Beef tallow deslagging and drying system and production process

A drying system and tallow technology, applied in the production of fat, fat oil/fat refining, etc., can solve the problems of long residence time of oil at high temperature, low utilization rate of steam introduction, and impact on oil quality, etc., and achieve a simple and easy-to-understand operation process. , Prevent bad by-products, the effect of stable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

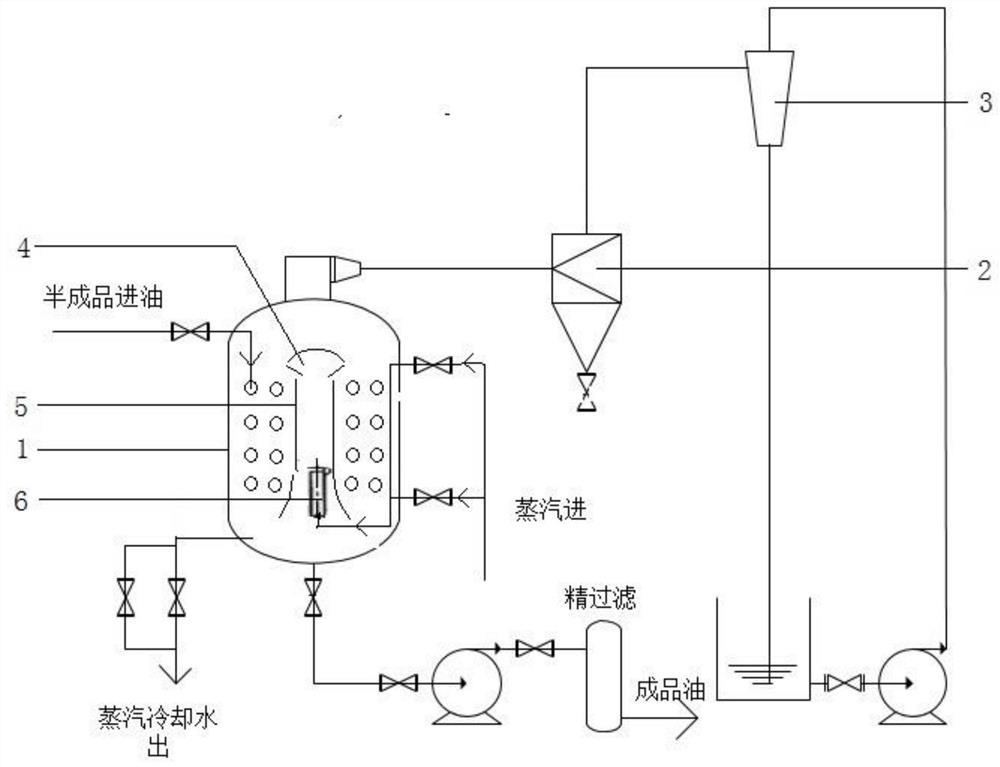

[0029] Such as figure 1 As shown, a kind of tallow deslagging and drying system includes a deodorization tank 1 connected with vacuum equipment, and the deodorization tank 1 is connected with subsequent fine filtration equipment. The vacuum equipment is a cyclone 2 and a high water level jet pump 3, and the cyclone The device 2 is connected to the air outlet of the deodorization tank 1, the high water level jet pump 3 is connected to the outlet of the cyclone 2, and the diversion pipe 5 of the deodorization tank 1 is provided with a distribution cap 4.

[0030] The pumping capacity of the high water level jet pump 3 is 300L / min.

[0031] The pipe diameter of the guide pipe 5 of the deodorization tank 1 is 375mm.

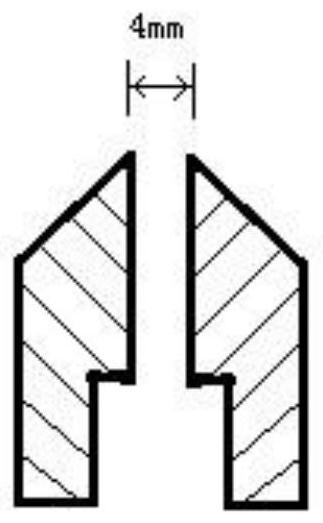

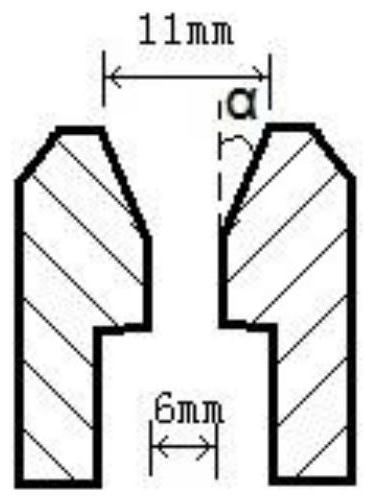

[0032] Such as figure 2 As shown, the nozzle of the Mammoth pump 6 is a 6mm straight hole, the nozzle opening is enlarged by 20-45°, and the diameter of the nozzle opening is 11mm.

Embodiment 2

[0034] 1) Transport the semi-finished butter into the deodorizing tank 1, turn on the steam, start the cyclone 2 and the high water level jet pump 3 at the same time, and form a high vacuum and high temperature environment with a temperature of 120-150°C;

[0035] 2) The high-temperature steam is injected into the guide pipe 5 through the mammoth pump 6, and the impurities of the semi-finished butter evaporate quickly and are sucked away under the thrust of the steam and the vacuum condition, and the deodorizing tank 1 continues to run for 30 minutes;

[0036] 3) The deslagging-dried butter is sent to the follow-up fine filtration equipment for filtration, and finally the finished butter with acid value ≤ 0.06 (KOH) mg / g, peroxide value ≤ 0.2g / 100g, and moisture ≤ 0.5g / 100g is obtained .

[0037] To sum up, the present invention provides a butter deslagging and drying system and production process with high yield, good deodorization effect, pure smell and taste of finished oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com