Patents

Literature

46results about How to "Get angry fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant carbon honeycomb briquette raw material and its producing process

The plant charcoal honeycomb briquette material consists of high energy plant charcoal 45-54 wt%, additive 10-15 wt%, adhesive 35-40 wt% and combustion promoter for the rest, and is produced through mixing in a compounding machine. The high energy plant charcoal is amorphous charcoal prepared with corn stalk, kaoliang stalk, wheat straw, bamboo and wood dust, wine stillage, Chinese medicine residue, etc and through charring in a charring machine with inlet temperature of 300deg.c and outlet temperature of 400deg.c for 2.0-2.5 min. The present invention changes waste into useful material.

Owner:陈家荣

Easy-to-kindling and high efficiency honeycomb coal briquet

This invention relates to a high-efficiency energy-saving ignition honecyomb briquette which is burnt by striking a fire on top. It is made up by mixing raw coal, yellow earth, charcoal, sodium chloride, calcium oxide and parafin, with this invented igntion honeycomb briquette, only a stick of matches is needed only for kindling other ordinary honeycomb briquettes.

Owner:徐加清 +2

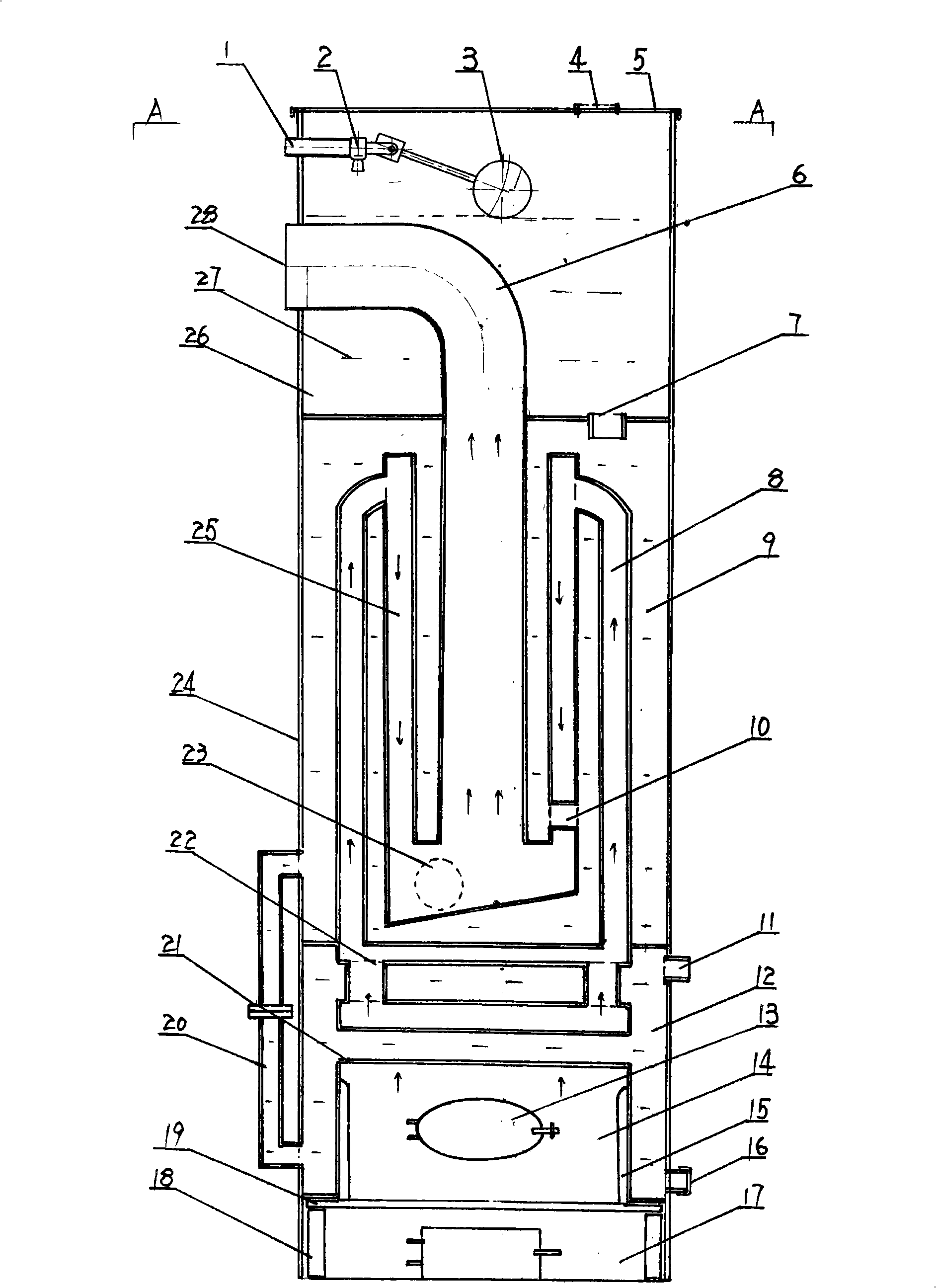

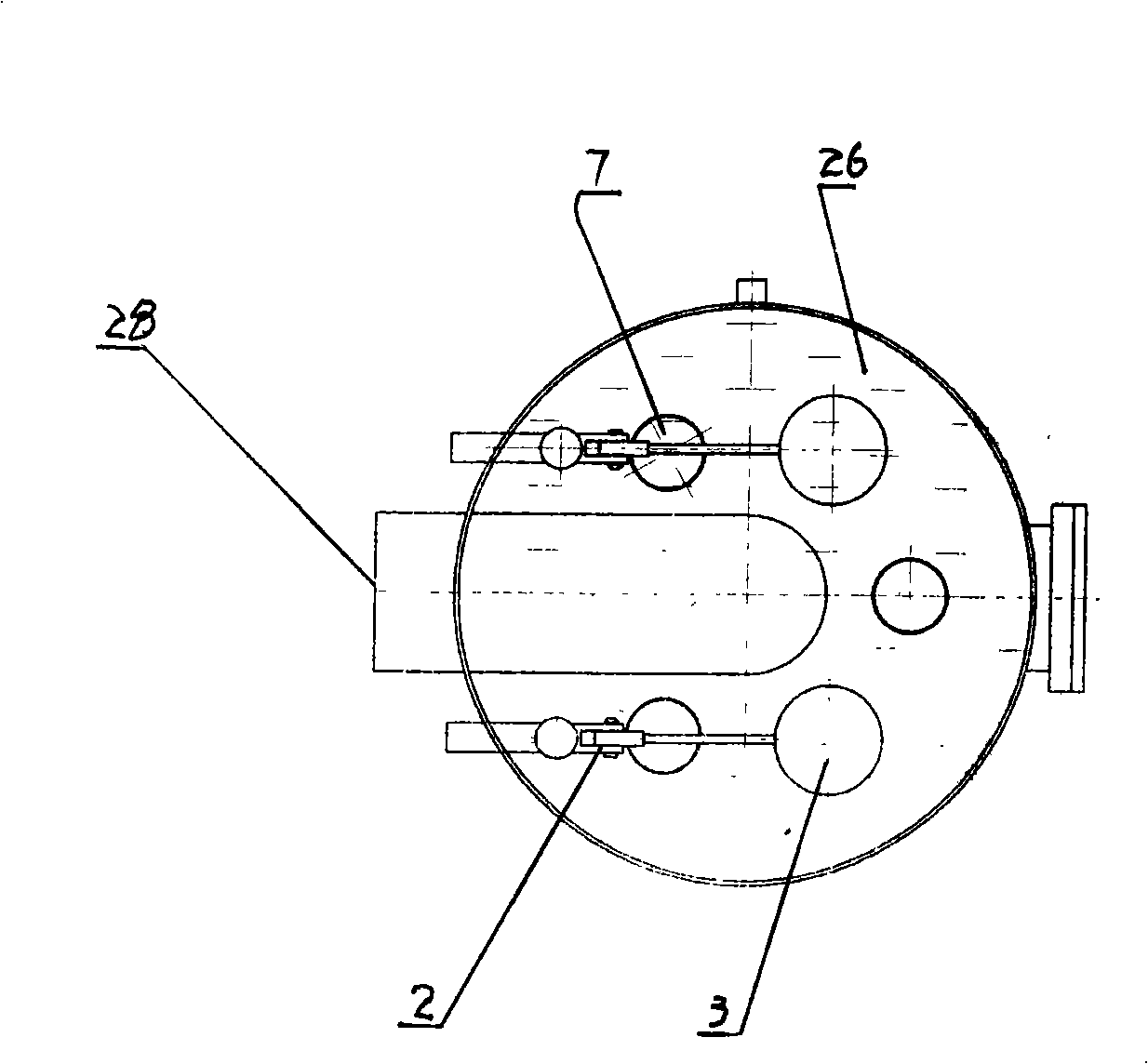

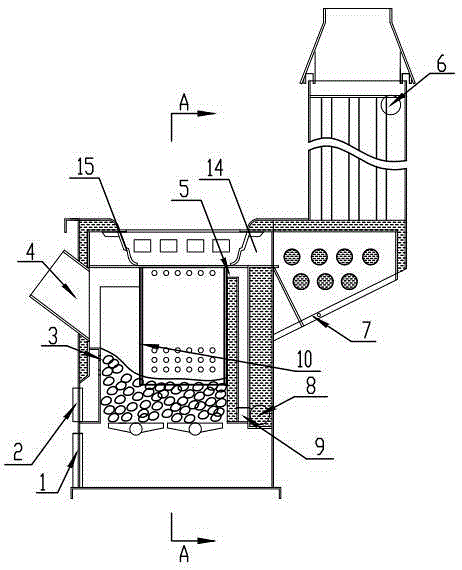

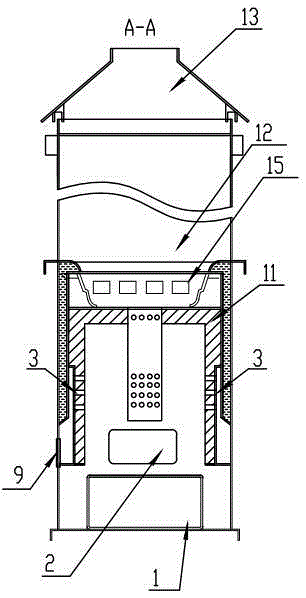

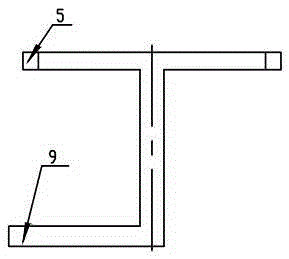

Open back water reciprocating flue type normal pressure boiler

InactiveCN101290161AImprove securityGood safety and high heat utilizationWater heatersWater storage tankHearth

The invention belongs to an opening inverted water reciprocating flue normal pressure boiler. The boiler body is divided into three parts, an upper part inside the boiler body is a water storage tank while a lower part inside the boiler body is a lower boiler body water liner and a furnace hearth, an upper boiler body water liner is arranged between the lower end of the boiler body water storage tank and the upper end of the lower boiler body water liner, the upper boiler body water bladder liner and the lower boiler body water liner are connected through a through water pipe; a water inlet pipe is arranged on the upper end of the boiler body and is communicated with the water storage tank through a ball float valve, a water outlet pipe is communicated with the lower boiler body water liner; a reciprocating flue is arranged in the lower boiler body water liner, which consists of an upper flue, a lower flue and a main flue. The opening inverted water reciprocating flue normal pressure boiler has an inverted water working way with inflowing on the upper part and outflowing at the lower part, which sufficiently absorbs heat energy of the boiler body, and has the advantages of coal conservation, simple structure, low production cost, rapid firing, good safety and high heat utilization rate.

Owner:吴军

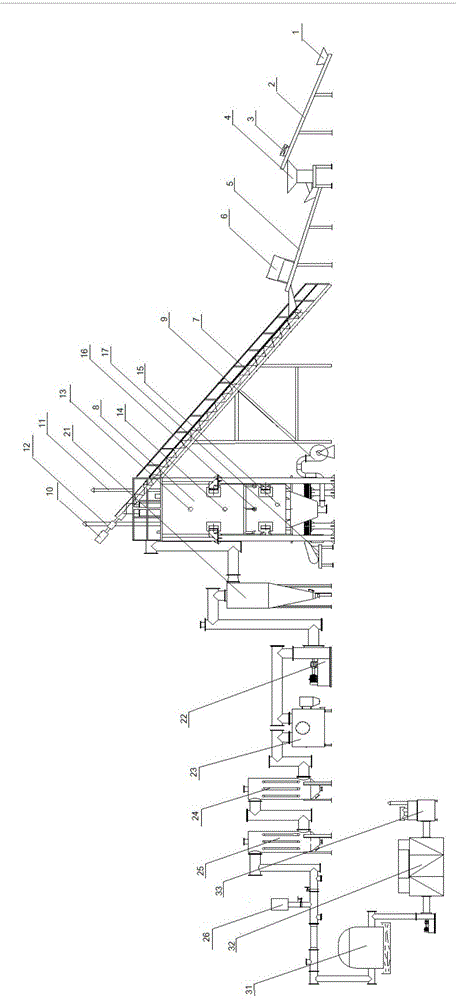

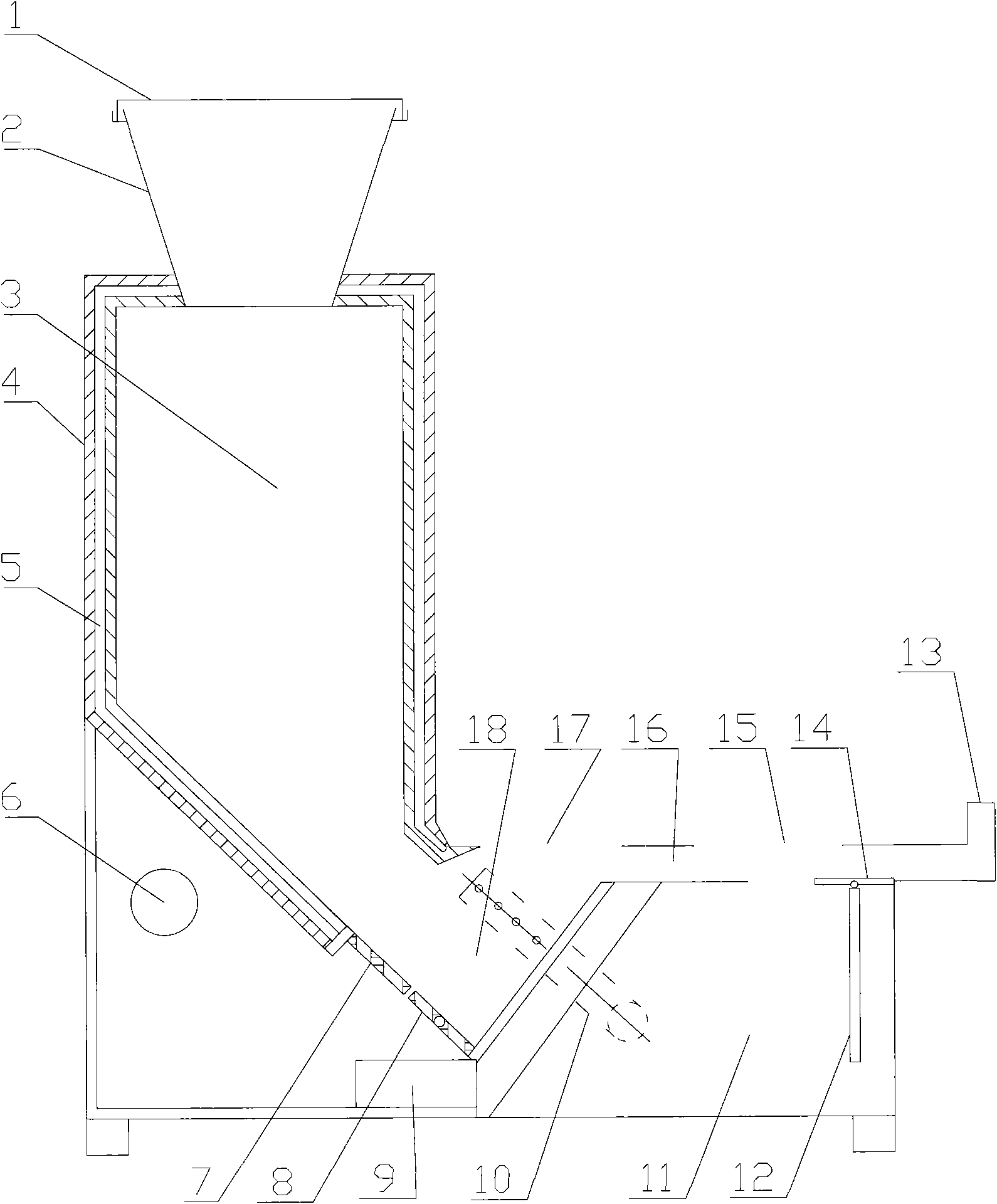

Solid household refuse pyrolysis and gasification power generation device

PendingCN107177380AFull pyrolysis and gasificationImprove gas production efficiencyTransportation and packagingSolid waste disposalCycloneTreatment completed

The invention relates to a solid household refuse pyrolysis and gasification power generation device. The solid household refuse pyrolysis and gasification power generation device is characterized by comprising a feeding tank (1), a magnetic separation conveying belt (2), a pulverizer (4), a spiral feeding machine (7), a gasifier (8), a cyclone removal device (21), a pressurizing induced draft fan (22), a water seal type dust removal explosion prevention device (23), a secondary decoking and cooling tower (24), a ternary decoking and cooling tower (25), a gas test fire head (26), a gas storage cabinet (31), a gas turbine generator (32) and a dust remover (33) which are serially connected with one another by pipes. The solid household refuse pyrolysis and gasification power generation device is high in universality of household refuse; requirements on household refuse composition on original refuse treatment are low; and complicated original refuse treatment procedures are reduced. The solid household refuse pyrolysis and gasification power generation device is simple to operate and use, stable in thermal efficient, high in gas yield and high in safety, and is harmless treatment complete equipment which can treat household refuse harmlessly, and further can carry out gasification by the household refuse secondarily.

Owner:福建龙迪环保设备科技有限公司

Method for preparing cement clinker by using chrome slag as mineralization agent

InactiveCN1477073AReduced heat distribution ratioAct as a seed crystalCement productionSlagCalcination

The method for preparing cement clinker by using chromium slag as mineralizer is mainly in the cement raw material the mineralizer chromium slag can be added, and the high-temp. calcination process is adopted to reduce hexavalent chromium into trivalent chromium, at the same time a catalytic stabilizer can be added in the clinker so as to obtain the invented cement clinker.

Owner:SICHUAN YINHE CHEM

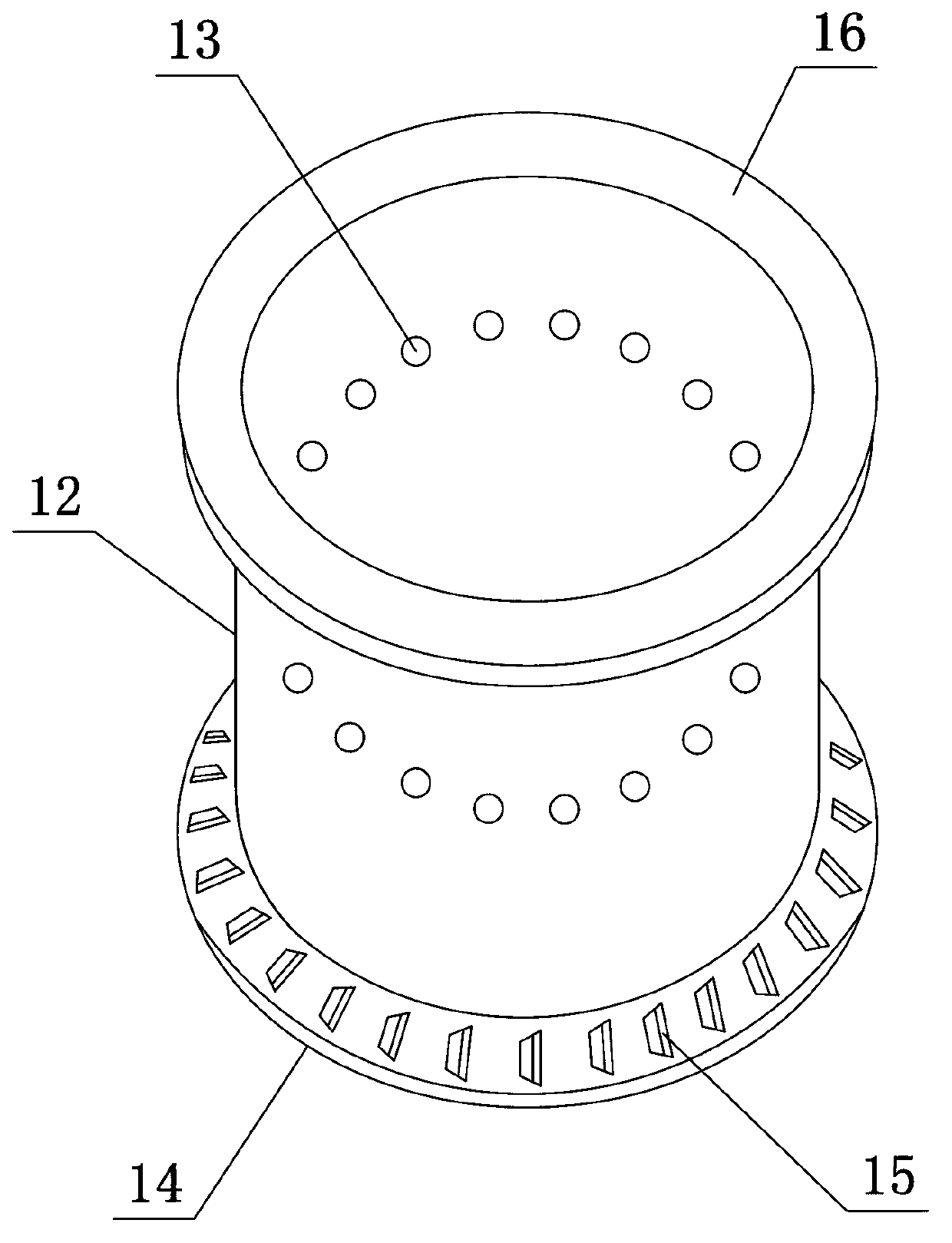

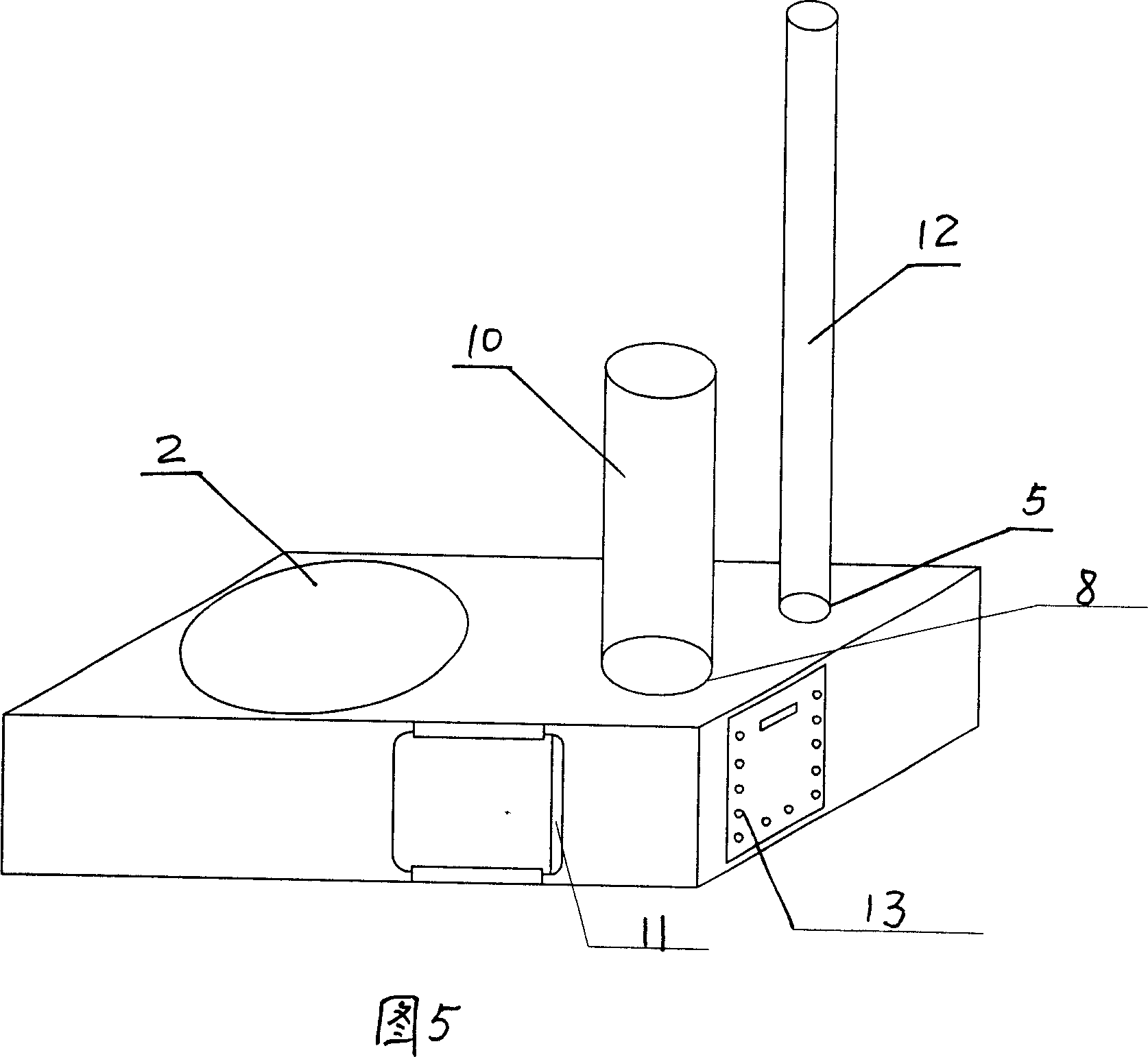

Gasification combustor of solid fuel cooking range

ActiveCN103123109ABurn fullyEasy to igniteSolid fuel combustionCombustion apparatusCombustorSolid fuel

The invention provides a gasification combustor of a solid fuel cooking range which comprises a first core body and a movable whirlwind combustion-supporting device. A plurality of air-in and gasification combustion-supporting holes are arranged on the first core body, a fire-sealing cover baffle plate is arranged on the inner wall of the first core body, and when an air blower is used for compulsorily supporting air for combustion supporting, the movable whirlwind combustion-supporting device is arranged on the fire-sealing cover baffle plate in the first core body. The movable whirlwind combustion-supporting device comprises a second core body, a top wall and a bottom wall, wherein the top wall is arranged on the upper portion of the second core body, and the bottom wall is arranged on the lower portion of the second core body. A plurality of second air-in and gasification combustion-supporting holes are arranged on the periphery of the second core body, and the bottom wall of the second core body is provided with a plurality of third air-in and gasification combustion-supporting holes which are coincident in slant directions. A cold furnace is easy to fire up and fast to inflame; flame rotates for combustion; and heat power is strong. The gasification combustor saves energy and is environment-friendly; and when fire is sealed, the movable whirlwind combustion-supporting holes are taken out, and the movable fire-sealing cover is arranged on the fire-sealing cover baffle plate to seal the fire. The gasification combustor is applicable to a boiler or a hot blast stove with solid fuel combusted, and use of combustion equipment with any structure such as the cooking range in a matched mode.

Owner:陕西华能恒大科技有限公司 +1

Preparation method of special-purpose charcoal for hot pot and barbecue

The invention provides a single-purpose charcoal for chafing dish, wherein the preparing process comprises, (1) subjecting the raw materials such as wood dust, rice stalk to charring, (2) disintegrating the materials, (3) charging 5-10% of zeolite powder into the material, watering and stirring, (5) carrying out extrusion molding, (5) curing or drying, (6) packaging the end product.

Owner:黄汉林

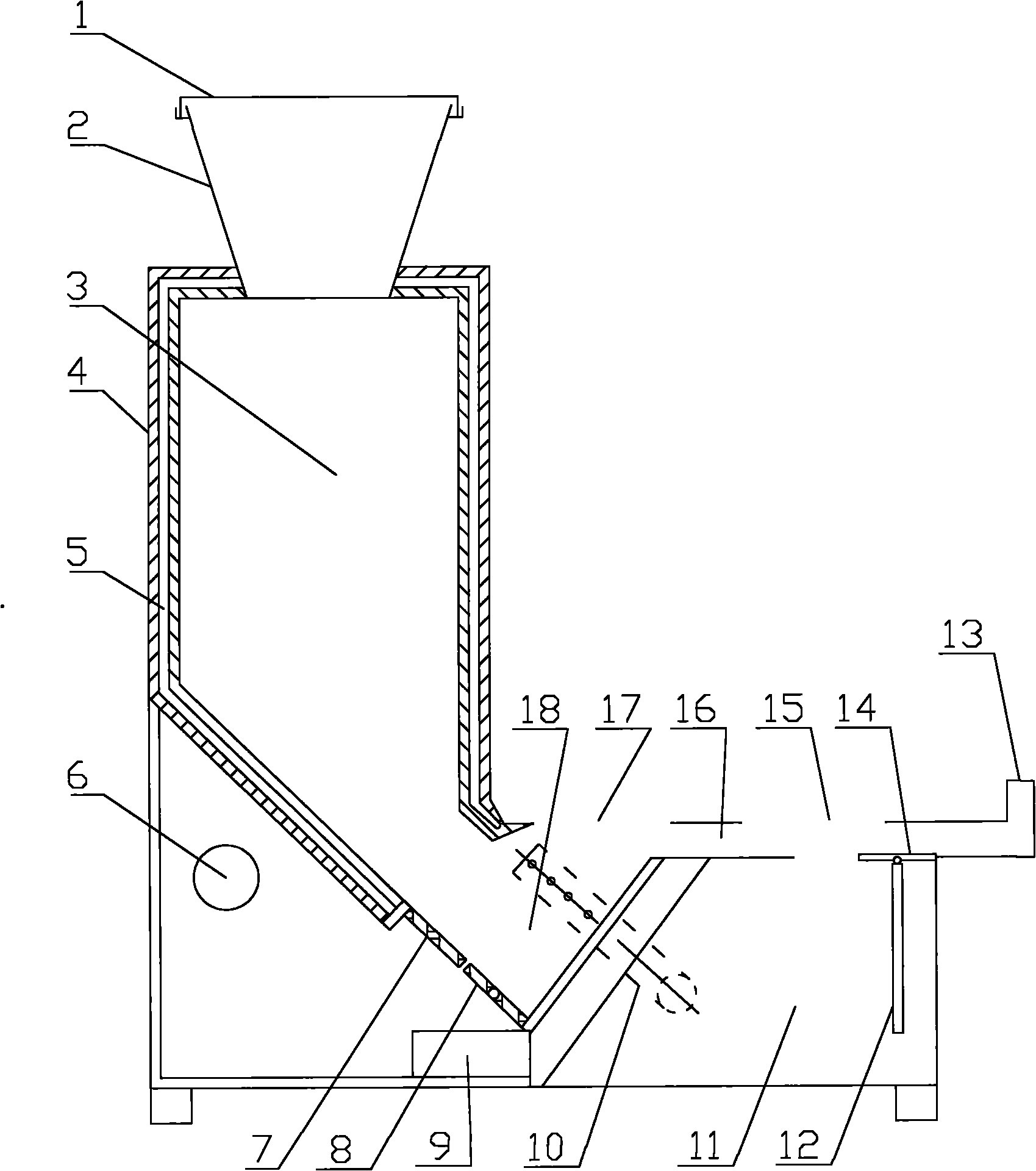

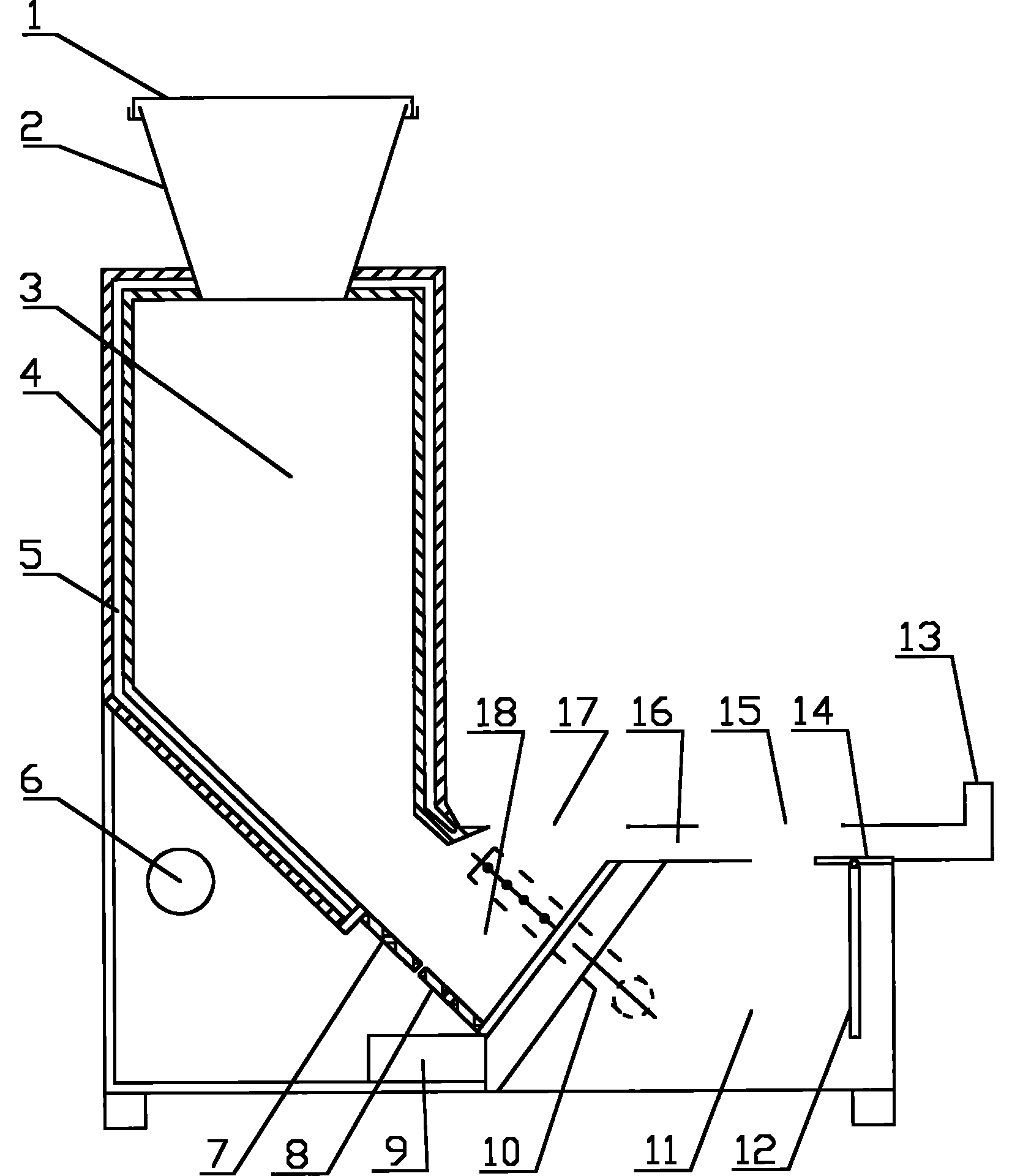

Transversely closed burning highly effective environment protective energy-saving direct combustion type biomass stove

InactiveCN101012938AExtended stroke of rotary combustionUnique designDomestic stoves or rangesLighting and heating apparatusDirect combustionEngineering

The invention discloses a horizontal-sealed high-efficiency energy-saving direct-combustion biological furnace, which comprises a furnace formed by front, back, left and right side panels, upper panel and bottom plate. The left of upper panel is arranged with a base opening. The right side of upper panel is arranged with an upper drawing cylinder opening and a lower feeding opening. The lower furnace of feeding opening contains an incline sliding plate screen whose lower end is connected with the furnace screen in the hearth. The right panel of furnace above the sliding plate screen is arranged with a wind inlet. One side of the base opening is arranged with an arc upright baffle plate to form an arc fire channel whose front is communicated with hearth and back is communicated with the drawing cylinder opening. Via the combustion drawing cylinder, the passive pressure in the furnace can be kept from continuous feeding to continuous burning. The semi-round fire channel of arc upright baffle plate can prolong the strike of fire in the channel to burn the fuel second time.

Owner:焦作市洁燃新能源有限公司

Recipe and making process of briquette desulfurizing waterproofing and combustion supporting binder

The briquette desulfurizing, waterproofing and combustion supporting binder consists of sodium nitrate 20-50 weight portions, magnesium chloride 10-30 weight portions, sodium chloride 10-20 weight portions, ammonium chloride 5-20 weight portions, light magnesia 10-40 weight portions, calcium oxide 5-20 weight portions, and cellulose 20-30 weight portions. The present invention has the advantages of low cost and the integrated functions of desulfurizing briquette, waterproofing, supporting and strengthening combustion.

Owner:陈国涛 +1

Coke particle clean combustion stove

ActiveCN105333416AImprove thermal efficiencySolve the disadvantages of airtight combustion and easy slaggingSolid fuel combustionAir/fuel supply for combustionCoal briquetteCombustion chamber

The invention discloses a coke particle clean combustion stove and relates to the technical field of civil clean stoves. The coke particle clean combustion stove comprises a stove body, a flue and a fire tube heat absorption cavity, wherein a combustion chamber is arranged in the center of the stove body and is divided into two layers namely a main combustion chamber on the lower layer and an intensified combustion chamber on the upper layer; the main combustion chamber is communicated with the flue through the fire tube heat absorption cavity; a fire gathering shield is arranged in the intensified combustion chamber; a fire gathering warming cylinder is arranged at the fire hole of the main combustion chamber; the upper end of the fire gathering warming cylinder is level with and matched with the outlet of the main combustion chamber; the lower end of the fire gathering warming cylinder stretches into the main combustion chamber and is contact with fuel at the bottom of the main combustion chamber; small holes are uniformly formed in the side walls at the upper part and the lower part of the fire gathering warming cylinder. The coke particle clean combustion stove is used for burning coke, coal briquette, bituminous coal or biomass, particularly suitable for burning small-grain-size coke, excellent in gas permeability, high in thermal efficiency, environment-friendly and efficient.

Owner:SHIJIAZHUANG CHUNYAN HEATING EQUIP

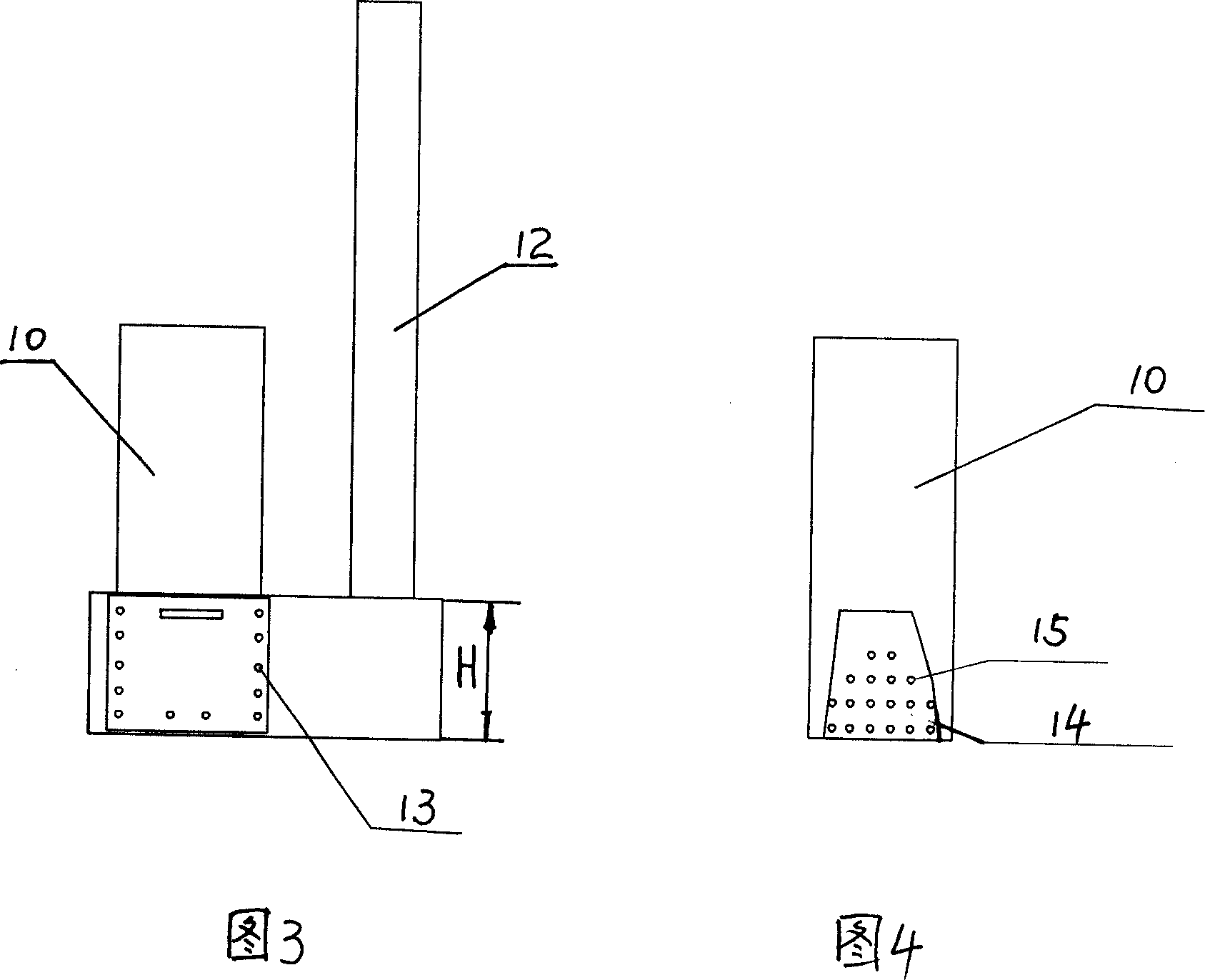

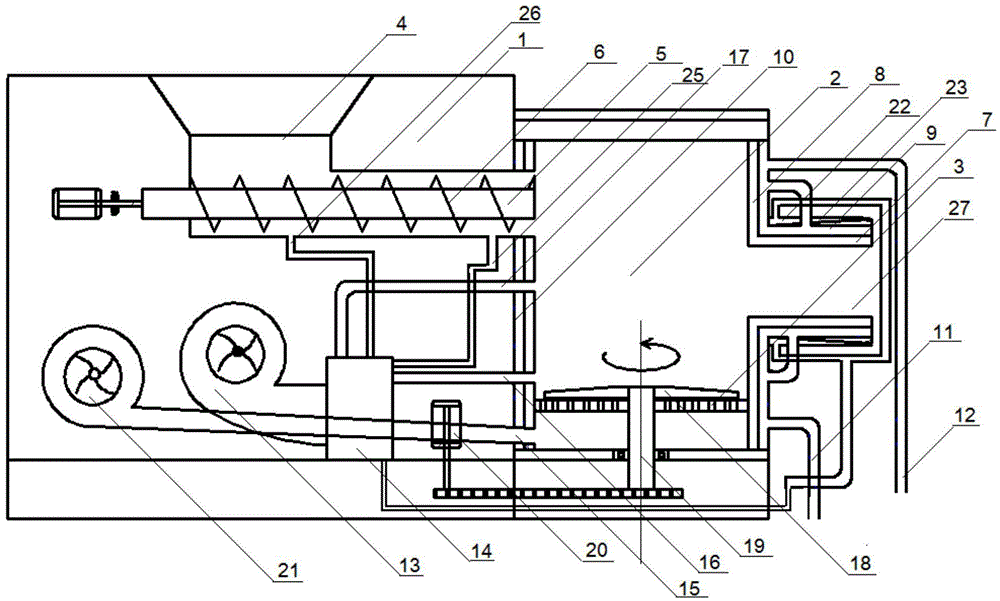

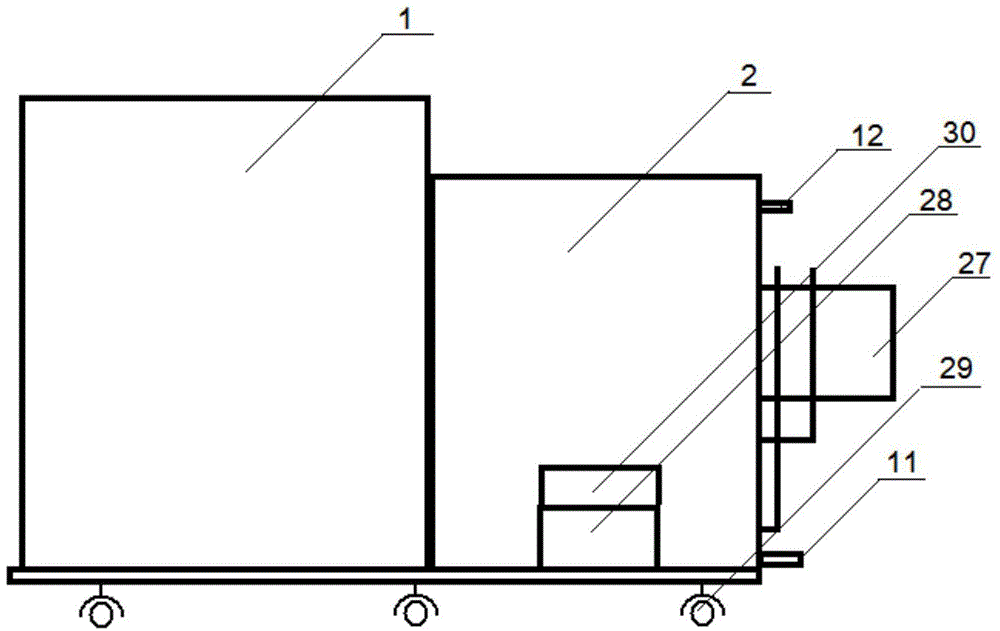

Biomass burning heating jetting furnace with fire grate

InactiveCN104819454AIncrease temperatureRaise the combustion temperatureSolid fuel combustionAir/fuel supply for combustionSpray nozzleEngineering

The invention relates to a biomass burning heating jetting furnace with a fire grate. The jetting furnace is characterized by comprising an equipment cabin (1), a hearth (2) and a nozzle (27). A feeding hopper (4) for adding fuels into a burning furnace is arranged in the equipment cabin (1). The hearth (2) is connected with the equipment cabin (1) and the nozzle (27). A grate bridge (3) is arranged on the lower portion in the hearth (2). A water inlet (11) and a water outlet (12) which are connected with a hearth clamping sleeve (10) are formed in the hearth (2). A nozzle flame retardant layer (7) is arranged on the innermost layer of the nozzle (27). A nozzle clamping sleeve (9) and a rotation air sandwich (22) are arranged in the nozzle (27). A rotation air guide sheet (23) arranged spirally is arranged in the rotation air sandwich (22). By means of the jetting furnace, the thermal efficiency is high, energy is saved by more than 30%, the furnace body temperature can reach more than 1000 DEG C, and the jetting furnace is an ideal biomass fuel furnace.

Owner:HUBEI HUANTAI BIOMASS EQUIP CO LTD

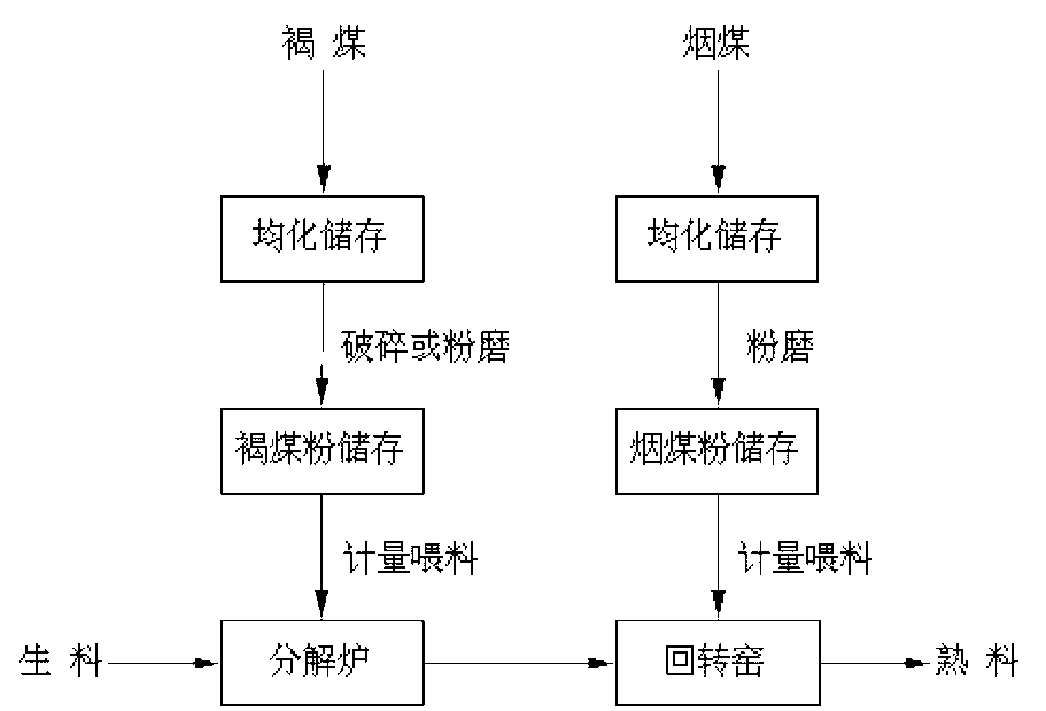

Method for calcining novel dry-method cement clinker by brown coal

The invention discloses a method for calcining novel dry-method cement clinker by brown coal, wherein the method comprises that the brown coal is sent to a decomposing furnace as a calcining fuel after crushed and homogenized. Based on characteristics of short combustion time of the decomposing furnace and long combustion time of a rotary kiln, the method of the invention uses brown coal to replace common novel dry-method soft coal as a fuel of the decomposing furnace, and the rotary kiln still uses soft coal or / and anthracite with characteristics of high heating value and long combustion time, wherein the brown coal has characteristics of low heating value, low price, fast flaming speed and short combustion time, and the soft coal has characteristics of high price and long combustion time. The method enables fuel characteristics to accord with different combustion characteristic requirements of the decomposing furnace and the rotary kiln, is in favor of raising a burn-off rate of coal dust and raising a decomposition speed of calcium carbonate, reducing buildups jam of a preheater system, enables a utilization rate of brown coal for producing novel dry-method cement to reach more than 60%, fully utilizes a local coal resource, raises an energy utilization rate, and further reduce a production cost of cement.

Owner:KUNMING IRON & STEEL HLDG CO LTD

Coal and wood dual purpose furnace for cooking and warming

InactiveCN101655247ABurn fullySave resourcesLighting and heating apparatusBiofuelsAutomotive engineeringCoal

The invention discloses a coal and wood dual purpose furnace for cooking and warming. The dual purpose furnace comprises a furnace body, a charging device, a fire grate, a furnace door and a cooking range, wherein the furnace body is provided with a fuel chamber and a combustion chamber, the fuel chamber is communicated with the combustion chamber, the fuel chamber is arranged above one side of the combustion chamber, the cooking range is arranged above the other side of the combustion chamber, the charging device is arranged on the furnace body and at the top of the fuel chamber, the fire grate is arranged in the combustion chamber, the lower part of the bottom of the fuel chamber is provided with a primary tuyere, and the upside of the fire grate is provided with a secondary tuyere. Thefuel chamber is arranged above one side of the combustion chamber and the cooking range is arranged above the other side of the combustion chamber so that the combustion chamber can not only heat thecooking range, but also perform dry distillation to the fuel in the fuel chamber, the volatile generated by the dry distillation of the fuel in the fuel chamber is mixed with the secondary air to burnin the combustion chamber while the fuel becomes loose after the dry distillation and carbonization so that the fuel is easy to drop into the combustion chamber to burn, the ash is discharged from the fire grate, and the combustion is extremely sufficient without black smoke.

Owner:慈鲁

Coal and biomass composite solid fuel

InactiveCN1804009ATake advantage ofReduce demandSolid fuelsWaste based fuelHexamethylenetetramineSolid fuel

The disclosed solid fuel composed by coal and biomass is prepared by: with coal powder, biomass from dried coal and yellow mud as material, adding KMnO4, hexamethylenetetramine, (NH4)2S2O4, H2O2 and NaCl as synergist; finally, fermenting, stirring, compressing, forming and drying to obtain the target with serious firepower and no toxin or odorless. This invention reduces coal consumption greatly benefit to solve the problem of lacking fuel and spread.

Owner:曾巨泓

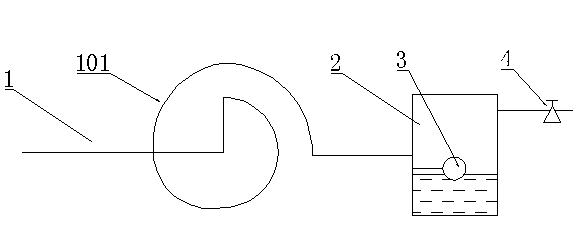

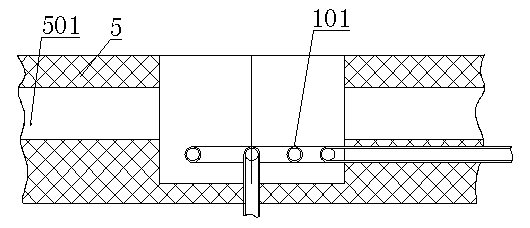

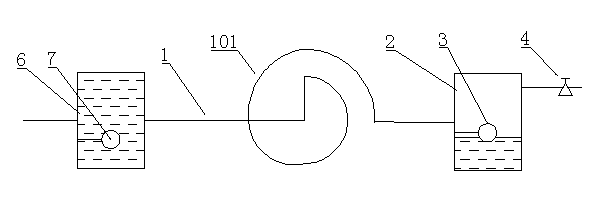

Combustible gas energy-saving gasification device for gas appliance

InactiveCN103216842ARealize forced gasificationEmission reductionFuel feedersCombustible gasProcess engineering

The invention discloses a combustible gas energy-saving gasification device for a gas appliance; the combustible gas energy-saving gasification device for the gas appliance is provided with a liquefied gas duct; the outlet of the liquefied gas duct is connected with a gas-liquid separation tank; the inlet of the liquefied gas duct and the outlet of the gas-liquid separation tank are respectively a liquid phase inlet and a gas phase outlet; the combustible gas energy-saving gasification device is characterized in that a first liquid level controller is arranged in the gas-liquid separation tank; and the liquefied gas duct is a waste heat heating gasification ring pipe or a waste heat heating gasification coil pipe. The combustible gas energy-saving gasification device fully utilizes waste heat generated in the combustion process of the gas appliance, realizes the forced gasification of combustible gas, is full in combustion, free from residual liquid, rapid in firing, strong in fire power, high in efficiency and energy-saving, and is in accordance with the policy of energy conservation and emission reduction in China. The combustible gas energy-saving gasification device is not needed to be preheated, can be immediately used after being ignited, can freely adjust the fire power, reduces the emission of harmful gas and the pollution to the environment caused by waste gas, is suitable for liquefying various combustible liquid, avoids the energy waste and reduces the using cost.

Owner:武海涛 +1

Energy-saving high-carbon eggette

The invention belongs to a kind of living coal, especially refers to a kind of energy saving high carbon coal balls, the character lies in: it is made up of compound materials of clay, coal inducing powder and the high-quality anthracite, the cement and water. The contents of components are: clay 0.5-1.2, coal inducing powder 1.8-2.4, high-quality anthracite 7.6-8.5; the content of the compound material and the cement are: the compound 7.5-8.5, cement 0.5-1.2, and some water. The result is that: the product has quick firing character, the combustion time is long, the fir is raging scorching, the combustion is full, and it has no contamination to the environment. The character of the invention is that it doesn't mind to be watered; it will expand or explode when the solidified cement meets naked flame, keeps the distance between coals spheres, the firing assistant gas can ventilate well.

Owner:简书增 +1

Electronics strike firing honeycomb briquet

InactiveCN1446891AUnbreakableThe quality directly affects the product use effectSolid fuelsWaxPotassium

An electronically ignited honeycomb briquette contains coal (15-60 wt.%), clay (1-30 wt%), lime (1-15 wt%), soap wax (0.01-0.1 wt%), combustible waste (10-30 wt%), potassium permagnate (0.1-0.6 wt%),starch (1-10 wt%) and sodium carbonate (1-10 wt%). Its advantages are easy ignition, high heat efficiency and less environmental pollution.

Owner:胡强

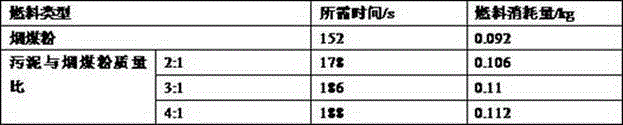

Sludge synthetic fuel and manufacturing method thereof

The invention provides sludge synthetic fuel and a manufacturing method thereof. Sludge generated when a sewage treatment plant treats industrial wastewater and urban domestic wastewater is used as a raw material, and the mass ratio of sludge to pulverized coal is 2:1-19:1. The sludge and the pulverized coal are uniformly mixed in a stirrer and other stirring devices according to the weight percentage, then the mixture is conveyed through a conveyer belt and other conveying devices to a pelletizer or a press machine for fuel forming, and the formed fuel is dried in the shade place for 3-5 days and then can be combusted. The sludge synthetic fuel is simple in formula and good in combustion working condition and environmental protection performance, saves coal resources, turns waste into wealth and greatly reduces sludge treatment cost.

Owner:卓宇轩

Preparation method of fuel oil for fuel stoves

InactiveCN106085518ASave the initial installation feeLow costLiquid carbonaceous fuelsAnhydrous ethanolCombustion

The invention relates to a preparation method of fuel oil for fuel stoves. The fuel oil is prepared from, by weight, 0.4-0.6% of sodium hydroxide, 0.1-0.3% of sodium nitrate, 4-15% of water, 70-82% of methanol, 2-5% of hydrogen peroxide, 3-5% of anhydrous ethanol, 0.1-0.3% of ferrocene, and 0.5-0.7% of edible essence, and the sum of the weight proportions of all above components is 100%. The preparation technology comprises the following steps: mixing sodium hydroxide and sodium nitrate with water, stirring sodium hydroxide, sodium nitrate and water to prepare a mixed solution A, adding methanol, hydrogen peroxide and anhydrous ethanol to the mixed solution A, stirring to prepare a mixed solution B, taking out 10-12% of the mixed solution B, adding ferrocene and the edible essence to prepare a mixed solution C, allowing the mixed solution C to stand and precipitate, taking the obtained clear liquid, pouring the clear liquid to the mixed solution B, and stirring the clear liquid and the mixed solution B to prepare the final product. The technology has the advantages of effective solving of the problems of low efficiency and insufficient combustion of present fuel oils, good safety and reliability, convenience in use, energy saving and high efficiency, and healthiness and environmental protection.

Owner:邓利强

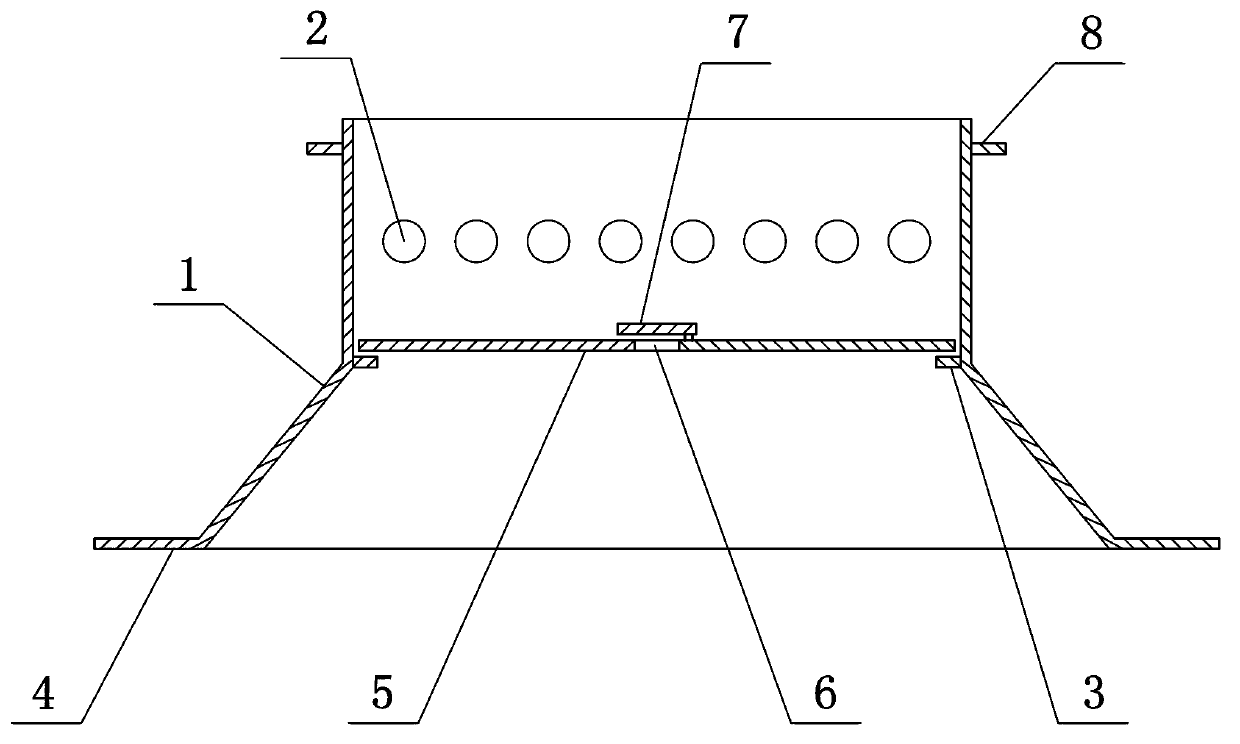

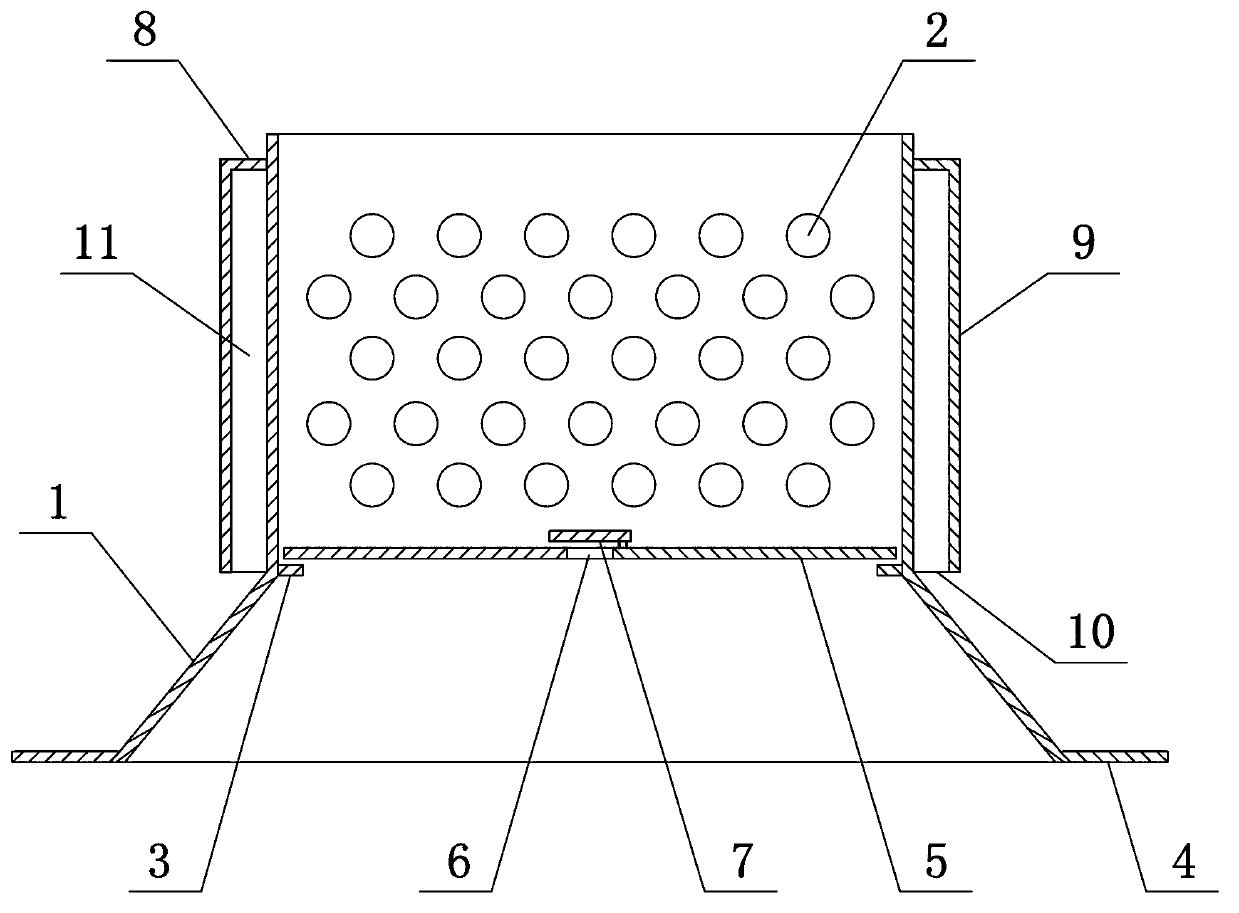

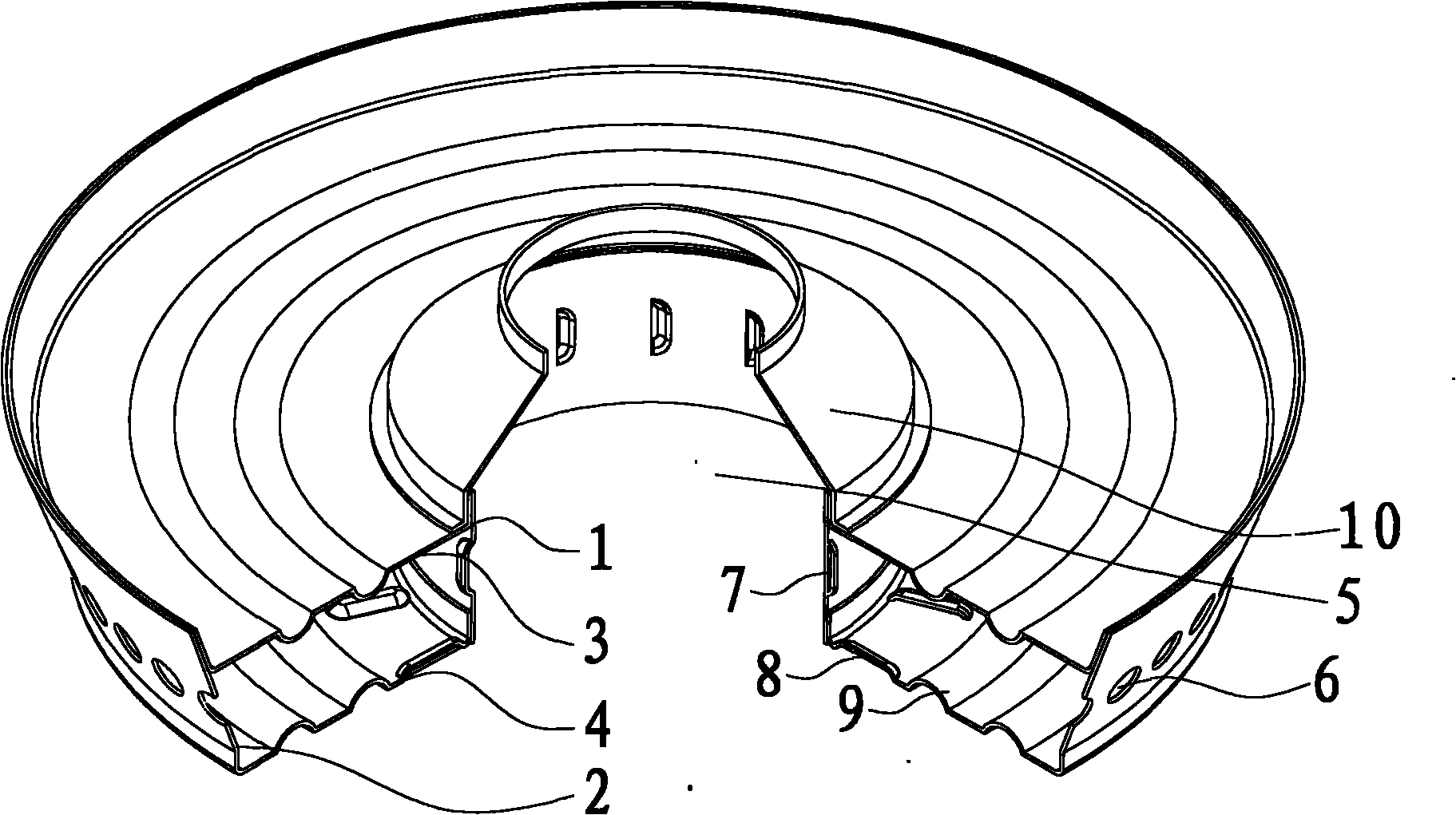

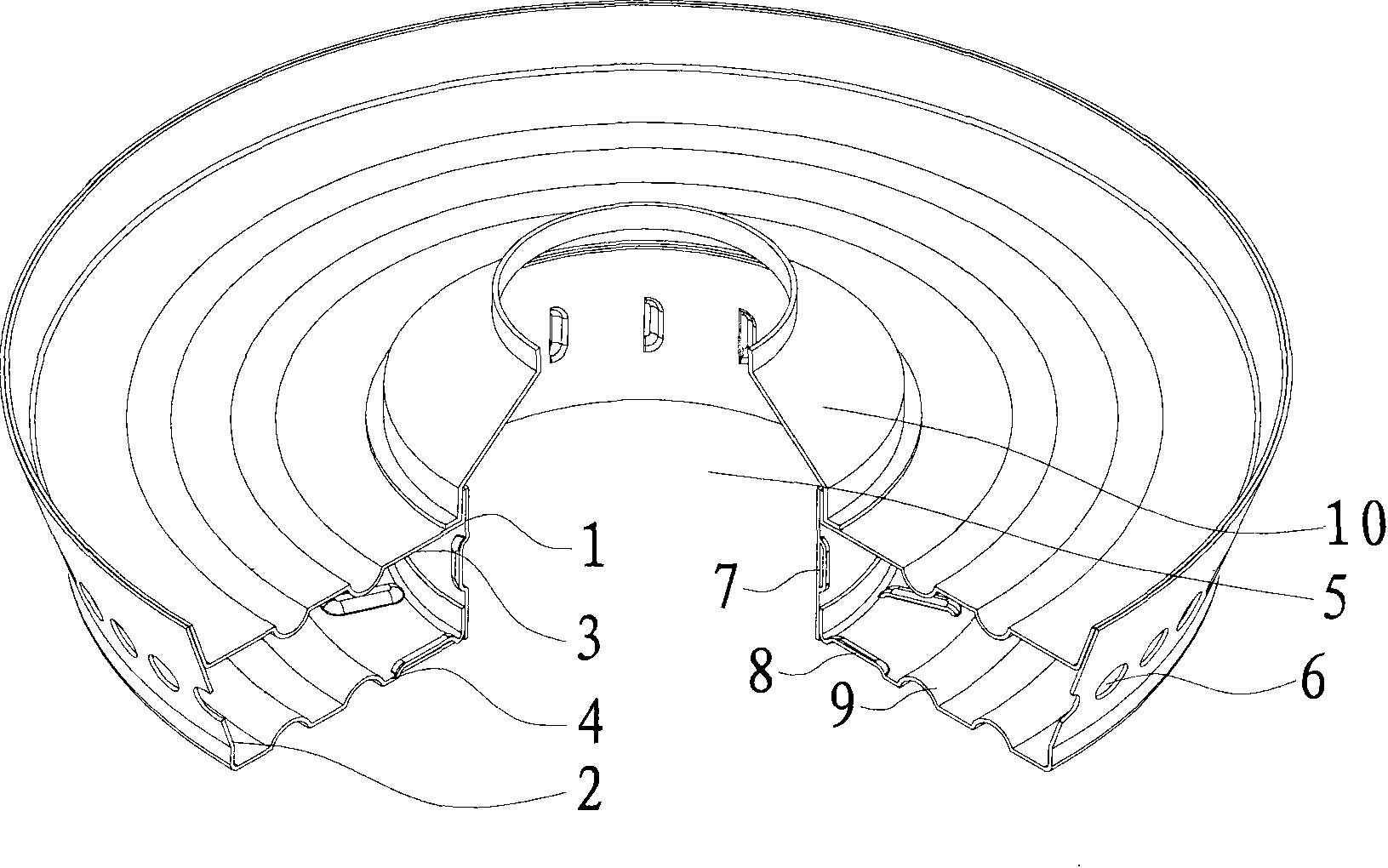

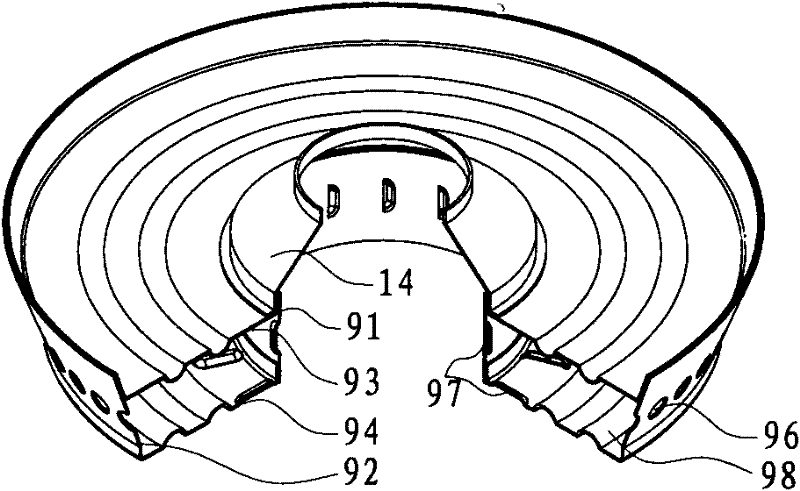

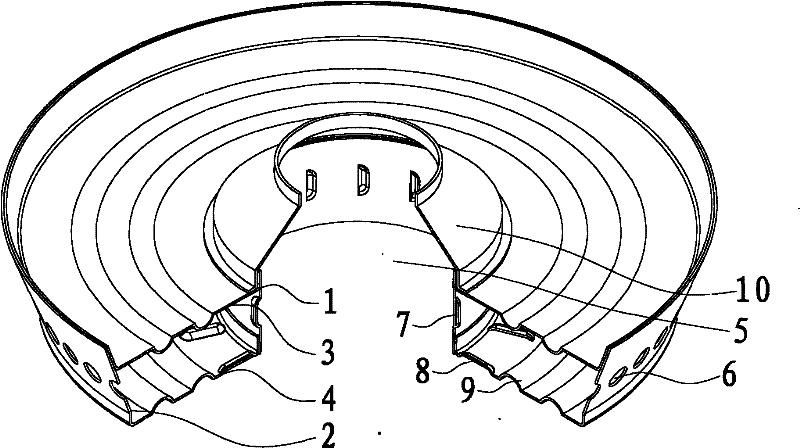

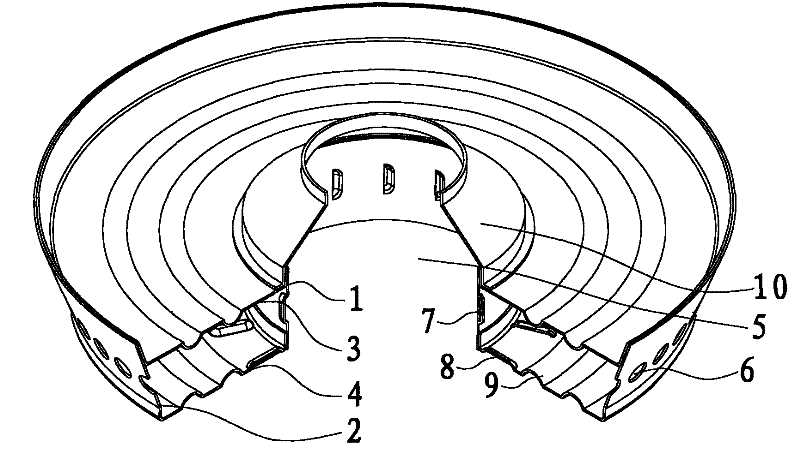

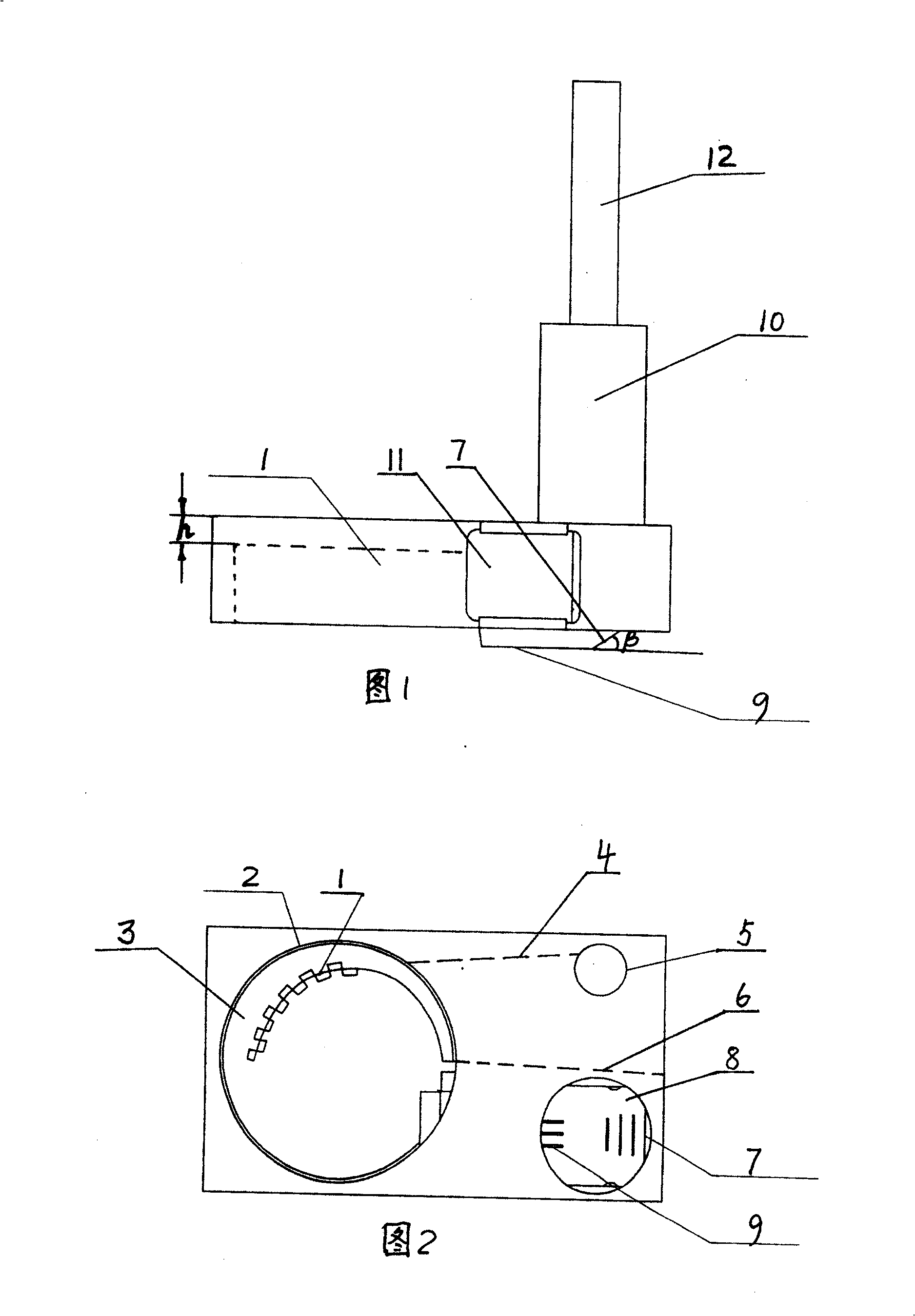

Secondary air distributor for biomass direct combustion furnace

ActiveCN101957000AEasy to igniteBurn fullyDomestic stoves or rangesNon-combustible gases/liquids supplyDirect combustionDistributor

A secondary air distributor for a biomass direct combustion furnace relates to a biomass stove and is arranged above a boiler. The secondary air distributor comprises a hollow cavity formed by enclosing an inner wall, an outer wall, an upper wall and a bottom wall, wherein the middle part is provided with a fire hole; an air inlet is arranged on the outer wall; a first air outlet is arranged on the inner wall; and a second air outlet is arranged on the bottom wall in order to fully combust the secondary air for compensating combustion by rotating the air. The secondary air distributor of the invention has simple structure, is characterized by easy ignition of cool furnace, quick combustion, high heating efficiency, strong fire power, being free from blow-off, less exhaust emission, and the like, and is specially fit for the biomass direct combustion furnace.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

Industrial shaped coal

The invention relates to shaped coal, in particular to industrial shaped coal which is prepared from the following components in parts by weight: 20-30 parts of bituminous coal, 2-10 parts of cement, 3-5 parts of light burning powder, 5-10 parts of prime carbon, 1-2 parts of pro-oxygenic agent and 20-50 parts of water. Compared with the prior art, the invention has the advantages of most adhesion, higher heat productivity, long combustion flame with much smoke in combustion, convenient use and rapid firing because the bituminous coal with the carbon content of 75-90 percent and without free humic acid is added to the shaped coal.

Owner:CHENGDU FANXINJIA TECH

Briquette binder and manufacture method thereof

The invention relates to a briquette binder and a preparation method, which is composed of the following ingredients in proportion by weight: sodium nitrate 20-50, magnesium chloride 10-30, sodium chloride 10-20, ammonium chloride 5- 20. Light magnesium oxide 10-40, calcium oxide 5-20, cellulose 20-30. The advantage is that the cost is low, and the purpose of coal desulfurization, waterproof, combustion-supporting and strengthening can be achieved at the same time.

Owner:陈国涛 +1

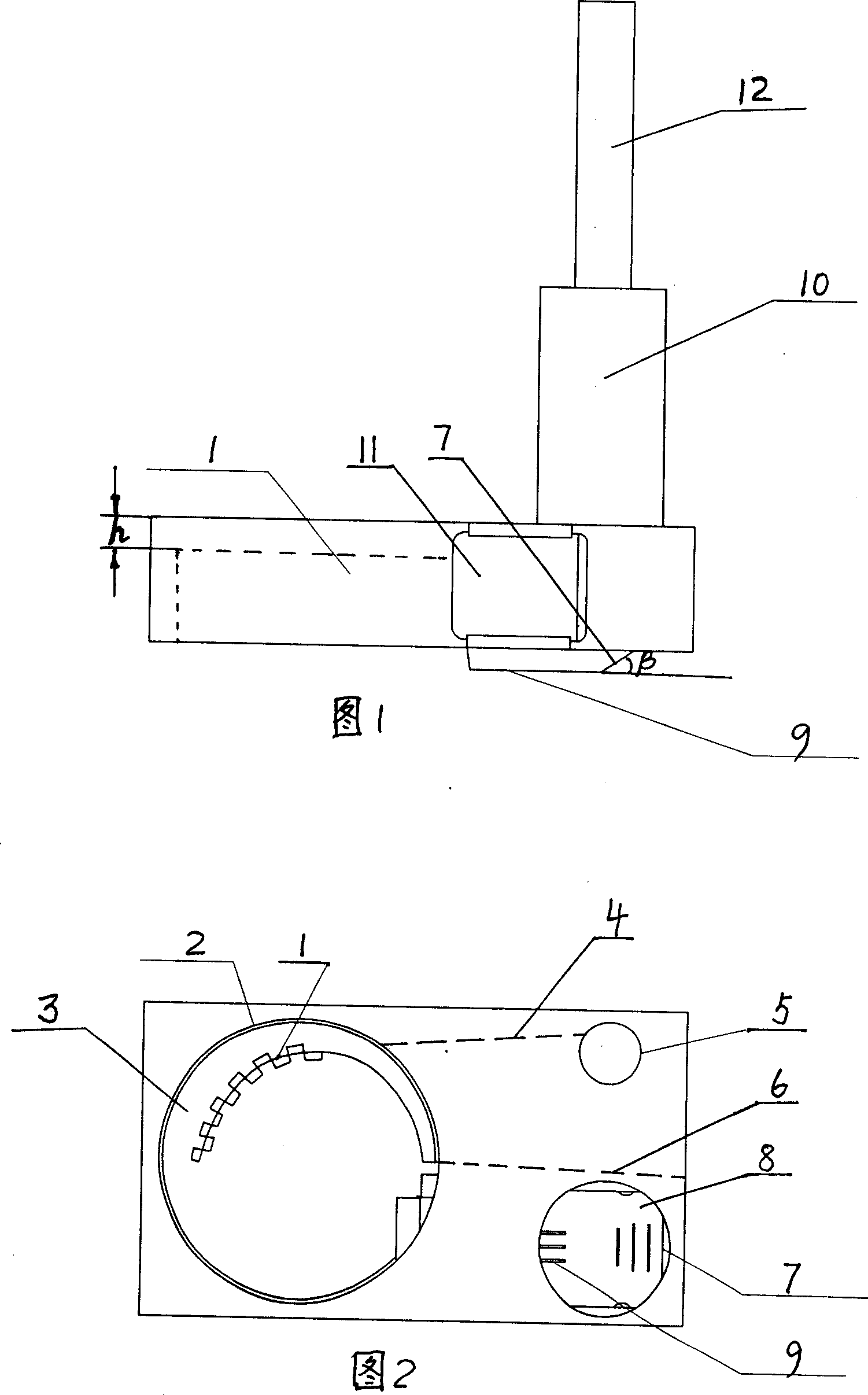

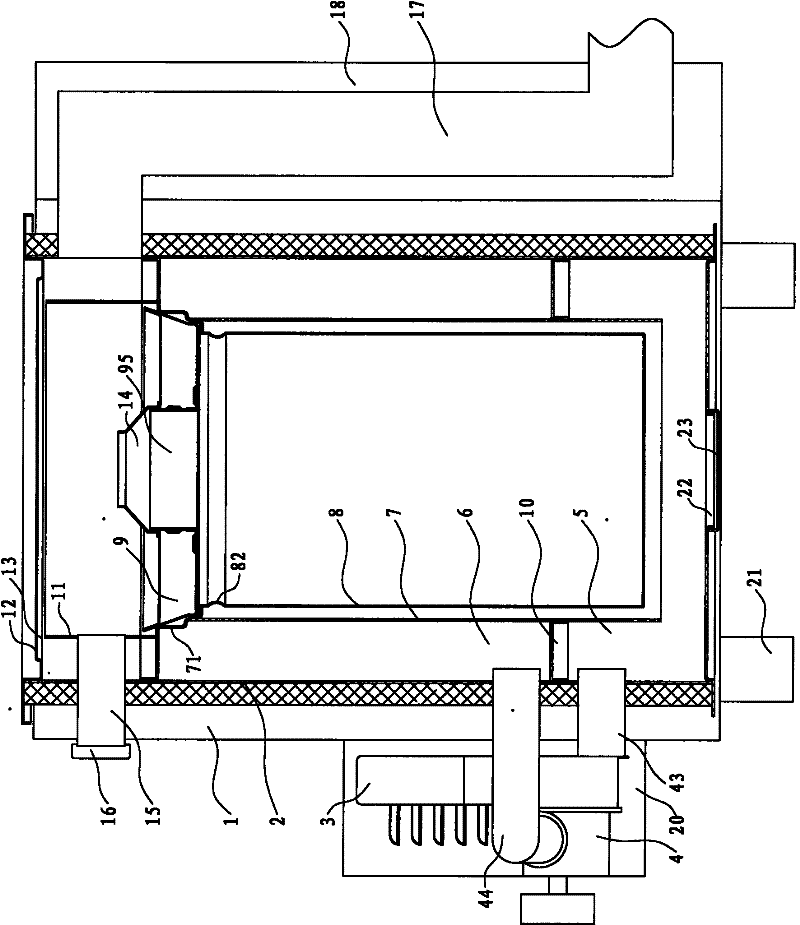

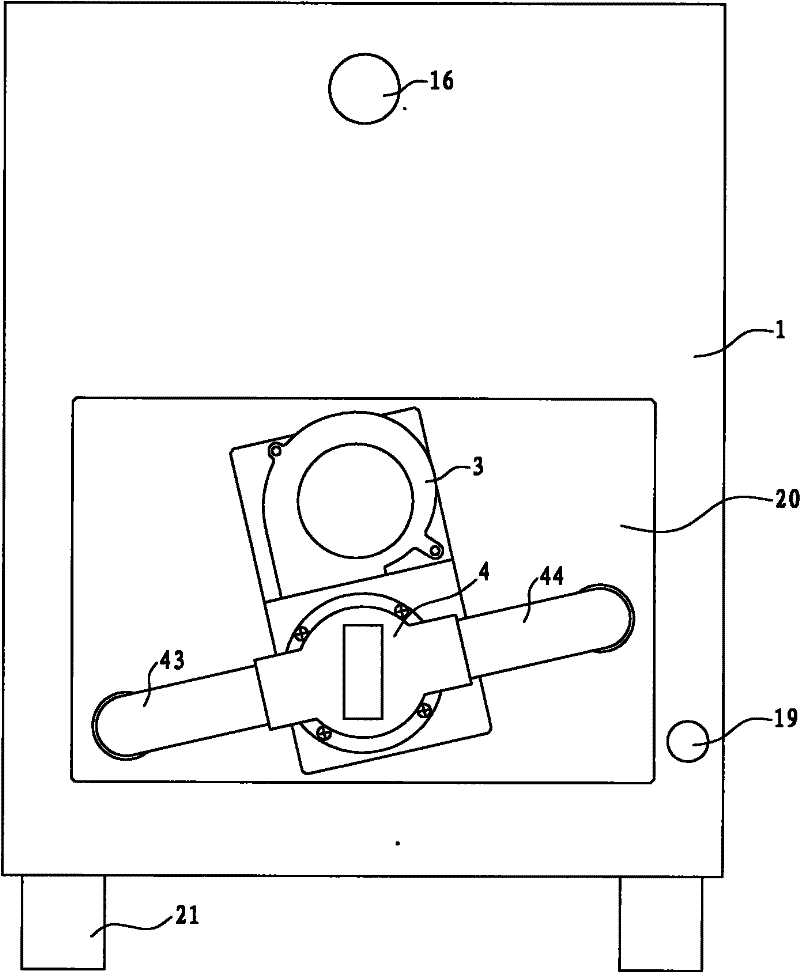

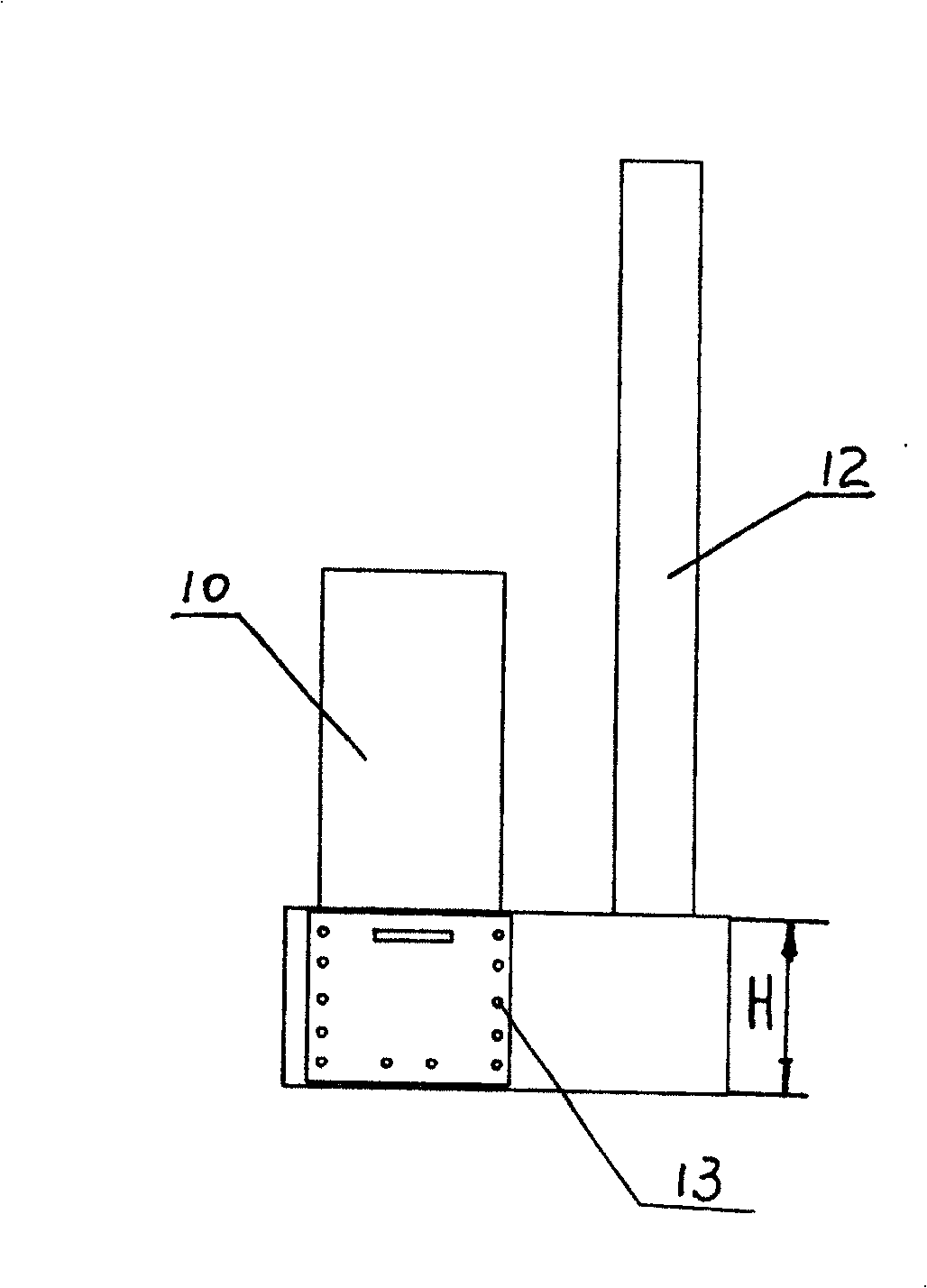

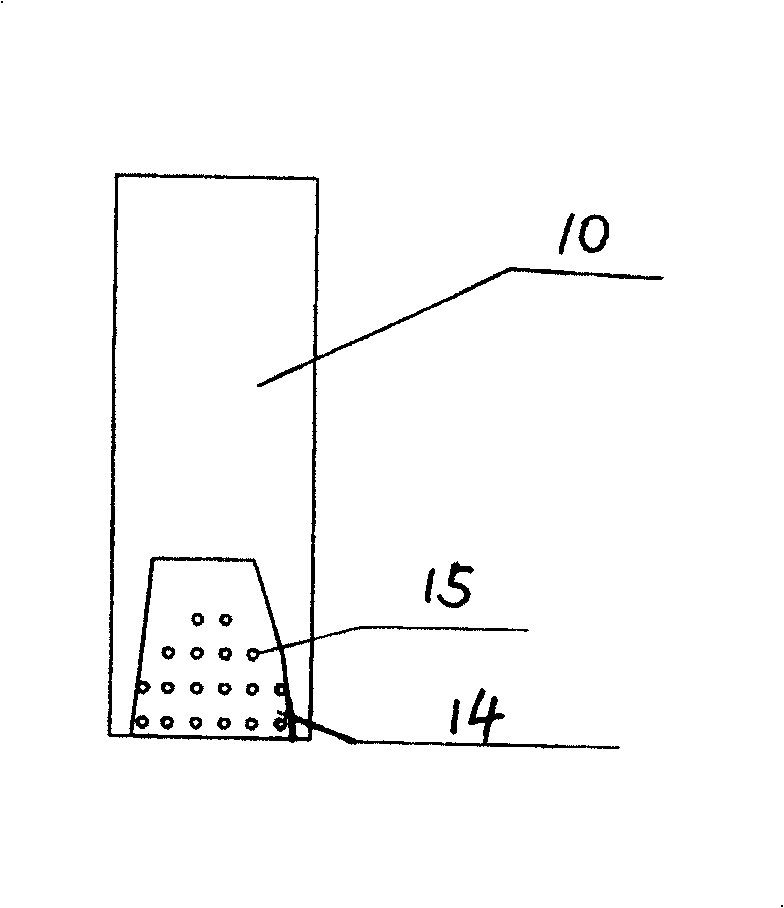

Biomass direct-fired furnace

ActiveCN101956999BSimple structureEasy to igniteStove/ranges for heating waterBlast-producing apparatusFirewoodSolid fuel

The invention provides a biomass direct-fired furnace which relates to a domestic furnace, comprising a shell, a furnace body and a fan. The fan is correspondingly connected with a primary air chamber and a secondary air chamber through a primary air delivery pipe and a secondary air delivery pipe; the upper end of the furnace body is provided with a chimney; the inner side wall of the furnace body is fixedly connected with an inner cylinder in which a charging cylinder is placed; a secondary air distributor is arranged above the charging cylinder; the secondary air distributor has a secondary air chamber air outlet for communicating the second air distributor; and the wall of the charging cylinder is provided with a charging cylinder air inlet for communicating the primary air chamber. The invention adopts a direct-fired manner and has the characteristics of simple structure, easy ignition, fast firing, good fire regulation property, simple operation, strong fire, high thermal efficiency, safety and sanitation, and sustainable combustion; and the like; the invention does not have special requirement on the shapes of the fuels; and the applicable fuels comprise various shaped fuels, firewood and agricultural byproducts such as chaff, lotus seed pot, straw, corncob, and the like, therefore, the invention is particularly suitable for the rural residents of China.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

Coal and wood dual purpose furnace for cooking and warming

InactiveCN101655247BBurn fullyAvoid smokyLighting and heating apparatusBiofuelsCombustion chamberCoal

The invention discloses a coal and wood dual purpose furnace for cooking and warming. The dual purpose furnace comprises a furnace body, a charging device, a fire grate, a furnace door and a cooking range, wherein the furnace body is provided with a fuel chamber and a combustion chamber, the fuel chamber is communicated with the combustion chamber, the fuel chamber is arranged above one side of the combustion chamber, the cooking range is arranged above the other side of the combustion chamber, the charging device is arranged on the furnace body and at the top of the fuel chamber, the fire grate is arranged in the combustion chamber, the lower part of the bottom of the fuel chamber is provided with a primary tuyere, and the upside of the fire grate is provided with a secondary tuyere. Thefuel chamber is arranged above one side of the combustion chamber and the cooking range is arranged above the other side of the combustion chamber so that the combustion chamber can not only heat thecooking range, but also perform dry distillation to the fuel in the fuel chamber, the volatile generated by the dry distillation of the fuel in the fuel chamber is mixed with the secondary air to burn in the combustion chamber while the fuel becomes loose after the dry distillation and carbonization so that the fuel is easy to drop into the combustion chamber to burn, the ash is discharged from the fire grate, and the combustion is extremely sufficient without black smoke.

Owner:慈鲁

Quick-lighting honeycomb briquette

The present invention relates to the field of fuel, and is a kind of quick-inflammating honeycomb briquette, its upper portion is a lighting coal layer and its lower portion is combustion coal layer.The composition of said lighting coal layer is composed of (by weight portion) 30-50 portions of coal, 25-40 portions of soil, 25-40 portions of saw-dust and 1-5 portions of soap paraffin, and the composition of said combustion coal layer is formed from (by weight portion) 40-65 portions of coal, 15-35 portions of soil and 10-25 portions of saw dust. Said invention can save energy source, its cinder carbon contents is about 1%, and said product is easily lighted, its combustion is complete and has no pollution.

Owner:商海涛

Solid fuel

A solid fuel is composed of the following raw materials in parts by weight: 30 to 60 parts of ethanol, 10 to 30 parts of stearic acid, 10 to 15 parts of sodium chloride, 5 to 10 parts of charcoal powder, 1 to 10 parts of potassium nitrate, 1 to 5 parts of sodium hydroxide, and 1 to 5 parts of adhesive. The solid fuel can be applied to travelling, geological exploring, outdoor adventures, and the like, is smoke-free and nontoxic, will not harm the human health, and has the advantages of easy ignition, rapid burning, long-lasting burning performance, user-friendliness, simple technology, and low cost.

Owner:XIAN RUNDA CHEM TECH

Secondary air distributor for biomass direct combustion furnace

ActiveCN101957000BSimple structureEasy to processDomestic stoves or rangesNon-combustible gases/liquids supplyDirect combustionDistributor

A secondary air distributor for a biomass direct combustion furnace relates to a biomass stove and is arranged above a boiler. The secondary air distributor comprises a hollow cavity formed by enclosing an inner wall, an outer wall, an upper wall and a bottom wall, wherein the middle part is provided with a fire hole; an air inlet is arranged on the outer wall; a first air outlet is arranged on the inner wall; and a second air outlet is arranged on the bottom wall in order to fully combust the secondary air for compensating combustion by rotating the air. The secondary air distributor of the invention has simple structure, is characterized by easy ignition of cool furnace, quick combustion, high heating efficiency, strong fire power, being free from blow-off, less exhaust emission, and the like, and is specially fit for the biomass direct combustion furnace.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

Transversely closed burning highly effective environment protective energy-saving direct combustion type biomass stove

InactiveCN100427830CExtended stroke of rotary combustionUnique designDomestic stoves or rangesLighting and heating apparatusDirect combustionHearth

The invention discloses a horizontal-sealed high-efficiency energy-saving direct-combustion biological furnace, which comprises a furnace formed by front, back, left and right side panels, upper panel and bottom plate. The left of upper panel is arranged with a base opening. The right side of upper panel is arranged with an upper drawing cylinder opening and a lower feeding opening. The lower furnace of feeding opening contains an incline sliding plate screen whose lower end is connected with the furnace screen in the hearth. The right panel of furnace above the sliding plate screen is arranged with a wind inlet. One side of the base opening is arranged with an arc upright baffle plate to form an arc fire channel whose front is communicated with hearth and back is communicated with the drawing cylinder opening. Via the combustion drawing cylinder, the passive pressure in the furnace can be kept from continuous feeding to continuous burning. The semi-round fire channel of arc upright baffle plate can prolong the strike of fire in the channel to burn the fuel second time.

Owner:焦作市洁燃新能源有限公司

Additive honeycomb briquette

Honeycomb briquettes with additives are made of coal, clay soil and additive in the process of batch feeder, disperse, stir and extrude. The additives comprise white lime, gangues, and combustion accelerator. According various uses, ingredients of additives can be adjusted. The honeycomb briquettes are efficiency and economical. It is proper for produce and use for areas of clinker and lime.

Owner:李卫东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com