Rice processing method

A kind of rice processing and rice technology, applied in the field of rice processing, can solve the problems such as rice cannot be realized, achieve the effect of improving the drying effect of rice, improving the drying effect, and avoiding the effect of incomplete drying of rice or excessive drying of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A rice processing method, comprising the following steps

[0034] Step 1: cleaning the rice taken out from the paddy;

[0035] Step 2: using a drying device to dry the rice;

[0036] Step 3: Take out the dried rice and pack it.

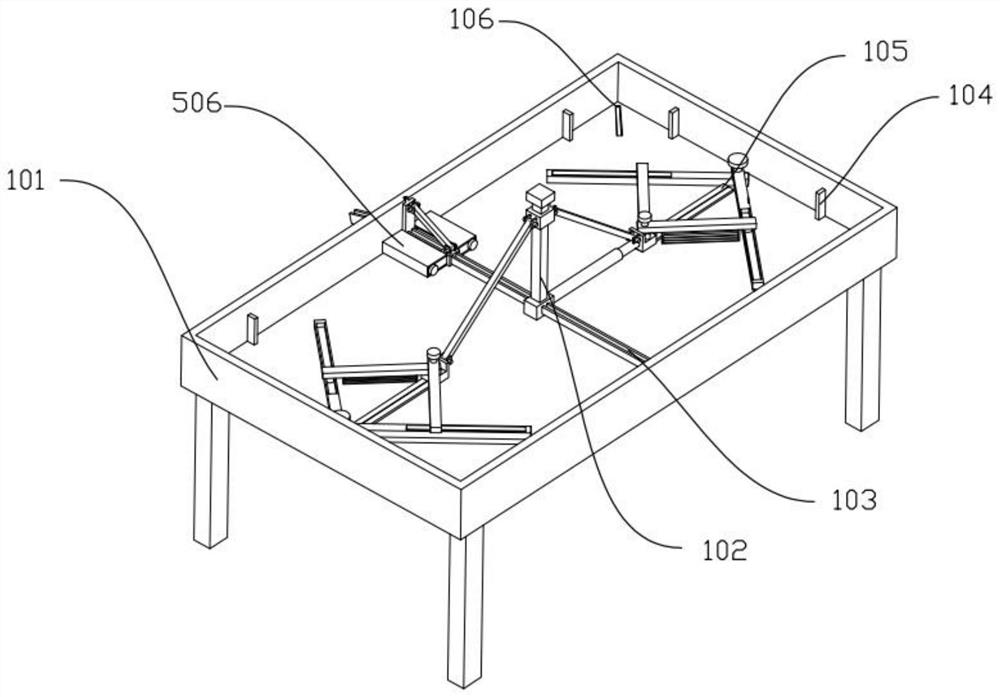

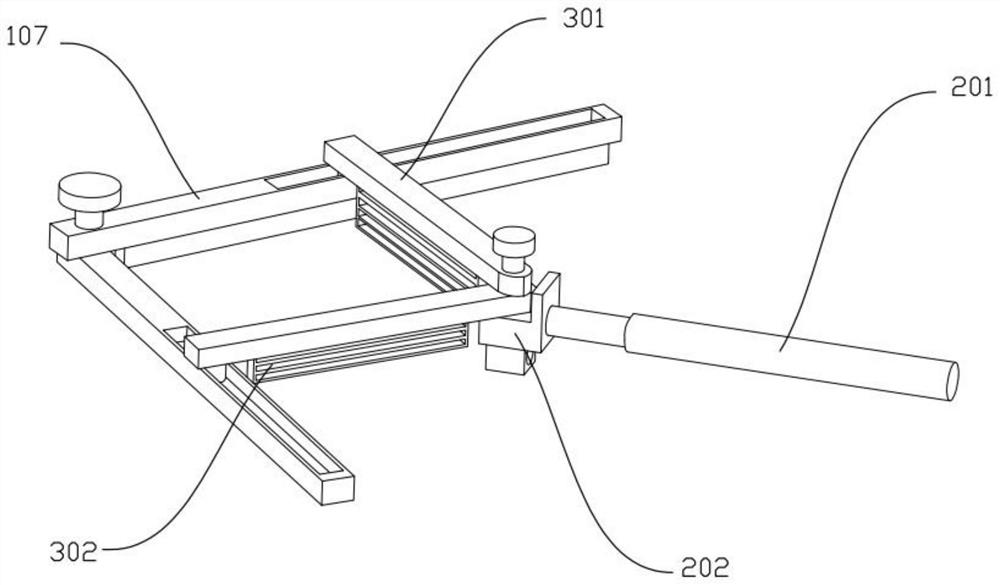

[0037] Also, as an example, such as figure 2 , image 3 As shown, this example solves the problem of turning over the four corners of the rice added to the drying box 101,

[0038] Since the two ends of the drying box 101 are rotatably connected with a plurality of turning parts I107, after the staff puts rice into the drying box 101, they start the heating source in the drying box 101, so that the drying box 101 is added to the drying box. The rice in the box continues to be dried in all directions, and at the same time, a plurality of turning parts I107 can be operated to rotate on the axis of rotation with the two ends of the drying box 101, so that the multiple turning parts I107 are in four pairs of drying boxes 101. The rice at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com