Low-energy-consumption multifunctional membrane biological treatment complete equipment

A complete set of equipment, multi-functional technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption and high operating costs, achieve simple operation, avoid pollution Good effect of mud deposition and water effluent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

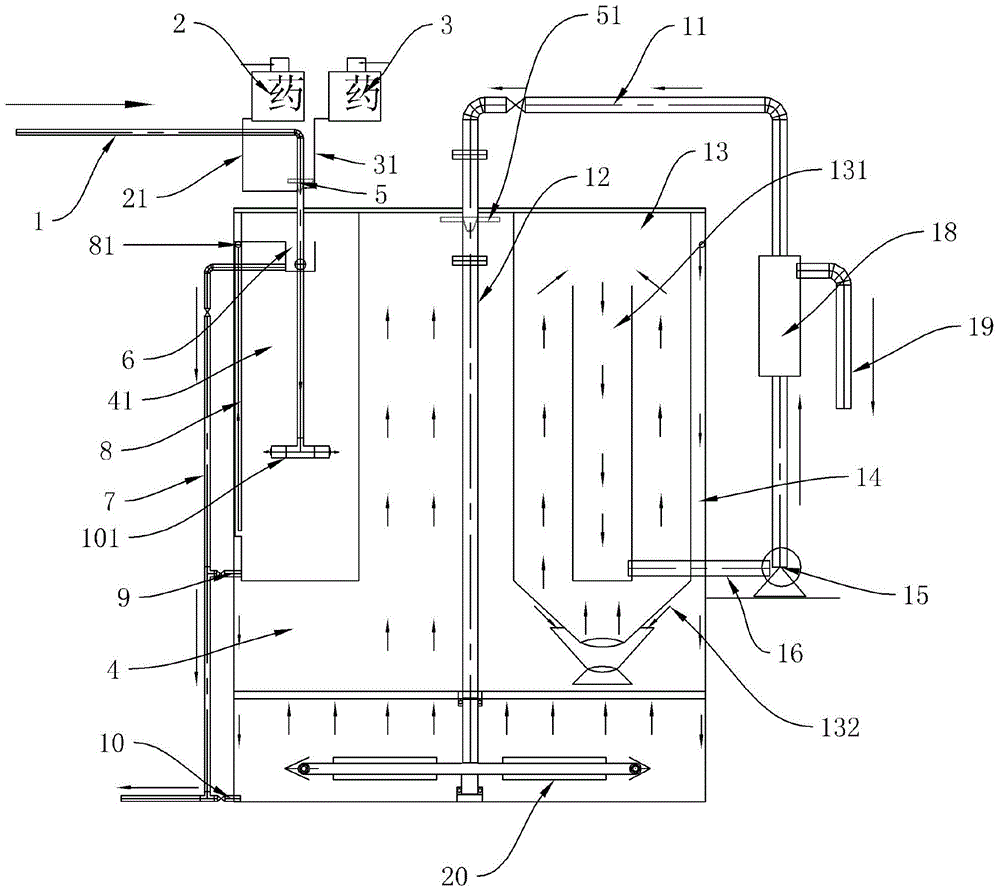

[0021] see figure 1 , a complete set of low-energy multifunctional membrane biological treatment equipment, including a water inlet pipe 1, the water inlet pipe 1 extends into the scum separation chamber 41, and a shunt pipe 101 is provided at the end port of the extension, and the shunt pipe and the water inlet pipe 1 at an angle, preferably 90°;

[0022] The bottom of the scum separation bin 41 is provided with a first sludge discharge pipe 9, and the top is provided with a scum collection tank 6, and the scum collection tank 6 is connected to the scum discharge pipe 7;

[0023] In order to increase the potential energy of sewage entering the scum separation chamber 41, the first jet 5 can be set in the water inlet pipe 1; on the water inlet 1, after the first jet 5, the water inlet passes through the first drug introduction pipe 21 and the first jet respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com