Metal-induced crystallization of amorphous silicon and metal removal techniques

An amorphous silicon film and technology technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting polysilicon crystallization quality and crystallization speed, affecting the final characteristics of TFT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0042] The specific embodiment preparation method is:

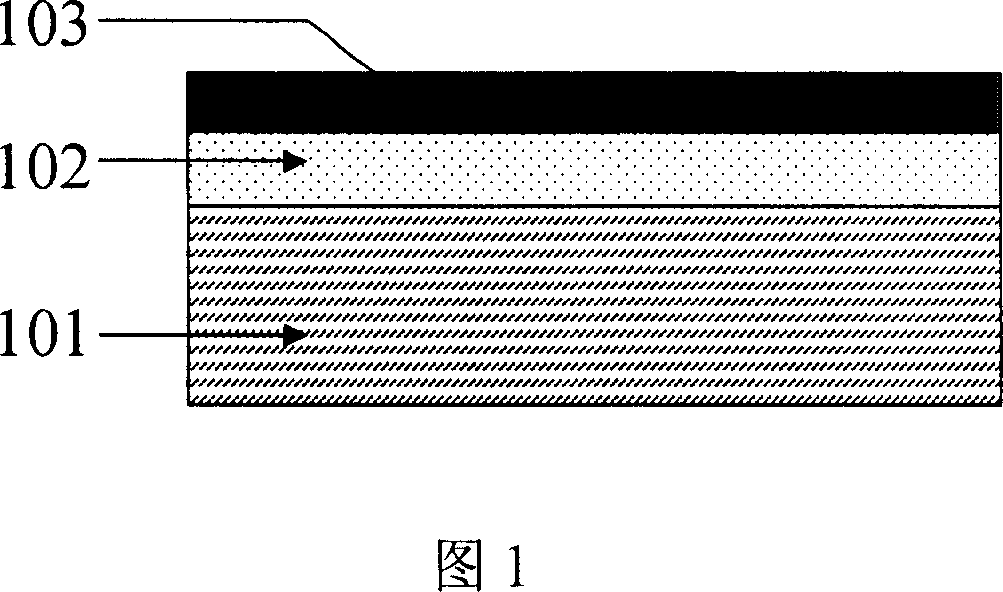

[0043] 1: 200 nanometers of silicon nitride and 100 nanometers of LTO are deposited as a barrier layer 102 on Corning 1737F glass 101 behind a thickness of 1.1 mm by PECVD. LPCVD at 550° C. to deposit a 50 nm amorphous silicon layer 103 .

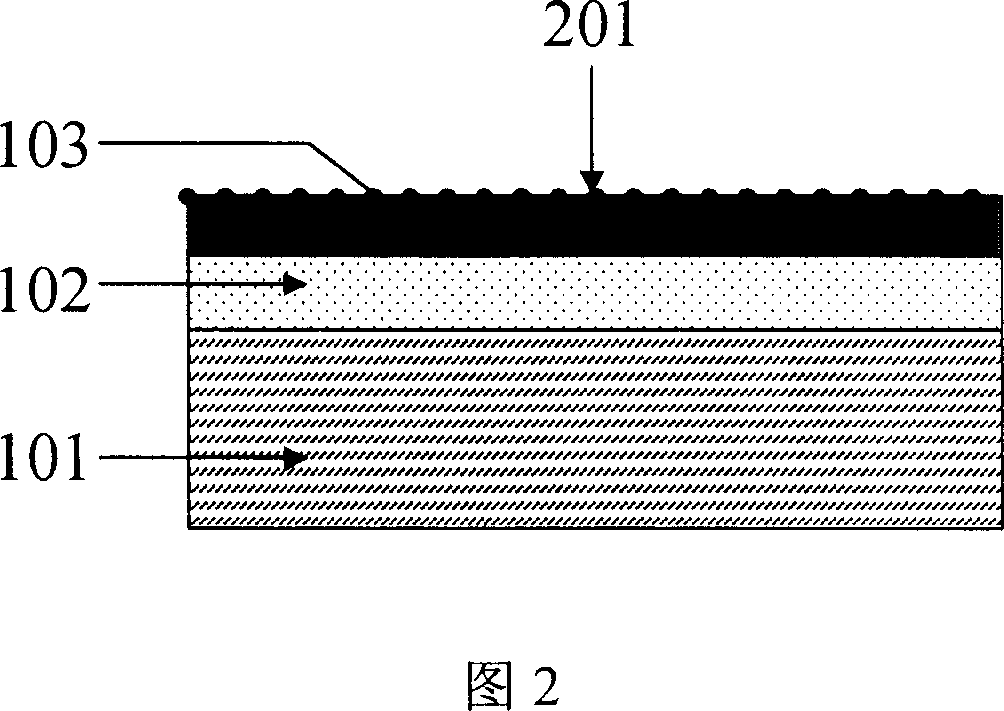

[0044] 2: Using a nickel-silicon mixed target, sputtering in an argon-oxygen atmosphere to achieve a small amount of nickel 201 attached to the surface of amorphous silicon.

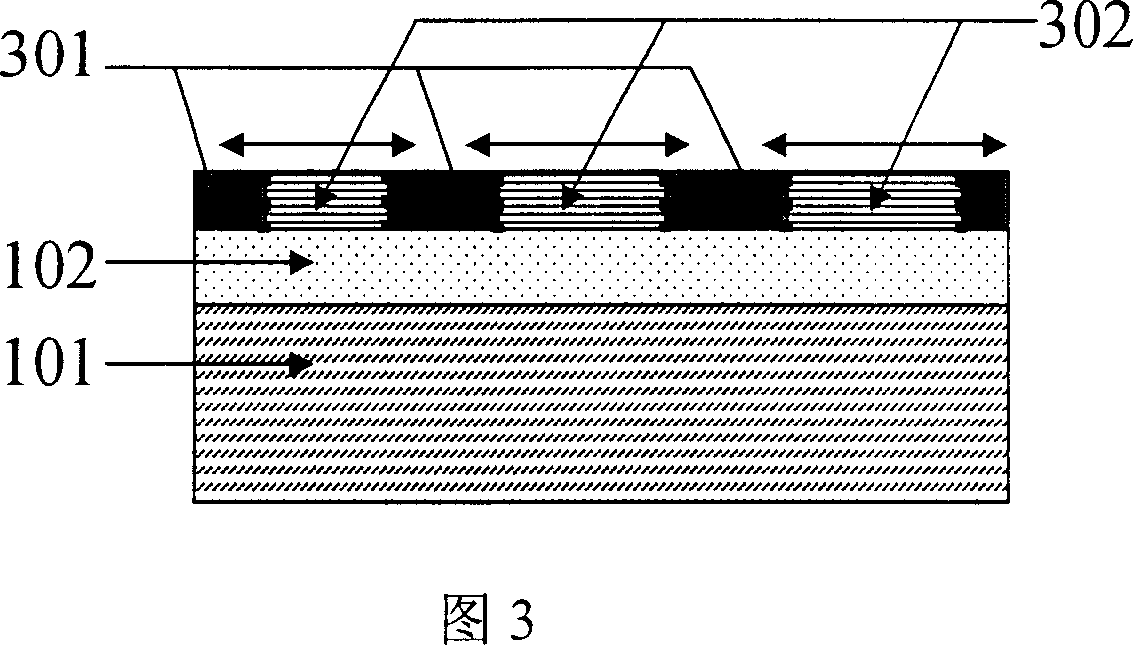

[0045] 3: The above samples were annealed in a nitrogen atmosphere at a temperature of 590° C. for 1 hour. It becomes a mixed film of the amorphous silicon film 301 and the polysilicon film 302 .

[0046] 4: Use diluted hydrofluoric acid to remove the natural oxide layer on the surface of the sample and clean the surface. Afterwards, LPCVD deposited PSG 501 with a thickness of 700 nm.

[0047] 5: The above sample is subjected to the second annealing process in a nitrogen atmosphere at a temperature of 590° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com