Solid household refuse pyrolysis and gasification power generation device

A technology for domestic waste, pyrolysis and gasification, applied in gasification process, solid waste removal, transportation and packaging, etc., can solve the problems of complex structure of waste-to-energy equipment, waste of land resources, inconvenient movement, etc. Discontinuous and unstable, energy saving, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

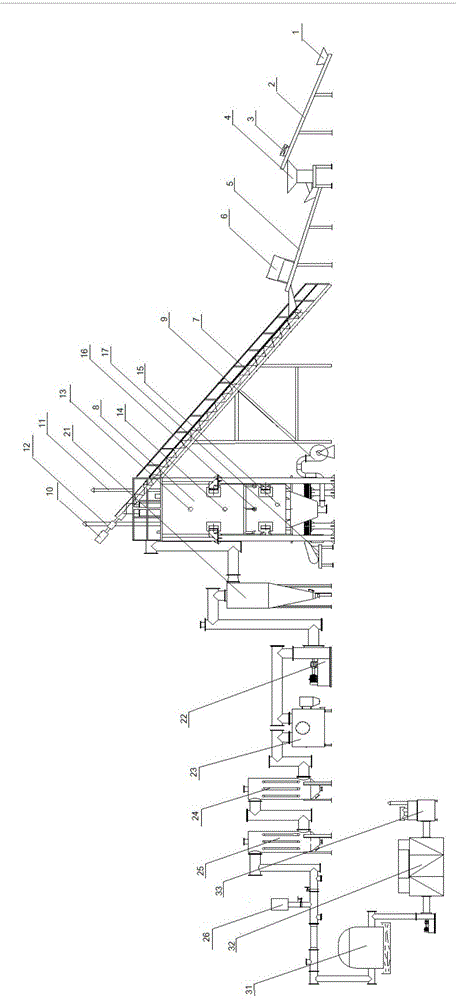

[0026] Embodiment 1: A power generation device for pyrolysis and gasification of solid domestic waste, consisting of a feed tank 1, a magnetic separation conveyor belt 2, an electromagnet 3, a pulverizer 4, a crushed material conveyor belt 5, a secondary electromagnet 6, and a screw feed Machine 7, gasification furnace 8, oxygen intake fan 9, spiral stirring motor 10, cyclone remover 21, pressurized induced draft fan 22, water-sealed dust removal and explosion-proof device 23, secondary decoking and cooling tower 24, and tertiary decoking and cooling A tower 25, a gas test burner 26, a gas storage cabinet 31, a gas generator 32 and a dust collector 33 are connected in series through pipelines, and the solid domestic waste enters from the feeding trough 1, which is arranged at the front end of the magnetic separation conveyor belt 2, and the magnetic The upper part of the selection conveyor belt 2 is provided with an electromagnet 3 for removing iron impurities, and the rear end...

Embodiment 2

[0027] Embodiment 2: A power generation device for pyrolysis and gasification of solid domestic waste, consisting of a feed tank 1, a magnetic separation conveyor belt 2, an electromagnet 3, a pulverizer 4, a crushed material conveyor belt 5, a secondary electromagnet 6, and a screw feed Machine 7, gasification furnace 8, oxygen intake fan 9, spiral stirring motor 10, cyclone remover 21, pressurized induced draft fan 22, water-sealed dust removal and explosion-proof device 23, secondary decoking and cooling tower 24, and tertiary decoking and cooling A tower 25, a gas test burner 26, a gas storage cabinet 31, a gas generator 32 and a dust collector 33 are connected in series through pipelines, and the solid domestic waste enters from the feeding trough 1, which is arranged at the front end of the magnetic separation conveyor belt 2, and the magnetic The upper part of the selection conveyor belt 2 is provided with an electromagnet 3 for removing iron impurities, and the rear end...

Embodiment 3

[0028] Embodiment 3: A power generation device for pyrolysis and gasification of solid domestic waste, consisting of a feed tank 1, a magnetic separation conveyor belt 2, an electromagnet 3, a pulverizer 4, a crushed material conveyor belt 5, a secondary electromagnet 6, and a screw feed Machine 7, gasification furnace 8, oxygen intake fan 9, spiral stirring motor 10, cyclone remover 21, pressurized induced draft fan 22, water-sealed dust removal and explosion-proof device 23, secondary decoking and cooling tower 24, and tertiary decoking and cooling A tower 25, a gas test burner 26, a gas storage cabinet 31, a gas generator 32 and a dust collector 33 are connected in series through pipelines, and the solid domestic waste enters from the feeding trough 1, which is arranged at the front end of the magnetic separation conveyor belt 2, and the magnetic The upper part of the selection conveyor belt 2 is provided with an electromagnet 3 for removing iron impurities, and the rear end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com