Wetting gluing mixer and mixing method for wood chips for making wooden polishing tools

A technology of polishing tools and mixers, which is applied in the direction of mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of difficult to meet the requirements of polishing rods, loss of wood chips, excessive humidity of wood chips, etc., and achieve good The effect of wood wetting and gluing, improving the mixing efficiency and shortening the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be described below in conjunction with the drawings.

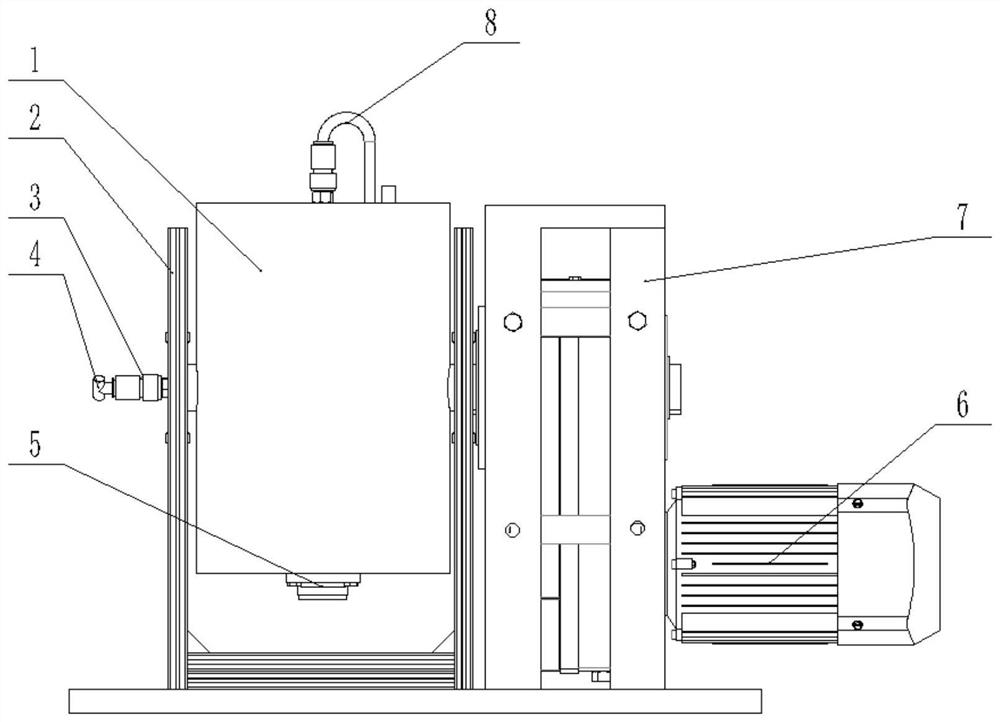

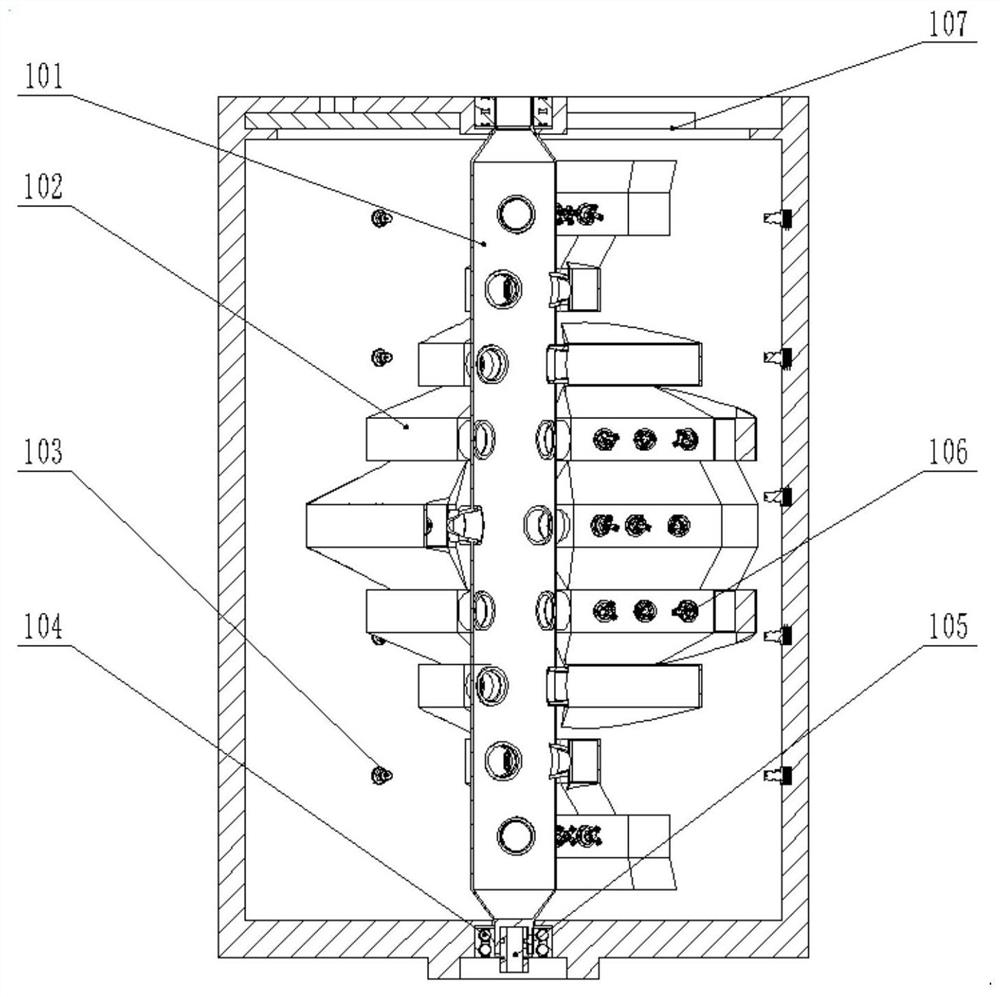

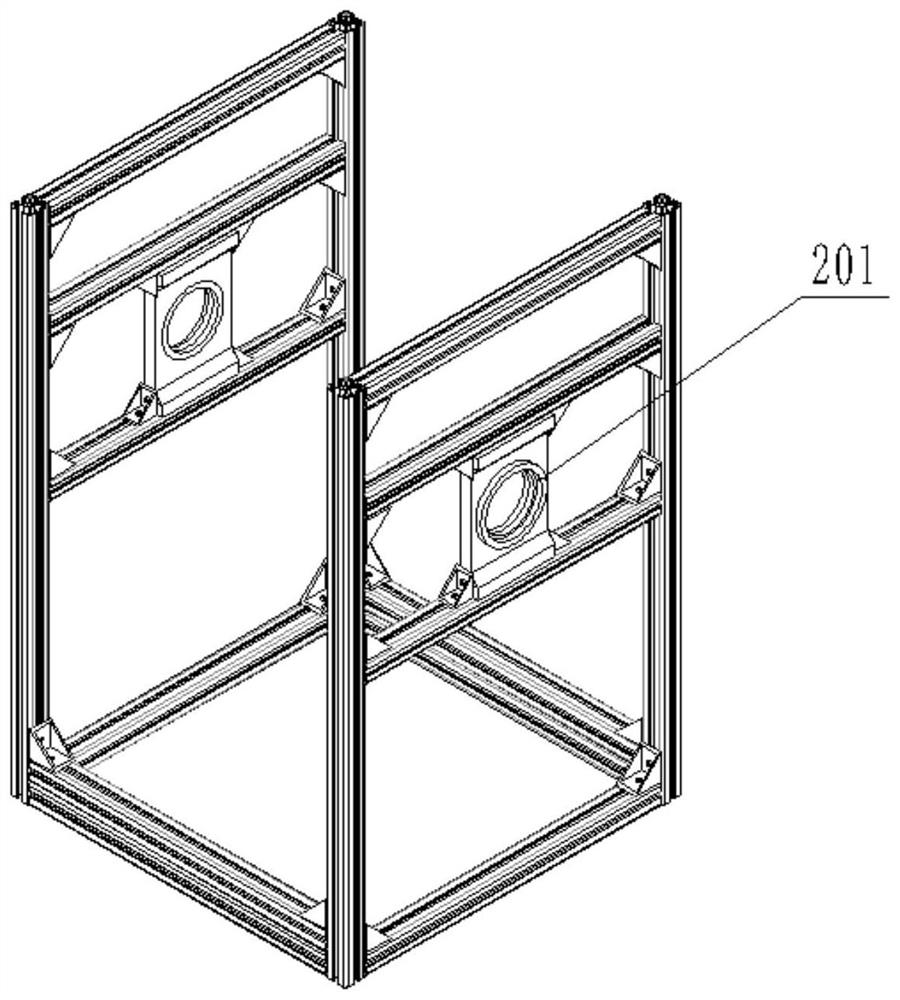

[0028] like figure 1 , 2 , 3 and 4 show the wetting machine for wood polishing tools, including tube assembly, aluminum bracket 2, high speed rotary joint 3, three-way joint 4, DC motor 5, reducer motor 6, group 7 and catheter 8; cartridge assembly includes a cartridge 1, a rotating shaft 101, a curved blade 102, an atomizing head 103, a porous head 106, and a barrel cover 107; pedestal 7 and aluminum bracket 2 welding; reduction motor 6 The base is fixed to the base 7; the bobbin 1 is fixed to both sides, and the two extension shafts are supported by the deep groove ball bearing 201 on the aluminum bracket 2; the channel opened by the tube 1 is threaded The high-speed rotary joint 3 is connected; all atomized nozzle 103 fixed to the inner wall of the tube 1 is in communication; the atomized nozzle 103 is provided with a three row along the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com