Membrane oxidation reactor and wastewater treatment method

A technology of oxidation reactor and waste liquid tank, which is applied in the field of membrane treatment, can solve the problems of increased cost, shortened service life, ceramic membrane pollution, etc., and achieves the effects of prolonging service life, no secondary pollution, and alleviating membrane pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

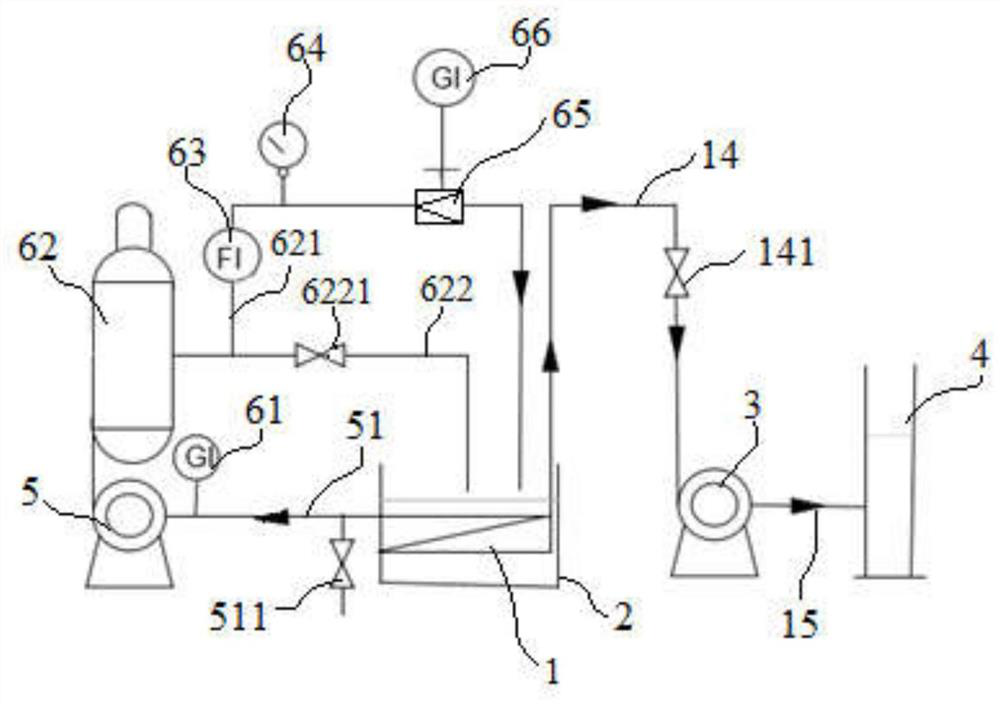

[0050] like figure 1 As shown, a membrane oxidation reactor includes a ceramic membrane module 1, a waste liquid tank 2, a self-priming pump 3, a water purification tank 4, a gas-liquid mixing pump 5, and a nano-micro bubble generating device;

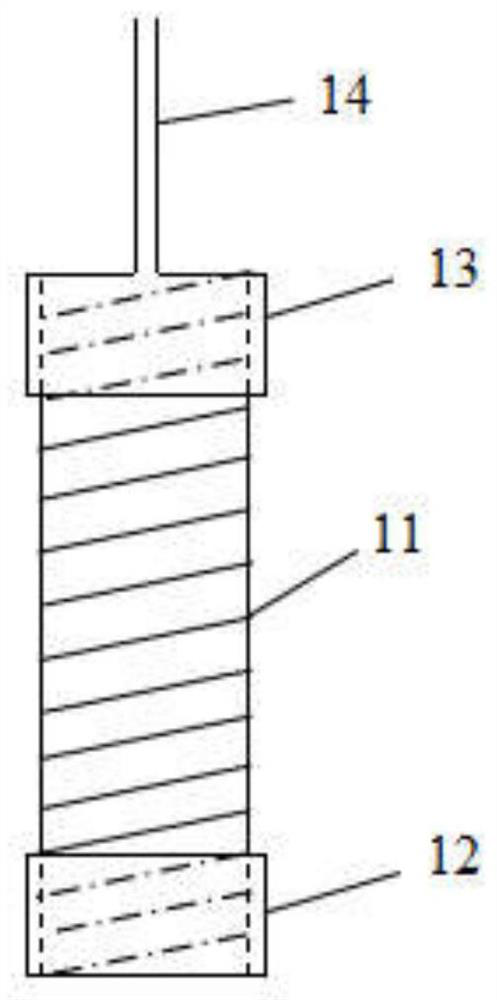

[0051] like figure 2 As shown, the ceramic membrane assembly 1 includes a tubular ceramic membrane 11, a first plug 12, a second plug 13, a connecting pipe 14, a first pipeline 15 and a first valve 141, and the tubular ceramic membrane 11 is placed in the waste liquid tank 2, one end of the tubular ceramic membrane 11 is connected to the first plug 12, and one end of the tubular ceramic membrane 11 is sealed through the first plug 12, and the other end of the tubular ceramic membrane 11 is connected to the second plug 13, through the first plug 12 The second plug 13 seals the other end of the tubular ceramic membrane 11, and the end of the second plug 13 away from the tubular ceramic membrane 11 communicates with the connecting pipe ...

Embodiment 2

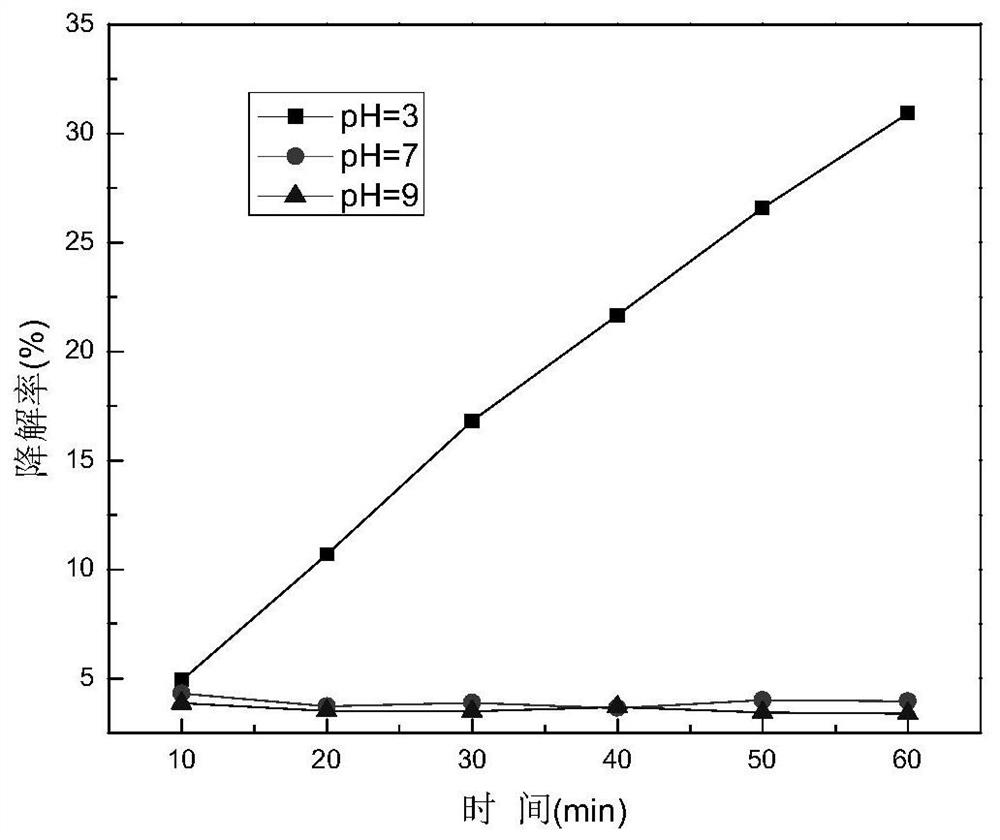

[0062] Under normal temperature conditions, with 8mg / L methyl orange aqueous solution as simulation dyestuff, adjust the pH of methyl orange aqueous solution, methyl orange aqueous solution is poured in waste liquid tank 2, self-priming pump speed is fixed at 100r / min, start gas Liquid mixing pump 5, under the suction of the gas-liquid mixing pump 5, the gas and the methyl orange aqueous solution in the waste liquid tank 2 enter the gas-dissolving tank 62 through the third pipeline 621, and the gas-liquid is fully mixed in the gas-liquid mixing tank 62 A uniform gas-liquid mixture is formed, and the gas-liquid mixture enters the ejector 65 through the liquid flow meter 63 and the pressure gauge 64, and air is inhaled again in the ejector 65, and the air and the gas-liquid mixture are fully fused again and mixed evenly. Nano-micron bubbles are ejected at the outlet of the ejector 65, and passed into the waste liquid tank 2 through the pipeline;

[0063] The tubular ceramic memb...

Embodiment 3

[0067] The difference between this embodiment and embodiment 2 is: the pH of the methyl orange aqueous solution is adjusted to 3, and the pump speed of the self-priming pump is adjusted to 60, 80, 100r / min

[0068] Membrane flux and methyl orange removal rate are measured, and its measuring method is as follows:

[0069] Membrane flux measurement: After the experiment starts, use a stopwatch to measure the volume in the water purification tank every ten minutes. The experiment is carried out for 60 minutes, and the change in the volume of the effluent is observed. The membrane flux is represented by J, and the volume is represented by V. The water surface area is represented by s, the time is represented by △t, J=V / (s·△t), and the unit of flux is L / (m 2 h).

[0070] Determination of the removal rate of methyl orange: measure the concentration of methyl orange by using an ultraviolet spectrophotometer. The methyl orange standard solution of 1, adjust pH=3 respectively, carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com