Patents

Literature

40 results about "Treatment completed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

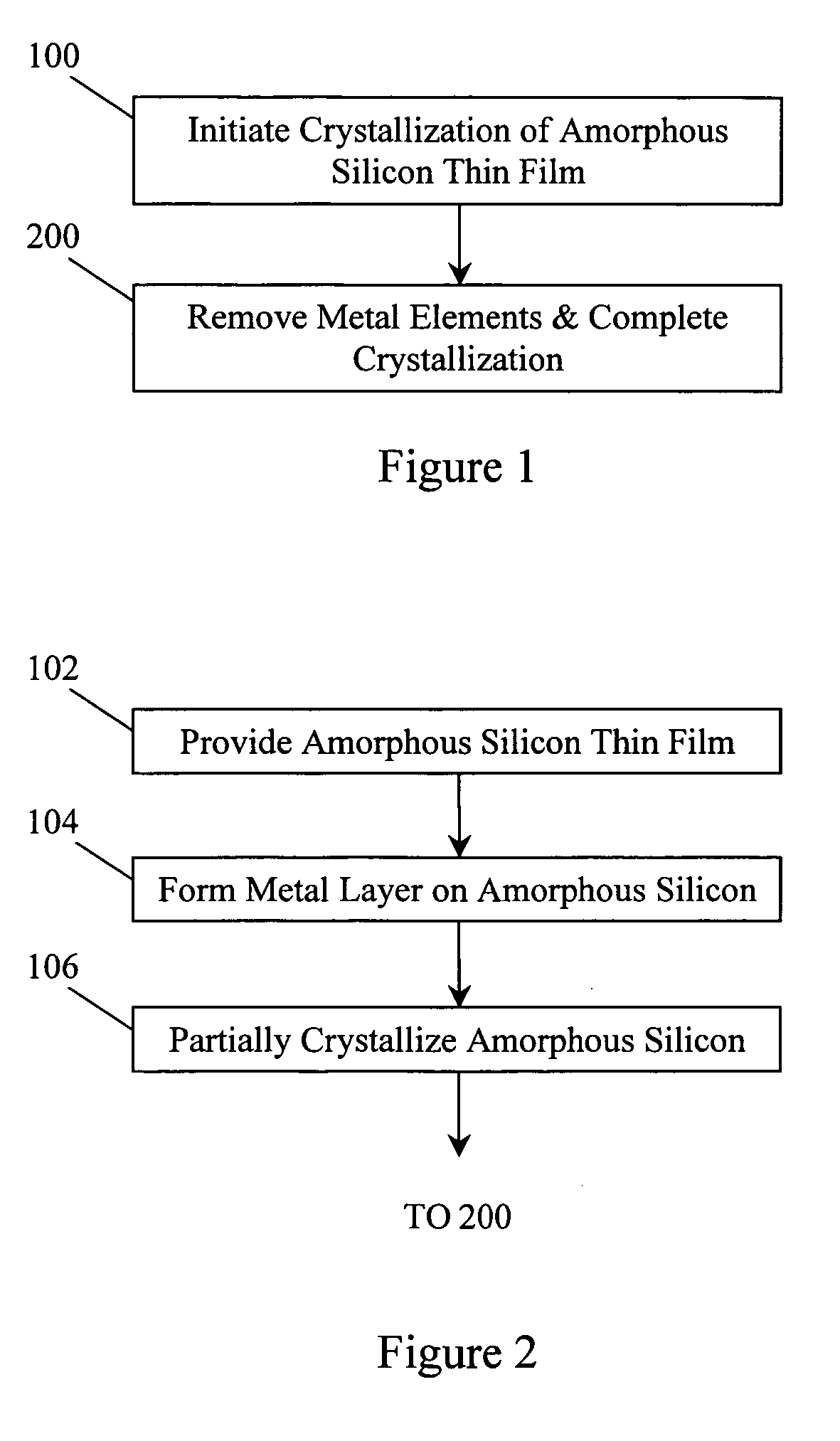

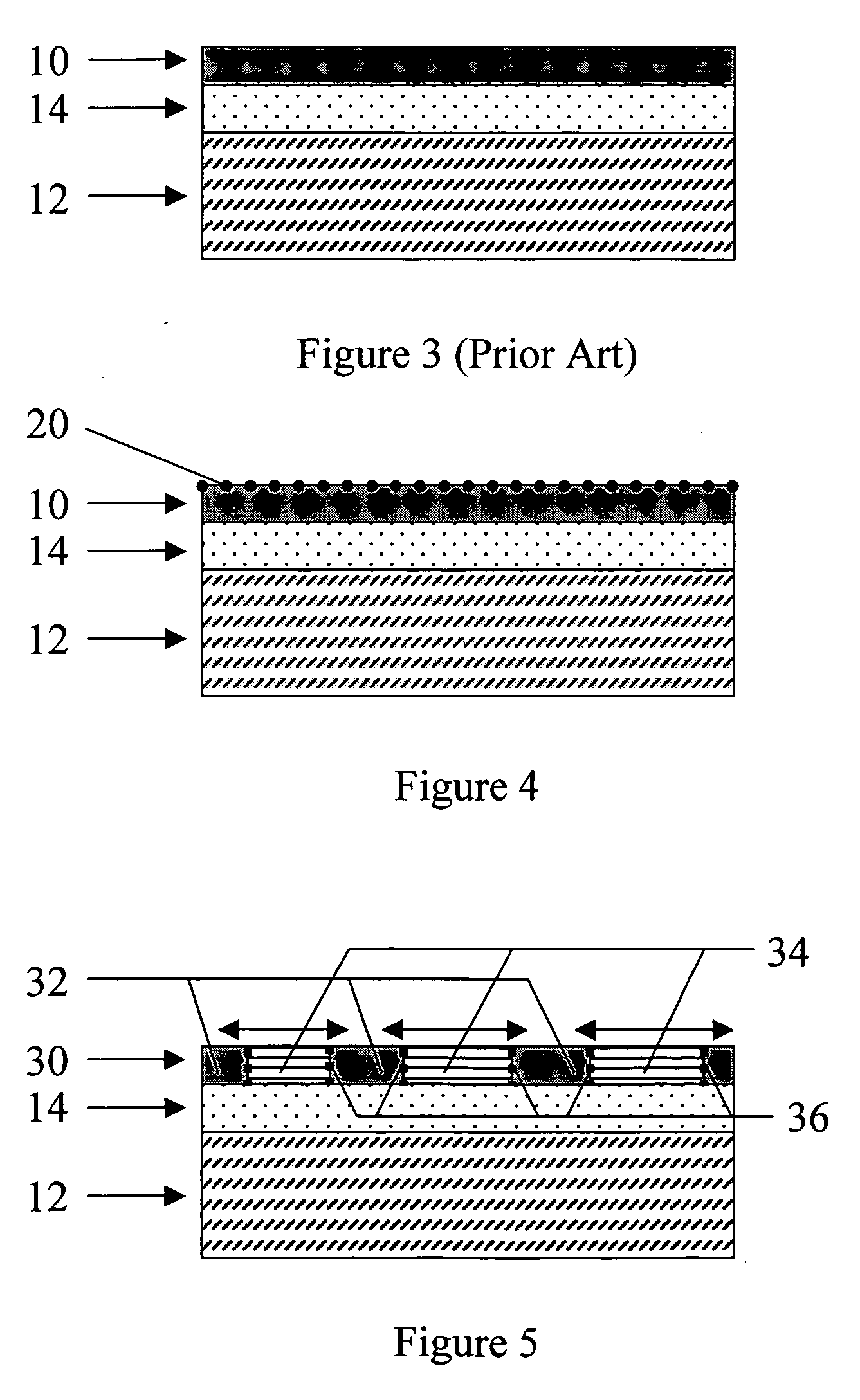

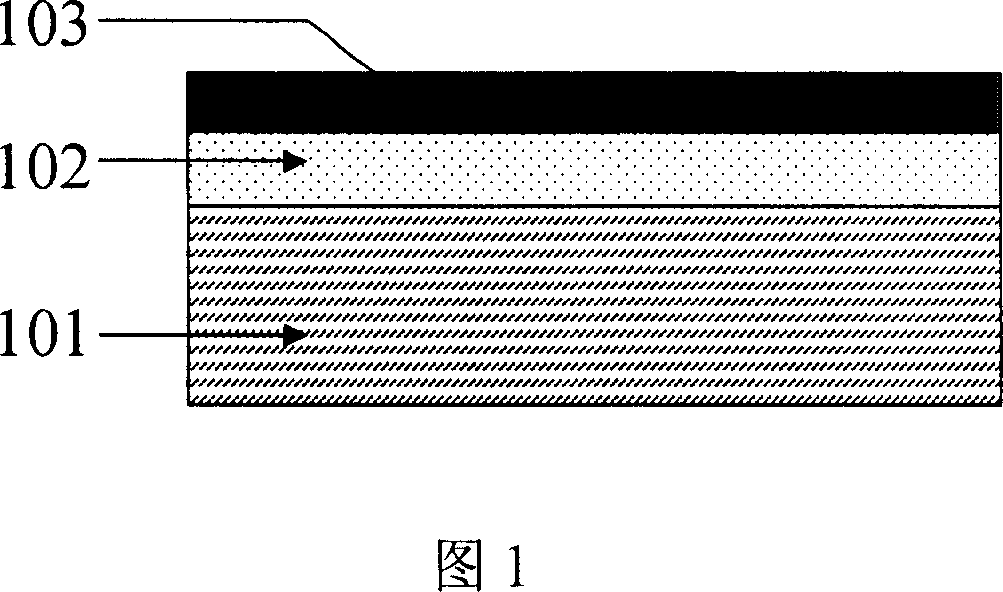

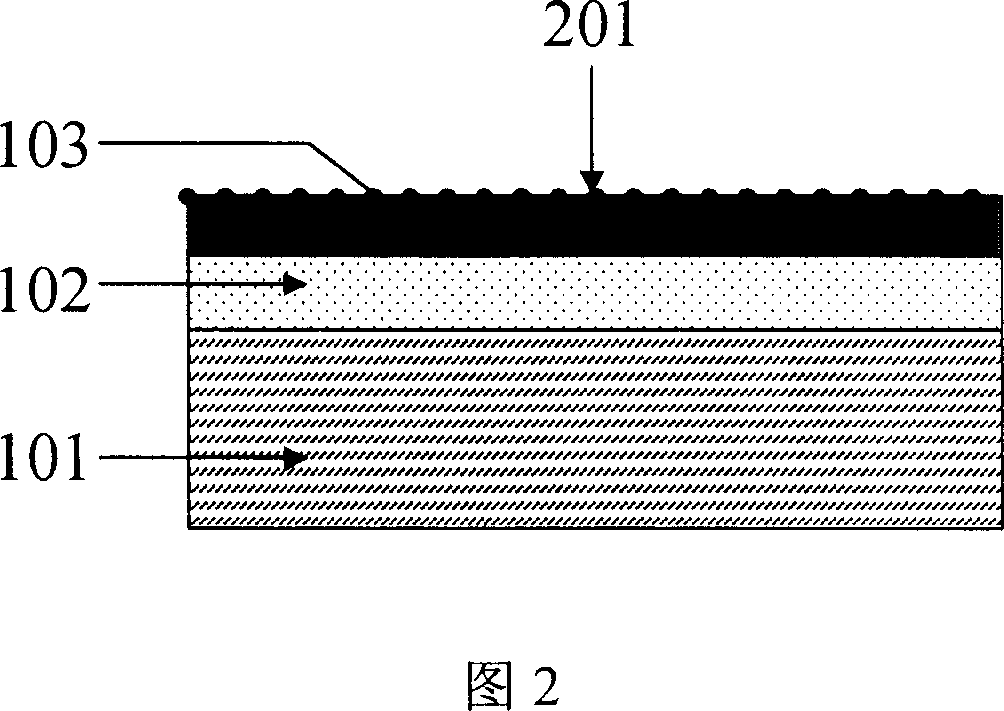

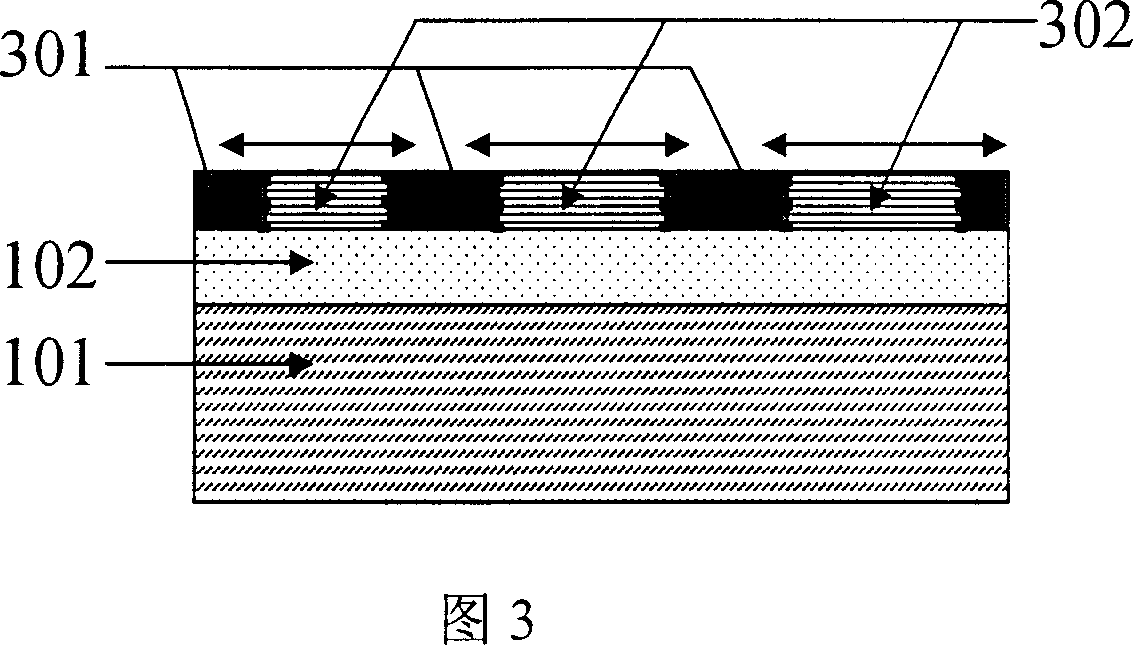

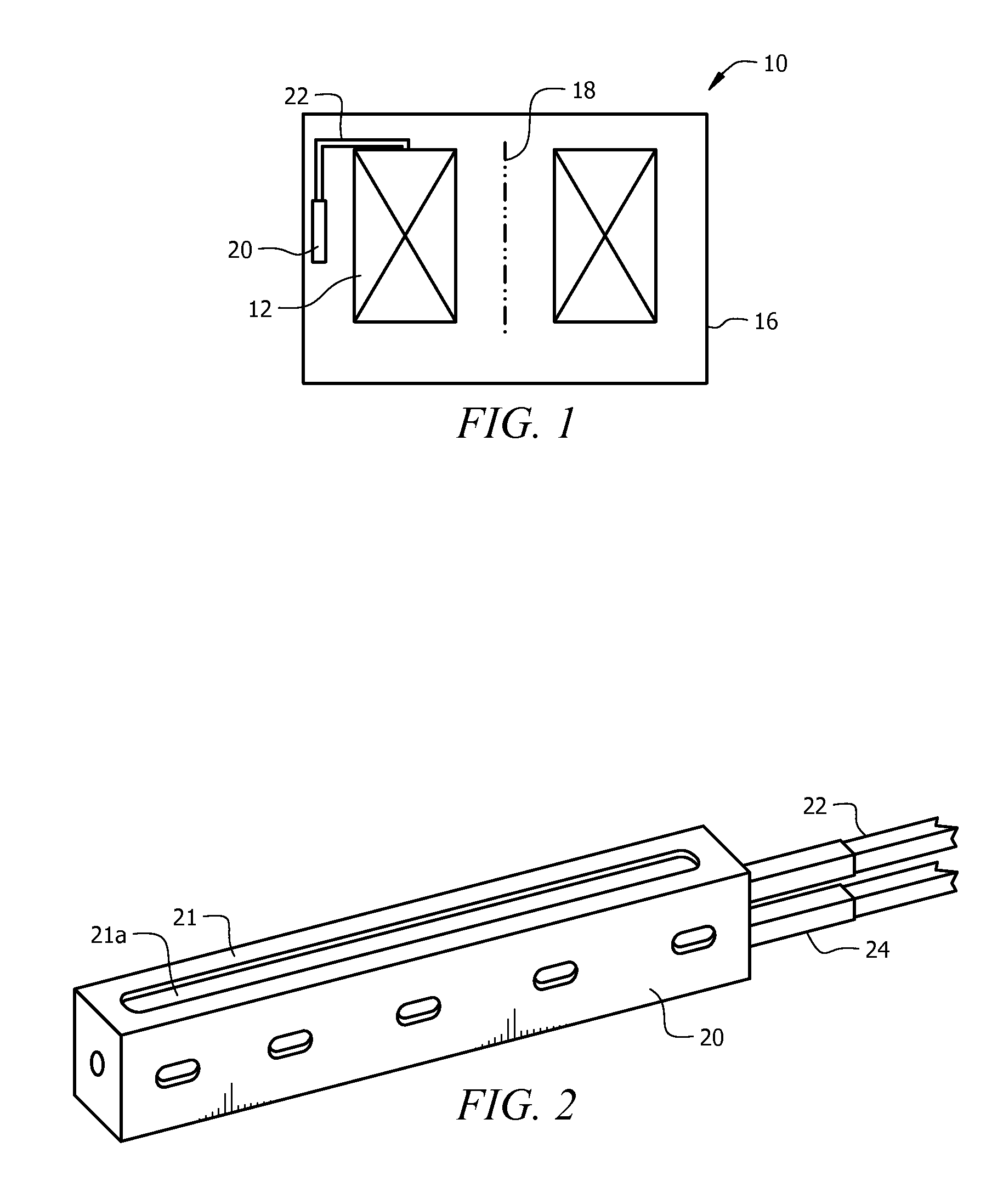

Metal-induced crystallization of amorphous silicon, polycrystalline silicon thin films produced thereby and thin film transistors produced therefrom

ActiveUS20060263957A1Quality improvementResidue reductionSolid-state devicesSemiconductor/solid-state device manufacturingTreatment completedNucleation

Crystallization-inducing metal elements are introduced onto an amorphous silicon thin film. A first, low-temperature, heat-treatment induces nucleation of metal-induced crystallization (MIC), resulting in the formation of small polycrystalline silicon “islands”. A metal-gettering layer is formed on the resulting partially crystallized thin film. A second, low-temperature, heat-treatment completes the MIC process, whilst gettering metal elements from the partially crystallized thin film. The process results in the desired polycrystalline silicon thin film.

Owner:THE HONG KONG UNIV OF SCI & TECH

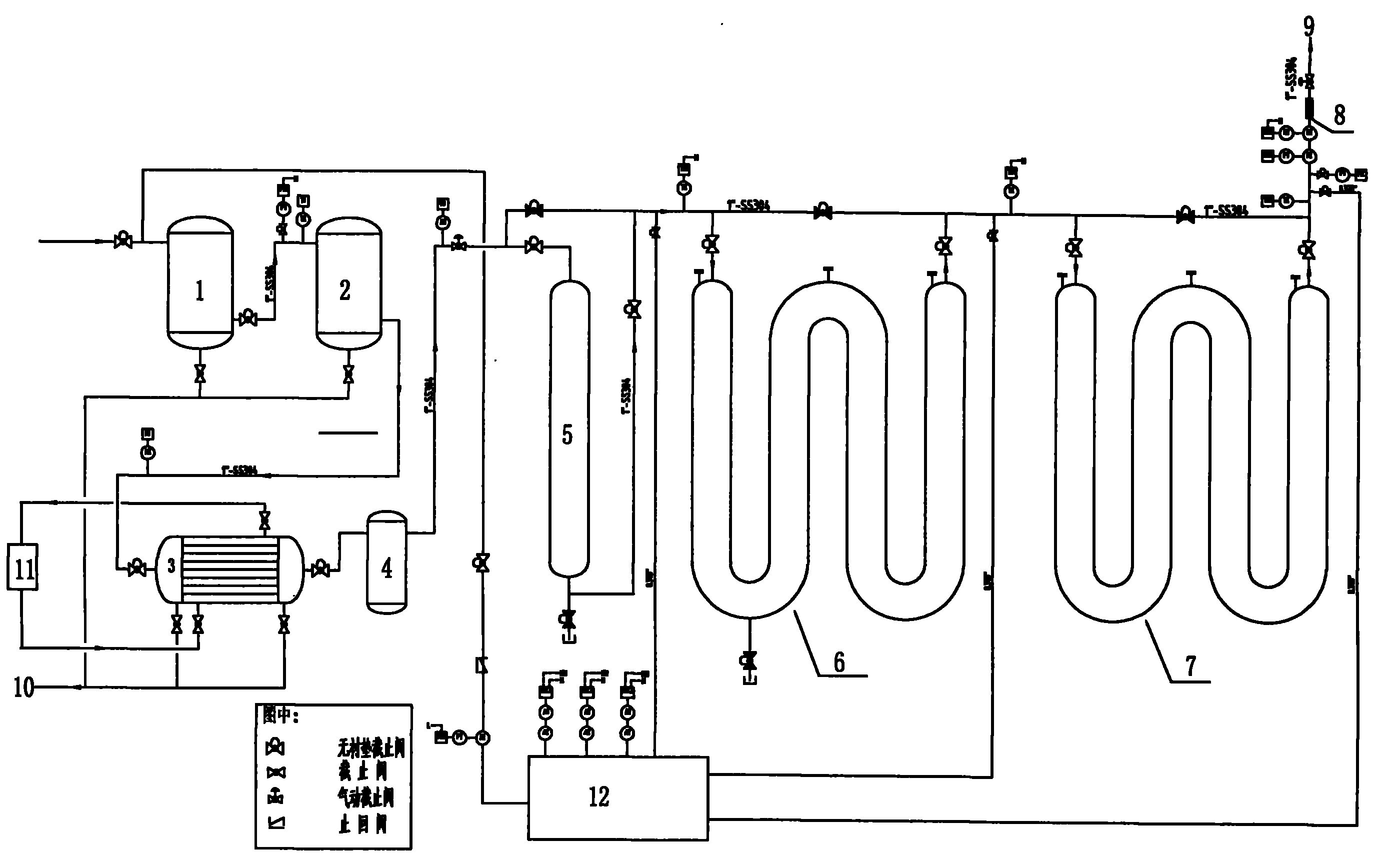

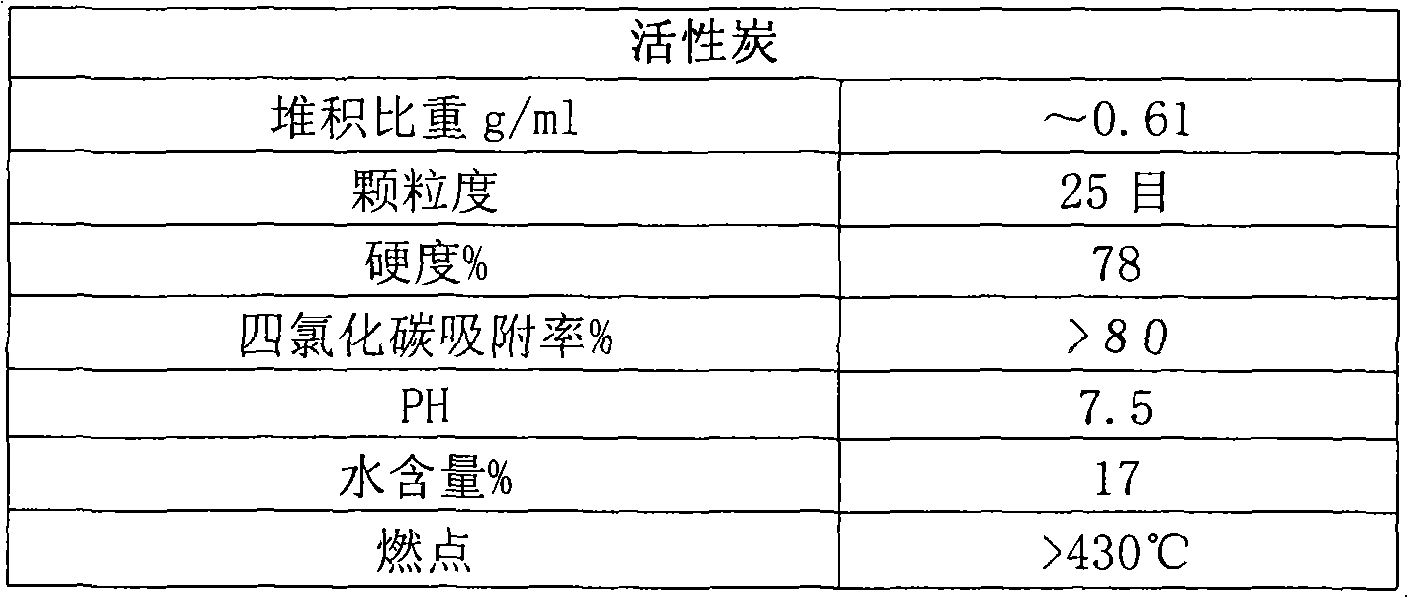

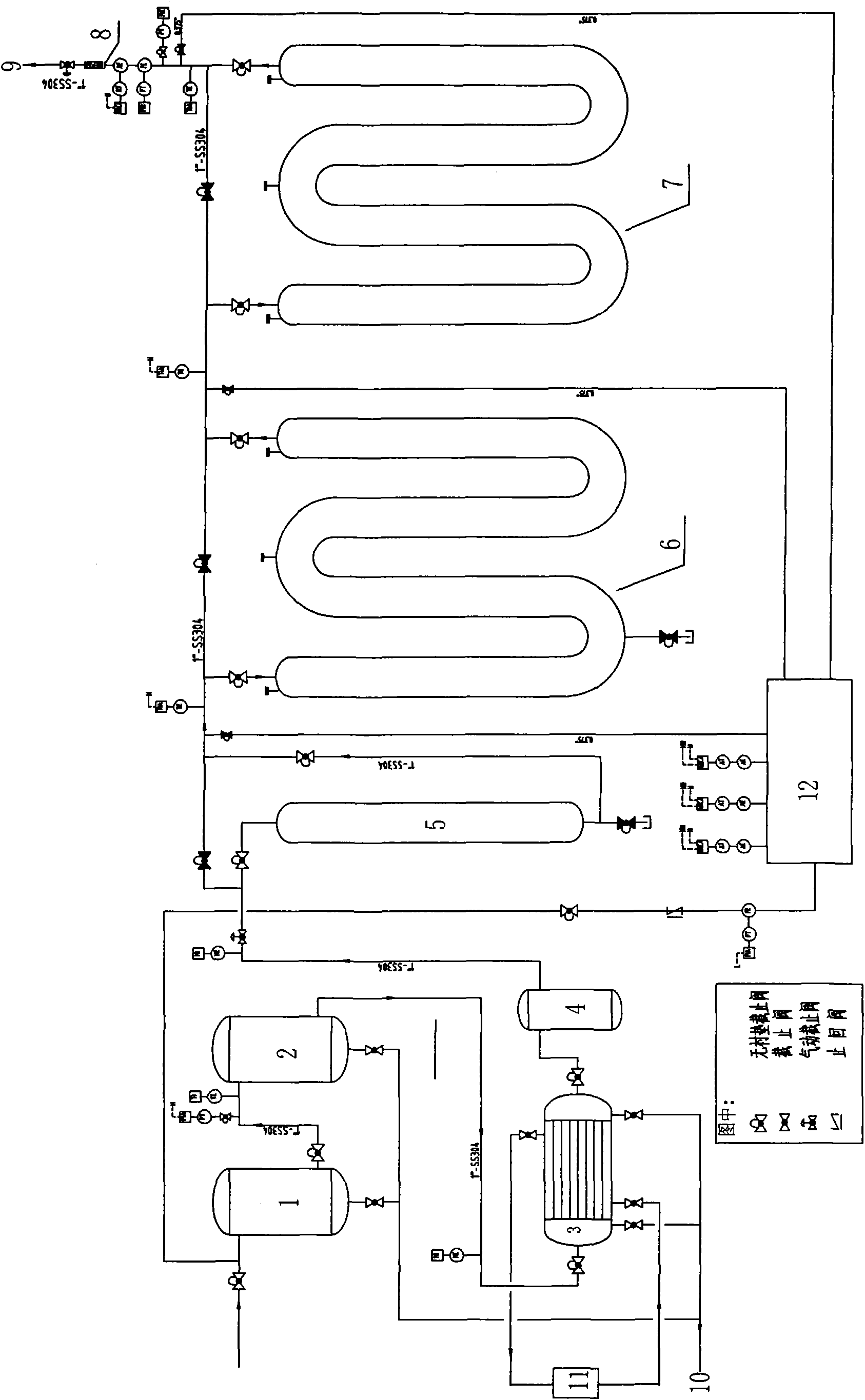

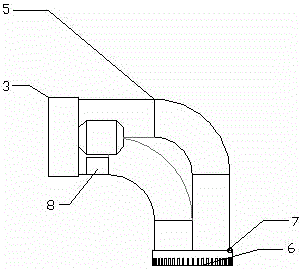

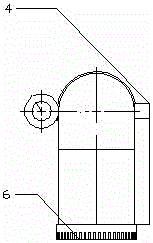

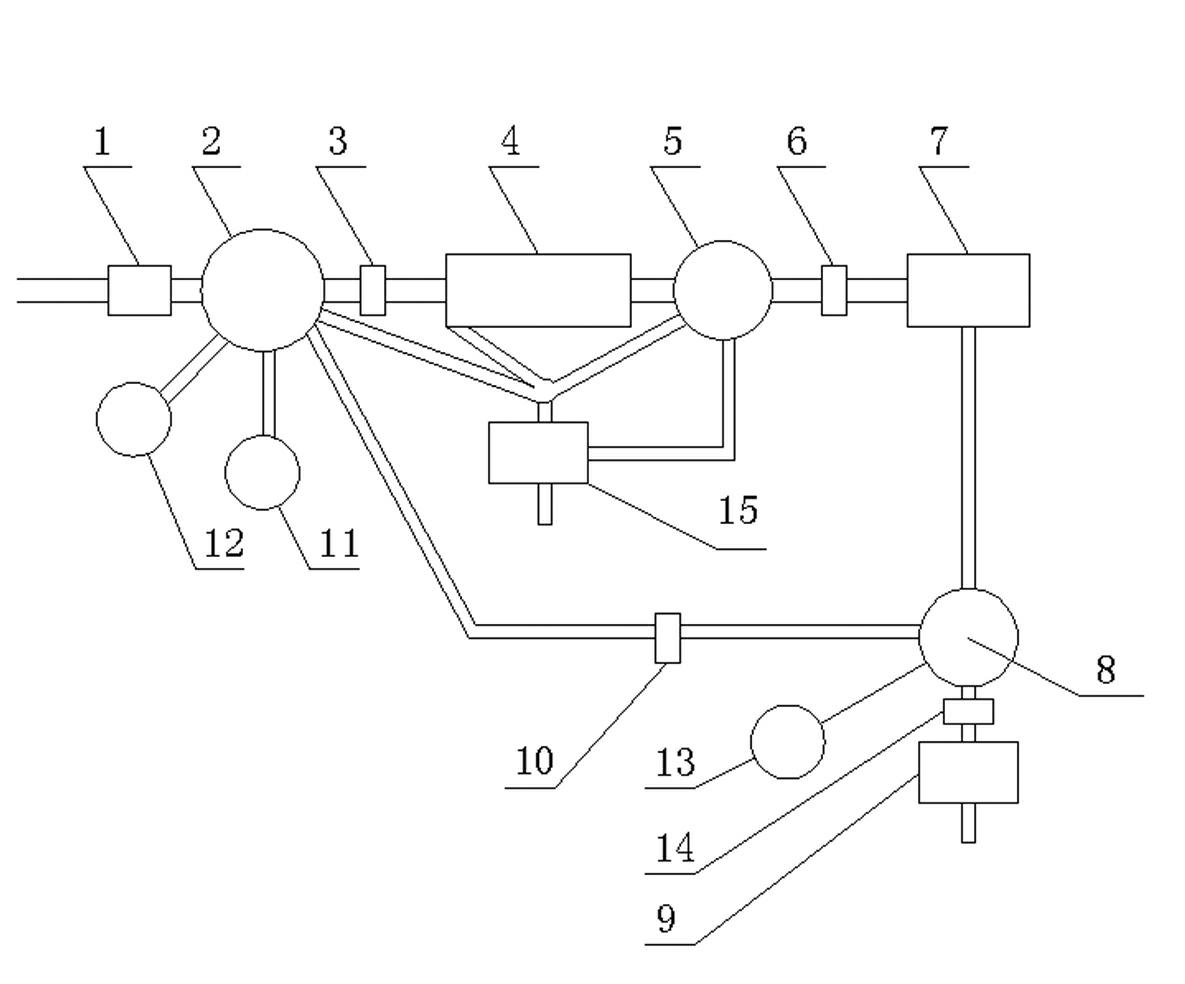

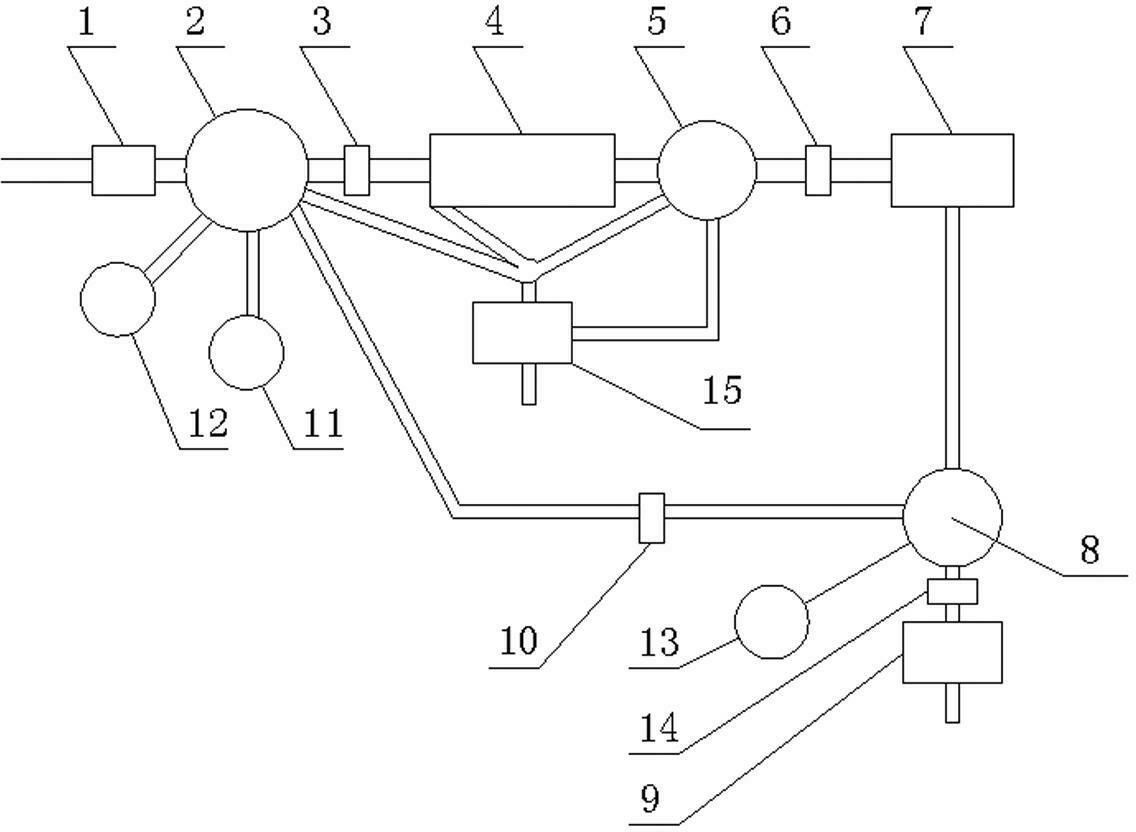

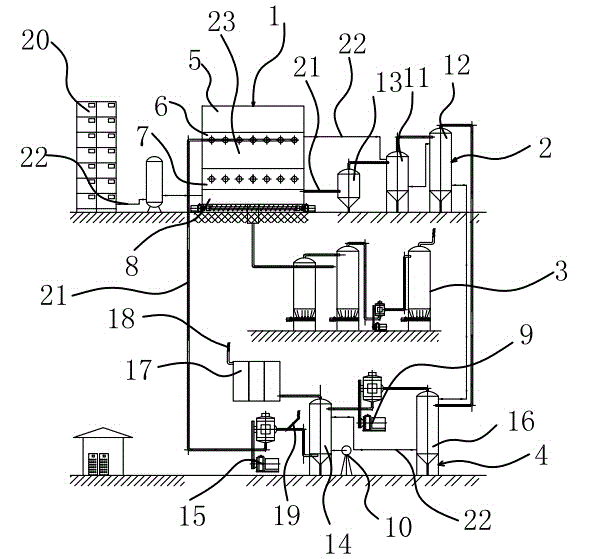

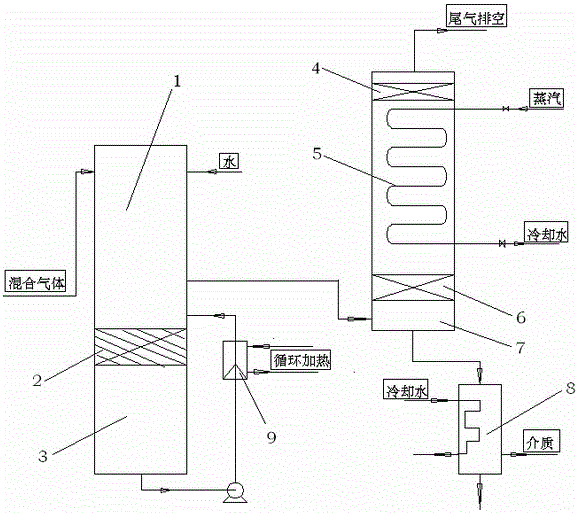

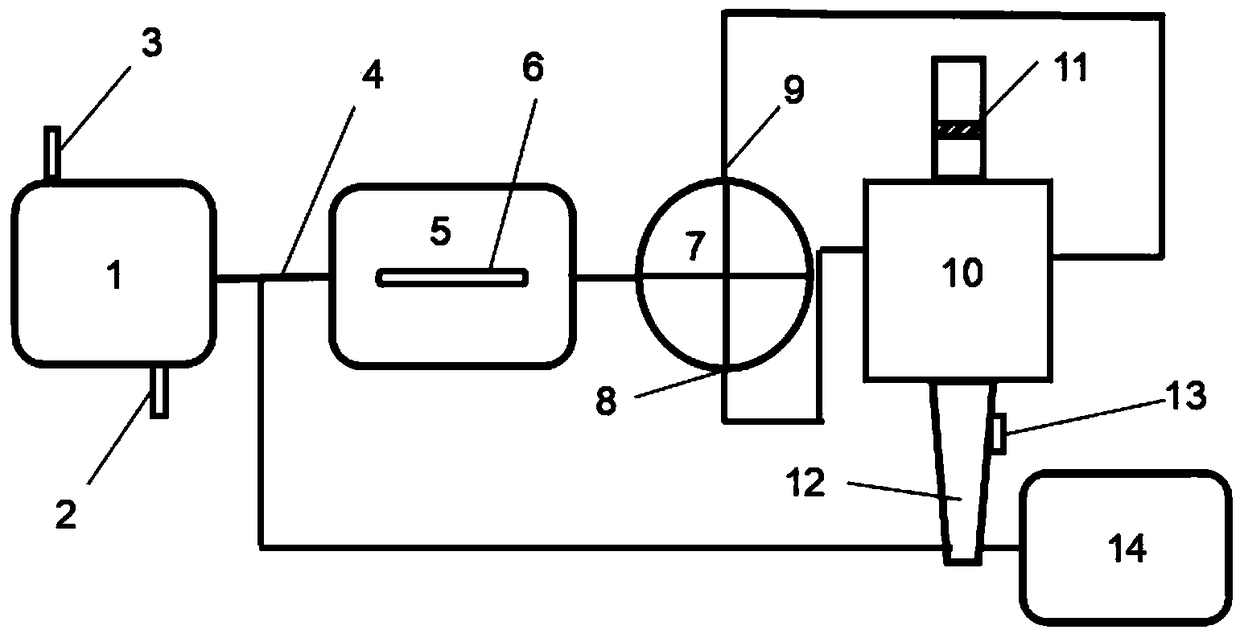

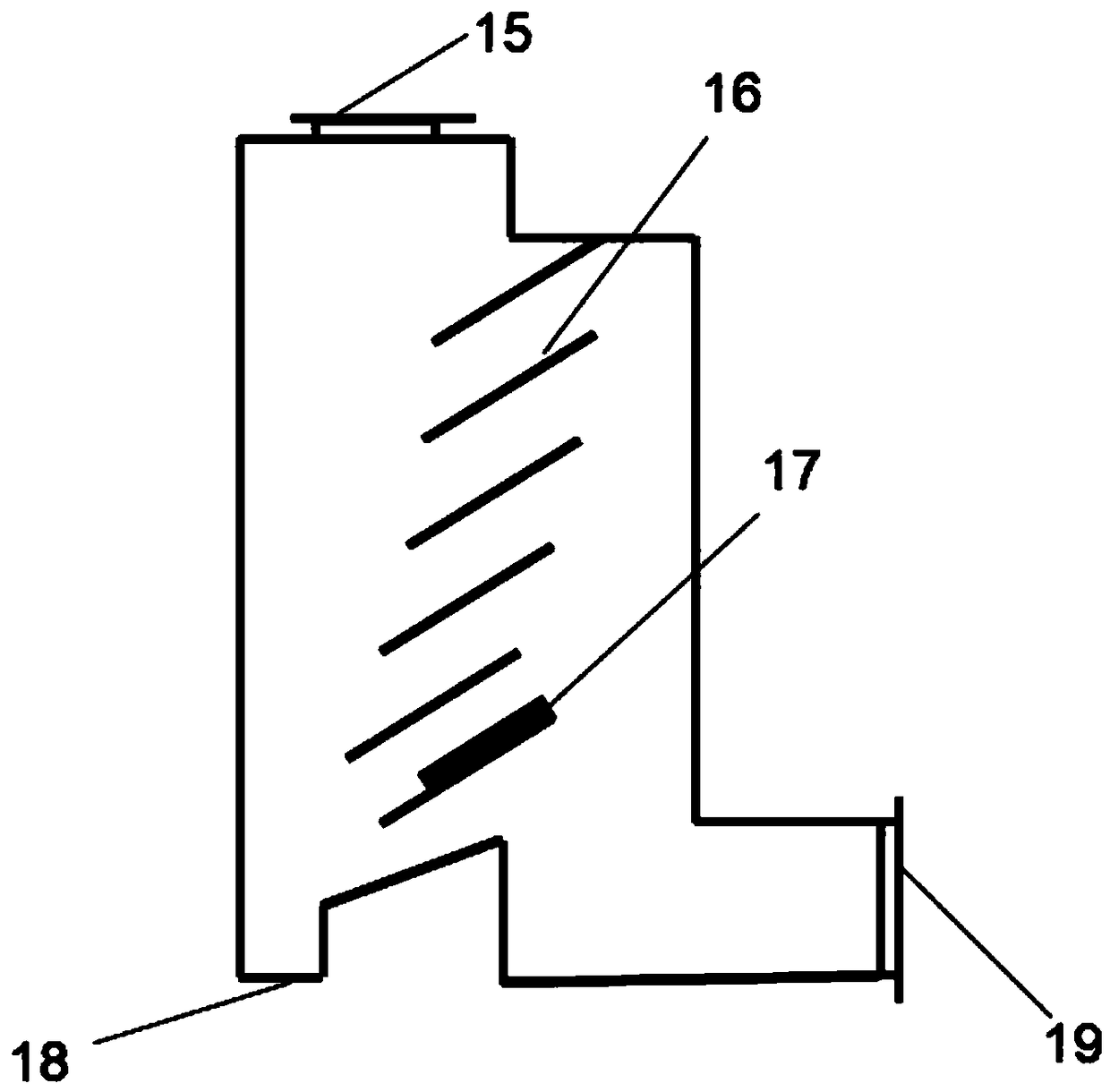

Pressure water reactor nuclear power plant high-radioactivity waste gas normal-temperature delay treatment complete equipment

InactiveCN101814326ALong-term safe and effective operationSimple structureRadioactive decontaminationTreatment completedActivated carbon

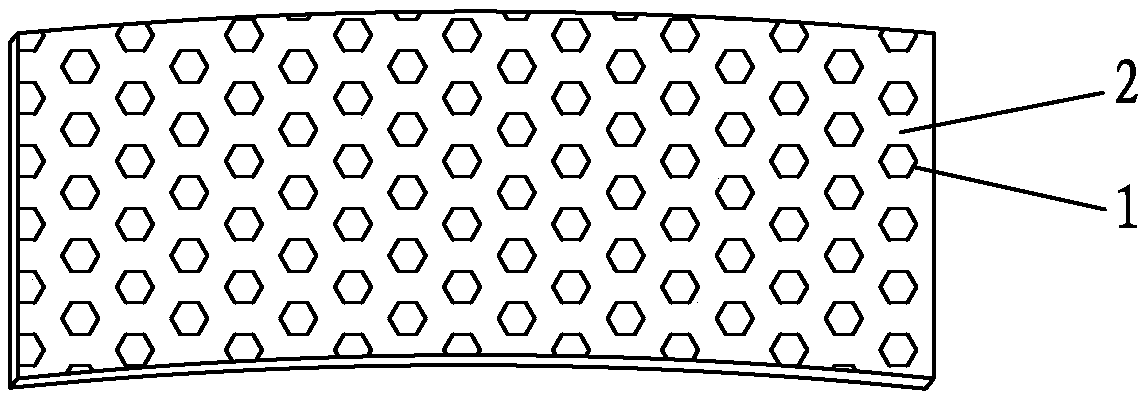

The invention relates to pressure water reactor nuclear power plant high-radioactivity waste gas normal-temperature delay treatment complete equipment, which is characterized in that the equipment mainly consists of a buffer tank (1), a prefilter (2), a drier (3), a heating device (4), a protection bed (5) and at least two delay beds (6) and (7), wherein the protection bed (5) is filled with active carbon, the delay beds (6) and (7) are connected in series, the gas inlet end of the buffer tank (1) is connected with the output end of a groove tank for collecting waste gas through a pipeline, the output end of the buffer tank (1) is connected with the input end of the prefilter (2), the output end of the prefilter (2) is connected with the input end of the drier (3), the output end of the drier (3) is connected with the input end of the heating device (4), the output end of the heating device (4) is connected with the input end of the protection bed (5), the output end of the protection bed (5) is connected with the input end of the delay bed (6), the output end of the delay bed (7) is connected with the input end of an efficient grain filter (8) through a pipeline, and the output end of the efficient grain filter (8) is connected with the corresponding input end of a plant building ventilation system (9). The invention has the advantages of simple structure, ground saving, energy saving, low operation and maintenance cost, safety and reliability.

Owner:江苏宝宸净化设备有限公司

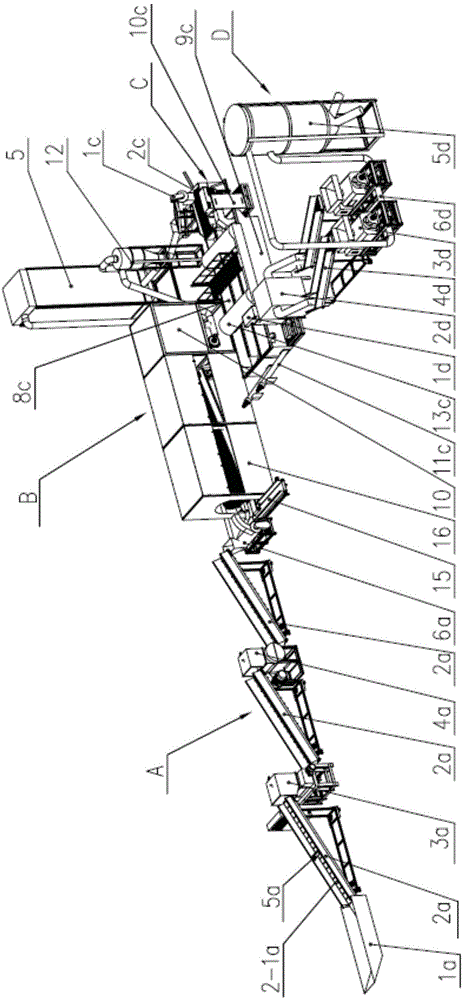

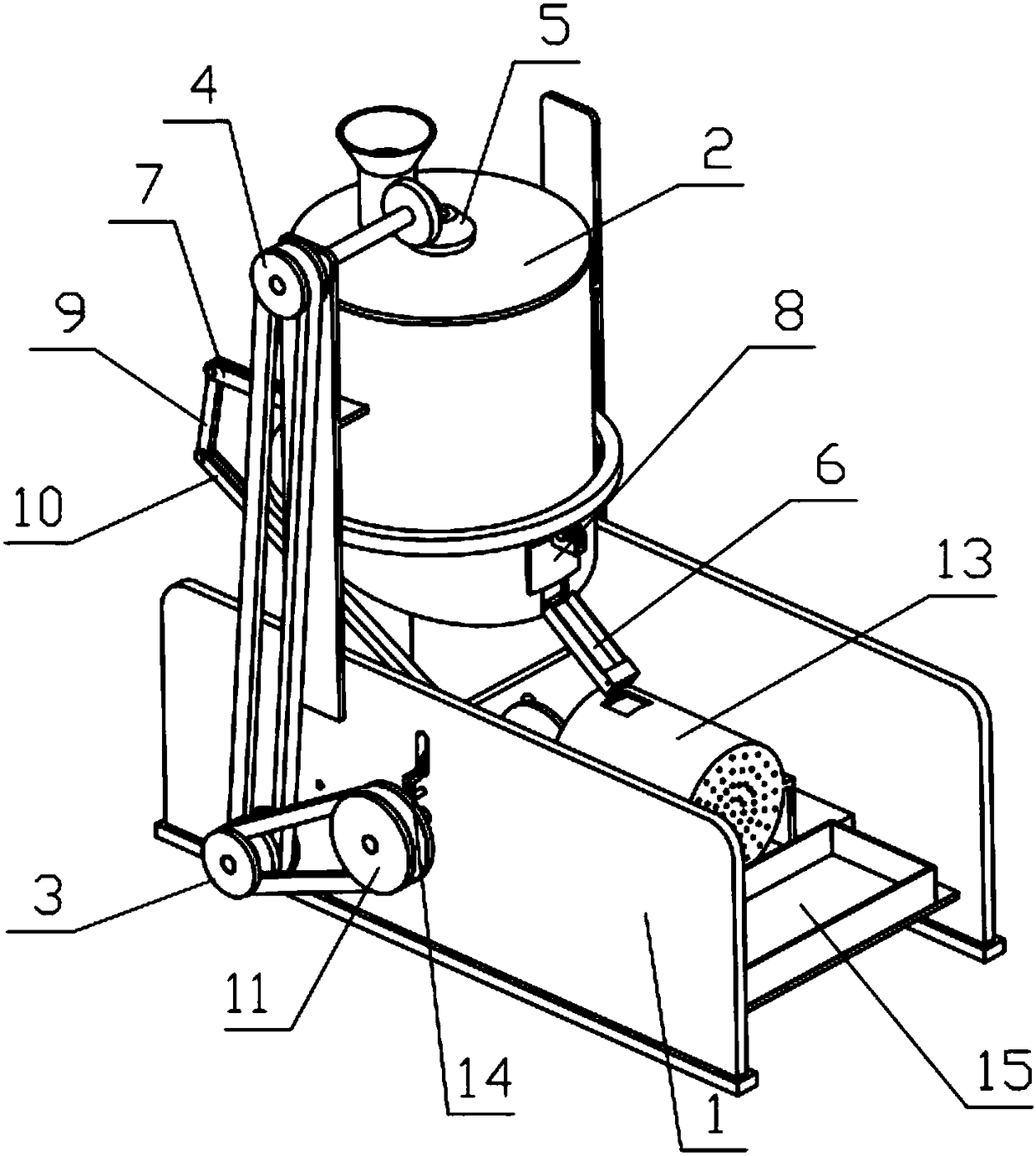

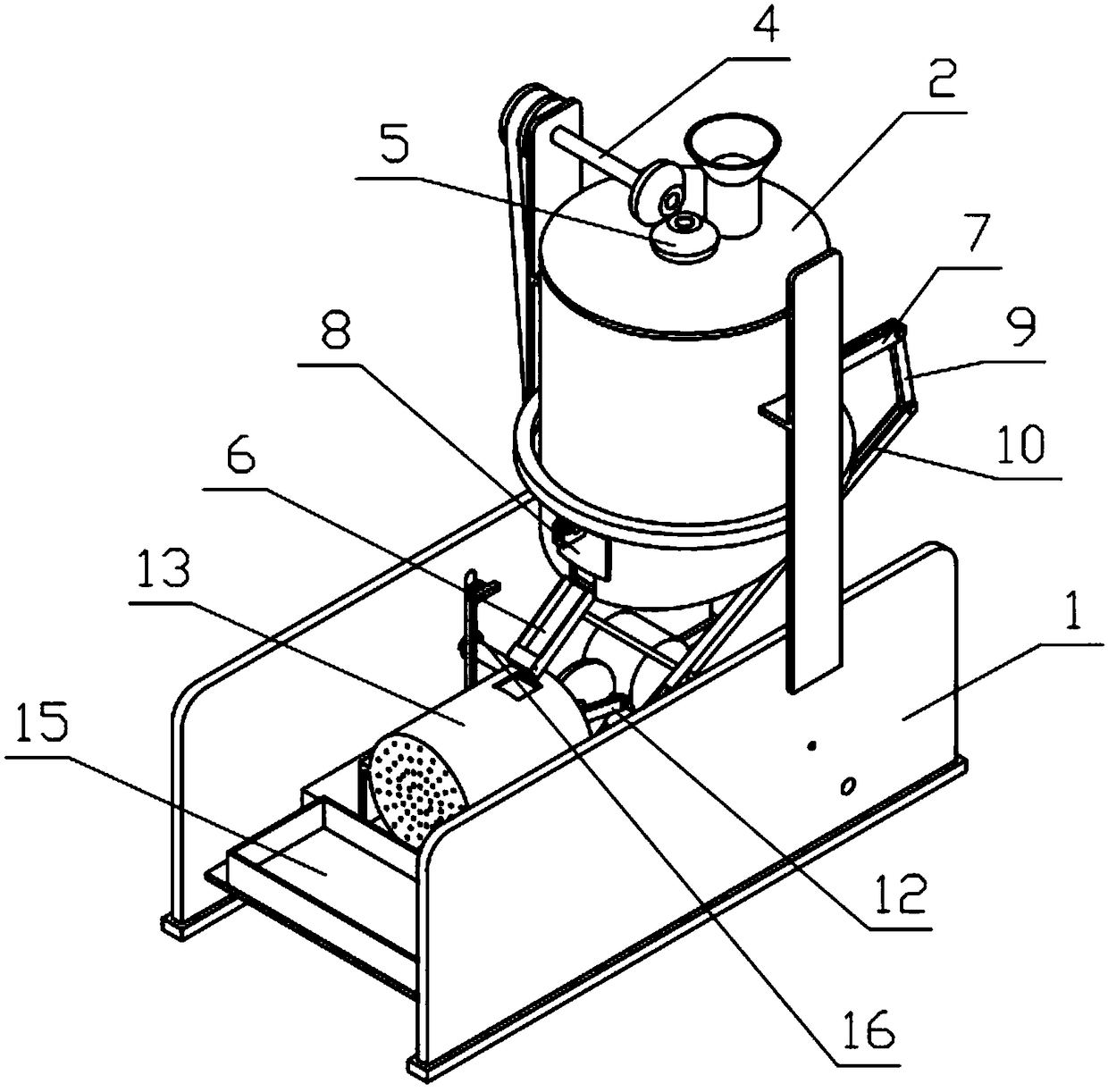

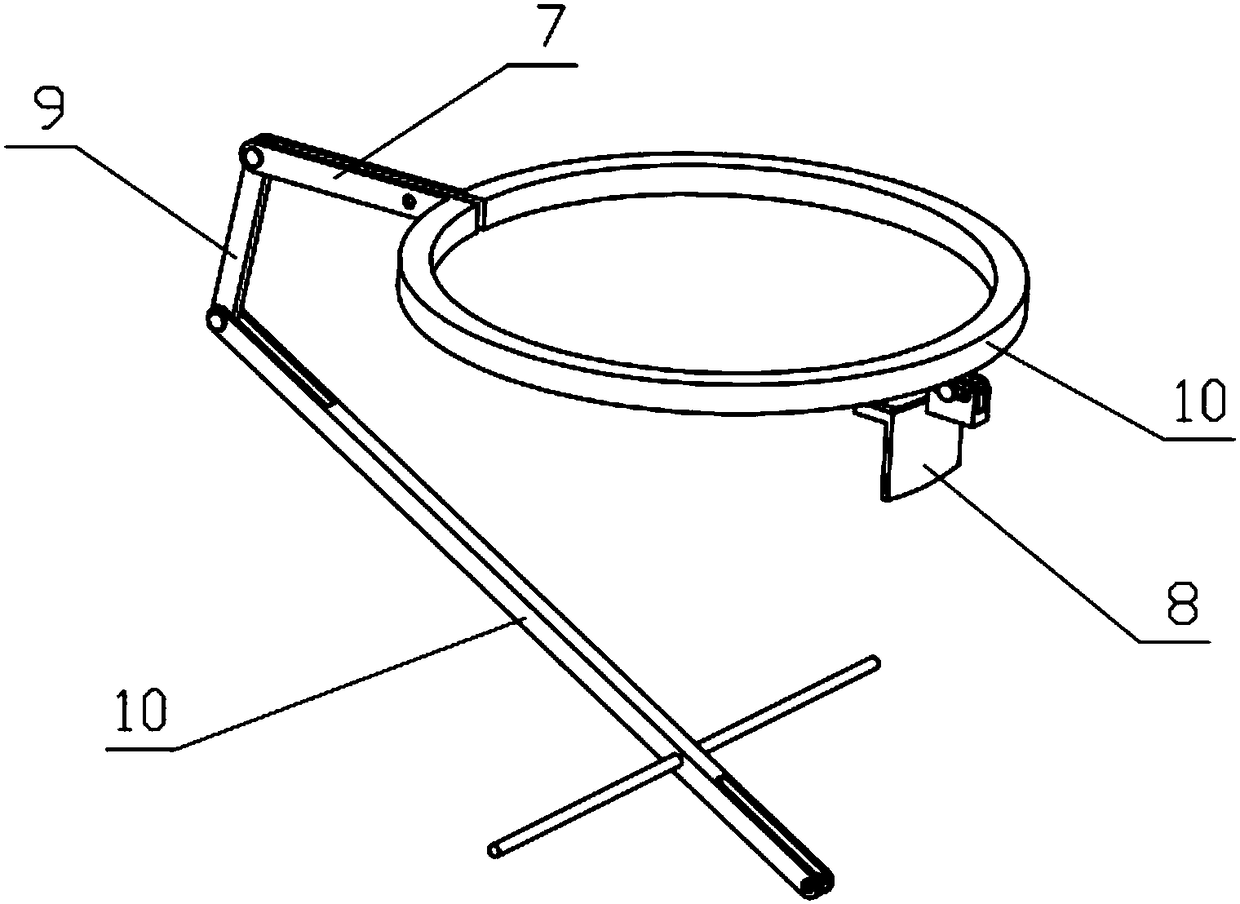

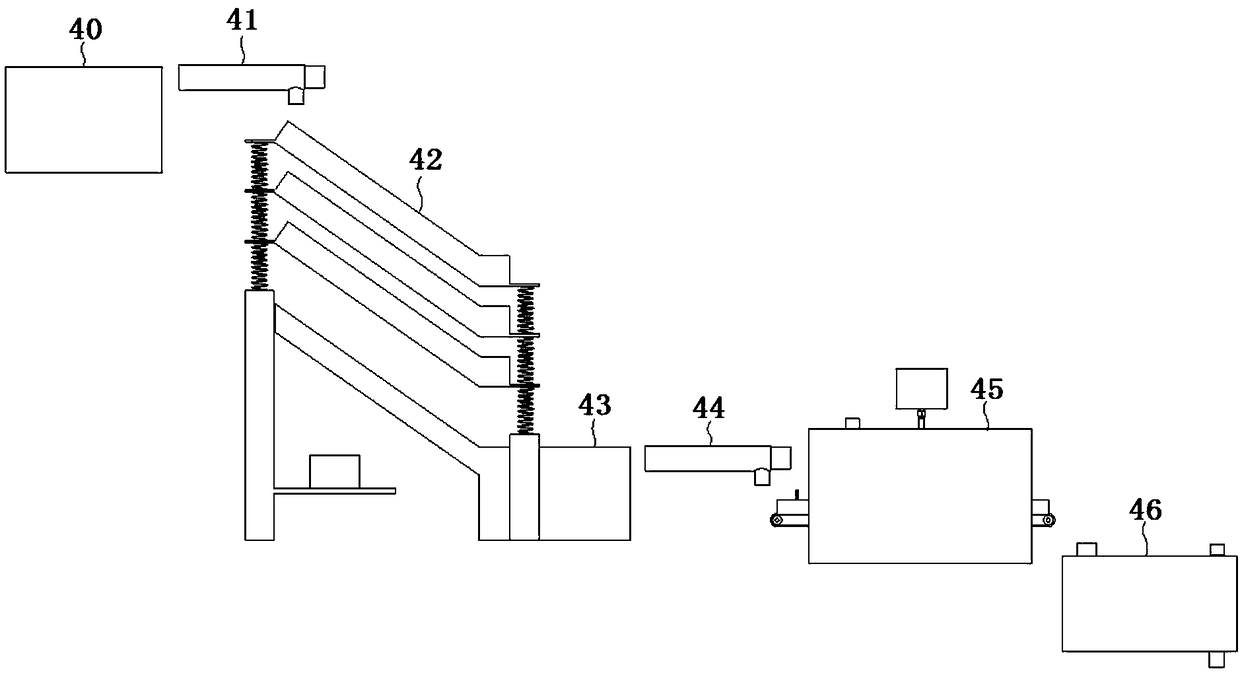

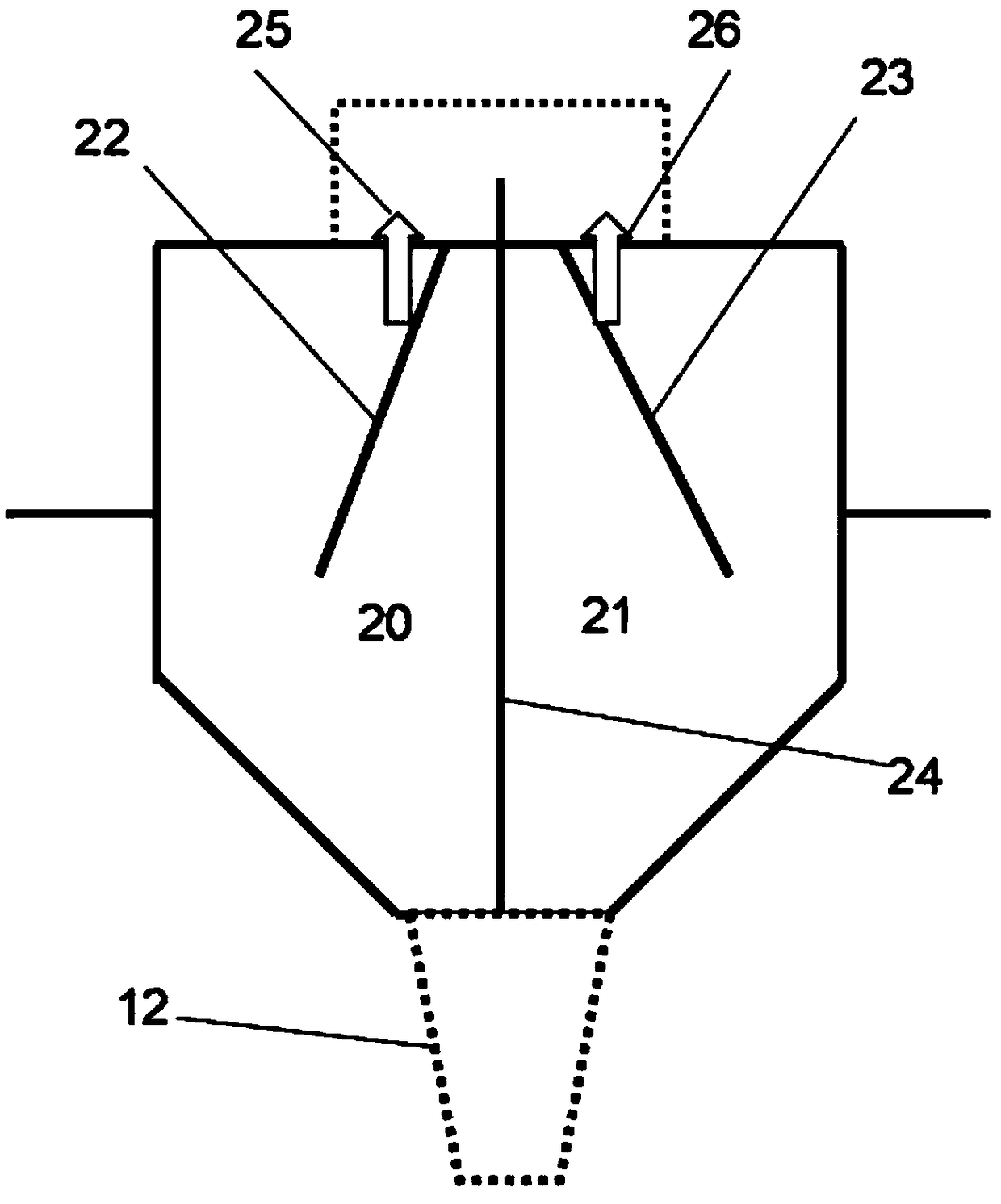

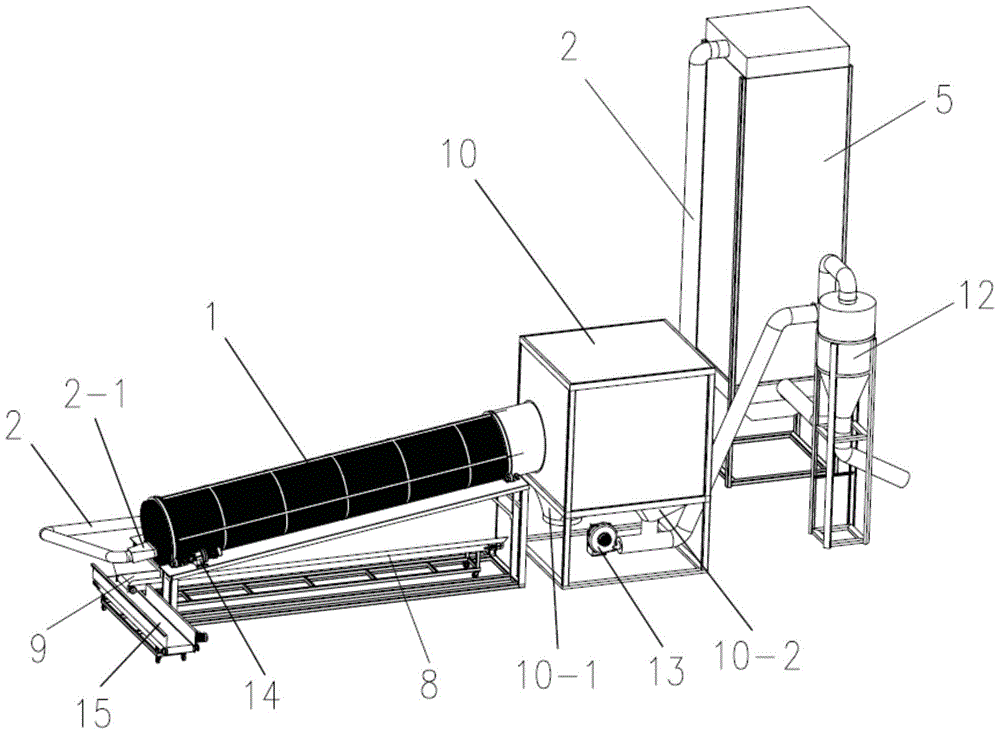

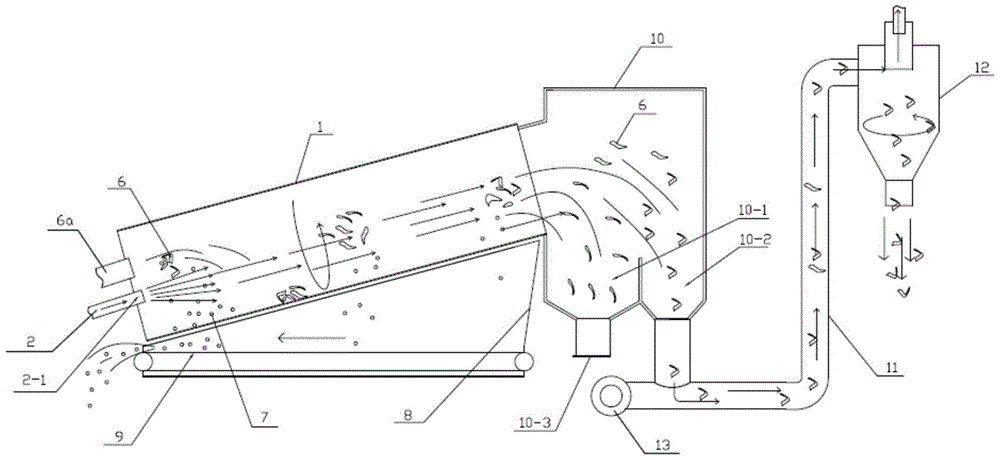

Recovery treatment complete device for soft sheet materials

ActiveCN104815835AReduce manual interventionIncrease productivityGas current separationSolid waste disposalTreatment completedSmall footprint

The invention discloses a recovery treatment complete device for soft sheet materials. The recovery treatment complete device comprises a crushing portion, an impurity separating portion, a cleaning portion and a dehydration briquetting portion which are respectively connected, the crushing portion comprises a shredding machine and a crushing machine which are sequentially connected together through a material conveying mechanism, the impurity separating portion comprises an air conveying device, a separating cylinder, a separating cylinder driving device and a soft sheet gas separating device, the separating cylinder driving device drives the separating cylinder to rotate, the air conveying device comprises a fan and an air pipe connected with the fan, sieve holes are formed in the wall of the separating cylinder, two ends of the separating cylinder are open, an air outlet of the air pipe is arranged at a feeding end of the separating cylinder, the cleaning portion comprises a washing cage, a vibrating sieve device and a cleaning water tank which are sequentially connected, and the dehydration briquetting portion comprises a dehydrator, an aggregating machine and a material storage tank which are sequentially connected. The recovery treatment device has the advantages of high production efficiency, low labor cost, small occupied area, no secondary pollution and the like.

Owner:冯愚斌

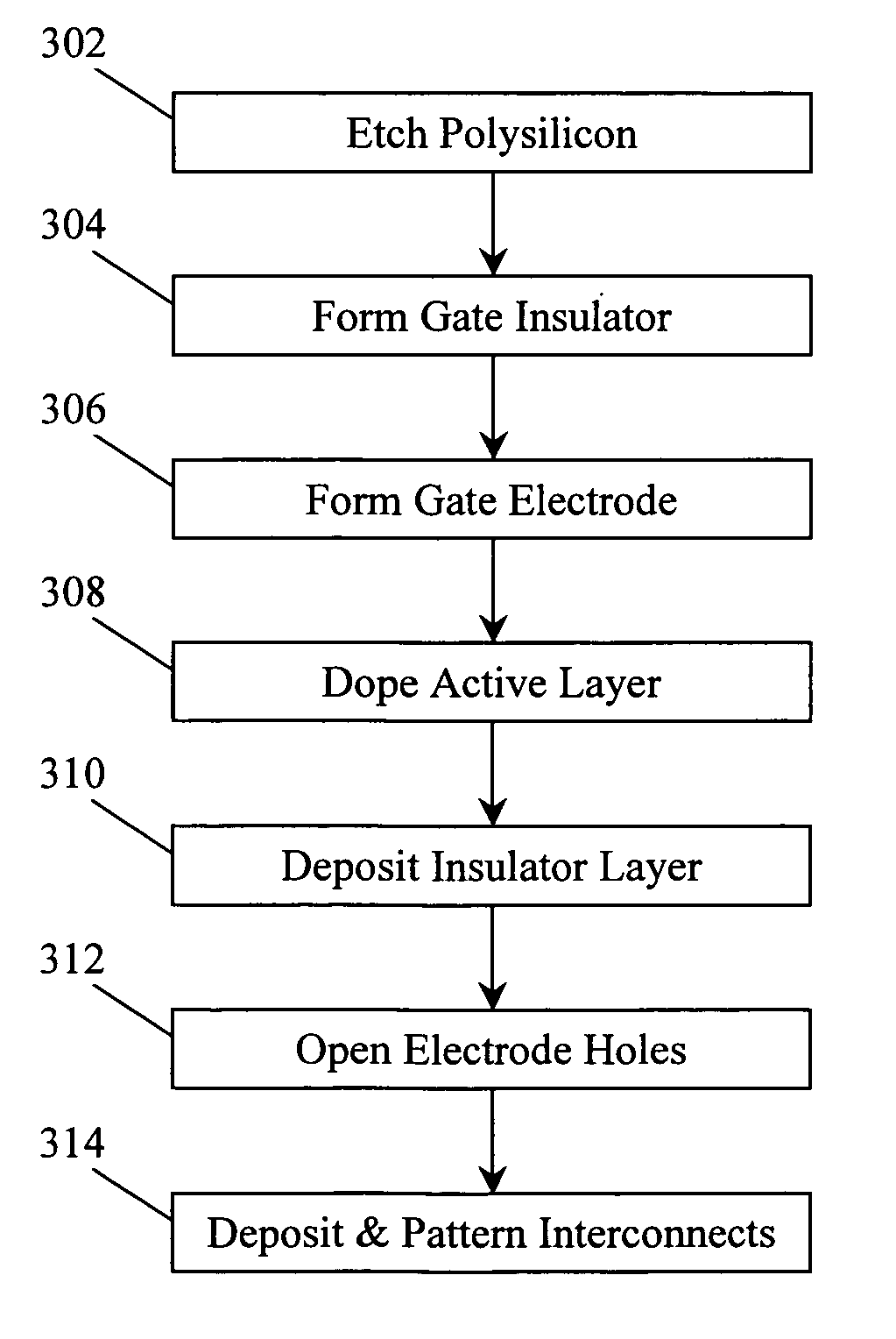

Metal-induced crystallization of amorphous silicon and metal removal techniques

InactiveCN101064246ASemiconductor/solid-state device manufacturingTreatment completedOptoelectronics

The invention relates to a technology for producing a high quality and large area polycrystalline silicon thin film by amorphous silicon-metal-induced crystallization. Crystallization-inducing metal elements of controllable amound are introduced onto an initial amorphous silicon thin film. A first, low-temperature, heat-treatment induces nucleation of metal-induced crystallization (MIC), resulting in the formation of small polycrystalline silicon''islands''. A metal-gettering layer is formed on the resulting partially crystallized thin film. A second, low-temperature, heat-treatment completes the MIC process to form the desired polycrystalline silicon thin film. while the metal-gettering layer can be removed at randon after crystallization heat-treatment.

Owner:THE HONG KONG UNIV OF SCI & TECH

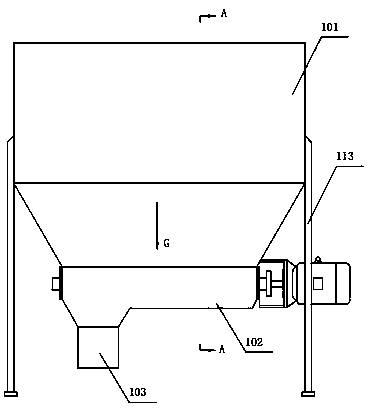

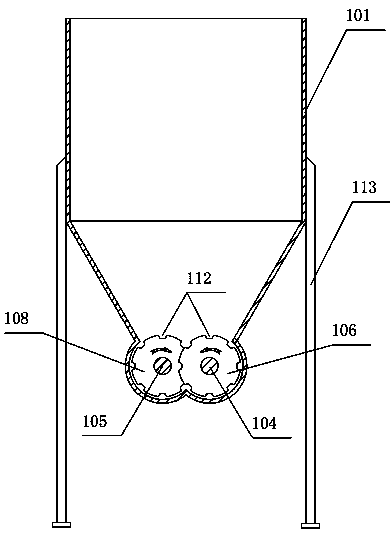

Oil-containing sludge treatment complete equipment

PendingCN110425547AThorough treatmentImprove efficiencyGranulation by pressingIncinerator apparatusTreatment completedSludge

The invention discloses oil-containing sludge treatment complete equipment. The oil-containing sludge treatment complete equipment comprises a material bin, a drying machine, a pulverizer, a stirrer,a granulator and an incinerator which are sequentially arranged from front to back; spiral feeders which are hermetically arranged are correspondingly installed between the material bin and the dryingmachine, between the drying machine and the pulverizer, between the pulverizer and the stirrer, between the stirrer and the granulator and between the granulator and the incinerator; dust recovery covers are correspondingly arranged on the material bin, the pulverizer and the stirrer, the dust recovery covers are connected to a dust treatment device through pipelines, and an exhaust pipe of the dust treatment device is connected to an air inlet pipe of the incinerator through a pipeline; and a smoke exhaust pipe of the incinerator is connected to a steam generating device, a steam dischargingpipe of the steam generating device is connected to the drying machine, and a gas discharging pipe of the drying machine is connected to the air inlet pipe of the incinerator through a pipeline. Theoil-containing sludge treatment complete equipment can be used for carrying out harmless and thorough treatment on oil-containing sludge without harmful emission, and has the advantages of being thorough in treatment and high in efficiency.

Owner:高密圣坤环保科技有限公司

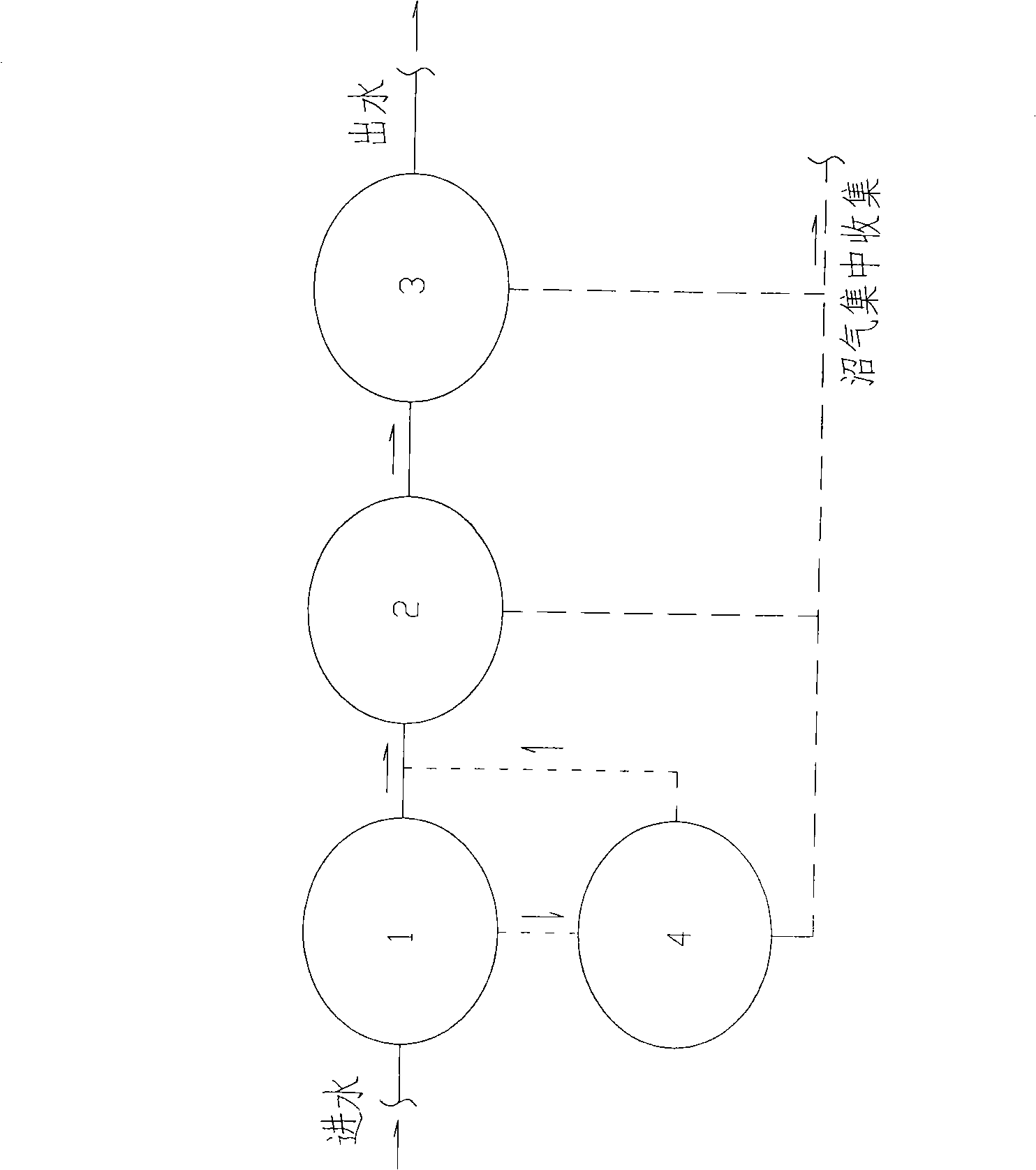

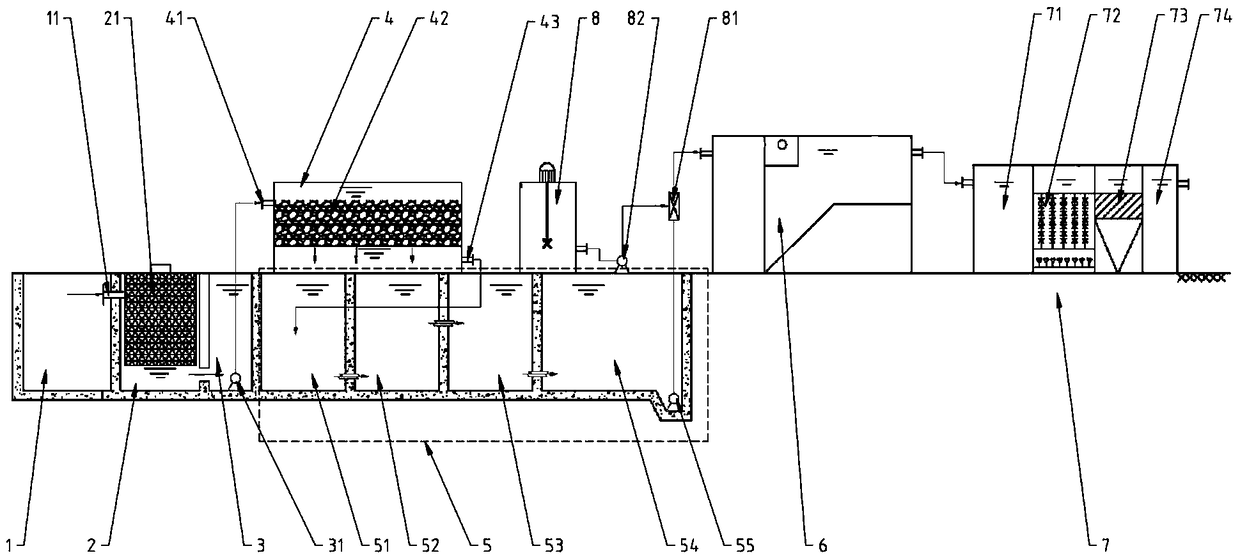

Passive highly effective dispersant type domestic wastewater treatment complete plant

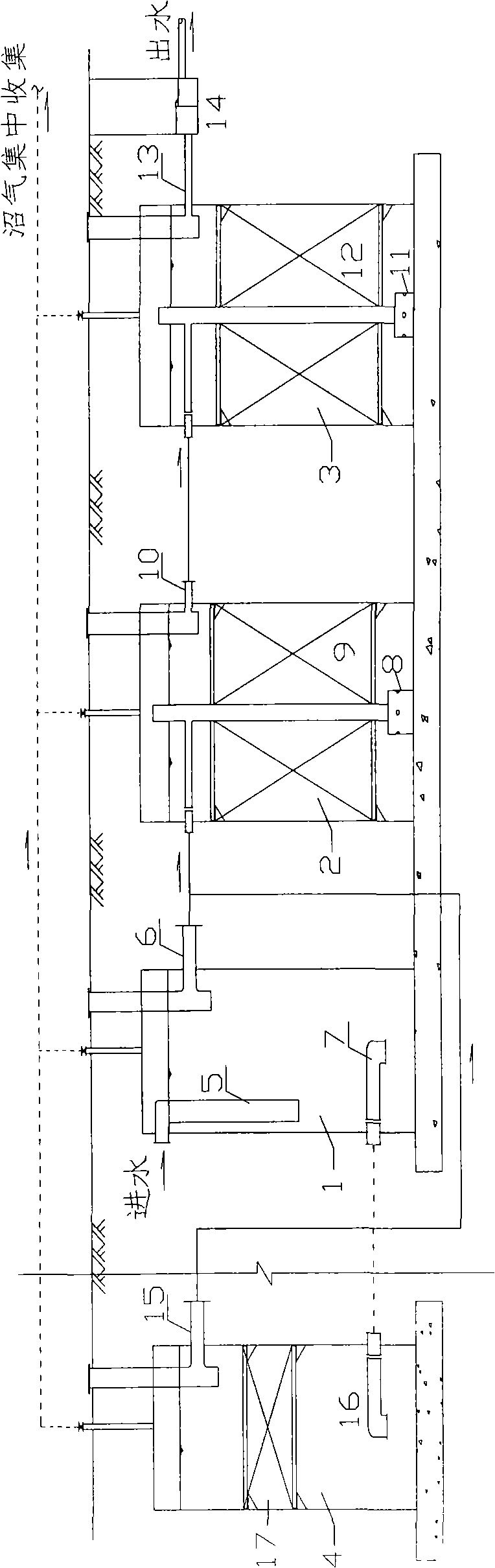

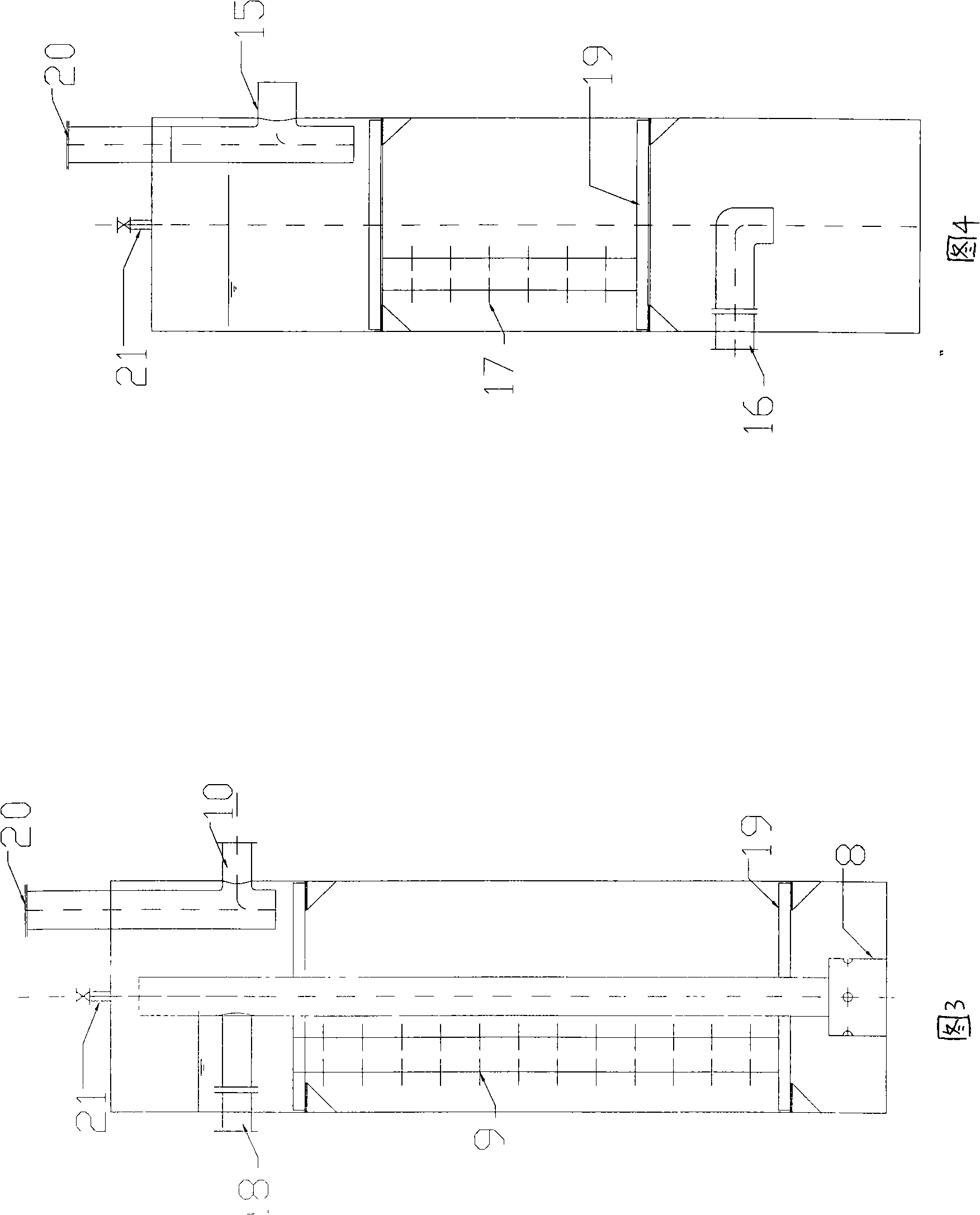

InactiveCN101254990AReduce security risksSafe and stable operationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTreatment completedRural area

The invention relates to sewage treatment equipment, in particular to a power-free highly effective dispersion type domestic sewage treatment integrated equipment designed for aiming at municipal housing plots, guesthouses, resorts, nursing homes, airports and rural areas. The equipment is composed of a sedimentation tank, two or more anaerobic reactors connected in series, and a sludge digestionreactor, wherein polypropylene elastic three-dimensional filling material is respectively arranged at the center parts of the anaerobic reactors and the sludge digestion reactor, and anaerobe grows on the elastic three-dimensional filling material in a way of biological membrane. The treatment equipment of the invention has the advantages: firstly, the treatment equipment has higher flexibility and adaptability, the one-time investment is low, the amount of sludge is small, and the management is convenient; secondly, the polypropylene elastic three-dimensional filling material is arranged inside through adopting the anaerobic contact process, the specific surface area is large, and the biomass is large; thirdly, the organic matter can be fully degraded; fourthly, the security performance is good; fifthly, the structure is simple, the complete set of the treatment equipment can realize promotion, and the treatment equipment is in favor of popularization; the treatment equipment is applicable to the dispersion type domestic sewage treatment in the residential districts, the guesthouses, the resorts, the nursing homes, the industrial enterprises and the troops and the rural areas.

Owner:SHANDONG JIANZHU UNIV

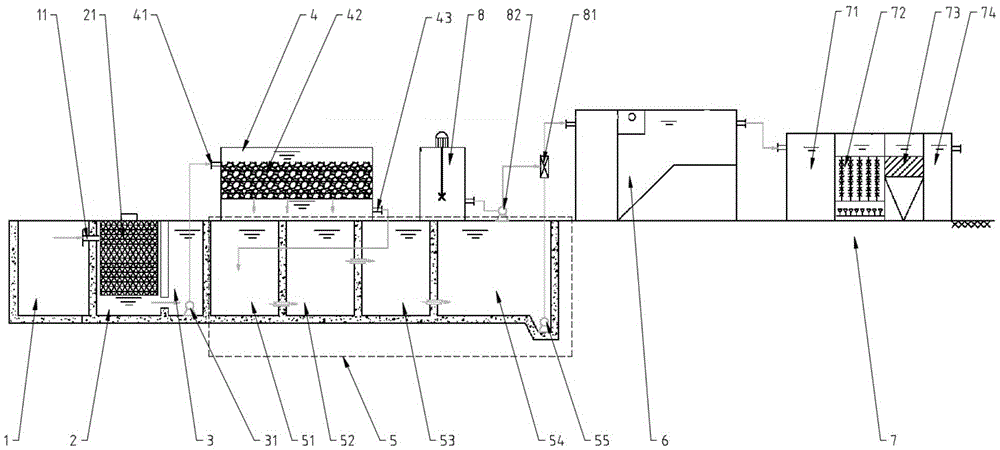

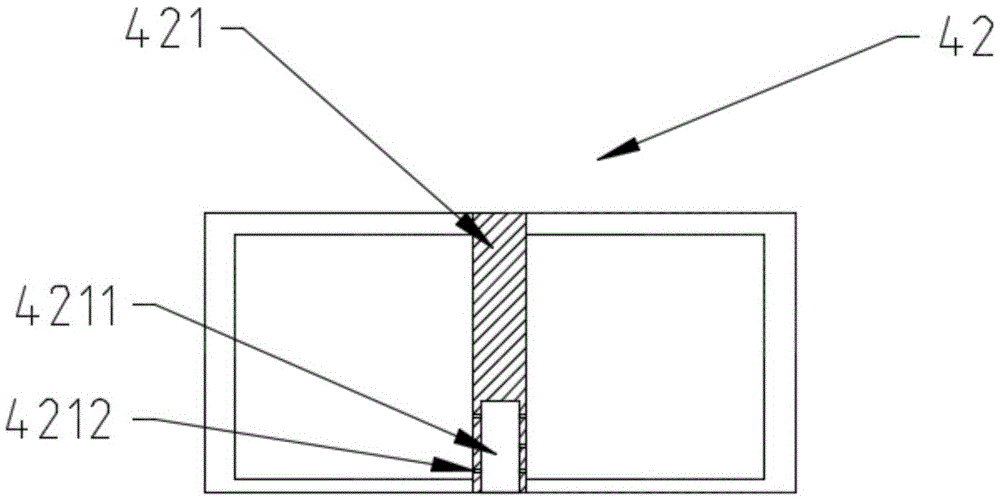

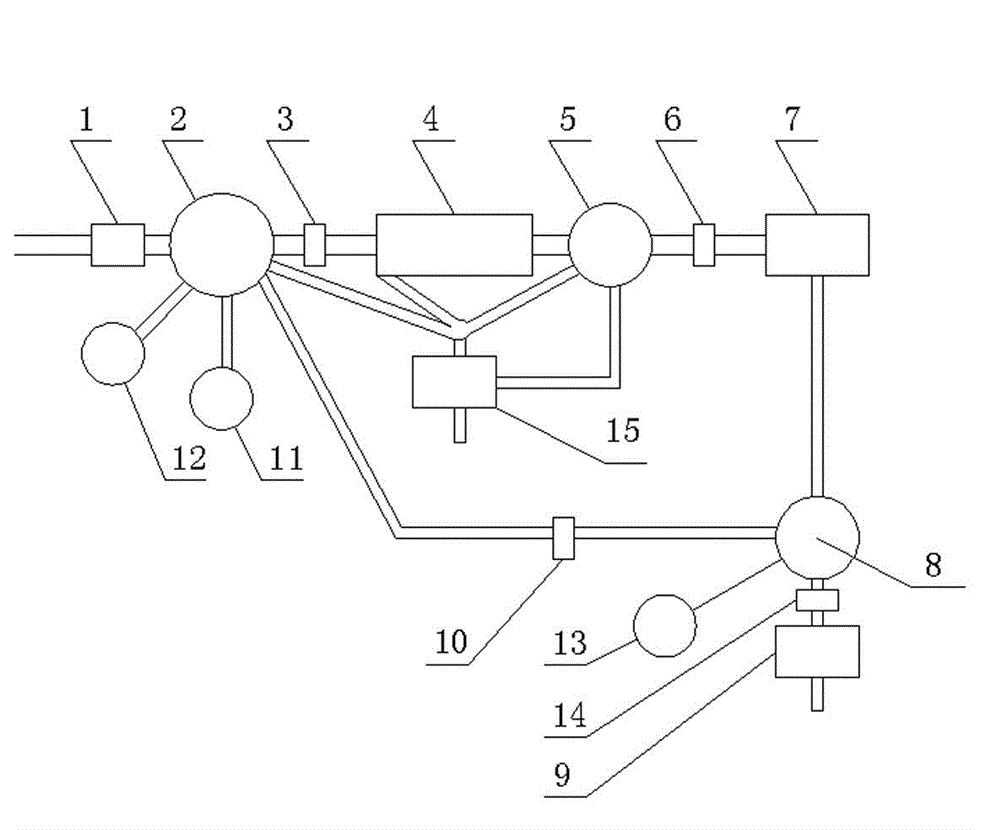

Slaughter wastewater treatment complete device and slaughter wastewater treatment method

ActiveCN105645688AReduce influent concentrationImprove biodegradabilityFatty/oily/floating substances removal devicesTreatment using aerobic processesTreatment completedSmall footprint

The invention discloses a slaughter wastewater treatment complete device and a method for treating wastewater through the device. The device comprises a water collecting basin, a first filtering basin, an oil separating basin, a second filter, a regulating basin, an air flotation device, an integrated biological treatment device and a dosing device. The technical principles of solid-liquid separation, hydrolytic acidification and aerobiotic treatment are adopted, and compared with slaughter wastewater treatment technologies such as a conventional biological method and a physical and chemical method, the device and the method have the advantages that the device can be combined and skid-mounted in a complete set mode, the equipment occupying area is small, the treatment efficiency is high, the one-time project investment is little, and the practicability is higher.

Owner:王祥 +1

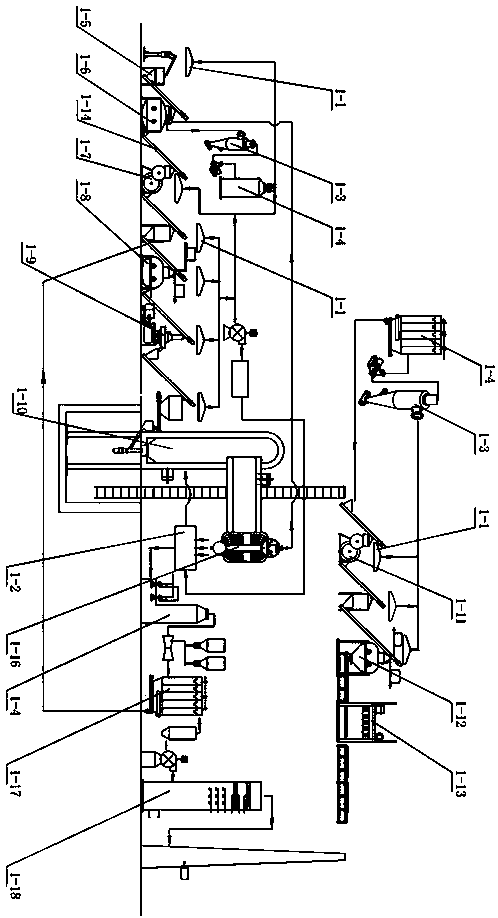

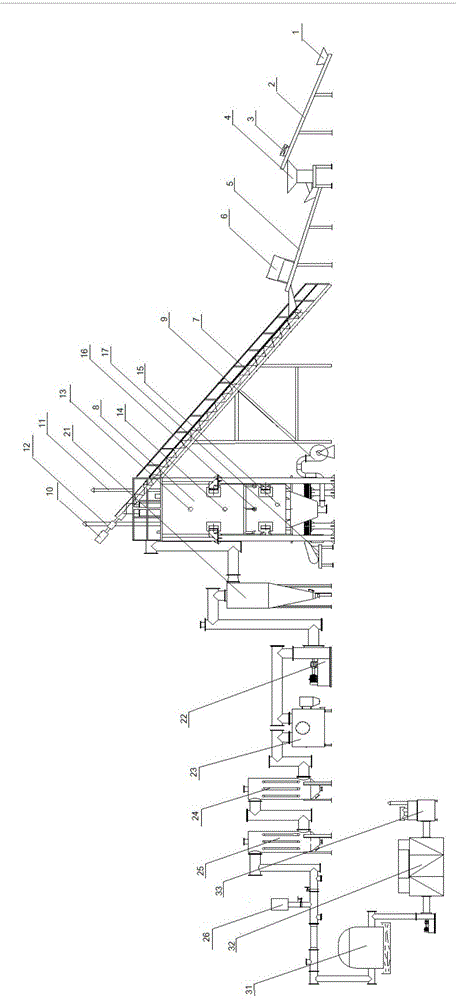

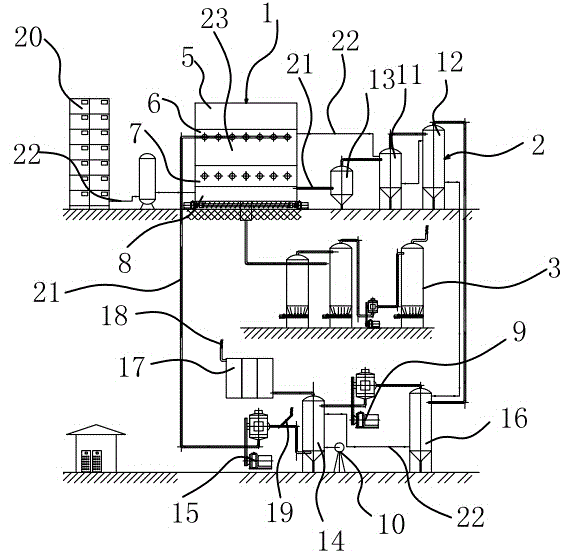

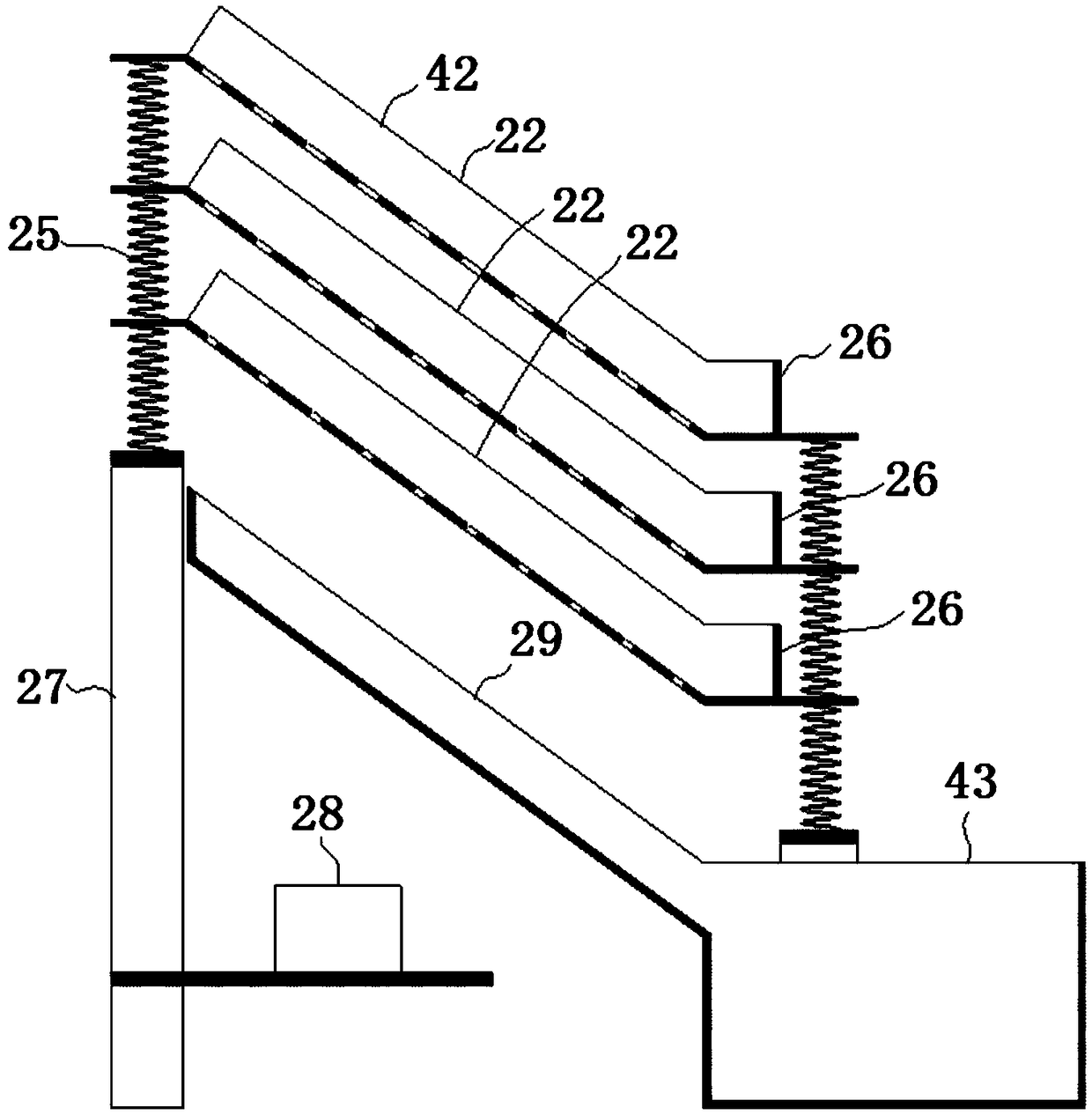

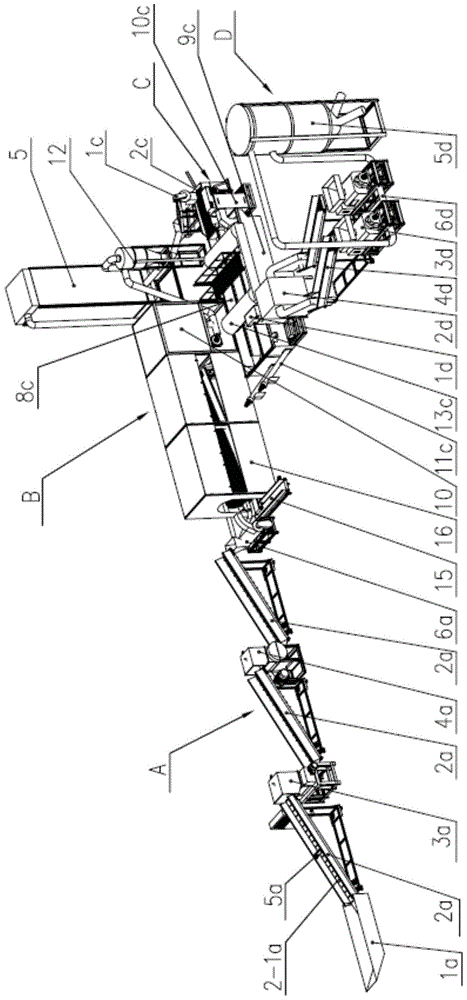

Solid household refuse pyrolysis and gasification power generation device

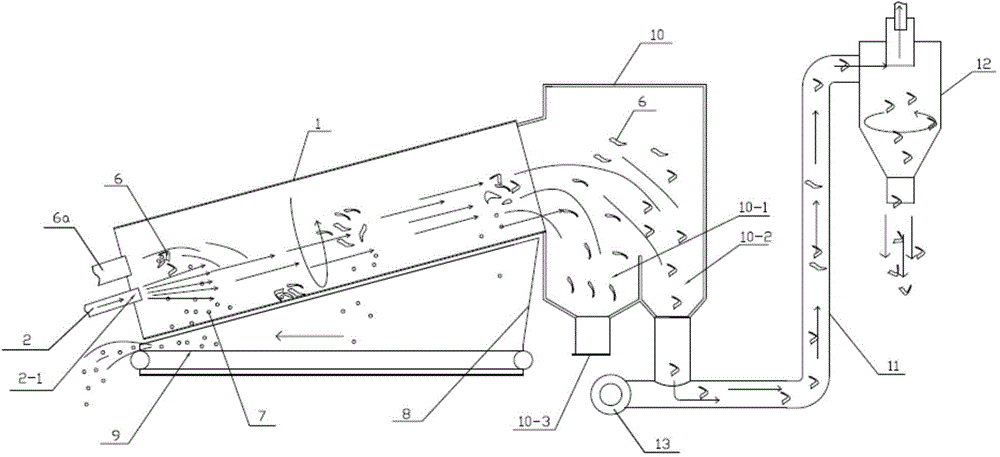

PendingCN107177380AFull pyrolysis and gasificationImprove gas production efficiencyTransportation and packagingSolid waste disposalCycloneTreatment completed

The invention relates to a solid household refuse pyrolysis and gasification power generation device. The solid household refuse pyrolysis and gasification power generation device is characterized by comprising a feeding tank (1), a magnetic separation conveying belt (2), a pulverizer (4), a spiral feeding machine (7), a gasifier (8), a cyclone removal device (21), a pressurizing induced draft fan (22), a water seal type dust removal explosion prevention device (23), a secondary decoking and cooling tower (24), a ternary decoking and cooling tower (25), a gas test fire head (26), a gas storage cabinet (31), a gas turbine generator (32) and a dust remover (33) which are serially connected with one another by pipes. The solid household refuse pyrolysis and gasification power generation device is high in universality of household refuse; requirements on household refuse composition on original refuse treatment are low; and complicated original refuse treatment procedures are reduced. The solid household refuse pyrolysis and gasification power generation device is simple to operate and use, stable in thermal efficient, high in gas yield and high in safety, and is harmless treatment complete equipment which can treat household refuse harmlessly, and further can carry out gasification by the household refuse secondarily.

Owner:福建龙迪环保设备科技有限公司

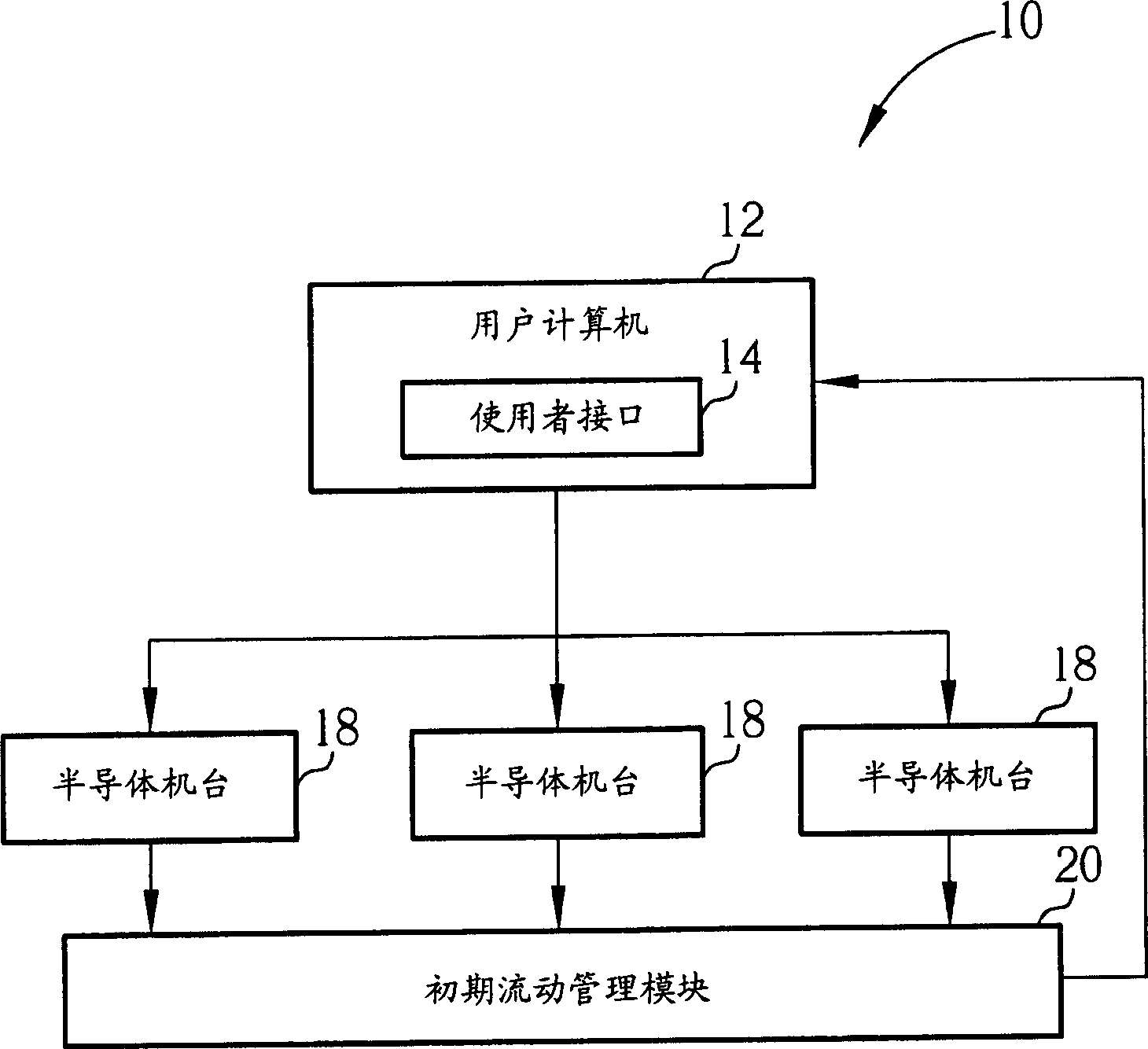

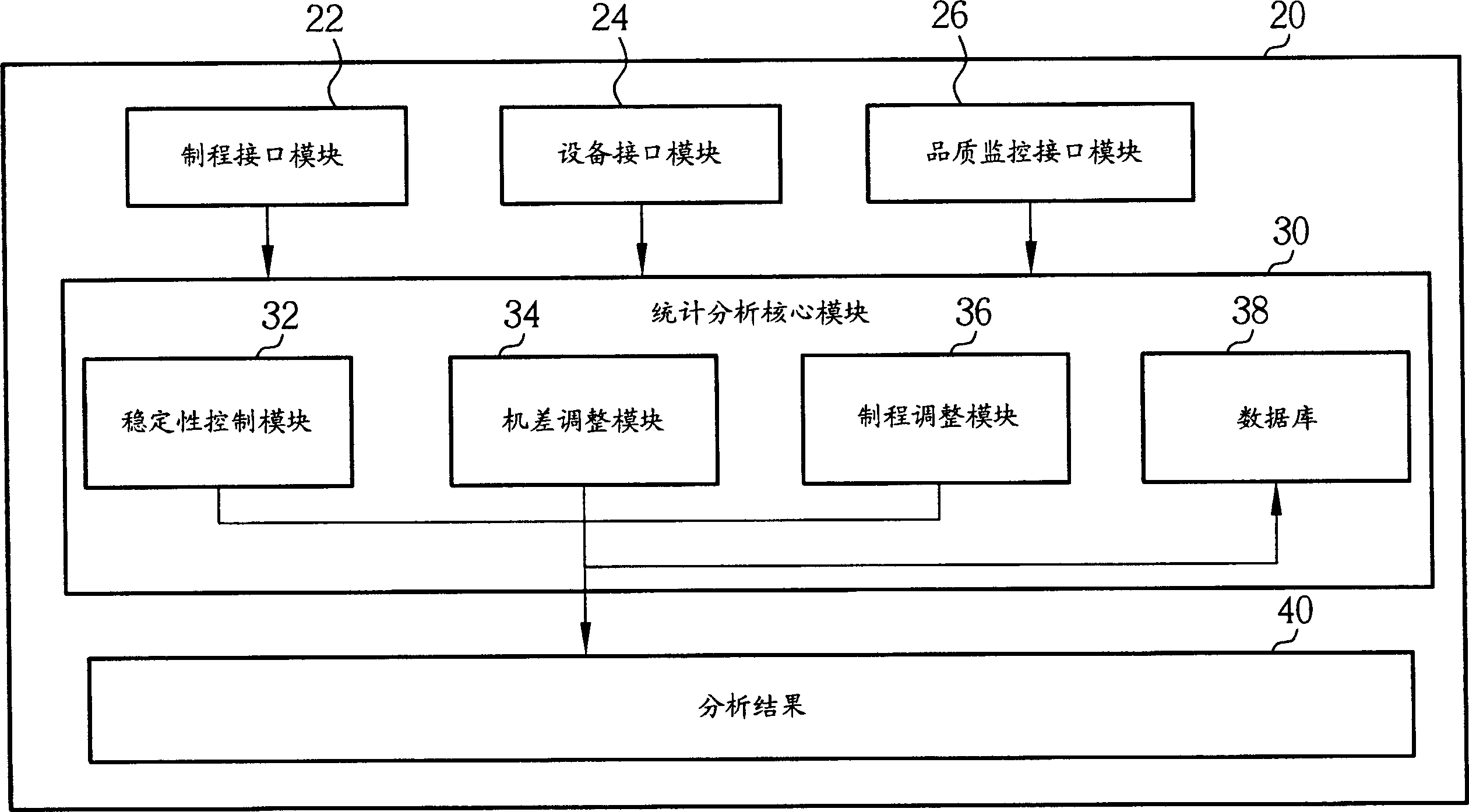

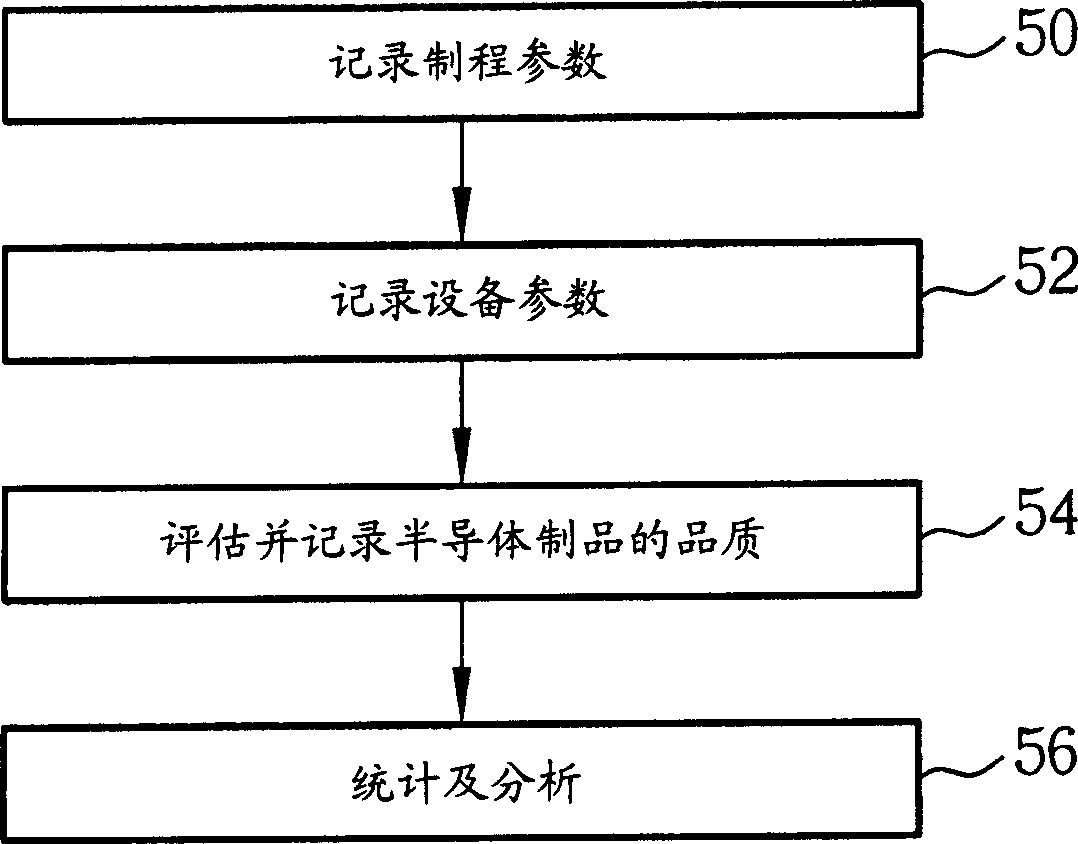

Method for early stage mobile management of semiconductor equipment and related system

InactiveCN1670905ASemiconductor/solid-state device manufacturingSpecial data processing applicationsTreatment completedBiochemical engineering

This invention provides a method and relative system of early stage drifting management for semiconductor productive platform, which contains recording every treatment parameter of every platform, recording relative equipment parameter, evaluating and recording the quality and relative measured parameter of treatment completed semiconductor products, and analyzing the relationship between every treatment parameter and equipment parameter and relative semiconductor products quality.

Owner:POWERCHIP SEMICON CORP

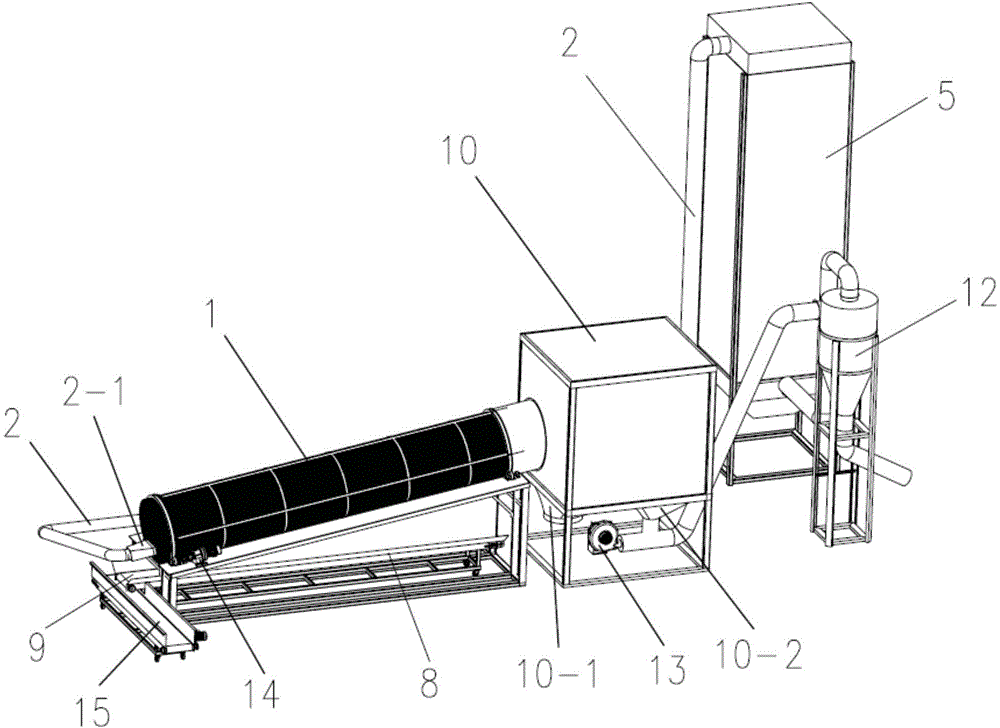

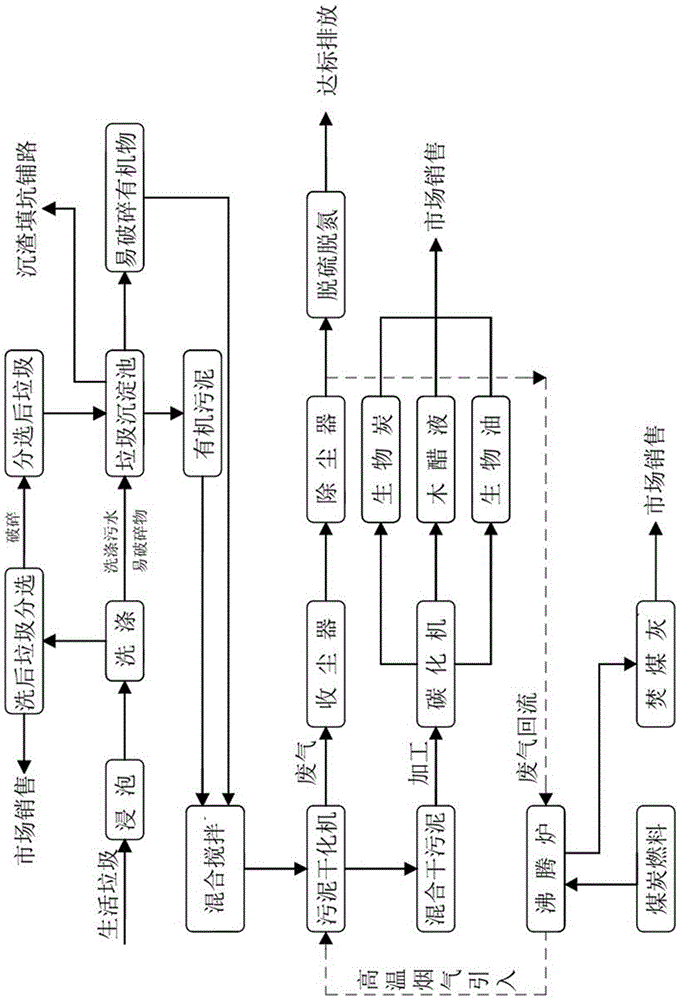

Household garbage commercialization treatment method and complete equipment

InactiveCN105772494AEasy site selectionImprove environmental safetyTransportation and packagingSolid waste disposalTreatment completedSoil organic matter

The invention relates to a household garbage treatment method and complete equipment.The household garbage commercialization treatment method comprises the processes of washing separating, organic matter desiccating and desiccated organic mixed sludge carbonizing, wherein washed, separated and dewatered organic sludge and dewatered and aired easily-crushed organic matter are stirred and mixed to be delivered into a rotary sludge desiccating machine for desiccating treatment, obtained desiccated organic mixed sludge with the water content of 7%-10% is subjected to carbonization treatment through a rotary sludge carbonizing machine, and charcoal, pyroligneous liquor and biological tar are generated to be sold on the market.The household garbage commercialization treatment complete equipment comprises garbage washing and separating equipment, organic mixed sludge desiccating treatment equipment and desiccated organic mixed sludge carbonizing treatment equipment; the garbage washing and separating equipment separates organic matter and inorganic matter in household garbage, the dewatered organic sludge and easily-crushed organic matter are fully mixed to be delivered into the rotary sludge desiccating machine for desiccating treatment, and the obtained desiccated organic mixed sludge is delivered into the rotary sludge carbonizing machine for carbonizing treatment.

Owner:柳建国

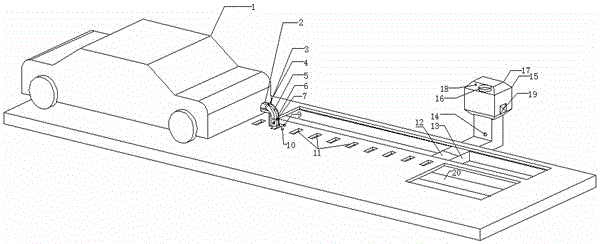

Vehicle tail gas centralized treatment complete equipment and method

PendingCN106774136ASolve pollutionEmission reductionDispersed particle separationProgramme control in sequence/logic controllersTreatment completedThroat

The invention provides vehicle tail gas centralized treatment complete equipment and method. The complete equipment comprises a vehicle smoke exhaust port connection lock throat, a telescopic adjusting device, a telescopic hose, a soft connector, a tail gas outlet sensor, a control box, a road gas suction opening sensor, a road PM2.5 and tail gas standard exceeding sensor, a road gas suction opening, a gas suction and drainage dual-purpose pipe, a tail gas concentration sensor, a tail gas treatment and purification device, a draught fan, an exhaust detection sensor and a PLC box. The invention further provides the vehicle tail gas centralized treatment method. By means of the complete equipment and method, high hazards, caused by vehicle tail gas to the nature, especially vehicle tail gas harm generated by bustling metropolis super-large-scale traffic jams, which are the root of haze can be solved.

Owner:深圳市世安菱卜环保科技有限公司

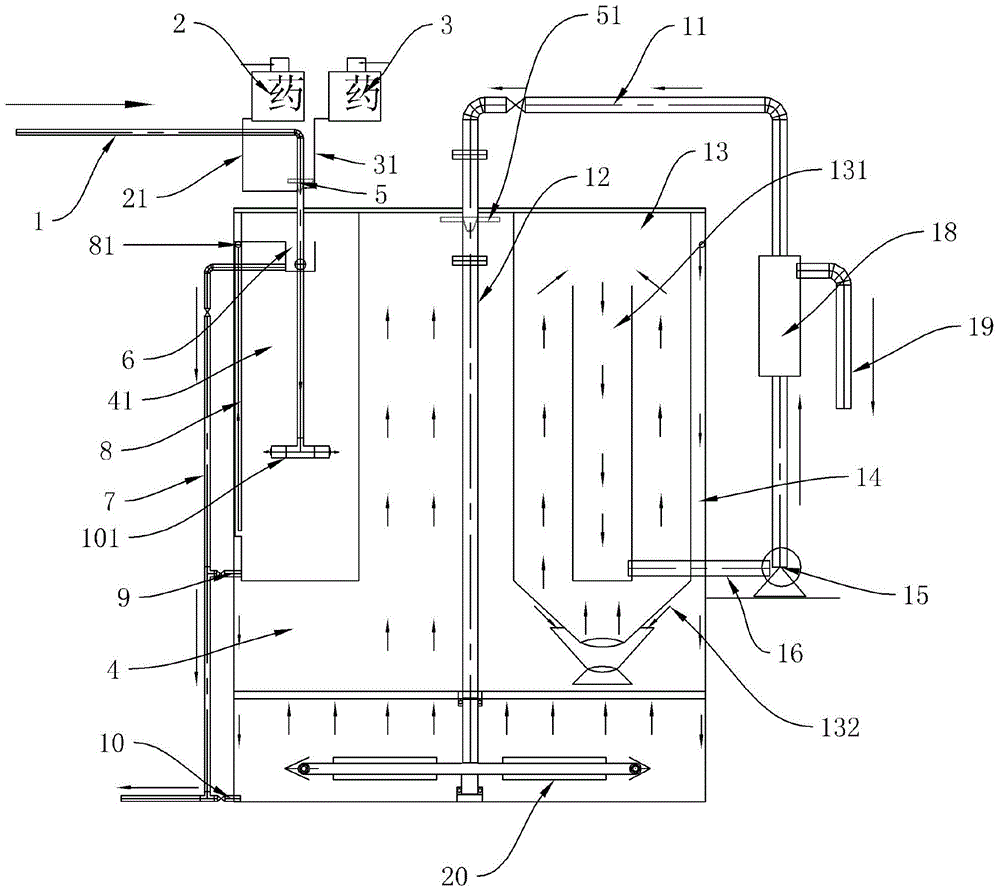

Sludge treatment complete equipment

ActiveCN102503058ARapid sterilizationDeodorize quicklySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTreatment completedSlag

Sludge treatment complete equipment comprises a to-be-processed sludge metering and feeding device, a stirring modified device, a metering and feeding device, a heating, sterilizing and deodorizing device, a transit tank, a metering and pumping device I, a dehydrating device I, a liquid bath, a dehydrating device II, a metering and water-feeding device, a drug A metering and administrating device, a drug B metering and administrating device, a drug C metering and administrating device, a metering and pumping device II and a waste gas collecting and treating device. The sludge treatment complete equipment has the advantages that the treatment flow time is short, the environment protection is achieved during treatment, no secondary pollution exists, the energy consumption during treatment is low, the cost is low, and dewatered sludge obtained and heavy metal slag can be comprehensively utilized.

Owner:湖南隆辉环保有限公司

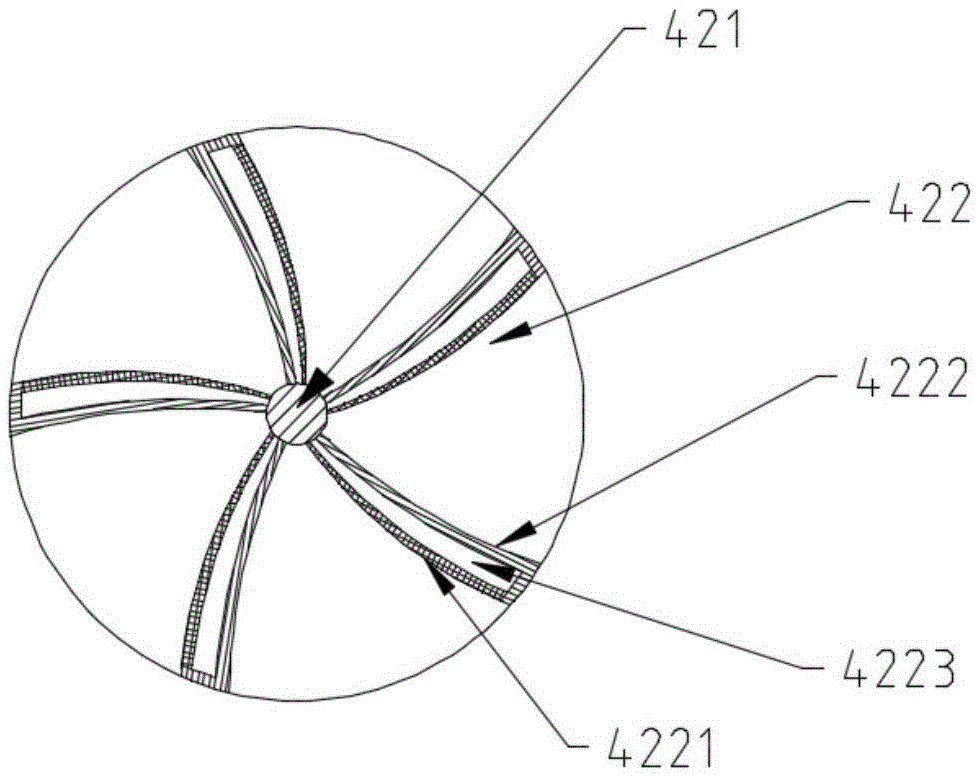

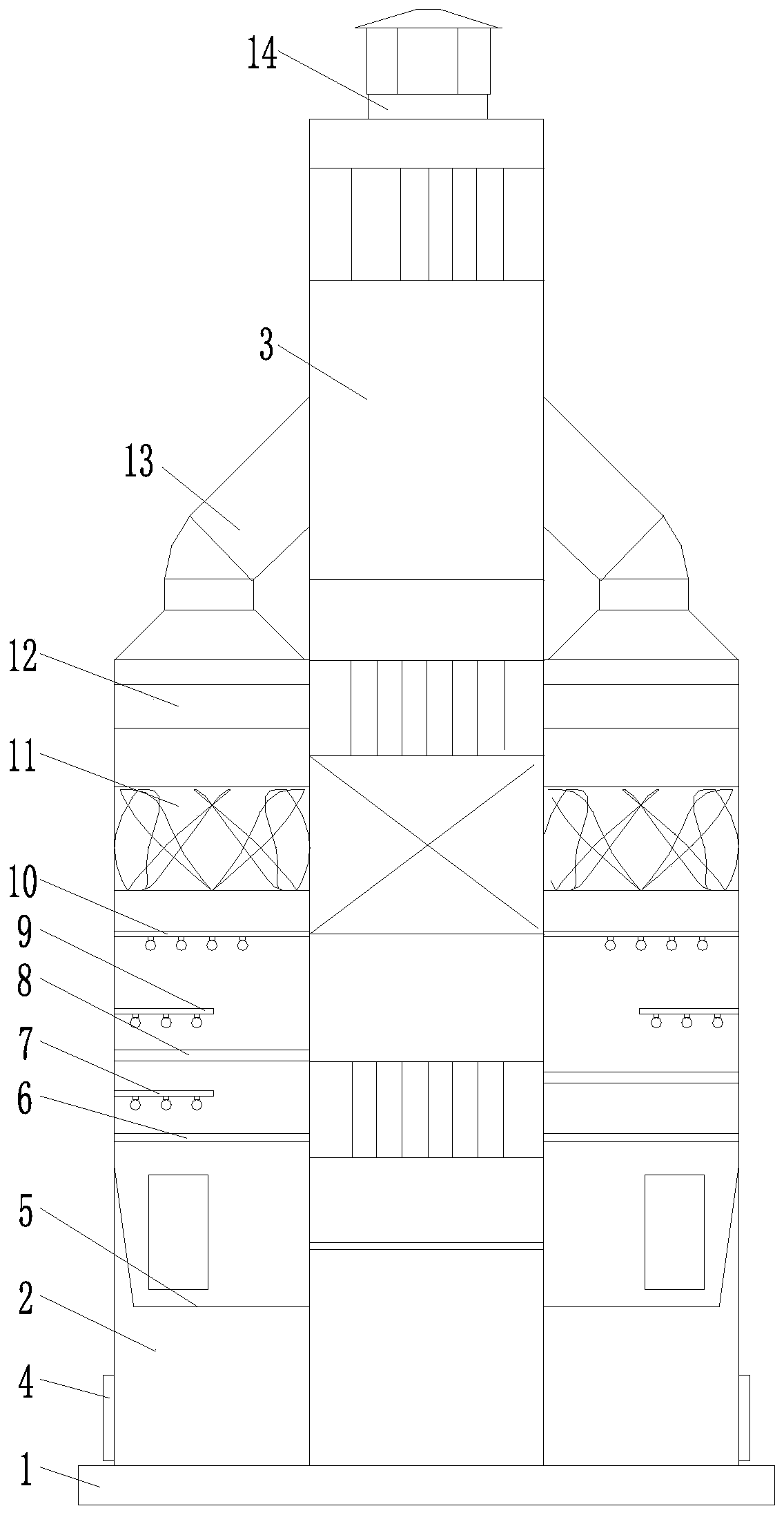

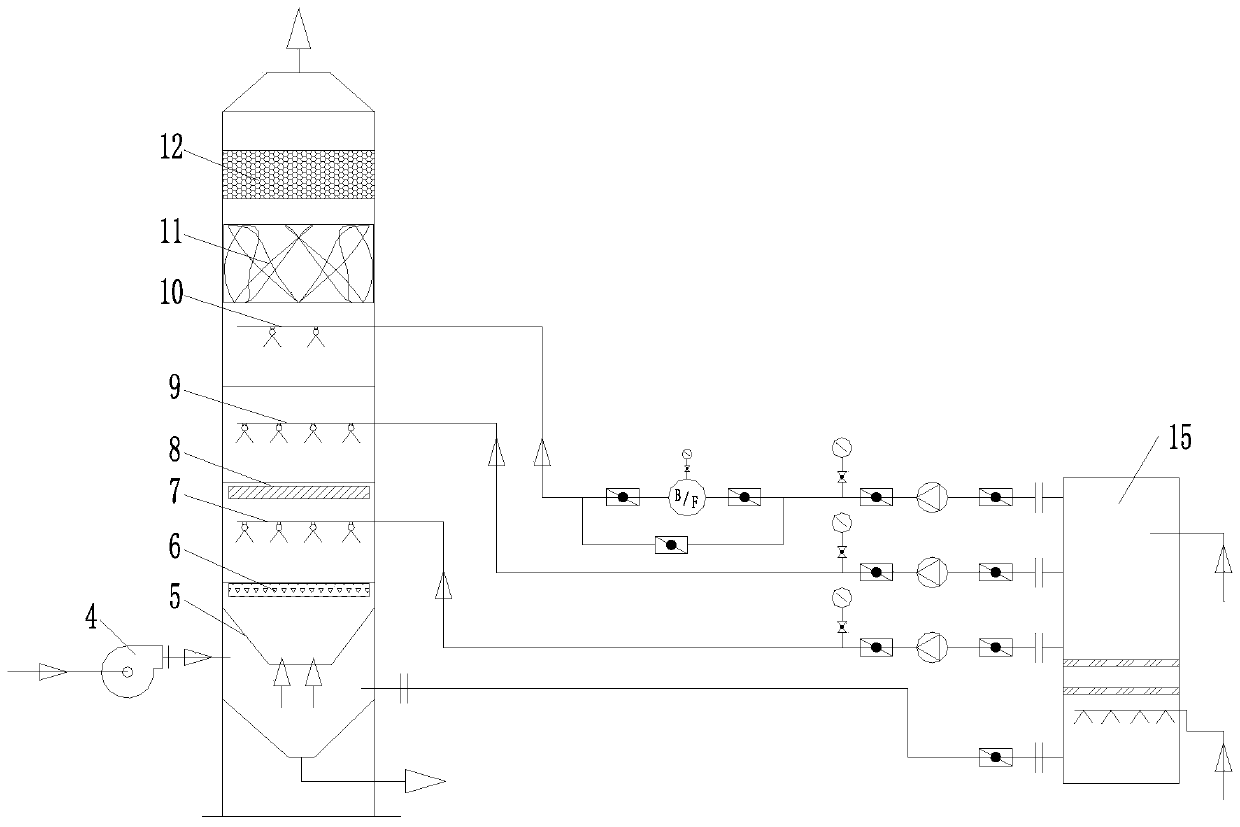

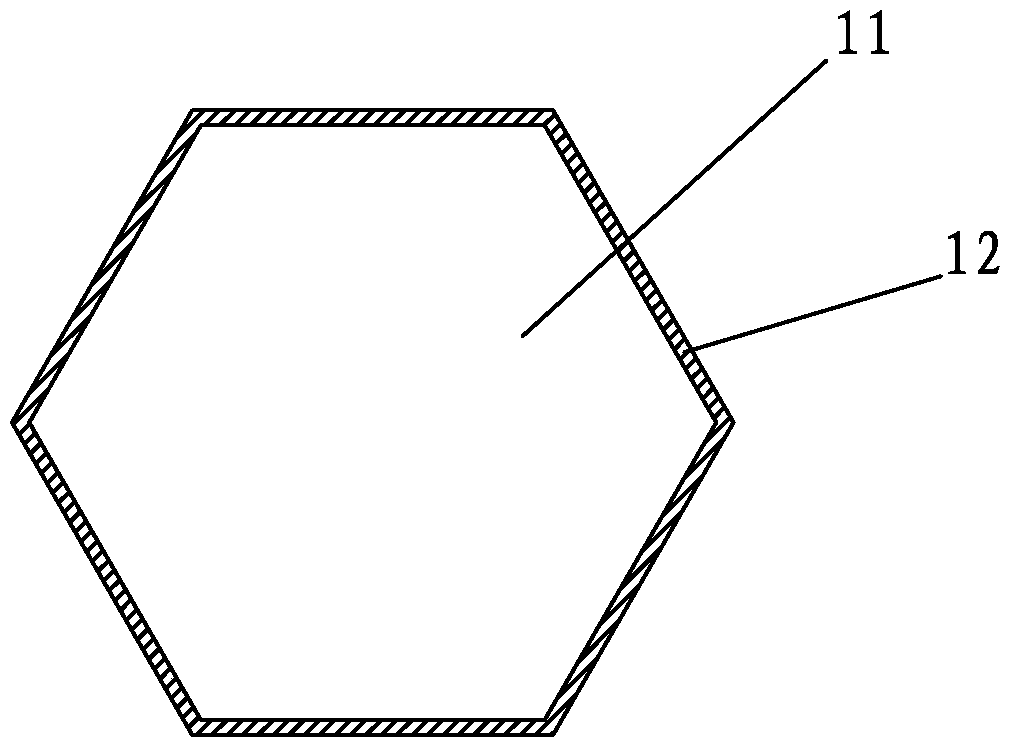

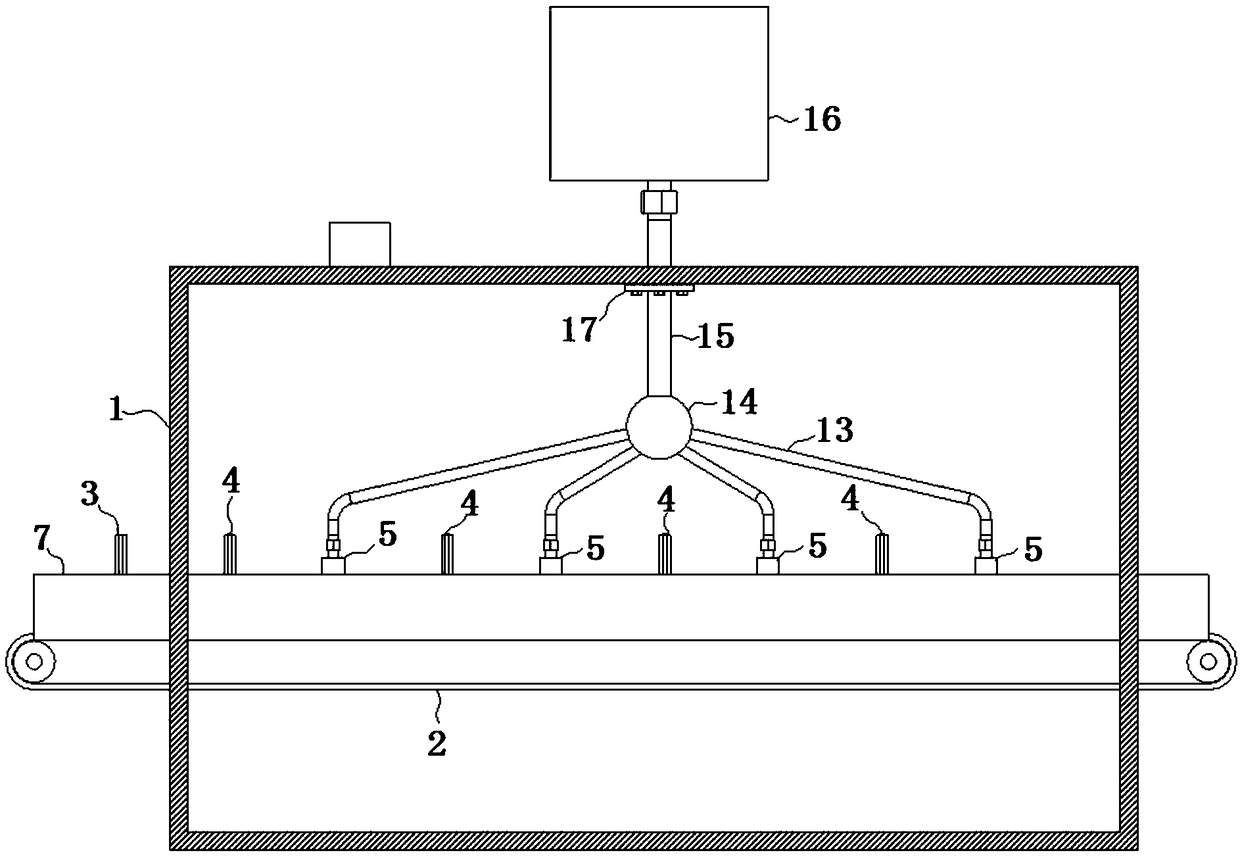

Nano-micro bubble apparatus of industrial organic exhaust gas purification treatment complete apparatus

InactiveCN110496520AHigh removal rateEasy to operateDispersed particle separationTreatment completedSmall footprint

The invention relates to the technical field of exhaust gas purification, and especially relates to a nano-micro bubble apparatus of an industrial organic exhaust gas purification treatment complete apparatus. The nano-micro bubble apparatus comprises a bottom plate, purification towers, centrifugal high-pressure fans, conical flow equalizers, flow equalizing air dispersing plates, first-layer spiral spraying devices, rotational flow plates, second-layer spiral spraying devices, micro-bubble generators, spiral water baffle plates and filler water baffle plates, the number of the purification towers is two, the two purification towers are symmetrically and fixedly connected to two sides of the top of the bottom plate, the centrifugal high-pressure fans are fixedly connected to one sides ofthe bottoms of the purification towers, and the air exhaust ends of the centrifugal high-pressure fans are communicated with the bottoms of the side surfaces of the purification towers. The nano-microbubble apparatus is suitable for the industries of spraying, coating, printing, chemical engineering and coating production, does not need to be preprocessed, can be used for organic exhaust gas withvarious concentrations, and has the advantages of high removal rate, simplicity in operation, low operation cost, low construction cost, short construction period, small occupied area, stability andreliability in facility operation, and simplicity and convenience in maintenance.

Owner:广东创智智能装备有限公司

Slaughter wastewater treatment complete device and slaughter wastewater treatment method

ActiveCN105645688BReduce influent concentrationImprove biodegradabilityFatty/oily/floating substances removal devicesTreatment using aerobic processesTreatment completedSmall footprint

The invention discloses a slaughter wastewater treatment complete device and a method for treating wastewater through the device. The device comprises a water collecting basin, a first filtering basin, an oil separating basin, a second filter, a regulating basin, an air flotation device, an integrated biological treatment device and a dosing device. The technical principles of solid-liquid separation, hydrolytic acidification and aerobiotic treatment are adopted, and compared with slaughter wastewater treatment technologies such as a conventional biological method and a physical and chemical method, the device and the method have the advantages that the device can be combined and skid-mounted in a complete set mode, the equipment occupying area is small, the treatment efficiency is high, the one-time project investment is little, and the practicability is higher.

Owner:王祥 +1

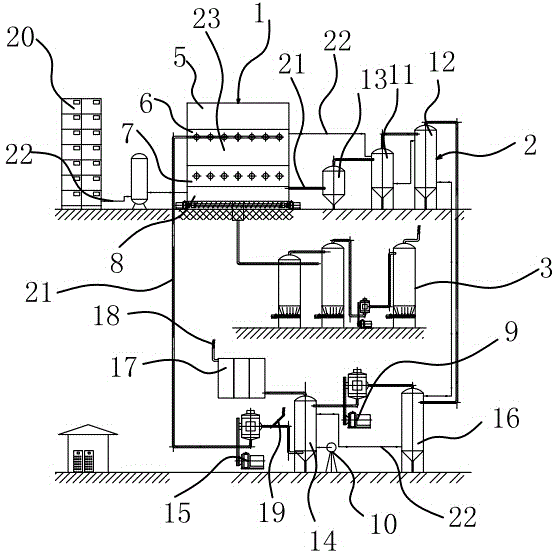

Garbage treatment complete equipment

ActiveCN105987384AAchieving self-powered dry combustionSave energyIncinerator apparatusTreatment completedCombustion system

The invention provides garbage treatment complete equipment, and belongs to the technical field of garbage treatment. The garbage treatment complete equipment solves the problem that the treating performance of existing garbage treatment complete equipment is poor. The garbage treatment complete equipment comprises a pyrolysis gasification burning system, a circulation water cooling heat exchange system and a smoke secondary burning system; the pyrolysis gasification burning system is connected with the circulation water cooling heat exchange system through a gas conveying pipe, and the circulation water cooling heat exchange system is connected with a heat source reusing system through a cooling water pipe; and a slag classifying system is connected with the pyrolysis gasification burning system through a material conveying pipe, one end of the smoke secondary burning system is connected with the circulation water cooling heat exchange system through a gas conveying pipe, and the other end of the smoke secondary burning system is connected with the pyrolysis gasification burning system through a gas conveying pipe. By means of the garbage treatment complete equipment, the garbage treatment performance can be improved.

Owner:深圳市鑫旭源环保有限公司

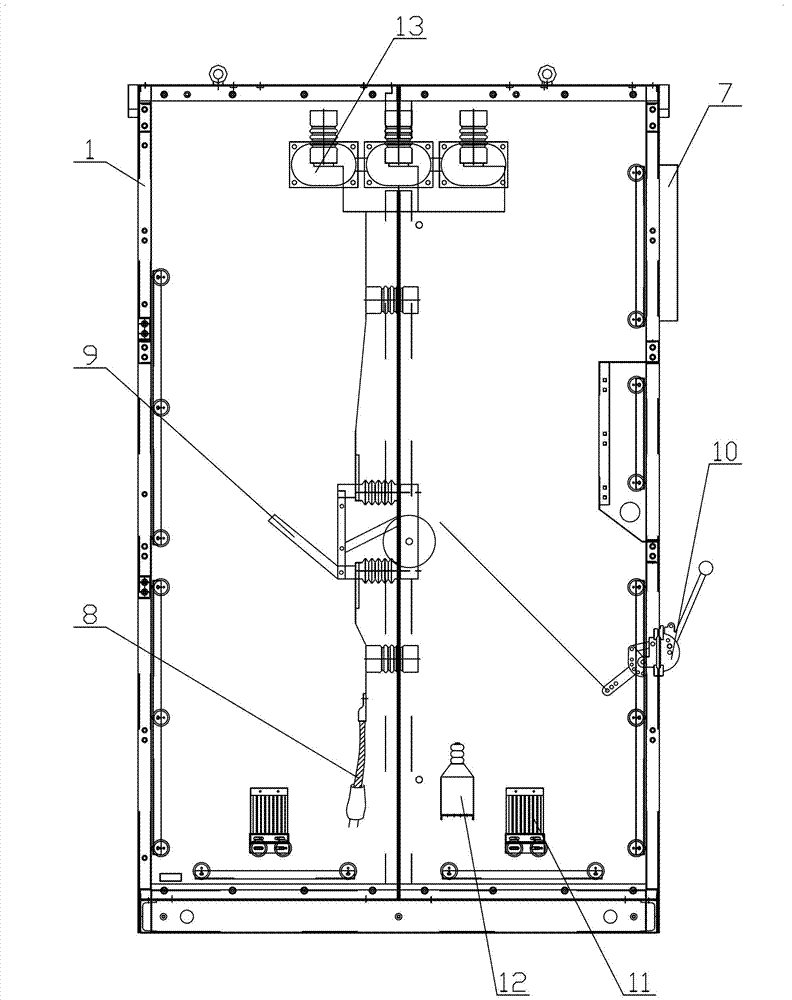

Dynamic reactive power compensation and harmonic treatment complete equipment

InactiveCN102820663ASolve the costSolve efficiency problemsReactive power adjustment/elimination/compensationReactive power compensationPower compensationTreatment completed

The invention discloses dynamic reactive power compensation and harmonic treatment complete equipment which comprises a capacitor box, wherein an incoming cabinet which is matched with the capacitor box is separately arranged, the incoming cabinet and the capacitor box are electrically connected with each other through a bus, the capacitor box comprises an electric reactor, a capacitor, a discharge coil and a lightning arrester, the electric reactor is connected with the capacitor in series through a connecting line, the discharge coil is connected with the capacitor in parallel, and the lightning arrester is connected with a circuit in a star shape. The dynamic reactive power compensation and harmonic treatment complete equipment has the excellent technical and economic indexes of reliable structure, simple manufacturing technology, advanced product performance, low cost and the like, and is used for solving the problems of high cost, low production efficiency, high temperature rise, loud noise, difficulty for application in practical production and the like of various harmonic treatment devices at present.

Owner:WUXI SHUANGLI POWER EQUIP CO LTD

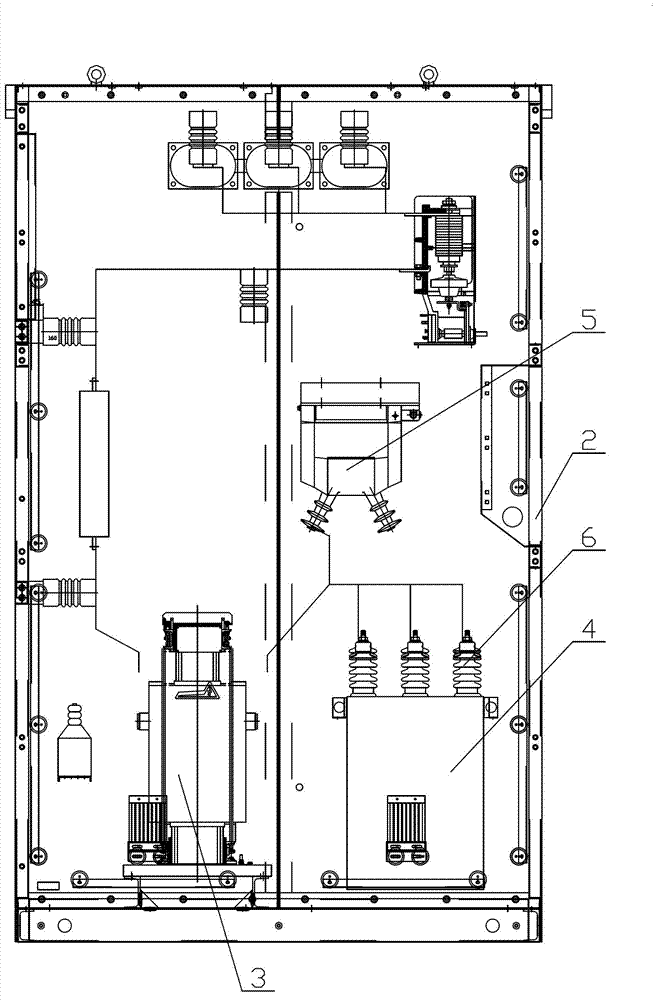

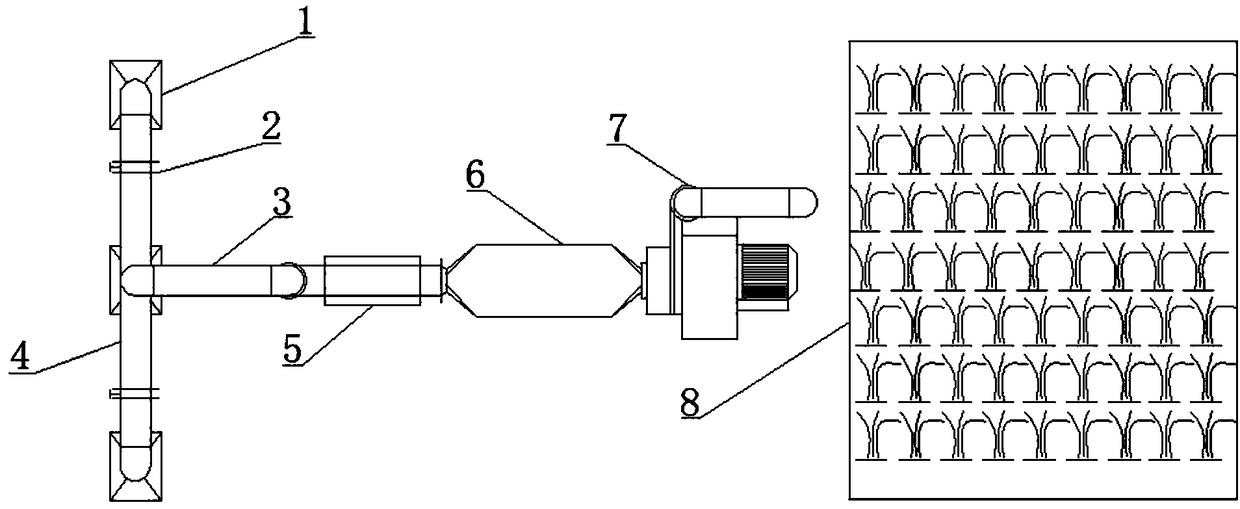

Energy-saving and environmental-friendly biomass fuel manufacturing device

The invention relates to a manufacturing device, and more specifically, relates to an energy-saving and environmental-friendly biomass fuel manufacturing device comprising a whole machine bracket, a feeding plate, a power mechanism, a transmission mechanism, a crushing mechanism, a connecting bracket, a circular connecting rod, a sliding baffle, a short connecting rod, a long connecting rod, an extrusion mechanism, an extrusion connecting rod, an extrusion bracket, a shifting fork and containing boxes; biomass can be subjected to crushing treatment, and the biomass having crushing treatment completed can enter the extrusion bracket through the connecting bracket; when the biomass in the extrusion bracket reaches a certain weight, the extrusion bracket extrudes a compression spring to movedownward to drive the sliding baffle to block a discharge outlet, and the biomass cannot enter the extrusion bracket; when the extrusion bracket moves downward, side teeth are pushed to be meshed withan extrusion pulley, an extrusion shaft transmits power to drive an extrusion crank to rotate to push an extrusion plate wheel to extrude the biomass to mold; when the containing boxes are taken down, a vortex spring extrudes the extrusion crank to reset, and the masses of the molded biomass in all the containing boxes are the same.

Owner:浙江蓝天知识产权运营管理有限公司

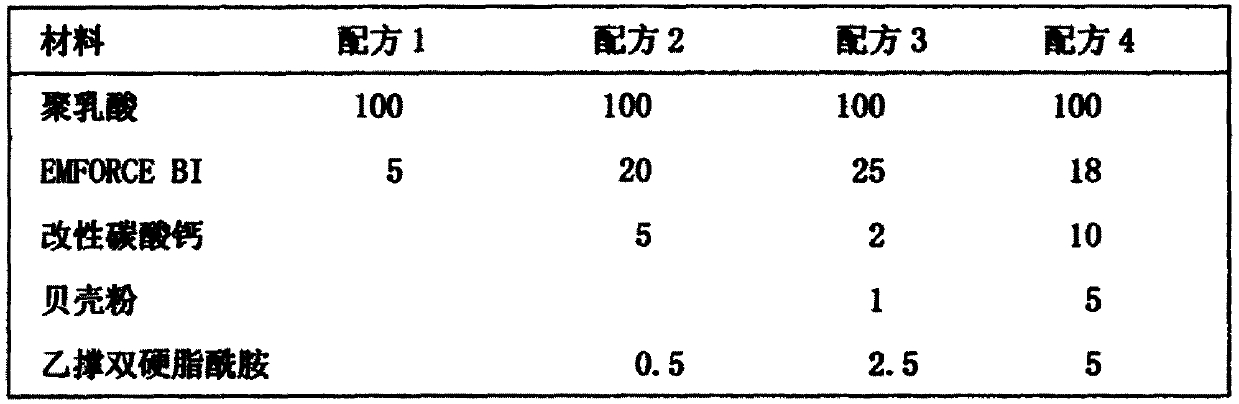

Disposable medical instrument prepared from full-degradable base material and method

InactiveCN107915968AReduce the temperatureReduce power consumptionEnvironmental resistanceAdditive ingredient

The invention provides a disposable medical device and method prepared from a fully degradable base material. Degradable disposable medical devices are made of degradable polymer main materials, reinforcing agents, etc. The injection molding process is: feed inlet 145-165°C, compression section 150-170°C, metering section 155-175°C, nozzle 155°C ‑175°C; mold temperature: 10‑45°C; injection pressure: 45‑100Mpa; injection cycle: 36‑58 seconds; dwell time: 0 seconds; screw speed: 180 rpm; obtained degradation The performance of the disposable medical device meets the requirements of the relevant products of the national pharmaceutical industry standards, and the injection temperature during production is much lower than that of petroleum-based plastics, which effectively saves electricity consumption, does not need to be incinerated after use, avoids polluting the environment, and can be composted Environmental and other treatments are completely degraded by microorganisms to achieve the goals of environmental protection, energy saving, safety and health, and the benefit of human beings.

Owner:宁波昆特医疗设备有限公司

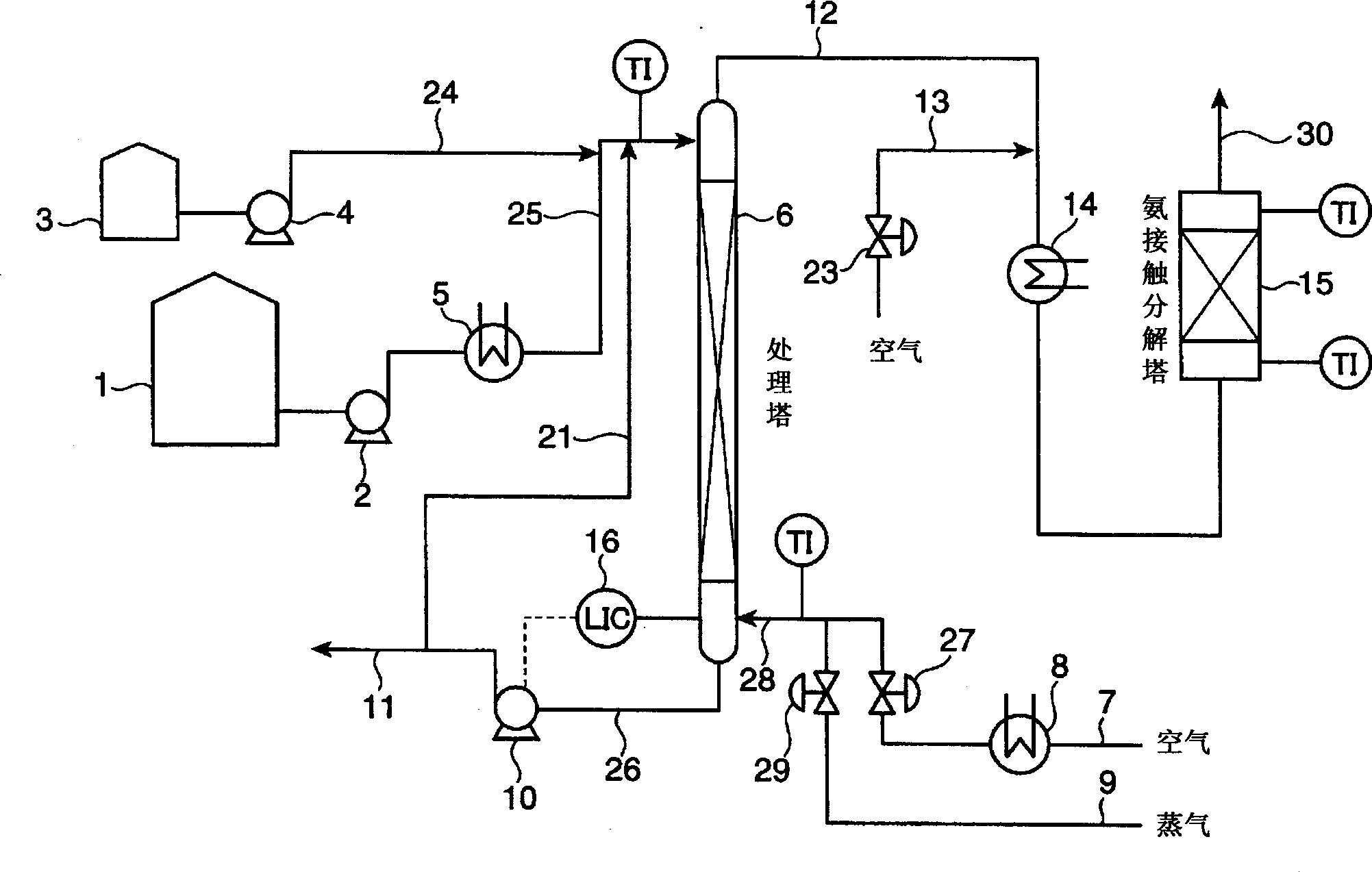

Waste water treatment process and treatment appts.

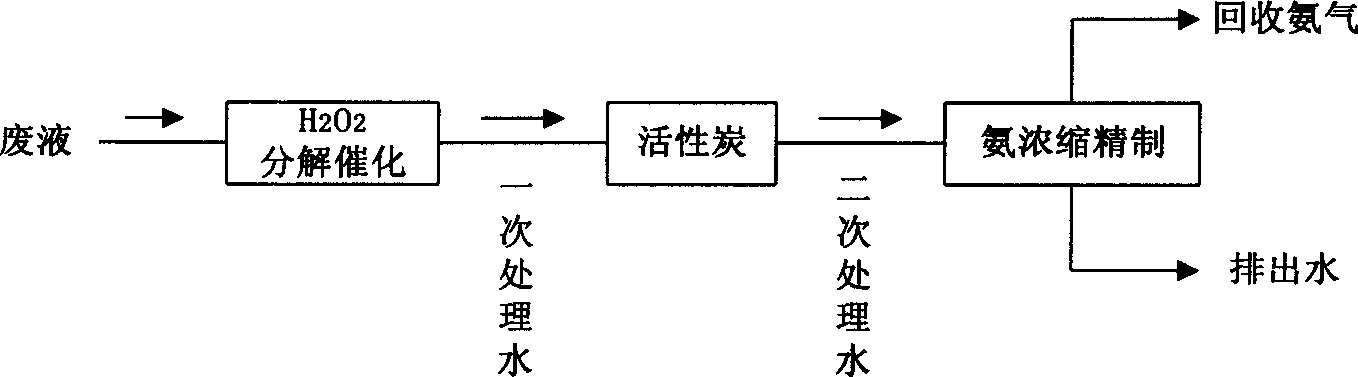

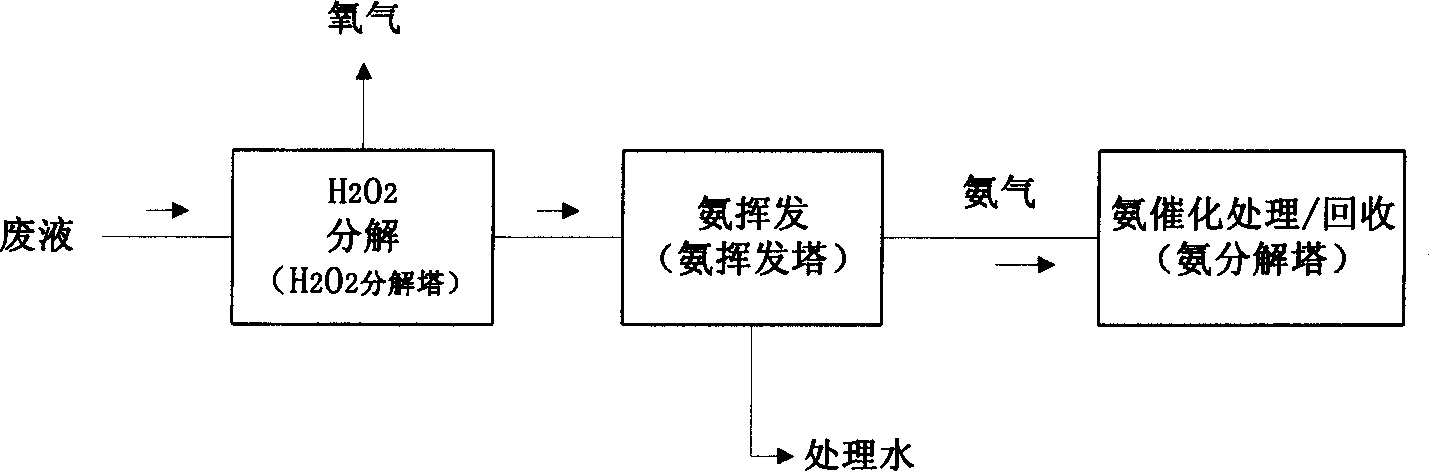

InactiveCN1369443ASuppress generationWater contaminantsMultistage water/sewage treatmentHydrogen peroxide breakdownTreatment completed

PURPOSE: A wastewater treatment method and a wastewater treatment apparatus are provided to efficiently treat wastewater containing hydrogen peroxide and ammonia using a treatment column. CONSTITUTION: In an apparatus for treating wastewater containing hydrogen peroxide and ammonia, the wastewater treatment apparatus is characterized in that the treatment apparatus comprises a treatment column (6) in which a packing material having hydrogen peroxide decomposition catalytic function is installed, on the upper part of which a wastewater supply member for supplying the wastewater is installed, and on the lower part of which a gas supply member for supplying a gas for diffusion and a discharge member for discharging treatment completed water are installed, wherein the treatment column decomposes hydrogen peroxide in wastewater contacted with the packing material, exhausts an ammonia contained gas and discharges the treatment completed water at the same time.

Owner:NIPPON SHOKUBAI CO LTD

Diamond tool with metallized diamond surface and preparation method thereof

PendingCN108823532AImprove effective utilizationIncrease profitVacuum evaporation coatingSputtering coatingTreatment completedTitanium metal

The invention discloses a diamond tool with metallized diamond surface and a preparation method thereof, wherein the preparation method comprises the following steps: 1) selecting a diamond tool matrix, wherein the matrix is a specific metal-series pre-alloyed powder, and the specific metal comprises at least two metal components; 2) firstly carrying out film plating treatment on the diamond surface with titanium powder, and followed by, carrying out film plating treatment with at least one metal except titanium metal sequentially, wherein at least one metal is selected from at least two metalcomponents; 3) mixing the diamond having film plating treatment completed with the selected diamond tool matrix to form a required mixture; and 4) carrying out hot-press sintering of the mixture to produce the diamond tool. The bonding force between the diamond and the metal matrix can be improved by carrying out film plating treatment on the diamond surface with different metals, so as to increase the holding force of the bonder matrix to the diamond, increase the effective utilization rate of the diamond and improve the sharpness and life of the tool.

Owner:泉州众志金刚石工具有限公司

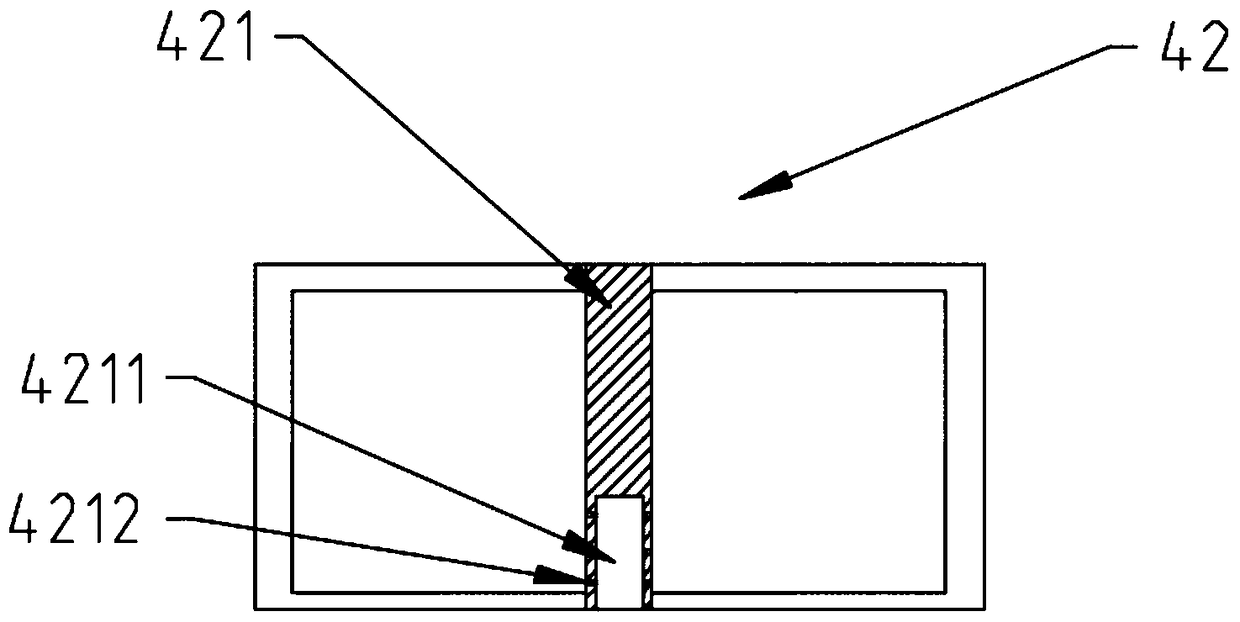

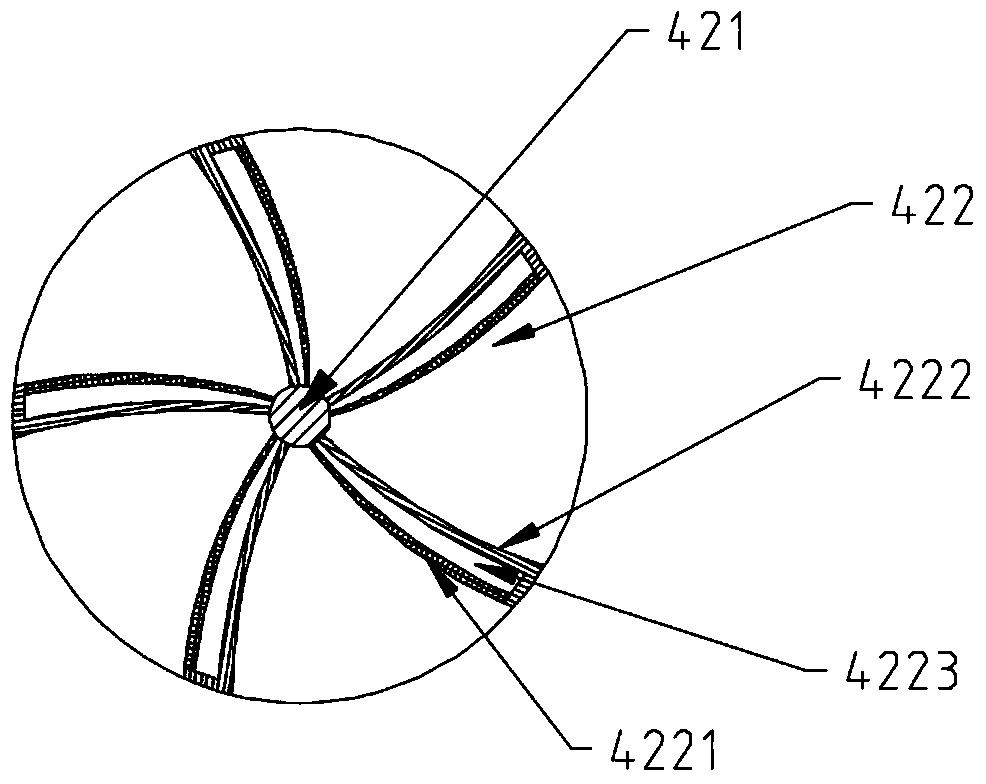

Low-energy-consumption multifunctional membrane biological treatment complete equipment

InactiveCN104828930AProcessing is no longer cumbersomeAchieve separationBiological water/sewage treatmentTreatment completedImpeller

The invention discloses low-energy-consumption multifunctional membrane biological treatment complete equipment. The complete equipment comprises a water inlet pipe, which stretches into a scum separating chamber, the opening in the end in the scum separating chamber is provided with a diverging pipe, and a certain angle is formed between the diverging pipe and the water inlet pipe. The bottom of the scum separating chamber is provided with a first sludge discharge pipe, the top is provided with a scum collecting tank, and the scum collecting tank is connected to a scum discharge pipe. The side wall of the scum separating chamber is provided with a water distribution pipe, the end in the scum separating chamber of the water distribution pipe is arranged on the bottom of the scum separating chamber, the leading-out end is connected to the leading-out tank of a reaction chamber, and the opening end of the leading-out tank is arranged on the bottom of the reaction chamber. A precipitation area is arranged in the reaction chamber, a leading-out chamber is arranged in the precipitation area, the bottom is provided with a slope; the bottom of the leading-out chamber is connected to a filter device containing a filter membrane through a second water pipe, and the water outlet end of the filter device is connected to a water outlet pipe. The leading-out chamber is connected to a water pump through a connection water pipe, the water outlet end of the water pump is connected to the top end of a dynamic pipe, and the bottom end of the dynamic pipe is connected to an impeller.

Owner:重庆市艳阳环保工程有限公司

Circulation water cooling heat exchange system in garbage treatment complete equipment

The invention provides a circulation water cooling heat exchange system in garbage treatment complete equipment, and belongs to the technical field of garbage treatment. The circulation water cooling heat exchange system solves the technical problem that the treating performance of existing garbage treatment complete equipment is poor. The equipment comprises a pyrolysis gasification burning system, the circulation water cooling heat exchange system and a heat source reusing system; the pyrolysis gasification burning system can convey gas formed after garbage pyrolysis gasification into the circulation water cooling heat exchange system through a gas conveying pipe; the circulation water cooling heat exchange system comprises an induced draft fan, a water pump and a plurality of heat exchangers, one end of the induced draft fan is connected with the pyrolysis gasification burning system through a gas conveying pipe, the other end of the induced draft fan is connected with one heat exchanger through a gas conveying pipe, and the heat exchanger also penetrates a garbage drying bin through a cooling water pipe to be connected with the heat source reusing system; and the water pump is connected with all heat exchangers through cooling water pipes. By means of the circulation water cooling heat exchange system, the garbage treatment performance can be improved.

Owner:深圳市鑫旭源环保有限公司

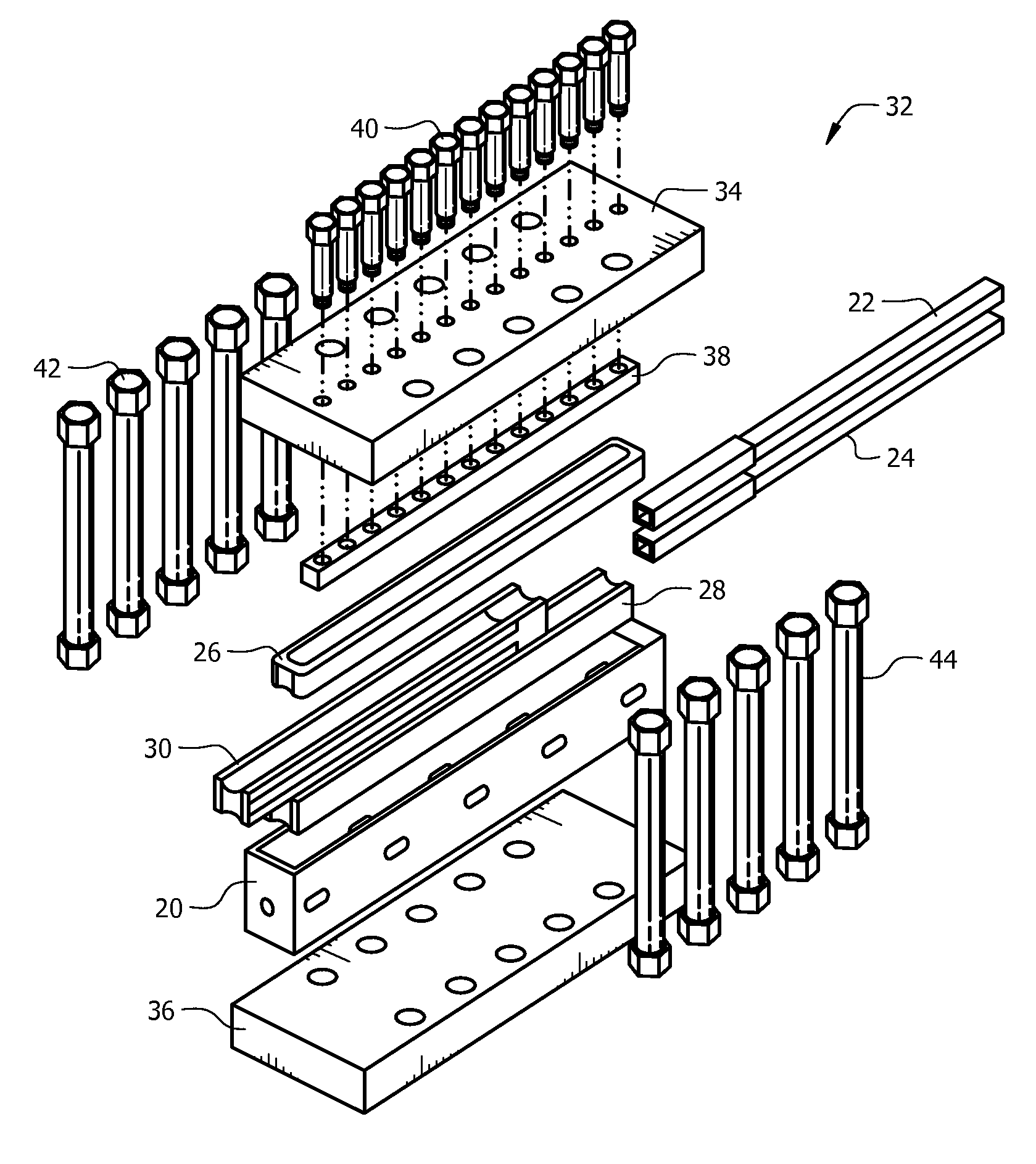

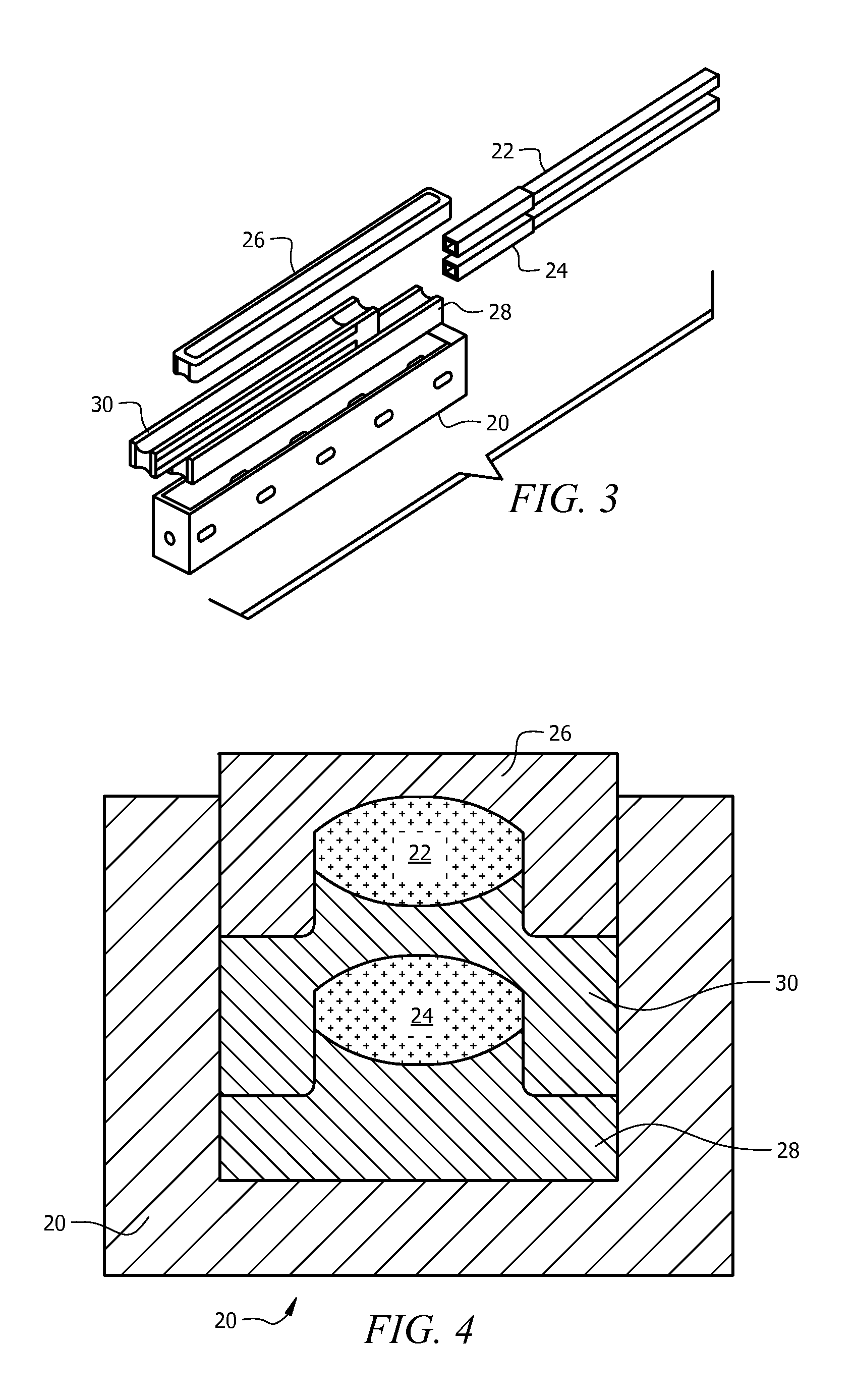

Solderless cable-in-conduit-conductor (CICC) joint

InactiveUS7977573B1Reduce DC resistanceLow magnetic fieldSoldered/welded conductive connectionsSuperconductor detailsTreatment completedEngineering

A cable-in-conduit-conductor (CICC) joint for use with a hybrid magnet. An elongate copper member is disposed in sandwiched relation between a first and second cable that are disposed in parallel, spaced apart relation to one another. A first elongate member is disposed in overlying relation to the first cable and a second elongate member is disposed in underlying relation to the second cable. All of the parts are positioned within a joint box, and the joint box is sandwiched between first and second flat plates that are interconnected to one another by elongate bolts. Tightening the bolts compresses the parts within the joint box. A heat treatment completes the solderless joint.

Owner:FLORIDA STATE UNIVERSITY

Sludge treatment complete equipment provided with sludge pre-drying device and method of sludge treatment complete equipment

ActiveCN109160710AEasy to handleImprove efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTreatment completedTreatment effect

The invention discloses sludge treatment complete equipment provided with a sludge pre-drying device and a method of the sludge treatment complete equipment. The sludge treatment complete equipment comprises a first screw conveyor, a sludge impurity removal device, a second screw conveyor, a sludge pre-drying device and a sludge dryer; the sludge impurity removal device is provided with a sludge temporary storage box and an impurity collection box; the sludge impurity removal device can perform sludge and impurity separation on the sludge with impurities, and the separated sludge is collectedto the sludge temporary storage box and the separated impurities are collected to the impurity collection box; the sludge pre-drying device can perform pre-drying work on the sludge, and the sludge after the pre-drying work is accomplished is sent into the sludge dyer to perform sludge drying work. The invention provides the sludge treatment complete equipment provided with the sludge pre-drying device and the method of the sludge treatment complete equipment; functions of sludge impurity removal, sludge pre-drying and sludge drying are integrated; the sludge treatment effect is good, and theefficiency is high.

Owner:榆林市中科环保科技发展有限公司

Sludge treatment complete equipment

ActiveCN102503058BRapid sterilizationDeodorize quicklySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTreatment completedSlag

Sludge treatment complete equipment comprises a to-be-processed sludge metering and feeding device, a stirring modified device, a metering and feeding device, a heating, sterilizing and deodorizing device, a transit tank, a metering and pumping device I, a dehydrating device I, a liquid bath, a dehydrating device II, a metering and water-feeding device, a drug A metering and administrating device, a drug B metering and administrating device, a drug C metering and administrating device, a metering and pumping device II and a waste gas collecting and treating device. The sludge treatment complete equipment has the advantages that the treatment flow time is short, the environment protection is achieved during treatment, no secondary pollution exists, the energy consumption during treatment is low, the cost is low, and dewatered sludge obtained and heavy metal slag can be comprehensively utilized.

Owner:湖南隆泰资源再生利用技术有限公司

Smoke secondary burning system in garbage treatment complete equipment

The invention provides a smoke secondary burning system in garbage treatment complete equipment, and belongs to the technical field of garbage treatment. The smoke secondary burning system solves the problem that the treating performance of existing garbage treatment complete equipment is poor. The garbage treatment complete equipment comprises a pyrolysis gasification burning system and the smoke secondary burning system; and the smoke secondary burning system comprises a second separating tower, an induced draft fan and an air blower, the two ends of the induced draft fan are connected with the pyrolysis gasification burning system and the second separating tower through gas conveying pipes, and the two ends of the air blower are connected with the second separating tower and the pyrolysis gasification burning system. By means of the smoke secondary burning system, the garbage treatment performance can be improved.

Owner:深圳市鑫旭源环保有限公司

Carbon fiber reinforced graphite industrial exhaust gas treatment complete set of equipment

ActiveCN104383789BVersatilePerfect processing functionDispersed particle separationFiberCooling tower

The present invention provides industrial tail gas treatment complete equipment of carbon fiber reinforced graphite. The industrial tail gas treatment complete equipment comprises a falling film absorbing tower, a filler tower and a cooling tower. According to the industrial tail gas treatment complete equipment, in the falling film absorbing tower, the position contacting the tail gas is made from the full-carbon fiber reinforced graphite, the lower portion of the falling film absorbing tower is connected with a solution tank, the position in the solution tank and with the height lower than the liquid level is connected with a solution heating and thermal cycling device, and the thermal cycling solution temperature is 50-80 DEG C; in the filler tower, the position contacting the gas is made from the full-carbon fiber reinforced graphite, the gas sequentially passes through the lower filler layer, the cooling coil pipe layer and the upper filler layer, and the purified tail gas is discharged into the atmosphere through the evacuation port; the filler in the filler tower is active carbon fibers; and in the cooling tower, the cooling temperature is less than -10 DEG C, such that most of the organic substances are subjected to liquefaction chromatography separation. According to the present invention, the tail gas treatment function is complete, the tail gas treatment is clean and complete, the useful ingredients are recovered, and the housing of the equipment has characteristics of high mechanical strength and good corrosion resistance.

Owner:DATONG YULINDE CARBON MATERIALS TECH

Waste plastic processing waste gas treatment process and waste plastic processing waste gas treatment complete equipment

ActiveCN109260943AImprove purification efficiencyProlong photocatalytic action timeCombination devicesTreatment completedPollution

The invention discloses a waste plastic processing waste gas treatment process and waste plastic processing waste gas treatment complete equipment. The production process comprises: 1) dust removal, wherein the pollution on the catalyst of the subsequent process can be avoided; 2) degradation of pollution waste gas, wherein pollution waste gas is subjected to a reaction in a photocatalytic chamberso as to degrade into non-toxic and harmless gas; 3) separation of purified gas and catalyst, wherein a gas path is controlled by a valve device, and the circulation of the purified gas and the catalyst is achieved through the synergetic operation with the magnetic fields of magnetic field chambers; and 4) reducing of excess ozone, wherein the purified gas is discharged from the magnetic field chamber, and the reducing of excess ozone is achieved through a reducing filling layer. According to the present invention, various devices of the complete equipment are reasonably matched, the waste gas is effectively purified, and no secondary pollution is generated during the treatment.

Owner:FUJIAN NORMAL UNIV

Device and process for treating odorous waste gas based on plasma technology in cooperation with biodegradation

PendingCN109499350ACompletely degradedDegradation: exhaust gas is thoroughly treated by low-temperature plasma exhaust gasGas treatmentDispersed particle filtrationTreatment completedSoil treatment

The invention relates to a device and a process for treating odorous waste gas based on a plasma technology in cooperation with biodegradation. The device comprises a low-temperature plasma waste gastreatment complete device; a collecting system is arranged at the upstream of the low-temperature plasma waste gas treatment complete device, an induced draft fan is arranged at the downstream of thelow-temperature plasma waste gas treatment complete device and is connected with a biological soil treatment system through a connecting pipeline, a discharge system is arranged at the downstream of the biological soil treatment system, and a de-fogging system is arranged between the low-temperature plasma waste gas treatment complete device and the collecting system; the low-temperature plasma generation adopts a double dielectric barrier generation technology; a gas collecting hood performs accurate collection on an odorous source, the control over air volume is realized by an adjusting valve, odorous waste gas is deeply treated by the biodegradation technology after being treated by the low-temperature plasma treatment technology, the treated odorous waste gas can be directly dischargedfrom a lawn above biological soil, and the standard requirements for unorganized discharge can be met.

Owner:CAS NEW WORLD HEFEI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com