Walnut kernel peeling equipment

A technology for walnut kernels and equipment, applied in the field of food processing, can solve problems such as affecting production efficiency, unfavorable peeling treatment, low peeling efficiency, etc., and achieves uniform peeling effect, high peeling efficiency, and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, invention is described in further detail:

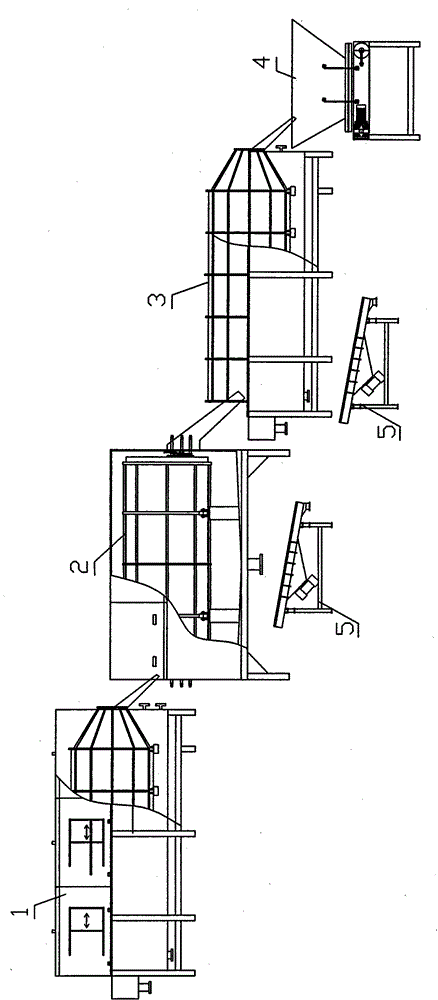

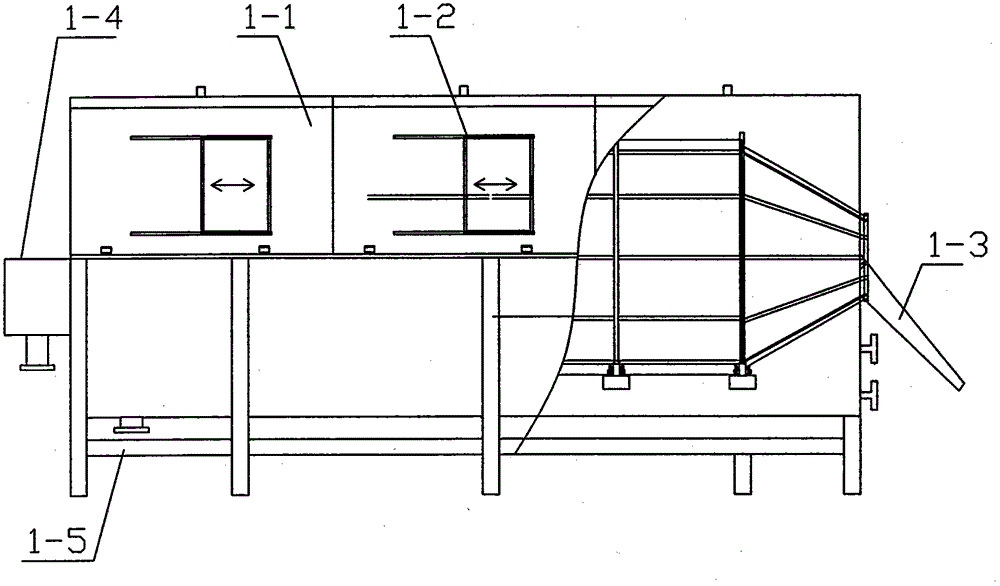

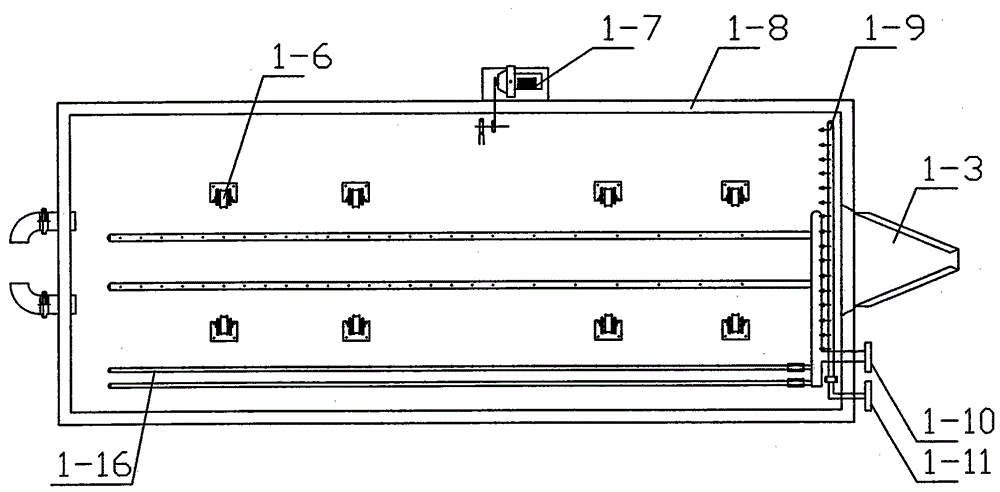

[0032] The present invention relates to a kind of peeling equipment of walnut kernel seed coat (red soft skin on the surface of walnut kernel). It is composed of separate equipment. The feeding device is used to deliver walnut kernels to the cooking equipment. The cooking equipment is used to cook the walnut kernels at high temperature to soften the red skin and peel off the red skin and walnut kernels. The skinning equipment is used to cook the walnut kernels. After breaking through the red skin of the walnut kernels, the walnut kernels are completely peeled off. The soaking device is used to soak the peeled walnut kernels to remove bitterness and make them more white and sweet. The water circulation device is used to recycle and reuse water in each device. It is used to filter the water with walnut husk so that it can be recycled again, and the belt conveyor is used to send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com