Slaughter wastewater treatment complete device and slaughter wastewater treatment method

A technology for slaughter wastewater and complete equipment, which is applied in animal processing wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve problems such as uneconomical, high energy consumption in operation, and large one-time investment to reduce the processing load , high processing efficiency and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

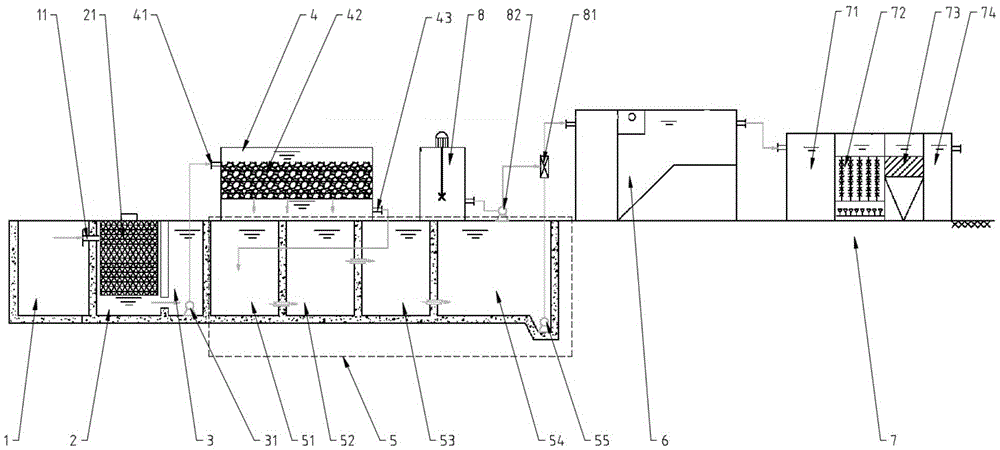

[0025] like figure 1As shown, the first embodiment of the complete set of slaughter wastewater treatment equipment of the present invention includes a sump 1 for intermittent drainage, a first filter tank 2, a grease trap 3, a second filter 4, a regulating tank 5, and an air flotation device 6 , an integrated biological treatment device 7, a dosing device 8, wherein: the water collection tank 1, the first filter tank 2, the grease trap 3, and the adjustment tank 5 are located at the same height,

[0026] The sump 1 collects the waste water produced during the slaughtering process. The top of the side wall is provided with a water outlet 11 connected to the first filter pool 2. The waste water flows into the first filter pool 2 through the water outlet 11. The water outlet 11 is provided with a flow valve and a cut-off valve. Valve, to control the opening / closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com