Washing machine deceleration clutch, washing machine and washing mode thereof

A technology of deceleration clutch and washing machine, applied in the field of washing machine, can solve the problems of unachieved washing effect and simple water flow, and achieve the effects of saving washing time, high washing efficiency and improving washing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

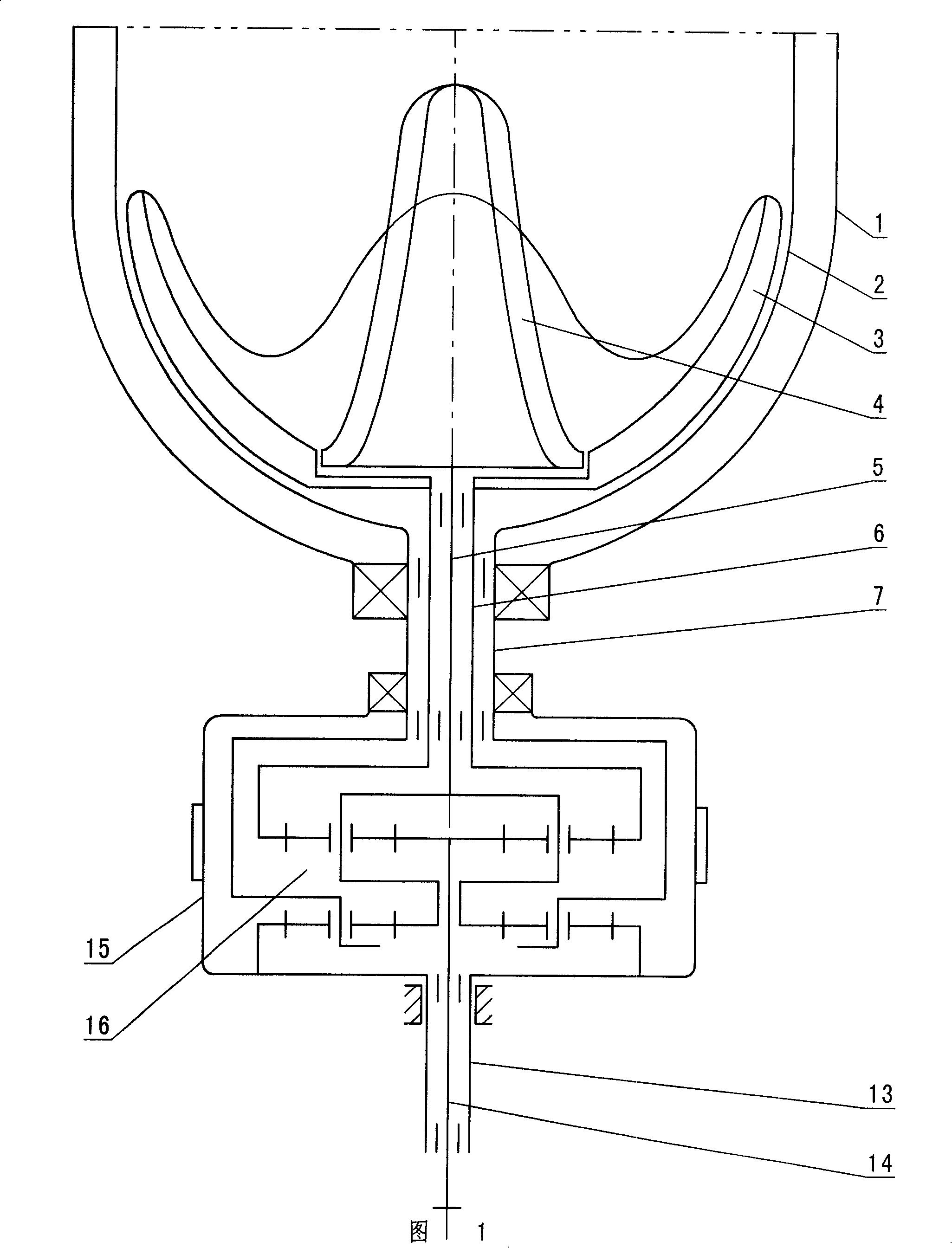

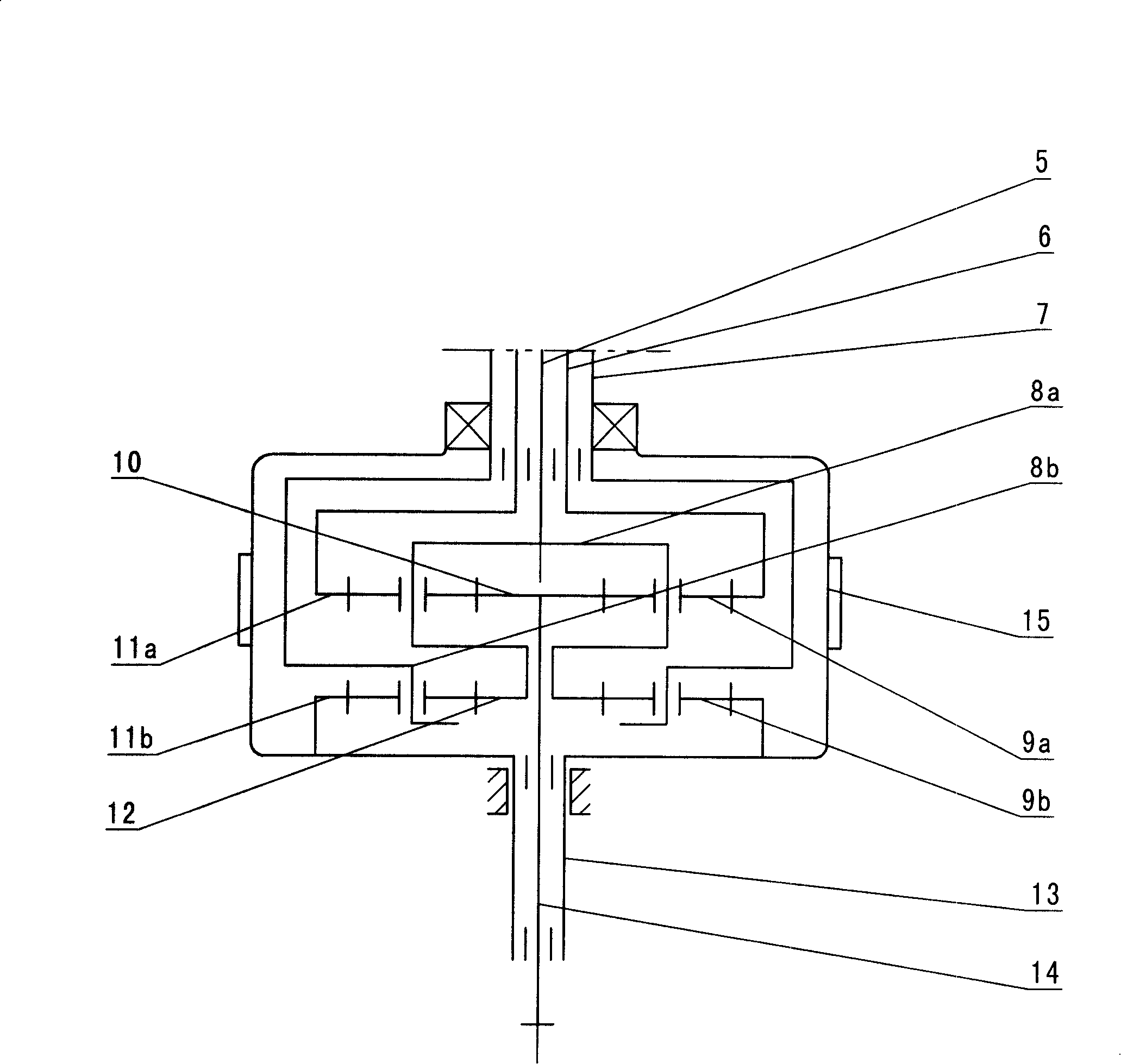

[0024] Referring to Fig. 1, a deceleration clutch for a washing machine is mainly composed of an input shaft 14, an input shaft sleeve 13, a deceleration mechanism 16, a brake wheel 15, a small wave wheel shaft 5, a large wave wheel shaft 6 and an inner barrel shaft 7, and the input shaft 14 is supported on the input shaft In the sleeve 13, the small wave wheel shaft 5, the large wave wheel shaft 6 and the inner barrel shaft 7 are respectively connected through the deceleration mechanism 16, the brake wheel 15 is connected with the input shaft sleeve 13, and the deceleration mechanism 16 is placed inside the brake wheel 15; the wavelet wheel shaft 5 The three output shafts of the large wave wheel shaft 6 and the inner barrel shaft 7 are concentrically fitted, the small wave wheel shaft 5 is supported in the large wave wheel shaft 6, and its upper and lower ends are respectively connected with the small wave wheel 3 and the reduction mechanism 16, and the large wave wheel shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com