Patents

Literature

49results about How to "Tumble full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

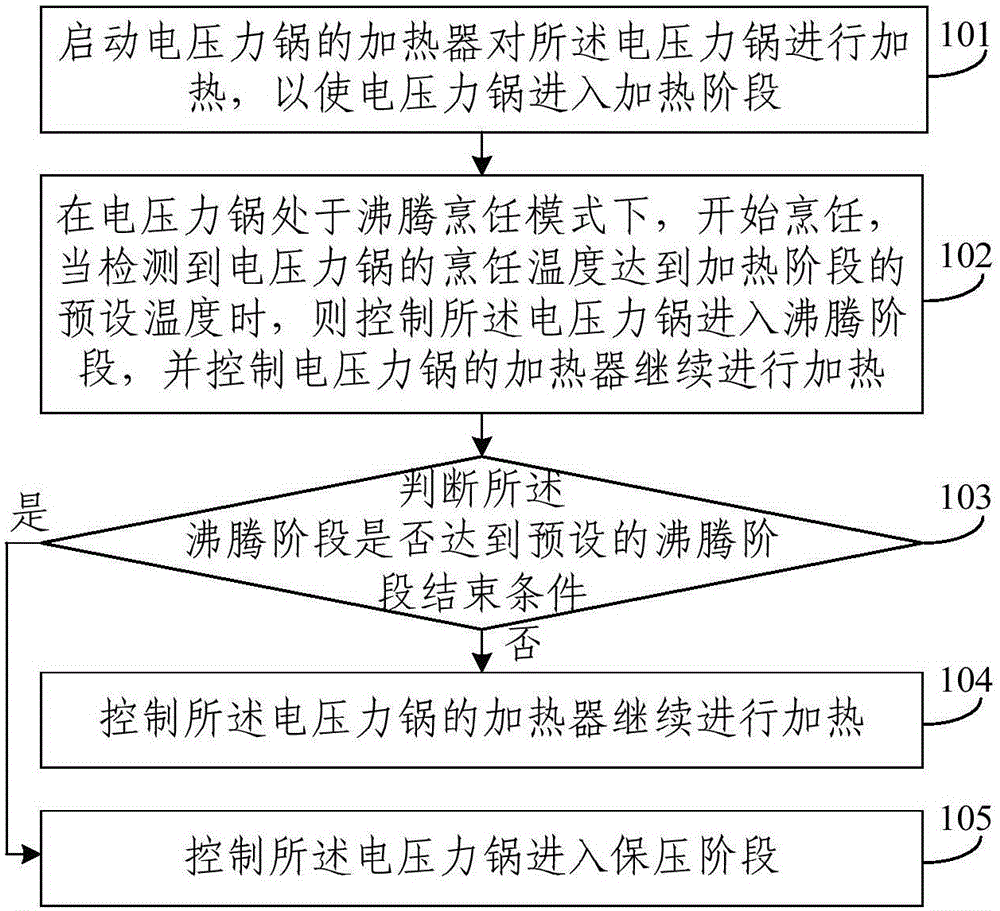

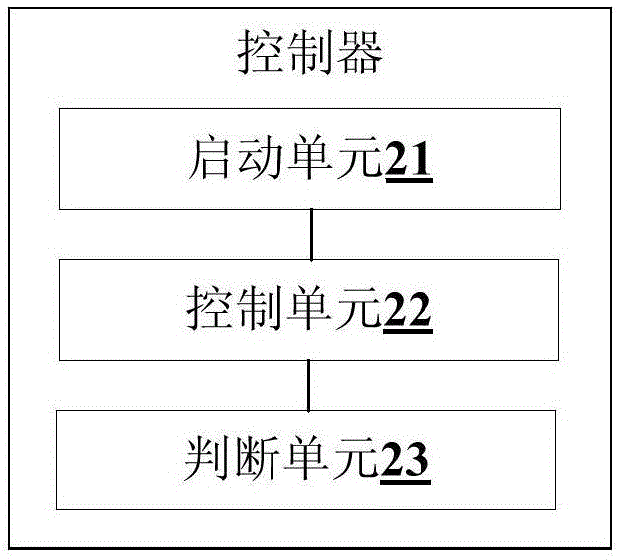

Electronic pressure cooker control method, controller and electronic pressure cooker

ActiveCN105105626AIncreased boiling phaseFully boiledPressure-cookersCooking processPressure controlled method

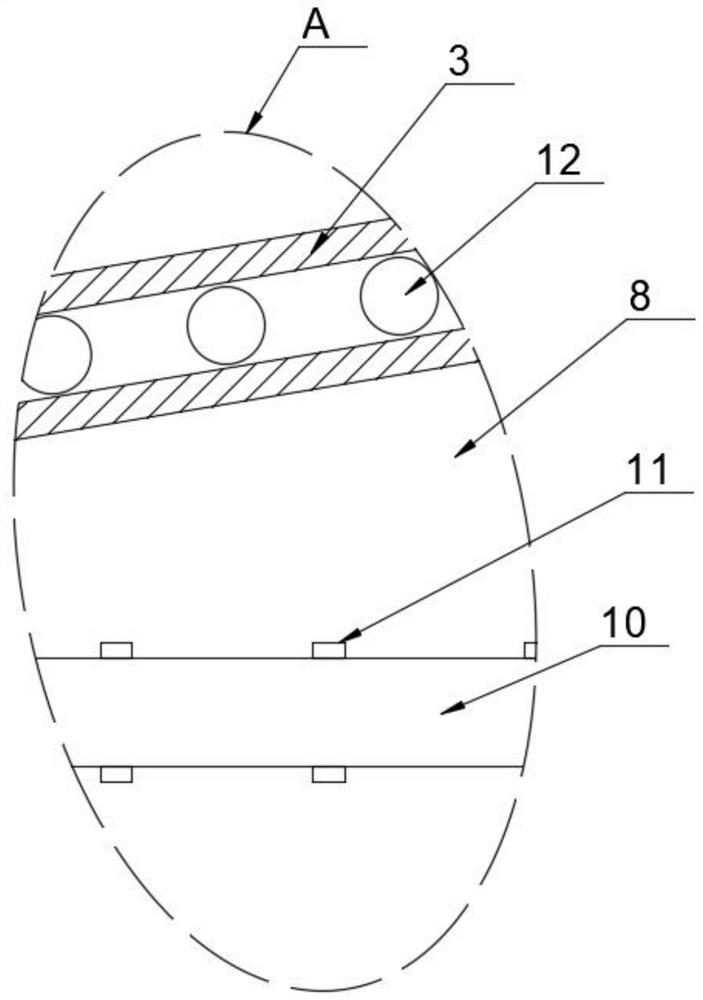

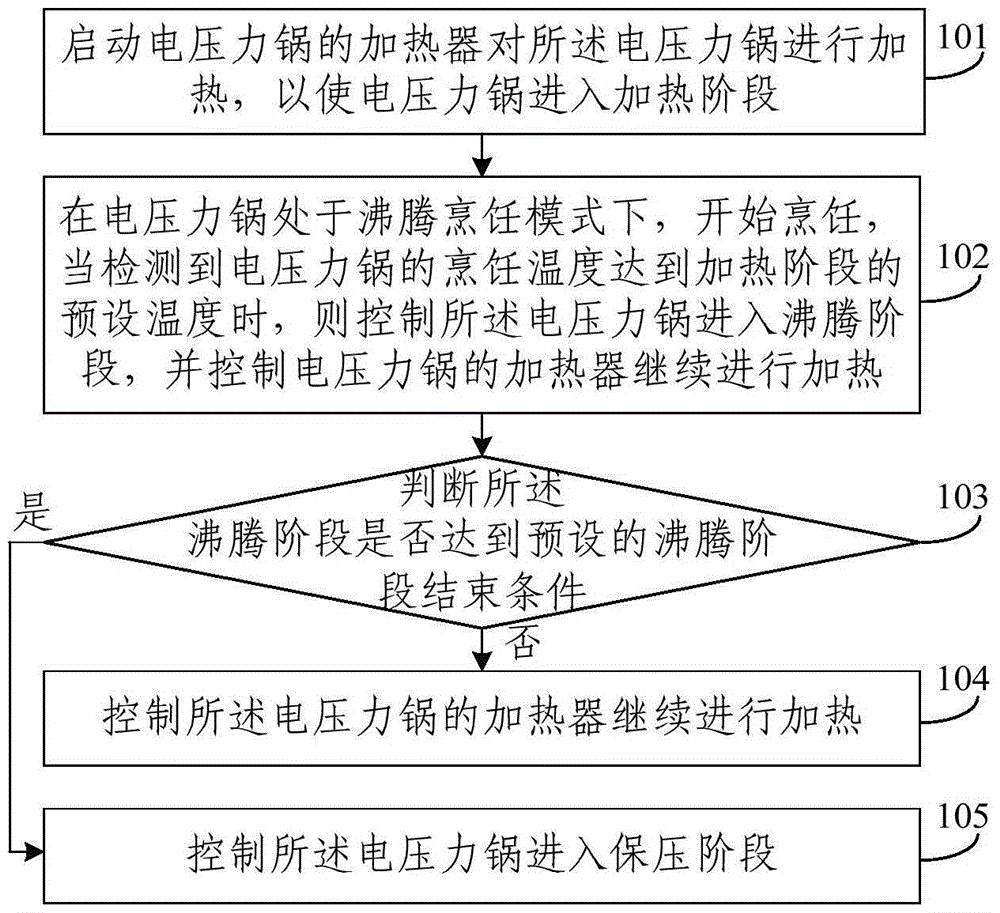

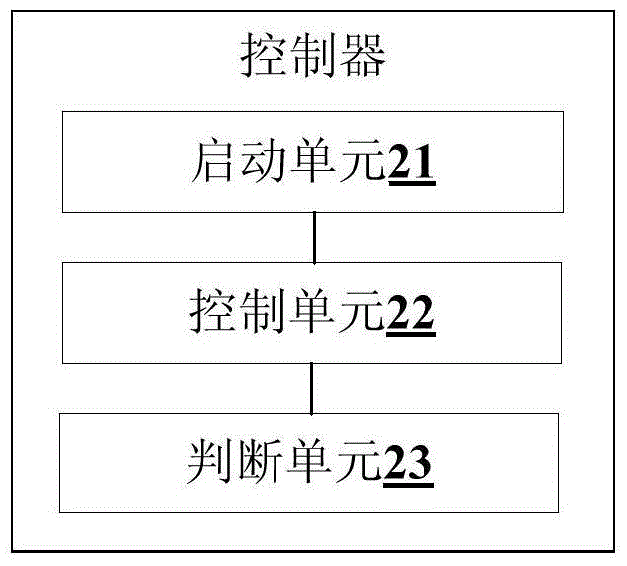

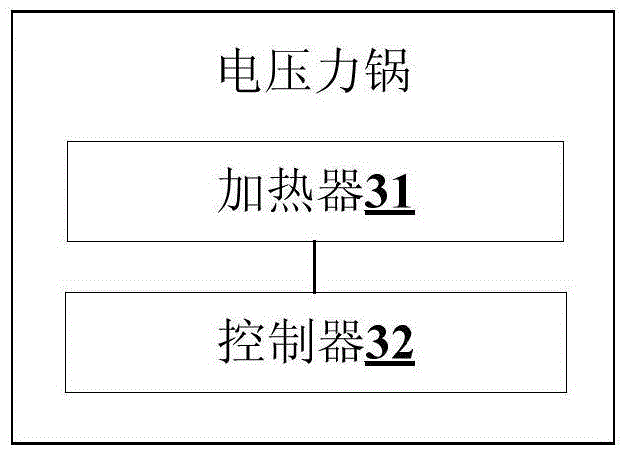

The invention discloses an electronic pressure cooker control method, a controller and an electronic pressure cooker, wherein the electronic pressure cooker control method comprises: starting a heater of the electronic pressure cooker to heat the electronic pressure cooker so as to make the electronic pressure cooker enter into a heating stage; beginning to cook when the electronic pressure cooker is under a boiling cooking mode; when the cooking temperature of the electronic pressure cooker reaches at the preset temperature of the heating stage, the electronic pressure cooker is controlled into a boiling stage and the heater of the electronic pressure cooker is controlled to continuously heat; judging whether the boiling stage meets the preset finish conditions of the boiling stage or not; if the boiling stage doesn't meet the preset finish conditions of the boiling stage, the heater of the electronic pressure cooker is controlled to continuously heat; and if the boiling stage meets the preset finish conditions of the boiling stage, the electronic pressure cooker is controlled into a pressure maintaining stage. By adopting the electronic pressure control method, the controller and the electronic pressure cooker disclosed by the invention, before the electronic pressure cooker enters the pressure maintaining stage, the boiling stage is increased, thus the problem that the existing electronic pressure cooker is not boiling or is not boiling enough during the cooking process is solved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

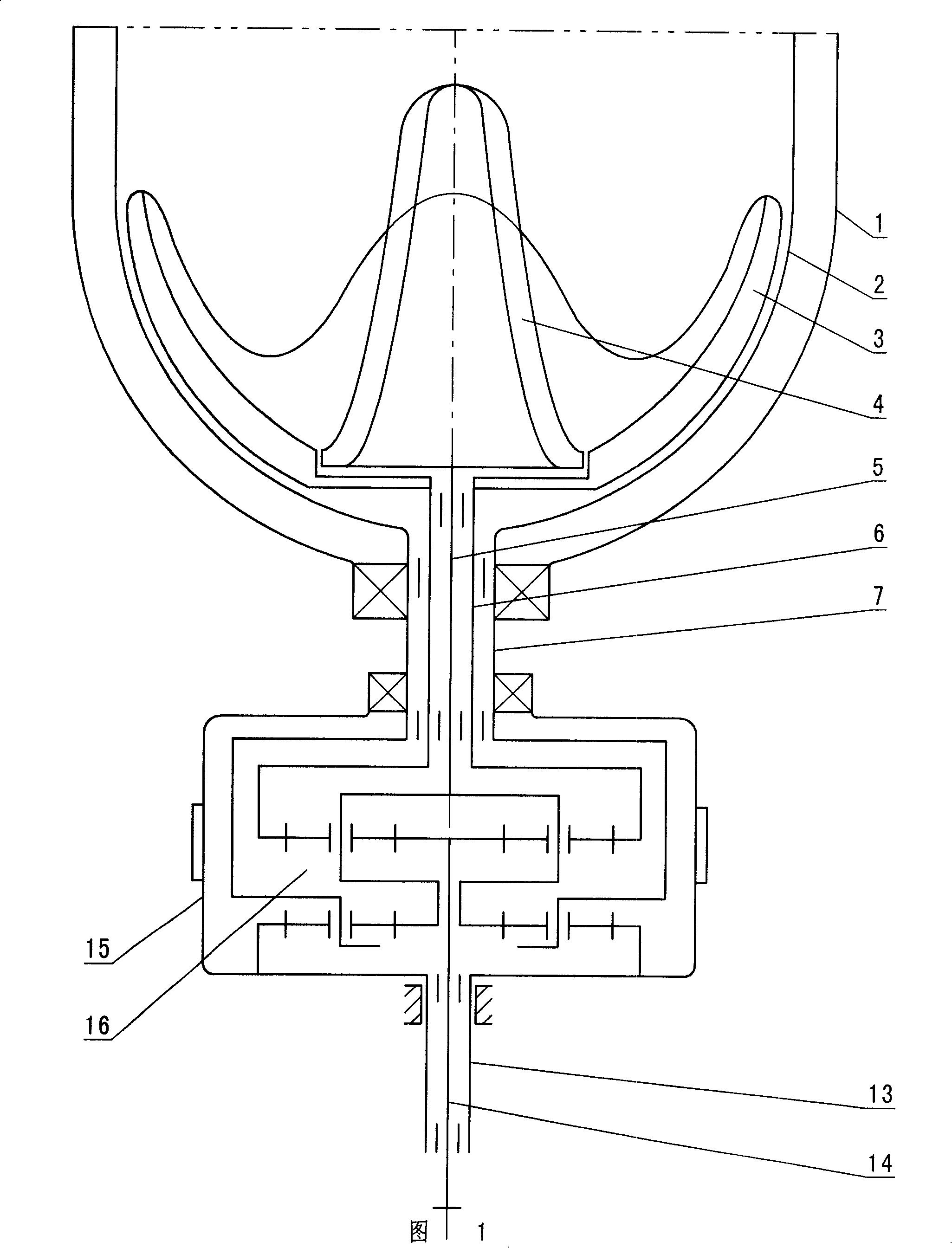

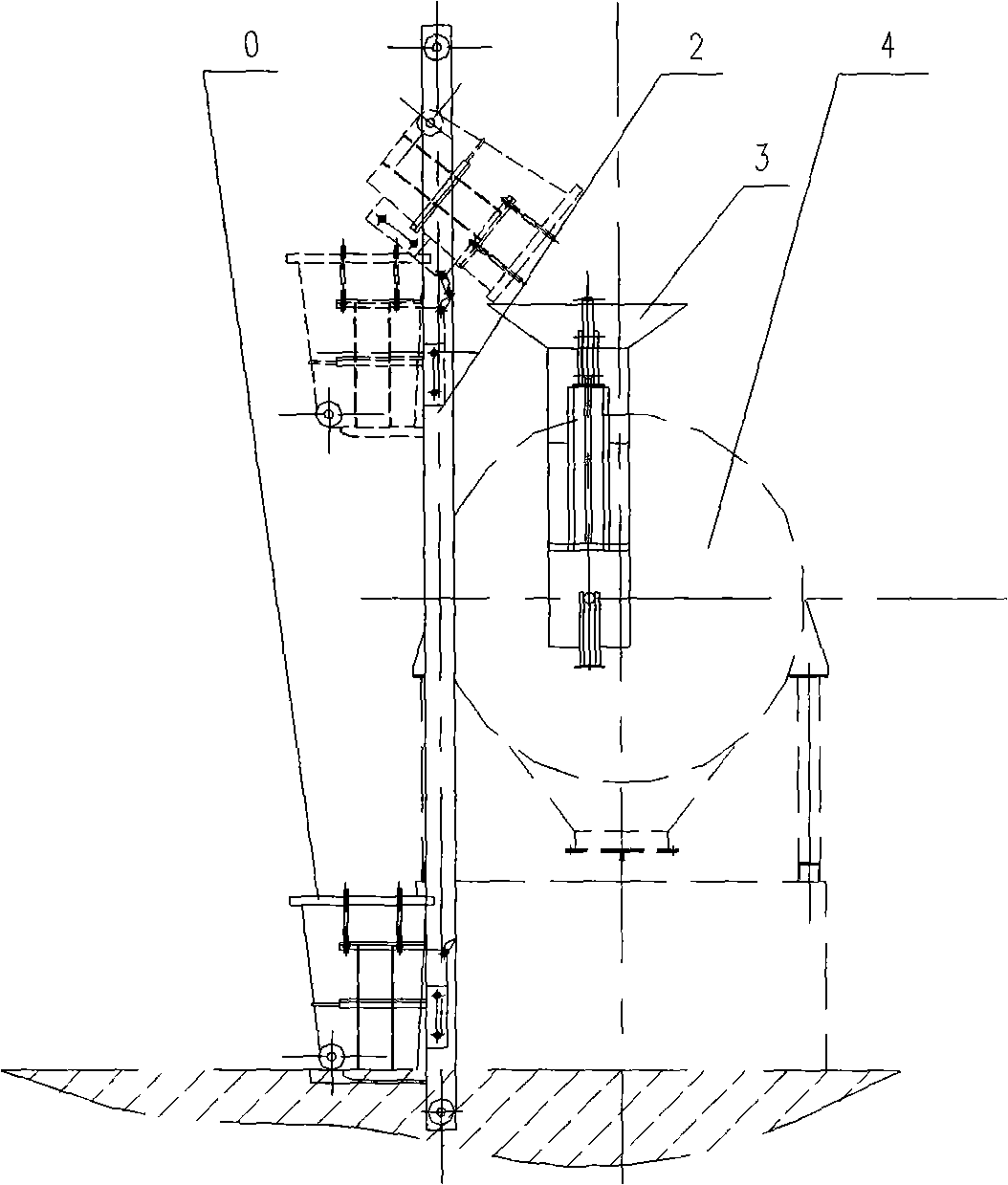

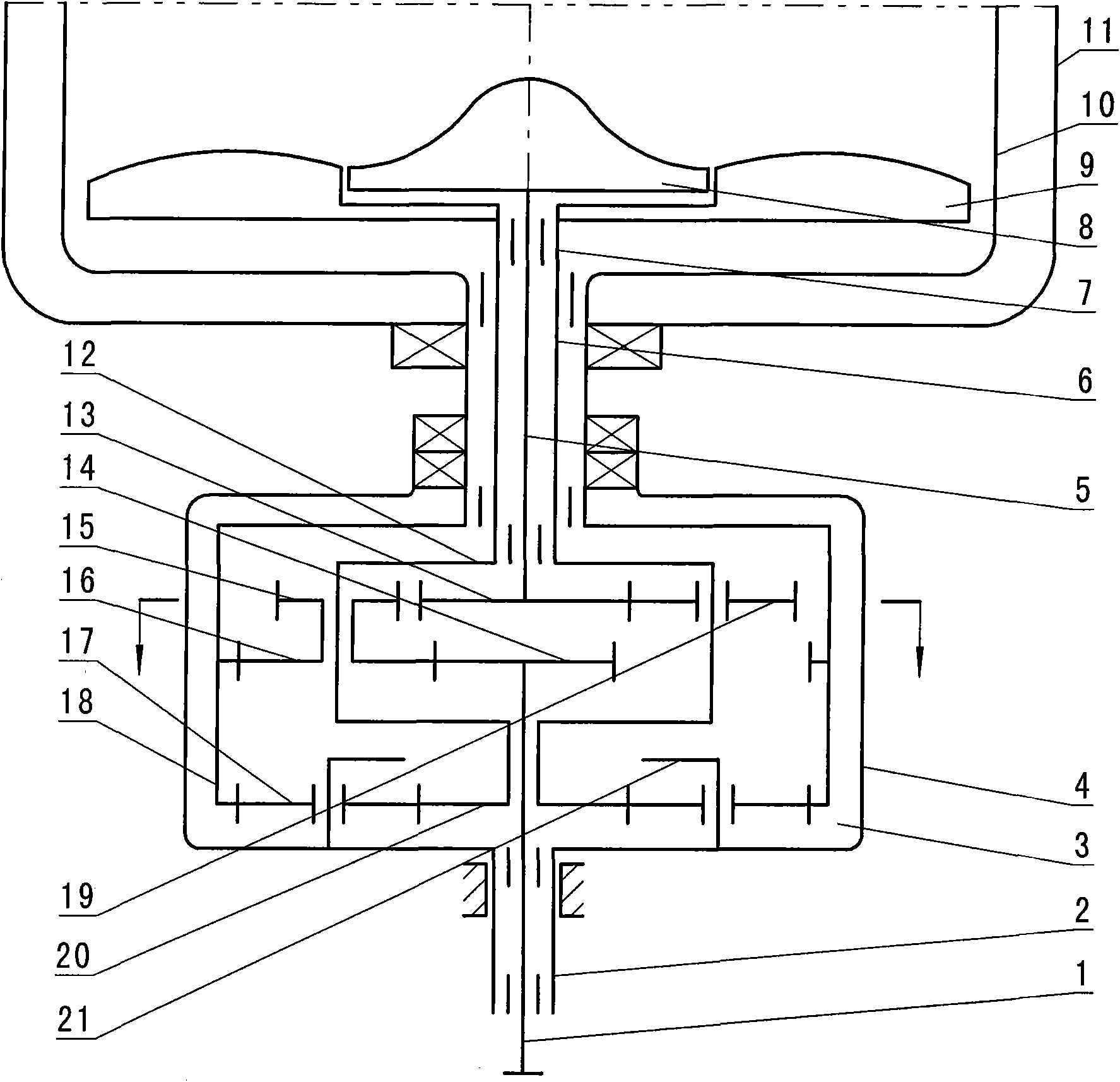

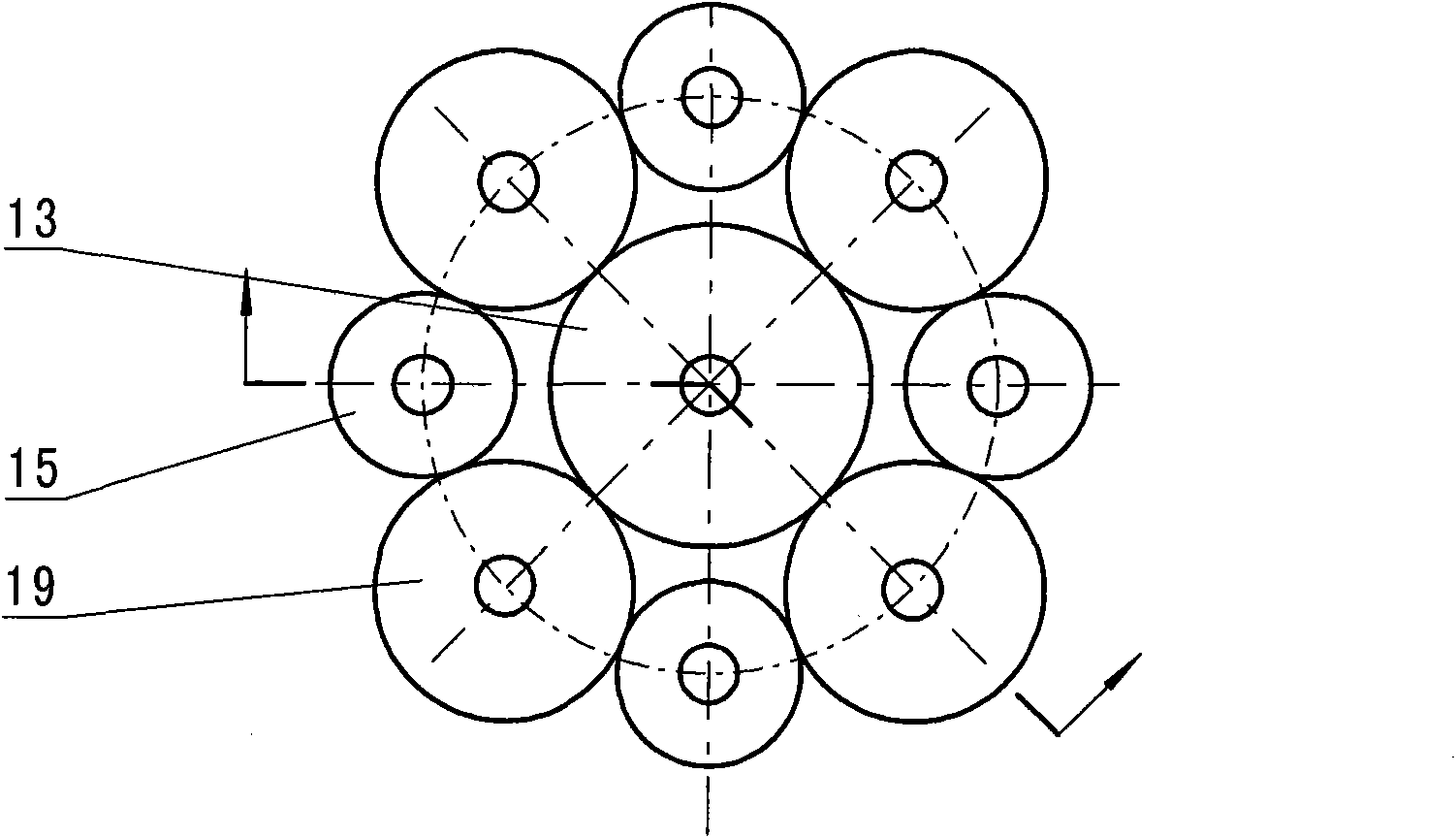

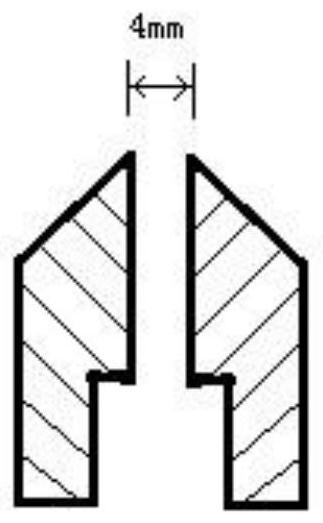

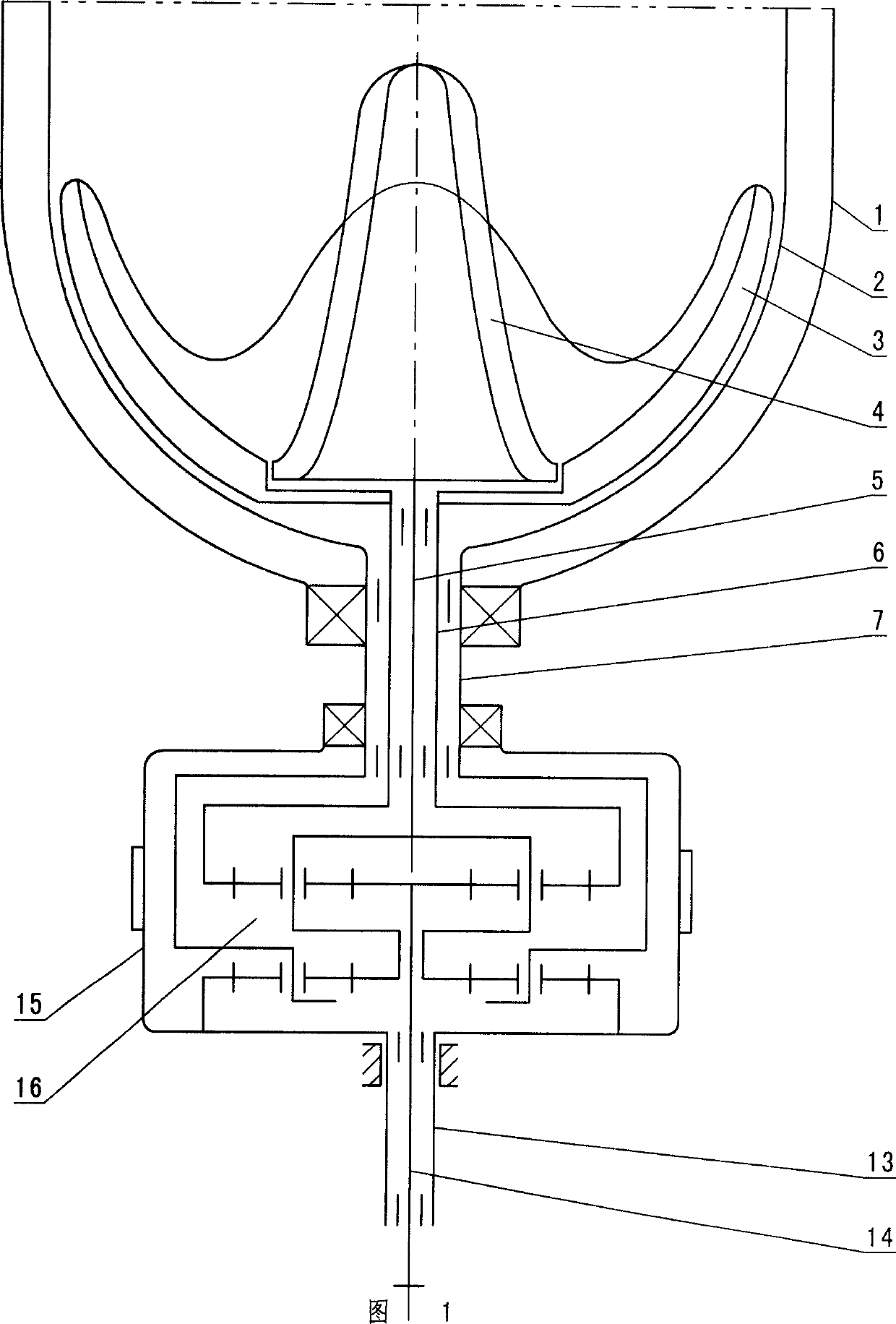

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372ATumble fullImprove cleaning rateToothed gearingsOther washing machinesWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force and improving the cleaning rate.

Owner:NINGGUO JULONG IND

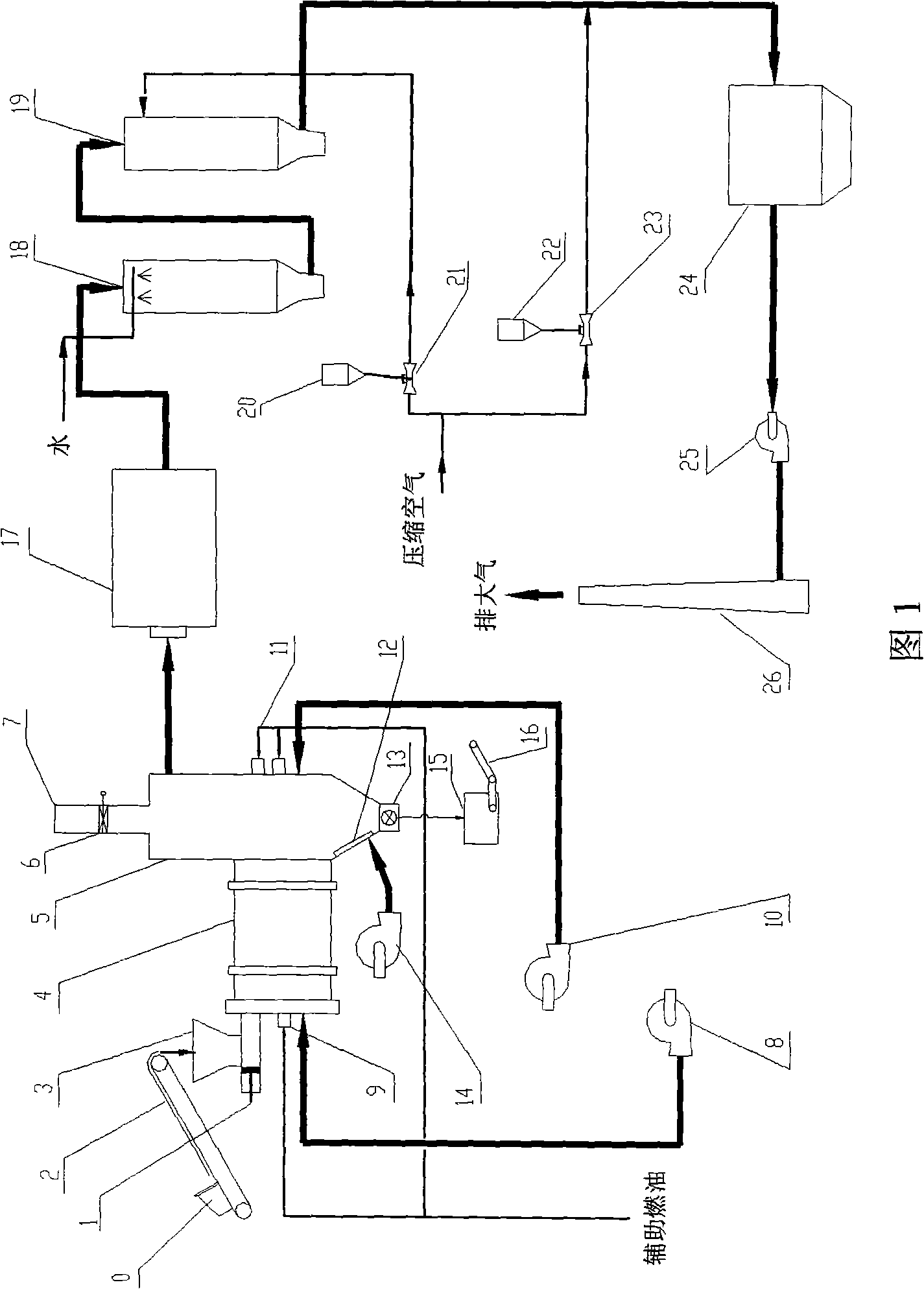

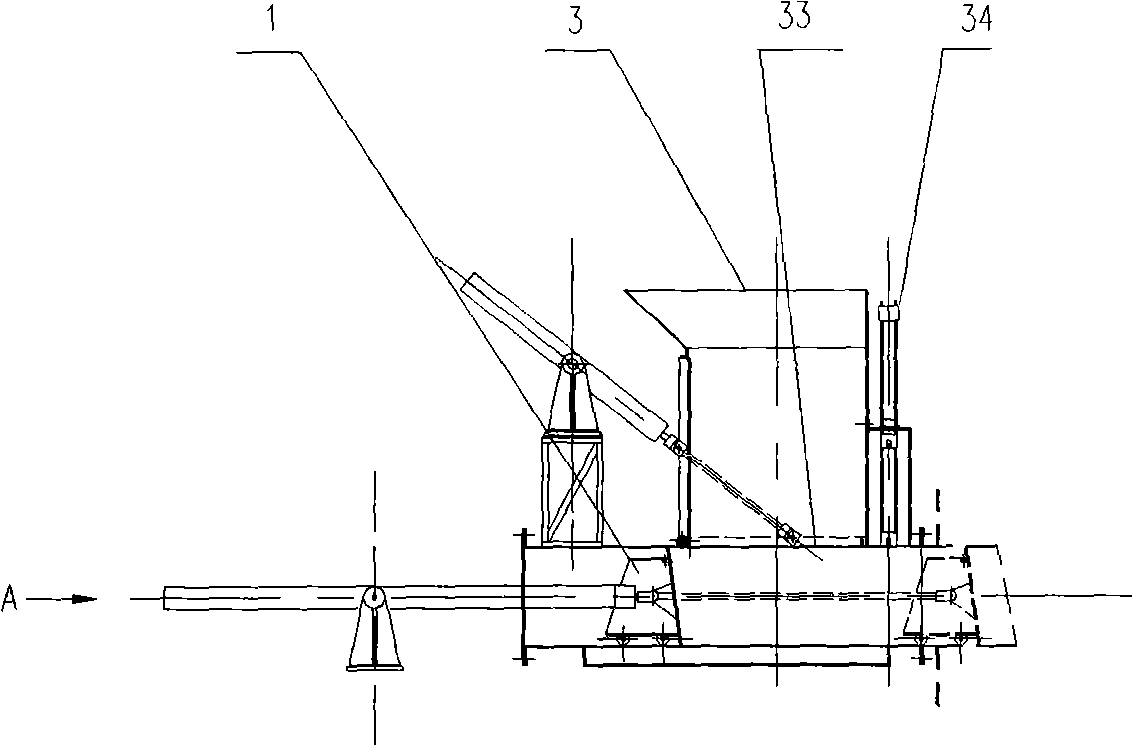

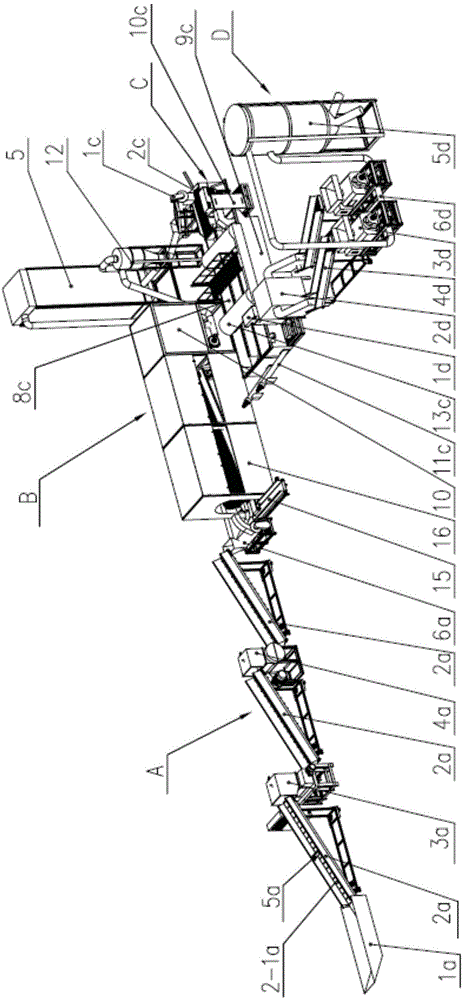

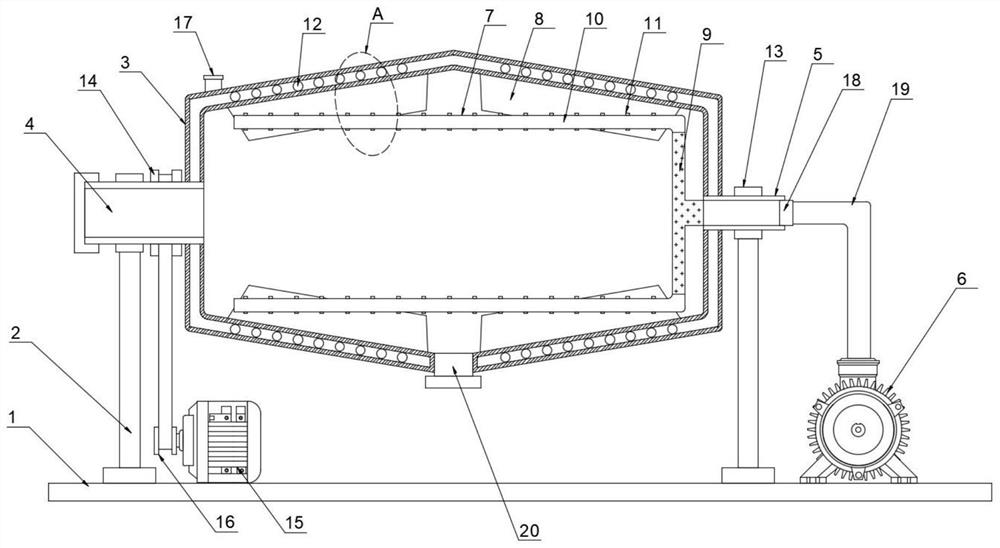

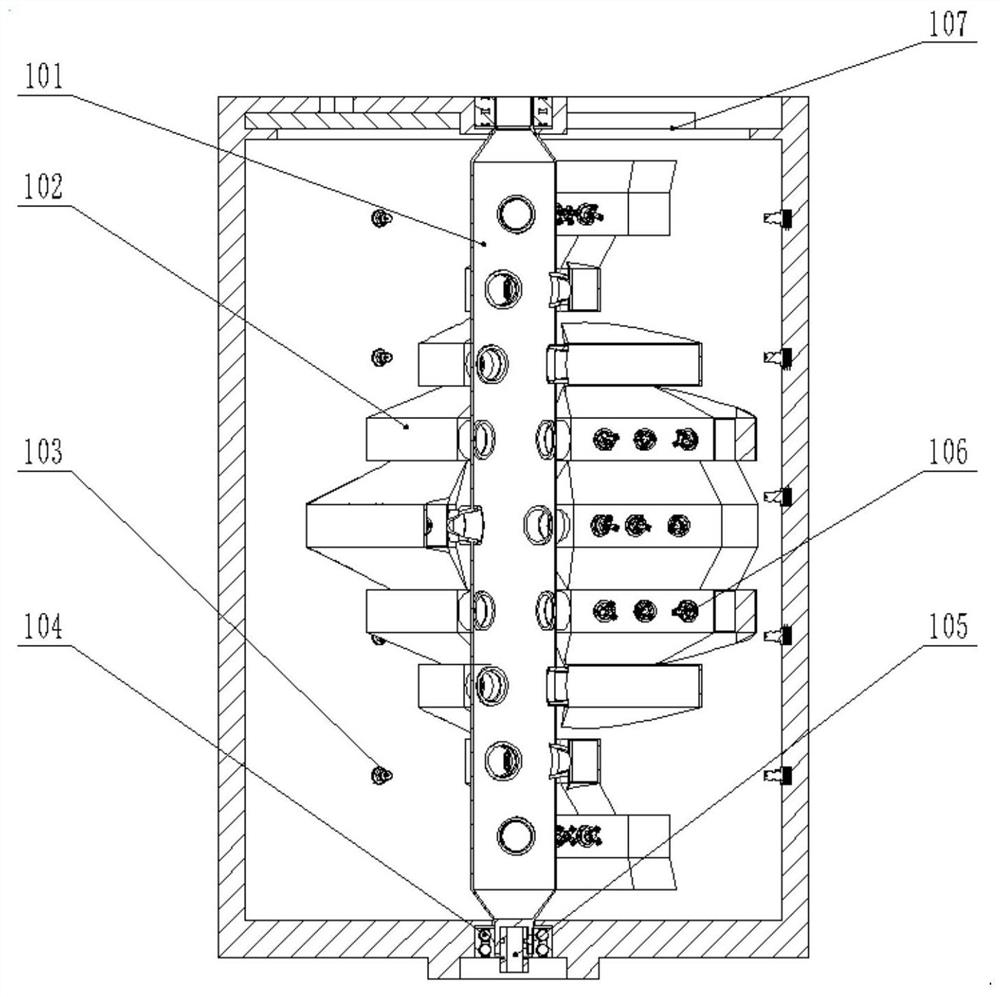

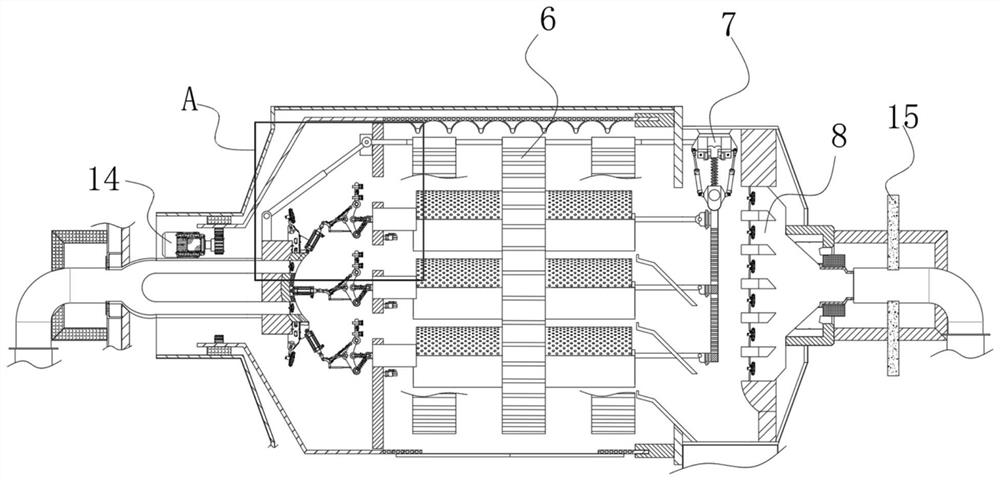

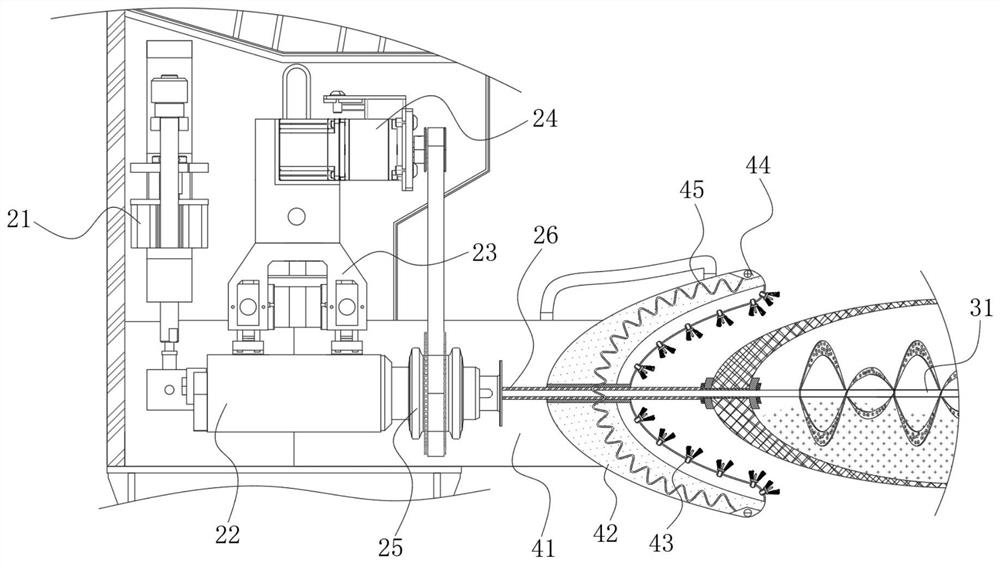

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

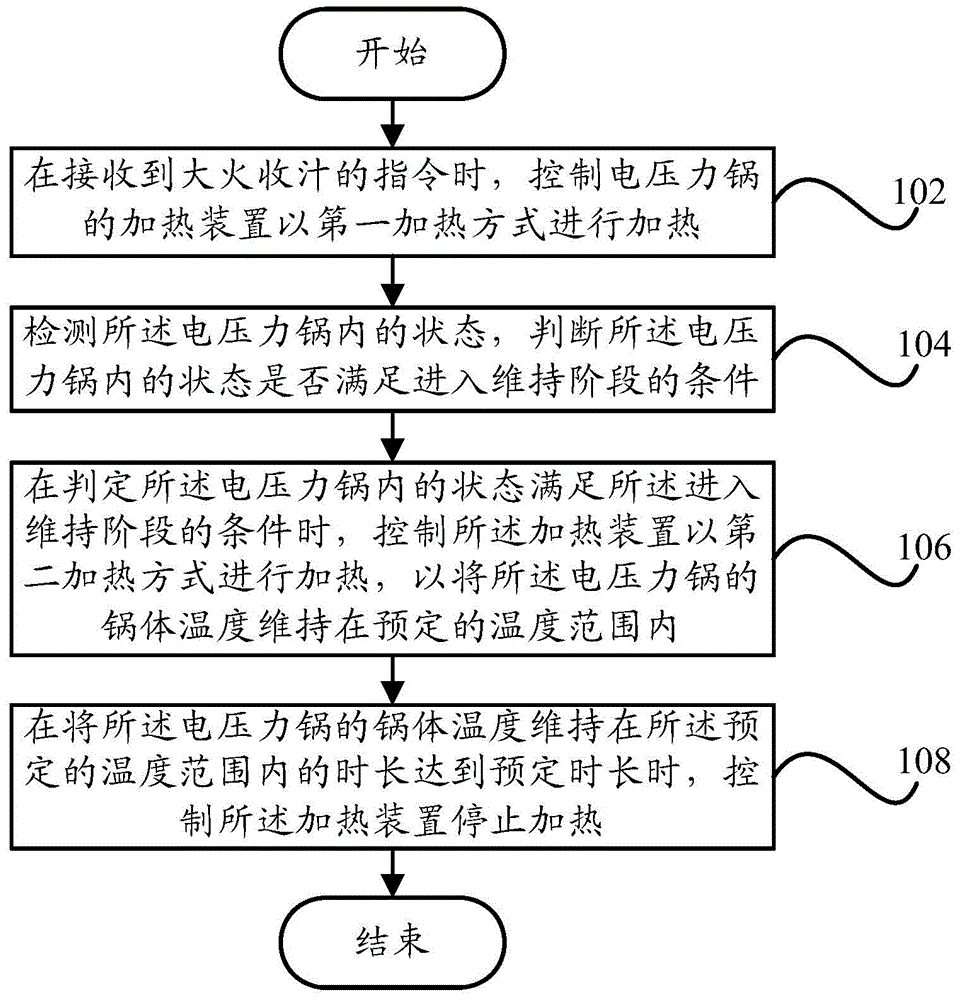

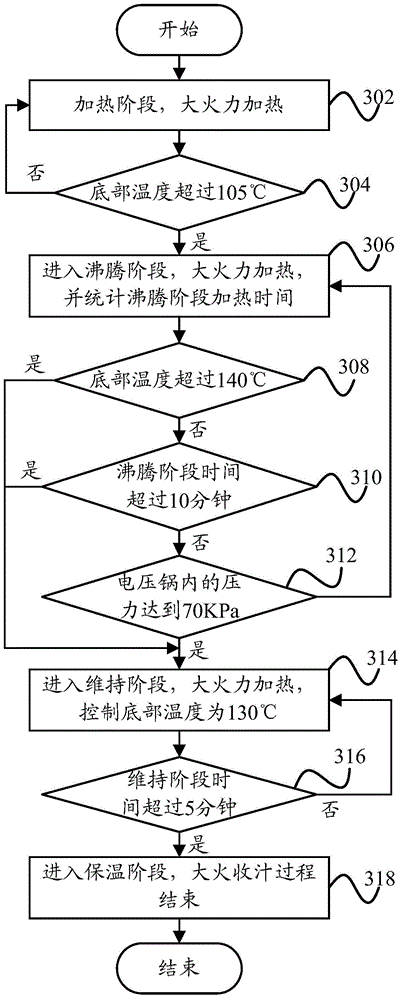

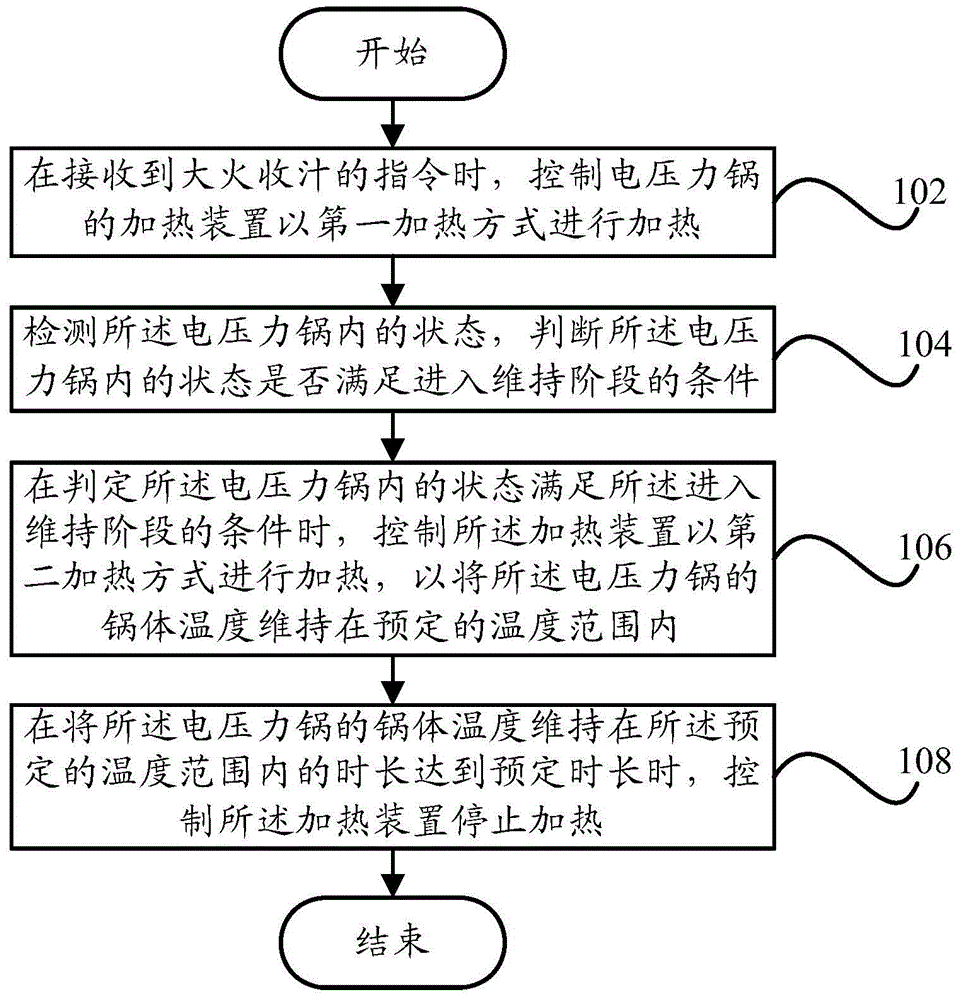

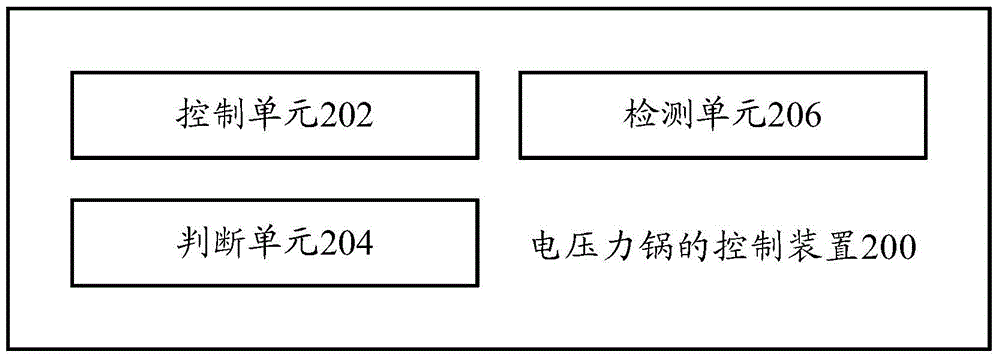

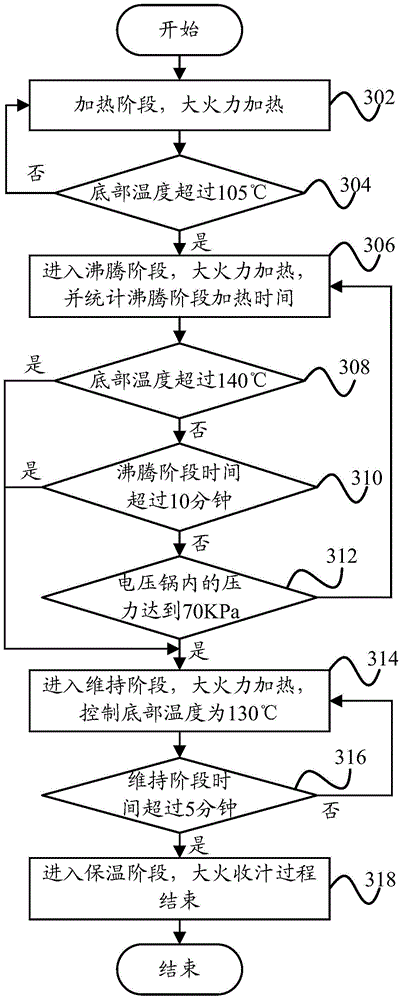

Control method and control device of electric pressure cooker and electric pressure cooker

ActiveCN104083078AGood cooking effectTumble fullAuxillary controllers with auxillary heating devicesPressure-cookersBoiling pointMaintenance stage

The invention provides a control method of an electric pressure cooker, a control device of the electric pressure cooker, and the electric pressure cooker. The control method of the electric pressure cooker comprises the steps that when an instruction of high flames for concentration is received, a heating device of the electric pressure cooker is controlled to carry out heating in a first heating mode; the interior state of the electric pressure cooker is detected, and whether the interior state of the electric pressure cooker meets the conditions of a maintenance stage or not is judged; when it is determined that the interior state of the electric pressure cooker meets conditions of the maintenance stage, the heating device is controlled to carry out heating in a second heating mode, so that the temperature of a cooker body of the electric pressure cooker is kept within a preset temperature range; when the time length of the situation that the temperature of the cooker body of the electric pressure cooker is kept within the preset temperature range reaches a preset time length, the heating device is controlled to stop heating. According to the technical scheme of the control method of the electric pressure cooker, the control device of the electric pressure cooker, and the electric pressure cooker, the temperature of food in the cooker can be kept above the boiling point so as to achieve the effect of sufficient boiling, the taste of soup in the electric pressure cooker can be rich, and the requirements of users for cooking are met.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

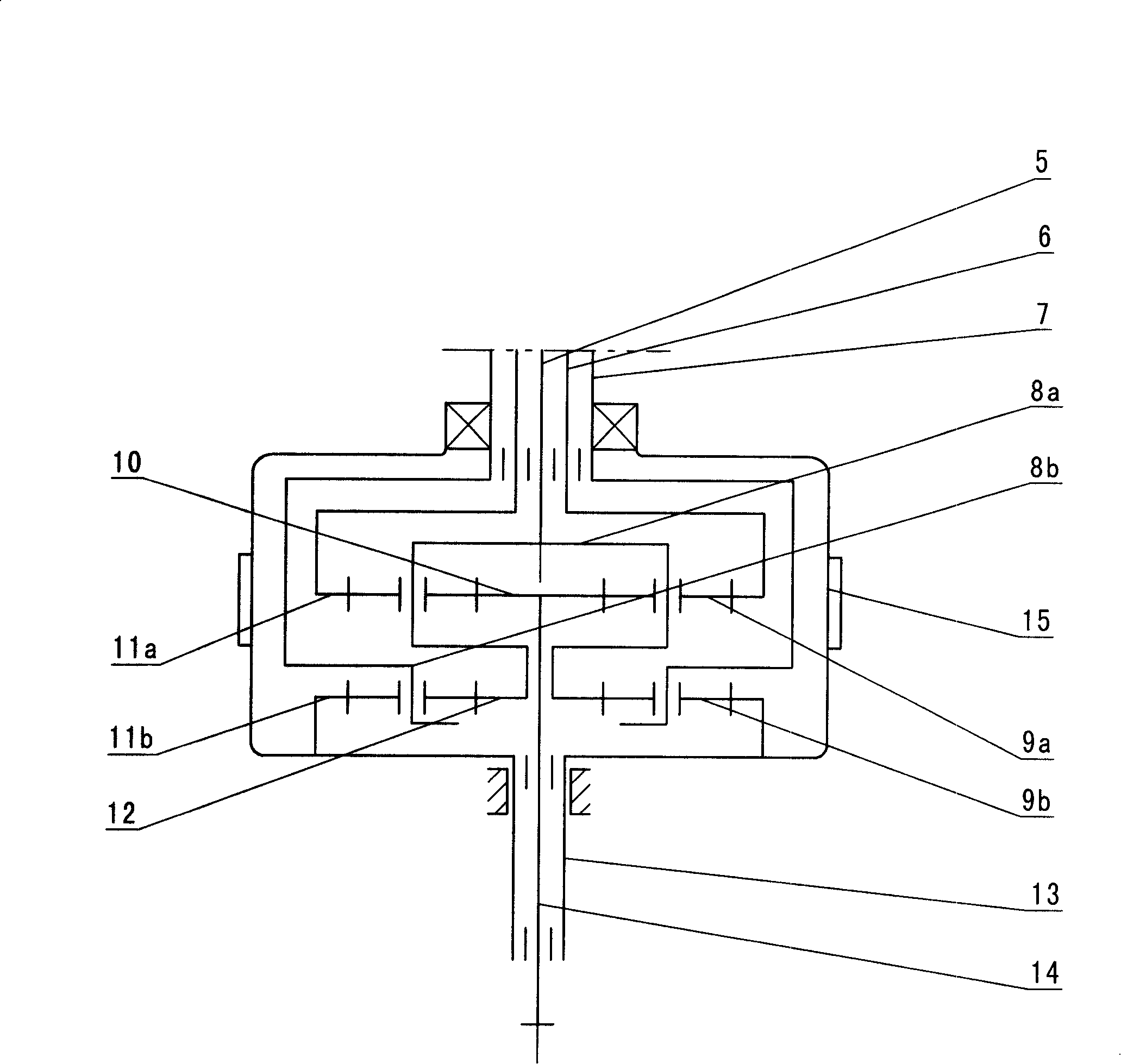

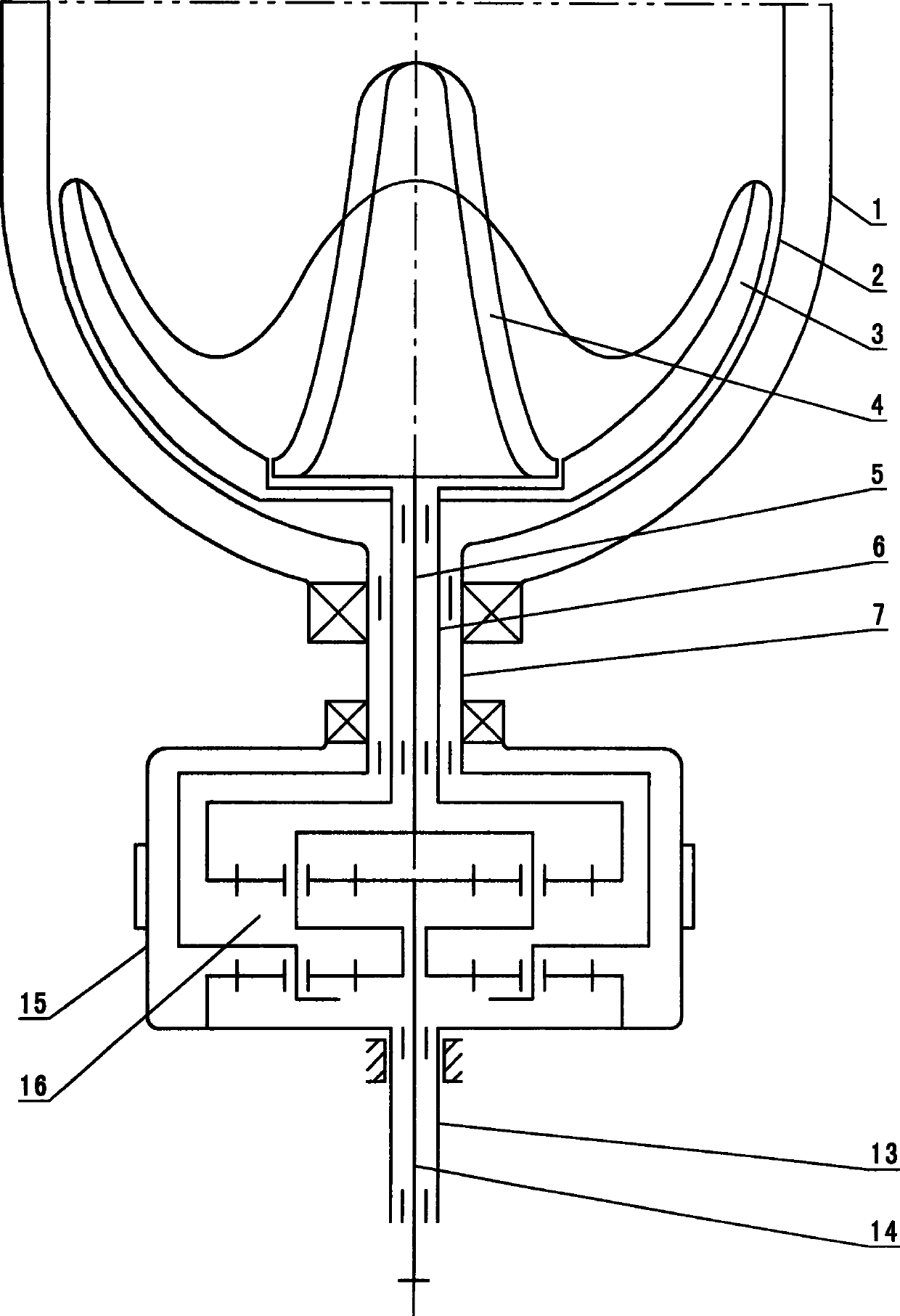

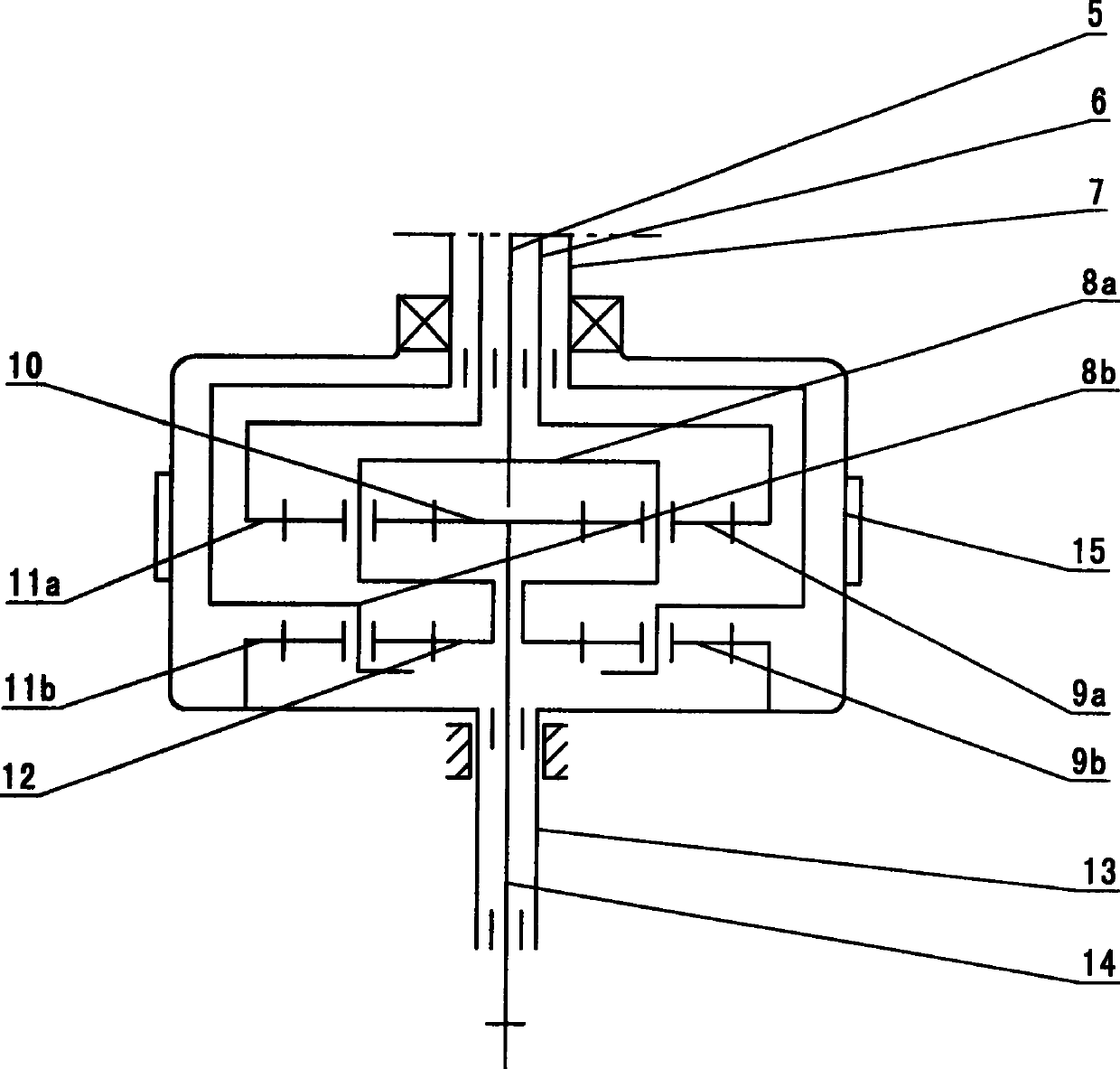

Triple-driving washer decelerating clutch and washer and washing mode thereof

ActiveCN101581028ATumble fullImprove cleaning rateOther washing machinesWashing machine with receptaclesShock waveGear wheel

The invention relates to a triple-driving washer decelerating clutch and a washer and a washing mode thereof, which belong to the technical filed of washers; a decelerating mechanism of the triple-driving washer decelerating clutch consists of three groups of satellite gears, an upper central gear is connected with a small wave wheel shaft, an upper planet carrier is connected with a large wave wheel shaft sleeve, and an inner gear is connected with an inner barrel shaft. The wave wheels of the washer manufactured by using the triple-driving washer decelerating clutch comprise a small wave wheel and a large wave wheel, the small wave wheel is fixedly installed on the small wave wheel shaft and positioned at the central position of the large wave wheel, the large wave wheel is fixedly installed on the large wave wheel shaft sleeve, and an inner barrel is fixedly installed on the inner barrel shaft. The washer manufactured by using the triple-driving washer decelerating clutch has the washing mode that the small wave wheel, the large wave wheel and the inner barrel sequentially and reversely rotate to and fro at different speeds and different rotation angles in two directions in proportion, generate complicated and interlaced shock wave currents, flap and scour clothes, sufficiently overturn and strongly rub and swing the clothes, and improve the cleaning rate.

Owner:NINGGUO JULONG IND

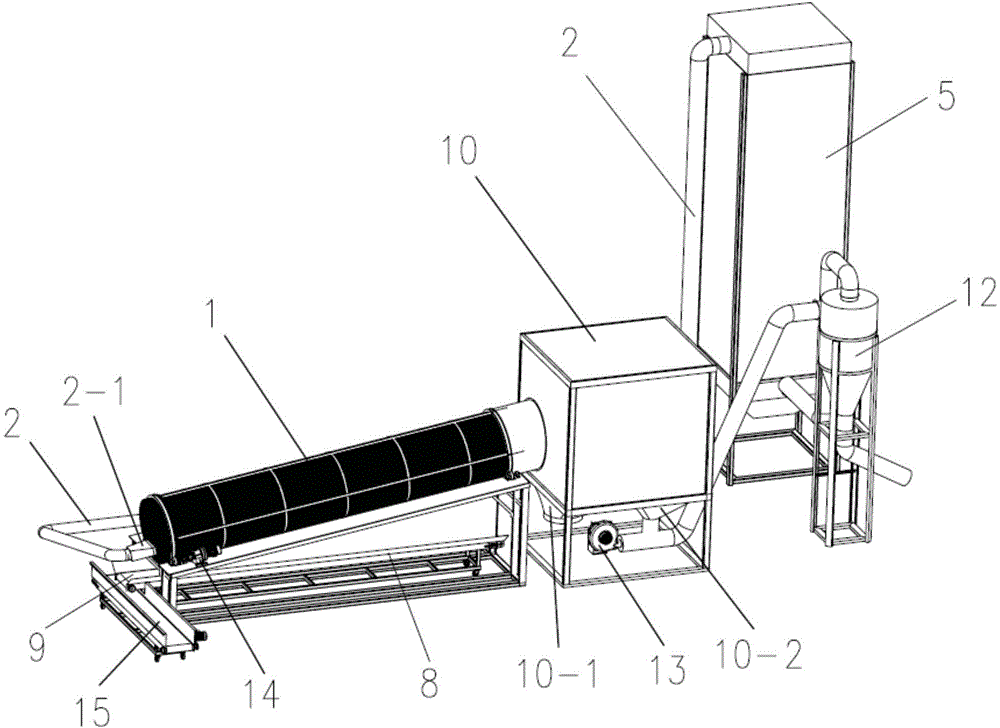

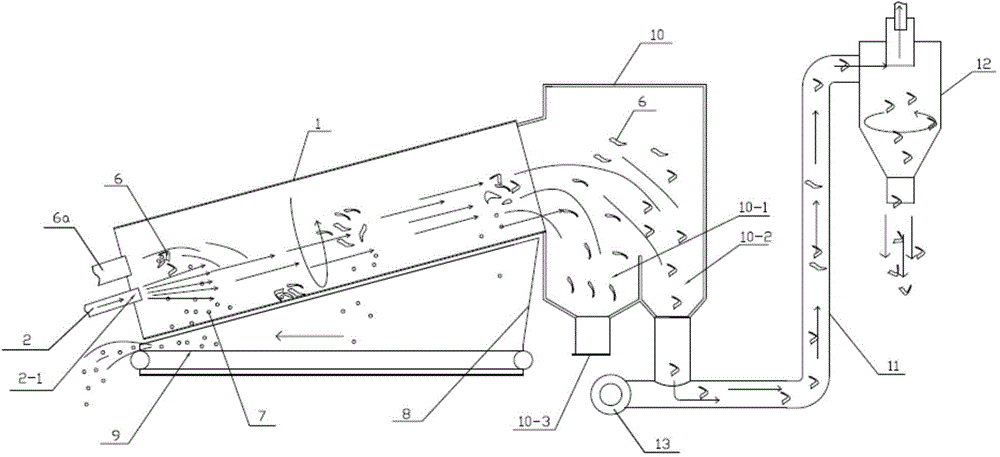

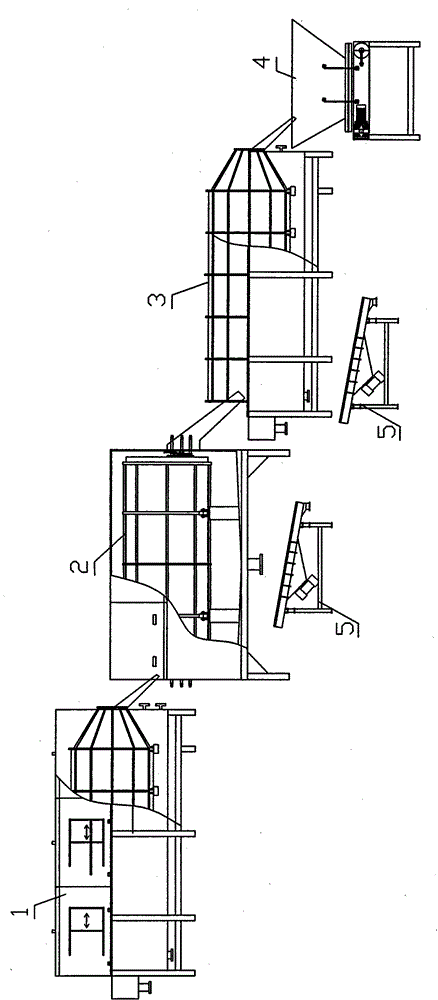

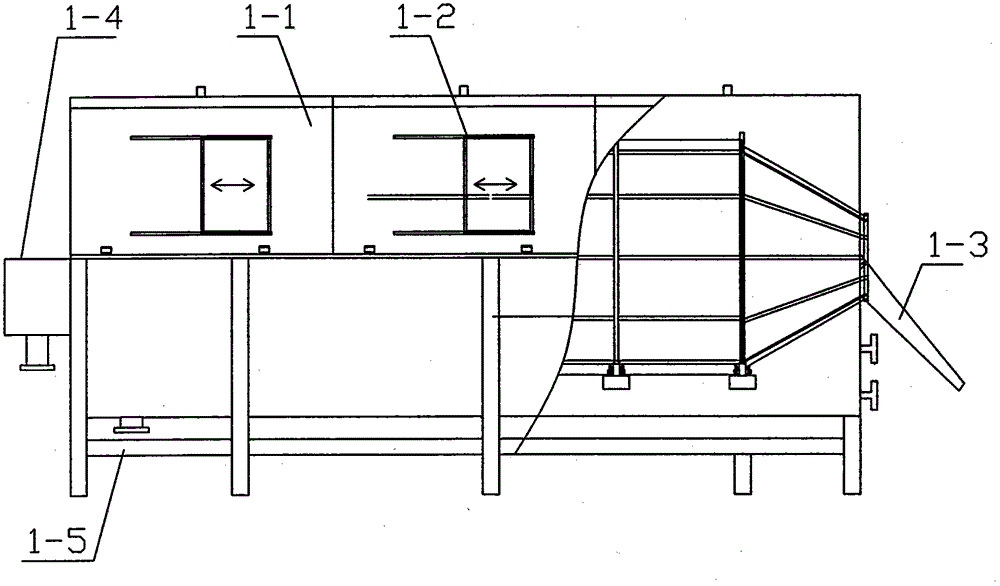

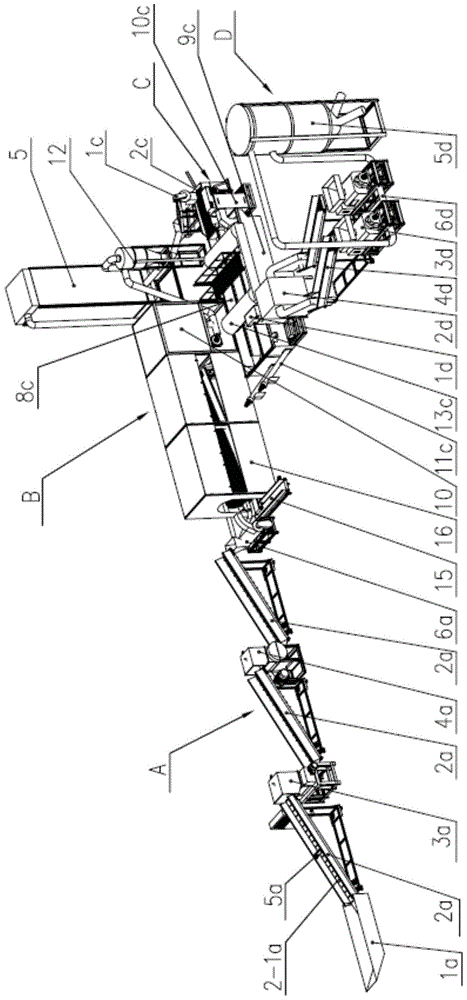

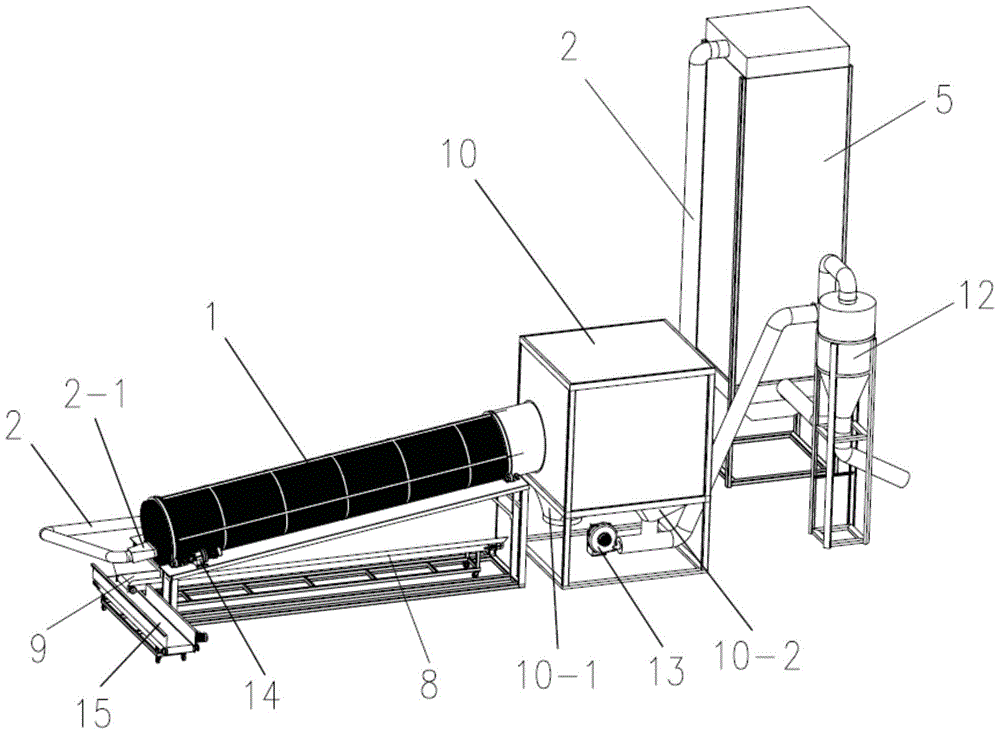

Recovery treatment complete device for soft sheet materials

ActiveCN104815835AReduce manual interventionIncrease productivityGas current separationSolid waste disposalTreatment completedSmall footprint

The invention discloses a recovery treatment complete device for soft sheet materials. The recovery treatment complete device comprises a crushing portion, an impurity separating portion, a cleaning portion and a dehydration briquetting portion which are respectively connected, the crushing portion comprises a shredding machine and a crushing machine which are sequentially connected together through a material conveying mechanism, the impurity separating portion comprises an air conveying device, a separating cylinder, a separating cylinder driving device and a soft sheet gas separating device, the separating cylinder driving device drives the separating cylinder to rotate, the air conveying device comprises a fan and an air pipe connected with the fan, sieve holes are formed in the wall of the separating cylinder, two ends of the separating cylinder are open, an air outlet of the air pipe is arranged at a feeding end of the separating cylinder, the cleaning portion comprises a washing cage, a vibrating sieve device and a cleaning water tank which are sequentially connected, and the dehydration briquetting portion comprises a dehydrator, an aggregating machine and a material storage tank which are sequentially connected. The recovery treatment device has the advantages of high production efficiency, low labor cost, small occupied area, no secondary pollution and the like.

Owner:冯愚斌

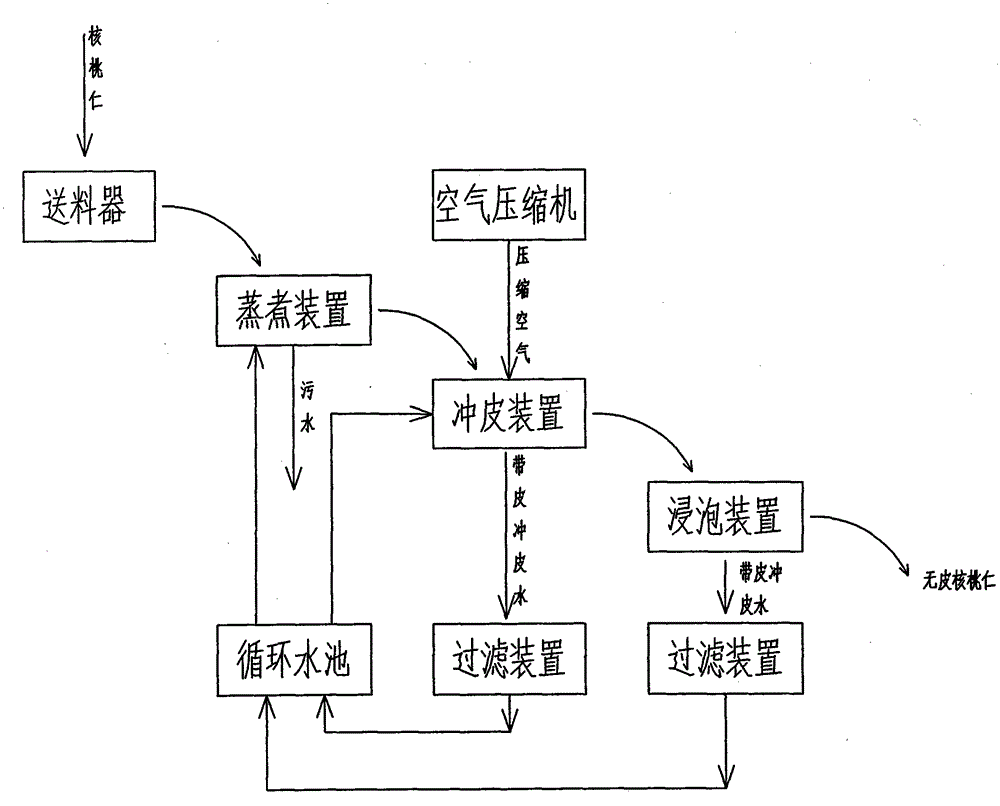

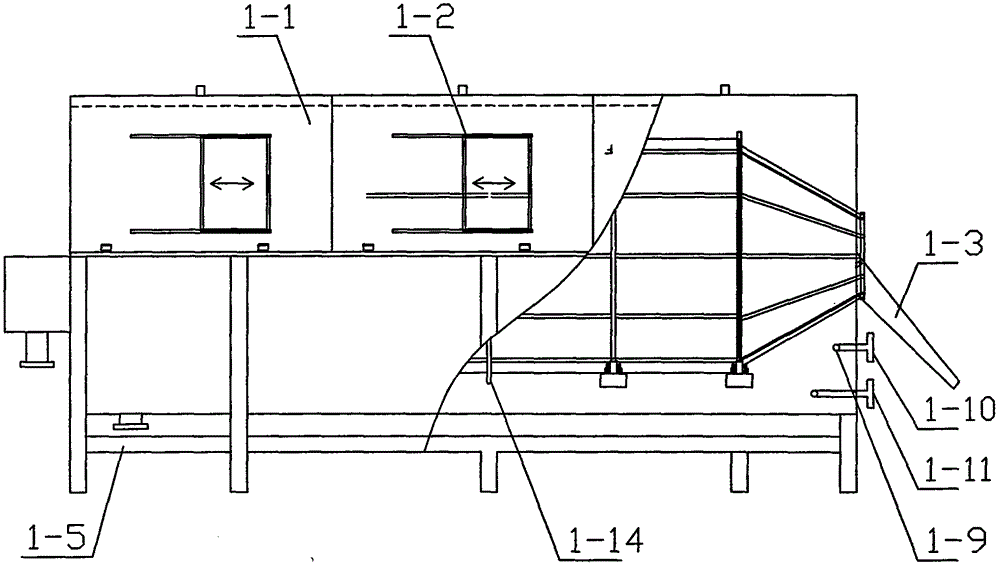

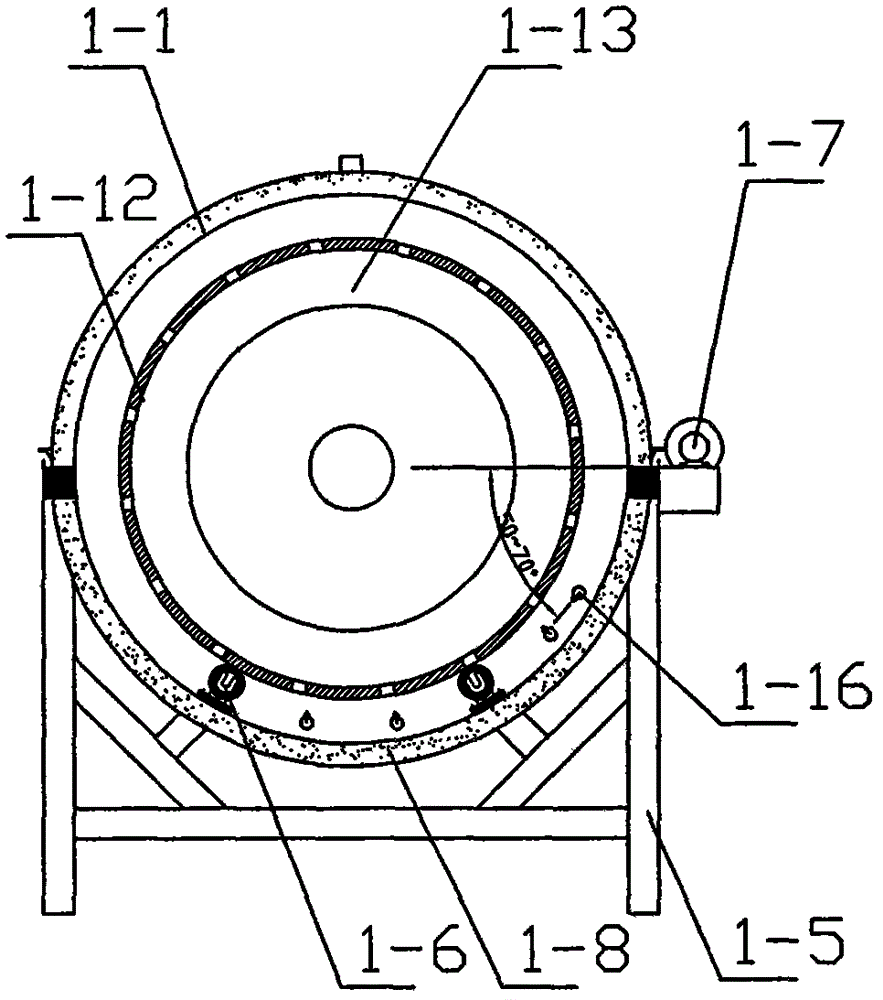

Walnut kernel peeling process

The invention discloses a walnut kernel peeling process. According to the walnut kernel peeling process, steaming and peeling are separated, and a soaking process is added and a rotary drum is used for realizing continuous production; the walnut kernel peeling process is suitable for a flow production line; a steaming rotary drum is used for realizing even steaming, steam is used for heating and the problems of walnut kernel floating and walnut kernel going out upwards due to the rotation of the rotary drum are solved by virtue of steam injection directions; a water-steam mixture is used for peeling; above 20-30% of water resources can be saved; the steam injection directions swing back and forth within a certain angle; peeling by use of a water gun is simulated, so that the walnut kernels can be turned over and peeled sufficiently, and the peeling effect is uniform and consistent and far better than that of artificial water gun peeling, and the peeling treatment rate is above 99.5%; meanwhile, the labor is greatly saved, and more than 95% of labor can be saved; soaking water is used for peeling or supplied to a steaming water tank by use of a water circulating system; the peeling water can be further applied peeling; only when the steaming water is high in color concentration, the water is discharged; the water consumption amount for treating 1 ton of walnut kernels is reduced to 0.6 ton now from 1.2 tons in the past, and the water is saved.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

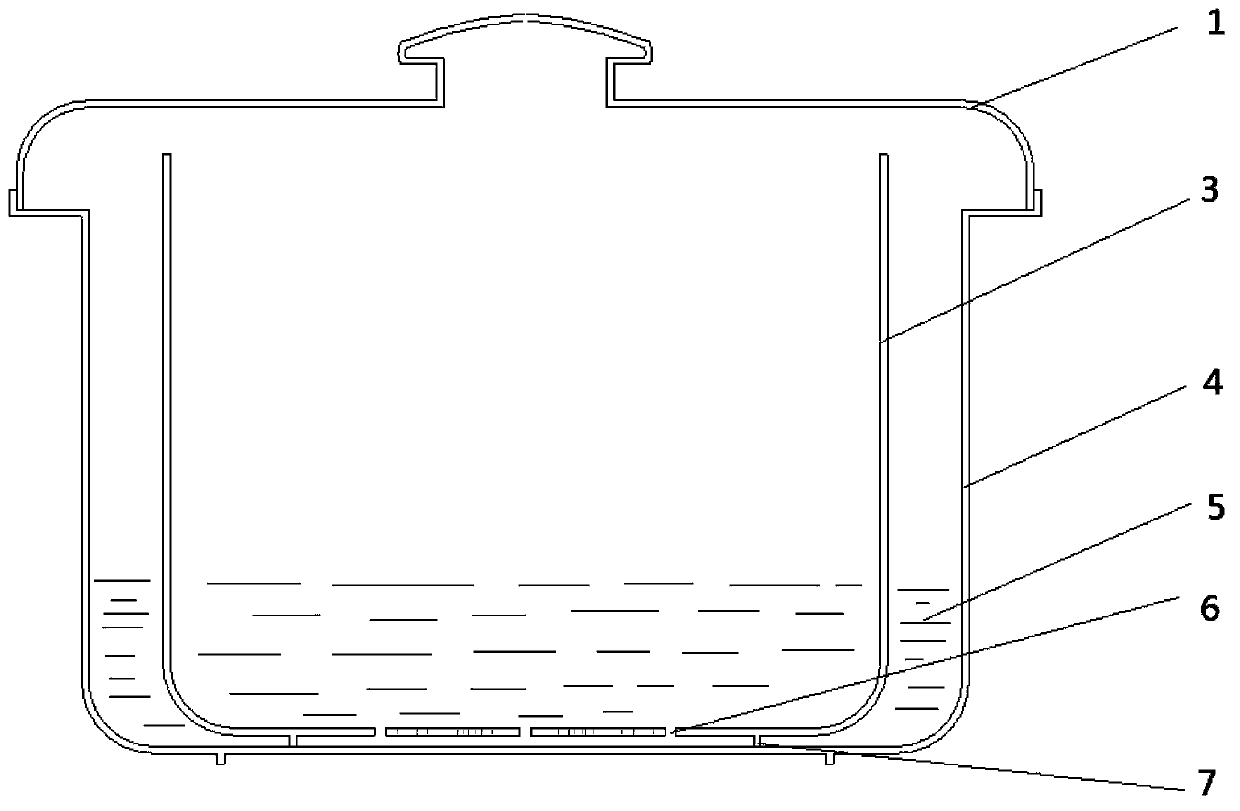

Pot for processing food

ActiveCN104207630AAvoid cost increaseFood tumbling violentlyWater-bath cooking vesselsCooking insertsFood processingMechanical engineering

A pot for processing food comprises a pot base and a pot cover and further comprises an inner pot container, wherein the inner pot container is arranged in the pot base and provided with water circulating holes. Due to the adoption of the method that the water circulating holes are formed in the bottom or the side faces of the inner pot container, water in the inner pot container and water in the pot base can be communicated; the inner pot container is not pressed through a weight, the inner pot container will not float up although buoyancy of water exists, and it is avoided that when the inner pot container is pressed through a weight, cost is increased, cleaning difficulty is increased and structural design difficulty is increased; due to the adoption of the method that a sealing ring is additionally arranged in a gap between the inner pot container and the pot base, when food is heated, water in the gap between the inner pot container and the pot base flows into the inner pot container through the water circulating holes because pressure in the gap between the inner pot container and the pot base is larger than atmospheric pressure, the problem that in the food processing process, the upper portion of the food is dry and hard, but the lower portion of the food is watery and soft is solved, meanwhile, under the action of pressure, food in the inner pot container can roll more violently and fully, and the processed food can be heated more evenly.

Owner:成都骏元科技发展有限责任公司

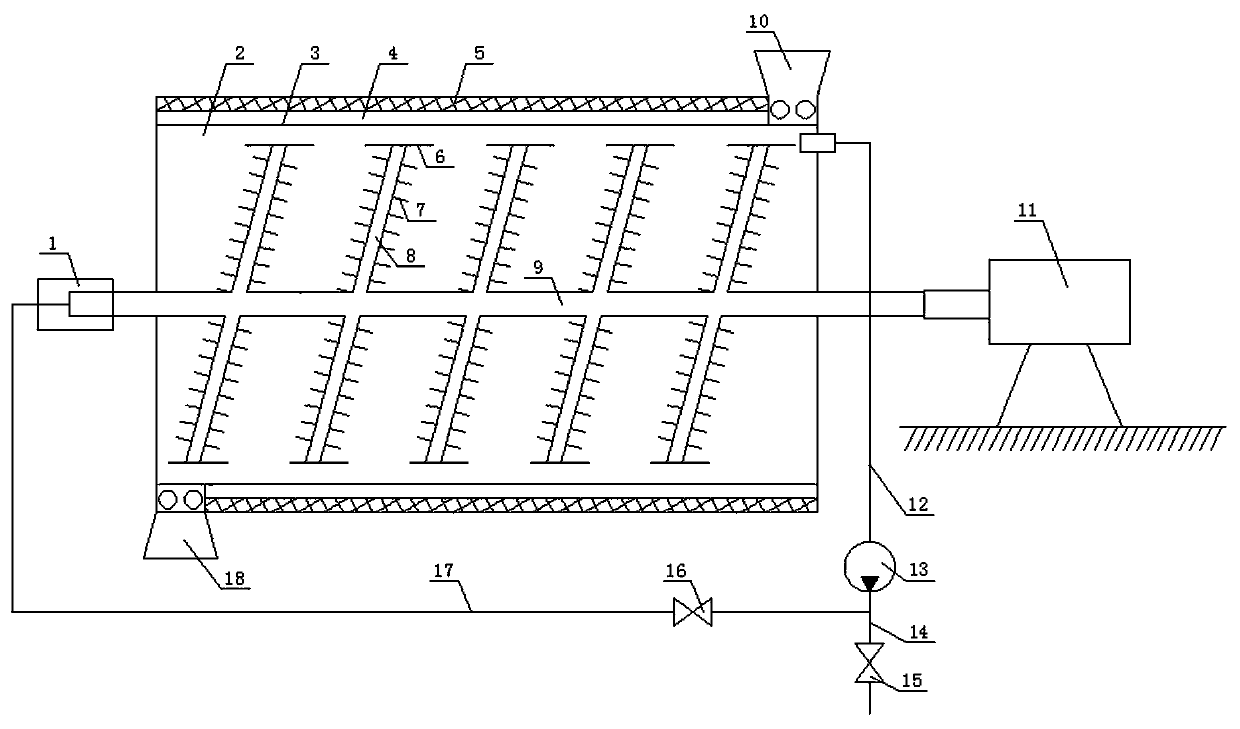

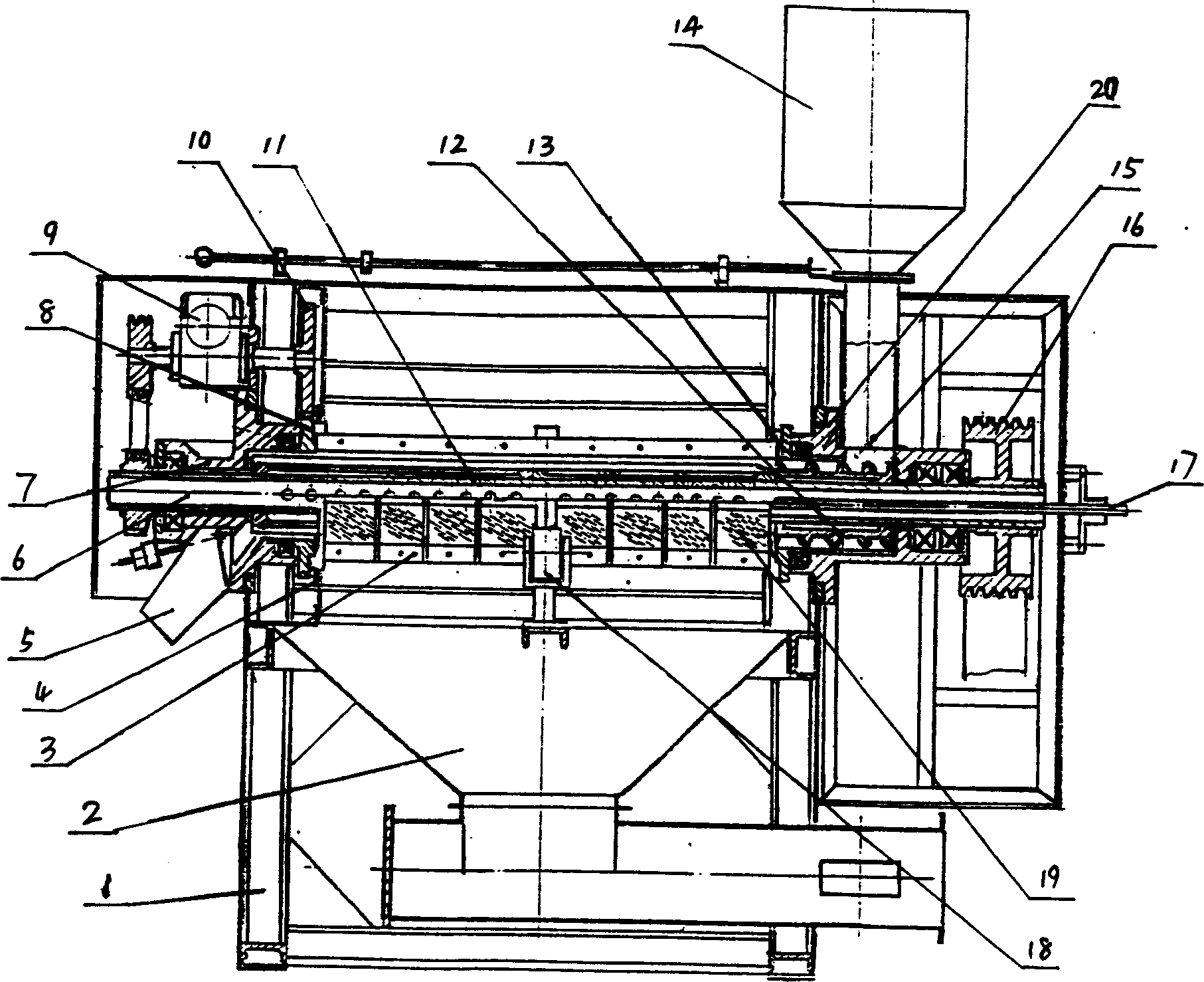

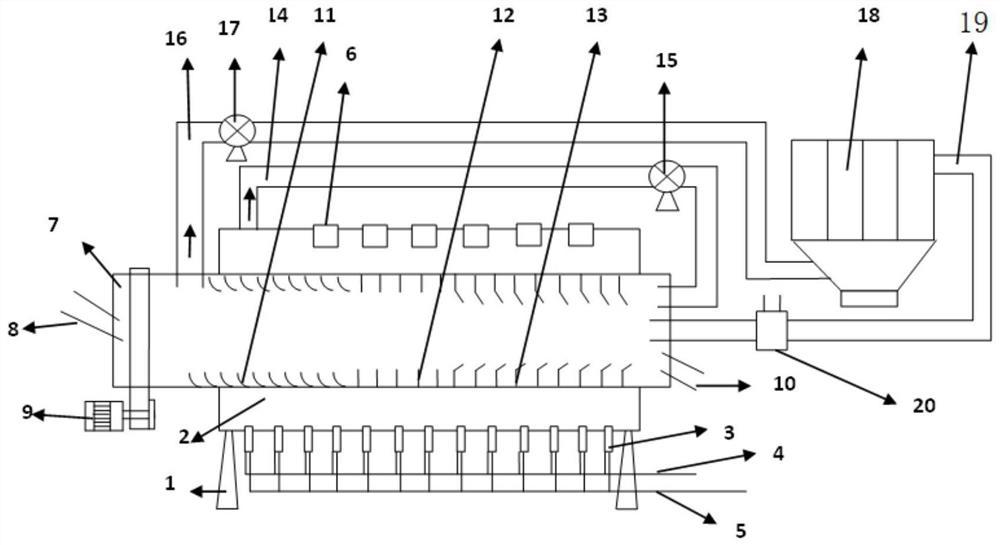

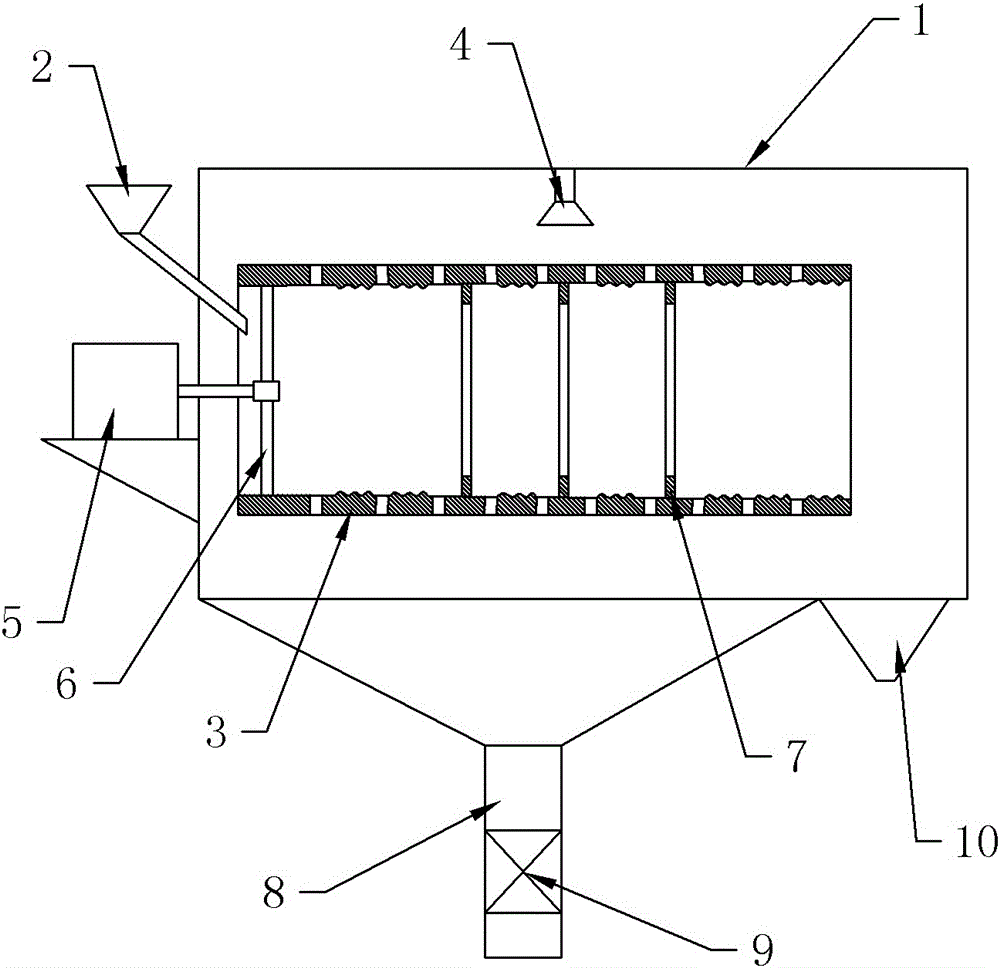

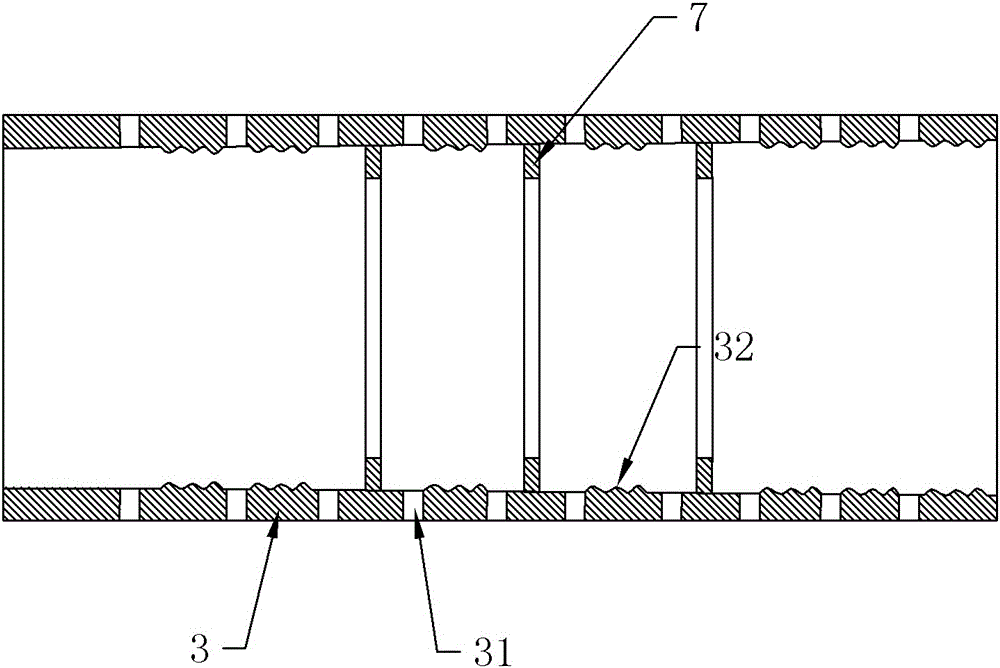

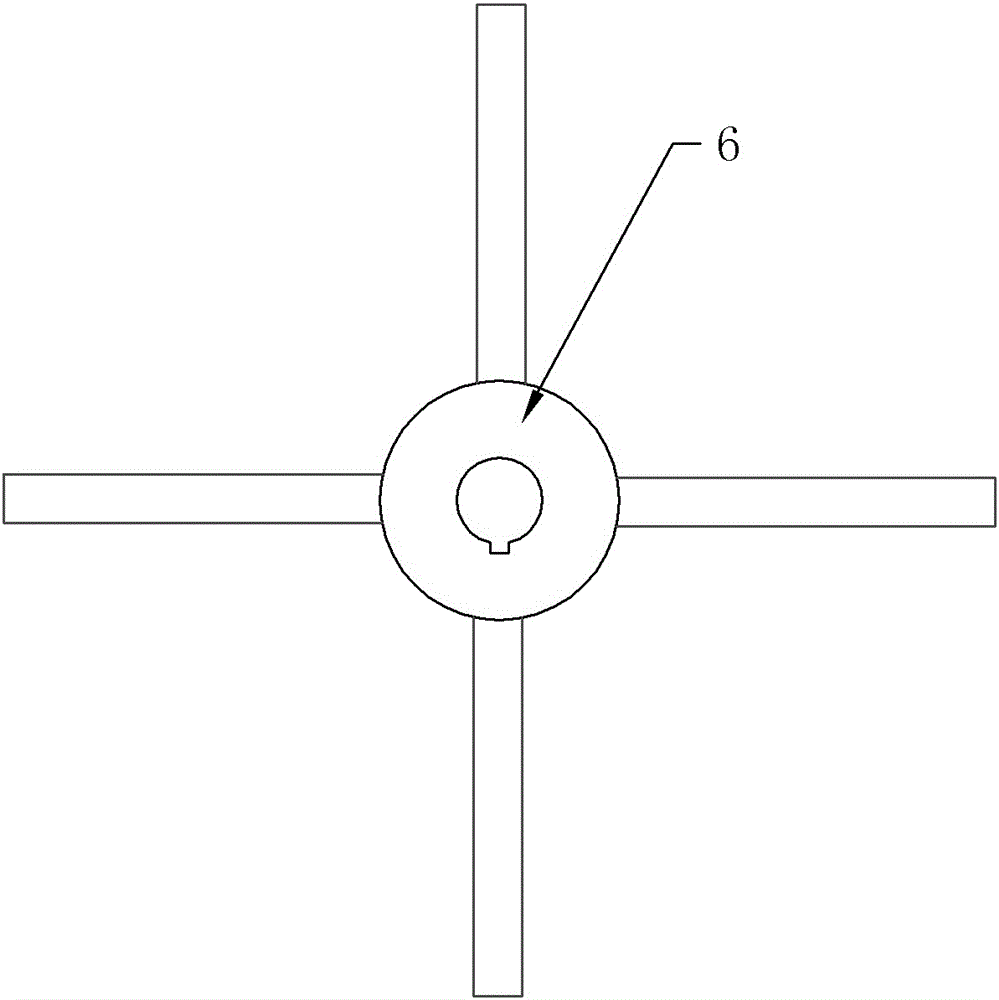

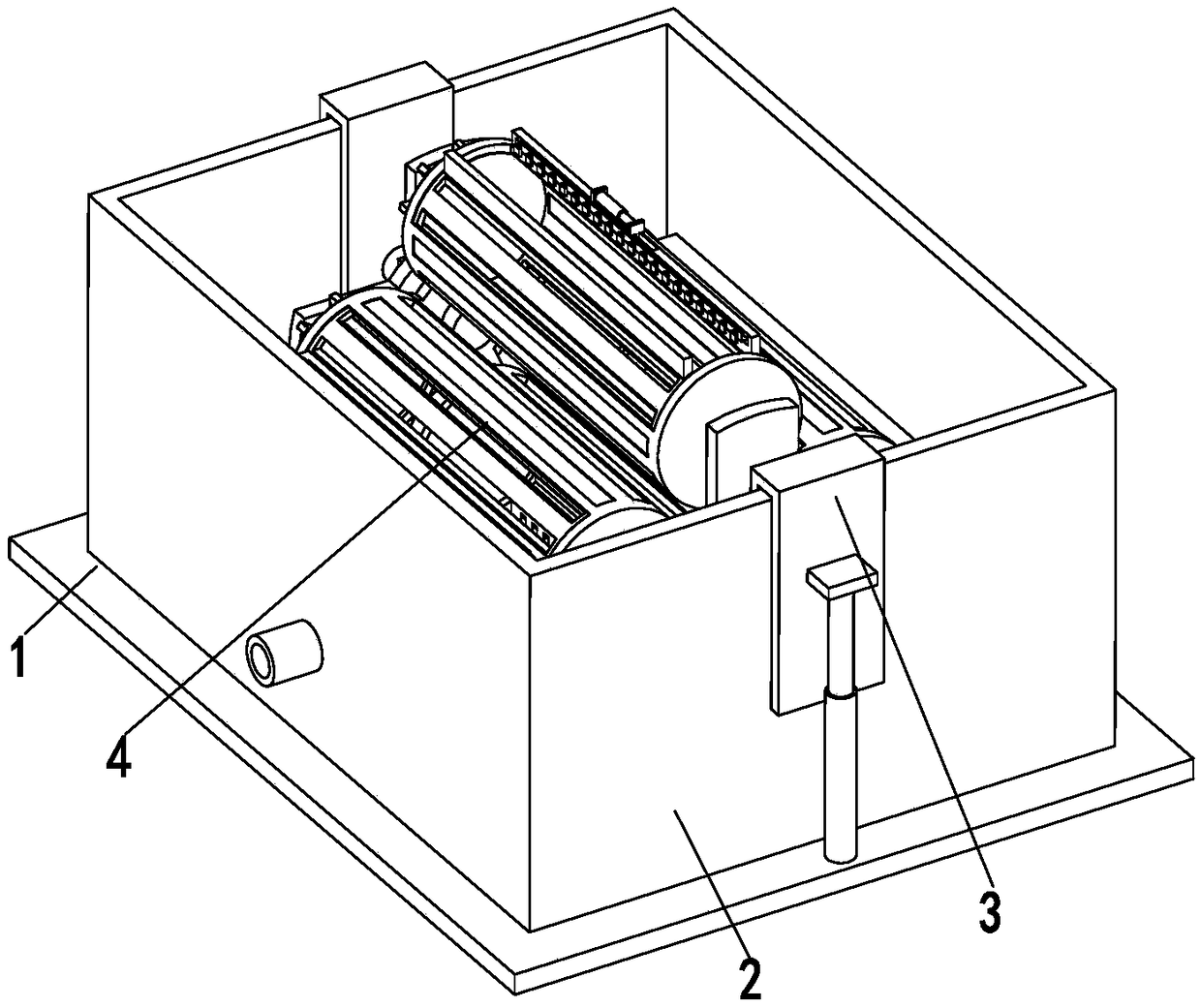

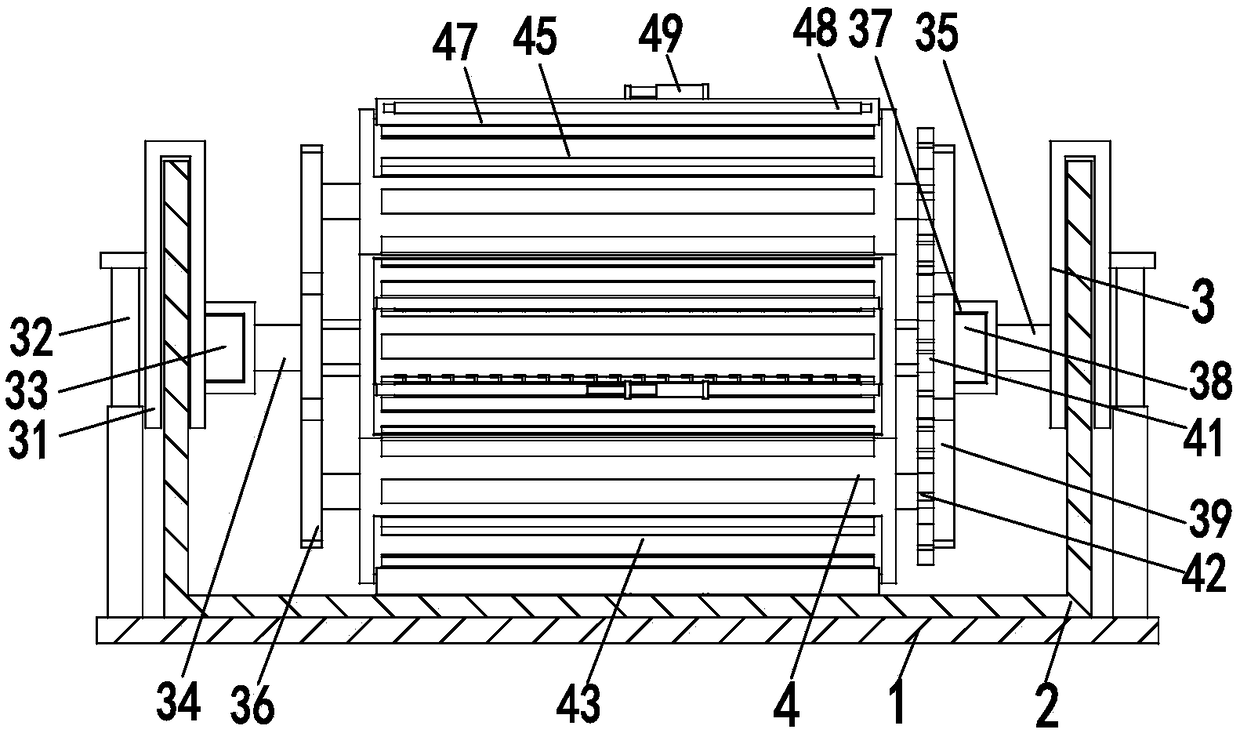

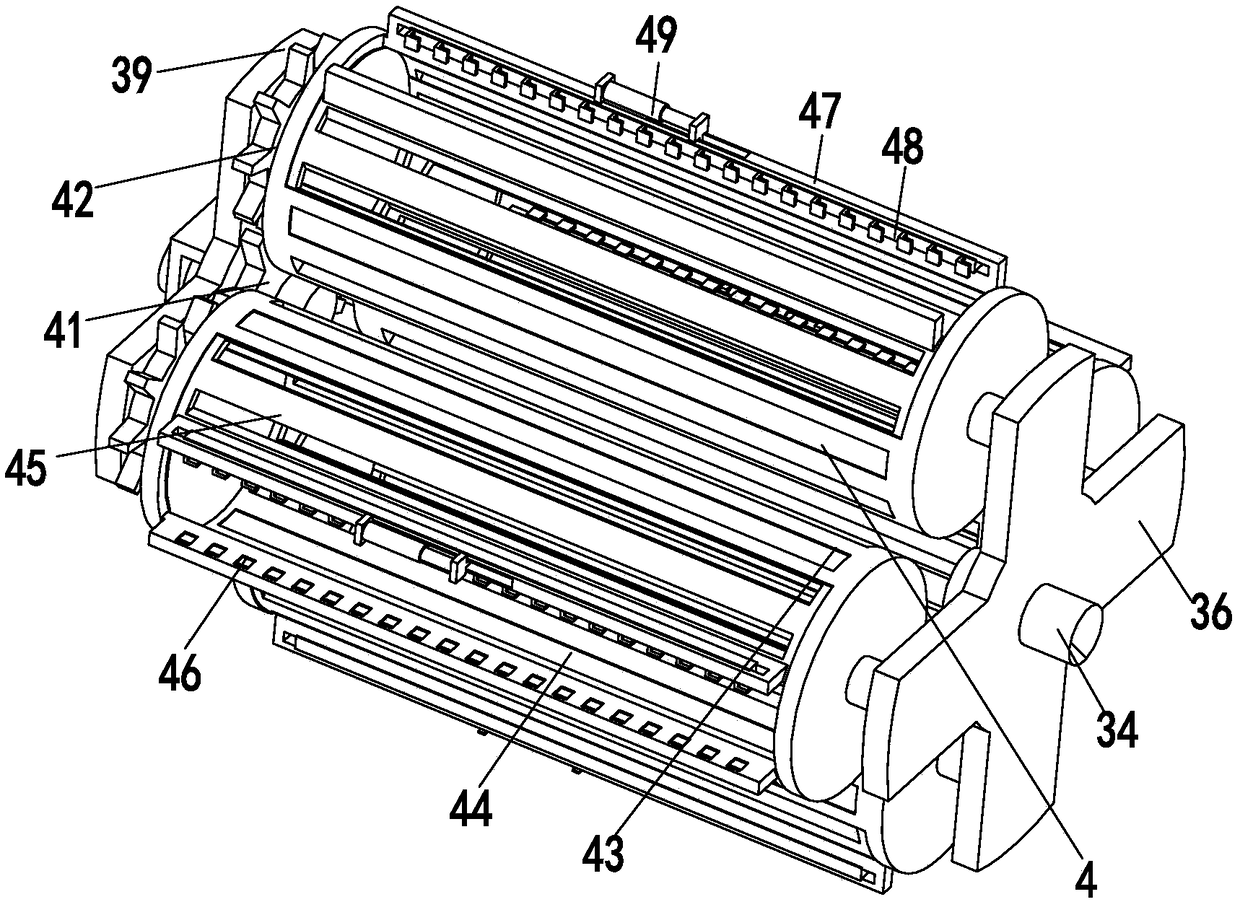

Horizontal type closed strong-drying device for town waste

InactiveCN110454796AStir wellTumble fullDrying gas arrangementsDrying solid materialsPulp and paper industryWaste treatment

The invention discloses a horizontal type closed strong-drying device for town waste, and belongs to the technical field of town waste treatment. The device comprises a closed drying box body, whereinthe top of the drying box body is provided with a closed feeder, and a closed discharger is arranged at the bottom of the drying box body; a hollow stirring shaft is coaxially and rotationally connected in the drying box body, and a plurality of hollow stirring rods are uniformly arranged on the stirring shaft; a hollow cavity in the stirring rod communicates with the hollow cavity in the stirring shaft; a plurality of air nozzles are uniformly arranged on the stirring rod; both of the two ends of the stirring shaft extend out of the drying box body; a power mechanism used for driving the stirring shaft to rotate is in transmission connection with one end of the stirring shaft, an air valve is rotationally connected to the other end of the stirring shaft in a sealing mode, and a hot air source is connected to the air valve; and thus, the horizontal type closed strong-drying device for the town waste is energy-saving and environment-friendly, high in drying degree and high in drying efficiency, and the waste can be directly used for smoldering pyrolysis treatment of a next process flow after being dried.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

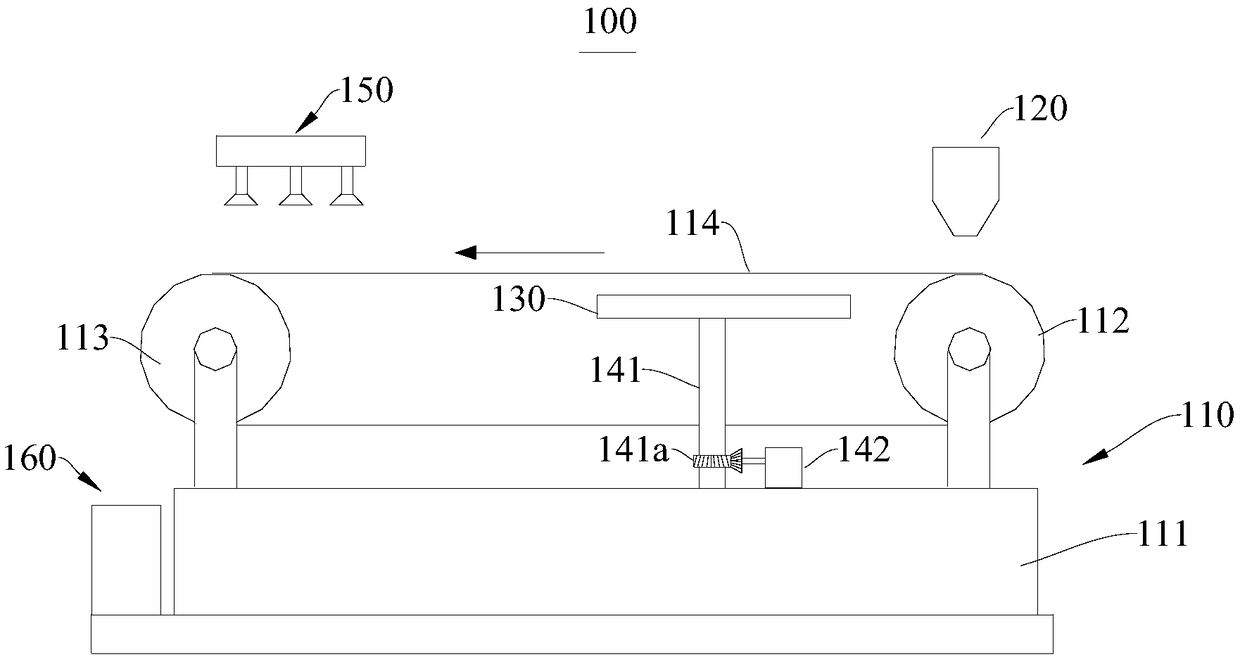

Magnetic-field-alterable belt type magnetic separator

The invention discloses a magnetic-field-alterable belt type magnetic separator. The magnetic-field-alterable belt type magnetic separator comprises a feeding conveying belt; a quantitative feeding bin is installed above the feeding conveying belt, to-be-separated materials are contained in the quantitative feeding bin and can be quantitatively conveyed onto the feeding conveying belt through the quantitative feeding bin according to requirements, and a magnetic separating conveying belt is installed on the upper portion of the tail end of the feeding conveying belt in the movement direction of the feeding conveying belt; a magnetic-field-alterable magnetic source body is installed in the magnetic separating conveying belt, a tail ore bucket, a middle ore bucket and a fine ore bucket are installed on the lower portion of the magnetic separating conveying belt in the movement direction of the magnetic separating conveying belt, and the to-be-separated materials are attracted by the magnetic-field-alterable magnetic source body and tightly attached to the magnetic separating conveying belt; and in the conveying process of the magnetic separating conveying belt, the magnetic-field direction of the magnetic-field-alterable magnetic source body changes so that the to-be-separated materials with different characters can be dropped into the tail ore bucket, the middle ore bucket and the fine ore bucket correspondingly, and through a low-frequency pulsing-type planer magnetic system, all magnetic-field spaces can be sufficiently used. The ore separating efficiency is greatly high, and manufacturing cost is reduced.

Owner:CHENGDU LEEJUN IND

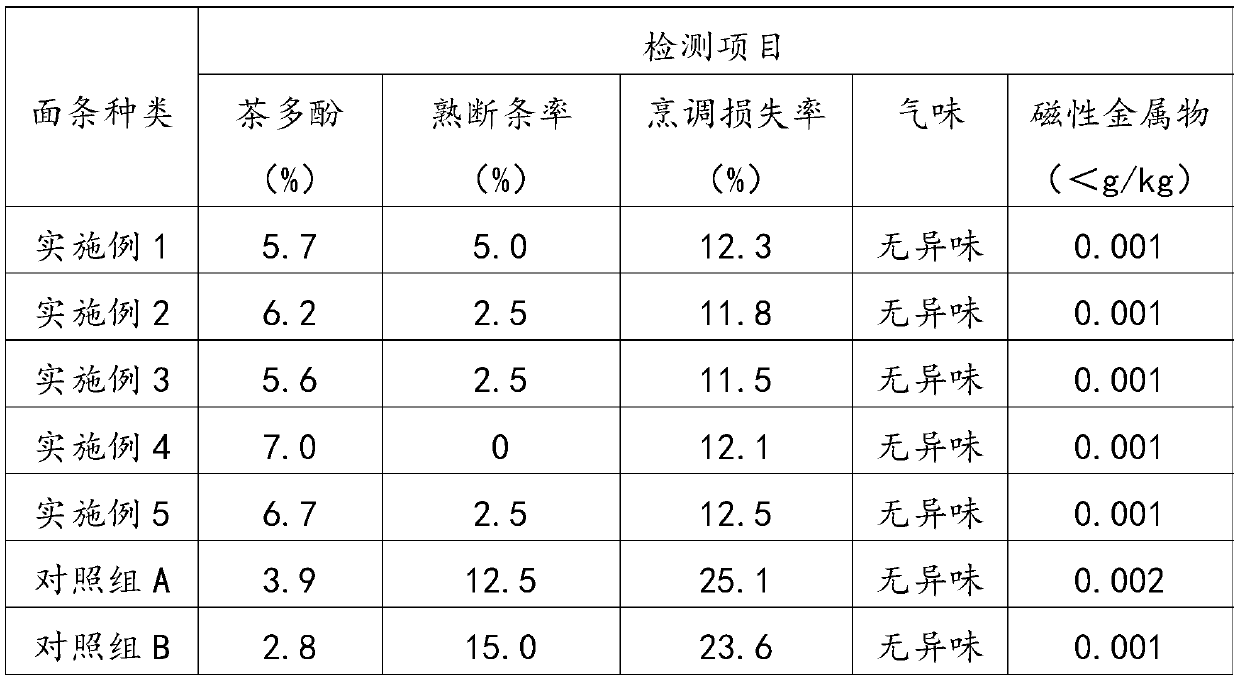

Tea-flavor type noodles and preparation method thereof

The invention relates to the technical field of food processing, in particular to tea-flavor type noodles and a preparation method thereof. The tea-flavor type noodles are prepared from flour, starch,tea residues, edible salt, a mixed preparation and yeast. By smashing and grinding the tea leaves, effective tea leaf ingredients in the tea residues are dissolved and extracted, the content of fibers in the tea residue powder is reduced, and the problem is solved that after common tea residues are directly added to dough, the gluten structure is broken, and the strength of the noodles is reduced.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

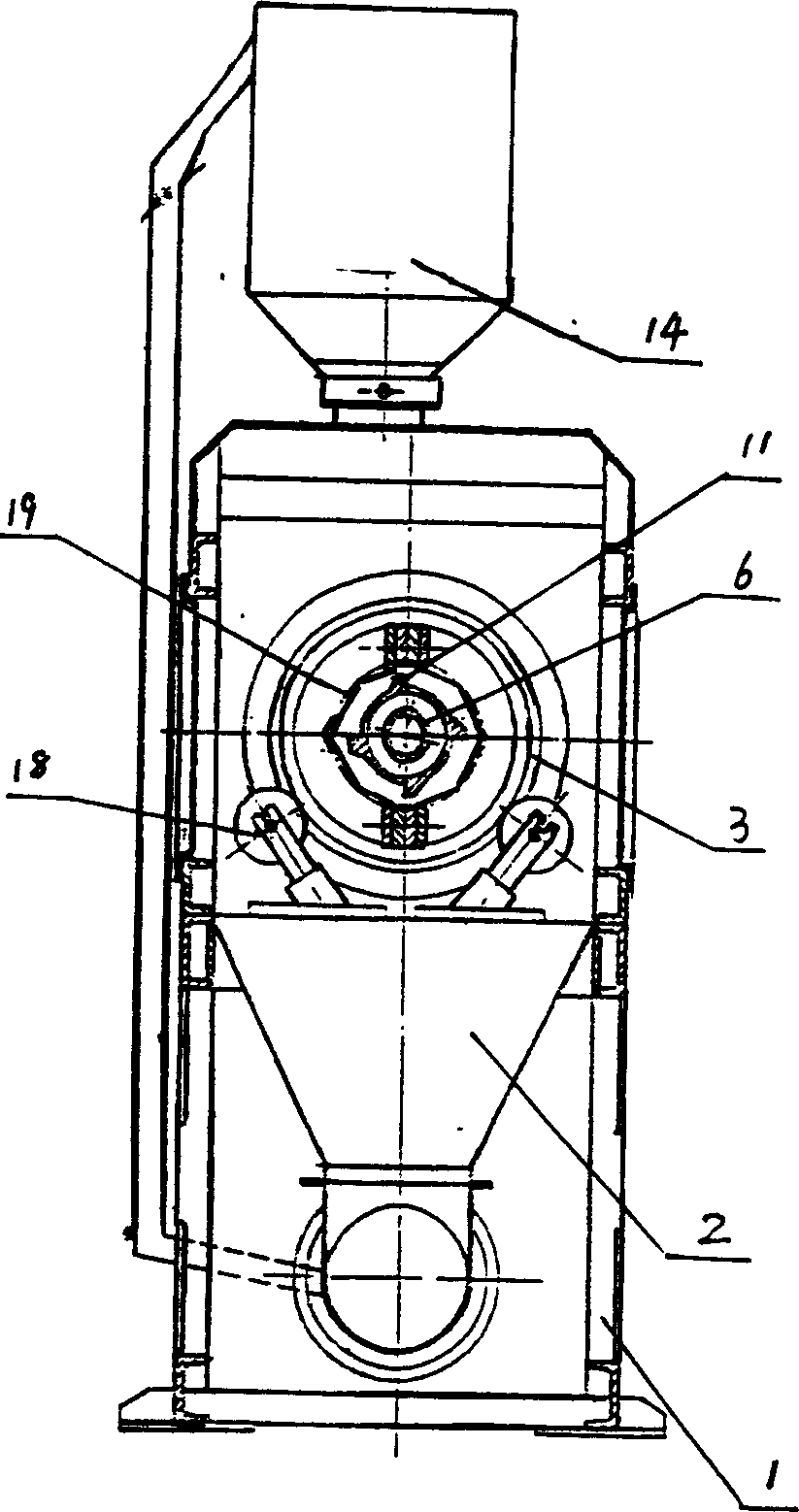

Rotary-sifting watermill polishing machine for rice

InactiveCN1836783ATumble fullImprove polishing effectGrain huskingGrain polishingDrive wheelReduction drive

The rice polisher with rotary sieve and water mill includes a frame, a bran collecting bin, a discharge port, a main shaft, a polishing roller, a screw conveyer, a rice sieve and a main driving belt wheel. It features the hollow main shaft with atomizing water pipe connected to water source inserted into its cavity and fixed on to the frame via bearing and other part; the rice sieve on the main shaft and with through hole to the cavity; the polishing roller with through hole for water to flow out; the main driving belt wheel connected to one end of the main shaft and the other belt wheel mounted to the other end of the main shaft and connected via a conveying belt to the reducer; the reducer meshed via a driving wheel to the driven gear on the rice sieve bracket; and the rice sieve bracket rotating in the same direction as and different speed from the main shaft. The rice polisher has the features of high rice polishing rate, high rice yield, low broken rice rate and low power consumption.

Owner:熊春辉

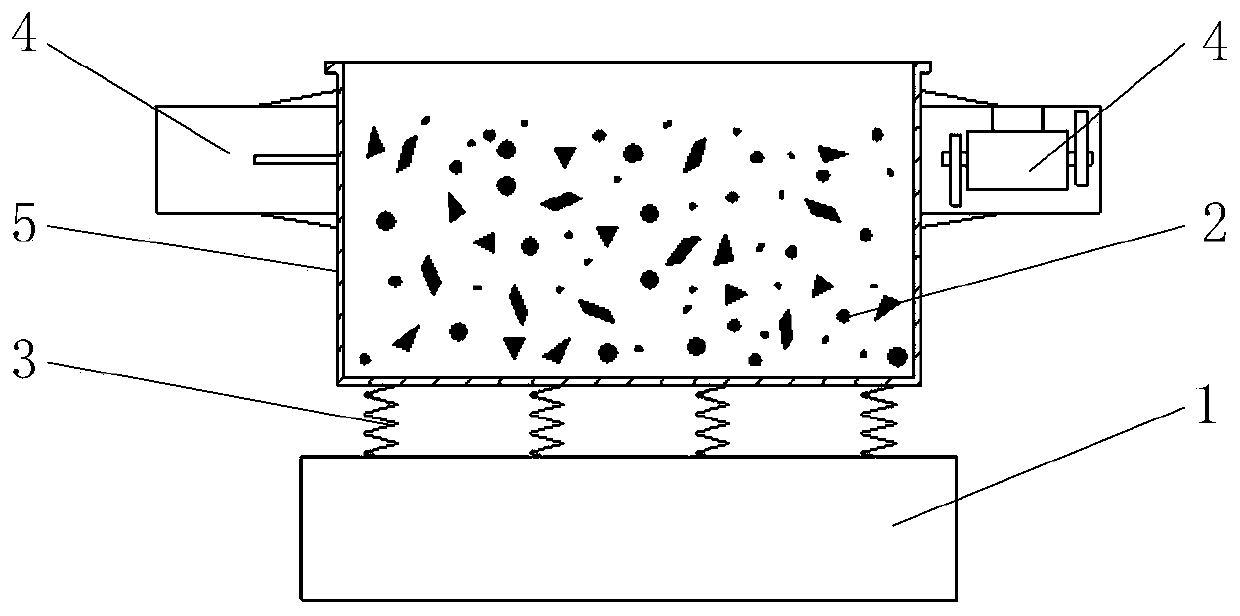

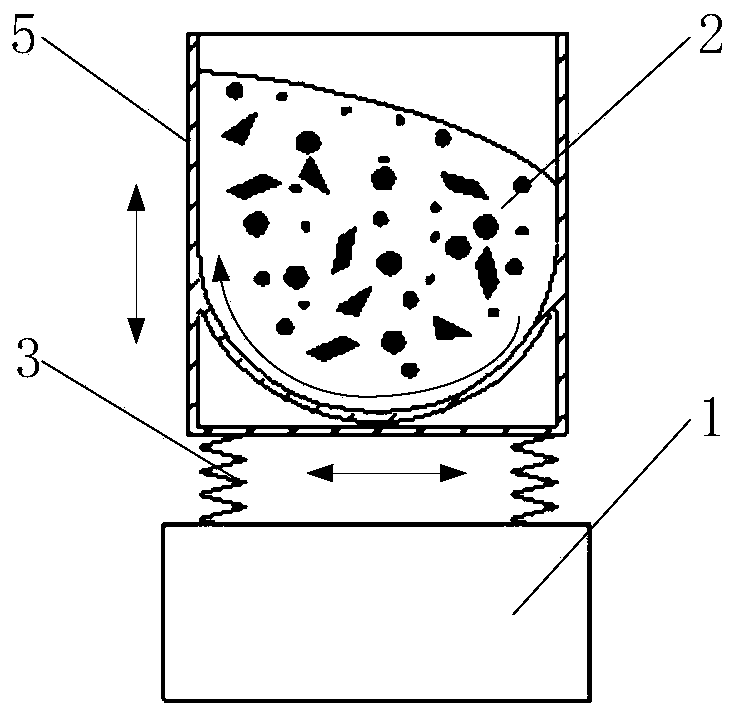

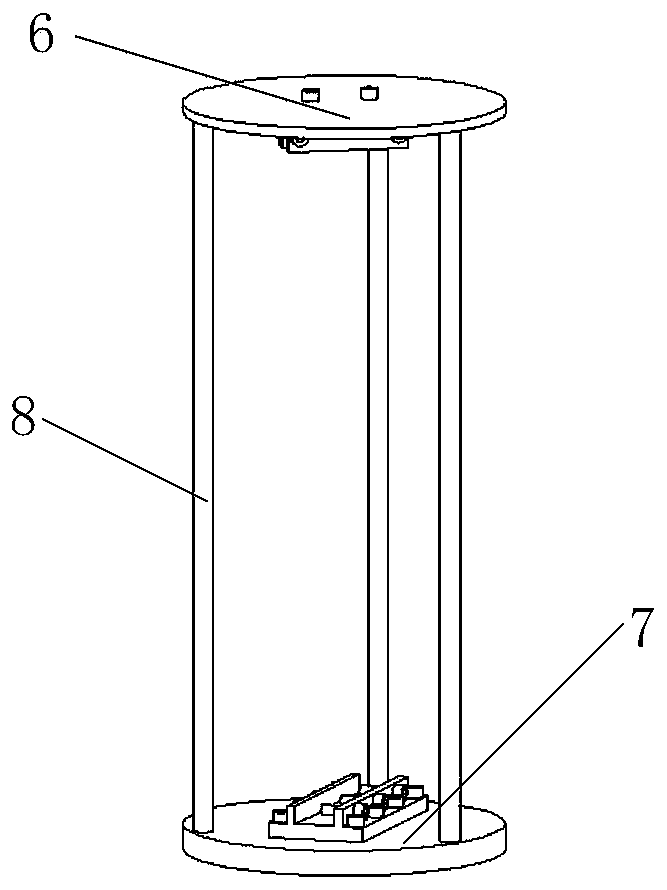

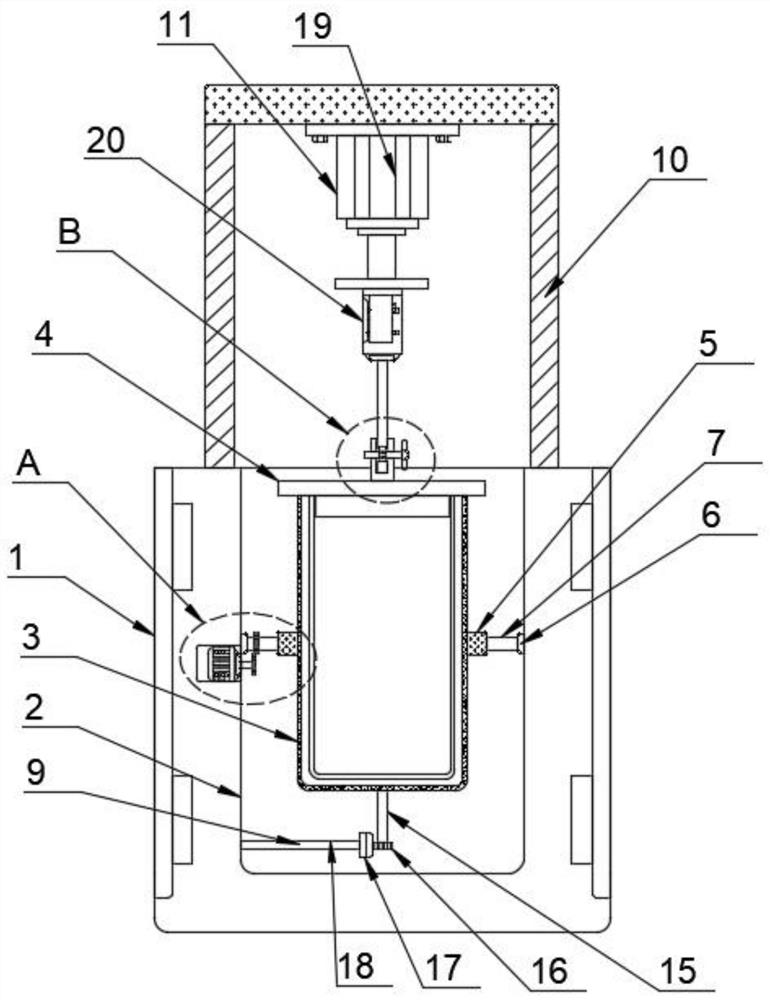

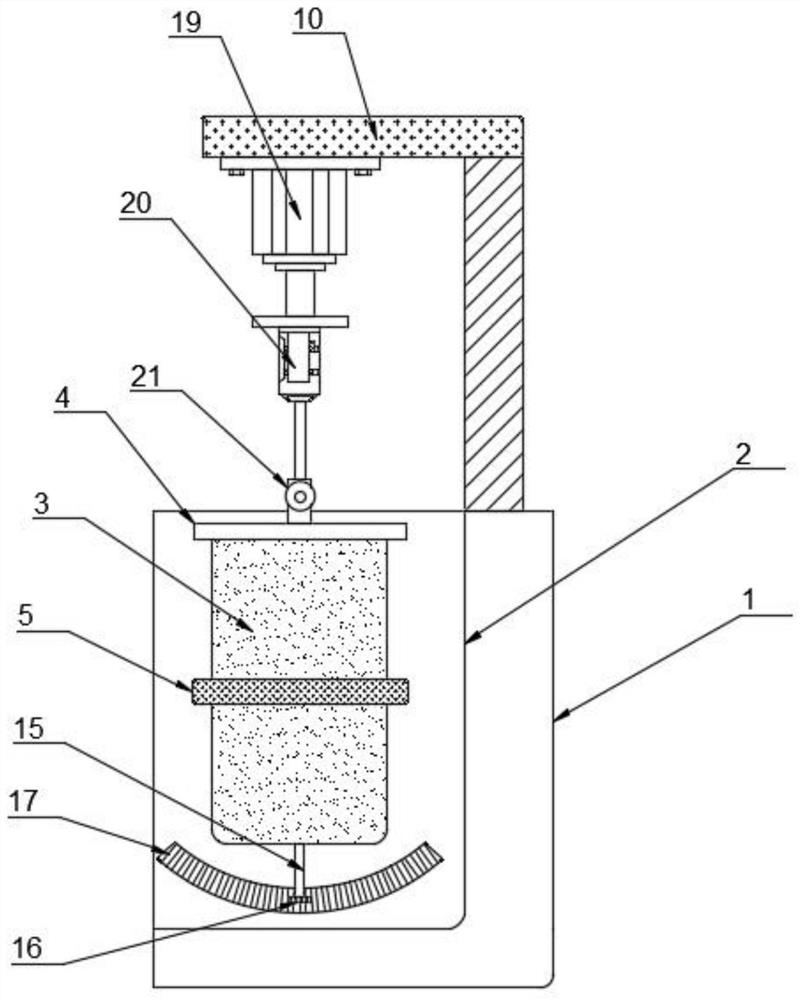

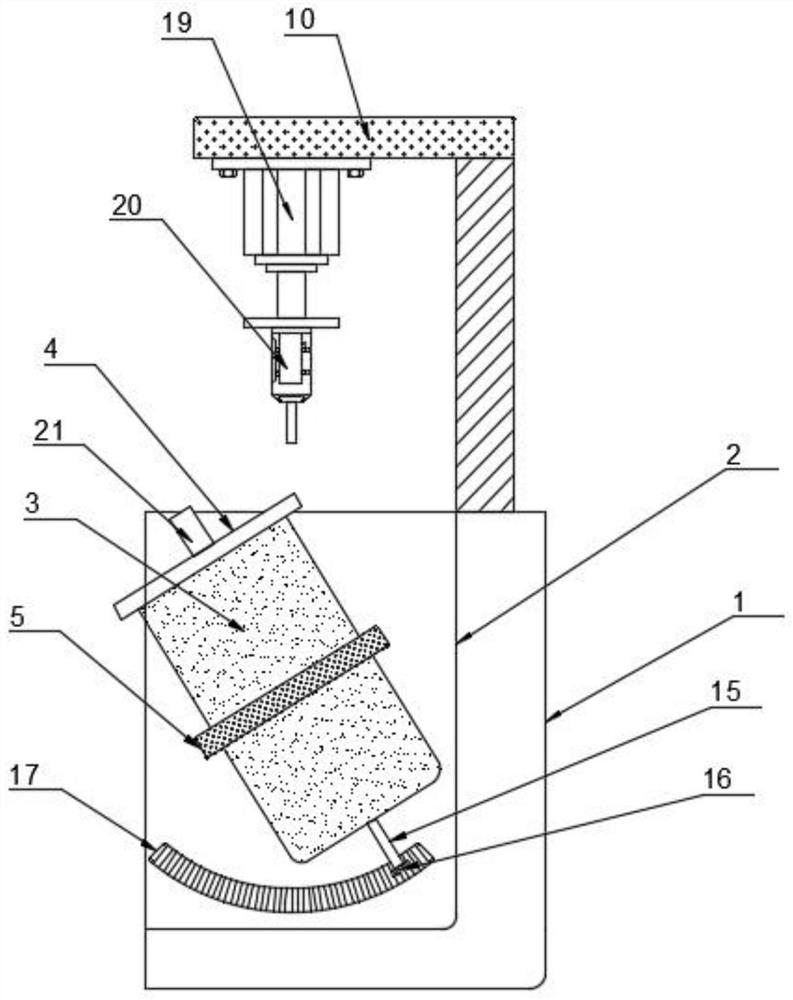

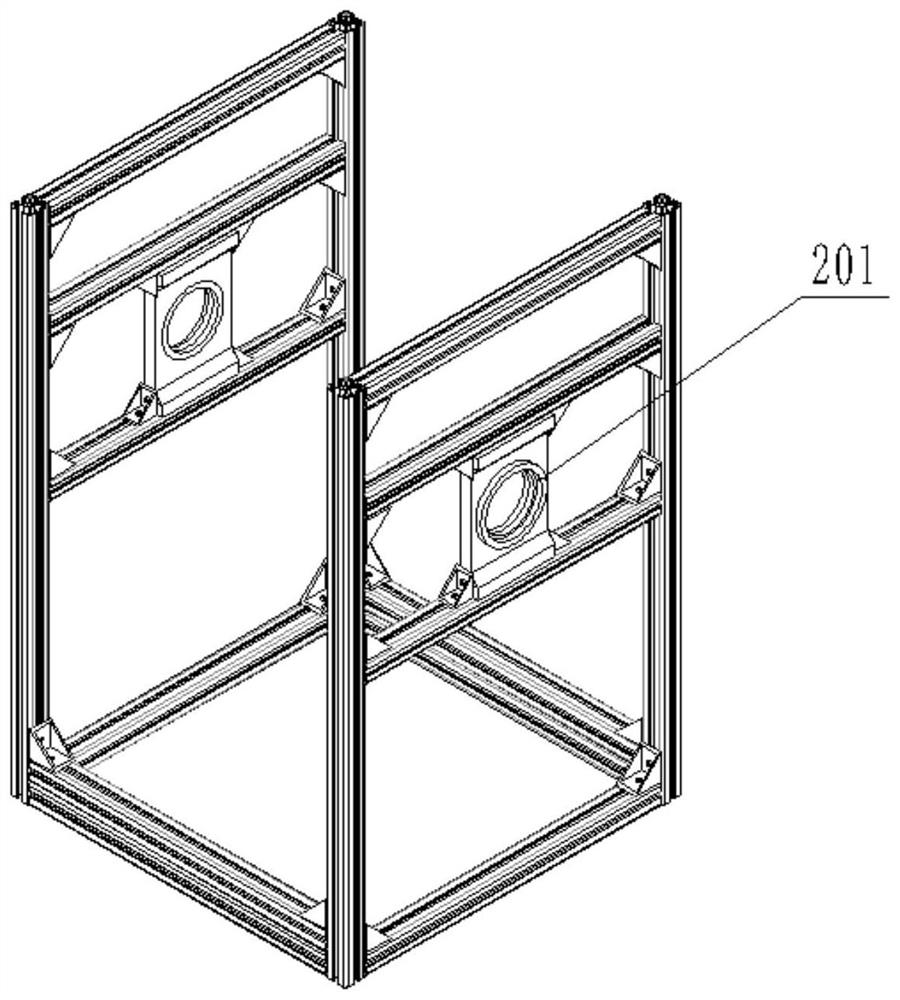

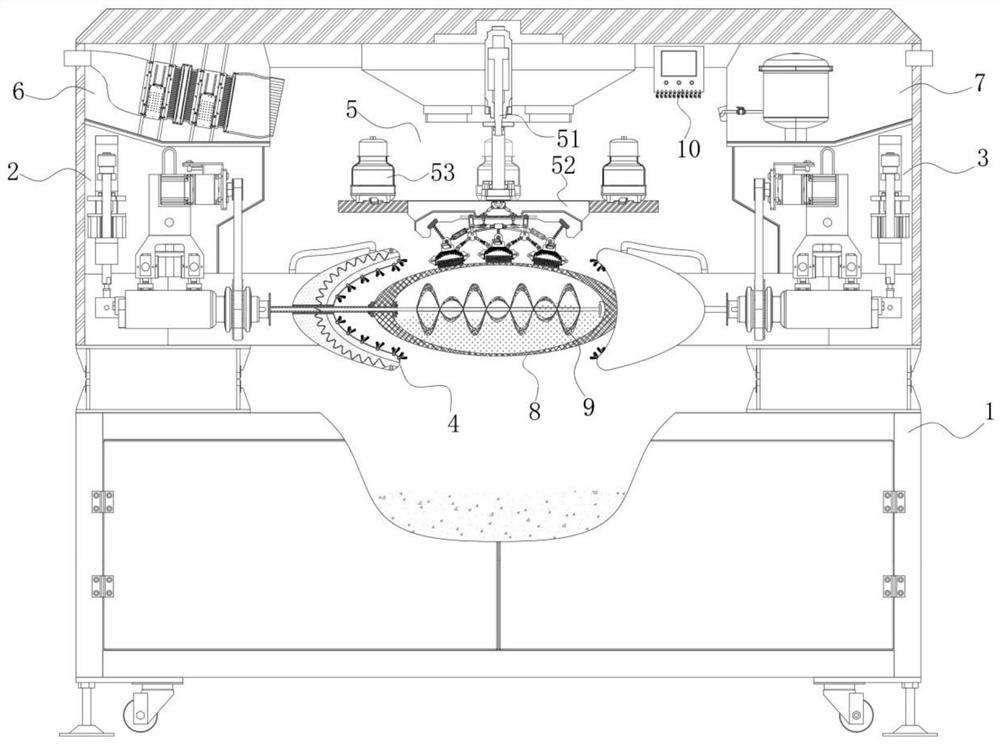

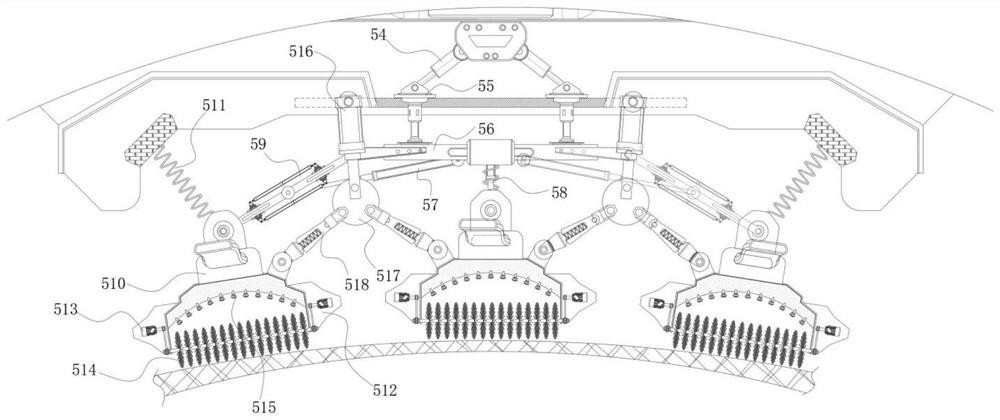

Horizontal composite vibration finishing device and method for large complex-structure rotor blades

InactiveCN110977746AFully automatedFine manufacturingEdge grinding machinesPolishing machinesCoil springVibration exciter

The invention discloses a horizontal composite vibration finishing device and method for large complex-structure rotor blades, and belongs to the technical field of aero-engine compressor blade surface finishing. The device comprises a vibration finishing mechanism and a clamp; the vibration finishing mechanism comprises a groove type container, and the groove type container is connected with a base through a plurality of spiral springs; vibration exciters are symmetrically arranged outside the groove type container, and a grinding medium is arranged in the groove type container and used forgrinding a rotor blade; the clamp is arranged in the groove type container and used for clamping the rotor blade; the clamp comprises a top base, a root base and a corresponding clamping mechanism, and the top base and the root base are connected through a plurality of protection columns. According to the horizontal composite vibration finishing device and method for the large complex-structure rotor blades, a traditional manual polishing mode can be replaced, automatic and refined manufacturing of the blade is achieved, and the surface integrity and the working reliability of parts are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

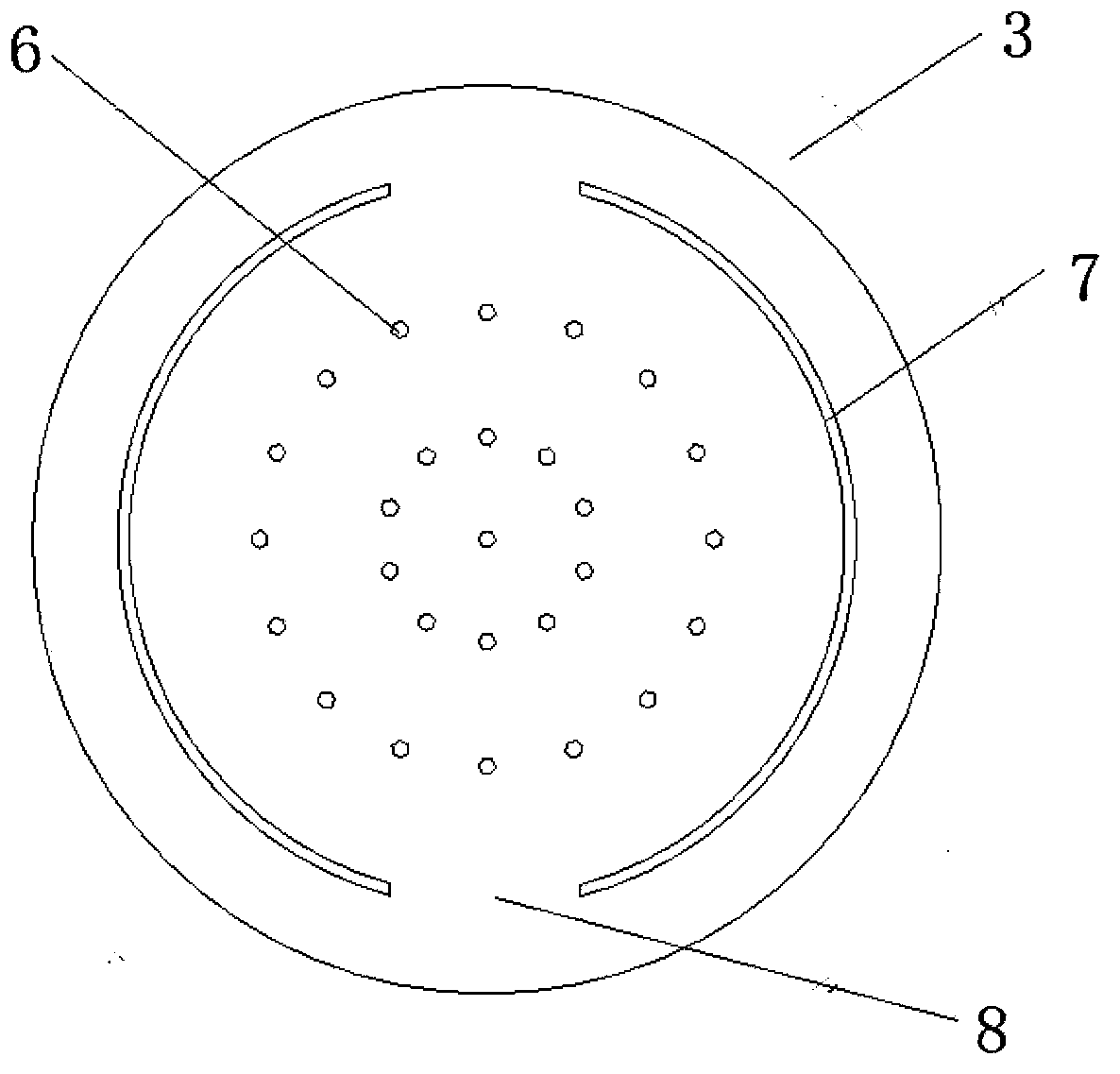

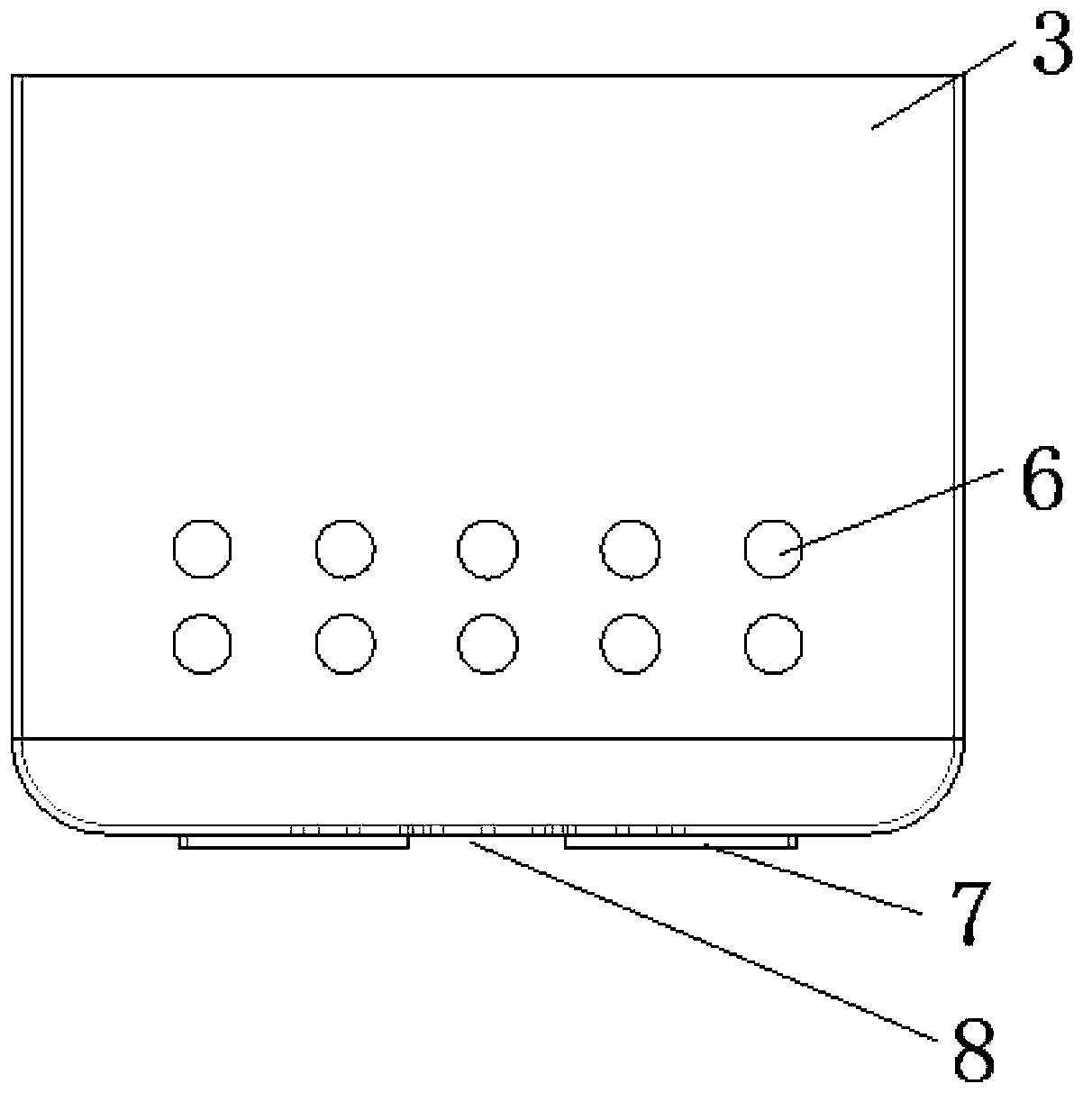

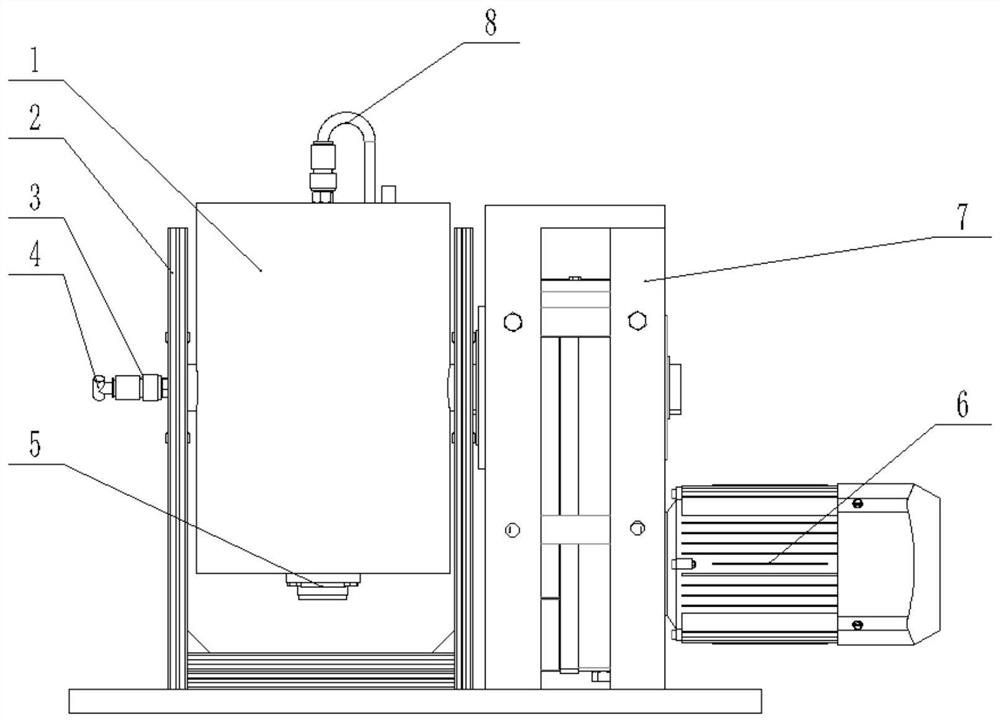

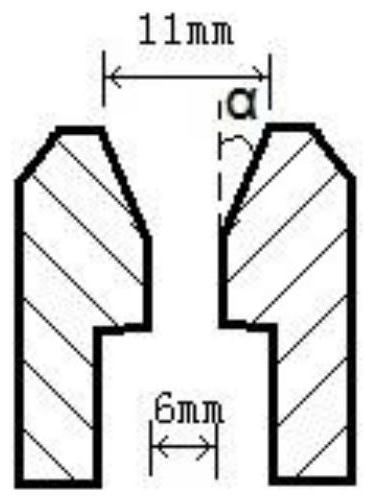

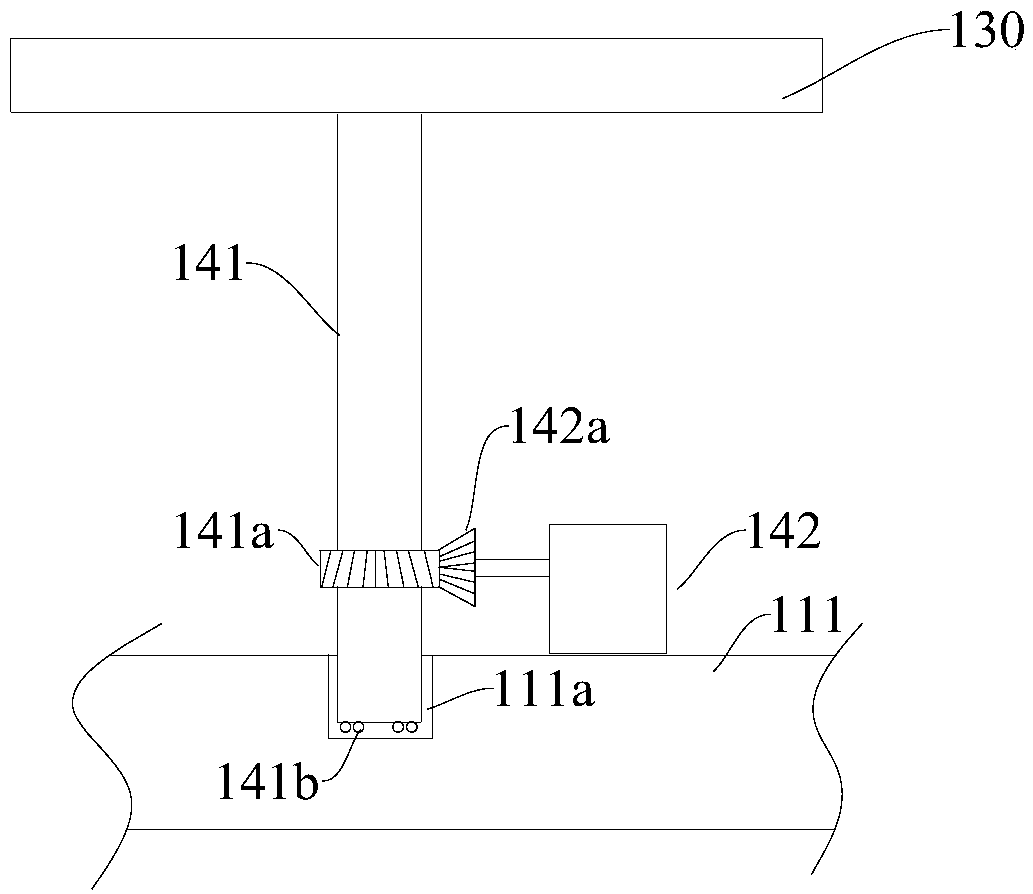

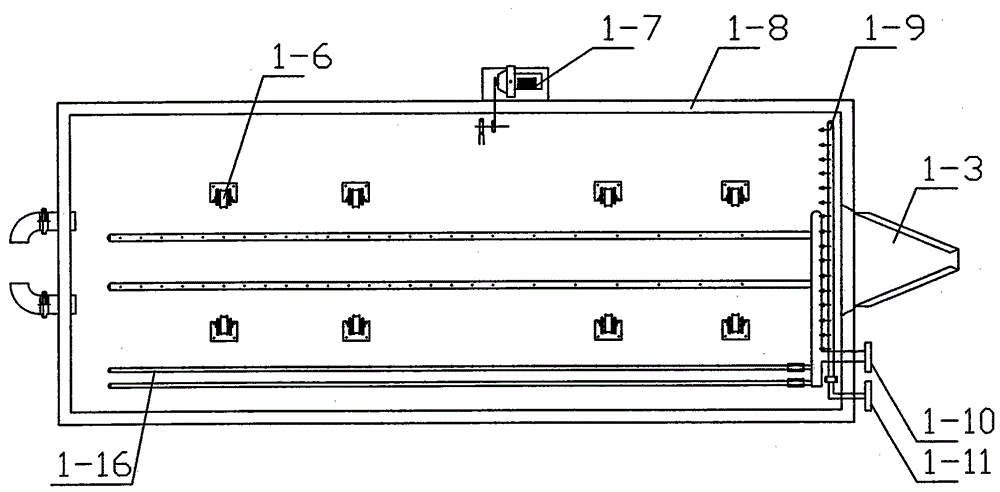

Wetting, gluing and mixing machine for wood chips for manufacturing wood polishing tools and mixing method thereof

ActiveCN112774496ATumble fullAvoid gatheringRotary stirring mixersTransportation and packagingRotational axisVertical axis

The invention discloses a wetting, gluing and mixing machine for wood chips for manufacturing wood polishing tools and a mixing method thereof. At present, no wetting, gluing and mixing equipment for wood chips for manufacturing wood polishing rods exists in the market. A rotating shaft is supported in a charging barrel, the rotating shaft and the charging barrel respectively rotate around two vertical axes, an atomizing nozzle is fixed on the inner wall of the charging barrel, and arc-shaped paddles which are arranged along a curve formed by connecting two sections of spiral lines with opposite rotating directions are fixed on the rotating shaft; three porous nozzles are fixed on the inner side cambered surface of the arc-shaped paddle; the arc-shaped paddles rotate along with the rotating shaft to shovel wood chips close to the inner wall of the charging barrel, so that the wood chips move along the curved surface, the wood chips at the two ends of the charging barrel are evenly brought to the middle of the charging barrel, and the wood chips in the middle fall down due to gravity after being accumulated. According to the wood chip wetting and gluing device, it can be guaranteed that wood chips are fully turned over and stirred in the charging barrel, the wood chips are fully sprayed through the atomization spray head and the porous spray head, the good wood wetting and gluing effect is achieved, and preparation is made for follow-up wood polishing rod forming and manufacturing.

Owner:HANGZHOU DIANZI UNIV

Electric pressure cooker control method, control device and electric pressure cooker

ActiveCN104083078BGood cooking effectTumble fullAuxillary controllers with auxillary heating devicesPressure-cookersBoiling pointEngineering

The invention provides a control method for an electric pressure cooker, a control device for the electric pressure cooker, and an electric pressure cooker. The control method for the electric pressure cooker includes: when receiving an instruction for collecting juice from a large fire, controlling the heating device of the electric pressure cooker to first Heating in a heating mode; detect the state in the electric pressure cooker, and judge whether the state in the electric pressure cooker meets the conditions for entering the maintenance stage; when it is determined that the state in the electric pressure cooker meets the conditions for entering the maintenance stage, control the heating device to use the second heating mode Heating is performed to maintain the pot body temperature of the electric pressure cooker within a predetermined temperature range; and when the duration of maintaining the pot body temperature of the electric pressure cooker within the predetermined temperature range reaches a predetermined time period, the heating device is controlled to stop heating. Through the technical solution of the present invention, the temperature of the food in the pot can be maintained above the boiling point to achieve the effect of full boiling, so that the soup in the electric pressure cooker can be rich in flavor and meet the cooking needs of users.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

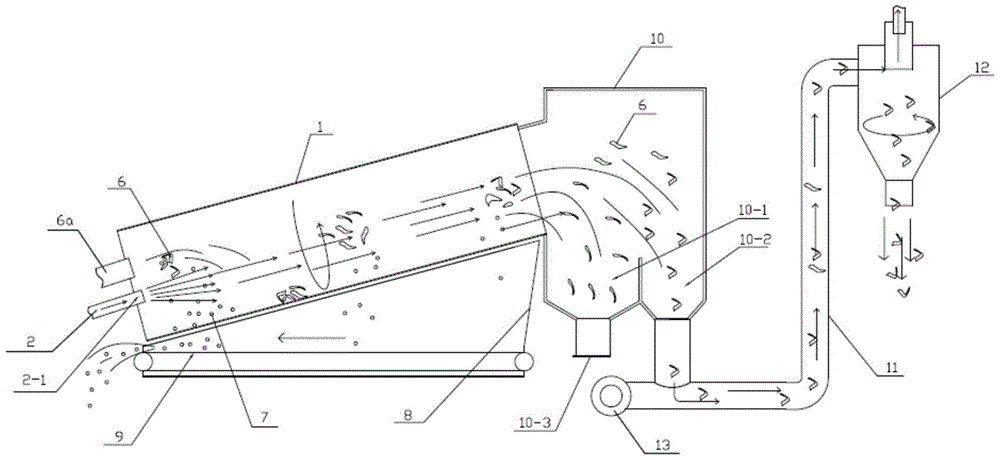

Efficient and rapid drying machine for granulated fertilizer and drying method

PendingCN113670033AEasy to manufactureEasy to useManure dryingGranular material dryingFertilizerHot blast

The invention discloses an efficient and rapid drying machine for a granulated fertilizer and a drying method. The drying machine is structurally characterized in that a heating furnace is arranged at the upper end of a base, wherein a plurality of burners are arranged on the heating furnace, and each burner is connected with a gas pipeline and an air pipeline; a drying roller is arranged in the heating furnace; a feeding hole and a motor are arranged at the left end of the drying roller; the motor controls the drying roller to roll; a discharging hole is formed in the right end of the drying roller; an air outlet pipe is arranged at the upper left end of the heating furnace; an induced draft fan is arranged on the air outlet pipe, and an air outlet of the induced draft fan is connected to the interior of the right end of the drying roller; a roller air outlet pipe is arranged at the left top end of the drying roller; a roller induced draft fan is arranged on the roller air outlet pipe, and an air outlet of the roller induced draft fan is connected to a dust collector; the dust collector is arranged at one side of the drying roller; an air inducing pipe and a three-way air distributing valve are arranged at the outlet end of the dust collector; and the air inducing pipe is connected to the interior of the right end of the drying roller through the three-way air distributing valve. Under the dual drying condition of drying roller wall heating and hot air convection heat exchange, the drying efficiency is improved, hot air is recycled, and the drying machine is efficient, energy-saving and environment-friendly.

Owner:HUBEI FORBON TECH

Watermelon seed continuous kneading device

InactiveCN105103704AReduce difficultyImprove efficiencySeed and root treatmentWater leakageEngineering

The present invention discloses a watermelon seed continuous kneading device. The watermelon seed continuous kneading device comprises a kneading chamber, a hopper, a drum, a nozzle, an electrical motor and a coupling member; a water leakage hole, the size of which is smaller than that of a watermelon seed, is arranged on the wall of the drum, and two ends of the drum are open; an output end of the electrical motor is connected to the drum by the coupling member; the drum is located within the kneading chamber; an inner wall of the drum is tilted and forms an angle of 1-2 degree with an axial direction of the drum; the hopper is communicated to an upper end of the drum by a feed line; the nozzle is mounted in the kneading chamber, and is arranged towards to the drum; the hopper is arranged in the kneading chamber, and the hopper can work coordinately to access watermelon seeds sliding from the lower end of the drum. By applying the scheme provided by the present invention, the device is less in difficulty to knead the watermelon seeds and is high in efficiency.

Owner:重庆益保西瓜种植专业合作社

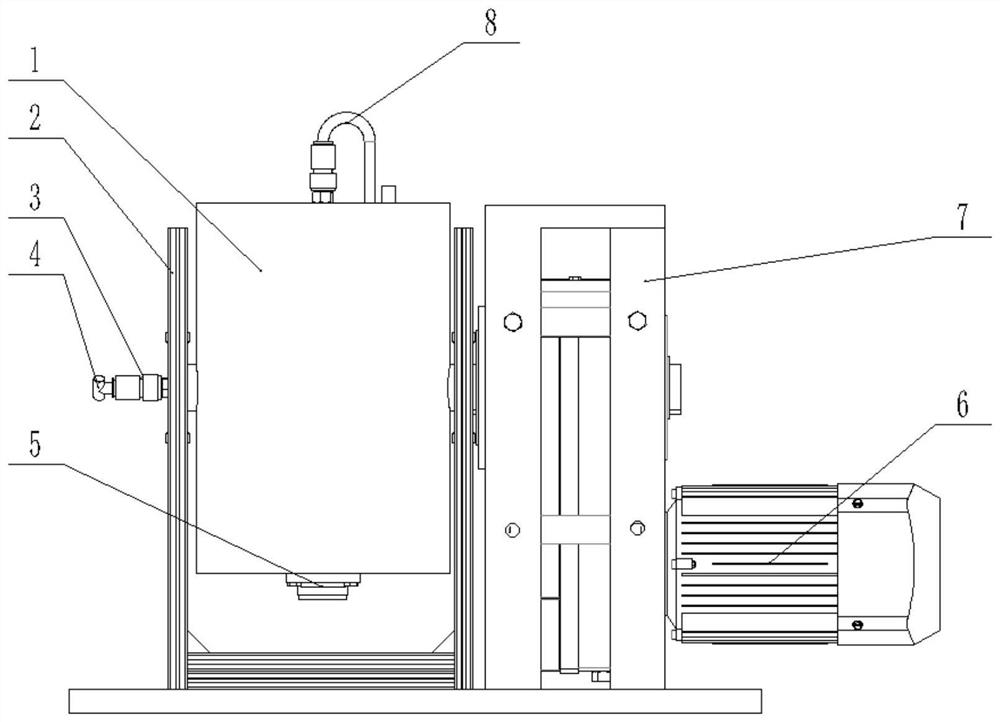

Mixed rubber cooling treatment device and rubber cooling treatment method

The invention relates to a mixed rubber cooling treatment device and a rubber cooling treatment method. The mixed rubber cooling treatment device comprises a base plate, a box body, an adjusting mechanism and a rotating mechanism. The box body is installed on the base plate, the adjusting mechanism is installed in the box body, and the rotating mechanism is installed on the side wall of the adjusting mechanism. A water inlet is formed in the left side wall of the box body, and a water outlet is formed in the right side wall of the box body. The adjusting mechanism comprises lifting frames, lifting cylinders, a rotary motor, a first rotating shaft, a second rotating shaft, a first rotating plate, a connecting frame, a rotating motor and a second rotating plate. The rotating mechanism comprises a rotating gear, driven gears, rotating drums, first opening and closing plates, second opening and closing plates, first connecting plates, second connecting plates, sliding plates and adjustingcylinders. The mixed rubber cooling treatment device and the rubber cooling treatment method can solve the problems that in the existing rubber cooling process, cooling is not uniform, the cooling speed is low, blocking is prone to being caused, and rubber is inconveniently taken out, and can fulfill the function of automatically cooling the rubber.

Owner:铁岭市嘉利橡塑制品有限公司

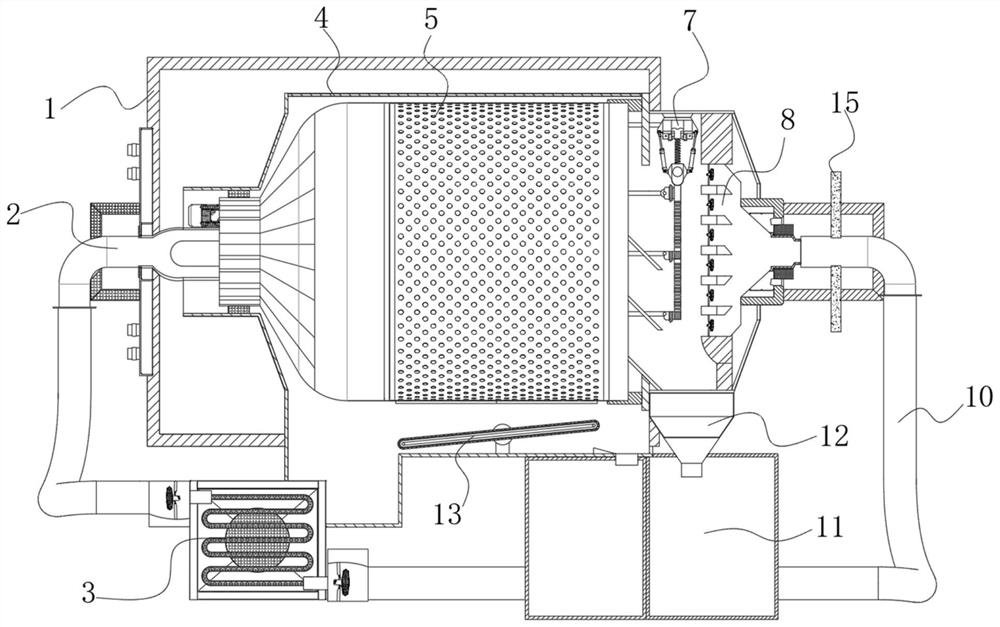

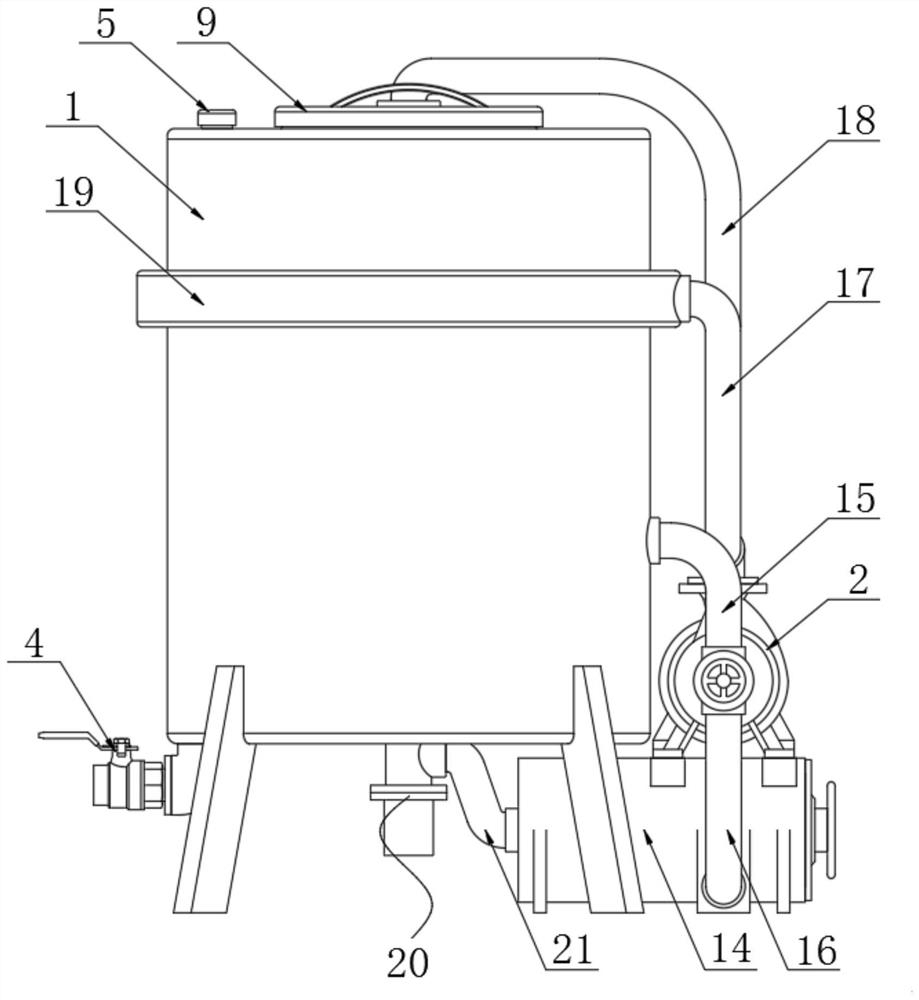

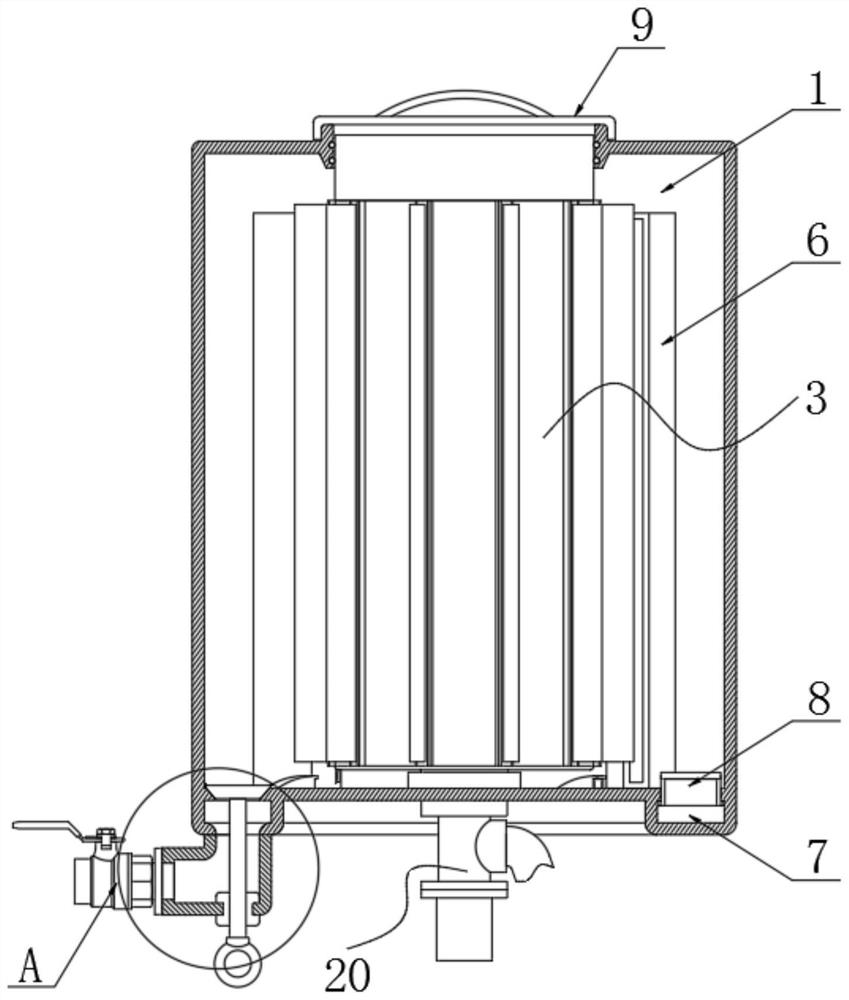

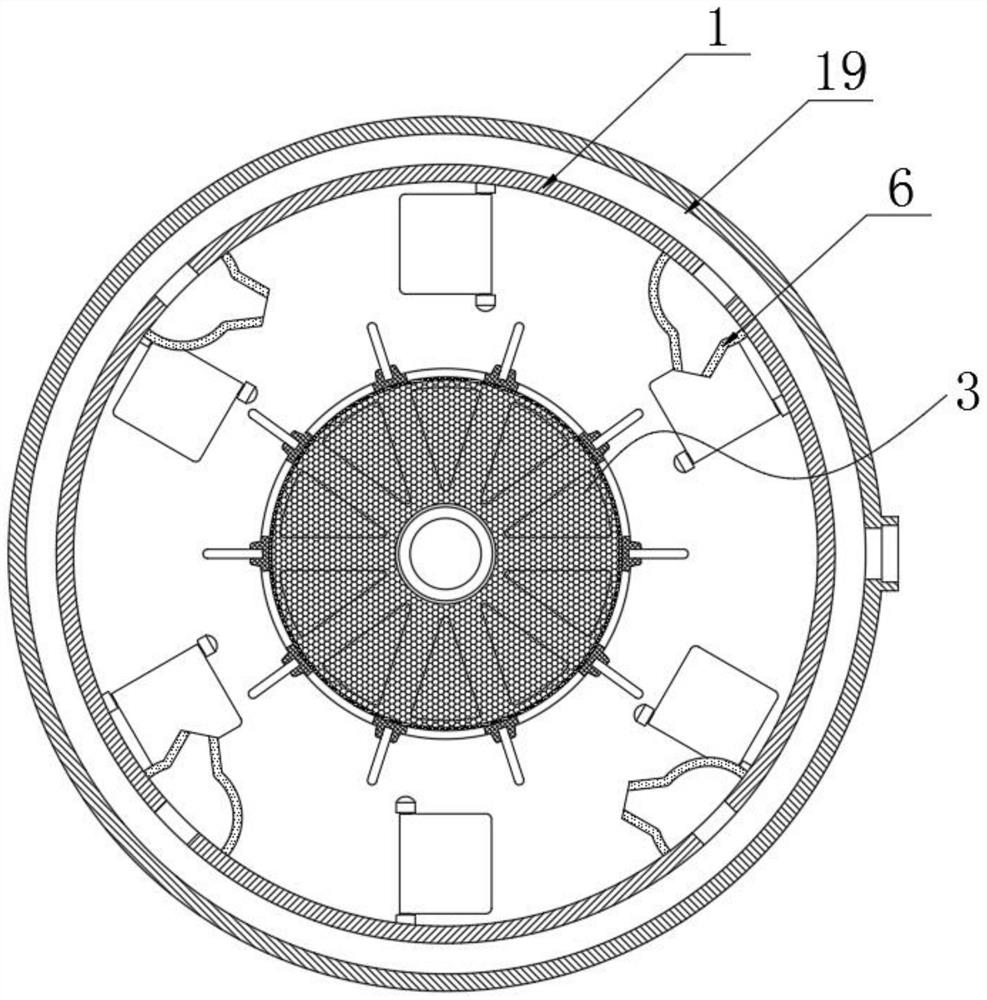

Feather drying device for shuttlecock processing

InactiveCN111912194ATumble fullAvoid incomplete dryingDrying solid materials with heatDrying gas arrangementsMechanical devicesComposite material

The invention discloses a feather drying device for shuttlecock processing, and particularly relates to the field of mechanical devices. The feather drying device comprises a base, two supporting rodslocated on the base and a drying cylinder which is rotationally connected to the two supporting rods. A feeding pipe is fixedly arranged at one end of the drying cylinder, and an air inlet pipe is fixedly arranged at the other end of the drying cylinder; the air inlet pipe is connected with a hot air pump used for conveying hot air through a pipeline; a heating component used for evenly diffusingthe hot air into the drying cylinder is arranged in the drying cylinder; stirring blades used for stirring feathers and arranged obliquely are arranged on the inner wall of the drying cylinder; and the inner diameter of the middle of the drying cylinder is larger than the inner diameters of the two ends of the drying cylinder. According to the feather drying device, feathers can be fully turned over in the drying process, each side of the feathers can be heated and dried, and incomplete drying caused by stacking of the feathers in the drying process is avoided.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

Electric pressure cooker control method, controller and electric pressure cooker

The invention discloses an electric pressure cooker control method, a controller and an electric pressure cooker. The electric pressure cooker control method comprises: starting a heater of the electric pressure cooker to heat the electric pressure cooker so that the electric pressure cooker enters a heating stage; In this mode, start cooking. When it is detected that the cooking temperature of the electric pressure cooker reaches the preset temperature of the heating stage, the electric pressure cooker is controlled to enter the boiling stage, and the heater of the electric pressure cooker is controlled to continue heating; to judge whether the boiling stage has reached the preset boiling stage Stage end condition; if the preset end condition of the boiling stage is not reached, the heater of the electric pressure cooker is controlled to continue heating; if the preset end condition of the boiling stage is met, the electric pressure cooker is controlled to enter the pressure maintaining stage. The electric pressure cooker control method, the controller and the electric pressure cooker disclosed by the invention add a boiling stage before the electric pressure cooker enters the pressure holding stage, which can solve the problem of no boiling or insufficient boiling in the cooking process of the existing electric pressure cooker.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

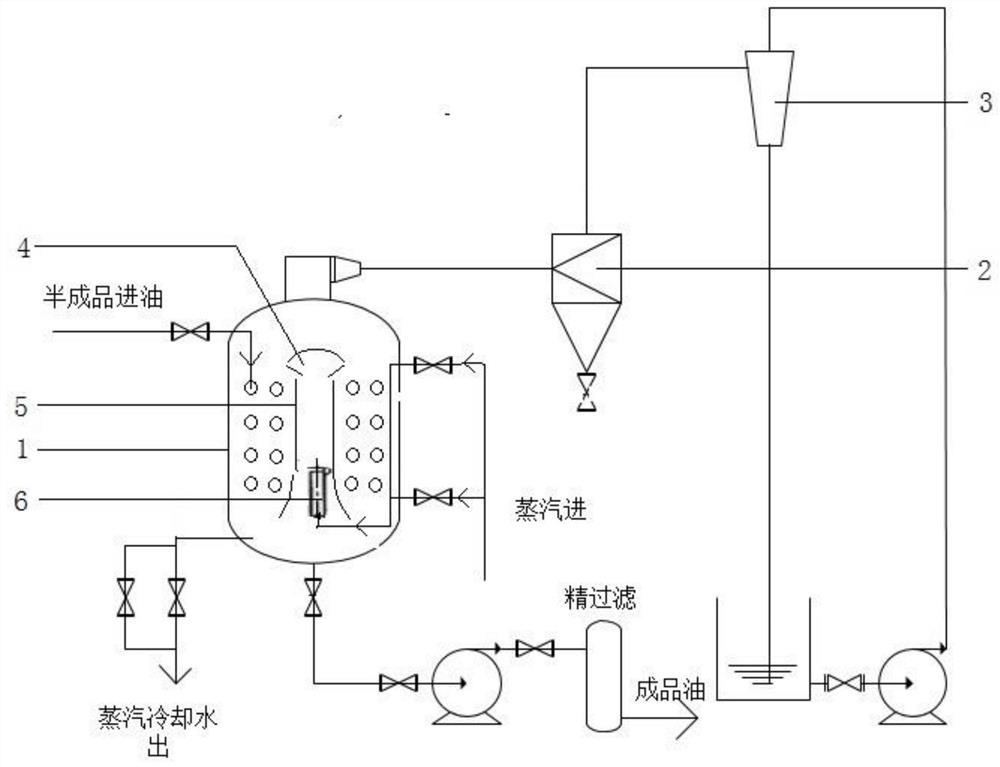

Beef tallow deslagging and drying system and production process

PendingCN112646658AImprove stabilityEasy to operateFatty-oils/fats refiningProcess engineeringBeef Tallow

The invention discloses a beef tallow deslagging and drying system which comprises a deodorization tank connected with vacuum equipment, the deodorization tank is connected with follow-up fine filtering equipment, the vacuum equipment comprises a cyclone and a high-water-level jet pump, a steam inlet in the bottom of the deodorization tank is connected with a mammoth pump with an improved nozzle, and the mammoth pump is connected with a flow guide pipe with an enlarged pipe diameter. A diffusion cap is arranged at the top of the flow guide pipe. The invention further provides a beef tallow deslagging and drying production process. According to the system, impurities and water are thoroughly removed, the yield in unit time is high, the odor removal time is only 30 min, the efficiency is improved, and energy is saved; the deodorizing, impurity-removing and drying effects are good, the finished product oil is pure in smell and taste and free of peculiar smell, and bad byproducts are prevented from being generated; the operation process is simple and easy to understand, no special requirements are needed for operators, equipment operation is stable, and the system is an important guarantee for obtaining high-quality deodorized finished beef tallow.

Owner:GUANGHAN HANGJIA FOOD CO LTD

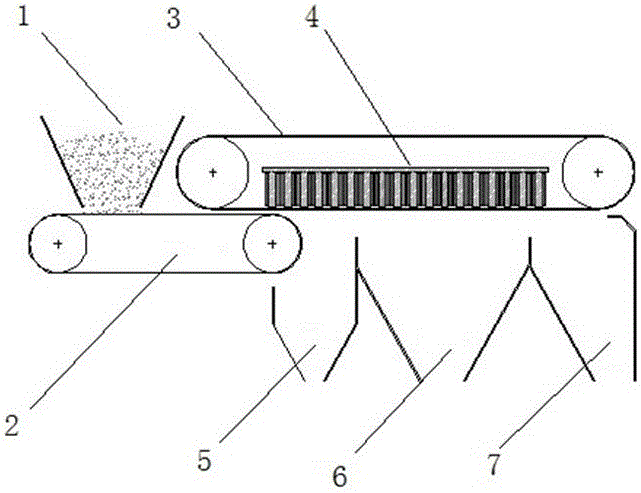

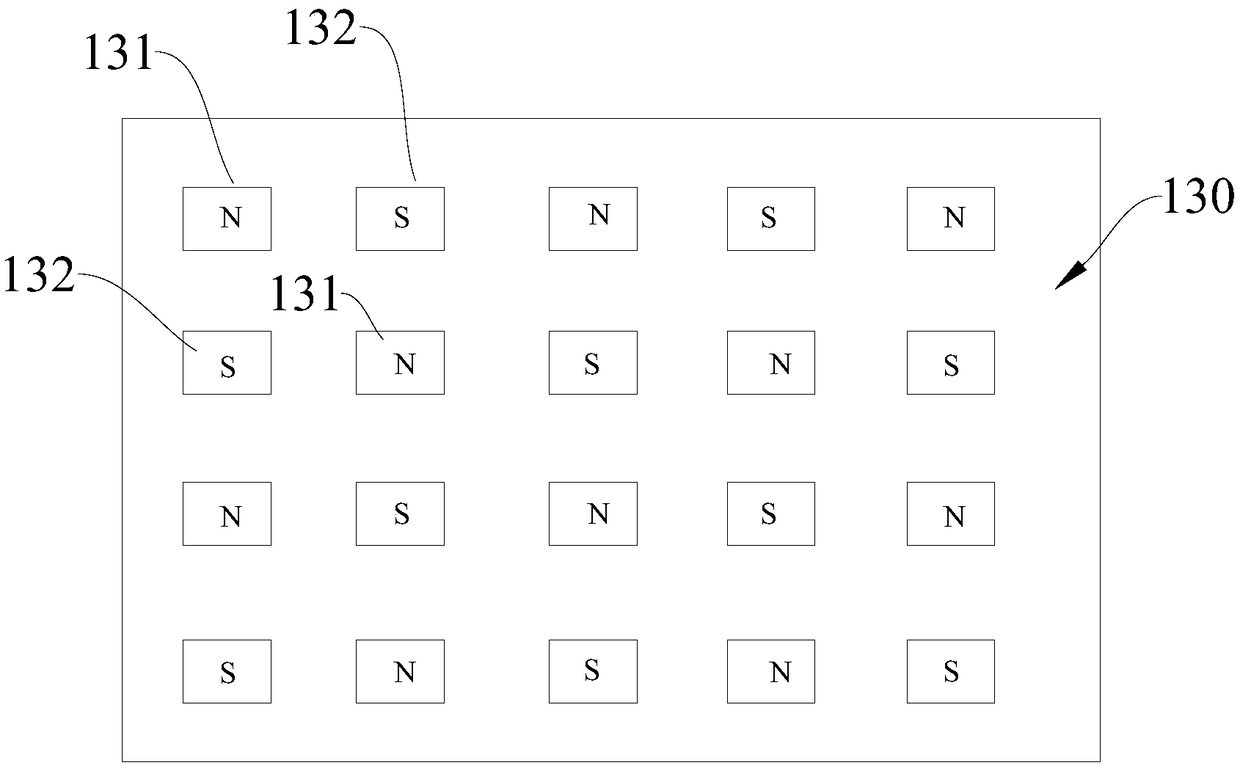

Rotary type flat plate magnetic separator and system

PendingCN108855605AMineral Tumble FullGood iron removal effectMagnetic separationMagnetic separatorMagnet

The invention provides a rotary type flat plate magnetic separator and system, and belongs to the technical field of ore beneficiation equipment. The rotary type flat plate magnetic separator comprises a conveying device, a charge device, a magnetic plate assembly and a spray device, wherein the conveying device comprises a rack, a drive wheel and a driven wheel which can be roatatably supported on the rack, a drive mechanism capable of driving the drive wheel to rotate, and a conveyor belt; the conveyor belt winds the drive wheel and the driven wheel, so that the drive wheel is in transmission connection with the driven wheel; the charge device is used for supplying materials onto the conveyor belt; the magnetic plate assembly comprises a magnetic plate, a connector and a drive part; theconnector is movably connected with the rack; the magnetic plate is connected with the connector; the drive part is used for driving the connector to rotate relative to the rack; a magnet block is mounted on the magnetic plate; the magnetic plate is arranged between upper and lower layers of the conveyor belt, and corresponds to the charge device; and the spray device and the charge device are arranged at opposite two ends of the conveying device, and the spray device is used for spraying the materials on the conveyor belt. The rotary type flat plate magnetic separator has relatively good ironremoval effect.

Owner:西双版纳海邦科技(集团)有限公司

Sealed cylinder type cooking robot

The invention discloses a sealed barrel type cooking robot, and particularly relates to the field of cooking robots, the sealed barrel type cooking robot comprises a machine base frame, a groove chamber is formed in the front side of the machine base frame, a frying barrel is installed in the groove chamber, and the frying barrel can rotate in the groove chamber. The sealed barrel type cooking robot is characterized in that a pot cover which is detachable through threads is mounted at the top end of the frying barrel. The outer wall of the frying barrel is fixedly sleeved with a first bearing, a second bearing is installed at the position, with the same height as the first bearing, of the inner wall of the groove chamber, and a first connecting rod with the end fixed to the outer wall of the first bearing is inserted into the second bearing. The sealable frying barrel structure is adopted, heat loss in the frying process can be reduced, meanwhile, the frying barrel is turned and rotated in different directions, raw materials can be fully turned in the barrel, the raw materials make continuous contact with the inner wall of the frying barrel to be heated, the frying efficiency is greatly improved, and the phenomenon that individual raw materials are not fried thoroughly is also avoided.

Owner:LUAN SOYEA ELECTRIC APPLIANCE MFG CO LTD

Walnut kernel peeling equipment

ActiveCN104921265BImprove peeling efficiencyReduce water consumptionHuskingHullingWalnut NutSteam cooking

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

A complete set of equipment for recycling and processing soft flake materials

ActiveCN104815835BReduce manual interventionIncrease productivityGas current separationSolid waste disposalTreatment completedSmall footprint

Owner:冯愚斌

Wetting gluing mixer and mixing method for wood chips for making wooden polishing tools

ActiveCN112774496BTumble fullAvoid gatheringRotary stirring mixersTransportation and packagingRotational axisVertical axis

Owner:HANGZHOU DIANZI UNIV

Processing device for germinated brown rice

ActiveCN112704003AImprove germination rateImprove germination qualitySievingScreeningAgricultural scienceAgricultural engineering

The invention discloses a processing device for germinated brown rice. The processing device comprises a box shell, a heating device, a constant temperature box, a germinated brown rice processing tank, a return pipe and a collecting box; the heating device and the collecting box are arranged at the left side and the right side of the lower portion of the box shell, and the constant temperature box is arranged in the box shell; the germinated brown rice processing tank is installed at the position, close to the upper portion, of the interior of the constant temperature box, an opening in the left end of the germinated brown rice processing tank communicates with an output port in the left side of the heating device through an air inlet pipe, and a lifting vibration assembly and a flow guide assembly are further sequentially arranged at the right side of the germinated brown rice processing tank; and the upper end of the return pipe is communicated with an exhaust opening in the right side of the flow guide assembly, the lower end of the return pipe is further communicated with an air inlet of the heating device, a slidable water absorption plate is arranged on the cross section of a transverse pipeline of the upper end of the return pipe, a conveying assembly located below the germinated brown rice processing tank drains and stores waste water and inferior brown rice generated inside the conveying assembly, and processed high-quality germinated brown rice enters the collecting box through a funnel.

Owner:TARIM UNIV

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372BTumble fullImprove cleaning rateOther washing machinesToothed gearingsWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using thedecelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbingforce and improving the cleaning rate.

Owner:NINGGUO JULONG IND

Extraction process based on novel graphene material

InactiveCN113716554AProblems Affecting Extraction PurityIncrease contactGaseous chemical processesGrapheneGraphene flakeWater flow

The invention discloses an extraction process based on a novel graphene material. A device used in the extraction process comprises an extraction box, wherein the center of the interior of the extraction box is rotatably connected with a separation barrel, and the left side of the top of the extraction box is provided with a material supplementing port. The invention relates to the technical field of graphene processing. According to the extraction process based on the novel graphene material, by arranging a water circulation structure, stripping liquid can circularly flow, and then the stripping liquid can better make contact with graphene flakes; meanwhile, the separation barrel containing the graphene flakes can be indirectly pushed to rotate by means of the pushing force of water circulation, the graphene flakes in the separation barrel can fully roll over through cooperation between the pushing force of water circulation with the pushing force of water flow, so stripping effect is better; and no extra stirring device needs to be arranged, a material blocking structure is arranged in the separation barrel and can block a part of turned graphene flakes, then the situation that the whole graphene flakes completely rotate along with water flow can be avoided, the graphene flakes make full contact with stripping liquid, and better effect is obtained compared with an existing stirring structure.

Owner:刘四保

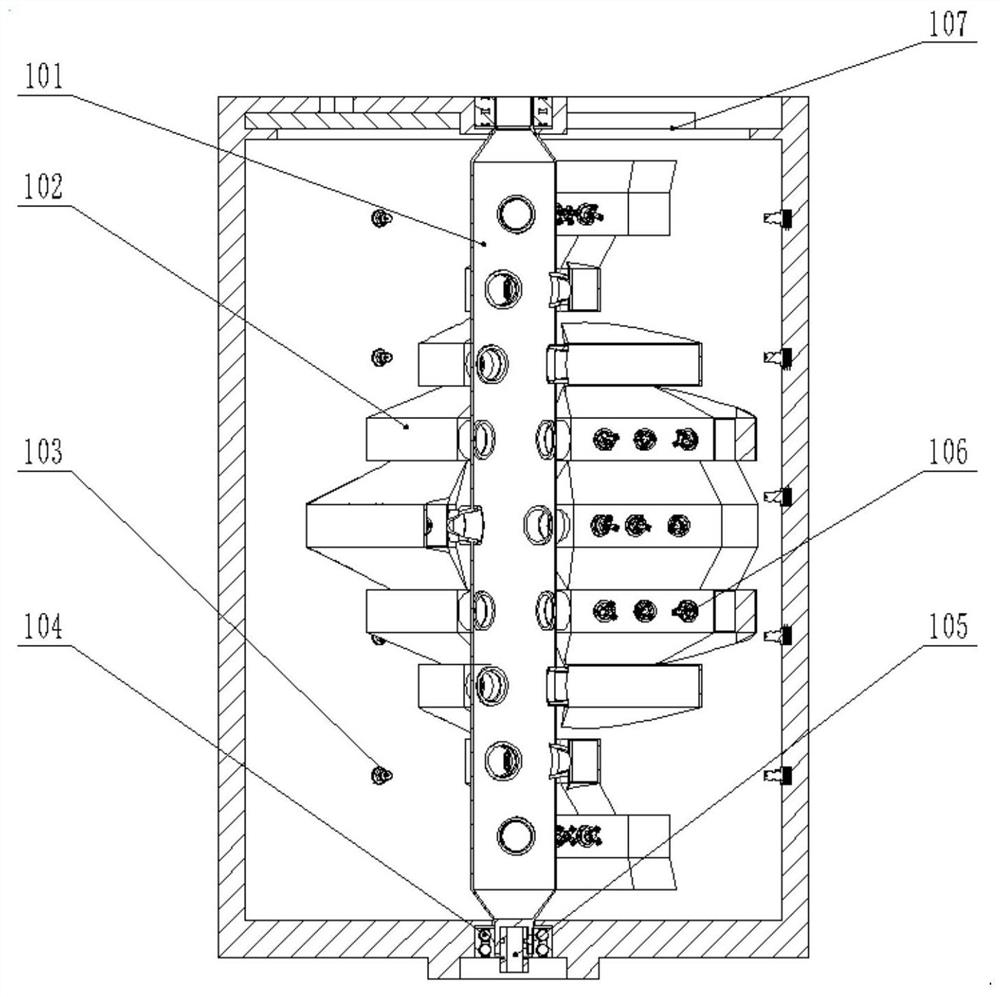

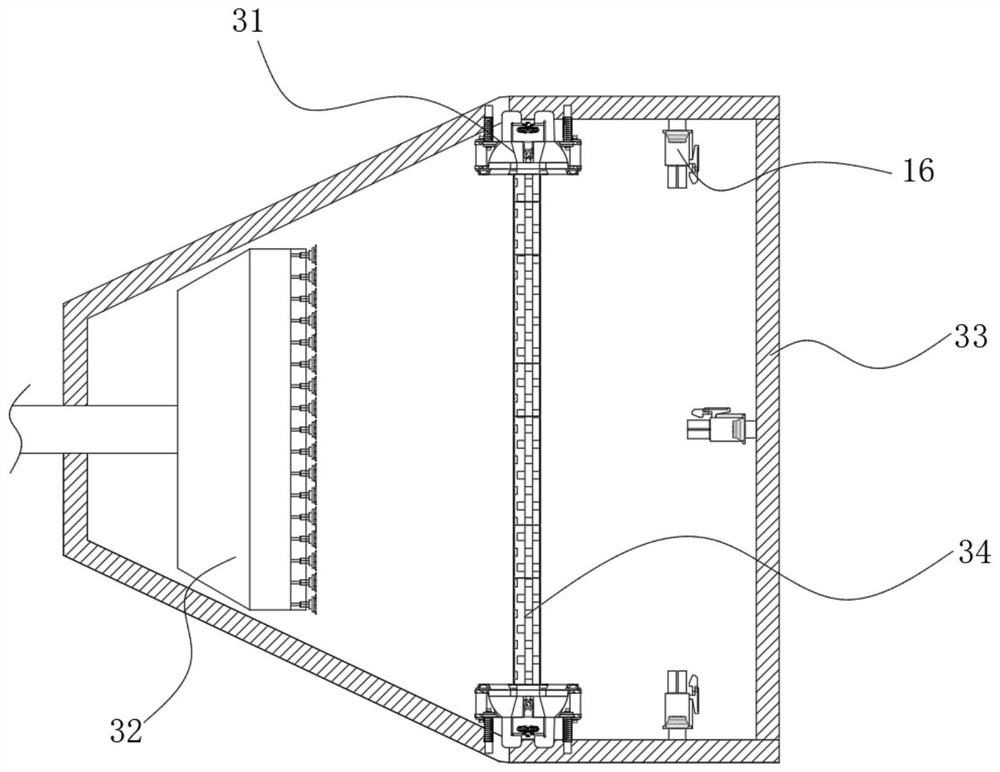

Raw material dissolving device and method for preparing porous inorganic material

ActiveCN113368715AImprove solubilityTumble fullRotating receptacle mixersTransportation and packagingEngineeringInorganic materials

The invention discloses a raw material dissolving device and method for preparing a porous inorganic material. The raw material dissolving device comprises a sealed cabinet, a left driving device, a right driving device, a spraying device, a cleaning device, a filter and a pressure supplementing device, the upper cavity and the square cavity in the sealed cabinet are respectively provided with a decomposition chamber and a collection chamber, and the center of the decomposition chamber is provided with a container. Stirring blades are arranged in the container, the left driving device drives the container to rotate along the transverse axis of the container, the right driving device drives the stirring blades to conduct rotary stirring and smashing in the container, spraying devices are installed on the left side and the right side of the container, and a cleaning device fixed to the center shell wall of the inner side of the sealed cabinet is arranged above the container. A pressure detector for monitoring the pressure intensity in the cavity is further installed on the right side of the sealing box cabinet, the filter is installed above the left driving device and filters generated gas, and the pressure supplementing device is installed above the right driving device and regulates and controls the pressure intensity in the sealed cabinet.

Owner:重庆新申世纪新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com