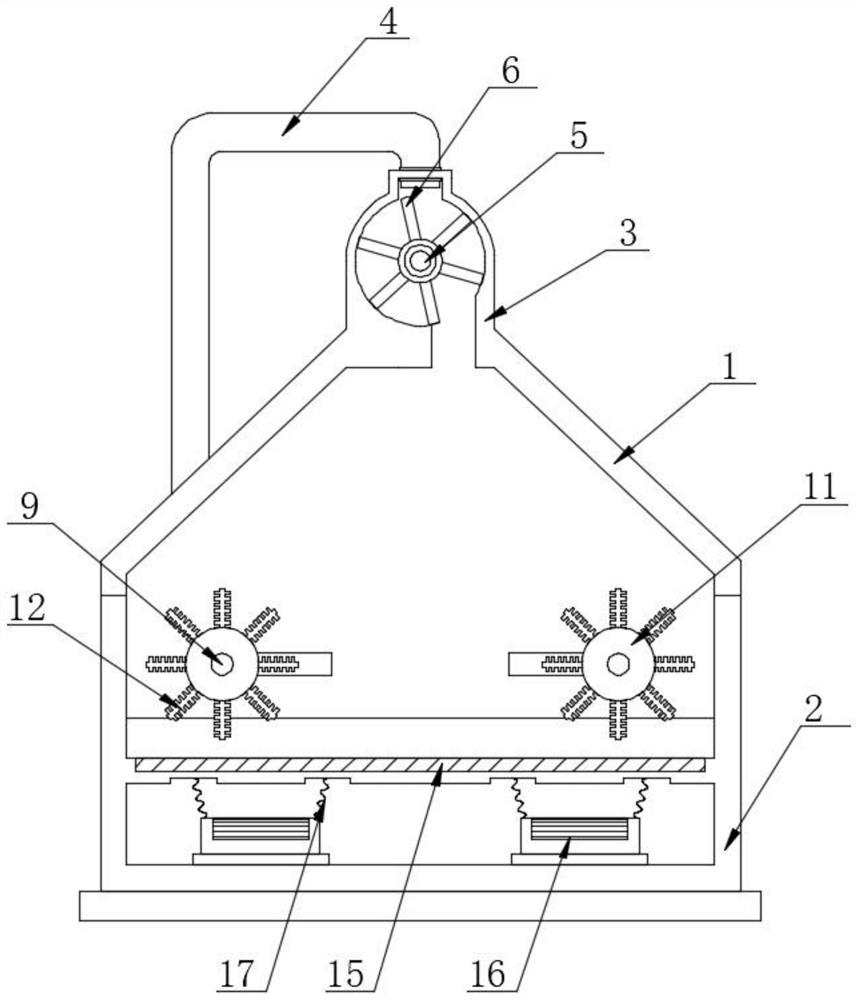

Double-sided drying device capable of carrying out turnover based on reciprocating motion to ensure uniform drying

ActiveCN111397341ADry evenlySpeed up dryingDrying chambers/containersDrying machines with non-progressive movementsGear driveReciprocating motion

The invention relates to the technical field of textiles, and discloses a double-sided drying device capable of carrying out turnover based on reciprocating motion to ensure uniform drying. The double-sided drying device comprises a base, a support rod is fixedly connected above the base to carry our supporting and stabilizing on a gear, and a rack is fixedly connected below the support rod. According to the double-sided drying device capable of carrying out turnover based on reciprocating motion to ensure uniform drying, through cooperative use of a sliding block, a first connecting rod, a swing rod, a cam, the support rod, a drying pipe and a second connecting rod, cloth is driven to move left and right, so that the purpose of uniform drying is achieved; through cooperative use of the support rod, the rack, a limiting plate, the gear and a dressing plate, reverse side drying is directly carried out after single-side drying is completed, so that the drying speed of fabric is increasedand the working efficiency is improved; and through cooperative use of a first rotating shaft and a second rotating shaft, the dressing board cannot rotate again in the process that the gear drives the dressing board to move back and forth, so that incomplete drying of the other face is avoided, enough drying time is guaranteed, and drying is more sufficient.

Owner:杭州查凤科技有限公司

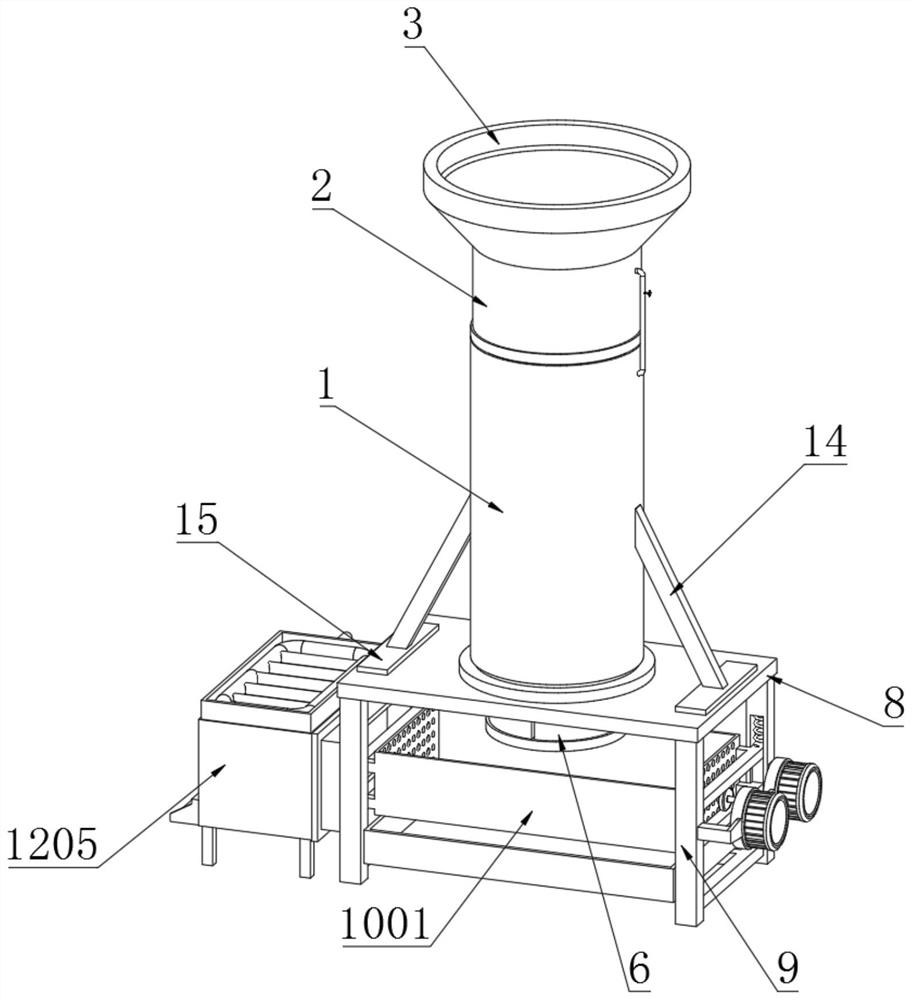

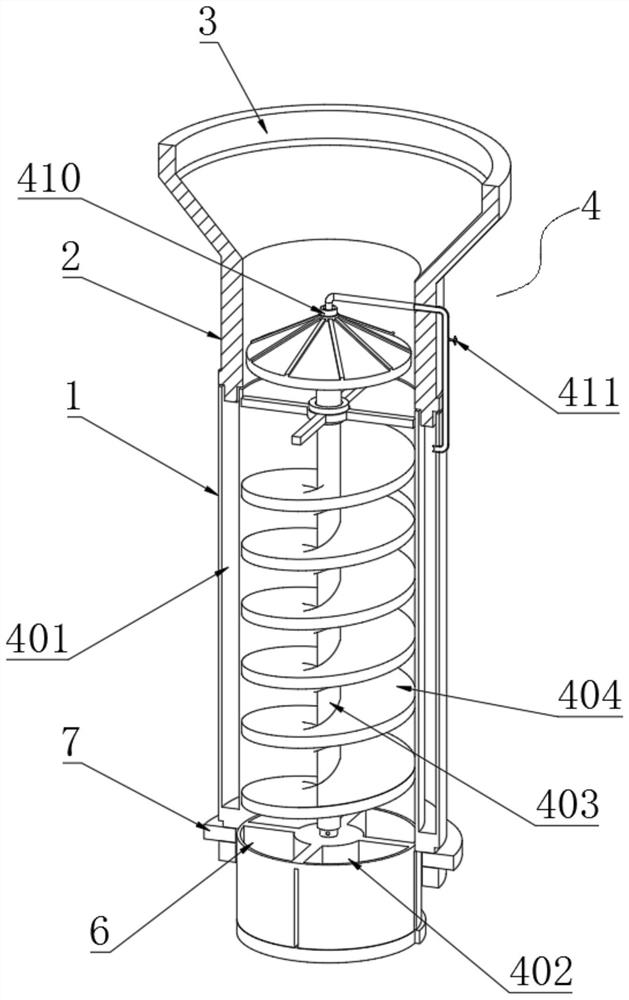

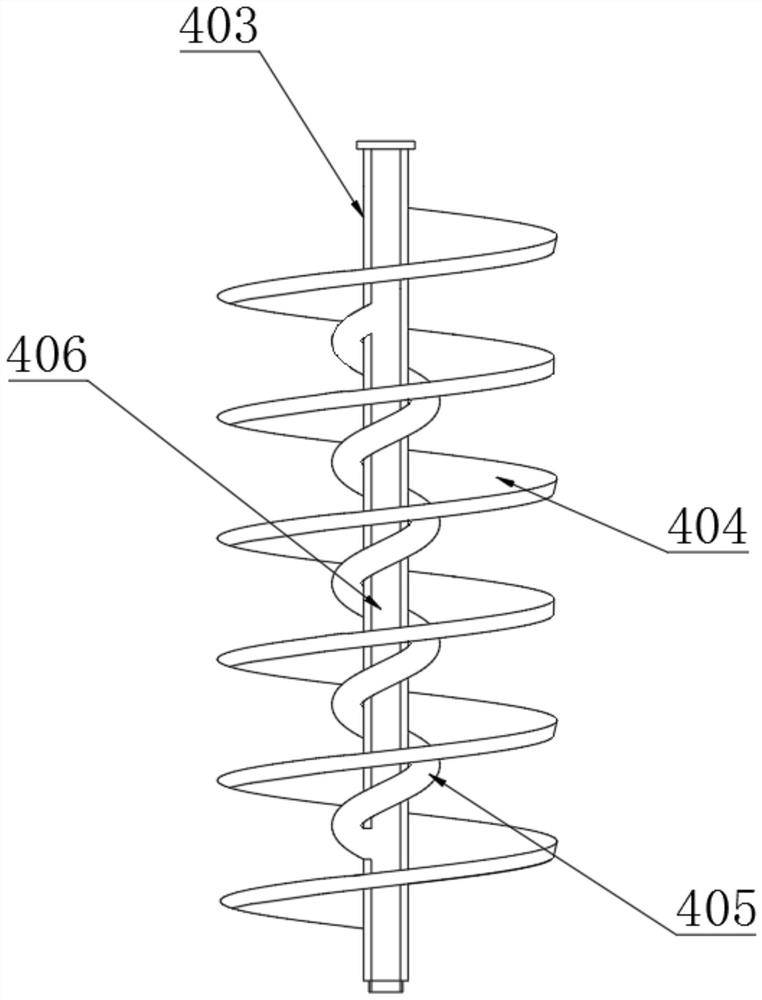

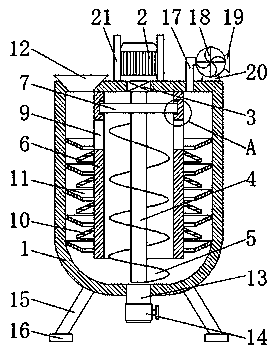

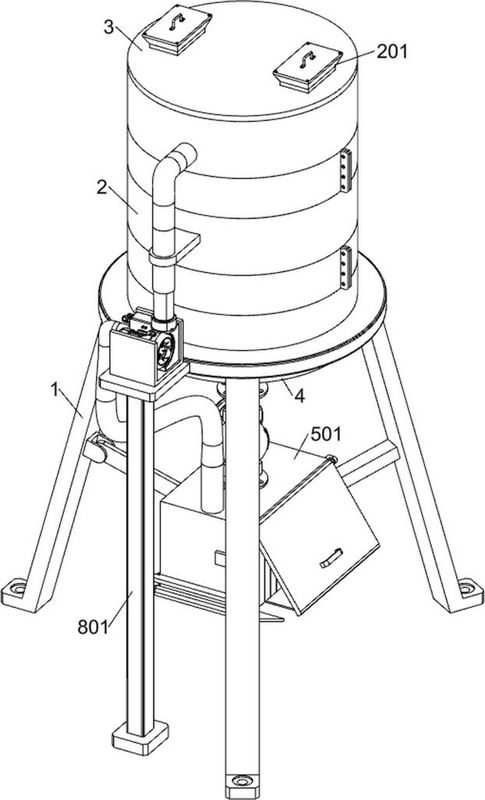

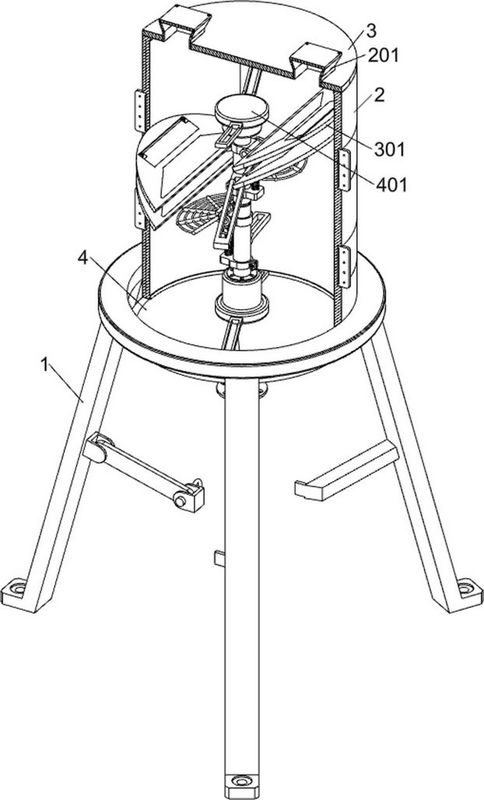

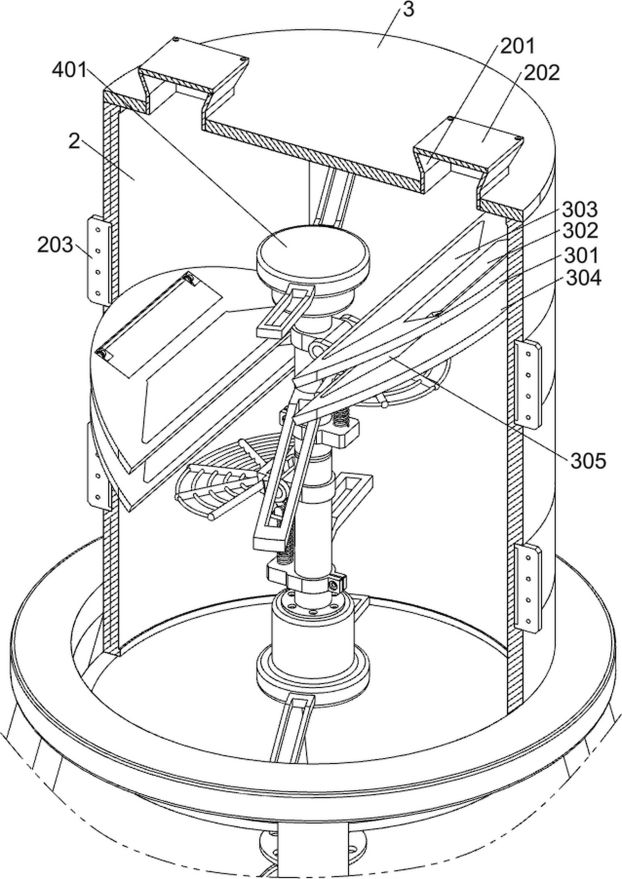

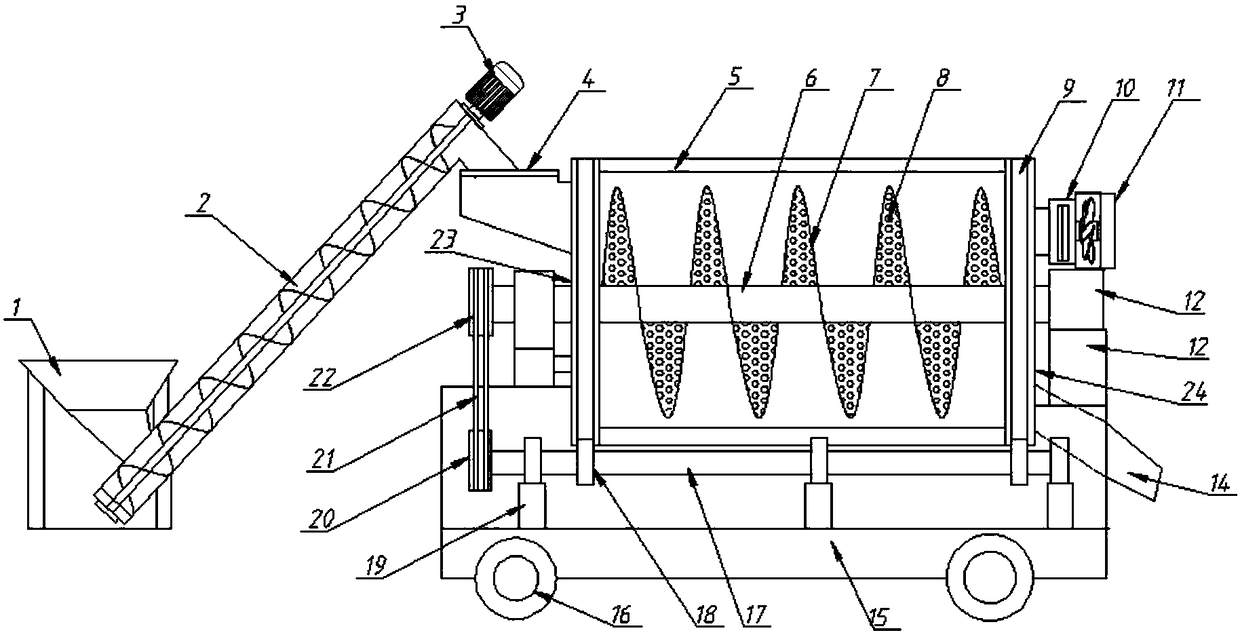

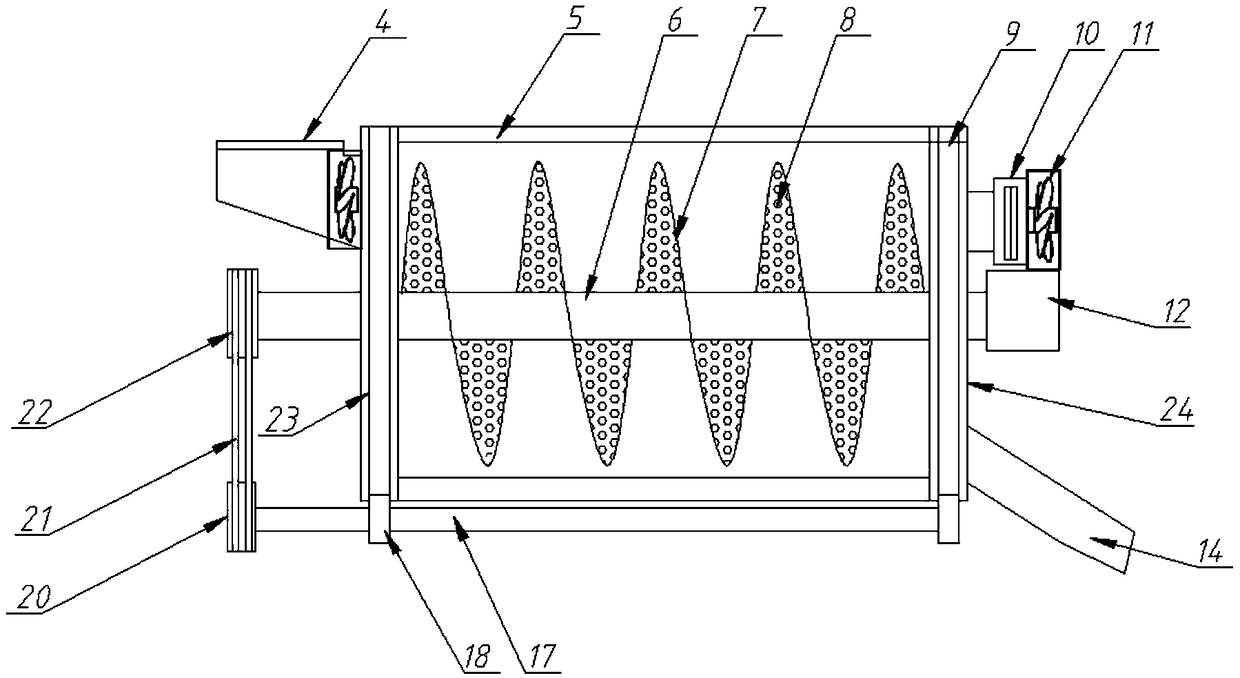

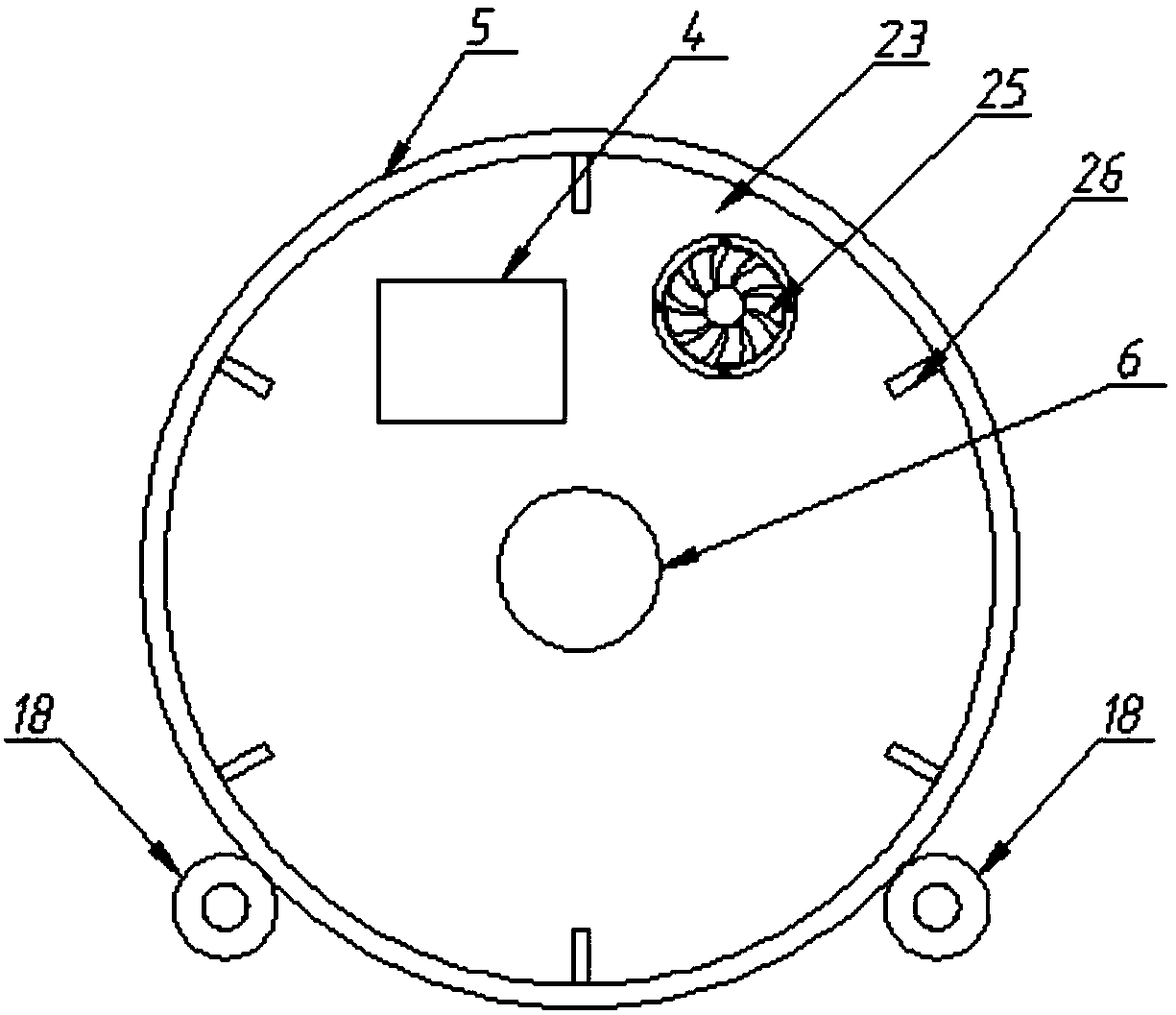

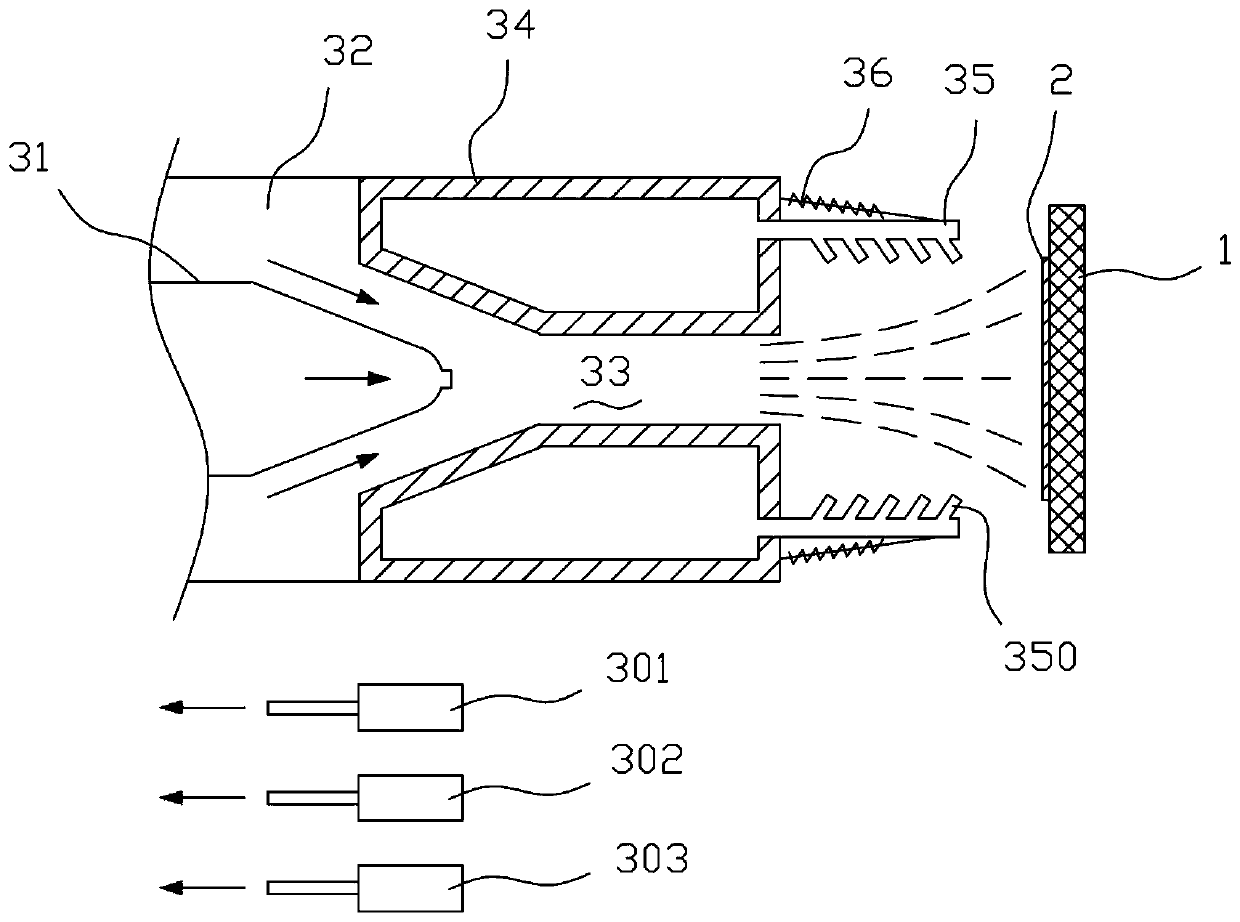

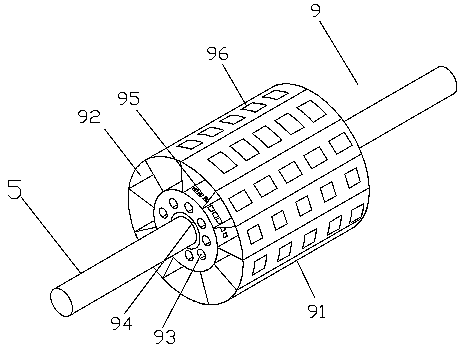

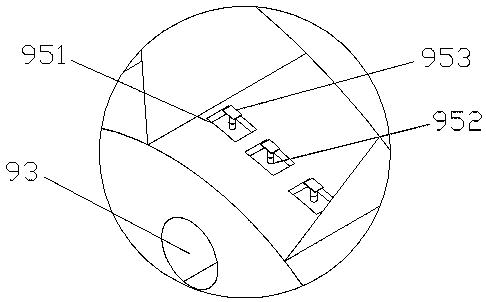

Seed surrounding type drying device for agriculture

ActiveCN113028816AFully dryEasy to transportSievingGas current separationAgricultural engineeringMechanical engineering

The invention discloses a seed surrounding type drying device for agriculture. A feeding cylinder is connected to the top end of a drying cylinder, a feeding hopper is connected to the top end of the feeding cylinder, and a surrounding drying mechanism is installed inside the drying cylinder. Through the surrounding drying mechanism, heat in the surrounding drying mechanism can be input into to-be-dried seeds from outside to inside through a heating cavity in the actual drying process, and heat water vapor generated by heating in the heating cavity can be uniformly distributed through a spiral gas distribution pipeline. Heat of the water vapor can be conveyed into the seeds from inside to outside, and therefore heat bands can be formed on two sides of the seeds when the seeds are dried, the seeds can be sufficiently and thoroughly dried, and the seeds can be conveniently conveyed and turned by a driving rotating shaft and a material uniformizing spiral blade in the drying process. Therefore, the phenomena of accumulation and incomplete drying during seed drying are further avoided, and the drying quality of the seeds is guaranteed.

Owner:邯圣种业集团股份有限公司

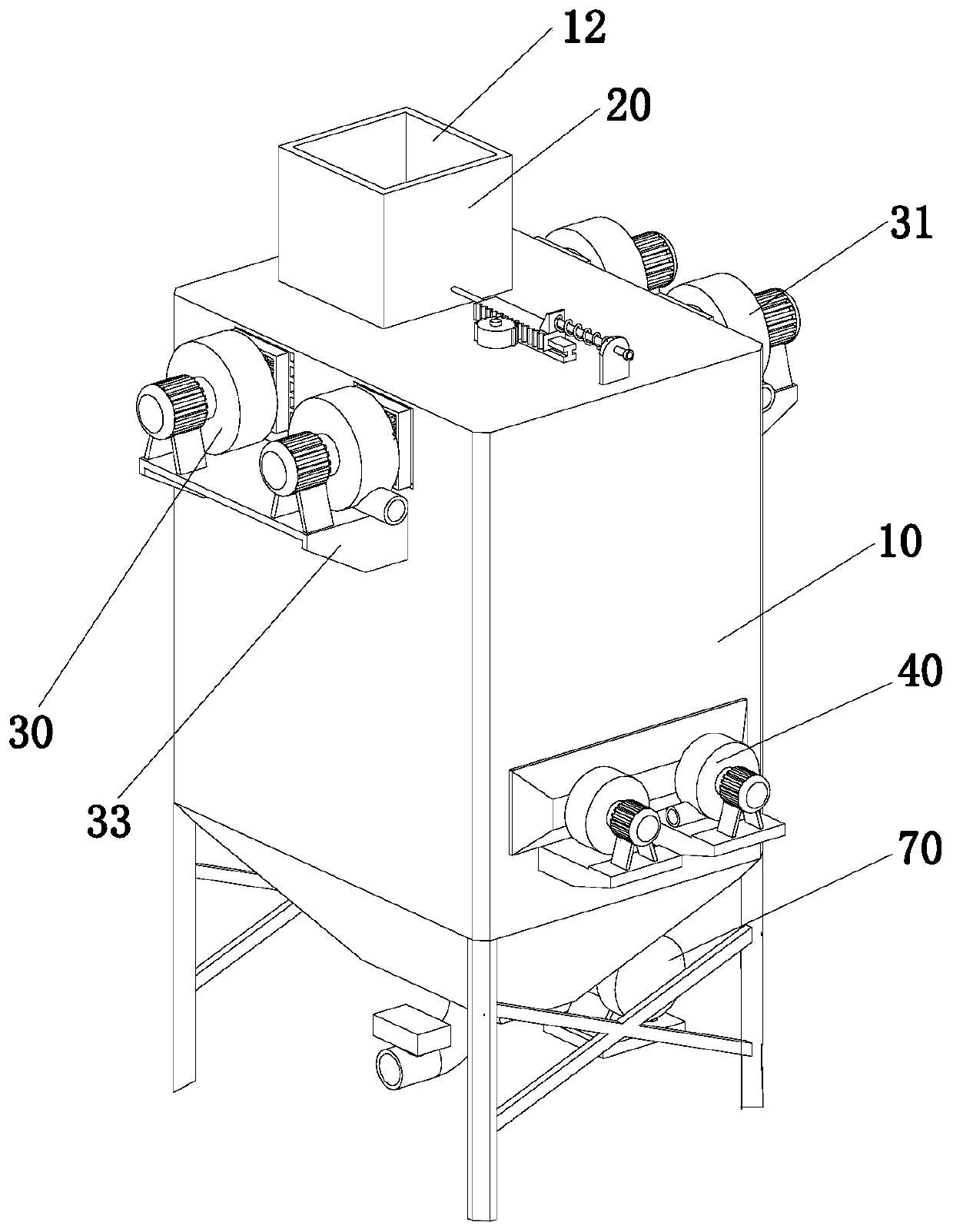

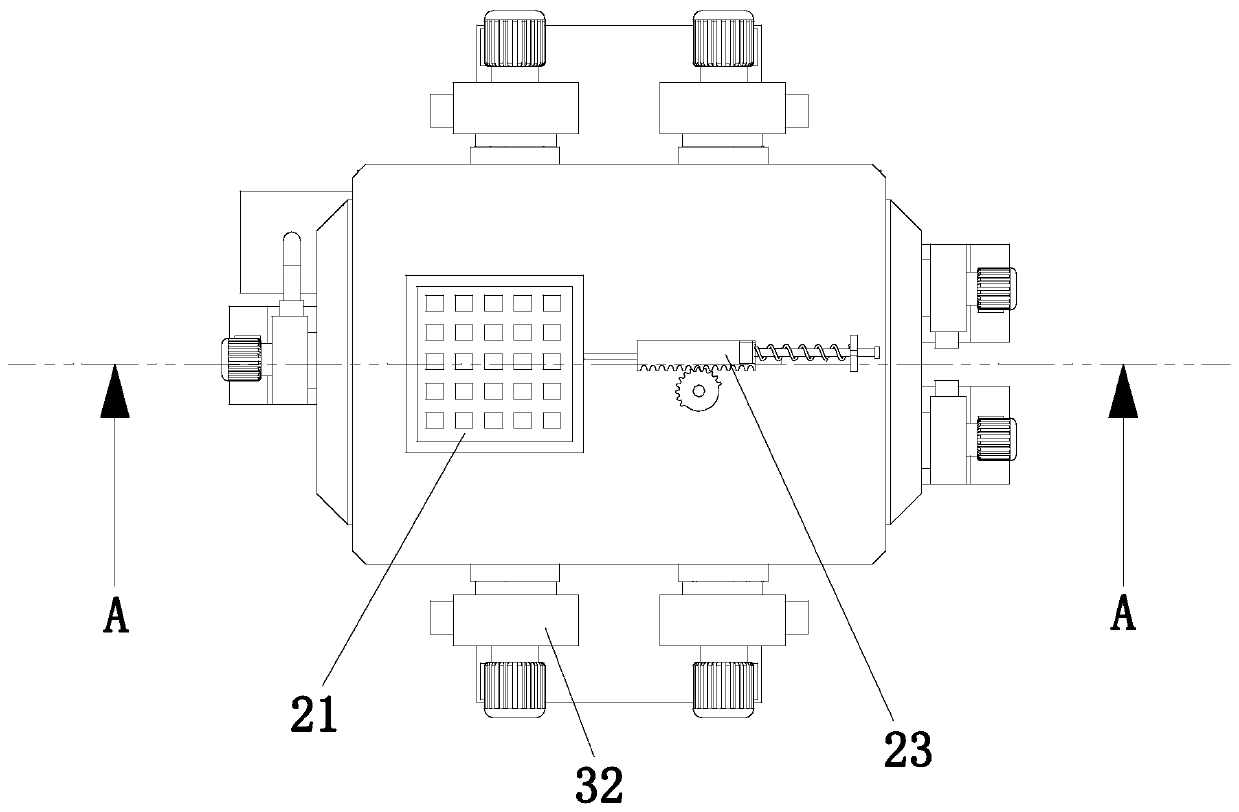

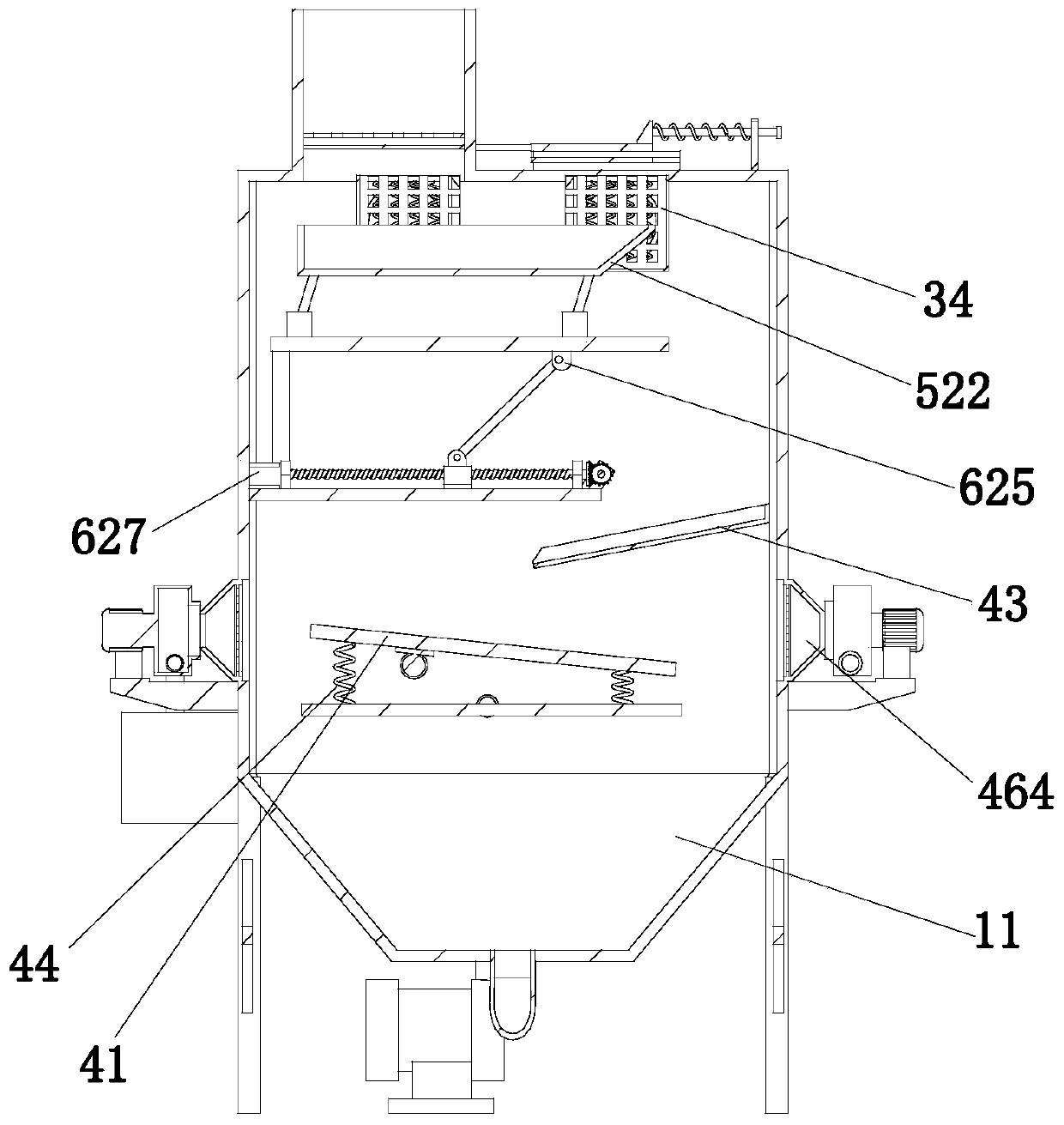

Cold storage cavern device for grain dust removal and freshness preservation

InactiveCN110553453AAvoid undriedEasy to operateLighting and heating apparatusStationary refrigeration devicesGrain storageEngineering

The invention discloses a cold storage cavern device for grain dust removal and freshness preservation, and belongs to the field of grain storage devices. The device comprises a storage cabinet, a quantitative feeding mechanism, a grain drying mechanism and a dust removal mechanism, wherein the grain drying mechanism and the dust removal mechanism are arranged inside the storage cabinet, a refrigerating chamber is arranged at the lower section inside the storage cabinet, a feeding box is arranged at the top of the storage cabinet, the grain drying mechanism comprises a drying assembly, a material turning assembly and a pouring assembly, the material turning assembly comprises a supporting table, a material turning component and a material turning box, the material turning box is provided with a vent hole, and the material turning box is provided with a material discharging nozzle. According to the device, by means of the dust removal mechanism, the dust removal operation can be carriedout on grains on a vibration plate and a material guide slide way, by means of the grain drying mechanism, the material turning operation can be carried out on the grains, and the situation that thegrains are not dried locally is avoided, and by means of the pouring assembly, the grains can be poured so as to enable the grains to fall onto the material guide slide way.

Owner:惠州市安谷农业开发有限公司

Drying device for plastic product recycling

PendingCN110779315ASimple structureExcellent drying resultsDrying gas arrangementsDrying chambers/containersPhysicsEngineering

The invention provides a drying device for plastic product recycling. The drying device for plastic product recycling comprises a conveying belt conveyor and supporting legs. The supporting legs are arranged on the surfaces of the two sides of the conveying belt conveyor. A vibration device is arranged in a belt of the conveying belt conveyor. A drying shell is arranged on the upper surface of theconveying belt conveyor. A drying cavity is formed by the drying shell and the upper portion of the belt of the conveying belt conveyor. The vibration device comprises a bottom plate, shock absorbers, a top plate, rollers and a vibrator. The bottom plate is fixed to the shell of the conveying belt conveyor. By means of the drying device for plastic product recycling, the vibration device, an airdrying device and a hot air blower are used so that smashed plastic products can be rapidly dried, the structure is simpler, the smashed plastic products can be dried at any angle, and the drying effect is also more outstanding.

Owner:常州汉华泡塑包装材料有限公司

Agricultural fertilizer drying device capable of achieving rapid drying

InactiveCN109520268AImprove drying efficiencyDry fastManure dryingDrying solid materialsSpiral bladeAgricultural engineering

The invention discloses an agricultural fertilizer drying device capable of achieving rapid drying. The agricultural fertilizer drying device comprises a tank. A motor is fixedly connected to the center of the top of the tank. A bearing is arranged in the center of the top of the tank in a penetrating manner. The output end of the motor penetrates through the bearing and is fixedly connected witha rotating shaft. According to the agricultural fertilizer drying device, by means of cooperative use of the motor, the bearing, the rotating shaft, spiral blades, a pipe body, an isolating plate, a sliding groove and a material falling opening, the problem that an existing agricultural fertilizer drying device is low in drying efficiency is solved, the agricultural fertilizer drying device capable of achieving rapid drying has the advantage of rapid drying, in the using process, the situations that fertilizer accumulates on the bottom of a drying machine, and the fertilizer piled up is not dried thoroughly can be avoided, moreover, time for drying the fertilizer is shortened, and the working efficiency of drying is improved. In addition, water in drying equipment is further prevented fromevaporating in a centralized manner, the situation that due to the fact that moisture of the drying equipment is too large, the drying effect is influenced is prevented, and the agricultural fertilizer drying device is worth being used and popularized.

Owner:陈启亮

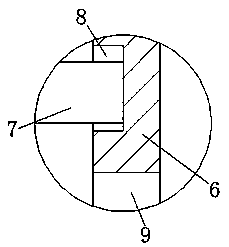

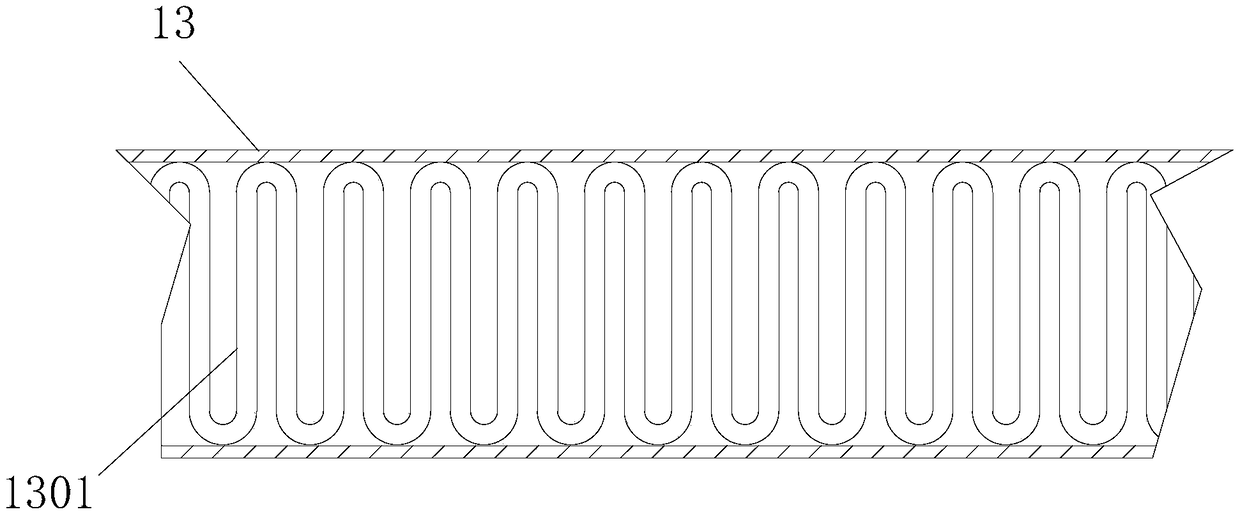

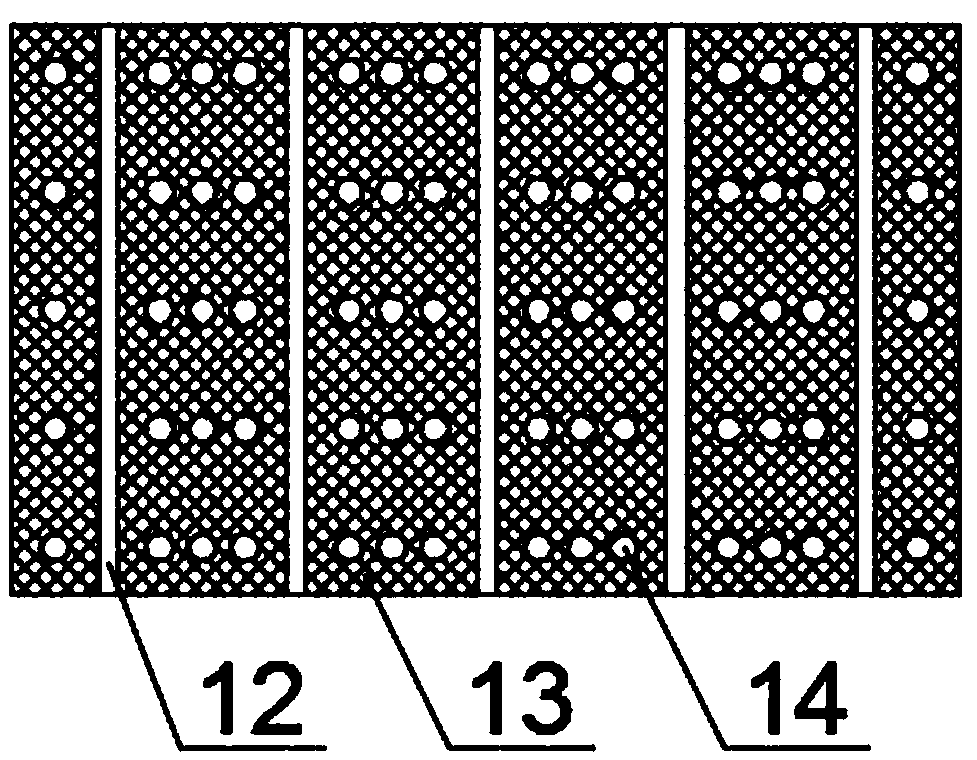

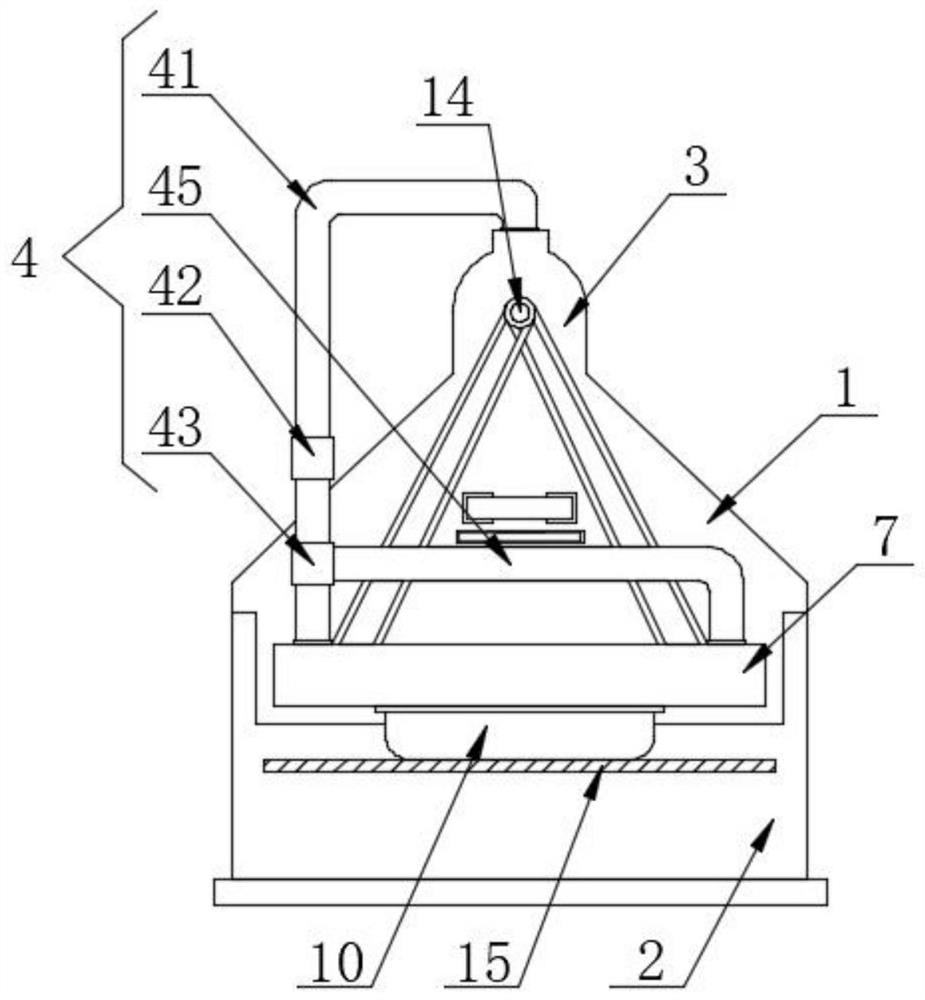

Heating forming plate of organic fertilizer granulator

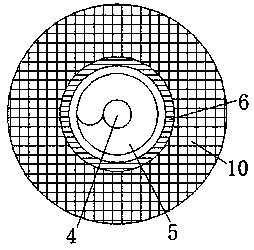

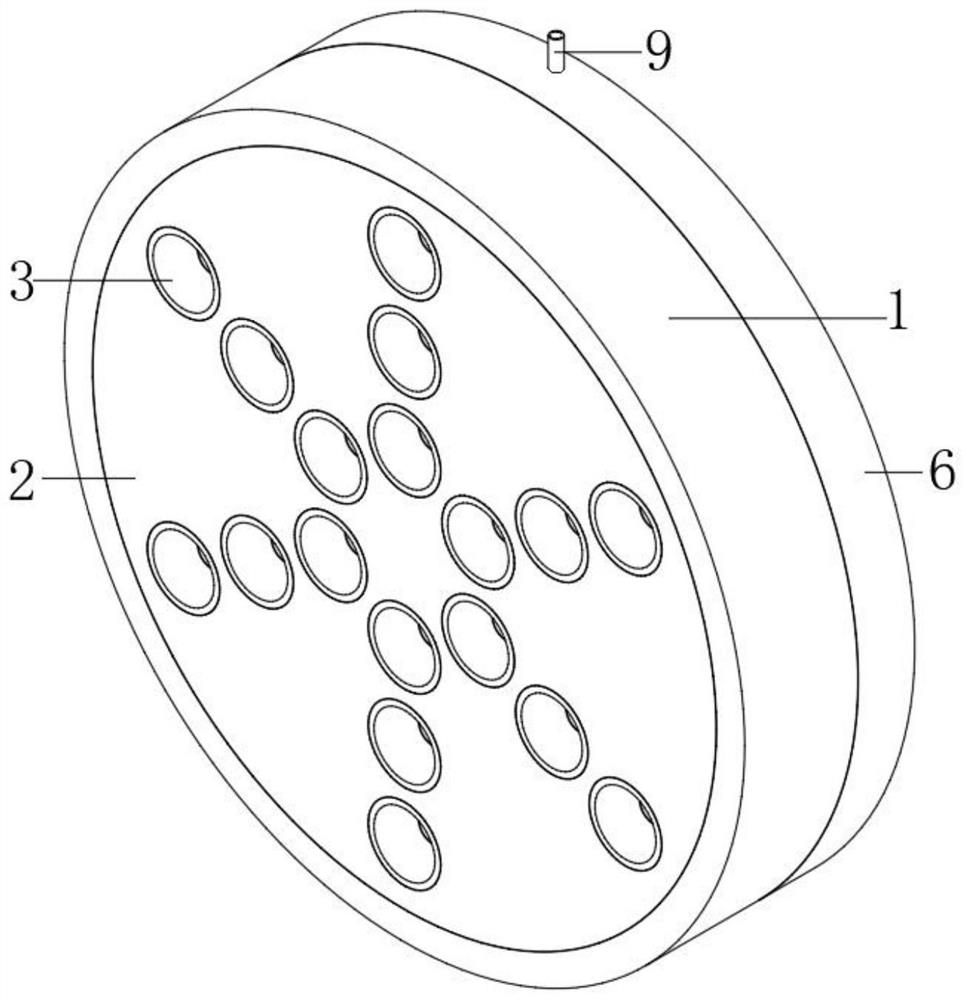

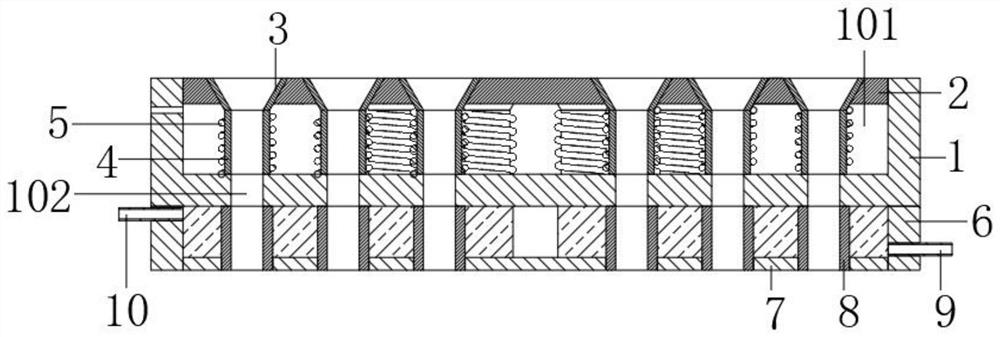

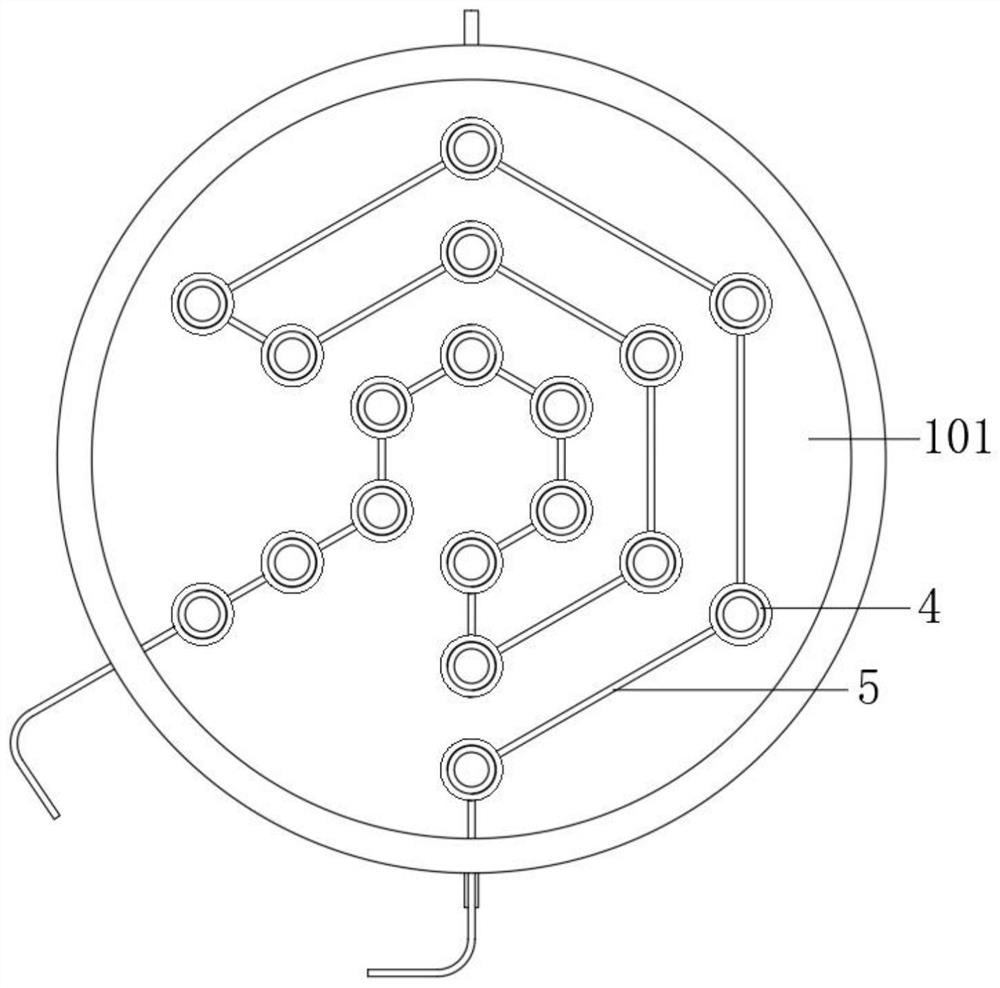

PendingCN111672417APrecise temperature controlEnsure stabilityGranulation by material expressionHeating arrangementThermodynamicsAgricultural engineering

The invention relates to the field of organic fertilizer treatment related equipment, and in particular, relates to an organic fertilizer granulator heating forming plate comprising a top plate; a mounting cavity is formed in the top end of the top plate; a plurality of groups of uniformly distributed communicating holes are formed in the bottom end of the mounting cavity; the top end of each communicating hole is fixedly connected with a circular pipe; the top end of the mounting cavity is fixedly connected with an extrusion plate; a plurality of groups of uniformly distributed conical holesare formed in the top end of the extrusion plate; a conical pipe is arranged in each conical hole; the bottom end of each conical pipe is fixedly connected with the top end of the corresponding circular pipe; each circular pipe is sleeved with a spiral heating wire; the bottom end of the top plate is fixedly connected with a cooling plate; a cooling cavity is formed in the inner side of the cooling plate; a bottom sealing plate is fixedly connected to the bottom end of the cooling cavity, a plurality of groups of connecting holes are evenly formed in the bottom sealing plate, and discharging pipes are fixedly connected into the connecting holes. The organic fertilizer granulator heating forming plate can well conduct dewatering treatment on organic fertilizer particles and can achieve rapid forming.

Owner:胡雪娇

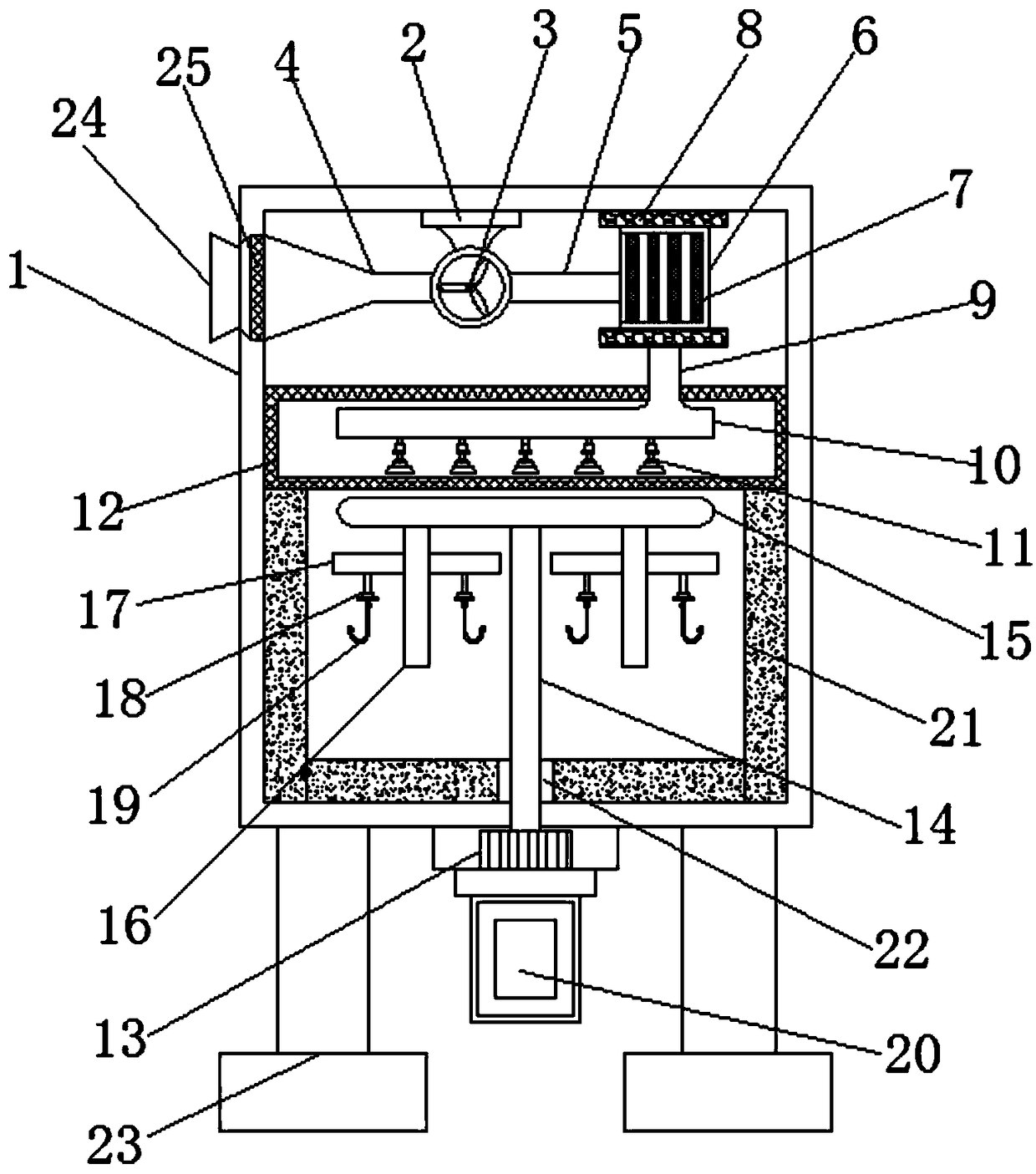

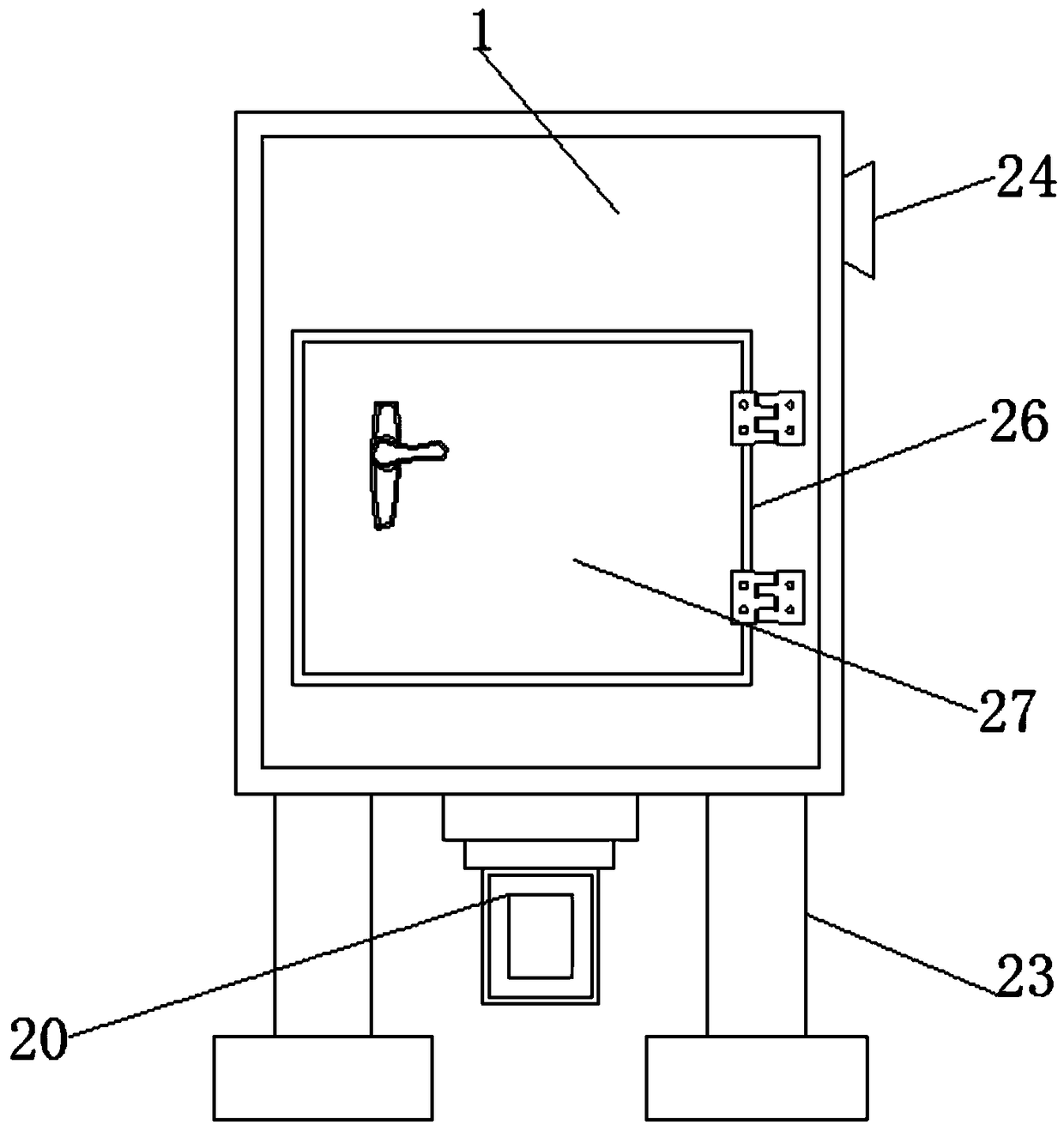

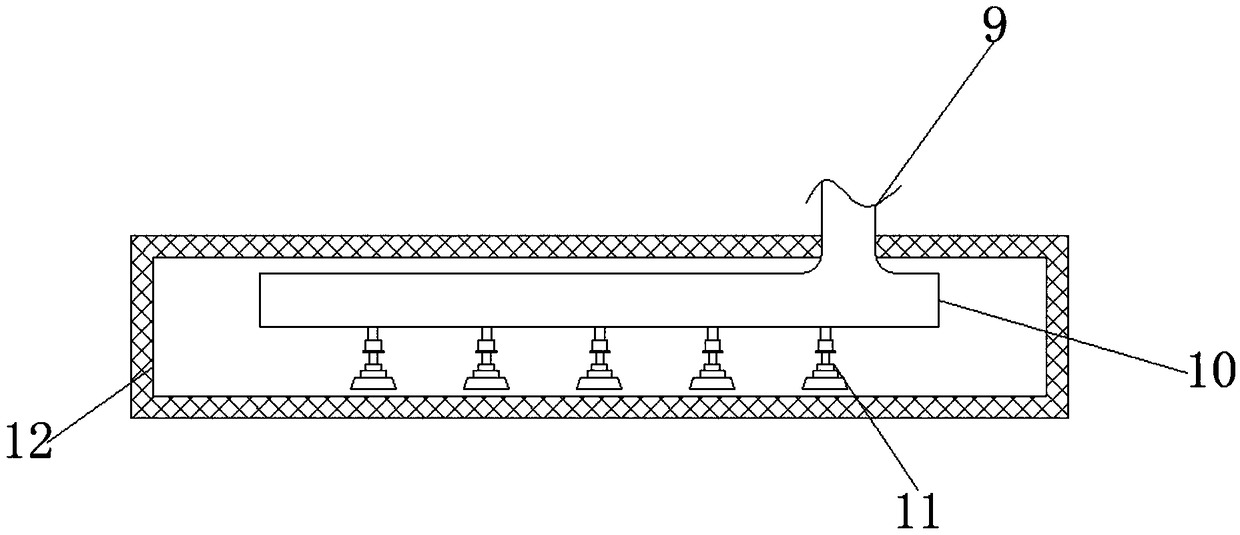

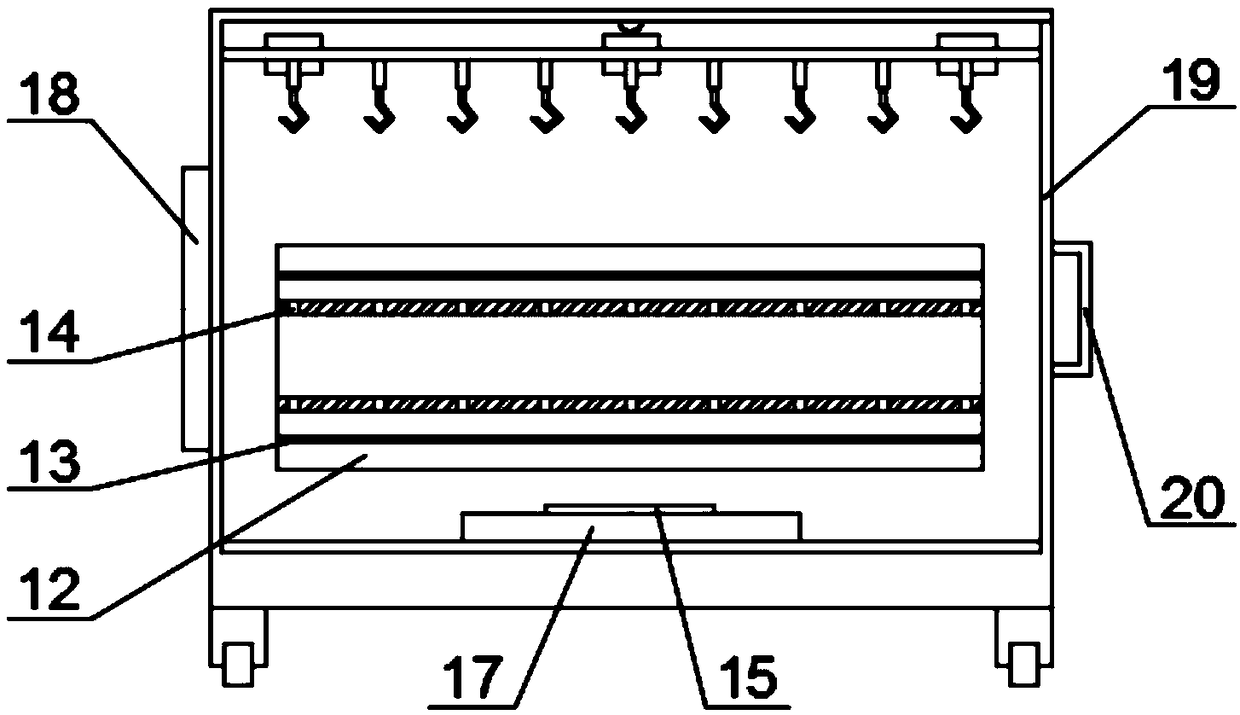

Fine dried noodle drying device capable of achieving uniform drying

InactiveCN108716835ADry evenlyImprove drying effectDrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

The invention discloses a fine dried noodle drying device capable of achieving uniform drying. The device comprises a drying box, the top of the inner wall of the drying box is fixedly connected witha connecting block, the bottom of the connecting block is fixedly connected with a hot air blower, a ventilation pipeline is fixedly embedded on one side of the hot air blower, an exhaust pipeline isfixedly embedded on the other end of the hot air blower, one end of the exhaust pipeline is fixedly connected with an electric heating box, an electric heating bar is fixedly connected into the electric heating box, and the top of the electric heating box is fixedly connected with a base plate. According to the fine dried noodle drying device capable of achieving uniform drying, the hot air blower, the electric heating box and the electric heating plate are arranged, hot air can be used for drying fine dried noodles, the drying effect of the fine dried noodles is good, the condition that finedried noodle drying is not thorough is avoided, a rotating shaft, a rotating disc and a hook are arranged, the fine dried noodle drying effect can be effectively improved, the fine dried noodles can be evenly dried in the drying box, and the machining quality of the fine dried noodles high.

Owner:蒙城于氏德霖食品科技有限公司

Manufacturing method of artificial composite particle board

ActiveCN112414060AReduce drying efficiencyReduce drynessDrying gas arrangementsDrying chambers/containersCold airProcess engineering

The invention relates to a manufacturing method of an artificial composite particle board. A bottom plate, a bearing device, a poking device and a vibration device are included, the bearing device isinstalled at the upper end of the bottom plate, the poking device is arranged on the left side of the bearing device, and the poking device is connected with the bottom plate in a sliding fit mode. According to the method, the problem that the situation that the wood chip drying efficiency is reduced due to the fact that the wood chips located inside cannot be completely dried due to the fact thattoo many wood chips are required to be dried appear easily due to the fact that the wood chips cannot be dried in a multi-station mode when existing equipment dries raw materials of the artificial composite particle board can be solved, meanwhile, the problem that drying treatment on the wood chips at the lower part is not facilitated due to the fact that wood chip particles located at the lowerpart cannot be overturned to the surface due to the fact that the wood chips cannot be poked when the wood chips are dried can be solved, and besides, the problems that the wood chip drying effect isreduced due to the fact that the wood chips are prone to scorching due to the excessively-high temperature due to the fact that hot air and cold air cannot be alternately used in the drying process and the like are solved.

Owner:临沂艾维新型装饰材料有限公司

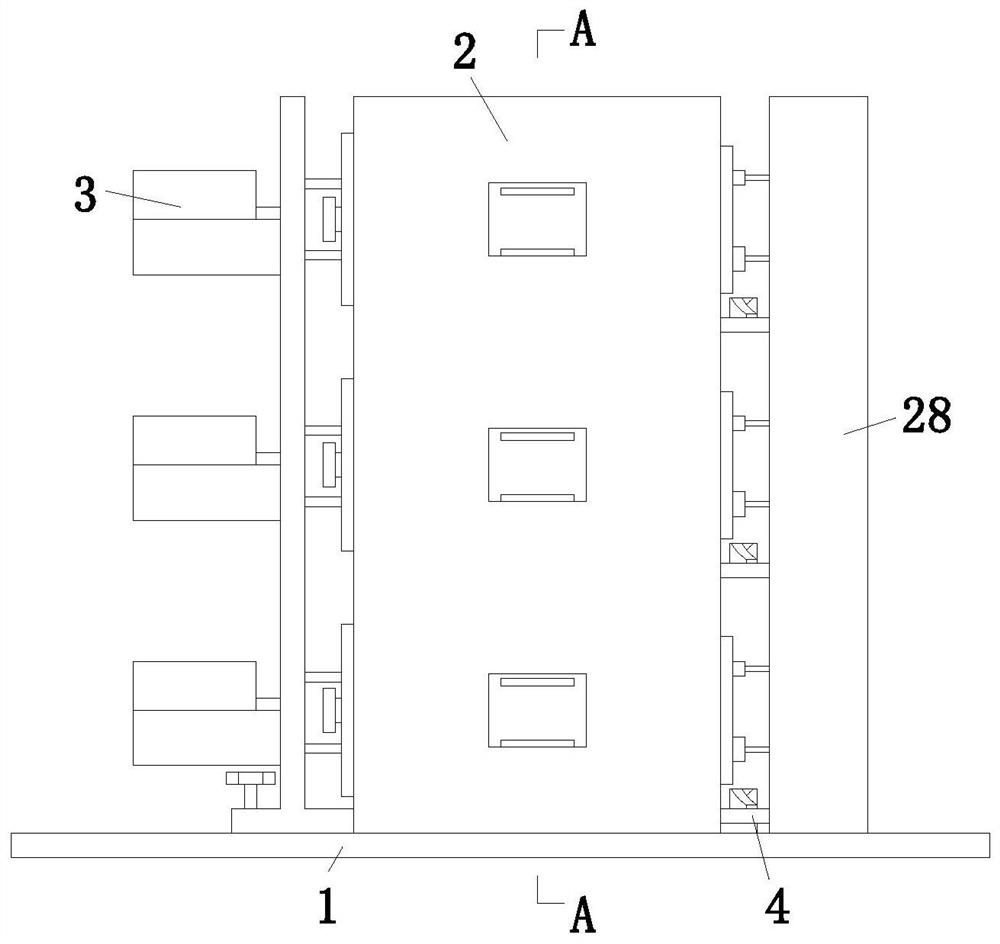

Treatment system for printing and dyeing sludge

InactiveCN110683742AFully dryAvoid incomplete dryingSludge treatment by de-watering/drying/thickeningDispersed particle filtrationElectric machineryProcess engineering

The invention provides a treatment system for printing and dyeing sludge. The treatment system for printing and dyeing sludge comprises a box body, wherein a crushing box is fixedly connected to one side of the bottom of the inner wall of the box body; the other side of the bottom of the inner wall of the box body is fixedly connected with a collecting box; a material guiding plate is fixedly connected to one side of the inner wall of the crushing box; one side of the material guiding plate sequentially penetrates through the crushing box and the collecting box and extends into the collectingbox; a first motor is fixedly connected to the bottom of the inner wall of the crushing box; a first rotating shaft is fixedly connected to an output shaft of the first motor; and a crushing cutter isfixedly connected to the surface of the first rotating shaft. The treatment system provided by the invention has the advantages that the interior of the printing and dyeing sludge can be dried, and the influence of uneven drying of the printing and dyeing sludge on later treatment is avoided; in addition, the printing and dyeing sludge treatment system provided by the invention can purify and discharge gas generated during drying, so the working environment of workers is guaranteed.

Owner:江苏鑫润辉科技有限公司

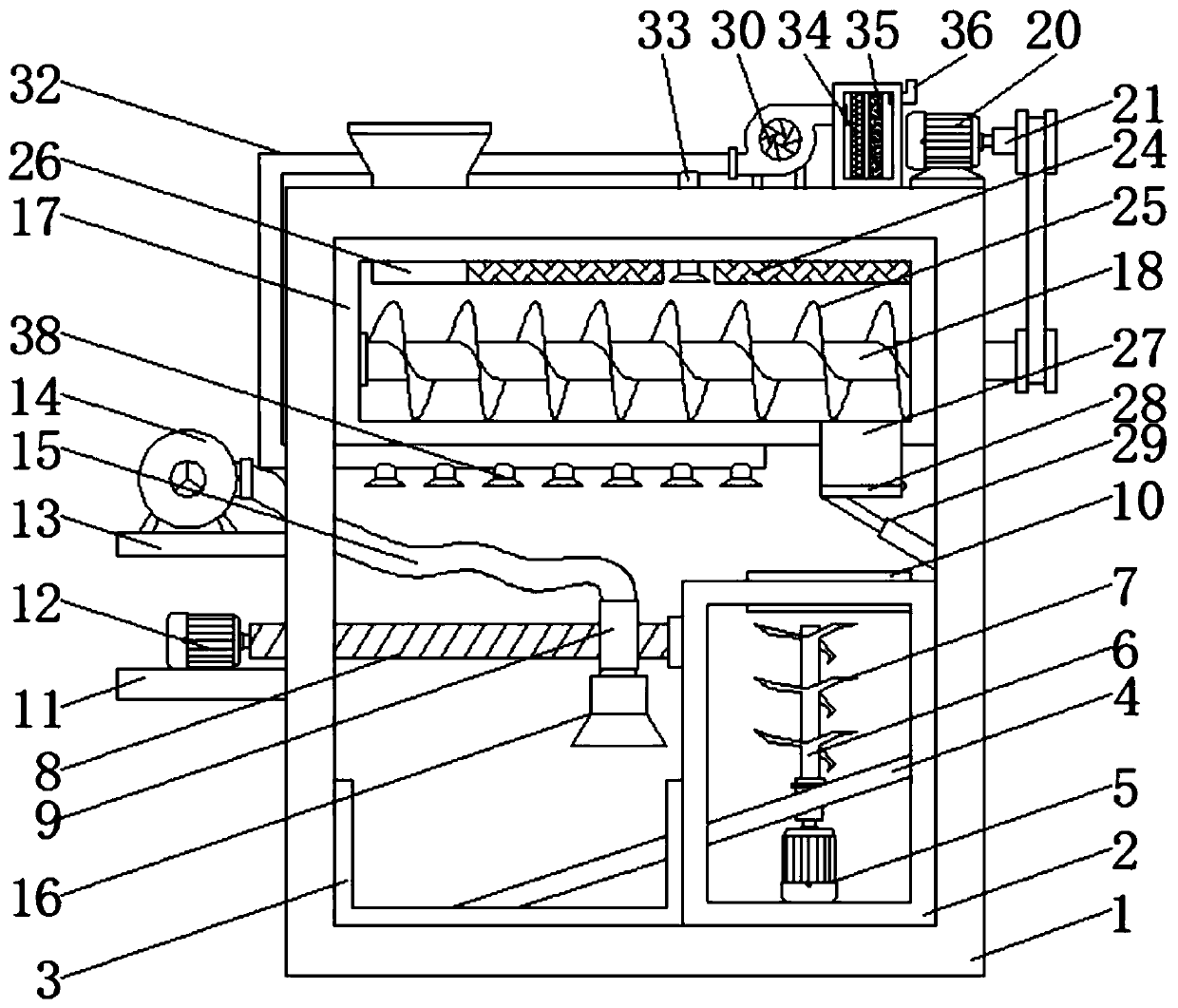

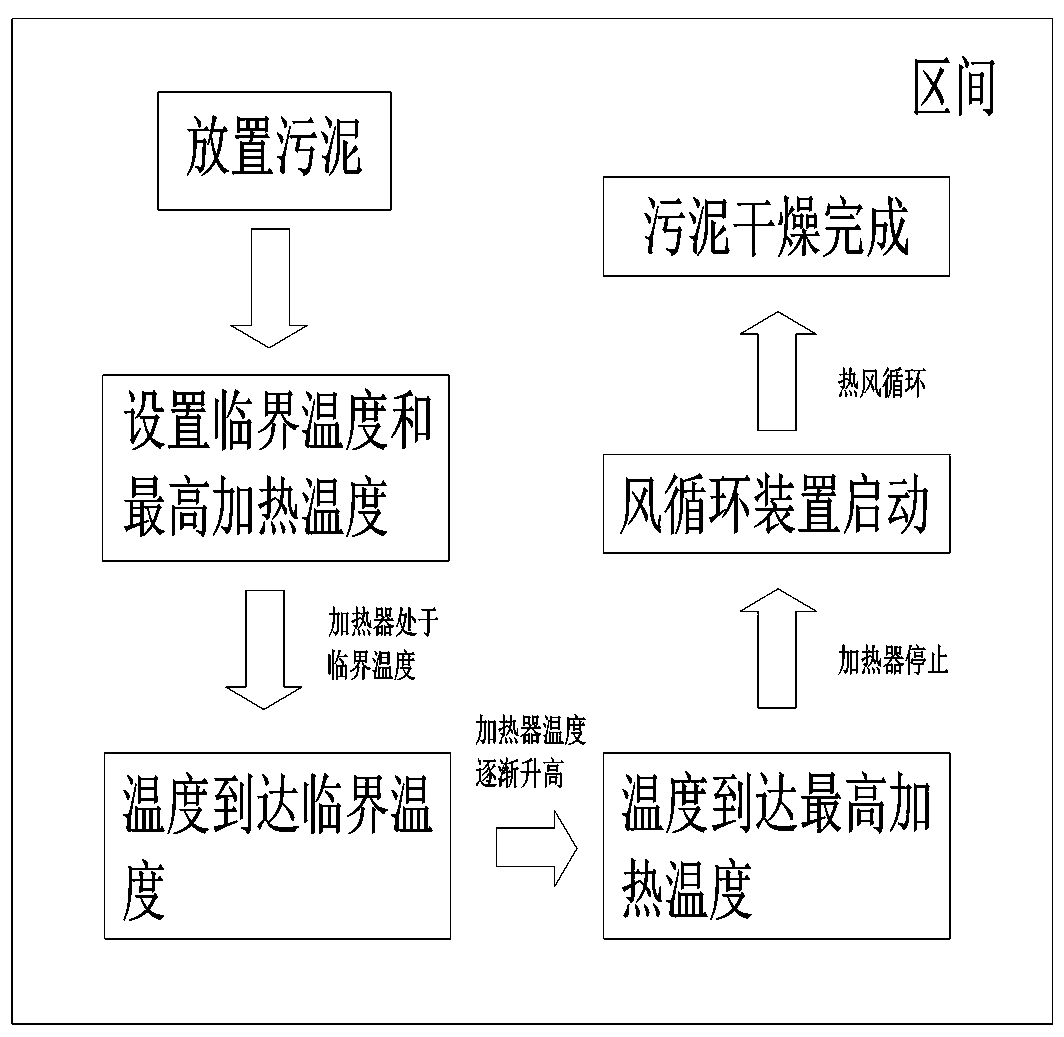

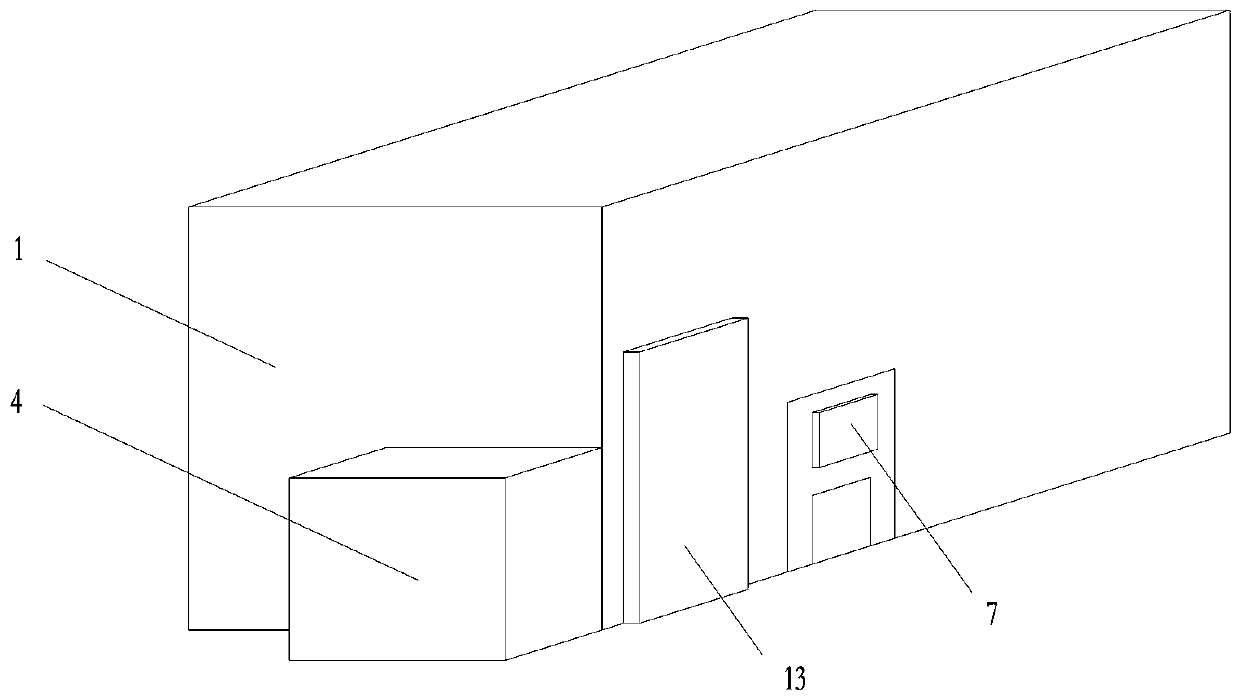

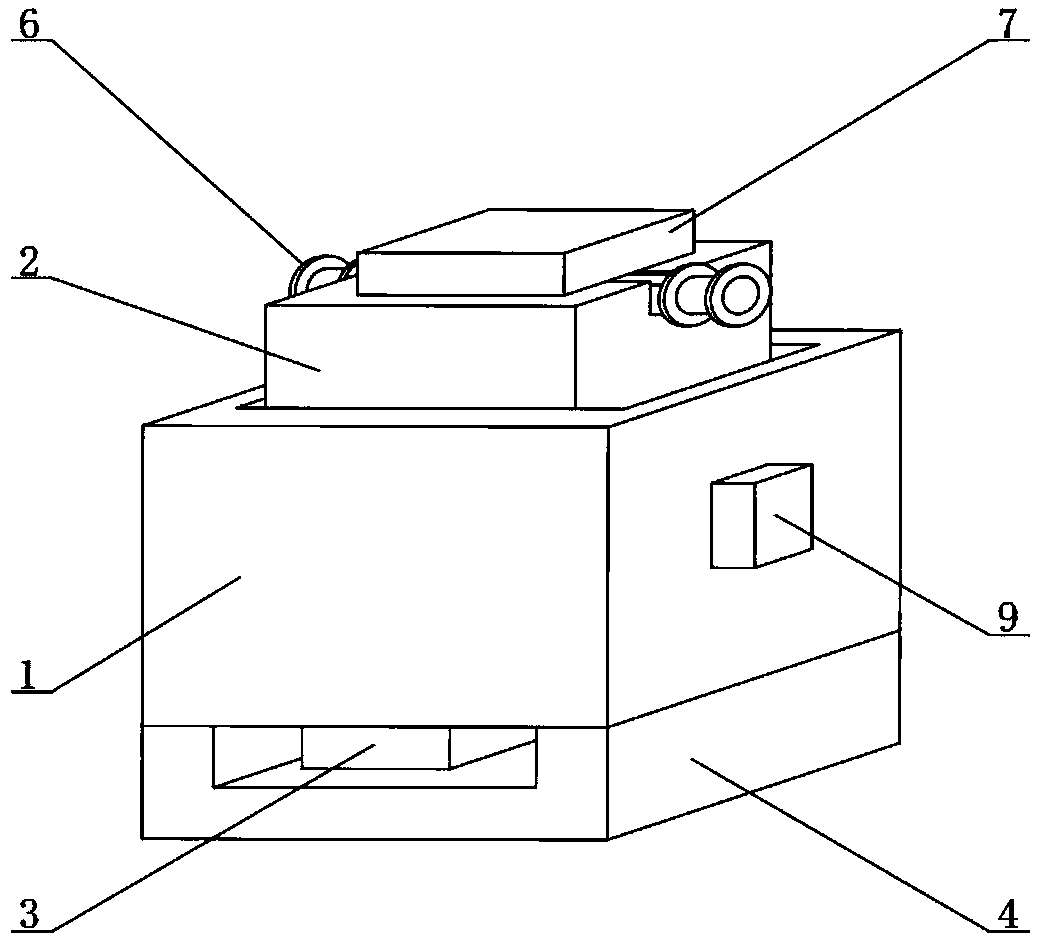

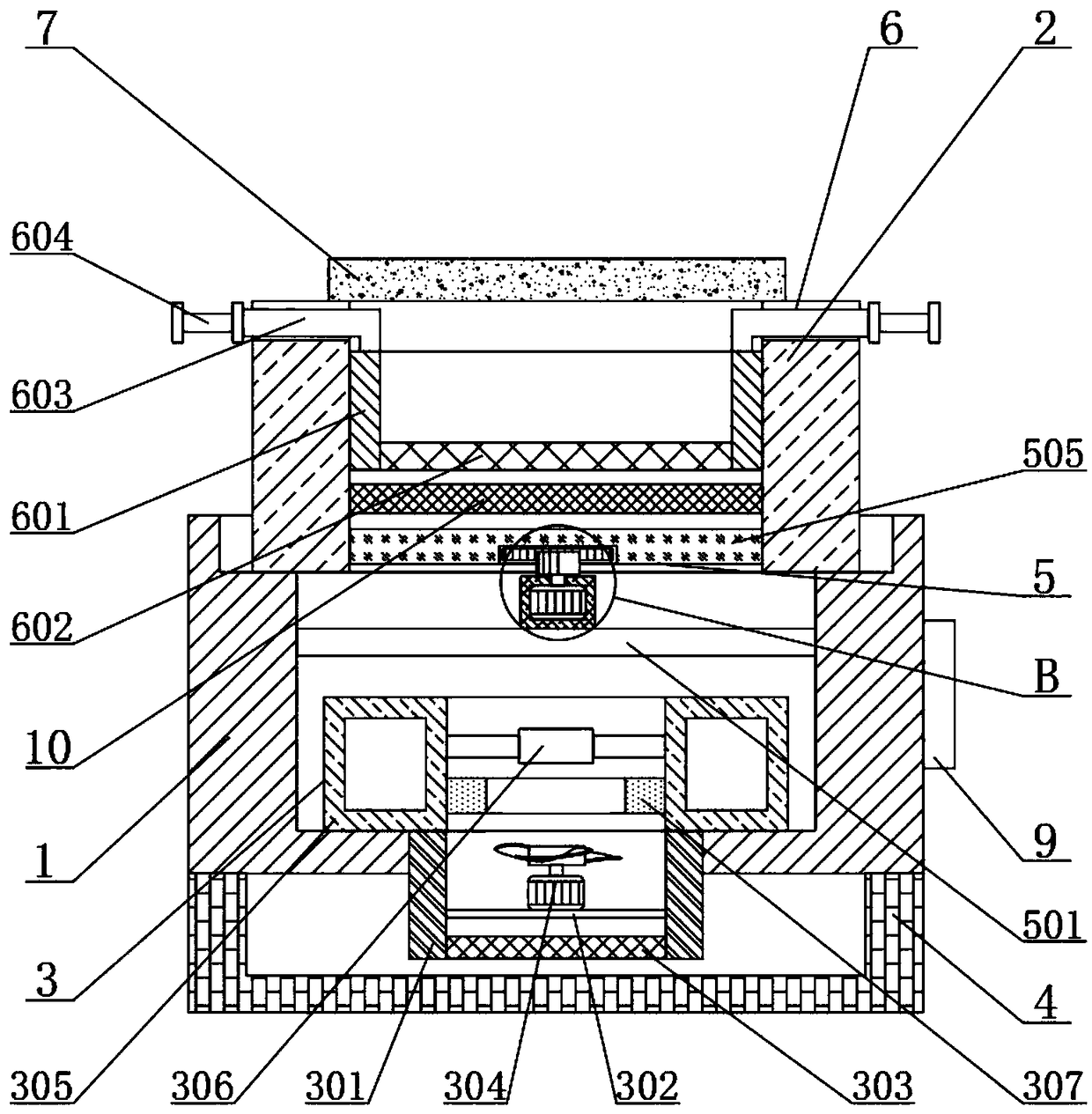

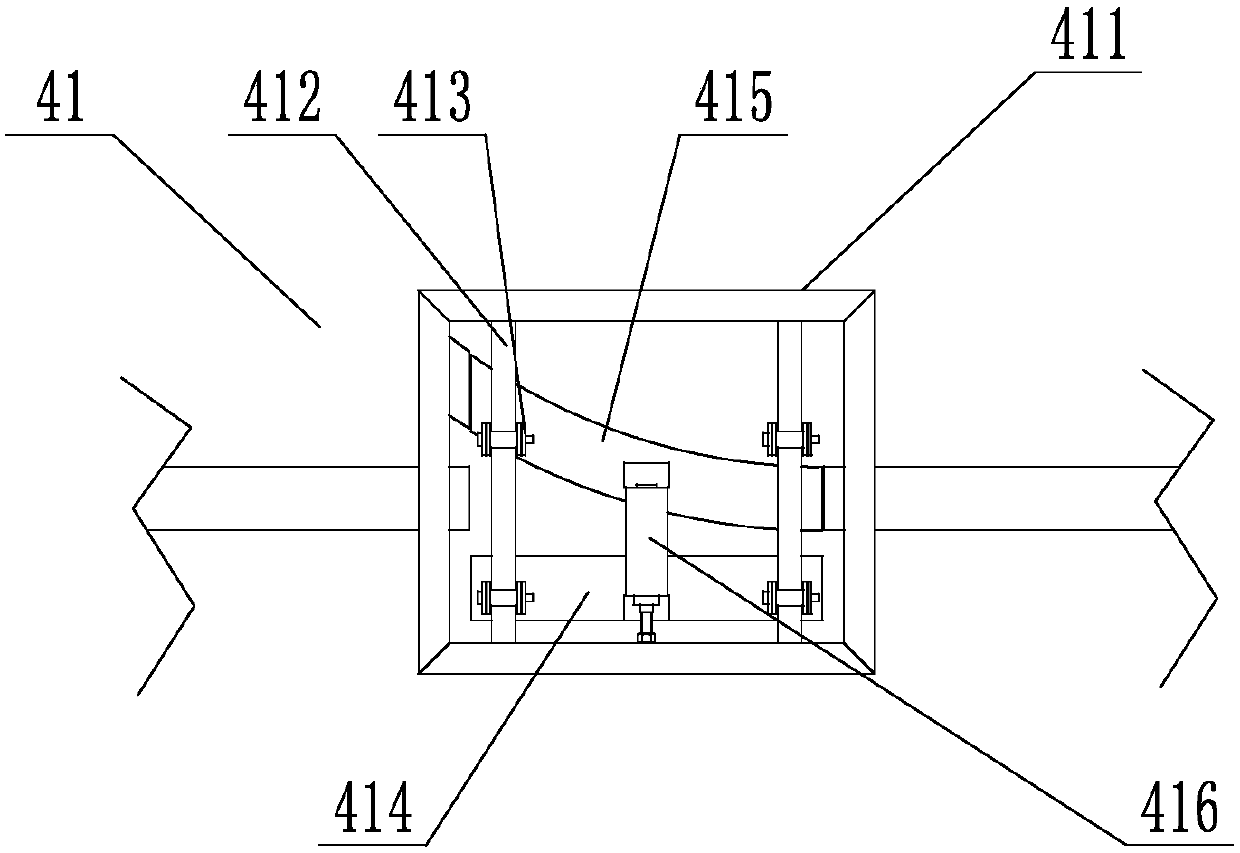

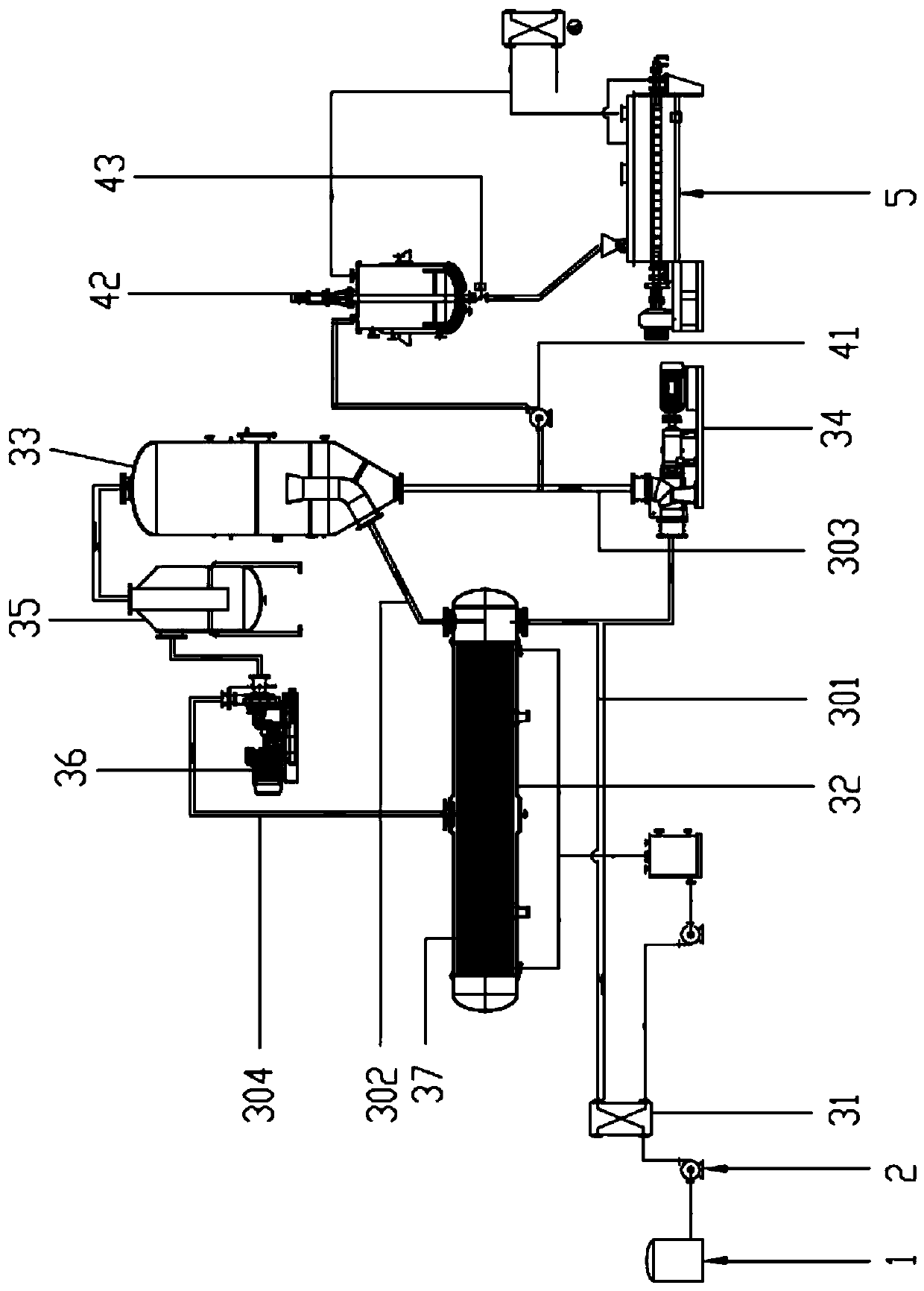

Sludge low-temperature drying process and sludge low-temperature dryer

ActiveCN109734278AGuaranteed moisture contentAvoid incomplete dryingSludge treatment by de-watering/drying/thickeningSludgeRoom temperature

The invention belongs to the technical field of environment protection, and particularly relates to a sludge low-temperature drying process and a sludge low-temperature dryer. The process includes: setting at least one interval, arranging a heating device and an air circulating device in the interval, and setting critical temperature and highest heating temperature in the heating device; putting sludge into the interval, and starting the heating device and the air circulating device to heat the sludge in the interval; when temperature in the interval reaches the critical temperature, graduallyincreasing the heating temperature of the heating device within certain time until the heating temperature of the heating device reaches the highest heating temperature; when the temperature in the interval reaches the highest heating temperature, stopping the heating device, and driving hot air for further drying through the air circulating device until the temperature in the interval reaches room temperature. By the process, energy can be saved while efficient sludge drying is realized; the dryer is provided with multiple intervals, thereby being capable of drying various types of sludge atthe same time, high in drying efficiency and wide in application range.

Owner:HANGZHOU CHUAN & ENVIRONMENTAL TECH CO LTD

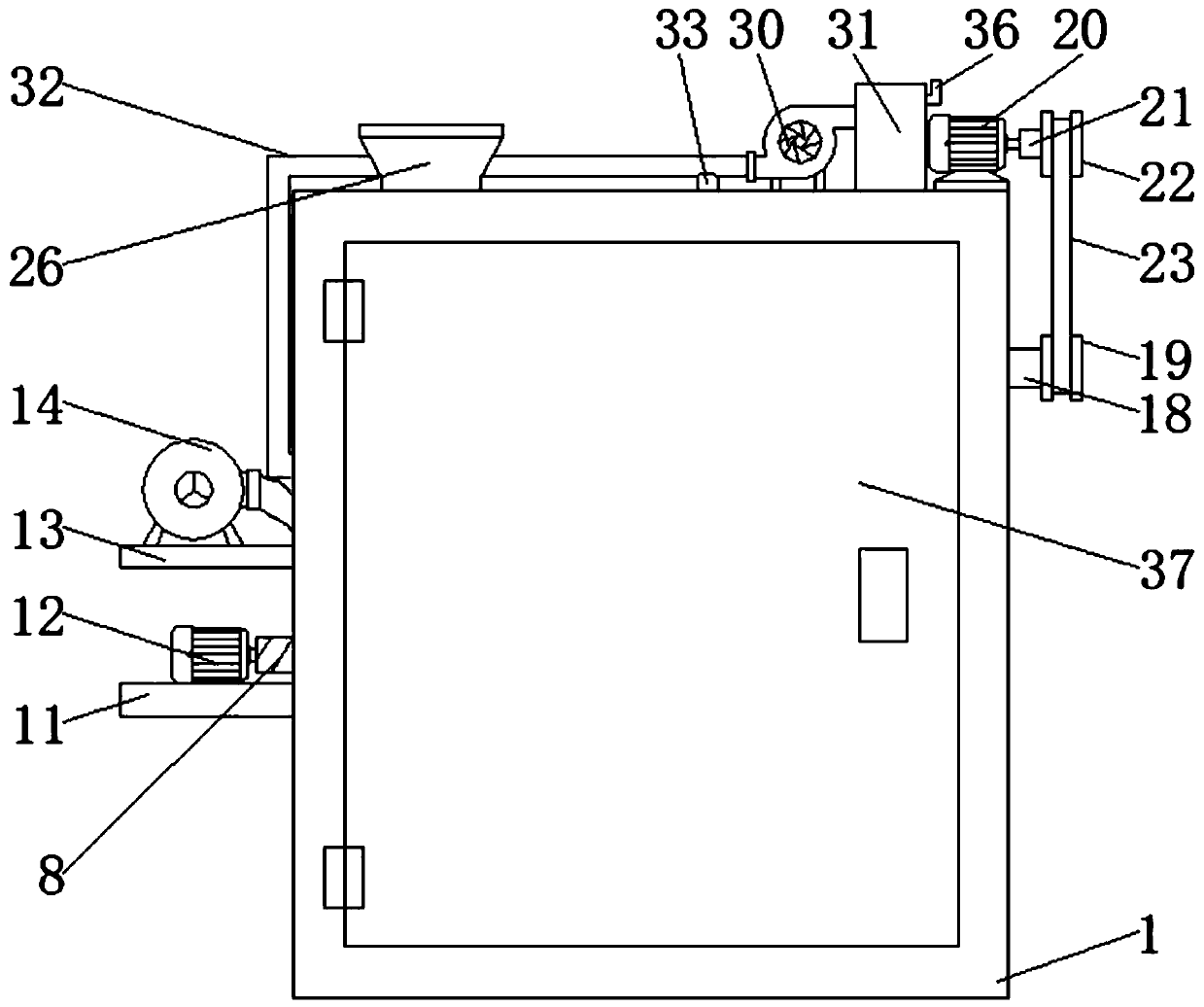

Drying device for honeysuckle production

InactiveCN109373718AAvoid wastingPlay a preheating roleDrying gas arrangementsDrying solid materialsEngineeringExcess heat

The invention relates to the technical field of honeysuckle production, in particular to a drying device for honeysuckle production. The drying device for honeysuckle production comprises a first boxbody, a drying device, a sliding device, a first anti-scalding device and a second anti-scalding device, wherein a second box body is slidably connected to the top end surface of the first box body; the drying device is arranged at the bottom end of the inner side of the first box body; a base is fixedly connected to the bottom end surface of the first box body; the sliding device is fixedly connected to the top end of the inner side of the first box body; and the sliding device is fixedly connected with the second box body, the inner side of the second box body is provided with a metal net fixedly connected with the second box body, and the first anti-scalding device is slidably connected to the top end of the inner side of the second box body. According to the drying device for honeysuckle production, due to the arrangement of a water tank, the characteristics of being large in specific heat capacity and absorbing heat of water and the water storage and heat conduction characteristics of the water tank, excess heat can be absorbed, a role of preheating is played for subsequent drying, and waste of heat energy and electric energy is avoided.

Owner:湖南龟寿堂健康产业发展有限公司

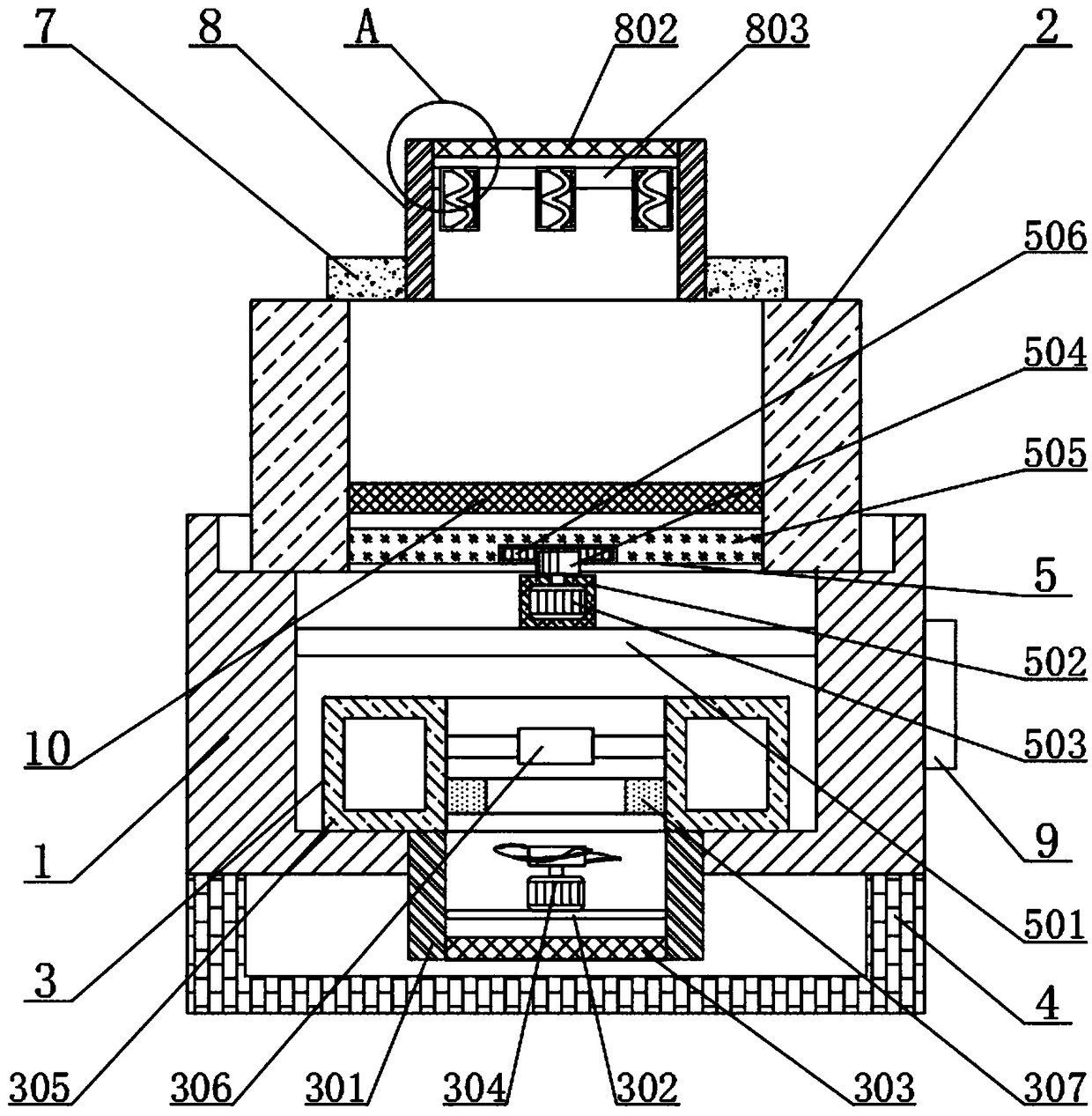

Washing and drying integrated multi-solvent dry cleaning machine

PendingCN110644204AEnsure safetySpeed up the flowDry-cleaning apparatusTextiles and paperProcess engineeringEnergy supply

The invention discloses a washing and drying integrated multi-solvent dry cleaning machine, which comprises a bottom plate, an air extraction device and a rolling device. The bottom plate is providedwith a groove, a clean solvent tank and a dirt solvent tank are arranged in the groove, supporting rods are fixed to four corners of the upper end of the bottom plate, and a fixing plate is fixed to upper ends of the four supporting rods jointly. Supporting plates are fixed to two sides of the upper end of the fixing plate, the rolling device is arranged on one of the supporting plates, an outer drum is fixed between the two supporting plates, a mounting rod is fixed to one side of the upper end of the outer drum, a mounting box is fixed to the upper end of the mounting rod, and an air inlet pipe is connected to the other end of the mounting box and connected with the outer drum. The washing and drying integrated multi-solvent dry cleaning machine has advantages that drying of clothes washed by a petroleum dry cleaning machine is realized, safety in use is achieved, external connection of other energy sources except for electricity is avoided, and dangerous situations of petroleum burning caused by overhigh gas temperature in use are avoided.

Owner:SHANDONG LONGLI ELECTRIC APPLIANCE

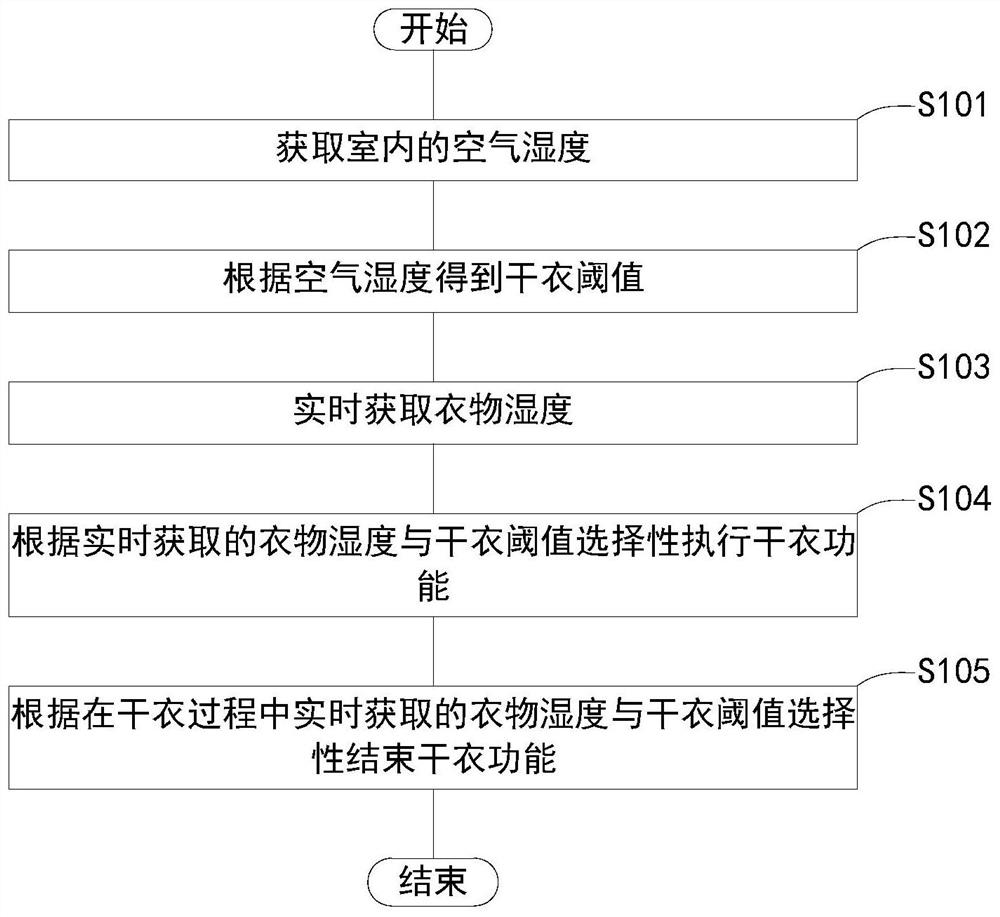

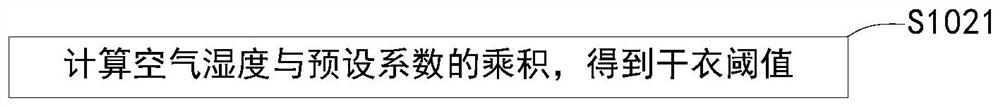

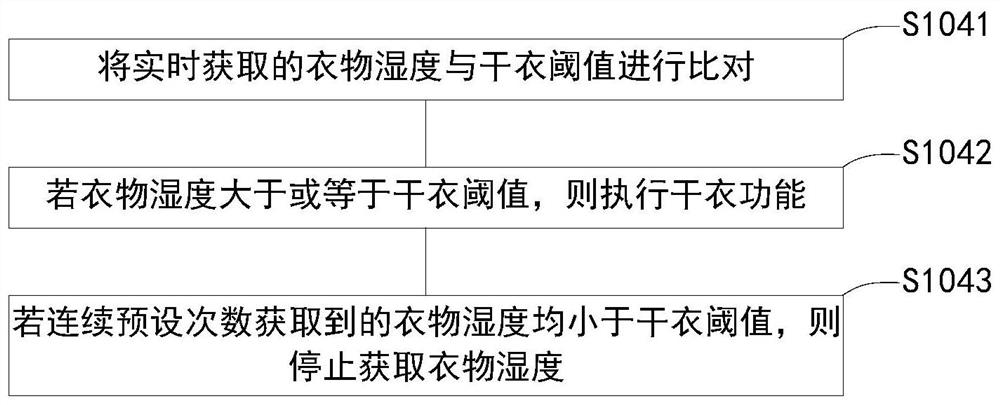

Clothes drying method and device and air conditioner

PendingCN113403820AGet humidity in real timeAvoid incomplete dryingMechanical apparatusTextiles and paperProcess engineeringAir humidity

The invention provides a clothes drying method and device and an air conditioner, and relates to the technical field of air conditioners. The clothes drying method comprises the following steps of obtaining indoor air humidity; obtaining a clothes drying threshold value according to the air humidity; obtaining the clothes humidity in real time; selectively executing a clothes drying function according to the clothes humidity obtained in real time and the clothes drying threshold value; and selectively ending the clothes drying function according to the clothes humidity and the clothes drying threshold value obtained in real time in the clothes drying process. The clothes drying method provided by the invention has the characteristics of energy conservation and better clothes drying effect.

Owner:NINGBO AUX ELECTRIC

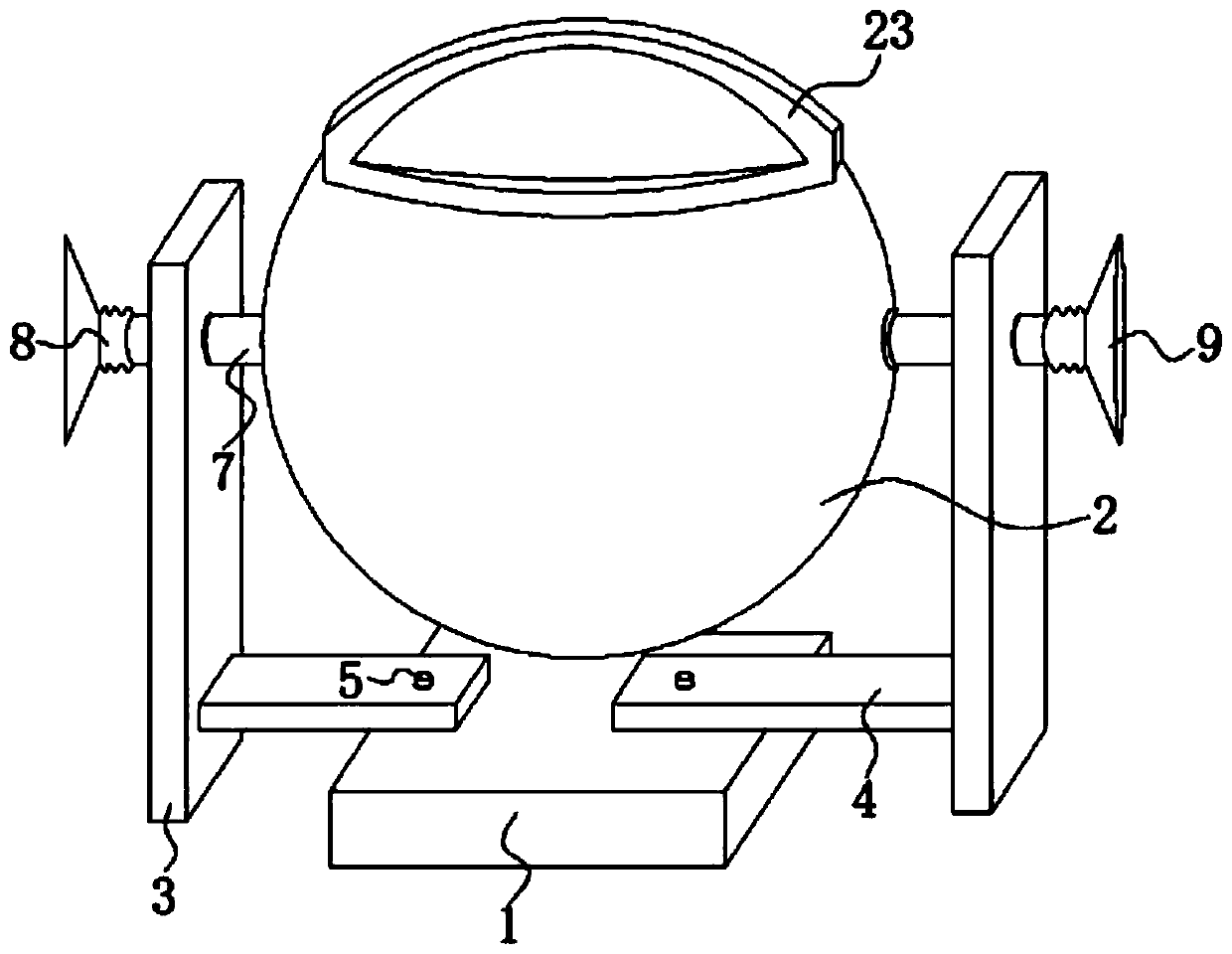

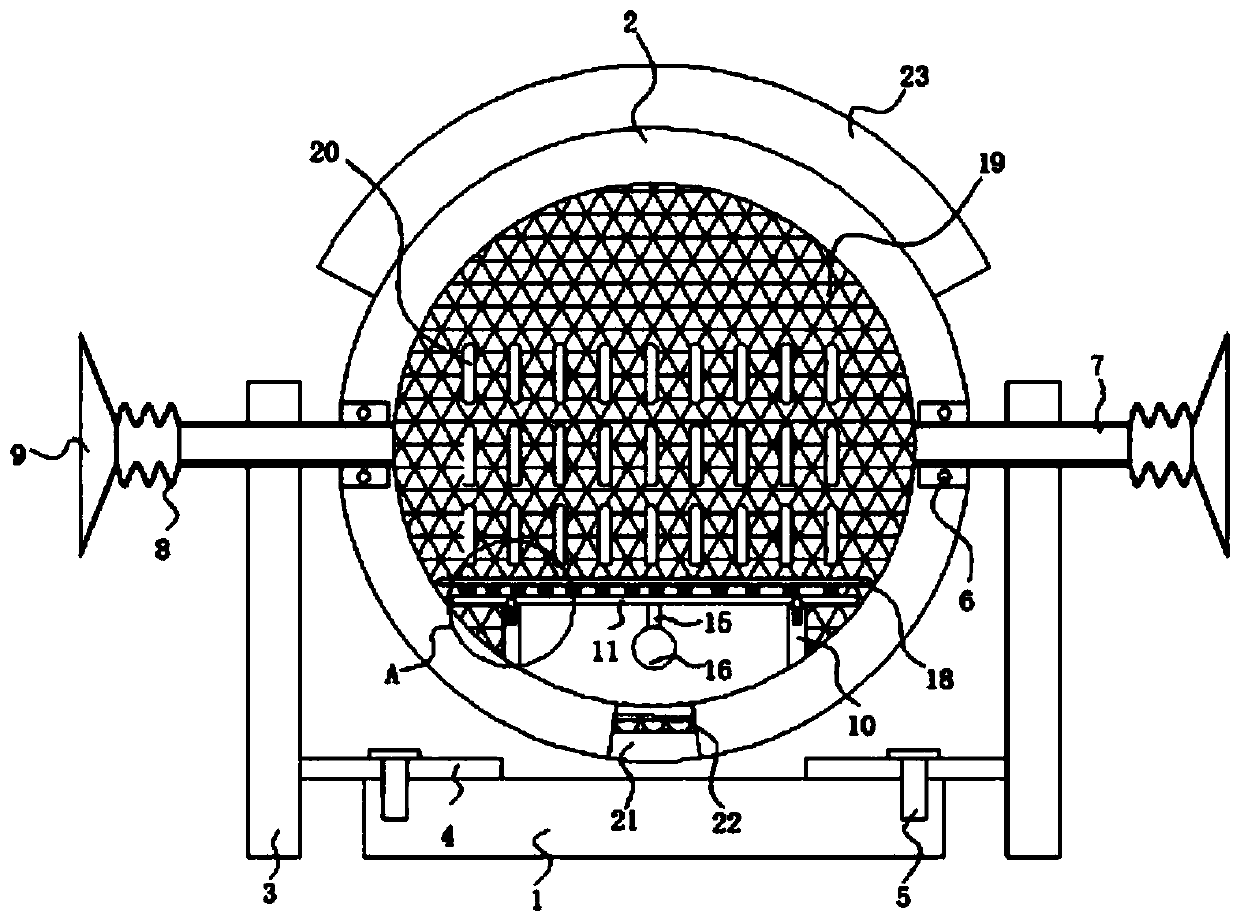

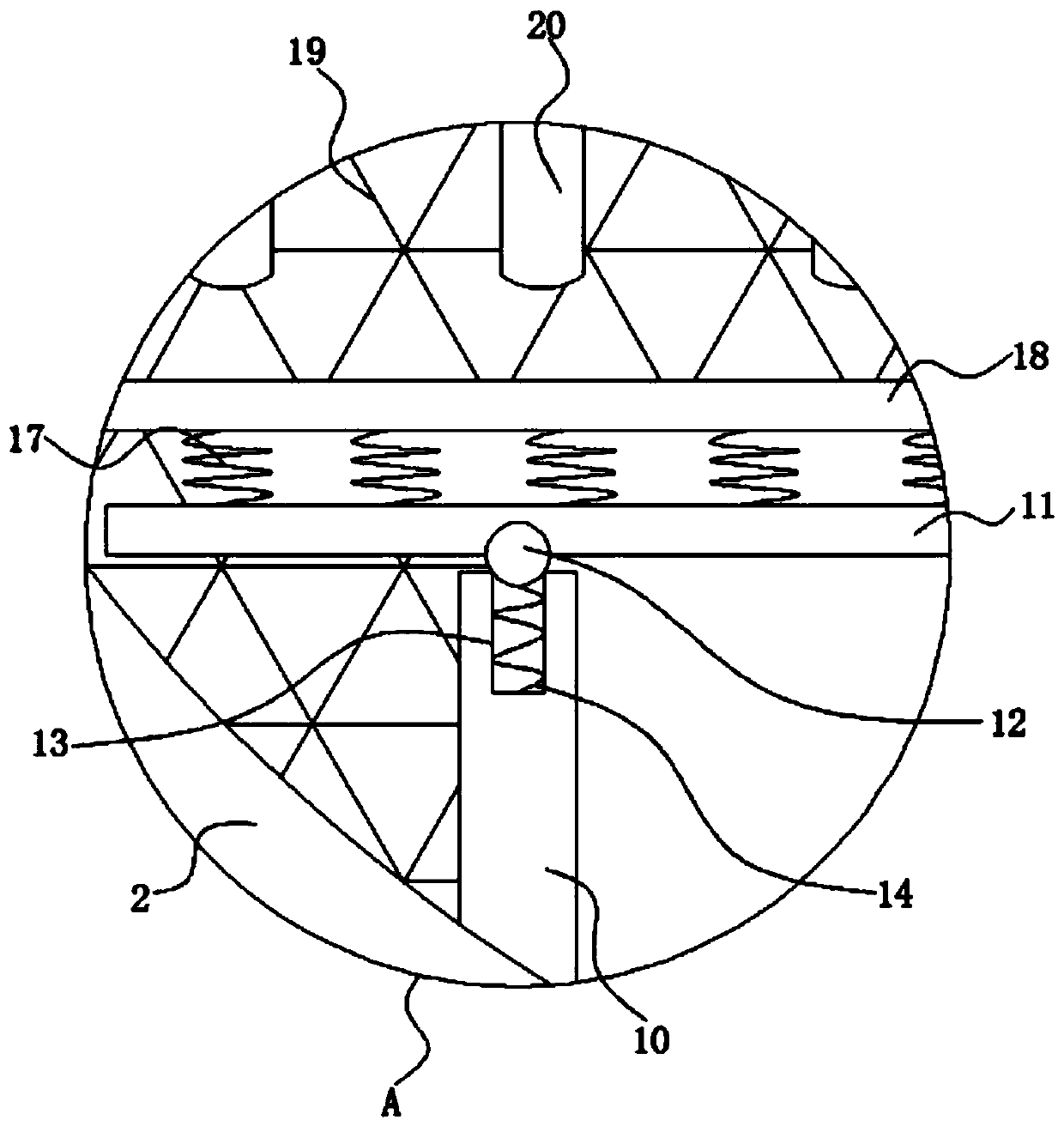

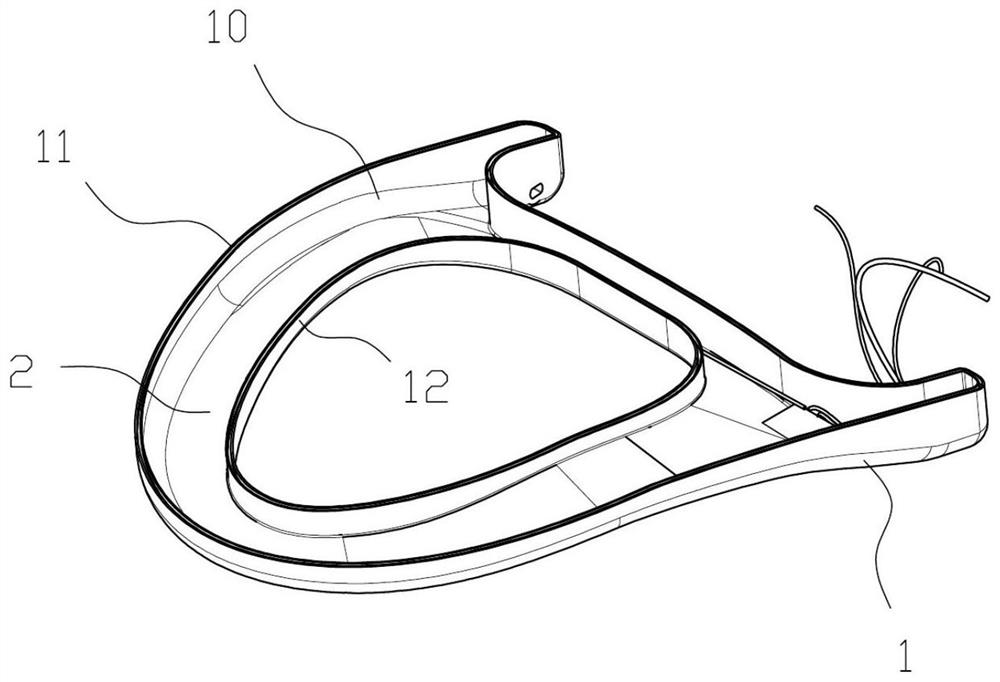

Rear seat box of tourist bicycle and using method

ActiveCN111348129AInfluence cycleAvoid incomplete dryingCycle containersClassical mechanicsMechanical engineering

The invention provides a rear seat box of a tourist bicycle and a using method. The rear seat box comprises a bicycle backseat, a spherical box body and a supporting plate; a mounting plate is joggledon the surface of the supporting plate; the surface of the mounting plate is in threaded connection with a fixing bolt; the surface of the mounting plate is fixedly connected with the surface of therear seat through fixing bolts; the surface of the spherical box body is spherical, the interior of the spherical box body is hollow, a bearing is arranged on the surface of the spherical box body, ahollow steel pipe is welded to an inner ring of the bearing, one end of the hollow steel pipe extends into the spherical box body, and the other end of the spherical box body penetrates through the supporting plate. The invention relates to the travel field. According to the rear seat box of the tourist bicycle, the bicycle is spherical; by means of regular flowing of wind power in the box and inertia and shaking, gaps of clothes are continuously opened, air drying of the clothes is accelerated, and therefore the problems that according to an ordinary traveling bicycle backseat box, the clothes cannot be naturally air-dried conveniently, wet clothes are likely to be found in the box, and wearing is uncomfortable are effectively solved.

Owner:绍兴漫翱创腾智能机械股份有限公司

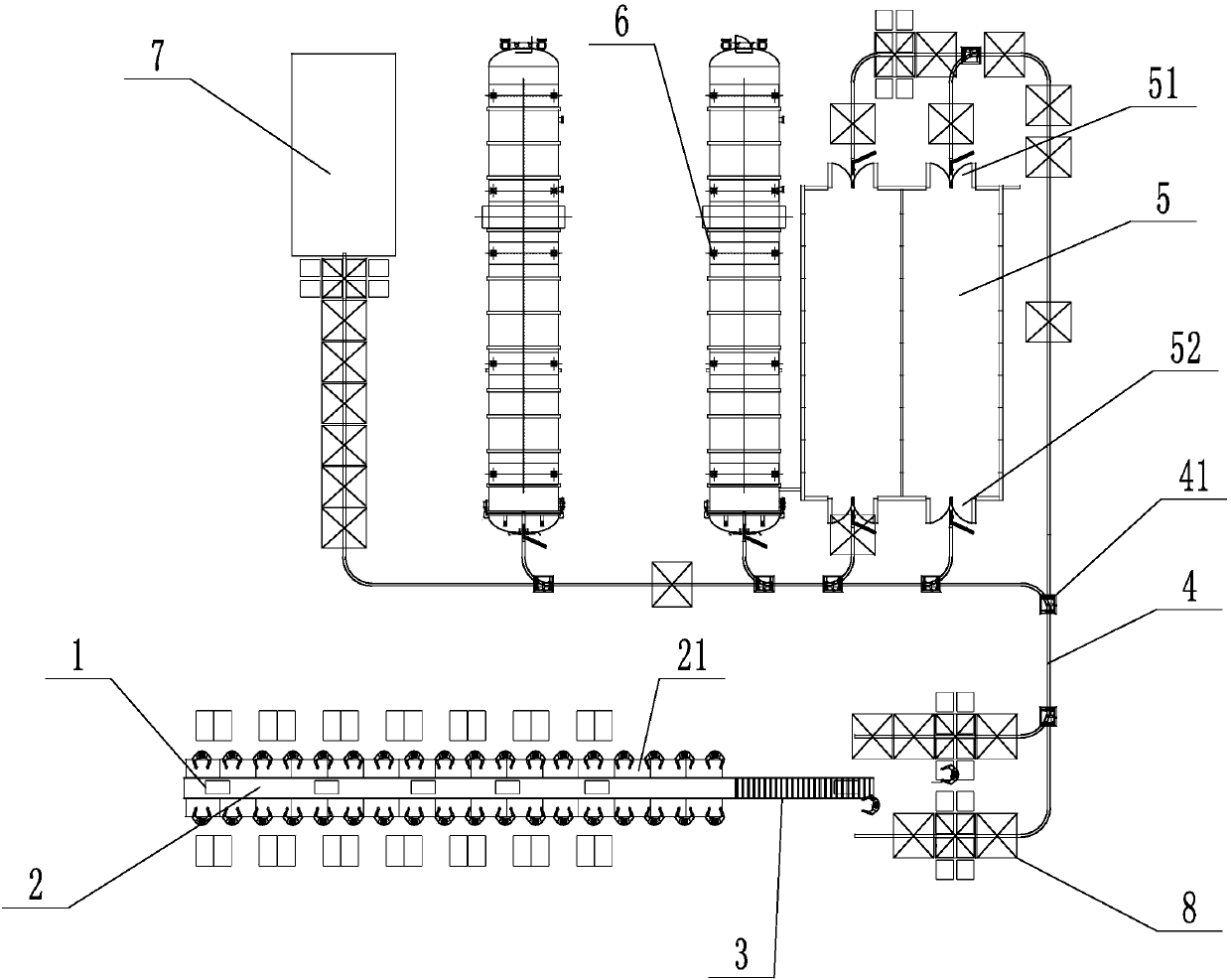

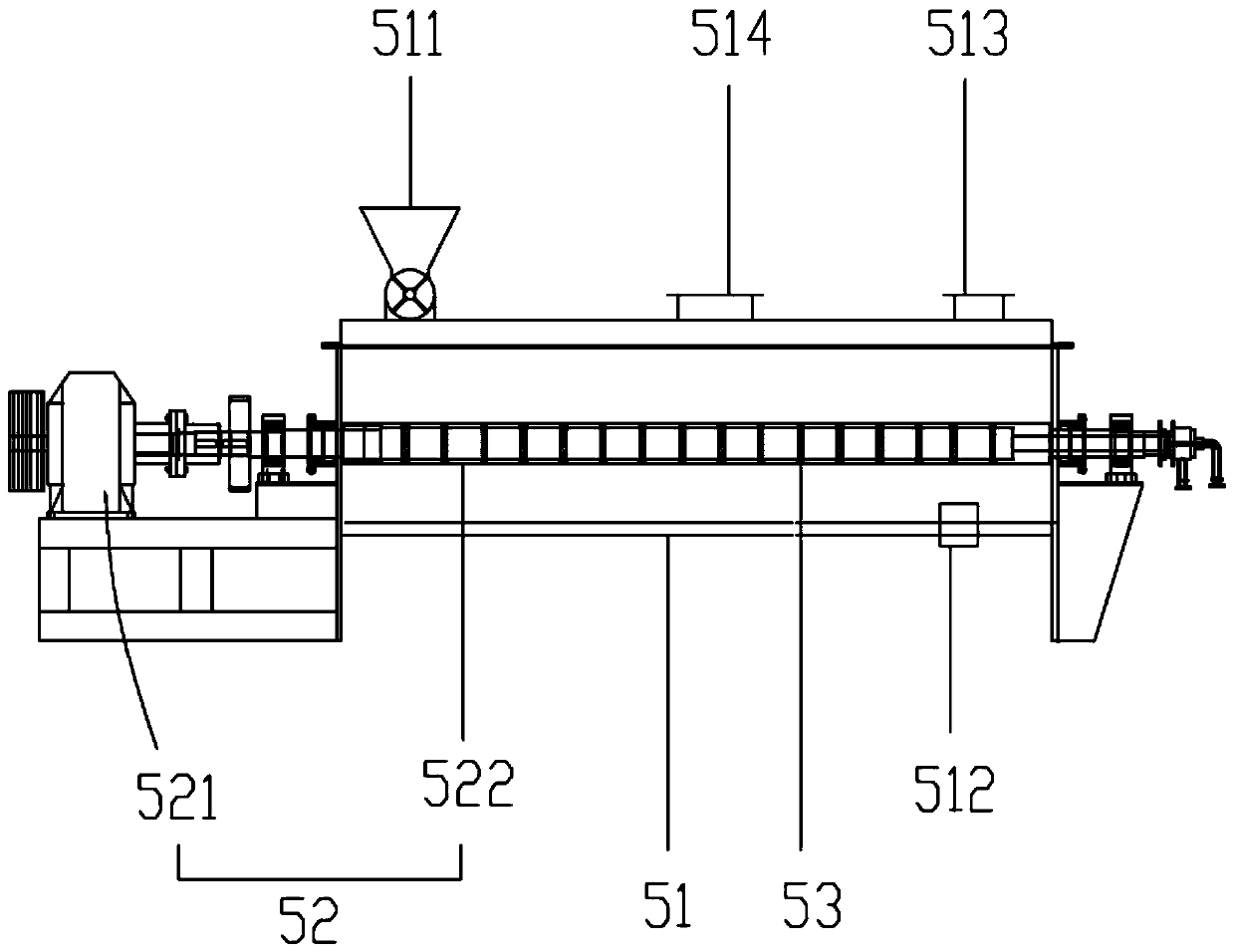

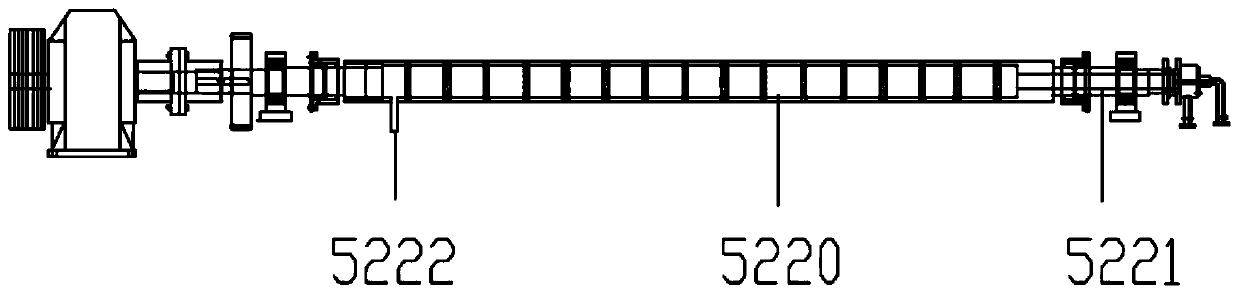

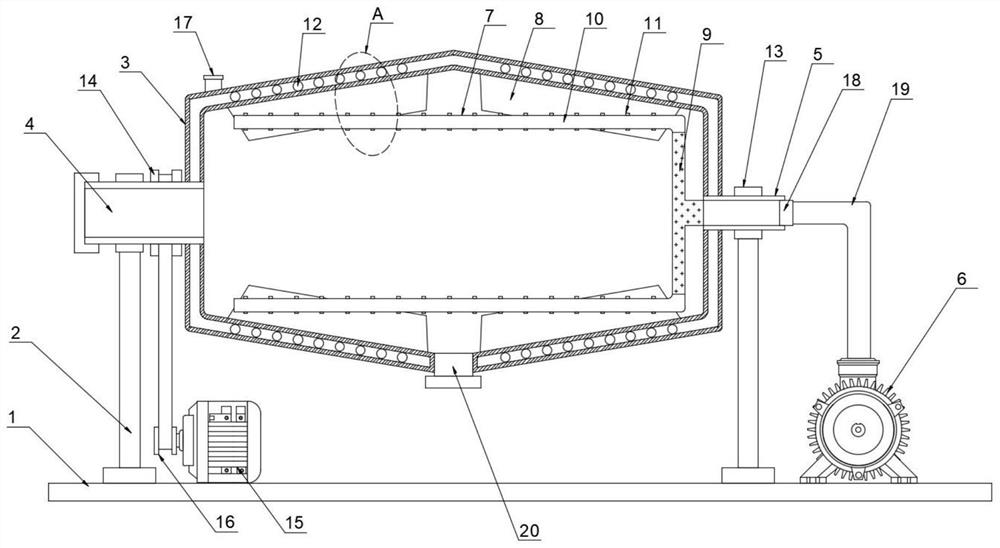

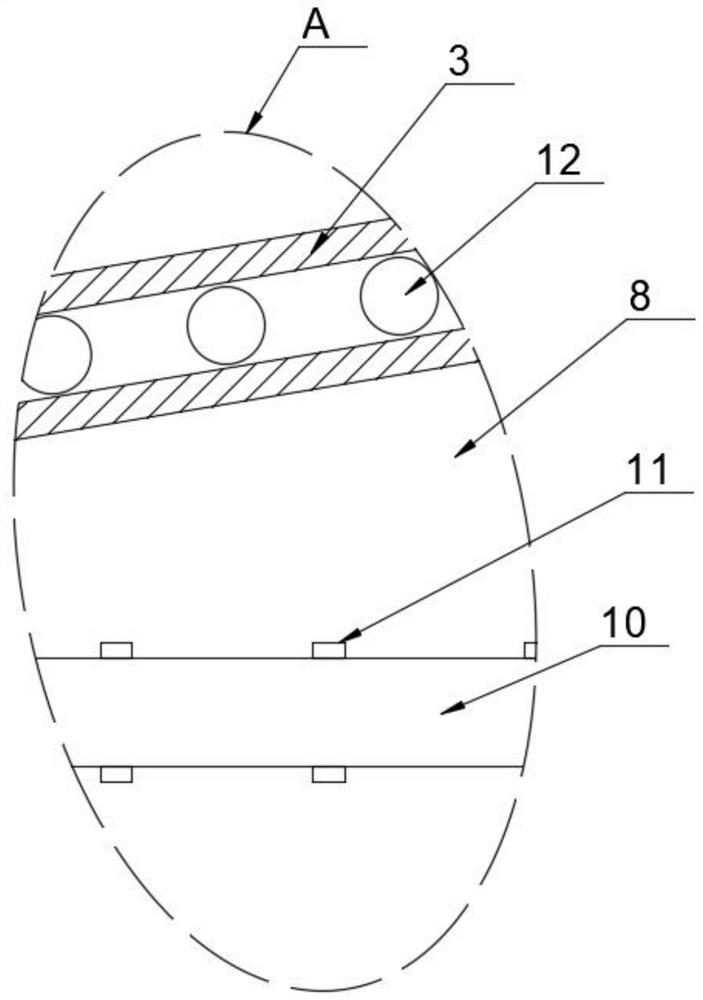

Rose industrialization freeze-drying production system and process

PendingCN107830689AShorten the durationShorten cooling timeDrying solid materials without heatDrying machines with progressive movementsFreeze-dryingProcess engineering

The invention discloses a rose industrialization freeze-drying production system which comprises trays and a horizontally-arranged conveying belt. The tail end of the conveying belt is connected witha roller conveying belt. Operation flat plates are fixedly arranged on the two sides of the conveying belt. A conveying trolley suspended on a guide rail is arranged at the tail end of the roller conveying belt. The guide rail is fixed above the conveying trolley through a supporting device. A tunnel type instant freezer, a freeze dryer and a packaging chamber are further included. The head end ofthe guide rail is arranged on one side of the roller conveying belt. The guide rail is divided into two branches by a conversion device, one branch directly leads to the packaging chamber and penetrates out from a rear door of the tunnel type instant freezer, and then the guide rail leads to the packaging chamber. A branch leading to the freezer dryer is arranged at the position, between the tunnel type instant freezer and the packaging chamber, of the guide rail, roses can be fast subjected to vacuum freeze drying, nutritional ingredients can be effectively kept in the roses, and the numberof roses suffering from color change damage is reduced.

Owner:SHANDONG HUAMEI BIOTECH LTD

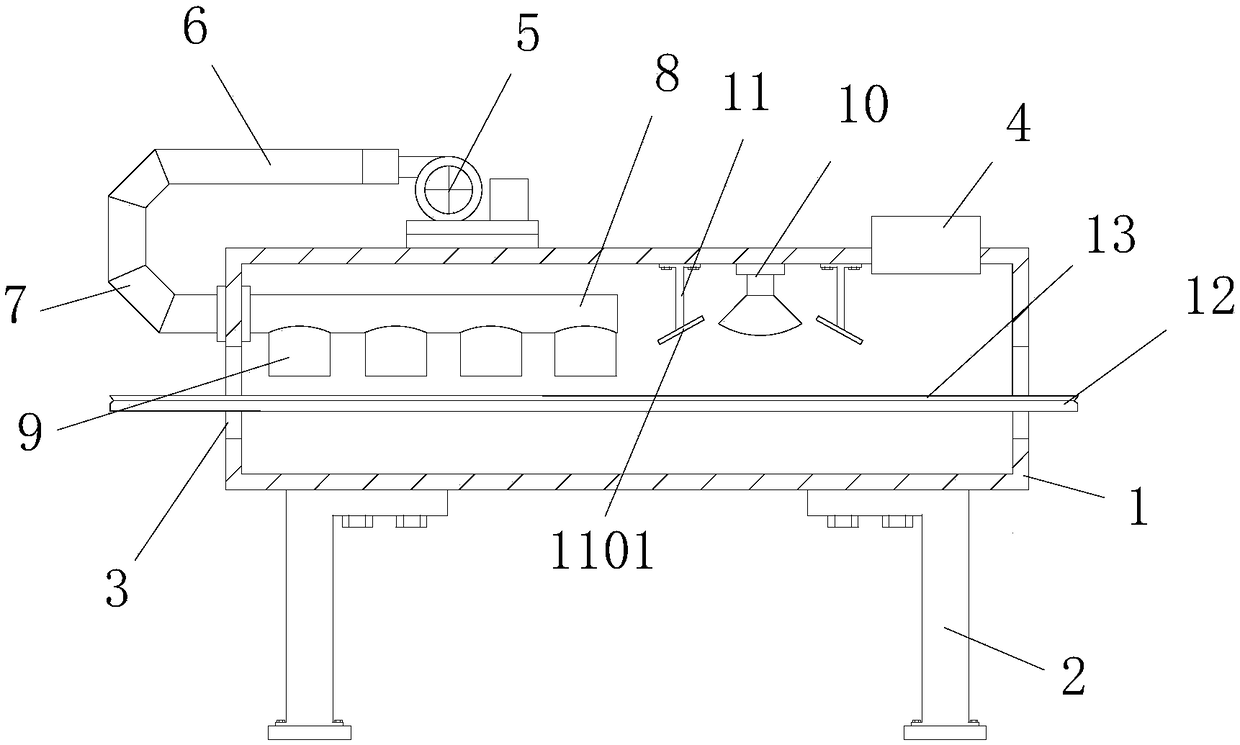

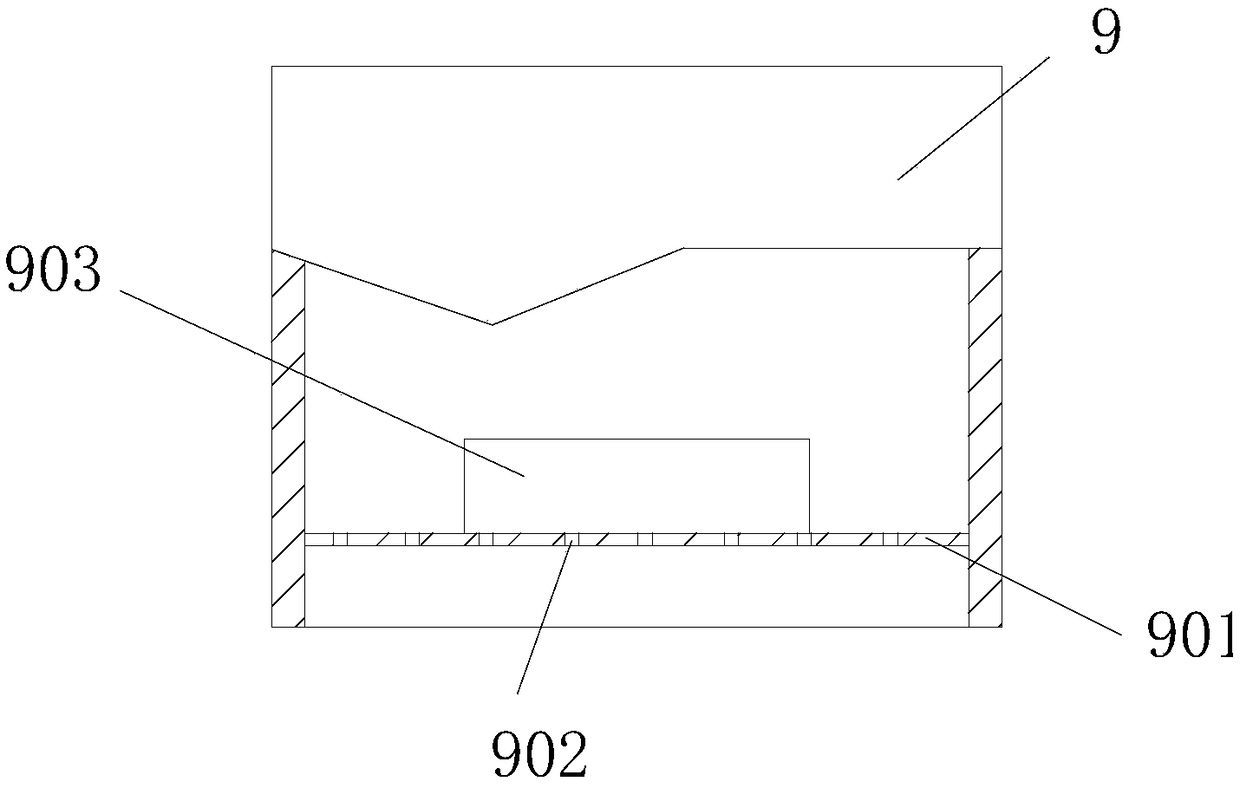

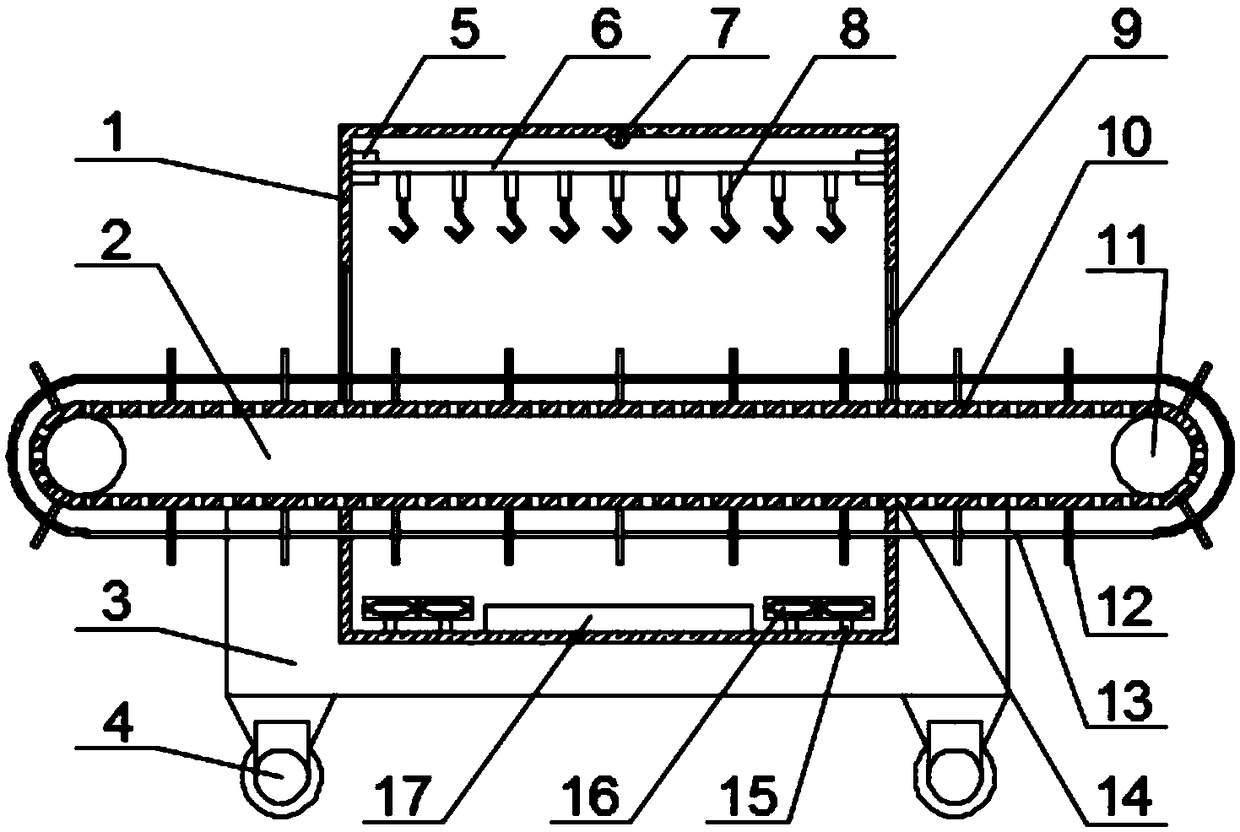

Multiple dehumidification box for textile fabric

InactiveCN109114932AAvoid incomplete dryingEliminate static electricityDrying gas arrangementsDrying machines with progressive movementsElectricityInfrared lamp

The invention discloses a multiple dehumidification box for textile fabric. The multiple dehumidification box comprises a box body, racks, openings, a pipeline fan, a fan, a first tube body, a bent tube, a second tube body, air outlet tubes, a plate body, air outlets, negative-ion generators, an infrared lamp, brackets, mirrors, a conveyor, a tinfoil layer and heating wires. Through a heating tubearranged in the multiple dehumidification box disclosed by the invention, moisture in the textile fabric placed on the surface of the tinfoil layer can be evaporated; through the air outlet tubes, flowing air generated by the fan can be blown to the surface of the textile fabric, and then the textile fabric can be air-dried; the infrared lamp can be adopted for irradiating the top surface of thetextile fabric, and then the moisture in the textile fabric can be further dried; accordingly, the phenomenon of incomplete drying caused by the only one drying mode of a conventional fabric drying machine can be avoided; and through the negative-ion generators arranged inside the air outlet tubes, the phenomenon of static electricity generated in the textile fabric can be effectively eliminated or the phenomenon of static electricity generated in power connection equipment can be eliminated, and then the safety of working personnel can be further protected.

Owner:吴江市欧鑫纺织品有限公司

Equipment used for treating high-salt high-organic-matter wastewater

PendingCN110143629AAvoid incomplete dryingRealize the purpose of all-round dryingSludge treatment by de-watering/drying/thickeningEvaporator accessoriesWastewaterEvaporation

The invention relates to the technical field of treatment equipment for salt-containing wastewater, and in particular relates to equipment used for treating high-salt high-organic-matter wastewater. The equipment comprises a material tank, a material inlet device, an evaporation device, a transfer device and a drying machine; and the external wastewater to be treated passes through the material tank, the material inlet device, the evaporation device, the transfer device and the drying machine in sequence to complete treatment, and the drying machine comprises a cylinder body, a rotating component and a plurality of stirring heating components. According to the equipment provided by the invention, the evaporation device and the drying machine are arranged, firstly evaporation treatment of the high-salt high-organic-matter wastewater is completed, then a viscous mixture is dried, so that the purpose of drying while stirring is realized, the purpose of all-dimensional drying is realized,and a phenomenon that the mixture is not dried thoroughly is avoided.

Owner:江苏川达能源科技有限公司

Preparation method of composite kraft paper

ActiveCN106192600BUnique appearanceBeautiful appearanceLamination ancillary operationsSpecial paperSurface layerPaper production

The invention discloses a composite brown paper. The composite brown paper is prepared from a bottom layer, a core layer, a surface layer and a decorative layer through compounding on an order. The bottom layer is prepared from waste paper pulp, bamboo-wood pulp and needlebush pulp. The core layer is prepared from a first sizing agent and essence. The surface layer is prepared from waste paper pulp, needlebush pulp and hardwood pulp. The decorative layer is prepared from a second sizing agent and dry flowers. A preparation method of the composite brown paper comprises bottom layer preparation, surface layer preparation, core layer preparation, bottom, surface and core layer compounding, drying, decorative layer compounding and drying. The outer surface of the composite brown paper is decorated through dry flowers so that the composite brown paper has unique and beautiful appearance, has a dry flower fragrance, provides natural and healthy experience for a user and is suitable for preparation of various high-grade gift bags and packaging bags. The preparation method has simple processes, utilizes a traditional brown paper production line for production, has a large waste paper pulp use amount and is environmentally friendly.

Owner:东莞市力山纸业有限公司

Dyed yarn airing and drying device

InactiveCN105865175AAvoid incomplete dryingImprove drying effectDrying machines with progressive movementsDrying solid materialsYarnMotor drive

The invention provides a dyed yarn airing and drying device, which includes a drying box, a placing rack is arranged inside the drying box, and clamping chucks are arranged on the placing rack, and the number of the clamping chucks is two set in parallel on the rack, a rotating motor is arranged between the rack and the clamping chuck, and the clamping chuck is driven to rotate by the rotating motor, heating belts are arranged on the inner four walls of the drying box, and the A drying pipe is arranged above the clamping chucks. Fix the material carrying rod wound with yarn by clamping chuck, and drive the clamping chuck to rotate by rotating the motor, set two clamping chucks, so that the yarn on one material carrying rod is dried At the same time, it is transported to another material carrying rod to avoid incomplete drying of the yarn wound inside the yarn during drying. A drying tube is set to dry the disassembled yarn to improve the drying effect.

Owner:WUHU FUCHUN DYEING & WEAVING

Automobile accessory surface drying device

InactiveCN108800878AAvoid incomplete dryingDry thoroughlyDrying gas arrangementsDrying chambers/containersEngineeringMachining

The invention relates to an automobile accessory surface drying device, and belongs to the technical field of automobile accessory machining. The device comprises a box body, a conveying device and abase. The conveying device, a temperature sensor, a first partition plate, a fixed block, a first box door, a door curtain, a heating unit and a fan are arranged in the box body, a conveying belt is provided with a through hole and a net plate, an automobile accessory is placed on the net plate to be dried, the contact area between the automobile accessory and the net plate is greatly reduced, thebottom of the automobile accessory is prevented from being incompletely dried, the surface of the automobile accessory is more thoroughly dried, the drying efficiency is higher, the partition plate with a hook is arranged, therefore, the utilization rate of the box body is improved, and the drying efficiency and drying quality are improved.

Owner:安徽傲尊电子科技股份有限公司

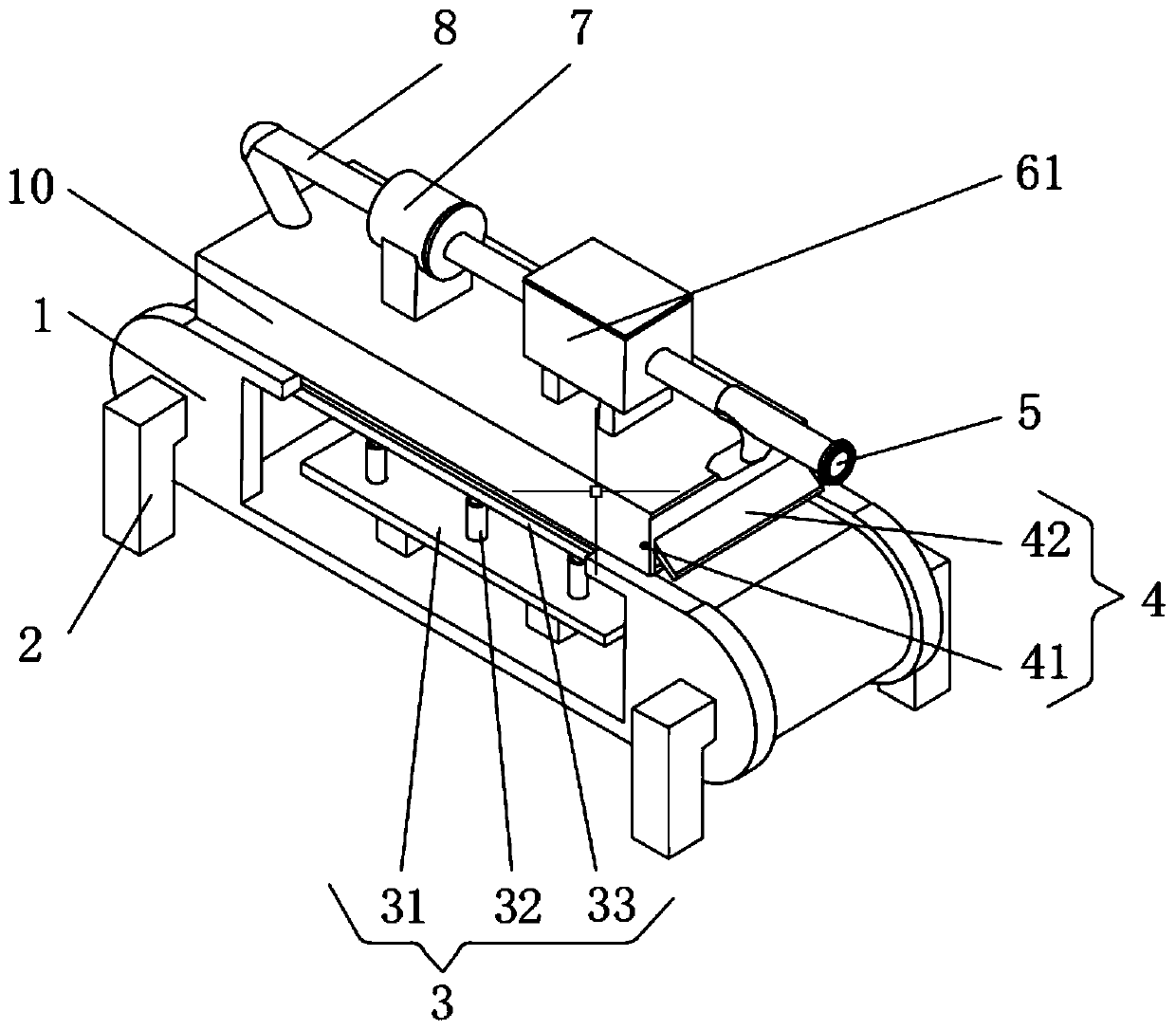

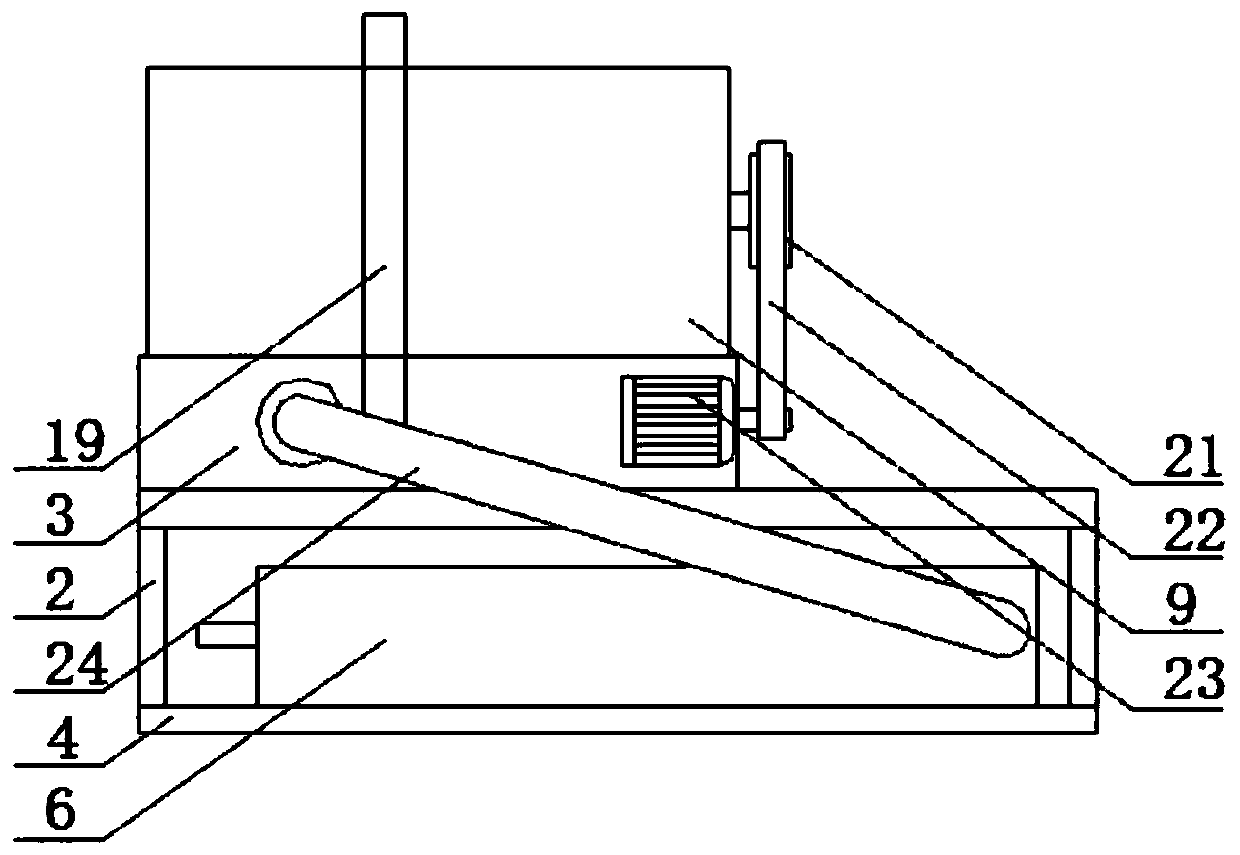

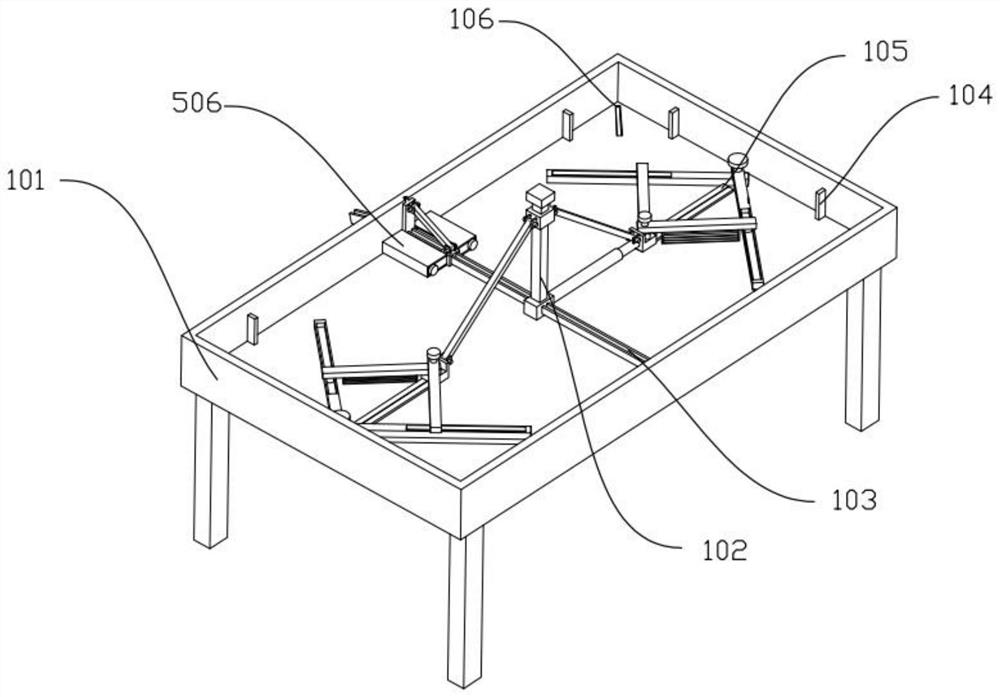

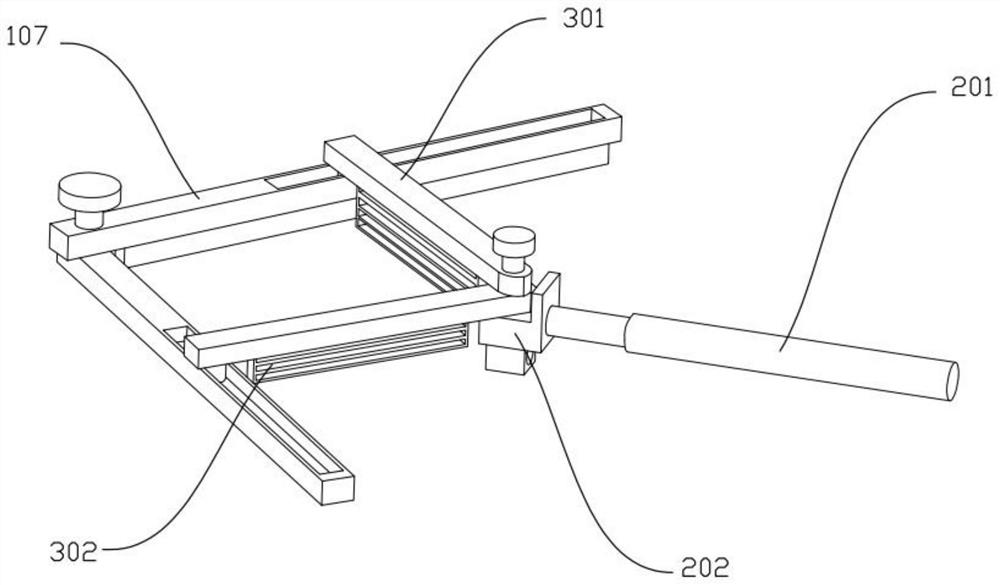

Rice processing method

ActiveCN113310284AImprove drying effectAvoid incomplete dryingDrying machines with non-progressive movementsPreliminary solid treatment for dryingAgricultural engineeringRice grain

The invention relates to the field of food processing, in particular to a rice processing method. The rice processing method comprises the following steps that firstly, rice taken out from unhulled rice is cleaned; secondly, the rice is dried by using a drying device; and thirdly, the dried rice is taken out and packaged. The drying device in the second step comprises a drying box and turning parts I, and the multiple turning parts I are rotationally connected to the two ends in the drying box. The drying device in the second step further comprises sliding grooves I, sliding blocks I, transmission parts and turning parts II, the two sliding grooves I are formed in the drying box, the two sliding blocks I are connected into the two sliding grooves I in a sliding manner, one ends of the multiple transmission parts are rotationally connected to the two sliding blocks I correspondingly, the other ends of the multiple transmission parts are connected to the multiple turning parts II correspondingly in a sliding manner, and the multiple turning parts II are fixedly connected to the multiple transmission parts correspondingly.

Owner:湖北兴鑫粮食股份有限公司

Storage device for special aluminum oxide

ActiveCN113716227AAvoid incomplete dryingReduce wasteLarge containersTank wagonsMetallurgyAluminium oxides

The invention relates to the field of aluminum oxide storage, in particular to a storage device for special aluminum oxide. The technical problems to be solved are that aluminum oxide powder located in the middle is relatively far away from the inner wall of a storage bin, so that the aluminum oxide powder is heated unevenly, then the aluminum oxide powder is dried incompletely, and the aluminum oxide powder goes bad in the storage process. According to the technical implementation scheme, the storage device for the special aluminum oxide comprises a first rack, a first tank body, a first top cover and the like; the first tank body is arranged at the upper part of the first rack; and the first top cover is fixedly connected to the upper part of the first tank body. When the storage device is used, the aluminum oxide powder is injected, and meanwhile, the aluminum oxide powder is automatically subjected to split-flow preheating, so that the drying efficiency is greatly improved, the aluminum oxide powder is automatically dried from the inner side and the outer side at the same time, and the phenomenon that the aluminum oxide powder is not dried completely is avoided.

Owner:苏州盛曼特新材料有限公司

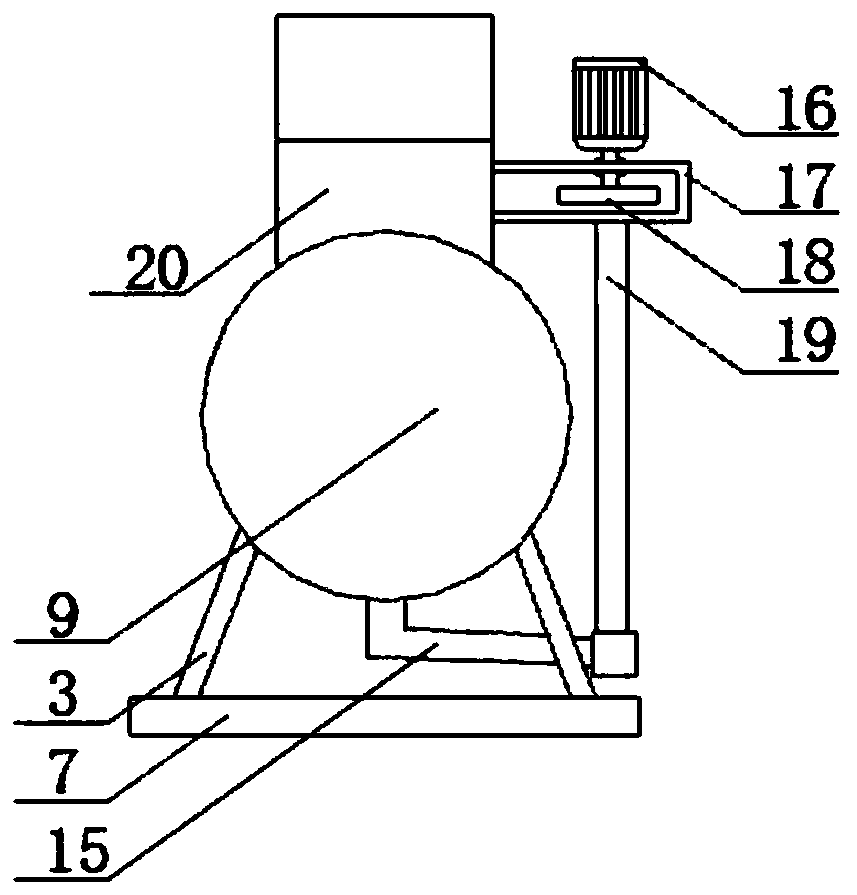

Feather drying device for shuttlecock processing

InactiveCN111912194ATumble fullAvoid incomplete dryingDrying solid materials with heatDrying gas arrangementsMechanical devicesComposite material

The invention discloses a feather drying device for shuttlecock processing, and particularly relates to the field of mechanical devices. The feather drying device comprises a base, two supporting rodslocated on the base and a drying cylinder which is rotationally connected to the two supporting rods. A feeding pipe is fixedly arranged at one end of the drying cylinder, and an air inlet pipe is fixedly arranged at the other end of the drying cylinder; the air inlet pipe is connected with a hot air pump used for conveying hot air through a pipeline; a heating component used for evenly diffusingthe hot air into the drying cylinder is arranged in the drying cylinder; stirring blades used for stirring feathers and arranged obliquely are arranged on the inner wall of the drying cylinder; and the inner diameter of the middle of the drying cylinder is larger than the inner diameters of the two ends of the drying cylinder. According to the feather drying device, feathers can be fully turned over in the drying process, each side of the feathers can be heated and dried, and incomplete drying caused by stacking of the feathers in the drying process is avoided.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

Fast cereal drying device

InactiveCN109114925ASimple structureGuaranteed uptimeDrying gas arrangementsDrying machines with non-progressive movementsPulp and paper industryAir blower

The invention provides a fast cereal drying device, and belongs to the field of agricultural machines. The fast cereal drying device comprises a screw feeder, a first motor, a drying cylinder, a second motor and a support; the screw feeder is arranged on the left side of the drying cylinder, the first motor is arranged on the upper part of the screw feeder, a feeding port is arranged in the lowerpart of the screw feeder, and a discharge port of the screw feeder is connected with the feeding port in the left side of the drying cylinder; the drying cylinder is arranged on the support, and the right side of the drying cylinder is connected to the second motor, the second motor is arranged on a motor bracket; and a heater is arranged on a right side plate, and the heater is connected to an air blower. The fast cereal drying device has the advantages of being simple in structure, stable in operation and convenient to maintain, being small in volume, suitable for use in family farms, smallgrain stations and granaries and low in cost, being uniform in feeding, avoiding incomplete drying caused by excessive accumulation of cereals, being smooth in feeding and discharging, being smooth inintake and exhaust, being high in drying efficiency and high in speed due to thorough overturning of the cereals in the drying cylinder, and being convenient to move due to the fact that casters arearranged at the bottom of the support.

Owner:苏州格瑞格登新材料科技有限公司

Silicon sludge drying device capable of recycling heat

ActiveCN114812131ADon't worry about uneven dryingImprove drying effectMachines/enginesDrying solid materialsSludgeProcess engineering

The silicon sludge drying device comprises an upper box body and a lower box body, the upper box body and the lower box body are connected in a clamped mode, fan blades are fixedly connected to the outer surface of a fixing shaft, and the fan blades are attached to the inner wall of a turbine box. And control boxes are fixedly connected to the middle parts of the front surface and the bottom of the back of the upper box body through fixing pieces. According to the silicon sludge drying device capable of recycling the heat, heat energy steam generated when silicon sludge is dried can be effectively recycled, the turbine is pushed to rotate in a steam engine mode along with rising of hot air, the turbine indirectly drives the claw below after rotating, the heat energy generated when the silicon sludge is dried is effectively utilized, and the silicon sludge drying device is energy-saving and environment-friendly. And all the silicon sludge is returned and applied to drying operation, so that the whole work saves more energy, the situation that the silicon sludge is dried unevenly does not need to be worried about, and on the premise that the energy is saved, people can use the silicon sludge drying device conveniently.

Owner:湖北麦格森特新材料科技有限公司

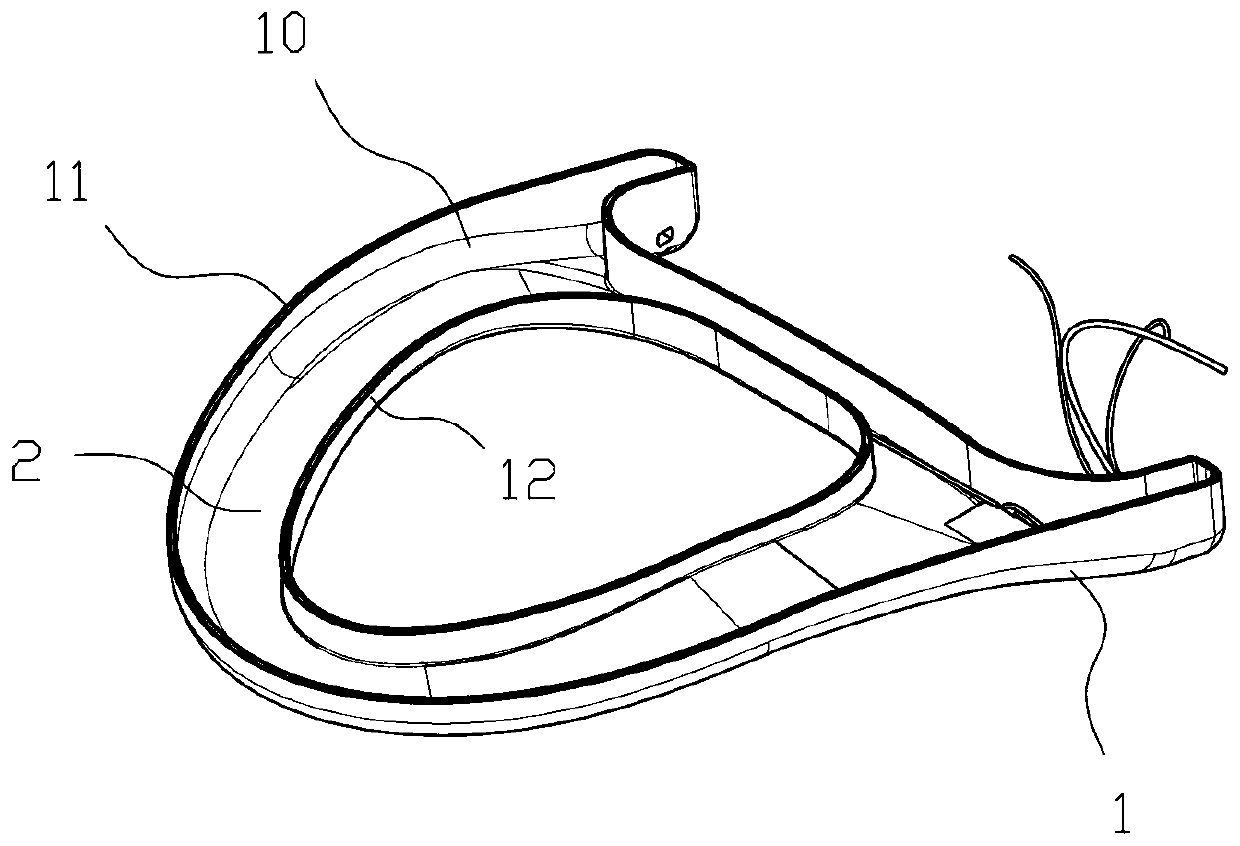

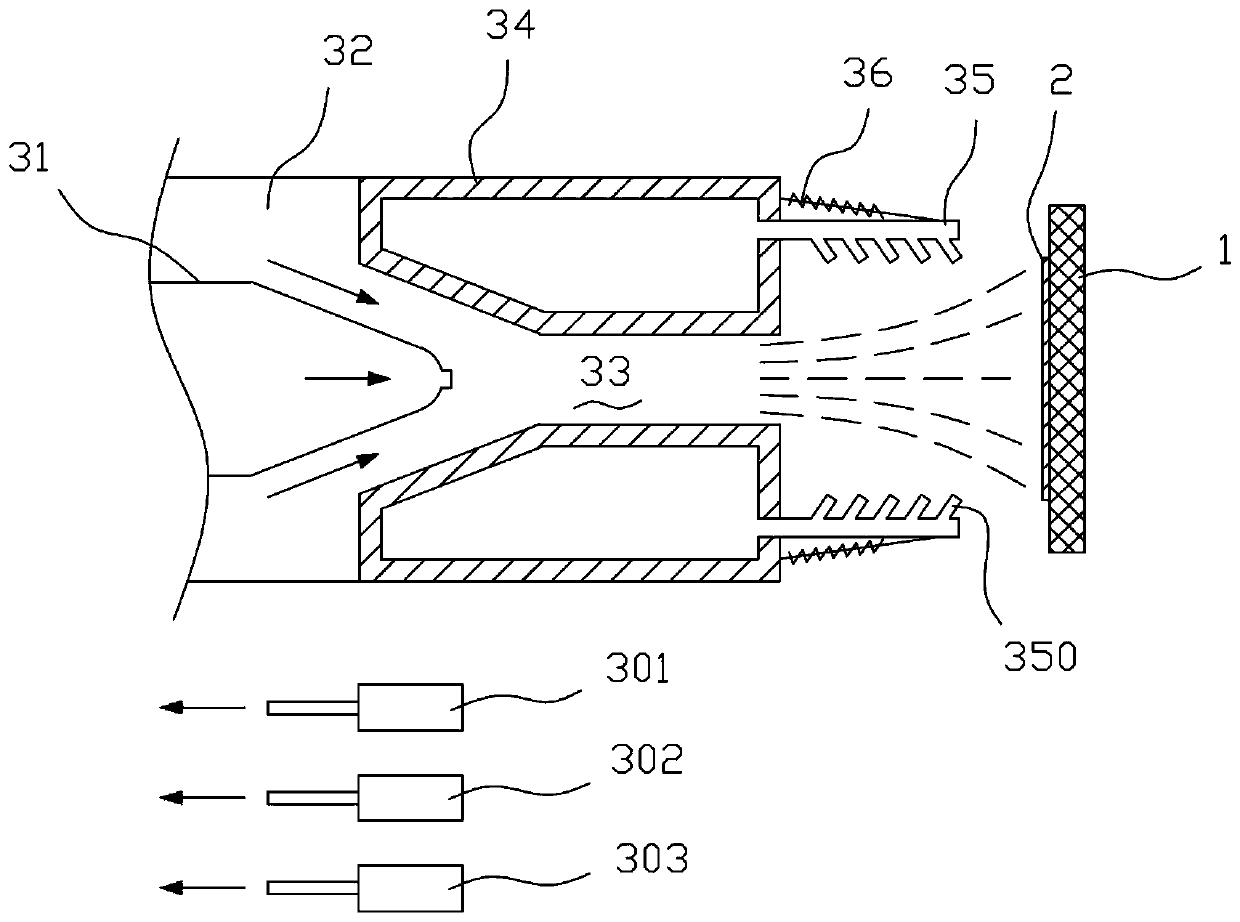

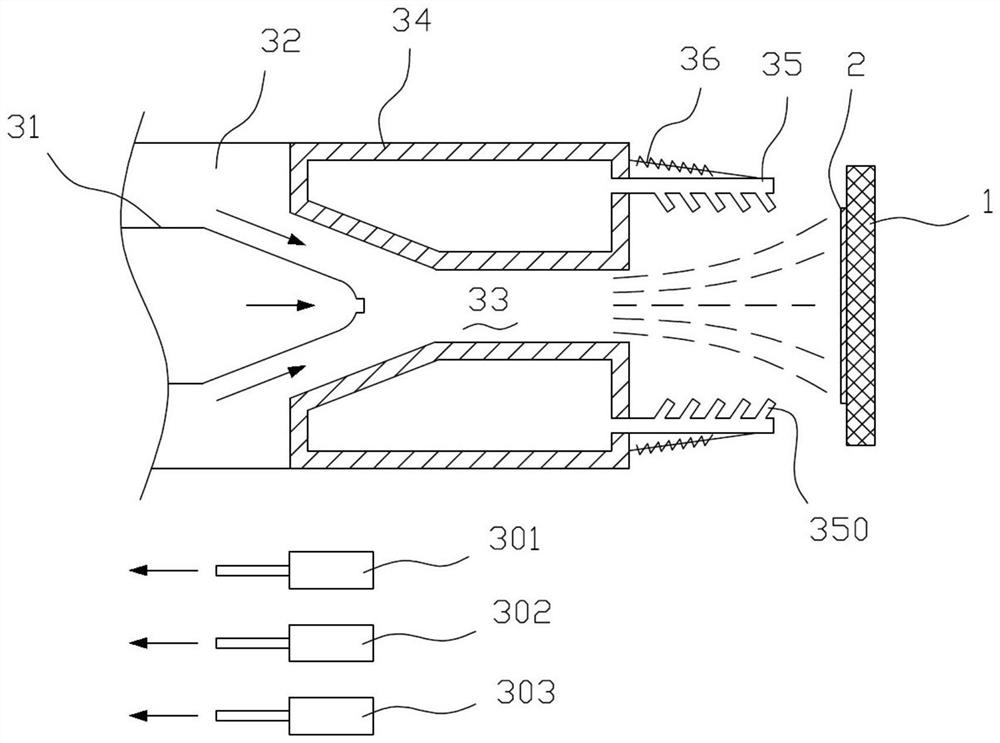

Spraying device for PTC heating material for toilet ring and spraying method

ActiveCN111111961AImprove spraying efficiencyAvoid incomplete dryingPretreated surfacesLiquid spraying apparatusMaterial supplyManufacturing engineering

The invention discloses a spraying device for a PTC heating material for a toilet ring. The spraying device comprises a material supply part, a material blowing and conveying part, spraying and guiding parts and a heating element, wherein the material supply part is used for storing and guiding out the PTC heating material. The material blowing and conveying part is used for blowing and conveyingthe PTC heating material to the toilet ring to form a PTC heating layer. The spraying and guiding parts are arranged on the side of an outlet of the material blowing and conveying part and is used forguiding the PTC heating material blown out from the material blowing and conveying part so as to prevent the PTC heating material from being sprayed out of the preset range and used for drying the PTC heating layer. The spraying and guiding parts guide the PTC heating material through cold air. The spraying and guiding parts dry the PTC heating layer through hot air. The heating element is used for heating the cold air into hot air. In the spraying process, the PTC heating material can be effectively prevented from being sprayed out of the preset range, the PTC heating material can also be dried in the spraying process, the spraying efficiency is improved, and incomplete drying of the PTC heating material layer is avoided.

Owner:SUZHOU LUZHIYAO TECH

A spraying device and spraying method of PTC heating material for toilet seat

ActiveCN111111961BAvoid spraying out of boundsAvoid incomplete dryingPretreated surfacesLiquid spraying apparatusCold airMaterial supply

The invention discloses a spraying device of PTC heating material for toilet seat, which comprises: a material supply part for storing and exporting PTC heating material; a material blowing part for blowing PTC heating material onto the toilet seat to form a PTC heating layer; spraying guide part, which is arranged on the side of the outlet of the material blowing part, for guiding the PTC heating material blown out from the material blowing part, to avoid the PTC heating material being sprayed outside the preset range , and used to dry the PTC heating layer; and a heating element; wherein, the spraying guide guides the PTC heating material through cold air, and the spraying guide dries the PTC heating layer through hot air; the heating element is used for The cold air is heated into the hot air. In the spraying process, not only can effectively avoid the PTC heating material spraying out of bounds, but also can dry the PTC heating material in the spraying process, improve the spraying efficiency, and avoid the incomplete drying of the PTC heating material layer.

Owner:SUZHOU LUZHIYAO TECH

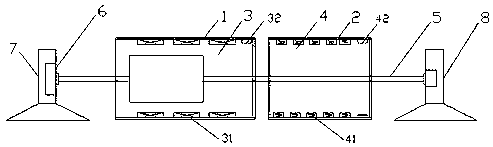

Intelligent drying device for waste steel strip

InactiveCN110779310AAvoid incomplete dryingDomestic cooling apparatusDrying gas arrangementsDrive shaftElectric machinery

The invention specifically discloses an intelligent drying device for a waste steel strip. The intelligent drying device comprises a first box body, wherein a drying device is arranged in the first box body; one side of the first box body is equipped with a second box body; a cooling device is arranged in the second box body; the first box body and the second box body are internally hollow, and are equipped with a lead screw; one end of the lead screw is connected to a drive motor drive shaft; a drive motor is internally arranged on a first base; the other end of the lead screw is connected with a second base through a bearing; a transportation device sleeves the lead screw; the transportation device moves the lead screw; the transportation device drives target waste steel strip to sequentially pass through the drying device and a cooling device to accomplish drying work of the waste steel strip.

Owner:苏师大半导体材料与设备研究院(邳州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com