Waste plastic processing waste gas treatment process and waste plastic processing waste gas treatment complete equipment

A waste gas treatment and complete set of equipment technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of short photocatalytic treatment time, not the ultimate goal of waste gas treatment, and the difficulty of exhaust gas to meet emission standards, etc., to improve Exhaust gas purification efficiency, improved photocatalytic effect, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0033] The magnetic photocatalyst described in the embodiment of the present invention can adopt TiO 2 It is a magnetic-loaded composite photocatalyst of a photocatalyst, or a conventional magnetic photocatalyst in the field, such as a magnetic photocatalyst with a patent number of CN200910186295. available in both.

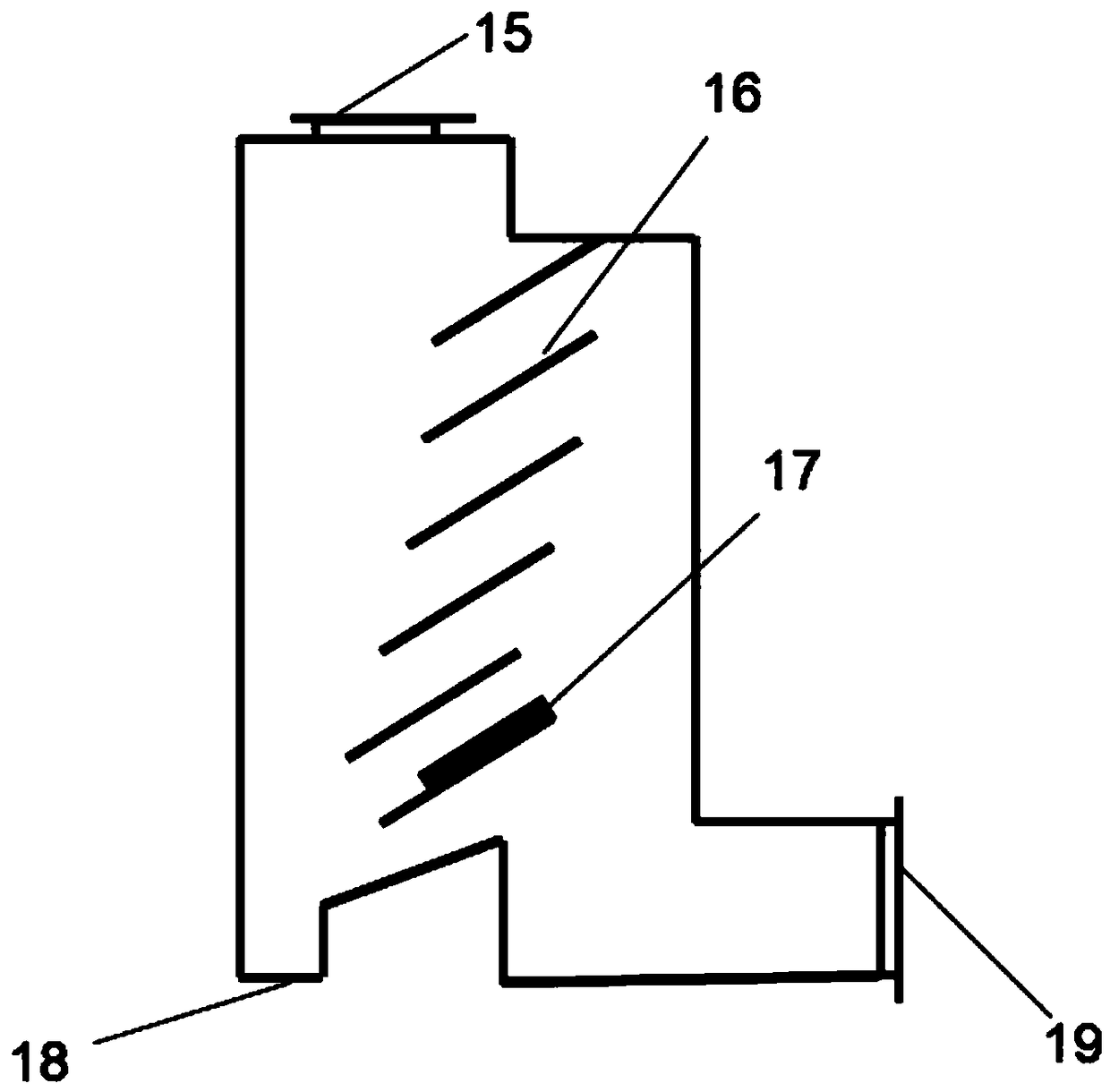

[0034] The magnetic field of the magnetic field plate described in the embodiments of the present invention adopts an electromagnetic field, and a magnetic field is generated after power-on, and the magnetic photocatalyst is adsorbed on the magnetic field plate; after power off, due to gravity, the photocatalyst of the outer layer gradually falls off until the magnetic photocatalyst All come off.

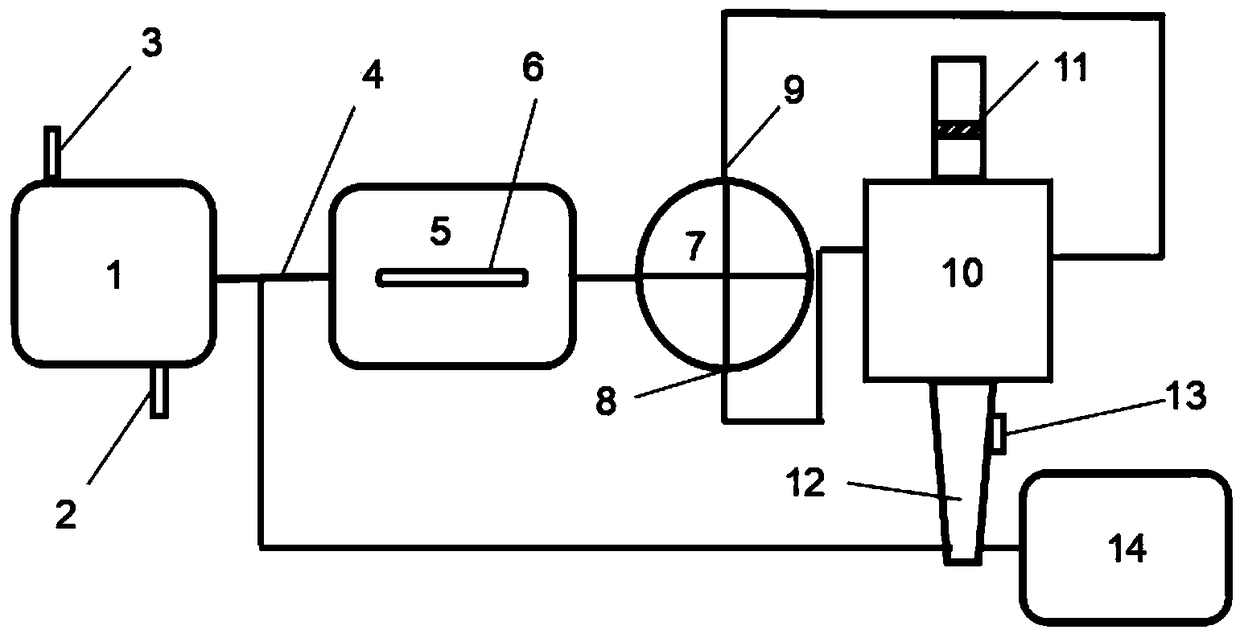

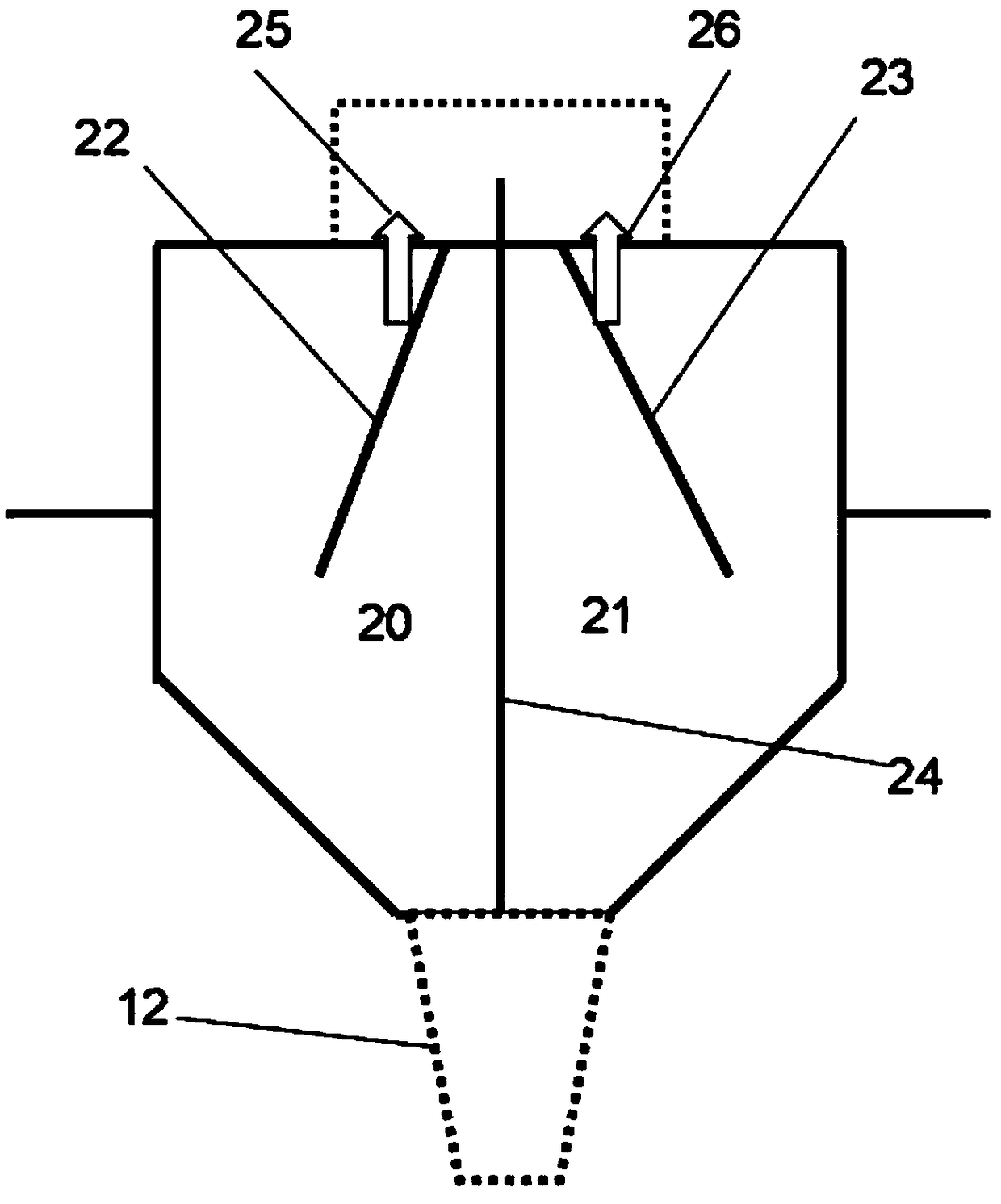

[0035] The embodiment of the present invention provides a complete set of equipment for waste plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com